Patents

Literature

44results about How to "Achieve granulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

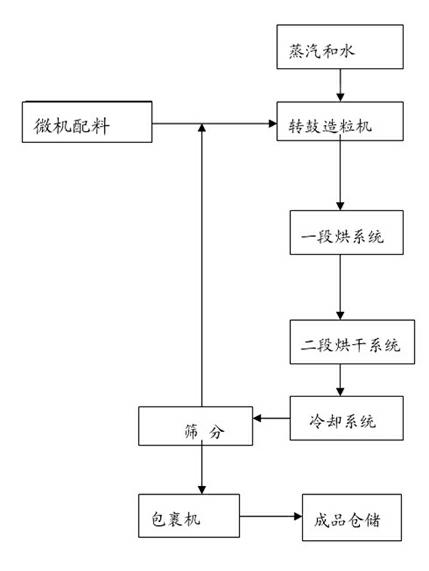

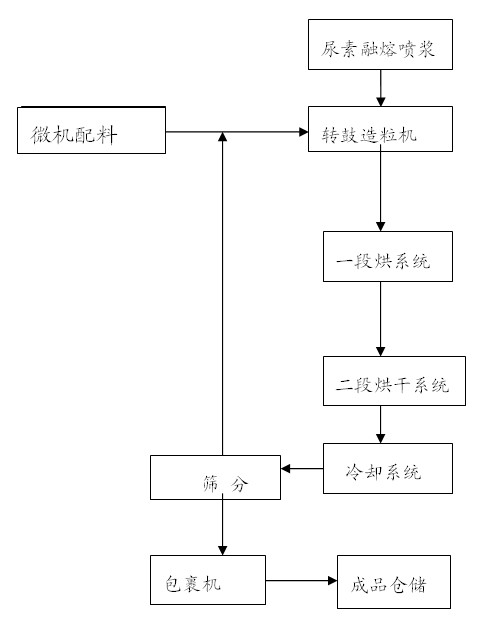

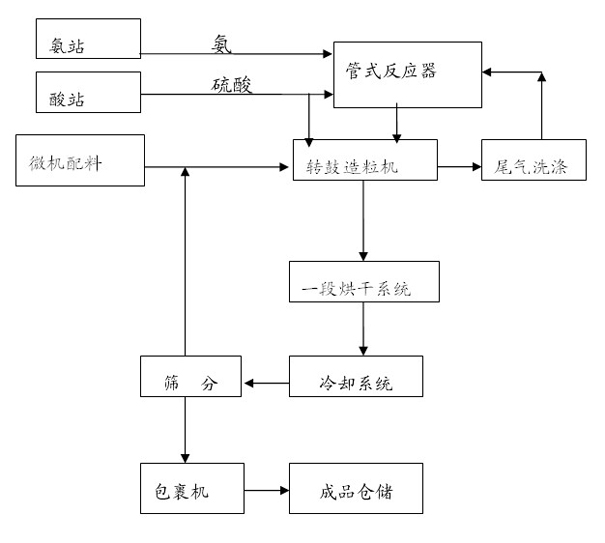

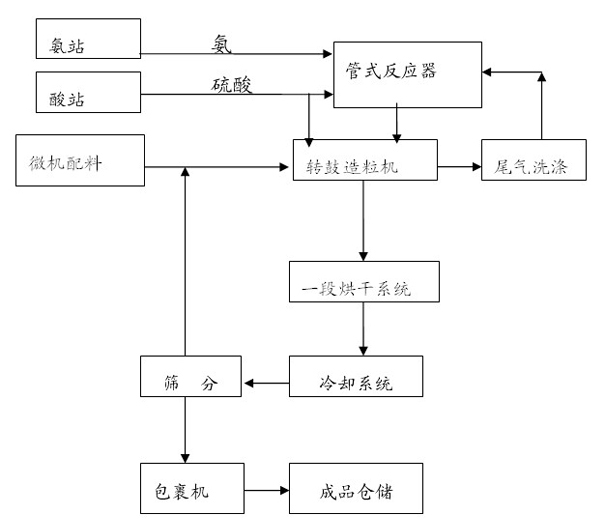

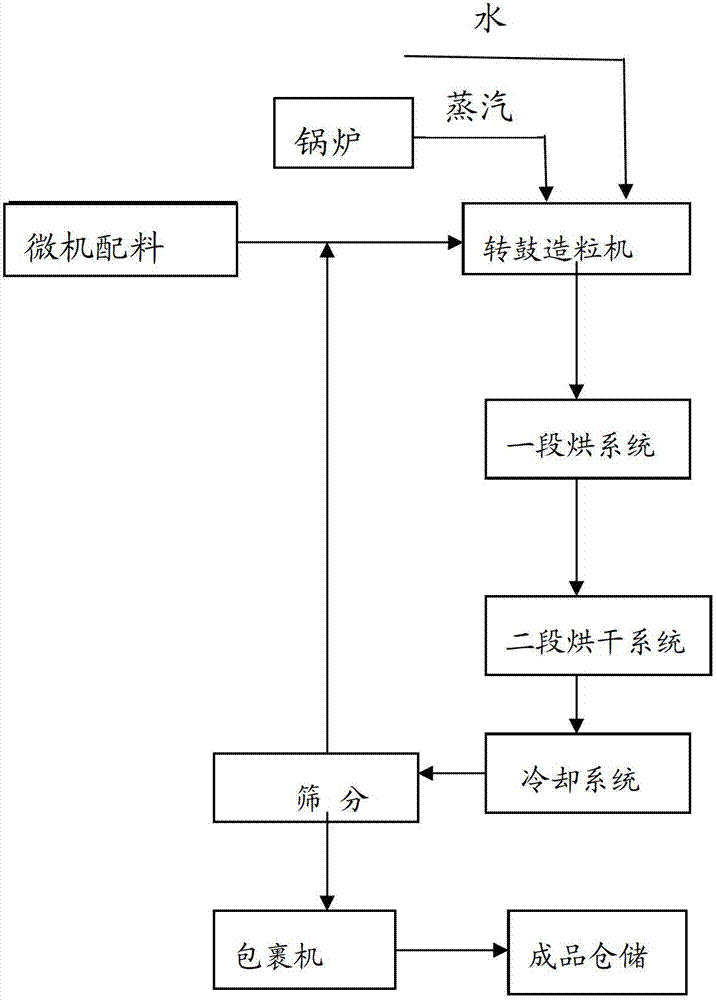

Method for producing Nitrogen-Phosphorus-Potassium compound fertilizer by ammonia and acid tubular reactor

