Patents

Literature

47results about How to "Both corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature-resistant, corrosion-resistant and high-adhesion adhesive and preparation method thereof

ActiveCN102559120AImprove impact resistanceImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCelluloseThermoplastic

The invention discloses a temperature-resistant, corrosion-resistant and high-adhesion adhesive and a preparation method thereof, and belongs to the technical field of adhesives. The temperature-resistant, corrosion-resistant and high-adhesion adhesive consists of two components, i. e., an adhesive A and an adhesive B, in the weight ratio of 100:1-10, wherein the adhesive A consists of chemical plasticizing vinyl ester resin, a polymerization inhibitor, a low shrinkage agent, a free radical curing solvent, gas-phase silicon dioxide, inorganic filler, a coupling agent, a defoaming agent, color paste or paint, a promoter and a promotion additive; and the adhesive B consists of phthalic ester, peroxide and inertial powder filler. The adhesive provided by the invention has the performance of heat resistance, corrosion resistance, penetration resistance, adhesion, positioning, impact resistance and the like, can be formed into different types at normal temperature, and medium and high temperature, is easy and convenient to operate, can bring the unique advantage of the adhesive into full play on some occasions requiring to paying attention to corrosion resistance, adhesion, heat resistance and the like, and is suitable for mutual adhesion among a continuous cellulose material, a concrete material, a metal material, stone, FRP (Fiber Reinforce Plastic), thermoplastic plastic and the like.

Owner:浙江天和树脂有限公司 +1

Boric low alloy wear resistant steel for pump

ActiveCN102367558AHigh strengthImprove wear resistanceProcess efficiency improvementTemperingWear resistant

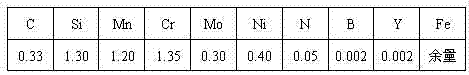

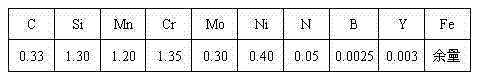

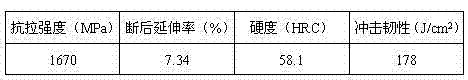

The invention relates to the technical field of metal casting materials, and concretely relates to boric low alloy wear resistant steel for a pump. The steel is characterized in that the steel comprises the following chemical components: 0.33 wt% of C, 1.20 wt% of Mn, 1.30 wt% of Si, 1.35 wt% of Cr, 0.30 wt% of Mo, 0.40 wt% of Ni, 0.05 wt% of N, 0.002-0.0025 wt% of B, 0.002-0.003 wt% of Y, and the balance Fe and avoidless impurities. The boric low alloy wear resistant steel for the pump, which has the characteristics of high strength and hardness, and excellent tissue and performance, is obtained through molding a boric low alloy wear resistant steel casting with resin sand, and carrying out heat treatment consisting of quenching and tempering on the casting. The boric low alloy wear resistant steel of the invention has the advantages of high hardness, good toughness effect, high wear resistance, certain corrosion resistance, simple production technology, low production cost and the like.

Owner:SHANDONG SHUANGLUN

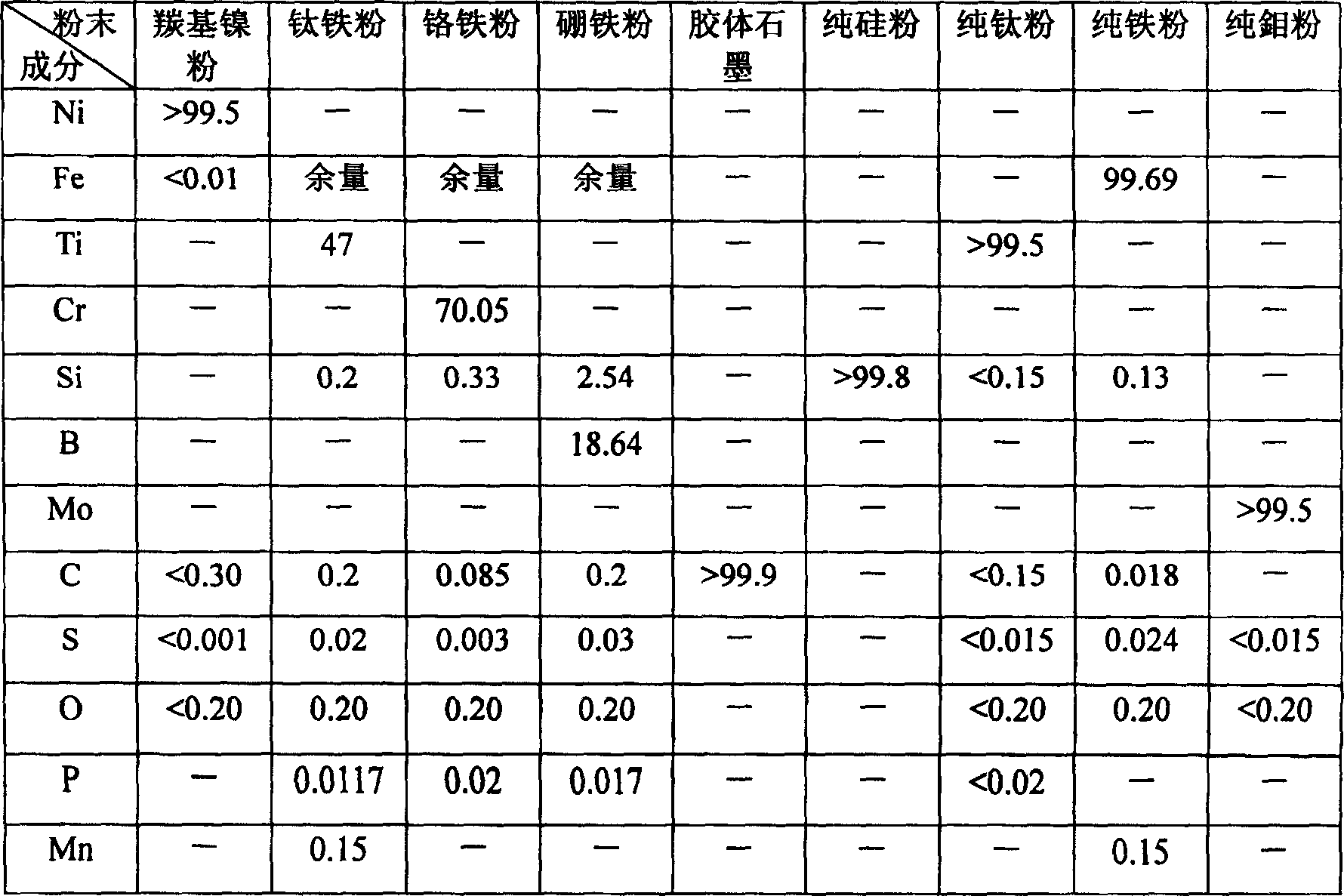

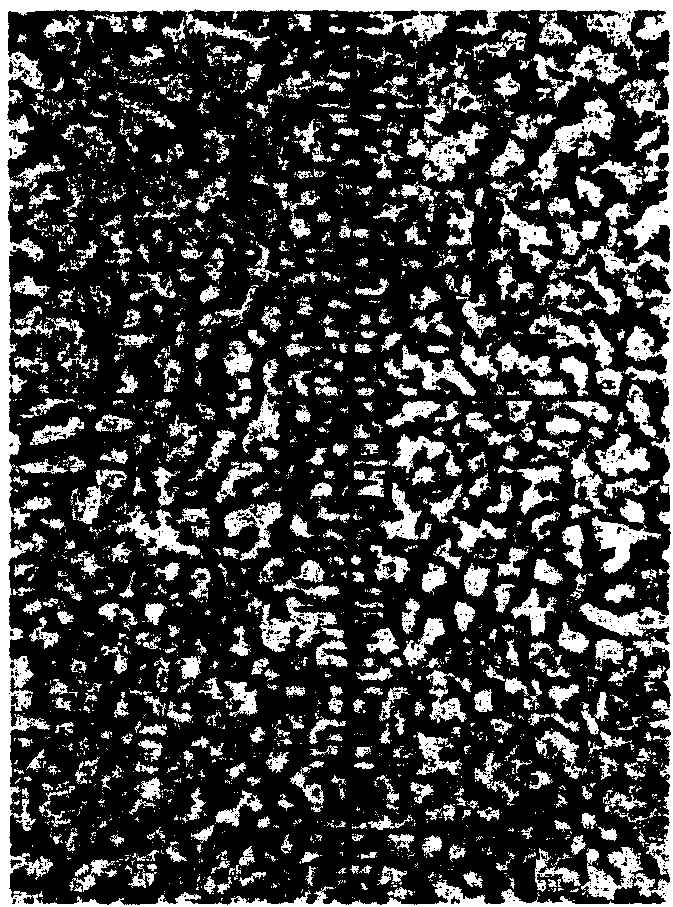

Carbonide / iron-base alloy composite coating and its reaction brass coating technology

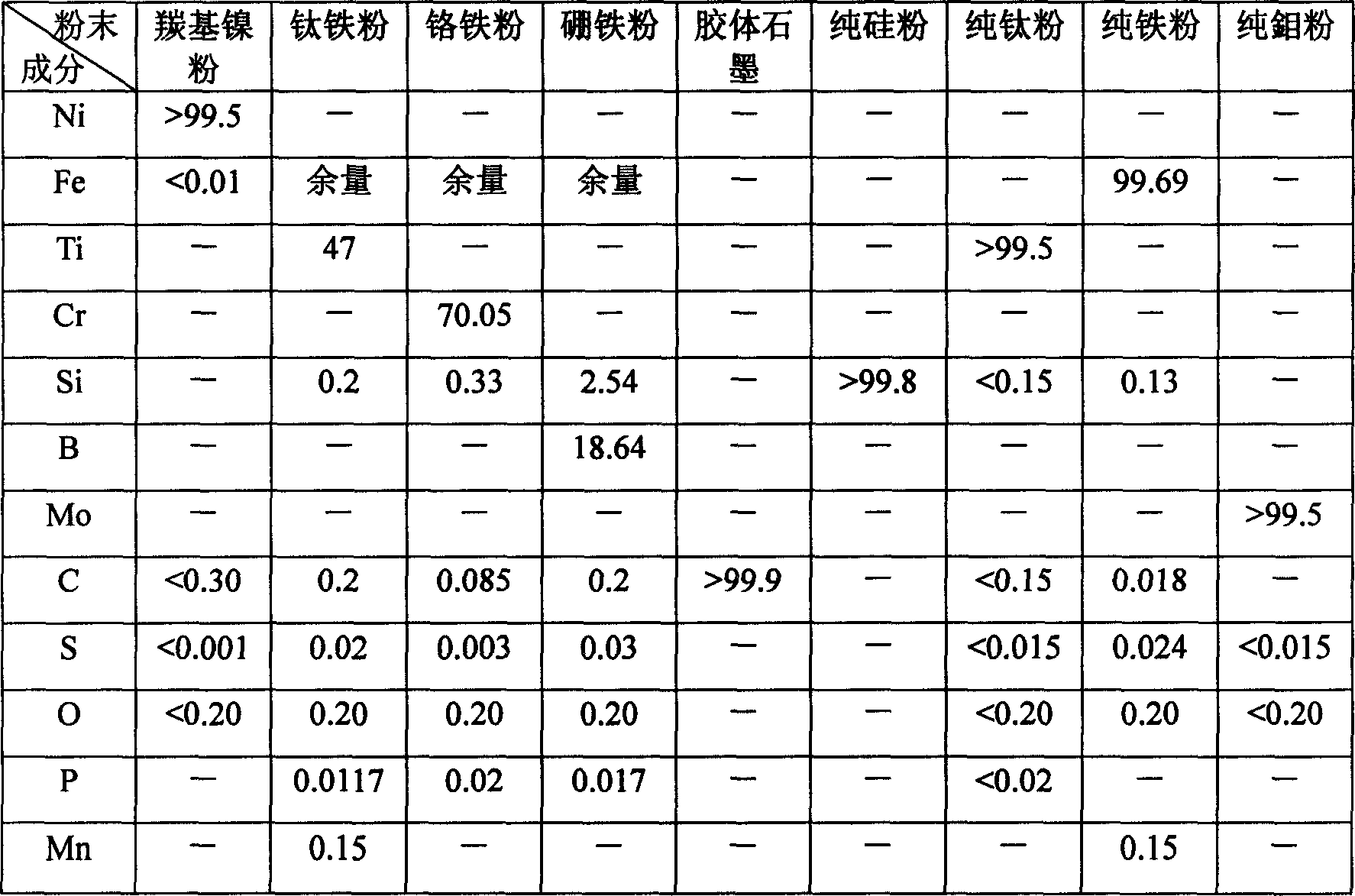

The present invention is one kind of composite (titanium carbide+chromium carbid) / ferroalloy coating and its reaction coating process, and belongs to the field of composite ceramic / metal coating. Industry Ti-Fe powder, Cr-Fe powder, B-Fe powder, Fe powder, etc. as main material, alcohol and organic adhesive are mixed to form slurry; the slurry is sprayed or painted onto the surface of base body; and through in-situ reaction and alloying under vacuum condition and at certain temperature, composite coating with hard phase of titanium carbide and chromium carbide and base phase of ferroalloy is formed after lowering the temperature. The present invention has low cost of forming the composite coating, and the composite coating has high heat resistance, high oxidation resistance, high corrosion resistance, high antiwear, etc. and may be used widely in metallurgy, thermal power generation and other fields.

