High-toughness corrosion-resistant 7xxx series aluminum alloy and processing method thereof

A processing method and technology for aluminum alloys, applied in the field of aluminum alloys, can solve problems such as limited application scope, difficult control, overburning, etc., and achieve the effects of improving purity, inhibiting precipitation, and improving alloy corrosion resistance and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

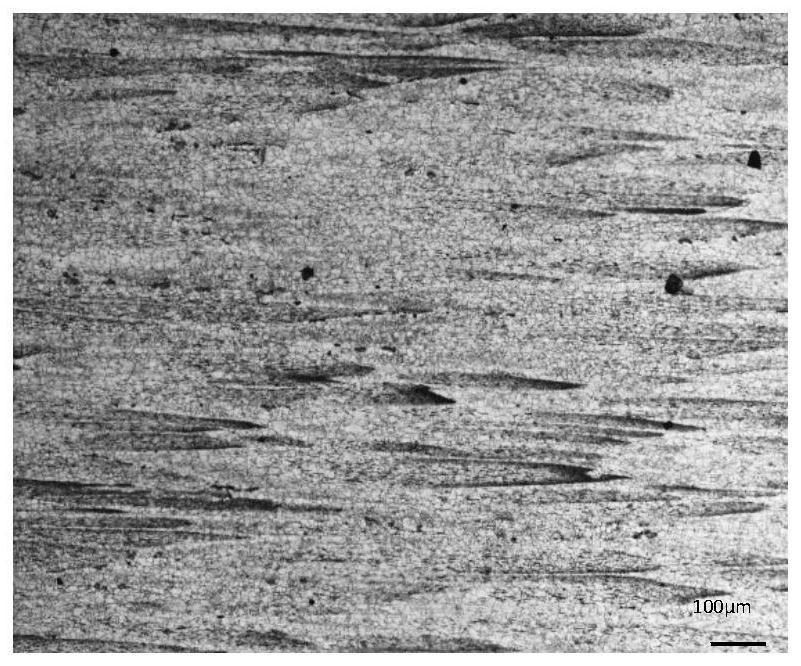

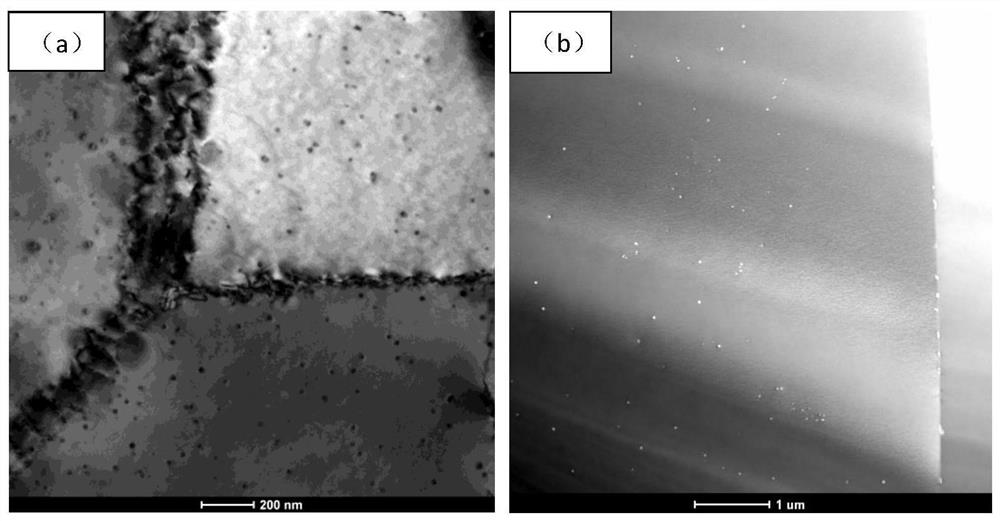

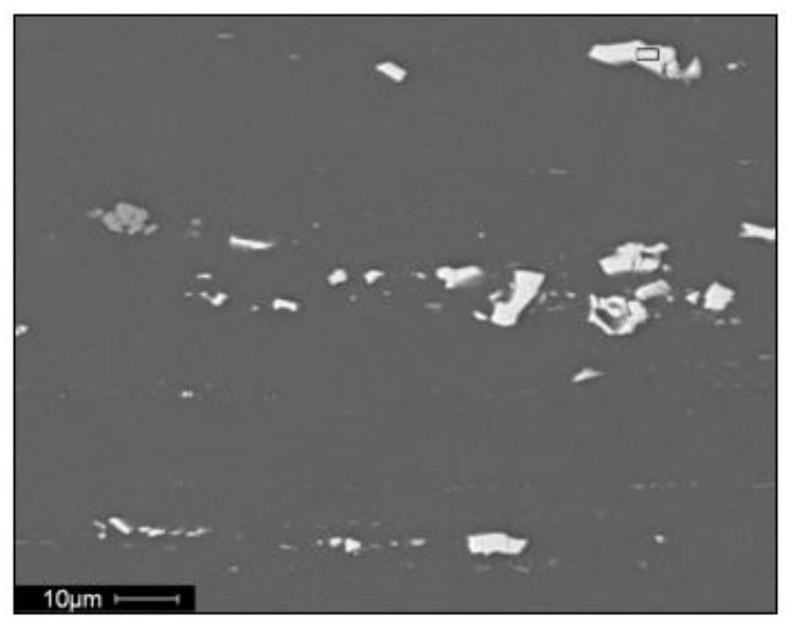

Image

Examples

Embodiment 1

[0034] A high-strength, toughness and corrosion-resistant 7xxx series aluminum alloy, its composition and weight percentage are: Zn 9.0%, Mg 2.2%, Cu 1.6%, Zr 0.12%, Ti 0.02%, Fe 0.1%, Si 0.08%, Mn 0.08 %, the rest is Al, Zn+Mg+Cu=12.8%, Zn / Mg=4.1, Cu / Mg=0.7.

[0035] The processing method of above-mentioned aluminum alloy comprises the following steps:

[0036] (1) Use aluminum ingots to add intermediate alloys to melt in a melting furnace, and use semi-continuous casting to obtain large-scale φ410mm ingots;

[0037] (2) Carry out homogenization heat treatment on the ingot, slowly raise the temperature from room temperature to 400°C at a heating rate of 50°C / h for 10 hours, then raise the temperature to 475°C at a heating rate of 5°C / h and hold for 48h, then heat at 30°C / h cooling speed for cooling;

[0038] (3) Carry the ingot, saw it, and heat it in an induction furnace before extrusion. The heating temperature of the ingot is 430°C. Extrude the material with an extrusi...

Embodiment 2

[0043] A high-strength, toughness and corrosion-resistant 7xxx series aluminum alloy, its composition and weight percentage are: Zn 9%, Mg 2.0%, Cu 1.0%, Zr 0.2%, Ti 0.15%, Fe 0.2%, Si 0.1%, Mn 0.08 %, the rest is Al, Zn+Mg+Cu=12%, Zn / Mg=4.5, Cu / Mg=0.5.