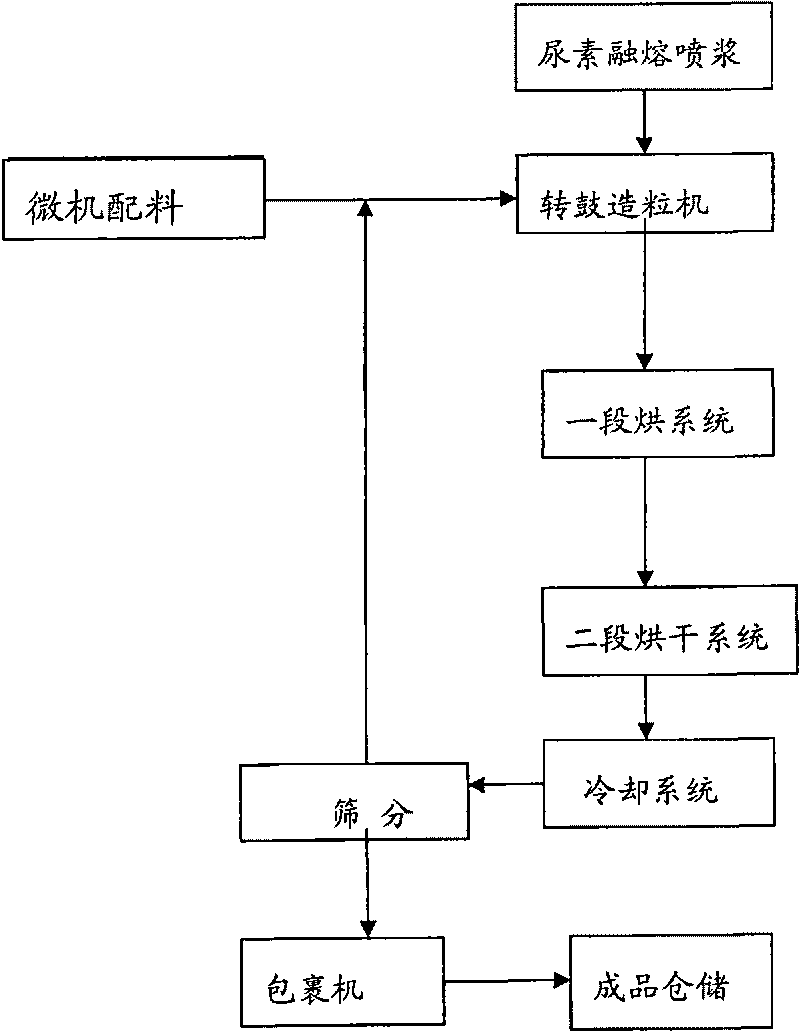

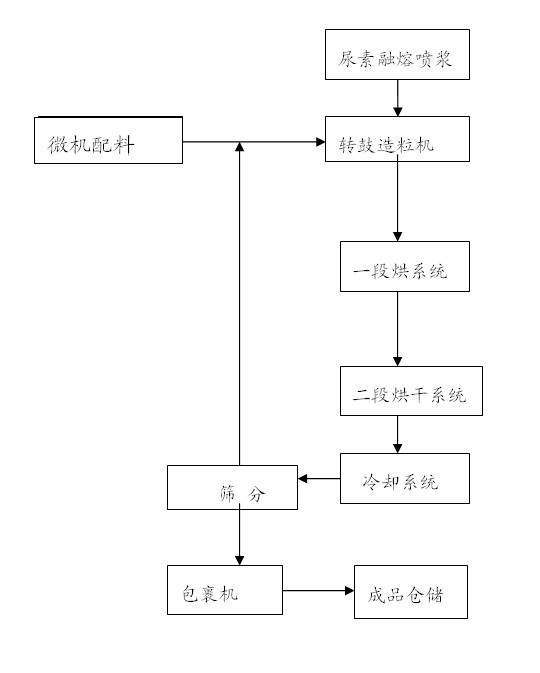

The invention discloses a method for producing a Nitrogen-Phosphorus-Potassium compound fertilizer by using an ammonia and acid tubular reactor. The method comprises the following steps of: preparing an ammonium sulfate solution at 180-220 DEG C by concentrated sulfuric acid, ammonia and water; controlling the reaction heat of ammonia and acid by the addition amount of the water; spraying in a granulator to granulate with other base fertilizers containing nitrogen, phosphorus and potassium; drying; cooling; screening; and filming to obtain a nitrogen-phosphorus-potassium compound fertilizer. The reaction heat of the ammonia and the acid is fully utilized, the ammonium sulfate solution generated by the reaction is in liquid phase and viscosity, the balling rate is high, the moisture of granulation materials is obviously reduced, the drying load is lowered, the production need can be satisfied by changing two-section drying into one-section drying, and the equipment investment and great energy consumption are saved.