Owner:UNIV OF SCI & TECH BEIJING

Method for producing ceramic-lined aluminum alloy pipe

The invention relates to a method for producing an ceramic-lined aluminum alloy pipe, comprising the following steps: producing a ceramic-lined steel pipe by adopting the SHS centrifugal process, casting paraffin inside the ceramic-lined steel pipe, fixing the ceramic-lined steel pipe on a turning lathe, turning the outer surface of the ceramic-lined steel pipe, heating an aluminum alloy pipe to make the aluminum alloy pipe expand, extruding the turned ceramic-lined steel pipe into the aluminum alloy pipe at high temperature, and heating the paraffin wholly to obtain the ceramic-lined aluminum alloy pipe. The SHS centrifugal process, the lathe processing process and the sleeving process are used to indirectly product the ceramic lining inside the aluminum alloy composite pipe. The method is simple and adopts the cheap raw materials. The ceramic-lined aluminum alloy pipe has the abrasion resistance and corrosion resistance of the ceramic-lined pipe, and the weight of the composite pipe is reduced greatly.

Owner:江阴东大新材料研究院

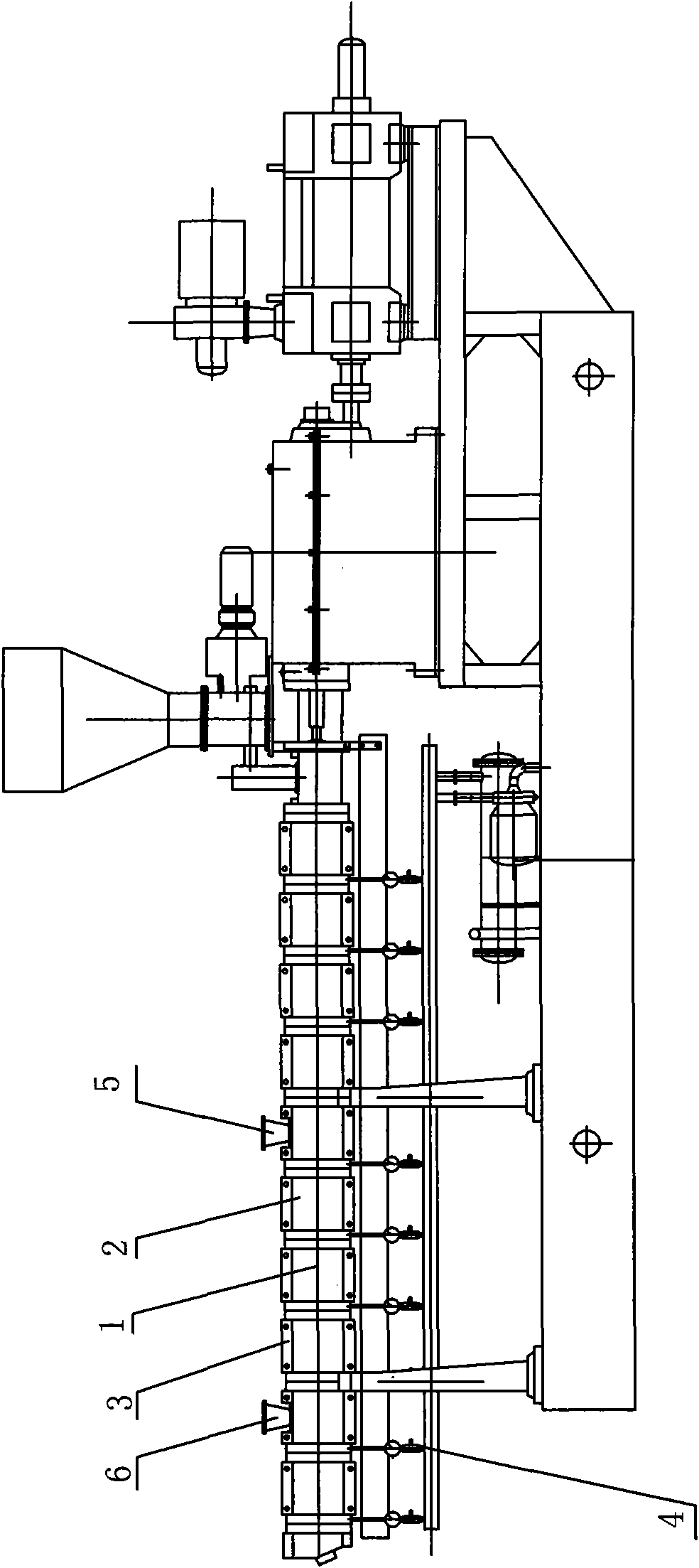

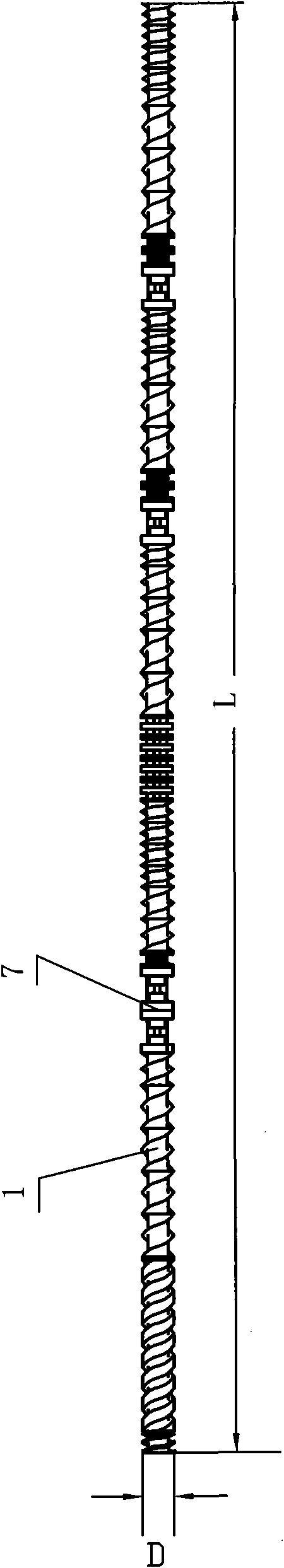

Pelleting extruder for FEP powder

The invention discloses a pelleting extruder for FEP powder, which comprises two parallel screws, a machine barrel which is arranged outside the screws, a heating system, a cooling system and a vacuumizing and de-volatilizing system, wherein a fluorine gas charging port is formed on the machine barrel. The invention aims to provide the dual-screw extruder for the FEP powders, which can shorten anFEP production and processing flow, simply and efficiently remove unstable end groups in products, control volatile matters of the products and has the advantages of high-temperature resistance, corrosion resistance and long service period. The double-screw extruder of the invention can efficiently remove the unstable end groups in molecular links and control the volatile matters of the products;and meanwhile, the machine barrel has corrosion resistance and high-temperature formation resistance and is very suitable for processing the FEP powder.

