Ink ribbon cassette

A technology for ink ribbon cassettes and ink ribbons, applied in the directions of ink ribbon cassettes, inking devices, printing, etc., can solve the problems of assembling the ink ribbon cassettes and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

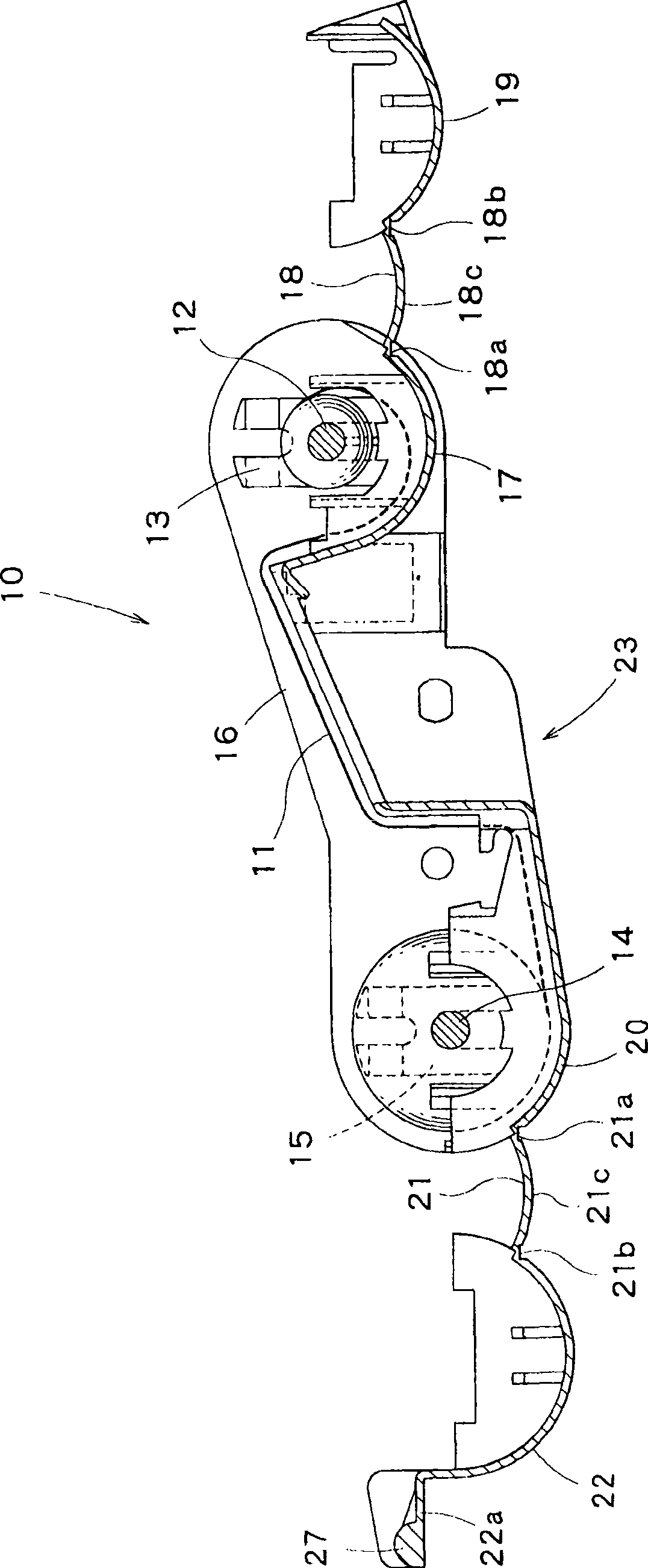

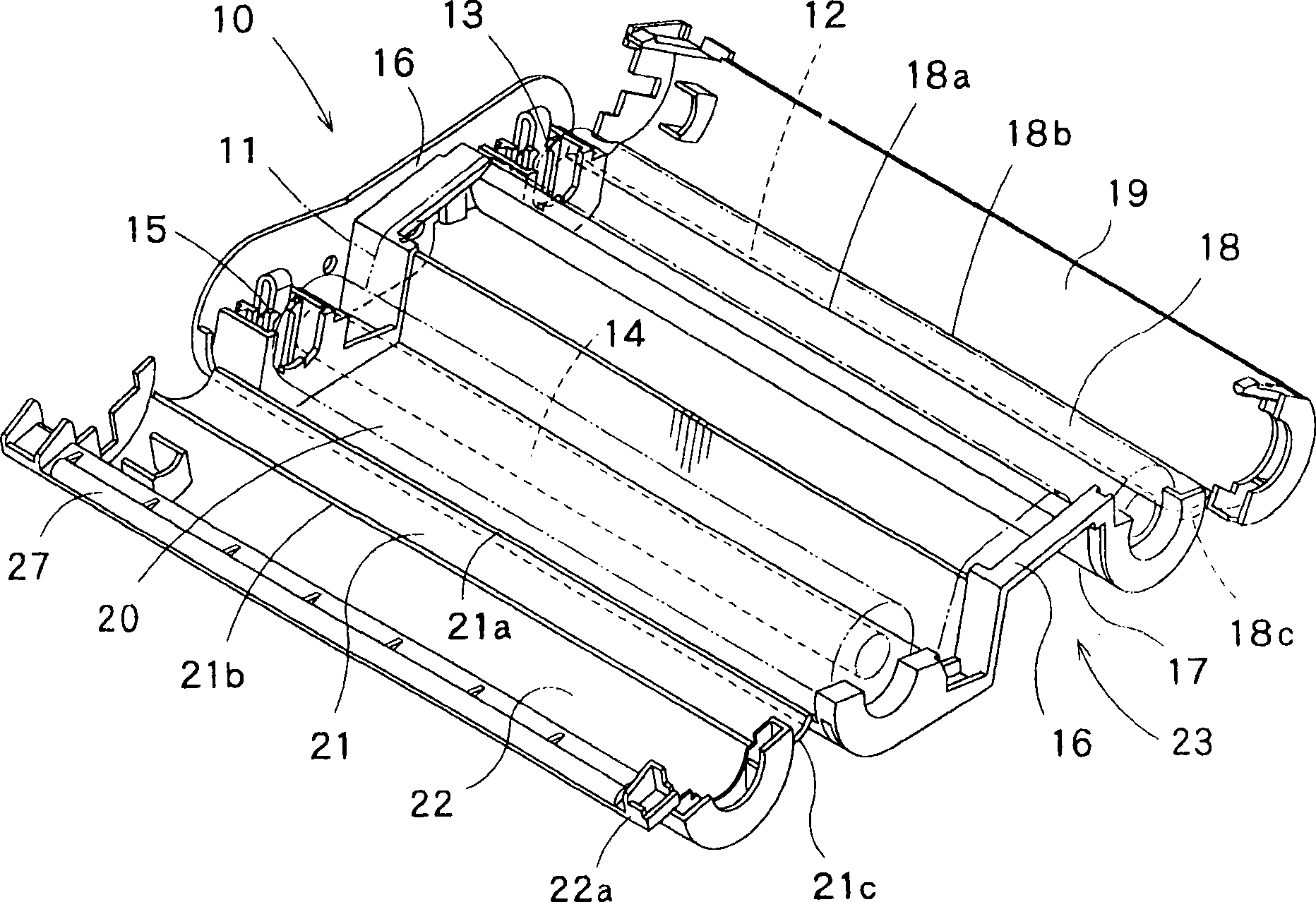

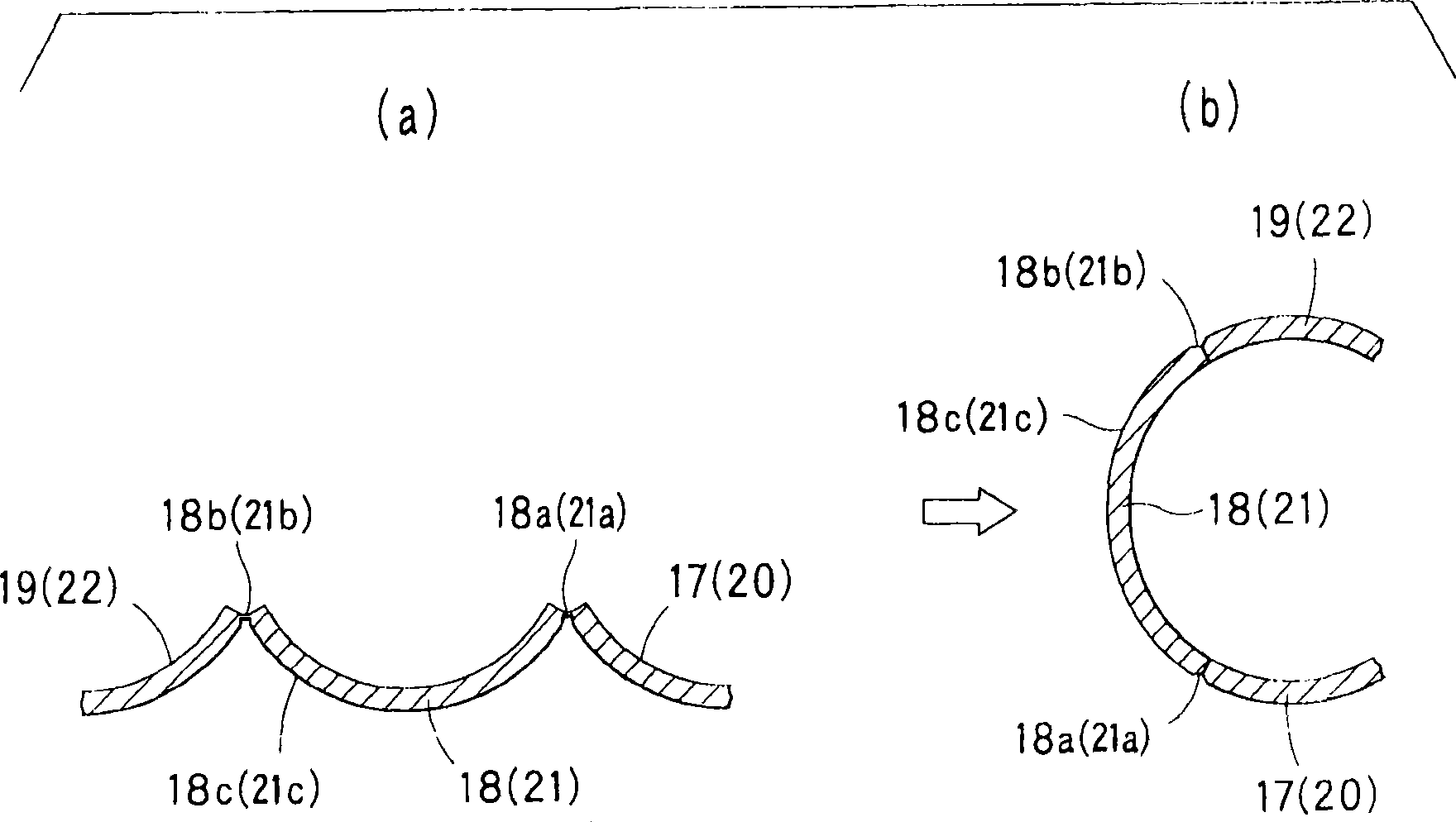

[0047] here, figure 1 Is a cross-sectional view showing the first embodiment of the present invention, figure 2 It is a perspective view showing the first embodiment of the present invention. In addition, image 3 (a) is a cross-sectional view showing a state where the winding bearing cover member (winding bearing cover member) of the bearing device is opened relative to the winding bearing body (winding bearing