Owner:天津达汇丰生物科技有限公司

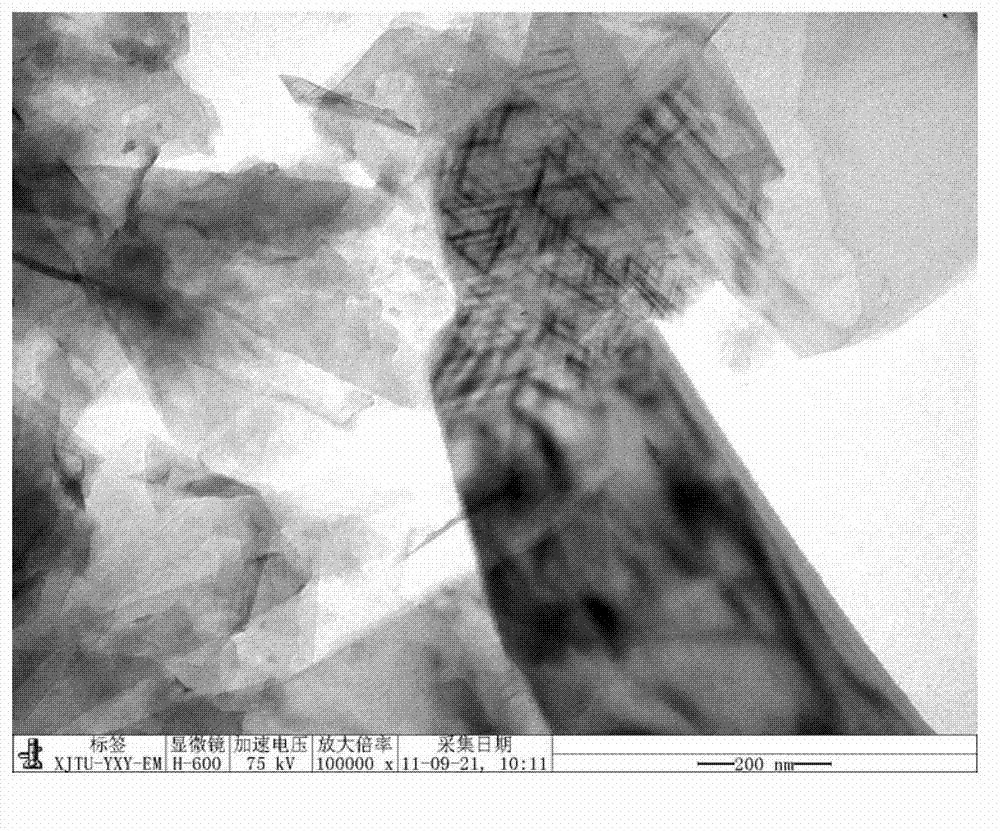

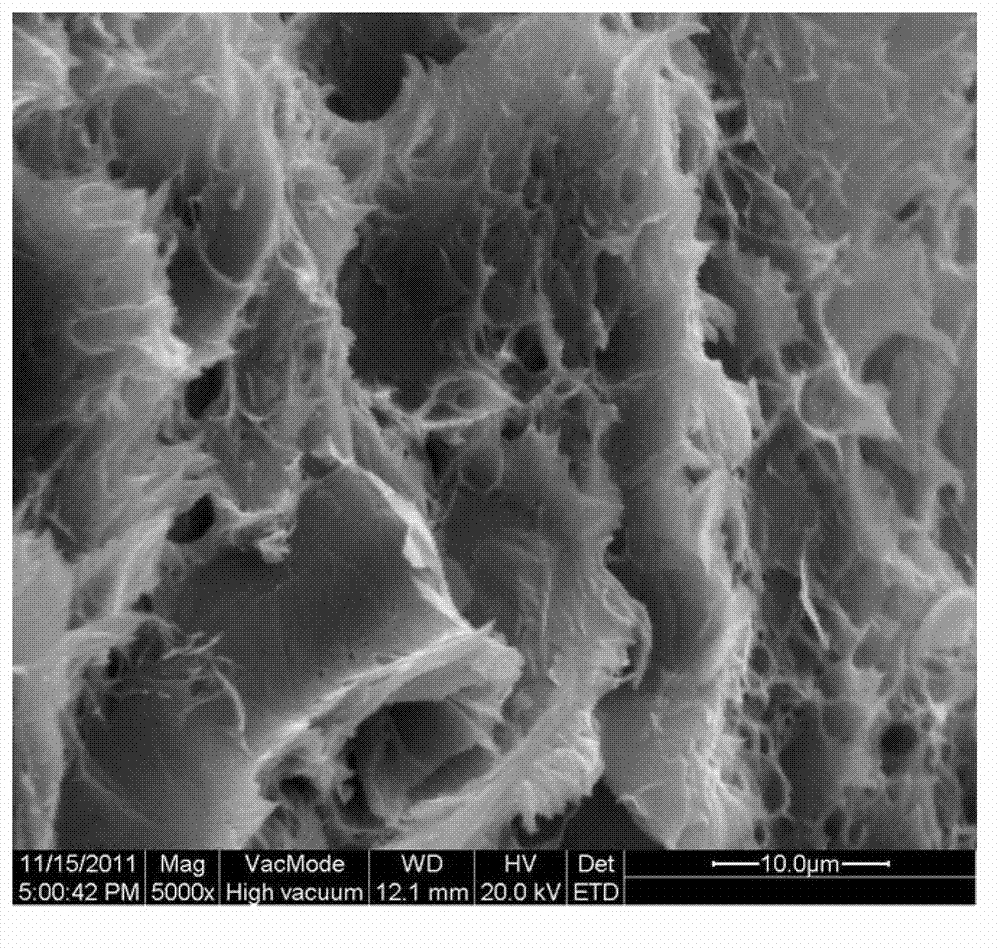

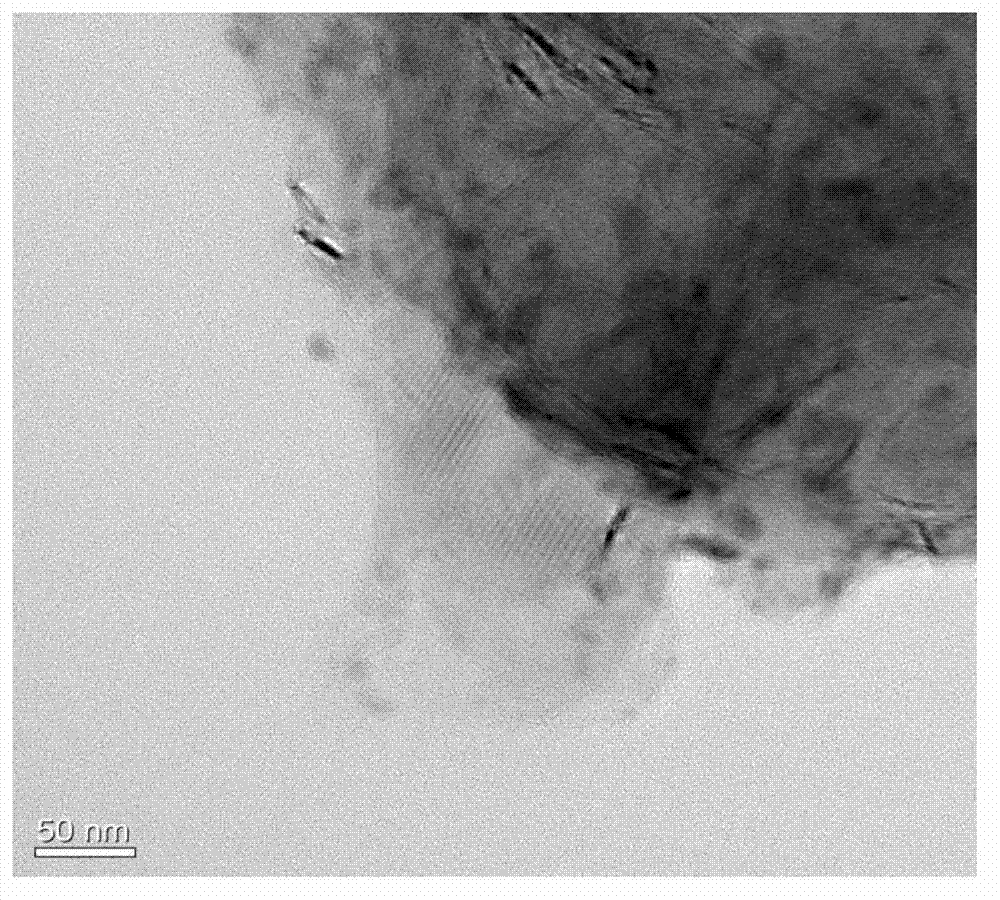

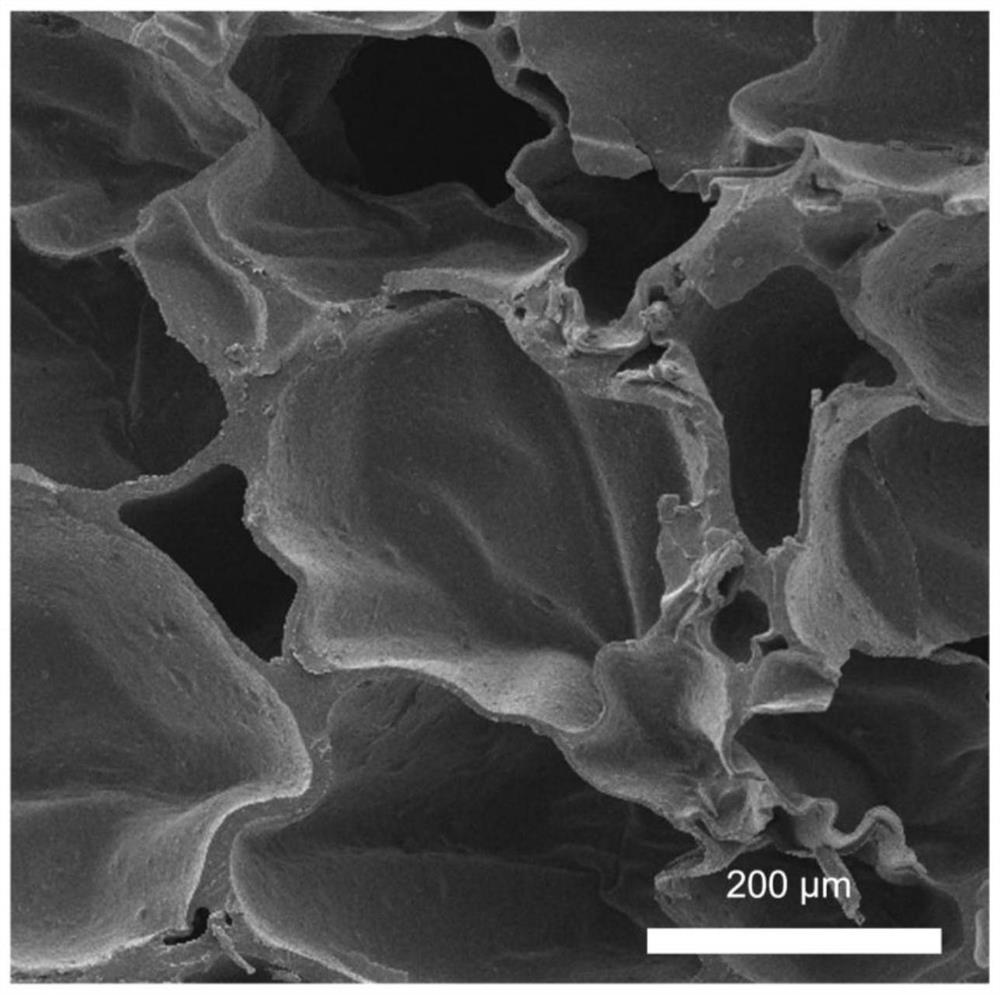

PVC (Polyvinyl Chloride)/graphite alkene antistatic composite material and preparation method thereof

The invention discloses a PVC (Polyvinyl Chloride) / graphite alkene antistatic composite material. The PVC graphite alkene antistatic composite material is prepared by the following ingredients in percentage by weight: 2-20% of a shock resistance modifying agent, 0.5-10% of an electric conductive filler, 2-20% of a processing agent and the balance of matrix resin. In addition, the invention also provides a preparation method of the PVC / graphite alkene antistatic composite material. Due to the adoption of the preparation method, the PVC has the antistatic property, and the enhancing and toughening are realized at the same time; and the surface resistivity of the prepared PVC / graphite alkene antistatic composite material is 104-108 omega, the volume resistivity is not more than 108 omega / cm, the tensile strength is not less than 50MPa, the impact strength is not less than 5kJ / m<2>, the elongation at break is not less than 75%, and the antistatic requirements on GB / T20105-2006 and MT164-2007 and MT165-2007 in the colliery industry are met.

