Manufacturing process of enamel for lamp

A manufacturing process and enamel technology, applied in the field of outdoor lamps, can solve the problems of easy falling off of the surface coating, high cost, unusability, etc., and achieve the effect of improving functionality and value, and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

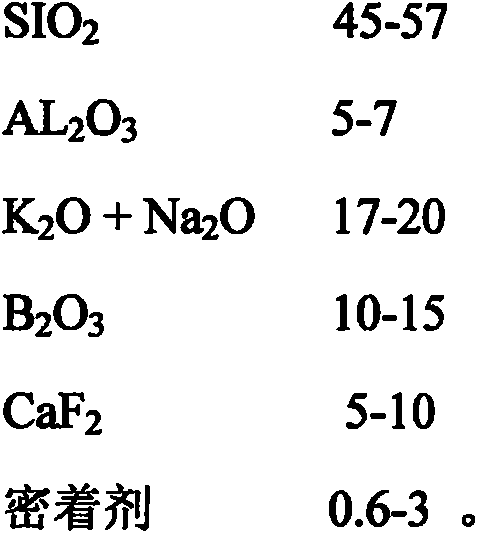

[0089] The following table is the chemical composition and raw material composition of the aluminum enamel bottom glaze.

[0090] Table 3 Chemical composition and raw material composition of aluminum enamel bottom glaze

[0091]

[0092]

Embodiment 2

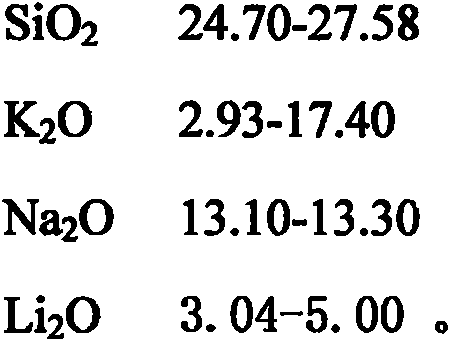

[0094] The following table is the chemical composition and raw material composition of titanium glaze enamel bottom glaze.

[0095] Chemical composition of titanium glaze (%) (steel plate)

[0096]

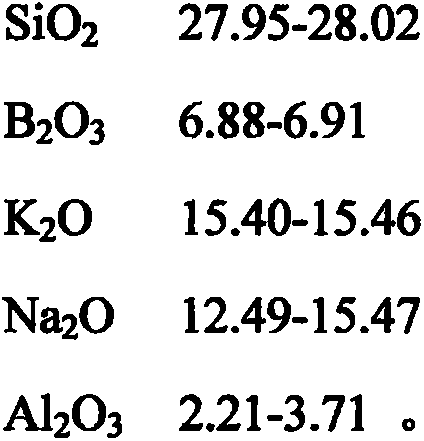

[0097] Table 4 Chemical composition and raw material composition of titanium surface glaze

[0098]

[0099]

[0100] Table 5 Chemical composition and raw material composition of titanium surface glaze aluminum enamel

[0101]

[0102] Table 6 The reaction, change and characteristics of the firing of the bottom glaze

[0103]

[0104]

[0105] Table 7 Response, change and characteristics of surface glaze firing

[0106]

[0107]

[0108] The invention relates to an advanced composite material product which is firmly combined with an inorganic non-metal material and a metal material and has special surface functions. The application of transformed new enamel material products in indoor and outdoor lamps. As the surface treatment process of existing indoo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com