Owner:ZHEJIANG JUHUA CO LTD

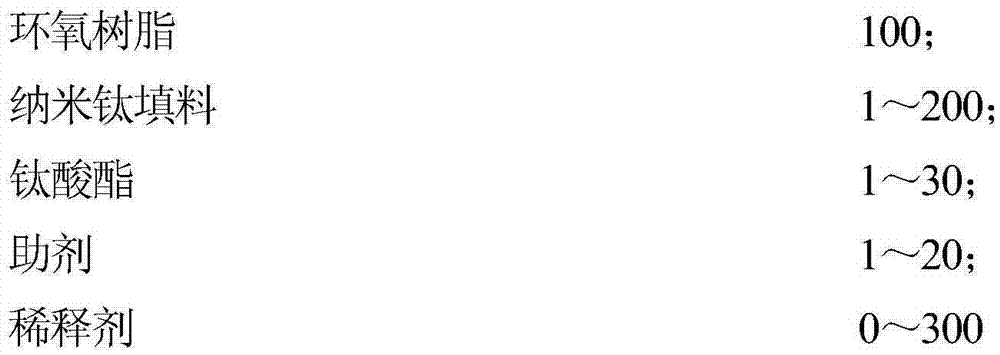

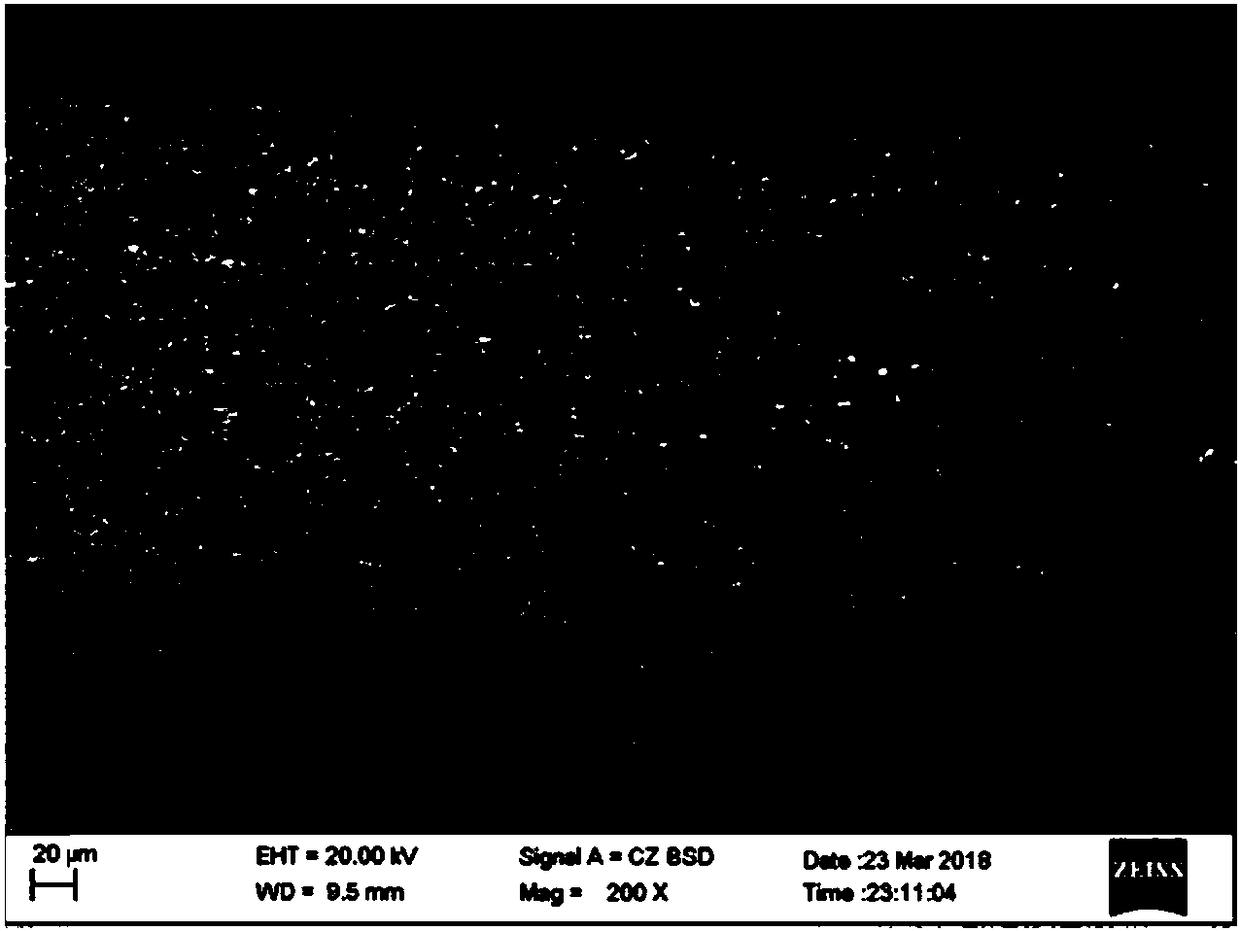

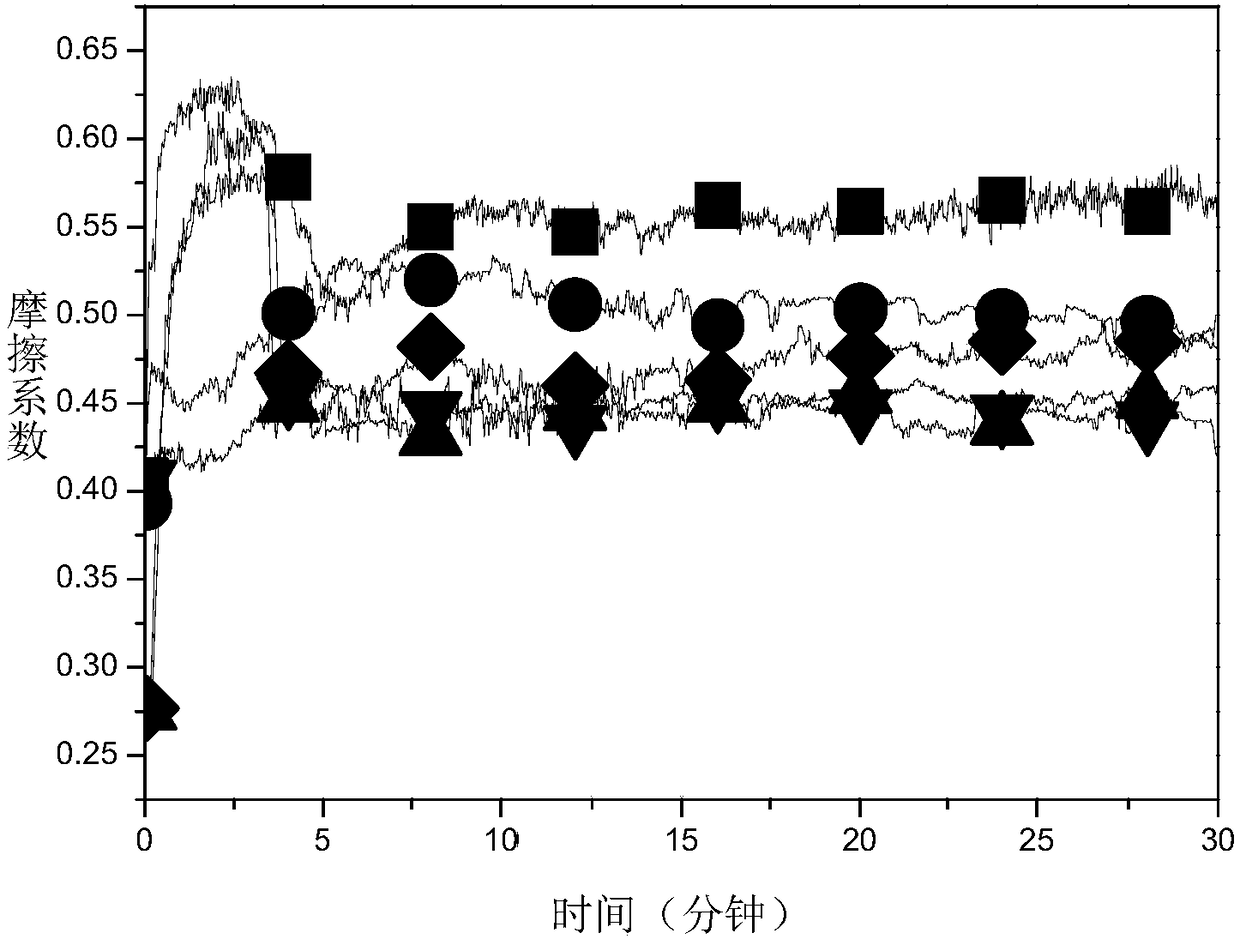

Epoxy resin-nano titanium interface chemical bonding anticorrosive coating and preparation method thereof

ActiveCN106893441ASimple production processBoth corrosion resistancePretreated surfacesAnti-corrosive paintsEpoxyWear resistant

The invention belongs to the technical field of coatings and in particular relates to an epoxy resin-nano titanium interface chemical bonding anticorrosive coating and a preparation method thereof. Firstly, a nano titanium filler grafted with epoxy resin is easily fully dissolved and wetted with coating resin, and the nano titanium filler can be uniformly dispersed in the epoxy resin of the coating and can be cross-linked with the coating resin and a curing agent together, so that the epoxy resin-nano titanium interface chemical bonding anticorrosive coating is obtained; and secondly, the metal titanium particle size of the grafted epoxy resin is in a nano scale, the grafted epoxy resin has a huge specific surface area and a good surface nano effect and can form firm interface bonding force with resin in the coating, the defects and pores of the anticorrosive coating are greatly eliminated, the phenomena such as embrittlement cracking and underfilm corrosion occurring on the anticorrosive coating are avoided, and the corrosion resistance of the coating is improved. Finally, the nano titanium filler is wear-resistant, high in strength and high in thermal stability, so that the wear resistance, mechanical properties and heat resistance of the anticorrosive coating are obviously improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Ultrasonic frequency induction heating technology based quick hot-dipping aluminizing technology

InactiveCN104313533AReduce concentrationReduce consumptionSolid state diffusion coatingThermal fatigueHeat resistance

The invention provides an ultrasonic frequency induction heating technology based quick hot-dipping aluminizing technology. The technology comprises the following steps: oil removing, acid pickling for rust removal, washing, surface activation, auxiliary infiltration, drying, and ultrasonic frequency induction heating technology based quick aluminizing. The technology has the following advantages: concentration and consumption of a pickling solution are reduced, and a rust removal speed is greatly increased; the hot-dipping aluminizing temperature is low, and the aluminizing process is short; compared with a heating method of a traditional resistance aluminizing furnace, the induction heating method adopted enables the utilization rate of electrical energy to be improved over 20%, and enables the annual output to be increased over one time; compared with traditional diffuse type aluminizing steel material, the new aluminizing steel material prepared with the technology retains a pure aluminium layer and an iron-aluminium alloy layer under a columnar eutectic state, and has the effects of corrosion resistance, heat resistance, abrasion resistance and photo-thermal reflectivity; a fragility area on the surface is eliminated; bending performance and punch forming performance are greatly improved; resistance to heat shocks and resistance to thermal fatigue are improved over 10%.

Owner:WUHAN TIANCONG CREATIVE TECH

Method for preparing centrifugal roller through laser cladding

PendingCN111945156AExtended service lifeBoth corrosion resistanceMetallic material coating processesSand blastingCorrosion resistant

The invention relates to a method for preparing a centrifugal roller through laser cladding. The method comprises the following steps that the working surface of a centrifugal roller blank is subjected to sand blasting treatment; alloy laser cladding powder is prepared to serve as a functional layer, a priming layer or a transition layer; the prepared alloy powder is placed in a drying oven to bedried; the centrifugal roller subjected to sand blasting treatment is installed on a positioner; the alloy powder is loaded into a powder feeder, and argon is adopted as carrier gas; laser cladding process debugging of the treated powder is carried out on a substrate made of the same material as the centrifugal roller to finish cladding on a block; after no defect is found, the centrifugal rollerstarts to be cladded; and dismounting is carried out after completion of clapping of the centrifugal roller. According to the method for preparing the centrifugal roller through laser cladding, different kinds of alloy powder are adopted for layered cladding, the surface is made of corrosion-resistant, high-temperature-resistant, abrasion-resistant, erosion-resistant and scouring-resistant cobalt-based alloy, the technological method for preparing the alloy layer on the centrifugal roller through the laser cladding technology is provided, and the problem that an existing surfacing stainless steel centrifugal roller is short in service life is solved; and meanwhile, a technical scheme is provided for preparation of related key parts in other industries.

Owner:宁夏北鼎新材料产业技术有限公司

Method for manufacturing high-conductivity corrosion-resistant pure copper special cable

InactiveCN104575874AImprove conductivityIntegrity guaranteedCable/conductor manufactureMaterials processingCopper

The invention discloses a method for manufacturing a high-conductivity corrosion-resistant pure copper special cable, and belongs to the technical field of material processing. High-purity cathode electrolytic copper is adopted as a substrate of a wire, and the cable is formed through mixing and preheating, smelting, heat preservation, traction, wire drawing, crystallization, annealing and cooling and oxide layer plating treatment. The TR specification volume resistivity of the cable is smaller than or equal to 0.01707omega.cm<3>, and the tensile strength of the cable is more than 420 MPa. The method can meet the requirement of submarine cables for high-conductivity corrosion-resistant materials well, and can be used for the field requiring high-conductivity high-strength materials. The method has the advantages of being simple in process and low in cost.

Owner:ANHUI CHUJIANG HIGH TECH ELECTRIC WIRE CO LTD

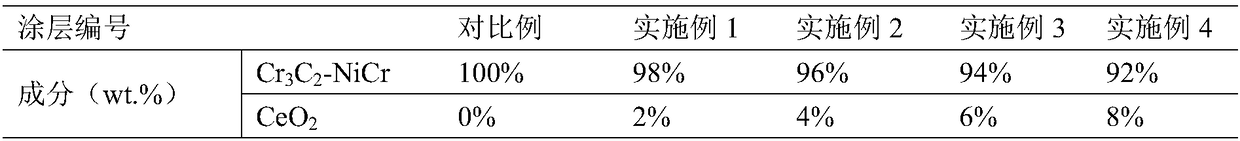

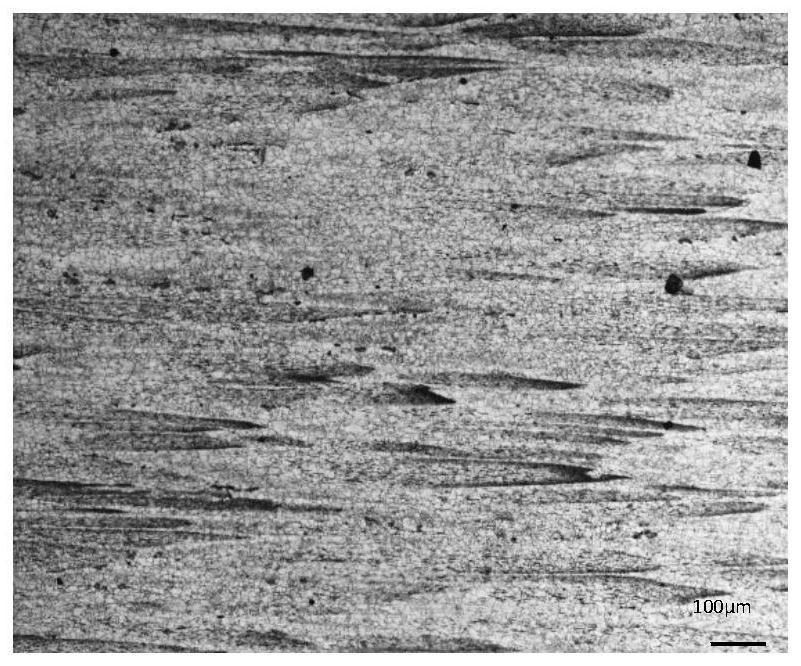

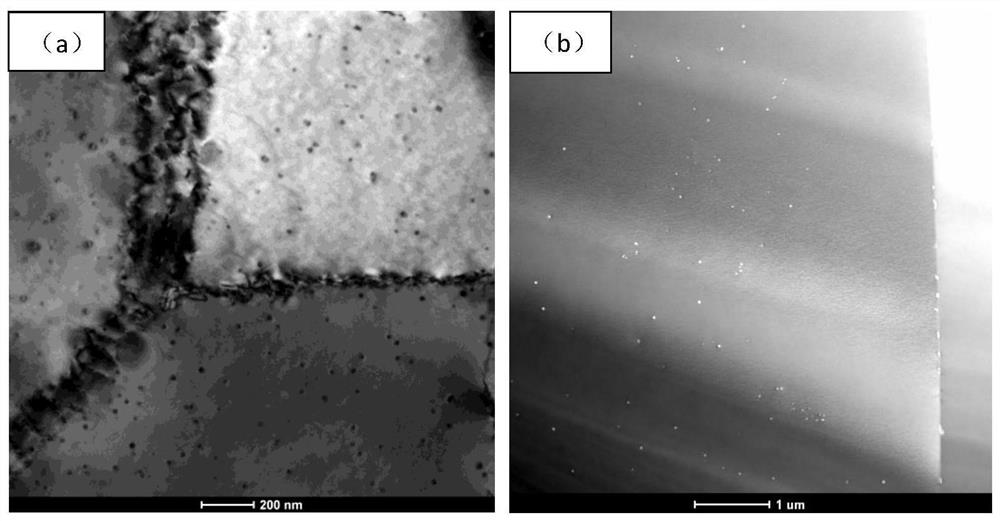

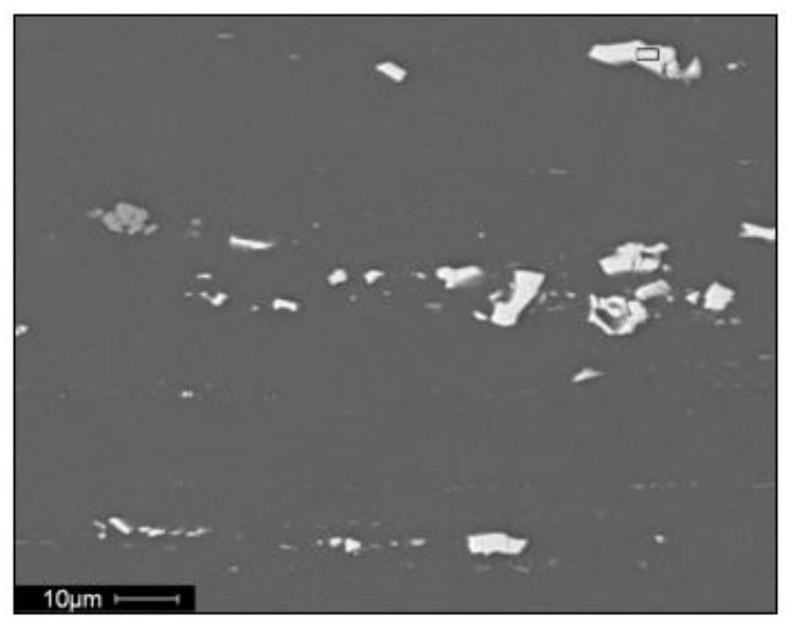

Preparation method of rare earth oxide doped high temperature oxidation resisting and abrasion resisting coating for H13 steel surface protecting

The invention discloses a rare earth oxide doped high temperature oxidation resisting and abrasion resisting coating for H13 steel surface protecting and a preparation method of the coating. Accordingto the method, an active combustion-high velocity air fuel (AC-HVAF) technology is adopted for spraying powder on a base body (H13 steel) to form the composite coating; and the powder comprises Cr3C2-NiCr powder and nanometer CeO2 powder, the doping content of the nanometer CeO2 powder is 2-8 wt%, and the balance is the Cr3C2-NiCr powder. The coating prepared through the method is compact in structure and uniform in distribution, a flattened structure is achieved, and the coating is closely combined with a boundary. Besides, after doping of the nanometer CeO2 powder, the tissue compactness ofthe coating is further improved, the porosity is reduced, the defects of non-molten matter, micro cracks and the like are less, better high temperature oxidation resisting performance and abrasion resisting performance are both achieved, and the high temperature oxidation resisting performance and the abrasion resisting performance of the H13 steel in the using process can be improved easily.