body), image 3 (b) is a cross-sectional view showing a state where the winding bearing cover member (winding bearing cover member) of the bearing device is closed with respect to the winding bearing body (winding bearing body). In addition Figure 4 It is a partial cross-sectional view of the winding bearing body in a state where the winding bearing cover member is closed with respect to the winding bearing body. In addition Figure 5 Is a cross-sectional view showing a modification of the first embodiment of the ink ribbon cassette of the present invention, Figure 6 I...

no. 2 approach

[0084] Next, refer to Figure 7 as well as Figure 8 The second embodiment of the present invention will be described.

[0085] here, Figure 7 Is a perspective view showing the second embodiment of the present invention, Figure 8 It is a figure which shows the guide rod of the bearing device of the ink ribbon cassette of the 2nd Embodiment of this invention. Figure 7 as well as Figure 8 The installation position of the guide rod 25 in the second embodiment shown is different, and the other structure is substantially the same as the first embodiment described above. in Figure 7 as well as Figure 8 Middle, right and Figure 1 to Figure 6 The same parts in the first embodiment shown are denoted by the same reference numerals and detailed descriptions are omitted.

[0086] Such as Figure 7 As shown, the bearing device 23 of the ink ribbon cassette 10 has a guide rod 25 that is fixed on the winding bearing body 20 and abuts the ink ribbon 11 and guides the ink ribbon 11. The gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com