Owner:XIAN UNIV OF SCI & TECH

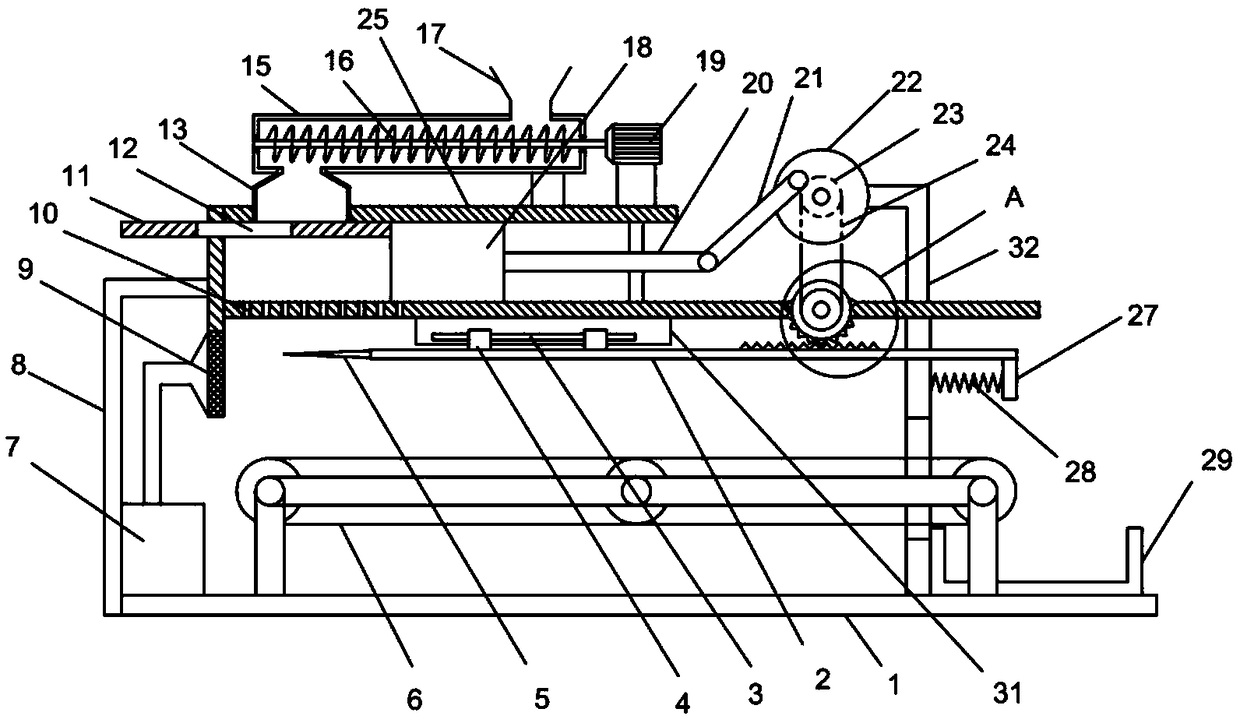

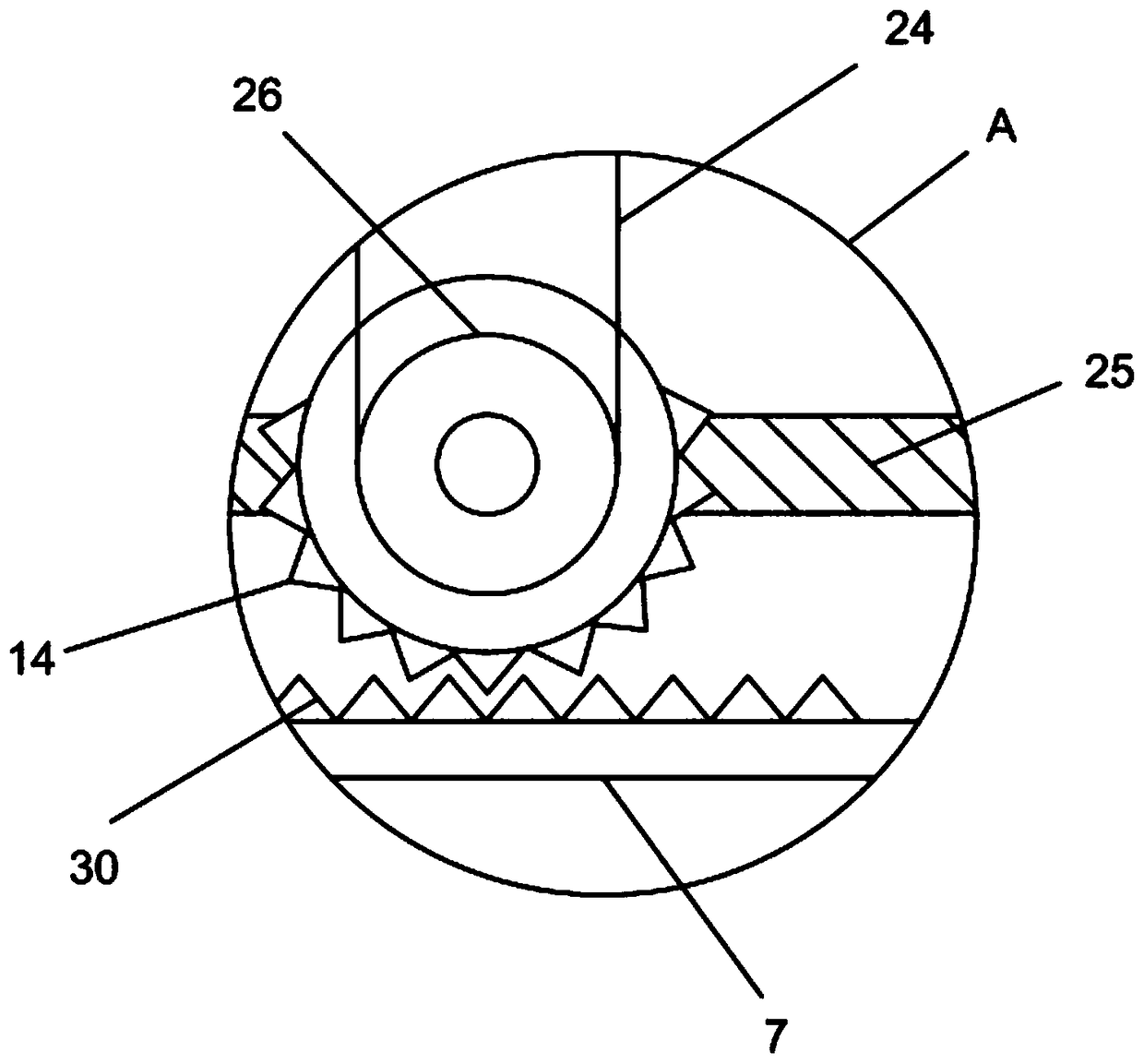

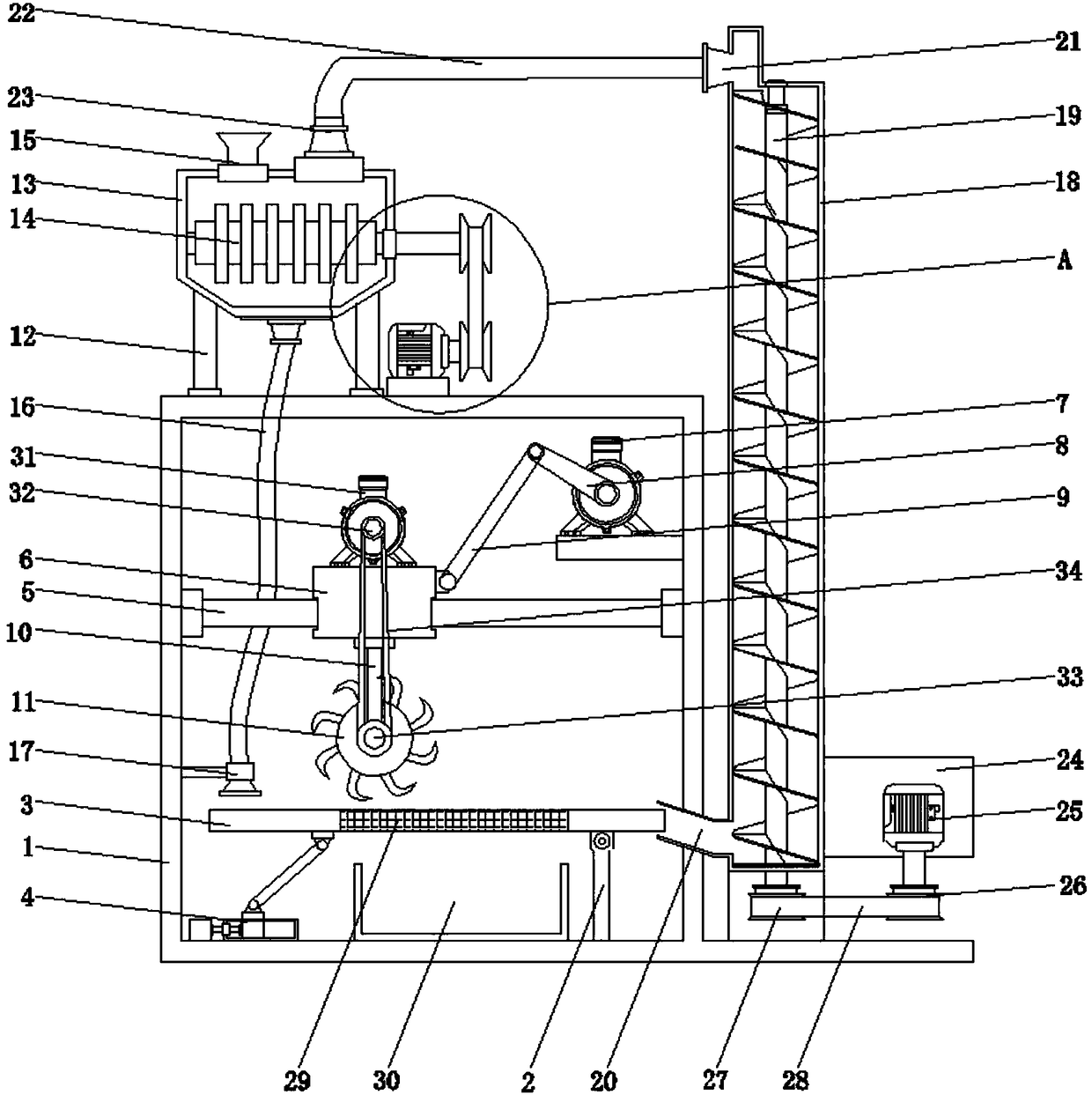

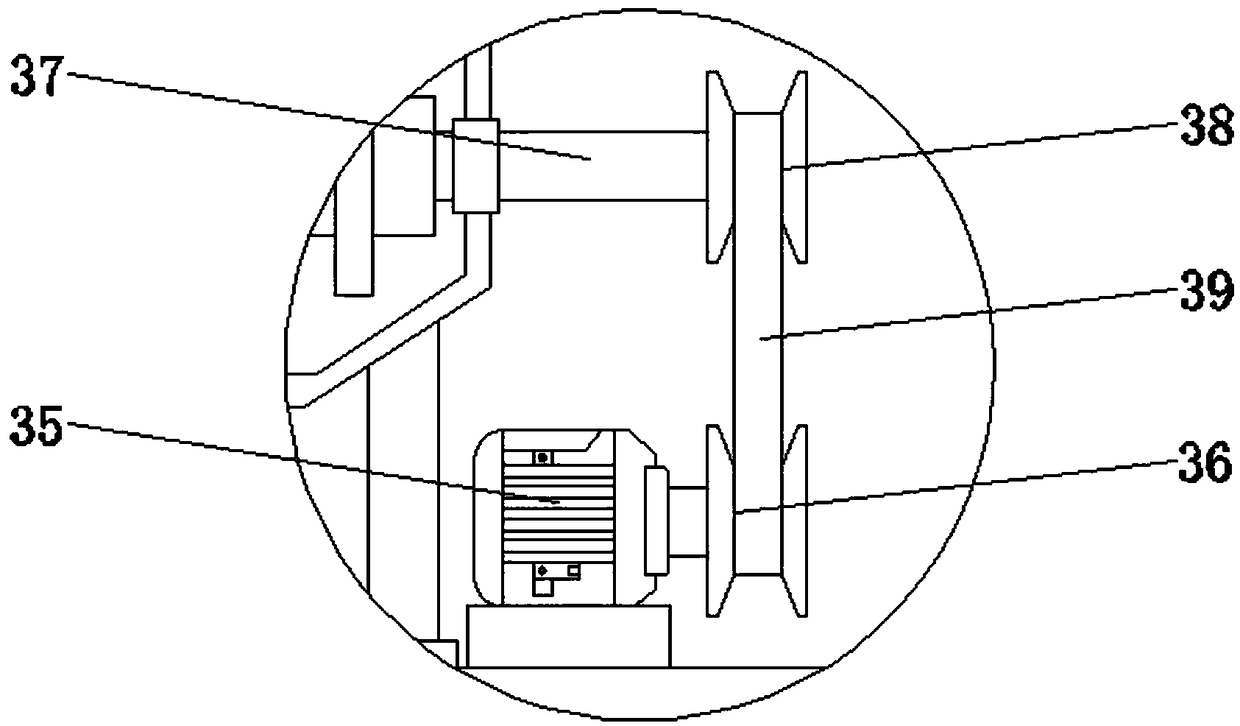

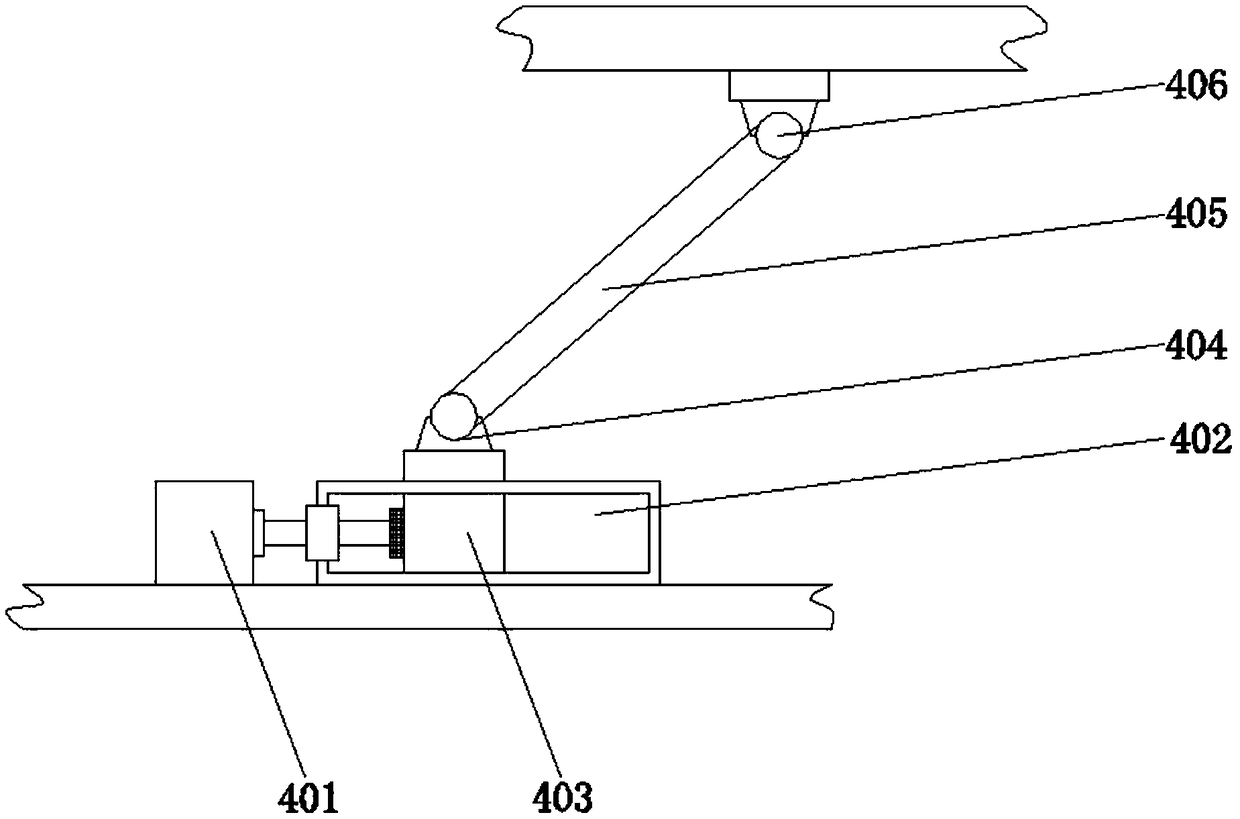

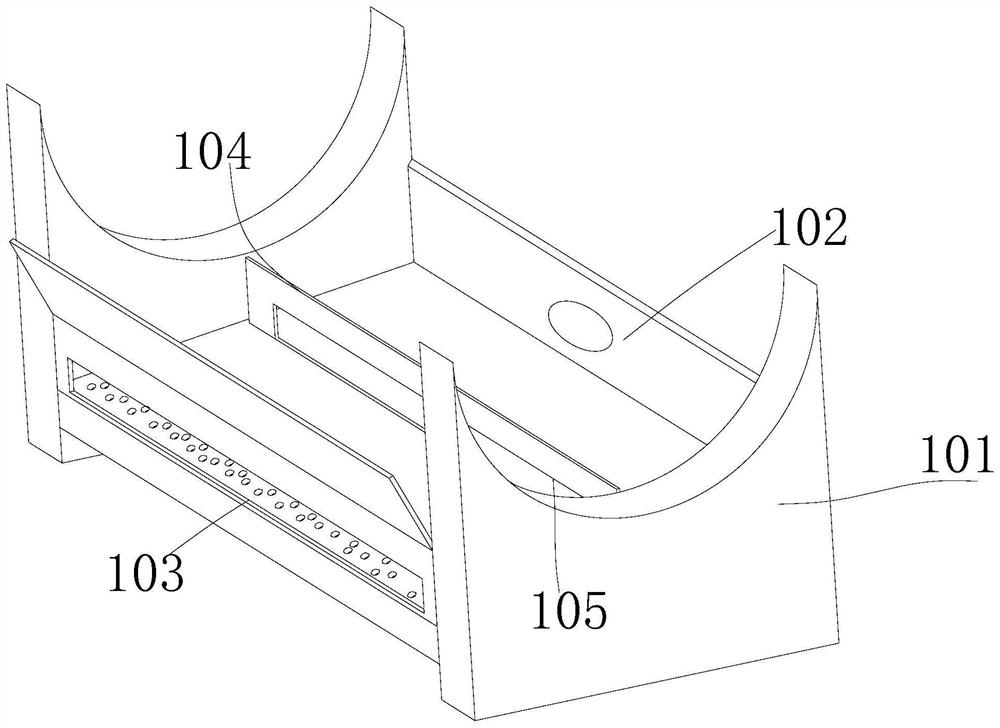

Feed extruding and granulating device for livestock feed processing

InactiveCN108654515AImprove the extrusion effectImprove work efficiencyFeeding-stuffGranulation by material expressionReciprocating motionEngineering

The invention discloses a feed extruding and granulating device for livestock feed processing. The feed extruding and granulating device is characterized in that a support rack is vertically fixedly mounted on a bottom plate, a limit extruding cylinder is fixedly mounted on the support rack, a slider is horizontally slidably arranged in the limit extruding cylinder, a slide plate is horizontally fixedly mounted at the left top end of the slider, the upper surface of the slide plate is abutted against the inner side of the limit extruding cylinder, and a feeding channel is vertically formed inthe slide plate; an air heater is fixedly mounted at the bottom of the bottom plate, and a collecting tank located at the right bottom of a conveying belt is fixedly mounted on the bottom plate. The feed extruding and granulating device has the advantages that feed intermittently enters the limit extruding cylinder is extruded into strip-shaped feed through extruding holes by the leftward and rightward reciprocating movement of the slider, and a good extruding effect and high work efficiency are achieved; the strip-shaped feed is repeated cut by a cutting blade which moves leftwards and rightwards in a reciprocating manner to achieve feed granulation, the feed is fast dried through hot air rightwards discharged by an exhaust mesh cover, feed adhesion is avoided, and the quality of feed granules is increased greatly.