Owner:GUANGDONG ZHENGDE MATERIAL SURFACE TECH

High-toughness corrosion-resistant 7xxx series aluminum alloy and processing method thereof

The invention discloses a high-toughness corrosion-resistant 7xxx series alloy and a processing method thereof. The aluminum alloy comprises the following components of, in percentage by weight, 8.8%-10% of Zn, 2.0%-3.0% of Mg, 1.0%-2.5% of Cu, 0.05%-0.2% of Zr, 0.01%-0.15% of Ti, less than or equal to 0.1% of Mn, less than or equal to 0.2% of Fe, less than or equal to 0.1% of Si, less than or equal to 0.15% of the total content of other impurity elements, and the balance Al, wherein Zn + Mg + Cu is greater than or equal to 12% and less than or equal to 15.5%, Zn / Mg is greater than or equal to 3 and less than or equal to 5, and Cu / Mg is greater than or equal to 0.3 and less than or equal to 1. The aluminum alloy has high toughness, good stress corrosion resistance and excellent forming machining performance, and the problems that in the prior art, a high-strength aluminum alloy material is insufficient in toughness matching, poor in stress corrosion and the like are effectively solved; under a peak aging T6 state, the yield strength of alloy bars and profiles is greater than 700MPa, the tensile strength is greater than 730MPa, the ductility is 9% or above, and the conductivity is greater than or equal to 30% IACS; and the prepared bars and profiles can be widely applied to the fields of aviation, spaceflight, nuclear industry, transportation, weapons and the like.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

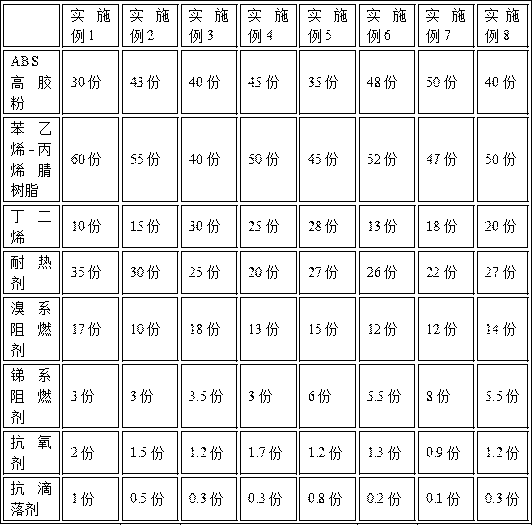

Special heat-resistant, high-impact and flame-retardant resin for outer casing of storage battery

InactiveCN108752840AImprove corrosion resistanceHigh heat resistanceJackets/cases materialsTO-18Styrene-acrylonitrile resin

The invention discloses special heat-resistant, high-impact and flame-retardant resin for an outer casing of a storage battery. The special heat-resistant, high-impact and flame-retardant resin is prepared from the following raw materials and components in parts by mass: 30 to 50 parts of ABS (acrylonitrile butadiene styrene) powder, 40 to 60 parts of styrene-acrylonitrile resin, 10 to 30 parts ofbutadiene, 20 to 35 parts of heat-resistant agent, 10 to 18 parts of bromine flame retardant, 3 to 8 parts of antinomy flame retardant, 0.5 to 2 parts of antioxidant, and 0.1 to 1 part of anti-dripping agent. The special heat-resistant, high-impact and flame-retardant resin has the beneficial effects that the ABS with high-impact property is used as the main raw material, and is added with the bromine flame retardant, the antinomy flame retardant and the anti-dripping agent, so that the flame-retardant property is obviously improved; by adding the heat-resistant property, the heat-resistant temperature of the ABS material is obviously increased; by adding the antioxidant, the corrosion-resistant property of the outer casing of the storage battery is improved; the heat-resistant property,corrosion-resistant property, high-impact property and obvious fireproof property are realized; the ABS material has good shrinkage property, so that the expanded and deformed outer casing can be restored in the charging process.

Owner:信丰永冠塑电科技有限公司

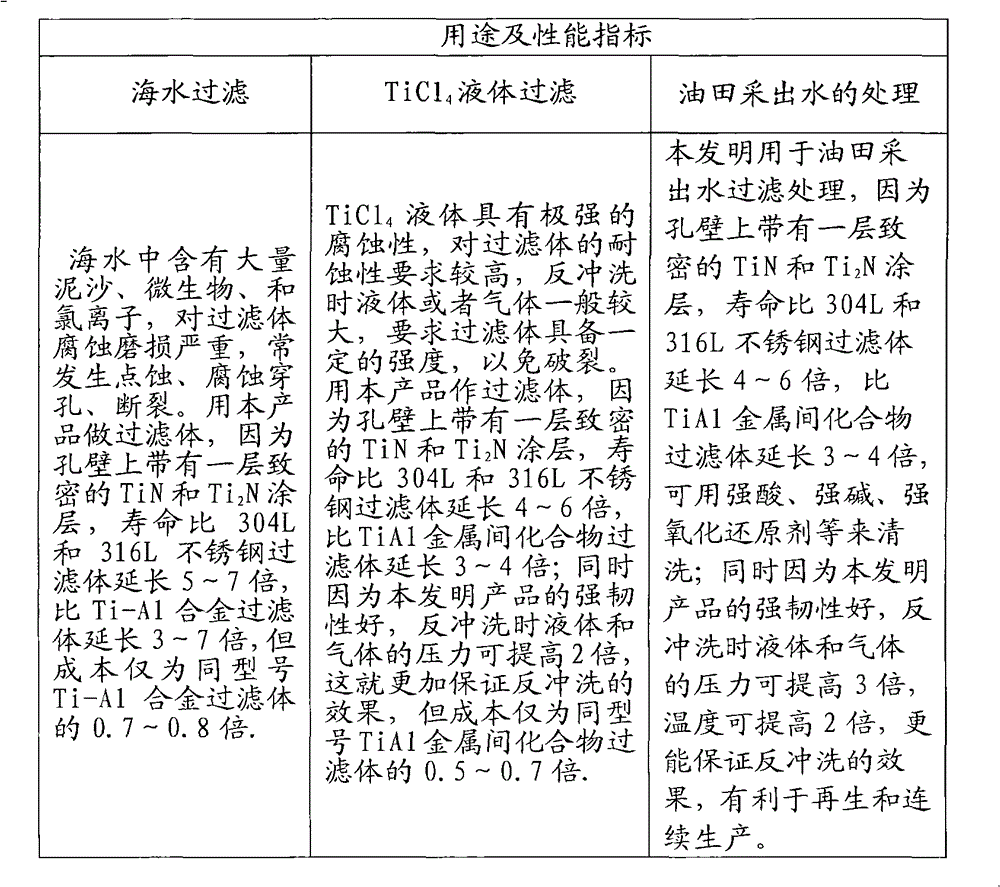

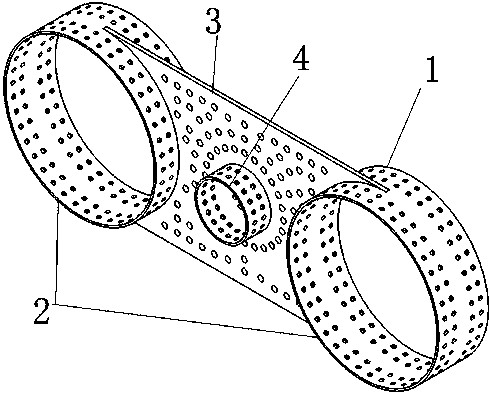

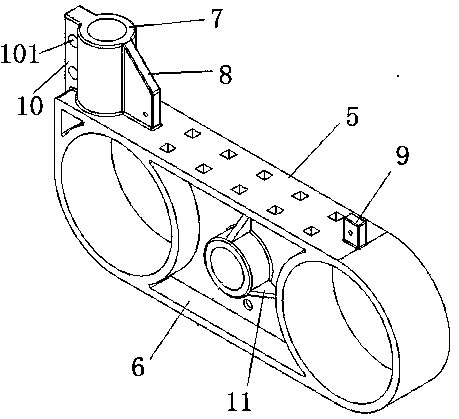

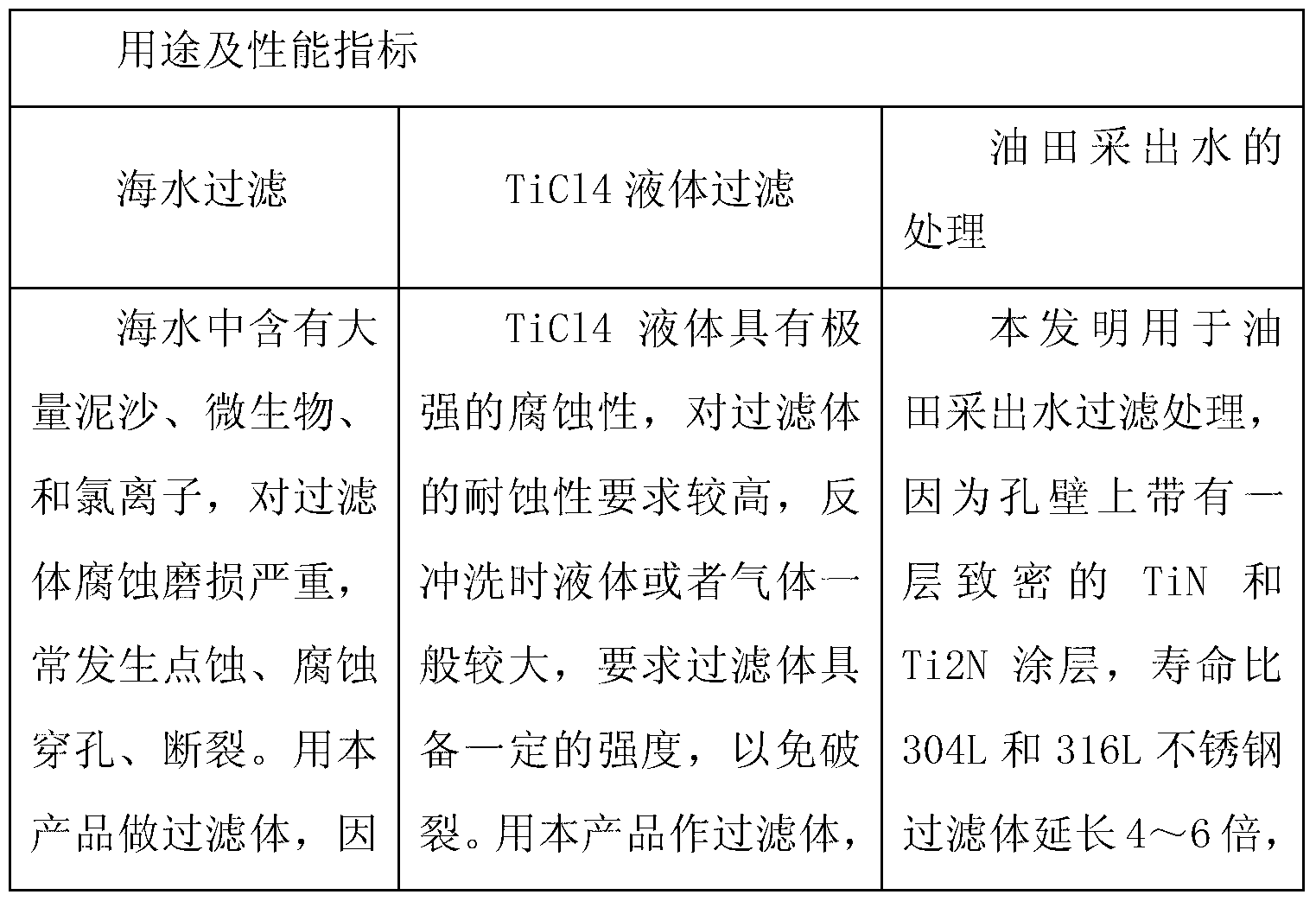

Porous membrane with TiN coating and preparation method thereof

ActiveCN102719691ABoth strengthBoth corrosion resistanceSolid state diffusion coatingFiltration separationNitrogen plasmaPorous membrane

A porous membrane with a TiN coating. A nitrogen plasma beam is utilized to carry out scanning heating azotizing treatment on a lamellar compact prepared from Ti and TiH2, so as to form a pore-like structure and obtain compact and continuous TiN coating and Ti2N coating surrounding a Ti skeleton matrix on the Ti skeleton among the pores. The method of the invention completes acquisition of the porous material and formation of the coating in one step, and has advantages of large porosity range of the film, short preparation process, high efficiency and high yield. The porous Ti membrane with TiN coatings on surfaces of the pores has uniform and dense tissue, is in good metallurgical combination with the matrix, and has micro hardness of 1270-1430 HV. The porous membrane has similar shape and size as a blank and good similarity. Besides, the membrane with good abrasion resistance and corrosion resistance can be used as a catalyst carrier and a filtering body in the industries of catalysis, environment purification and medicine, and has wide application prospects.

