Porous membrane with TiN coating and preparation method thereof

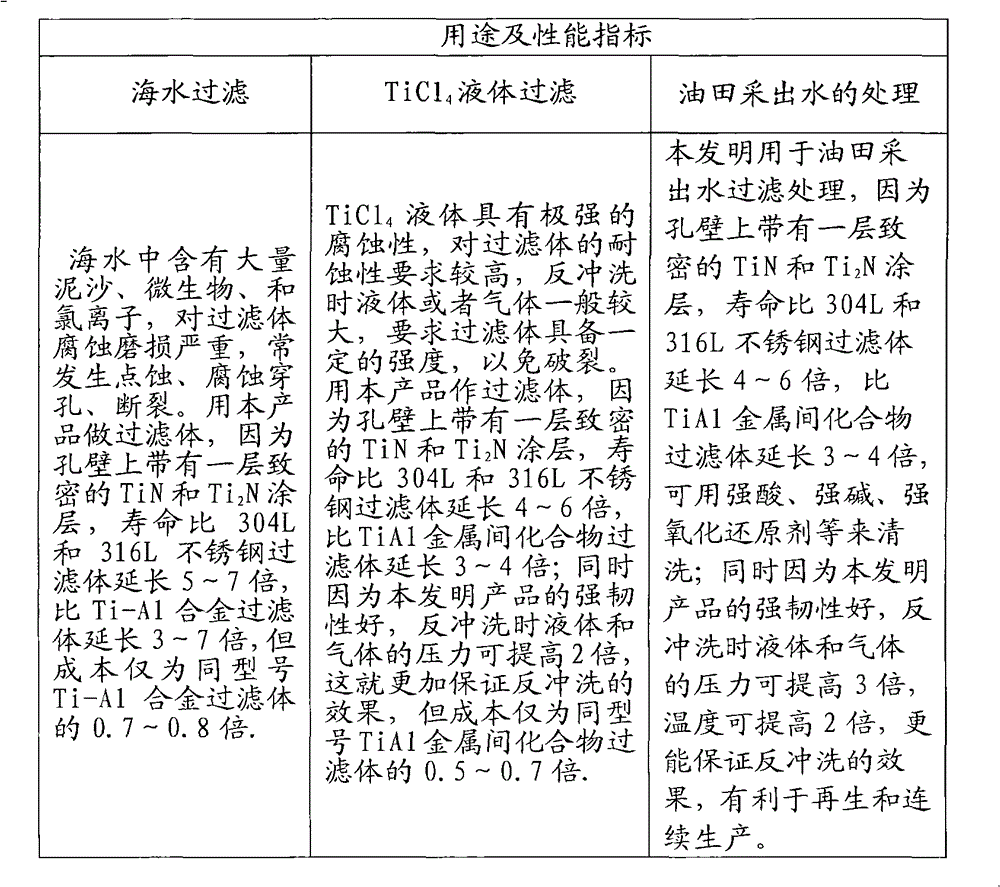

A porous film and coating technology, which is applied in the field of porous materials and their preparation, porous Ti and its preparation, can solve the problem that the surface wear resistance, corrosion resistance coating and TiN coating cannot achieve continuous, The problems of dense structure and insignificant effect of corrosion resistance can achieve the effect of low cost of raw materials, good controllability of product quality and narrow pore size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The porous membrane with TiN coating of the present embodiment is prepared by the following method:

[0020] Step 1: Take Ti powder and TiH 2 Powder, Ti, TiH 2 The powder purity is greater than 99.6%, and the average size is 40, 33 μm, respectively.

[0021] The second step: powder weighing and mixing

[0022] Raw material according to 1wt% TiH 2 powder, and the rest is weighed as Ti powder. Put the weighed powder into a ball mill and mix it for 4 hours, take it out, pour it into a mold, and press it into a square sheet compact of 30×30×5mm under a pressure of 120MP, with a relative density of about 63%.

[0023] Step Three: Warm Up

[0024] Slowly heat the compact in a vacuum furnace to 300°C for preheating, and keep it warm for 0.5 hours.

[0025] Step 4: Nitrogen plasma beam scanning heating process preparation

[0026] Turn on the power, water, and gas switches of the plasma equipment, first turn on the high-frequency arc, adjust and set the process parameter...

Embodiment 2

[0036] The difference with Example 1 is that the raw material is according to 2wt% TiH 2 powder, the rest is Ti powder, the plasma beam current is 90A, the plasma beam scanning speed is 3mm / s, the average hole size of the porous membrane is 46μm, and the porosity of the porous membrane is finally 45%.

[0037]The main process parameters and related properties of the samples are shown in Table 2.

[0038] Table 2.

[0039] Ti H 2 (wt%)

Embodiment 3

[0041] The difference with Example 1 is that the raw material is according to 3wt% TiH 2 powder, and the rest is Ti powder, the compaction pressure is 80MPa, the compaction relative density is 54%, the plasma beam current is 100A, and the plasma beam nitrogen flow rate is 0.3m 3 / h, the plasma beam scanning speed is 2mm / s, the average size of pores in the porous membrane is 53μm, and the porosity of the porous membrane is 47%. The main process parameters and related properties of the samples are shown in Table 3.

[0042] table 3.

[0043] TiH 2 (wt%)

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com