[0044] The processing method of above-mentioned aluminum alloy comprises the following steps:

[0045] (1) Use aluminum ingots to add intermediate alloys to melt in a melting furnace, and use semi-continuous casting to obtain large-scale φ410mm ingots;

[0046] (2) Carry out homogenization heat treatment on the ingot, slowly raise the temperature from room temperature to 450°C at a heating rate of 10°C / h for 10 hours, then raise the temperature to 480°C at a heating rate of 10°C / h for 60 hours, and heat at 70°C / h cooling speed for cooling;

[0047] (3) Carry the ingot, saw it, and heat it in an induction furnace before extrusion. The heating temperature of the ingot is 430°C. Extrude the material with an extrusion tempera...

Embodiment 3

[0052] A high-strength, toughness and corrosion-resistant 7xxx series aluminum alloy, its composition and weight percentage are: Zn 10%, Mg 2.8%, Cu 1.5%, Zr 0.15%, Ti 0.1%, Fe 0.05%, Si 0.05%, Mn 0.08 %, the rest is Al, Zn+Mg+Cu=14.3%, Zn / Mg=3.6, Cu / Mg=0.5.

[0053] The processing method of above-mentioned aluminum alloy comprises the following steps:

[0054] (1) Use aluminum ingots to add intermediate alloys to melt in a melting furnace, and use semi-continuous casting to obtain large-scale φ410mm ingots;

[0055] (2) Carry out homogenization heat treatment on the ingot, slowly raise the temperature from room temperature to 300°C for 10 hours at a heating rate of 15°C / h, and then heat it to 465°C at a heating rate of 15°C / h for 20 hours, then heat it at 100°C / h cooling speed for cooling;

[0056] (3) Carry the ingot, saw it, and heat it in an induction furnace before extrusion. The heating temperature of the ingot is 430°C. Extrude the material, the extrusion temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com