Owner:SHANDONG UNIV OF SCI & TECH

Preparation method of corrosion-resistant aluminum alloy automobile hub

InactiveCN108796263AHigh mechanical strengthImprove applicabilityAnti-corrosive paintsEpoxy resin coatingsStrontium carbonateRare earth

The invention discloses a corrosion-resistant aluminum alloy automobile hub. The corrosion-resistant aluminum alloy automobile hub comprises the following components, by weight, 95-97 parts of aluminum, 1-1.5 parts of magnesium, 0.2-0.5 part of chromium, 0.5-0.8 part of zinc, 0.05-0.1 part of tin, 0.5-0.8 parts of iron and 1-2 parts of corrosion-resistant nano powder, wherein the corrosion-resistant nano powder comprises the following components of, by weight, 60-80 parts of silicon tetrafluoride, 10-15 parts of silicon dioxide, 5-10 parts of strontium carbonate and 1-5 parts of rare earth powder. The invention provides a preparation method of the corrosion-resistant aluminum alloy automobile hub. The aluminum alloy automobile hub prepared by the method is high in mechanical strength, thedefect that the durability of an aluminum alloy hub in the prior art is poor is effectively overcome, meanwhile, the corrosion resistance is also considered, and then the applicability of the aluminumalloy hub is improved.

Owner:宁波展欣汽车科技发展有限公司

Steel-plastic support for breeding net cage

PendingCN108684593AHigh strengthStrength is easy to guaranteeClimate change adaptationPisciculture and aquariaSurface layerHigh intensity

The invention relates to the technical field of breeding, in particular to a steel-plastic support for a breeding net cage. The support comprises a metal frame and a plastic surface layer, the metal frame comprises two floating pipe fixing rings arranged in parallel, a steel plate is welded between the two floating pipe fixing rings, a steel ring with a hole is arranged in the center of the steelplate, the plastic surface layer wraps the metal frame, and the support is formed through integrated injection molding. The support adopts a steel-plastic integration structure, corrosion resistance and high strength of plastic are both achieved, mainstream plastic supports and few metal supports formed through a casting technology in the market are overturned thoroughly, the net cage can adapt tosevere environments such as violent typhoon, and better breeding net cage equipment is provided for farmers.

Owner:GUANGDONG LIANSU TECH INDAL

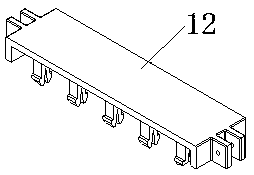

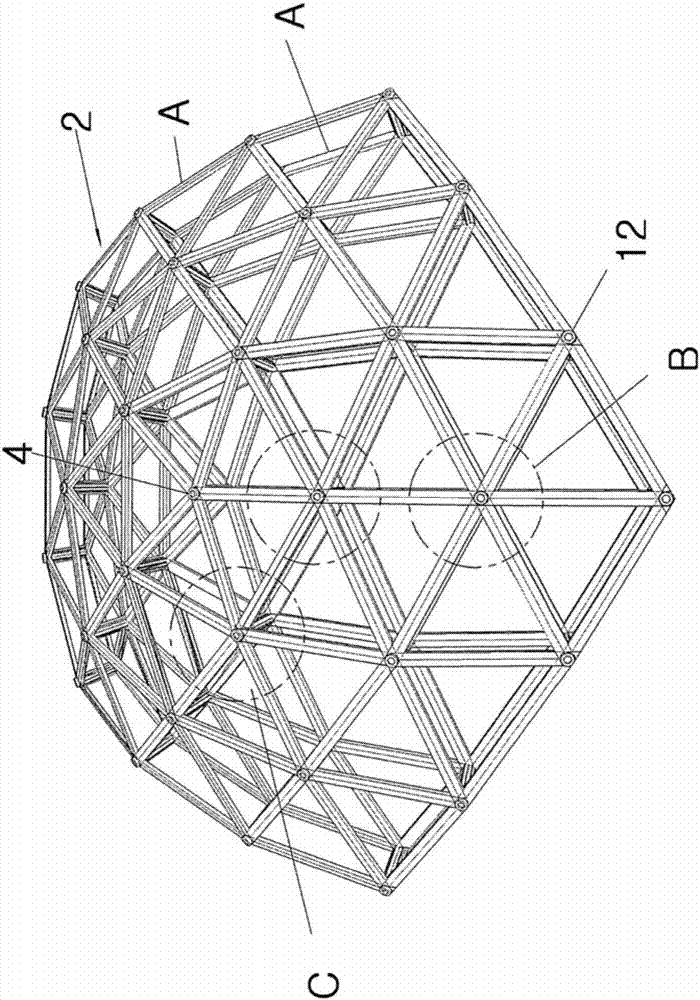

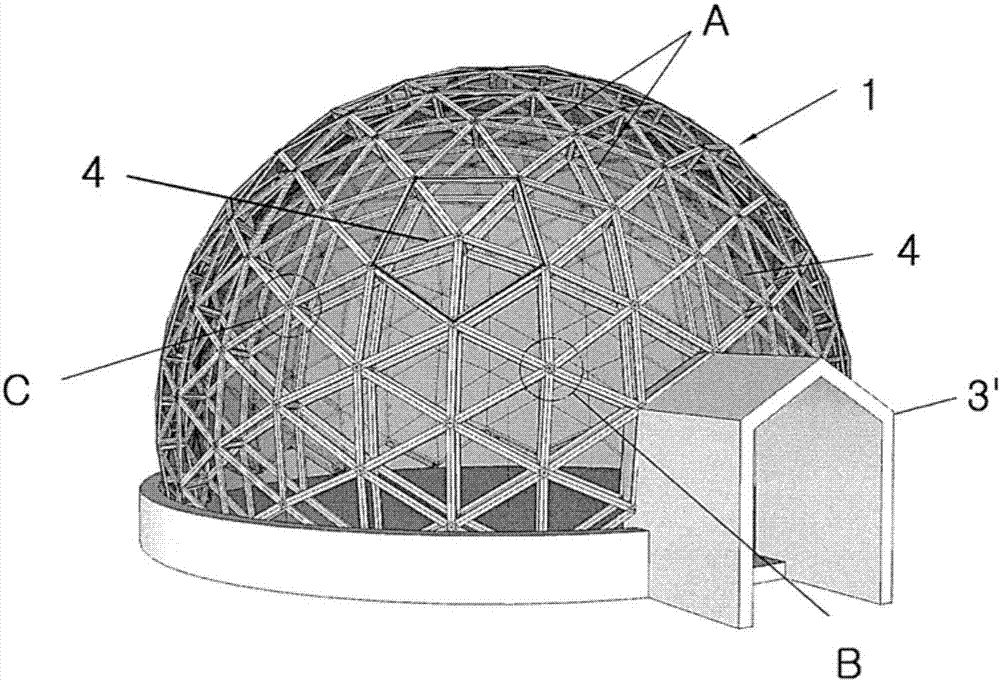

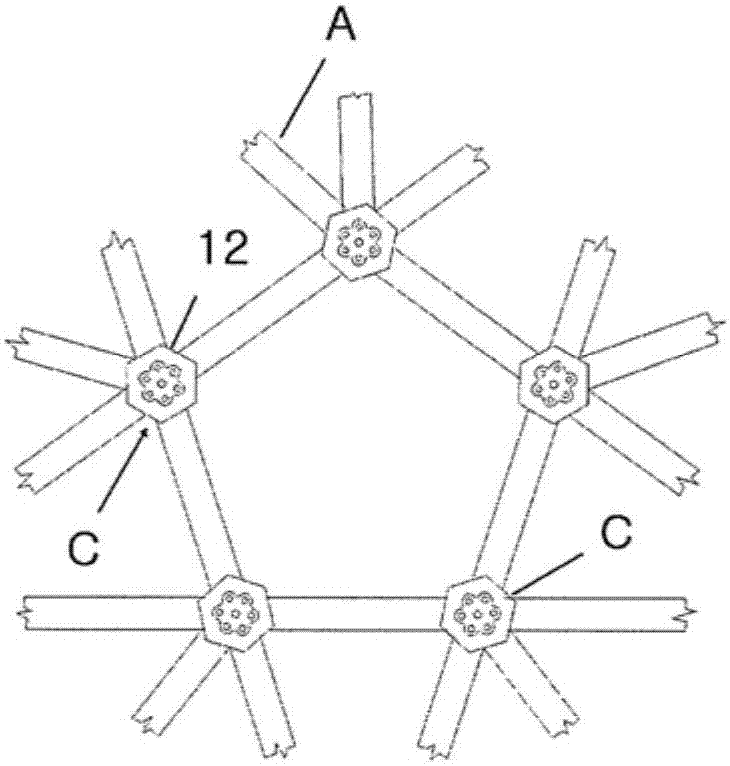

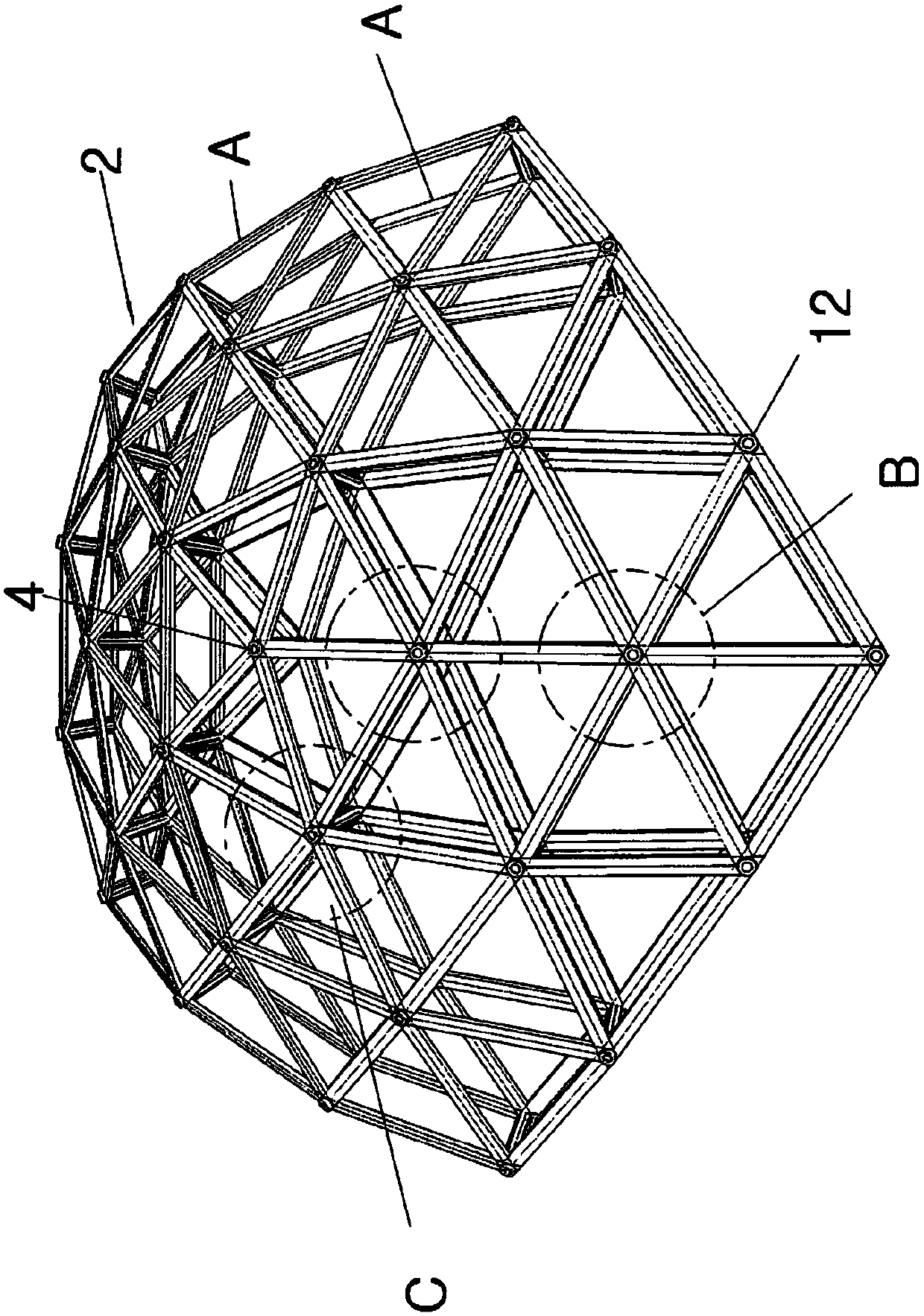

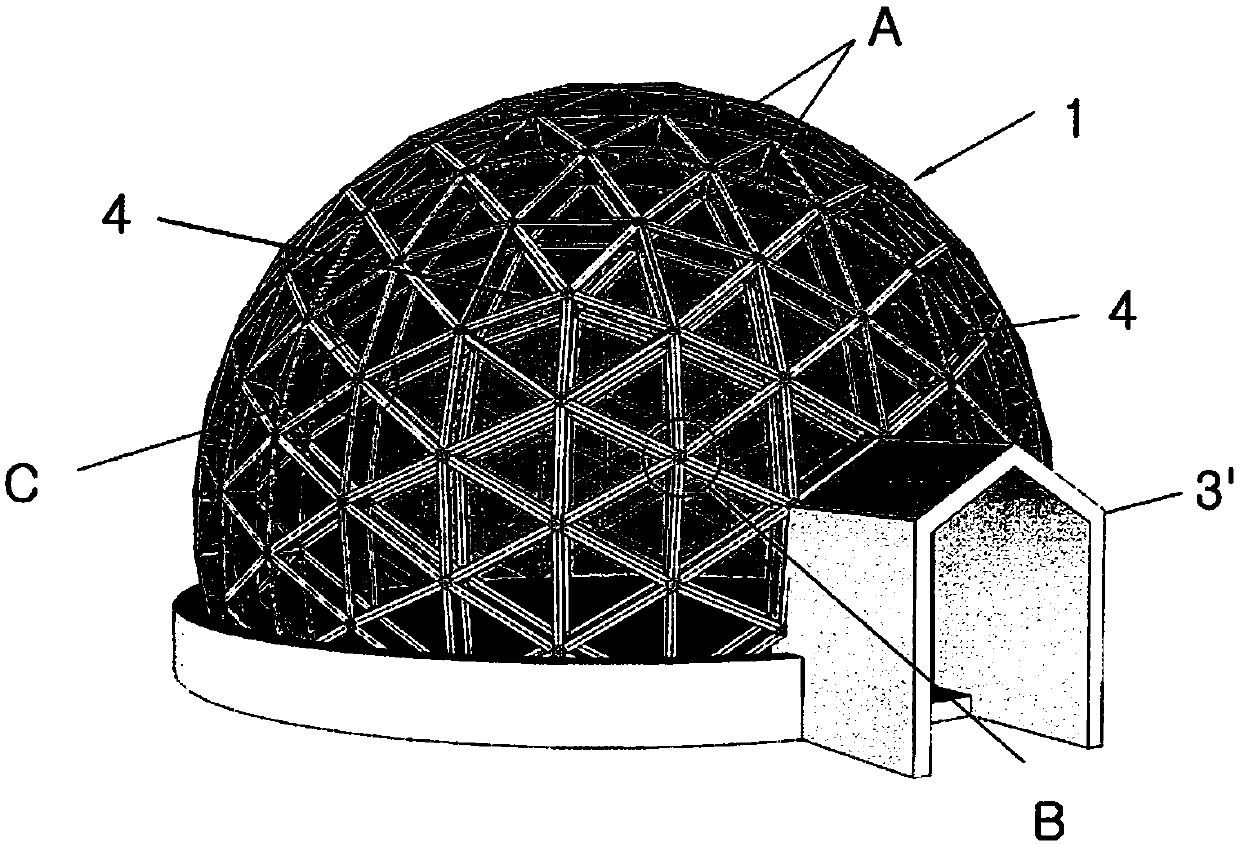

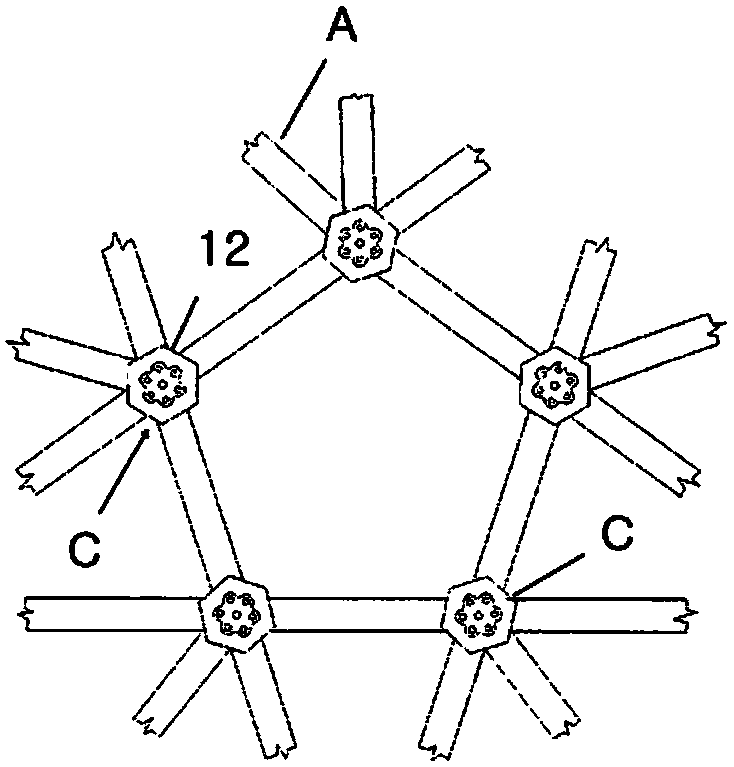

Assembled dome and spheroid

ActiveCN107201797AGood heat insulationImprove fire resistanceBuilding roofsArched structuresInsertion stentEngineering

The invention provides an assembled dome and spheroid. An assembled dome is formed by the combination of pentagons and hexagons. The assembled dome and spheroid is characterized in that the assembly method of five corners assembly is to assemble the outward and inward stents that form each cutting oblique face portion into double layers by using six corners assembly components and five corners assembly components, the outward stent and the inner stent that forms transverse beams are assembled into a stent assembly set, and upper and lower fixed bolts are used for fixing the stent assembly set on each shaft prop, so as to form a five corners assembly by the six corners assembly components and the five corners assembly components. 6 five corners assembly components are assembled into a hemispherical dome. For the stent assembly set, the stent assembly sets are separately assembled to the surface (upper end) and inner face (lower end) of a shaft support by using horizontal bolts and fixing bolts, and therefore the stent assembly sets are combined and fixed in opposite direction to form double layer. A spheroid architecture can be formed by 12 five corners assembly components.

Owner:李然熙

Polyphenylamine composition with clay ore as carrier and its preparing process

A clay ore-carried polyphenylamine composite material is prepared through separating and purifying clay ore, preparing 5-15% suspension mineral slurry, adding phenylamine and hyaluronic acid, stirring while slowly dropping oxidizing trigger, reaction for 6-24 hr while stirring, then filtering and dewatering, washing 2-4 times, and spray-drying or preparing suspension. This composite material possesses both the easy dispersivity of clay mineral and the excellent physico-chemical property of polyphenylamine (conductivity and corrosion-proofness). Its advantages are high dispersity, electric conductivity and corrosion resistance, and low cost.

Owner:ZHEJIANG UNIV

Porous membrane with TiN coating and preparation method thereof

ActiveCN102719691BBoth strengthBoth corrosion resistanceSolid state diffusion coatingFiltration separationNitrogen plasmaPorous membrane

Owner:SHANDONG UNIV OF SCI & TECH

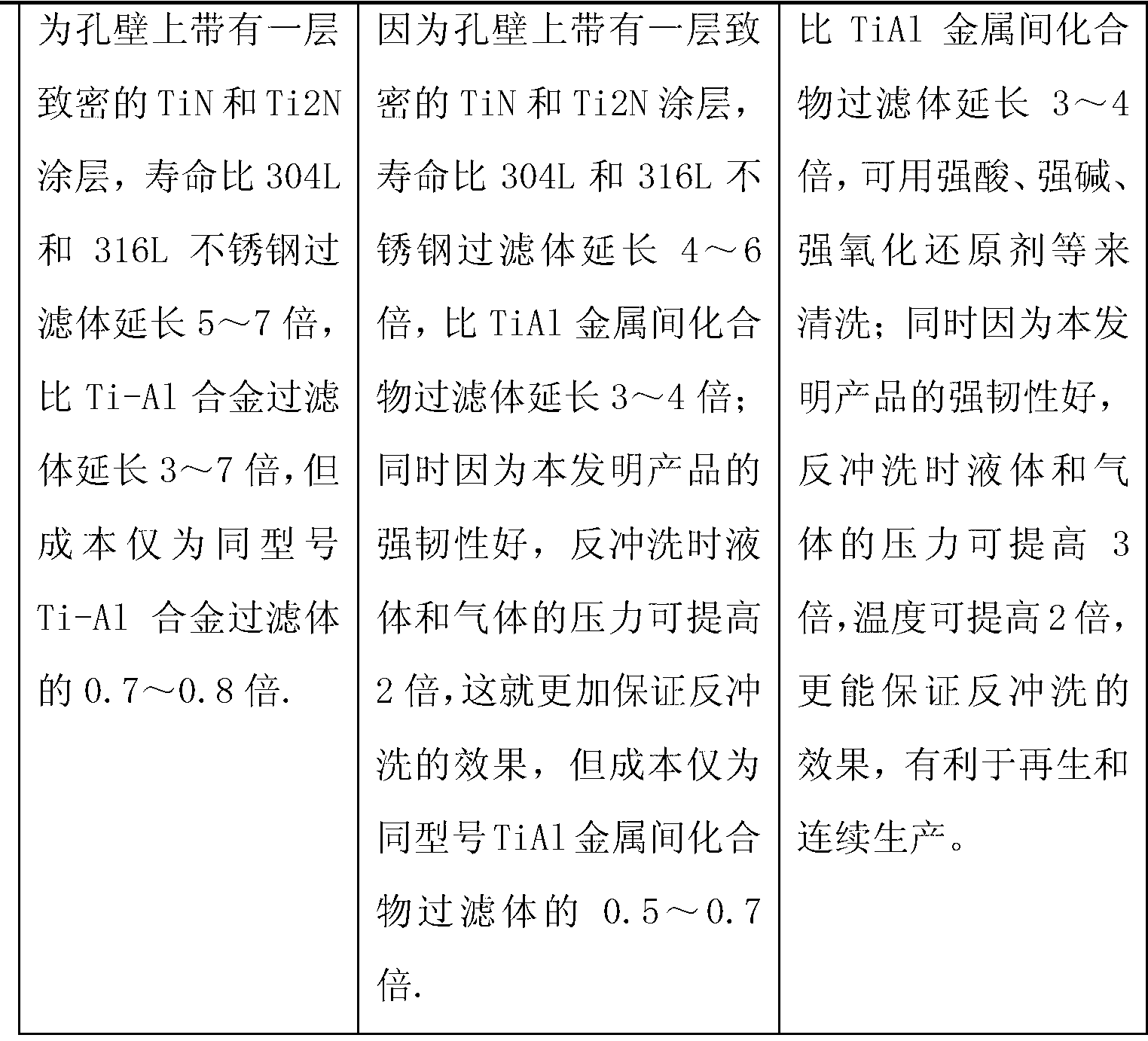

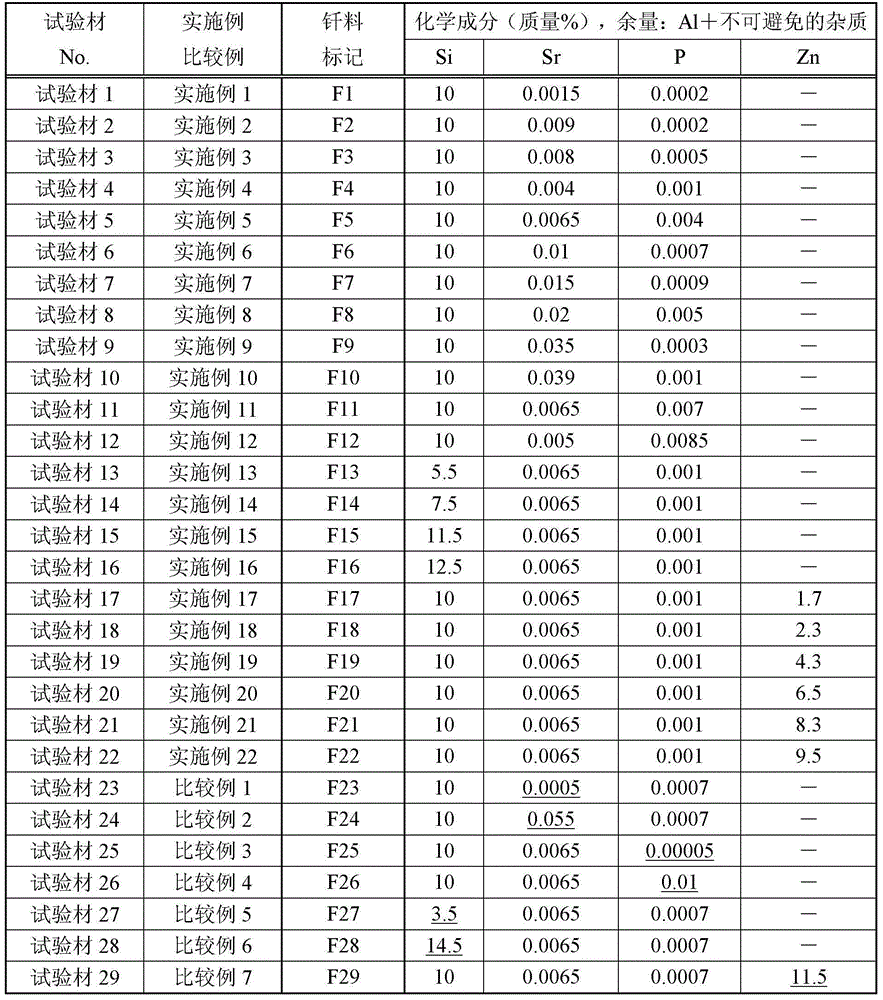

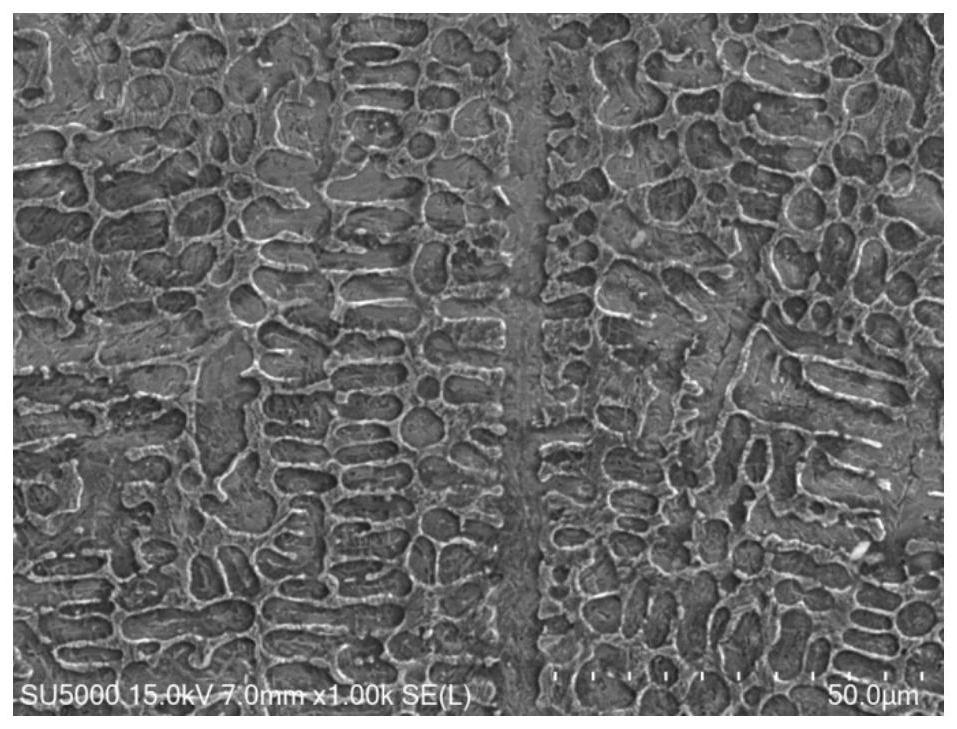

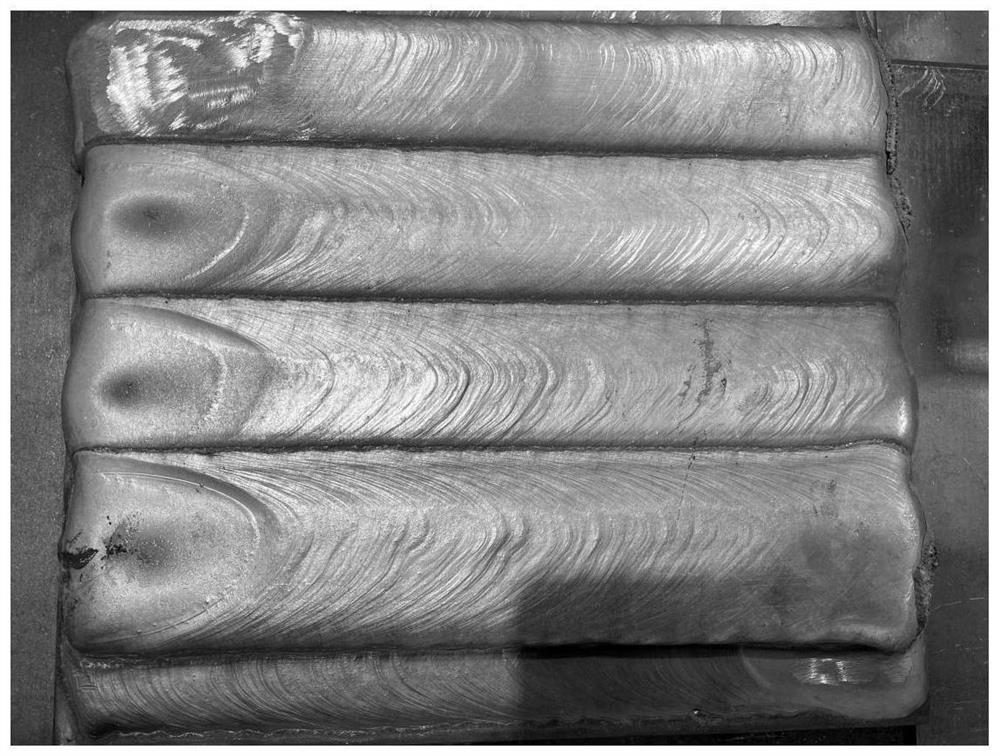

Aluminum alloy brazing filler metal and brazing plate

InactiveCN104070304AGood liquidityLess solder thicknessWelding/cutting media/materialsSoldering mediaForeign matterFiller metal

The invention discloses an aluminum alloy brazing filler metal constituted by Si in a range from 4.0 to 13.0wt%, Sr 0.001 to 0.050wt%, P 0.0001 to 0.0090 wt%, and other aluminum alloy formed by A1 and other inevitable foreign matters and a brazing plate using the same. The aluminum alloy brazing filler metal has advantages of excellent, strength, hard-solder performance, and anti-corrosion performance.

Owner:KOBE STEEL LTD

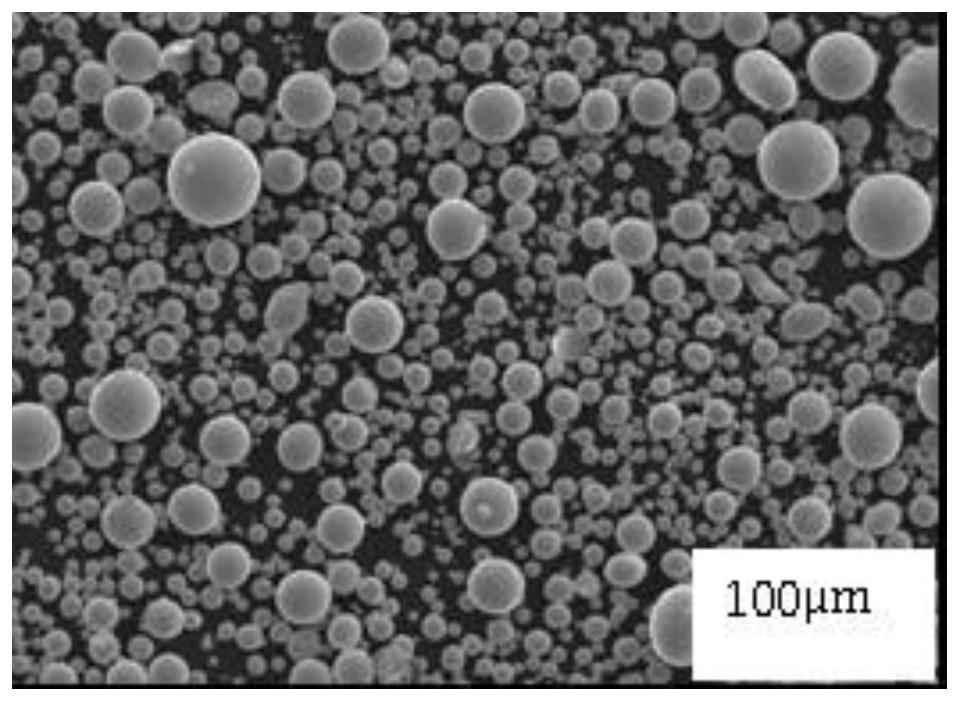

Iron-based alloy powder for laser cladding and preparation method thereof

ActiveCN113136532AHigh sphericityReduce oxygen contentTransportation and packagingMetal-working apparatusCrack resistanceHardness

The invention discloses iron-based alloy powder for laser cladding and a preparation method thereof. The powder comprises the following elements in percentage by weight: 0.05-0.2% of C, 10.6-15.6% of Cr, 1.5-2.5% of Ni, 10.5-15.4% of Mo, 0.4-0.6% of Mn, 0.9-1.2% of B, 0.8-1.0% of Si, 2.9-4.2% of V, and the balance of Fe and inevitable impurities. The preparation method comprises the steps of raw material weighing, smelting, steel casting, inert gas shielding atomization, airflow classification, screening and the like. The alloy powder prepared through the preparation method has excellent hardness, crack resistance and corrosion resistance.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Anti-corrosion wear-resistant material for industrial robots and manufacture method thereof

The invention discloses an anti-corrosion wear-resistant material for industrial robots. The anti-corrosion wear-resistant material is prepared from the following components by mass percentage: 0.52-0.56 of C, 0.5-1.7 of Si, 1.2-2 of Mn, less than or equal to 0.015 of P, less than or equal to 0.005 of S, 0.01-0.02 of V, 0.04-0.05 of Nb, and the balance of Fe and inevitable impurity elements. The outer surface hardness of the material is HB450 or above, and hardness of the part from outer surface to inside 20mm deep is HB430 or above. Gold phase tissues of the material comprise pearlite, bainite, ferrite and other gold phase tissues.

Owner:五河县纬立农业科技有限公司

Electronic electro-conductive paint and preparation method thereof

InactiveCN104974632AImprove conductivityGood film formingAnti-corrosive paintsElectrically-conductive paintsPolypyrroleGraphite

The invention discloses an electronic electro-conductive paint and a preparation method thereof, and belongs to the technical field of paints. The paint comprises the following components in parts by weight: 35 to 50 parts of phenolic resin, 5 to 10 parts of polyaniline, 3 to 7 parts of electro-conductive graphite powder, 5 to 10 parts of polypyrrole, 2 to 5 parts of lanthanum trichloride, 2 to 5 parts of nano aluminum powder, 5 to 12 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, and 15 to 32 parts of xylene. The preparation method comprises the following steps: (1) precisely weighing the raw materials; (2) evenly grinding the raw materials in a ball mill to obtain mixed powder; (3) placing the powder in a static mixer and evenly mixing to obtain premix; (4) allowing the premix to stand still for 24 to 48 hours in a room to obtain the electronic electro-conductive paint. The provided electronic electro-conductive paint has a good electro-conductive performance and a good film-forming effect, also has certain corrosion resistant, high temperature resistant, and weatherability performances, and is capable of preventing electronic elements from being corroded in a long time.

Owner:苏州洋杰电子有限公司

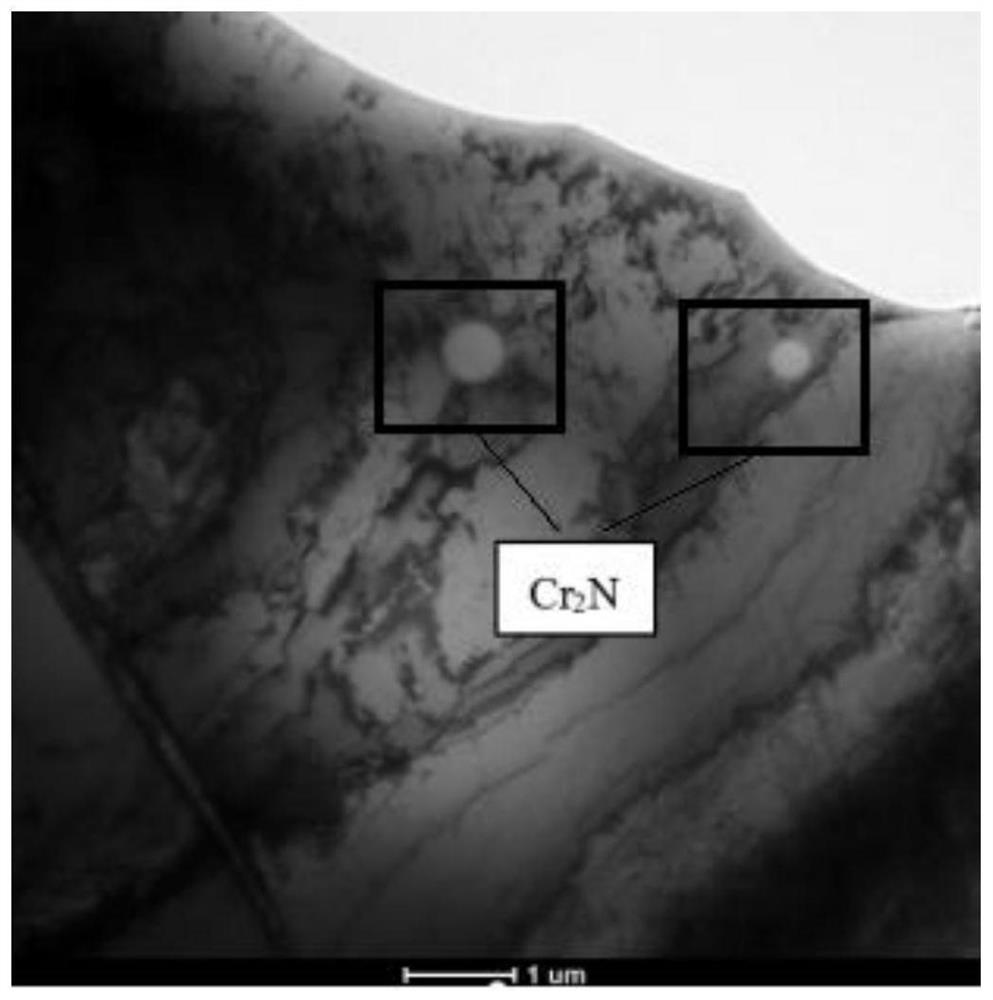

Low-nickel austenitic stainless steel flux-cored welding strip and preparation method thereof

PendingCN114734162AReduced propensity for hot crackingGuaranteed corrosion resistanceWelding/cutting media/materialsSoldering mediaPotassium feldsparAustenitic stainless steel

The invention discloses a low-nickel austenitic stainless steel flux-cored welding strip and a preparation method thereof. The invention belongs to the technical field of welding material preparation. The invention aims to solve the technical problems that the existing stainless steel welding strip for strip surfacing needs to be matched with a welding flux to protect a molten pool, and the corrosion resistance and the wear resistance of a cladding layer are poor. The invention discloses a low-nickel austenitic stainless steel flux-cored welding strip which is composed of a 06Cr18Mn5Ni4Cu2N stainless steel skin and flux core powder filled in the 06Cr18Mn5Ni4Cu2N stainless steel skin. The flux core powder is formed by mixing, by mass, 5%-7% of potassium feldspar, 17%-20% of rutile, 1%-2% of zircon sand, 0.5%-1% of Al-Mg alloy, 22%-25% of electrolytic manganese, 0.5%-1% of silicon iron, 10%-12% of chromium powder, 8%-10% of nickel powder, 0.5%-1% of ferromolybdenum, 5%-10% of copper powder, 1%-2% of metal cobalt powder, 0.5%-1% of titanium powder and the balance nitrided ferrochrome powder, and the nitrogen content of the nitrided ferrochrome powder is 8%-10%. By adding beneficial elements, the surfacing cladding layer has the advantages of high hardness, wear resistance, corrosion resistance and the like.

Owner:HARBIN WELDING INST LTD +1

Modular Domes and Spheroids

ActiveCN107201797BGood heat insulationImprove fire resistanceBuilding roofsArched structuresInsertion stentEngineering

The invention provides an assembled dome and spheroid. An assembled dome is formed by the combination of pentagons and hexagons. The assembled dome and spheroid is characterized in that the assembly method of five corners assembly is to assemble the outward and inward stents that form each cutting oblique face portion into double layers by using six corners assembly components and five corners assembly components, the outward stent and the inner stent that forms transverse beams are assembled into a stent assembly set, and upper and lower fixed bolts are used for fixing the stent assembly set on each shaft prop, so as to form a five corners assembly by the six corners assembly components and the five corners assembly components. 6 five corners assembly components are assembled into a hemispherical dome. For the stent assembly set, the stent assembly sets are separately assembled to the surface (upper end) and inner face (lower end) of a shaft support by using horizontal bolts and fixing bolts, and therefore the stent assembly sets are combined and fixed in opposite direction to form double layer. A spheroid architecture can be formed by 12 five corners assembly components.

Owner:李然熙

Carbonide / iron-base alloy composite coating and its reaction brass coating technology

The present invention is one kind of composite (titanium carbide+chromium carbid) / ferroalloy coating and its reaction coating process, and belongs to the field of composite ceramic / metal coating. Industry Ti-Fe powder, Cr-Fe powder, B-Fe powder, Fe powder, etc. as main material, alcohol and organic adhesive are mixed to form slurry; the slurry is sprayed or painted onto the surface of base body; and through in-situ reaction and alloying under vacuum condition and at certain temperature, composite coating with hard phase of titanium carbide and chromium carbide and base phase of ferroalloy is formed after lowering the temperature. The present invention has low cost of forming the composite coating, and the composite coating has high heat resistance, high oxidation resistance, high corrosion resistance, high antiwear, etc. and may be used widely in metallurgy, thermal power generation and other fields.

Owner:UNIV OF SCI & TECH BEIJING

Corrosion-resistant and wear-resistant material for industrial robots and manufacturing method thereof

The invention discloses an anti-corrosion wear-resistant material for industrial robots. The anti-corrosion wear-resistant material is prepared from the following components by mass percentage: 0.52-0.56 of C, 0.5-1.7 of Si, 1.2-2 of Mn, less than or equal to 0.015 of P, less than or equal to 0.005 of S, 0.01-0.02 of V, 0.04-0.05 of Nb, and the balance of Fe and inevitable impurity elements. The outer surface hardness of the material is HB450 or above, and hardness of the part from outer surface to inside 20mm deep is HB430 or above. Gold phase tissues of the material comprise pearlite, bainite, ferrite and other gold phase tissues.

Owner:五河县纬立农业科技有限公司

Low-plumbum copper alloy

The invention relates to a low-lead copper alloy comprising the following elements in percentage by weight: 0.05-0.3% of plumbum (Pb), 0.3-0.8% of aluminum (Al), 0.01-0.4% of bismuth (bi), 0.1-2% of nickel (Ni), and more than 96.5% of copper (Cu) and zinc (Zn), wherein the content of the copper in the low-plumbum copper alloy is 58-70%. The low-plumbum copper alloy of the invention has the advantages of favorable material performance, favorable tenacity and favorable processing performance, and can enhance the intensity and corrosion resistance of the alloy.

Owner:MODERN ISLANDS

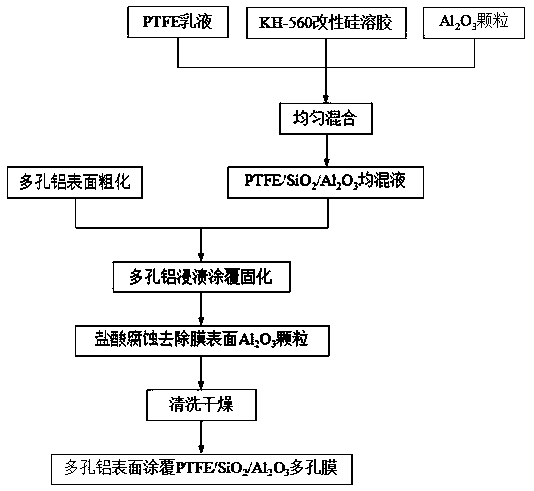

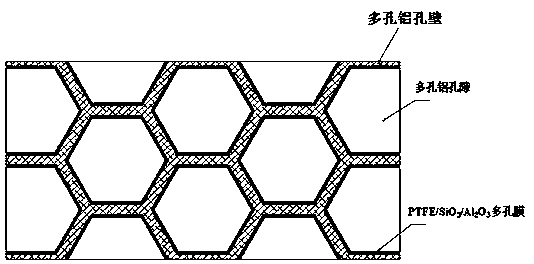

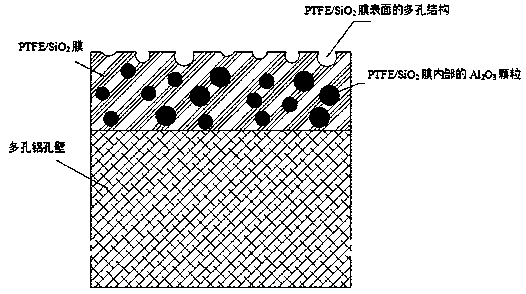

Preparation method of PTFE/SiO2/Al2O3 porous membrane coated on surface of porous aluminum

ActiveCN109332137ASimple processImprove preparation efficiencyPretreated surfacesCoatingsPorous membraneEmulsion

The invention discloses a preparation method of a PTFE / SiO2 / Al2O3 porous membrane coated on the surface of porous aluminum, and belongs to the technical field of porous metal material surface treatment. The preparation method comprises the steps of adopting a PTFE emulsion, a KH-560 modified silica sol and Al2O3 particles as raw materials, and uniformly mixing the raw materials according to the matching ratio so as to obtain a uniform PTFE / SiO2 / Al2O3 mixed solution; secondly, dipping the surface-roughened porous aluminum in the PTFE / SiO2 / Al2O3 mixed solution, coating, curing, and obtaining a PTFE / SiO2 / Al2O3 film layer with the thickness being 40 to 60mum on the surface of the porous aluminum; and finally, using hydrochloric acid for corroding and removing the Al2O3 particles exposed on thePTFE / SiO2 / Al2O3 membrane layer on the surface of the porous aluminum, and forming the PTFE / SiO2 / Al2O3 porous membrane with the surface porosity being 5 to 40 percent and the surface aperture being 1to 10mum on the surface of the porous aluminum. The PTFE / SiO2 / Al2O3 porous membrane coated on the surface of the porous aluminum prepared through the invention is high in specific surface area, controllable in surface hole structure, good in corrosion resistance and hydrophobicity, simple in preparation process, and capable of realizing industrial production.

Owner:KUNMING UNIV OF SCI & TECH

Temperature-resistant, corrosion-resistant and high-adhesion adhesive and preparation method thereof

ActiveCN102559120BImprove impact resistanceImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCelluloseThermoplastic

The invention discloses a temperature-resistant, corrosion-resistant and high-adhesion adhesive and a preparation method thereof, and belongs to the technical field of adhesives. The temperature-resistant, corrosion-resistant and high-adhesion adhesive consists of two components, i. e., an adhesive A and an adhesive B, in the weight ratio of 100:1-10, wherein the adhesive A consists of chemical plasticizing vinyl ester resin, a polymerization inhibitor, a low shrinkage agent, a free radical curing solvent, gas-phase silicon dioxide, inorganic filler, a coupling agent, a defoaming agent, color paste or paint, a promoter and a promotion additive; and the adhesive B consists of phthalic ester, peroxide and inertial powder filler. The adhesive provided by the invention has the performance of heat resistance, corrosion resistance, penetration resistance, adhesion, positioning, impact resistance and the like, can be formed into different types at normal temperature, and medium and high temperature, is easy and convenient to operate, can bring the unique advantage of the adhesive into full play on some occasions requiring to paying attention to corrosion resistance, adhesion, heat resistance and the like, and is suitable for mutual adhesion among a continuous cellulose material, a concrete material, a metal material, stone, FRP (Fiber Reinforce Plastic), thermoplastic plastic and the like.

Owner:浙江天和树脂有限公司 +1

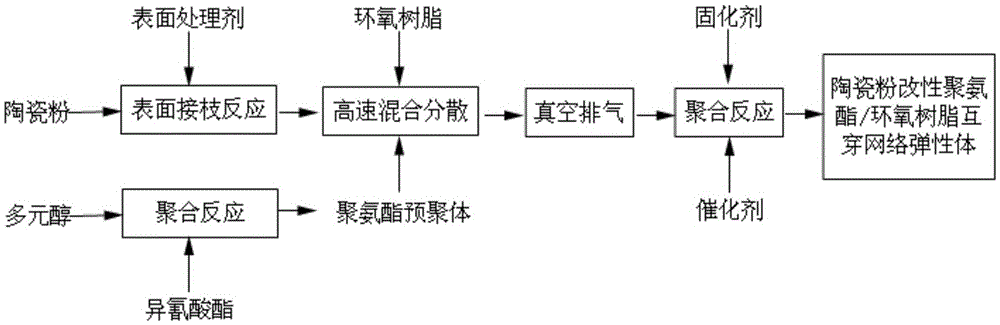

A kind of ceramic powder modified polyurethane/epoxy resin interpenetrating network elastomer

The invention discloses a ceramic powder modified polyurethane / epoxy resin interpenetrating network elastomer which comprises the following components in percentage by weight: 5-20% of modifying ceramic powder, 10-40% of epoxy resin, 50-80% of polyurethane prepolymer, 1-4% of catalyst and 4-20% of curing agent. The network elastomer can be used as a carrier roller of a conveyor. In the presence of the modifying ceramic powder, the wear resistance of the elastomer is further improved, and the dimensional stability is improved to some degree. Due to the carrier roller prepared from the elastomer, the technical bottleneck that a traditional carrier roller cannot have high wear resistance, high toughness, high-temperature resistance and low-temperature resistance at the same time is solved.

Owner:HUNAN YINGHONG SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com