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

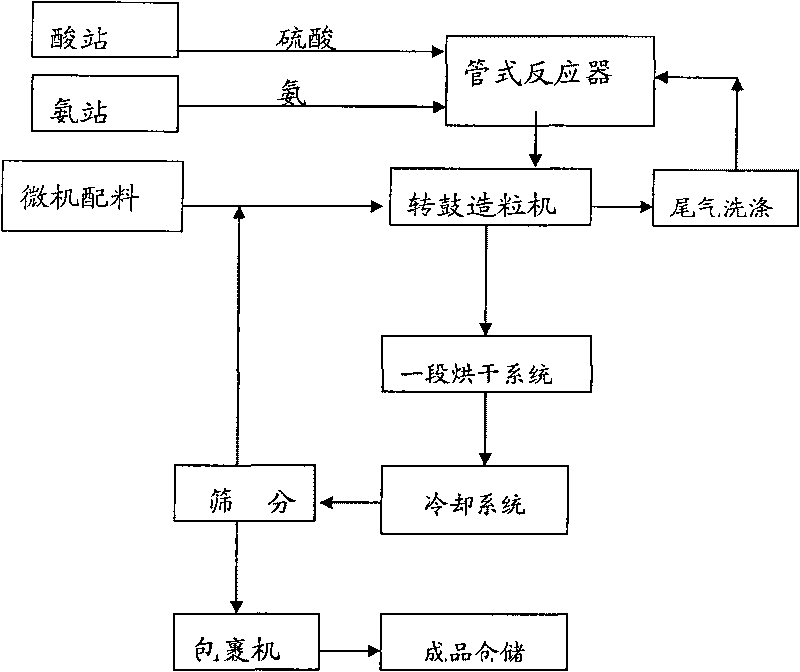

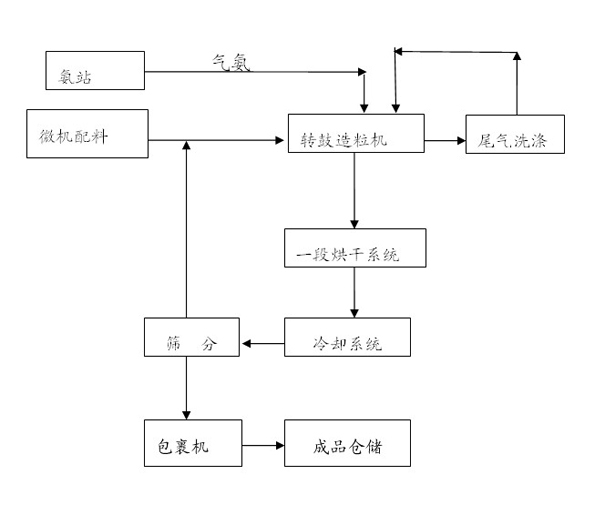

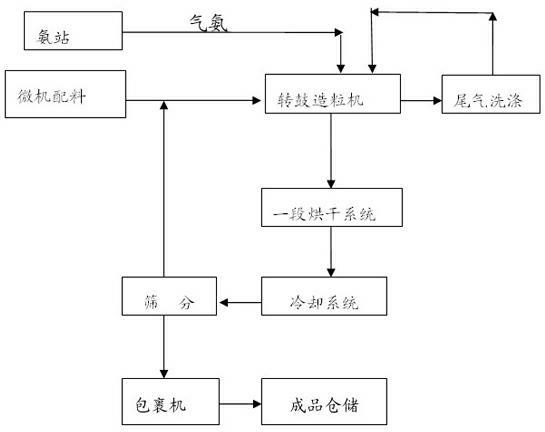

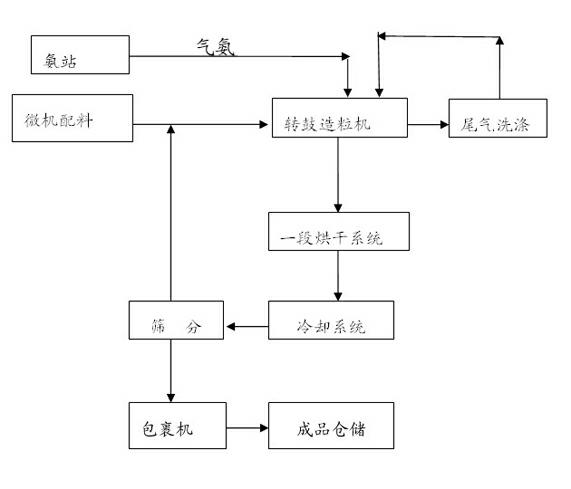

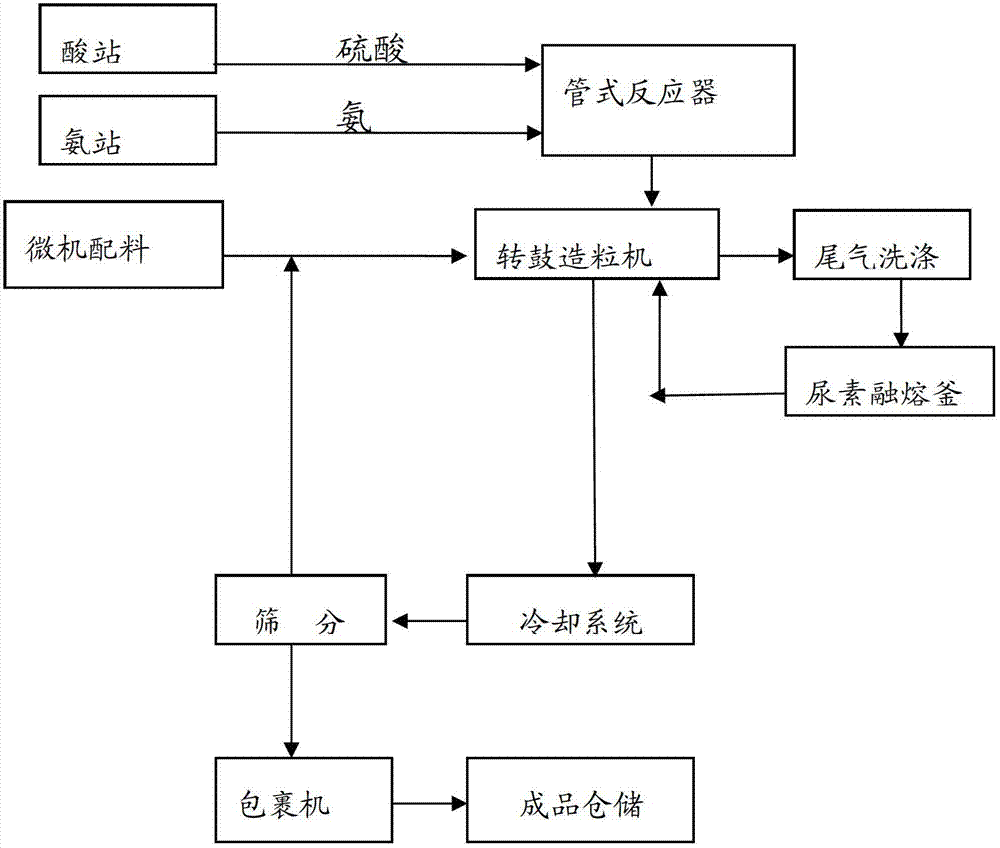

Method for producing chlorine-based high phosphorus compound fertilizer by ammoniation method

The invention discloses a method for producing a chlorine-based high phosphorus compound fertilizer by an ammoniation method. The method is characterized by directly introducing gas ammonia to a material layer of a rotary drum granulator to increase the neutralization degree of monoammonium phosphate, granulating gas ammonia with other powdered fundamental fertilizers containing nitrogen, phosphorus and potassium and obtaining the compound fertilizer containing nitrogen, phosphorus and potassium through drying, cooling, screening and enveloping after granulation. The method has the following advantages: the heat producing reaction between the gas ammonia and double superphosphate and heat of neutralization generated by the reaction between the gas ammonia and the monoammonium phosphate are fully used of to maintain the temperature of the materials, and the solubility of ammonium phosphate salt is improved to satisfy the liquid phase quantity needed by granulation; the higher granulation rate can be ensured without adding other adhesives, thus lowering the input cost of the materials; and the moisture of the materials to be granulated is obviously reduced, thus reducing the drying load and saving plenty of energy.

Owner:天津芦阳肥业股份有限公司

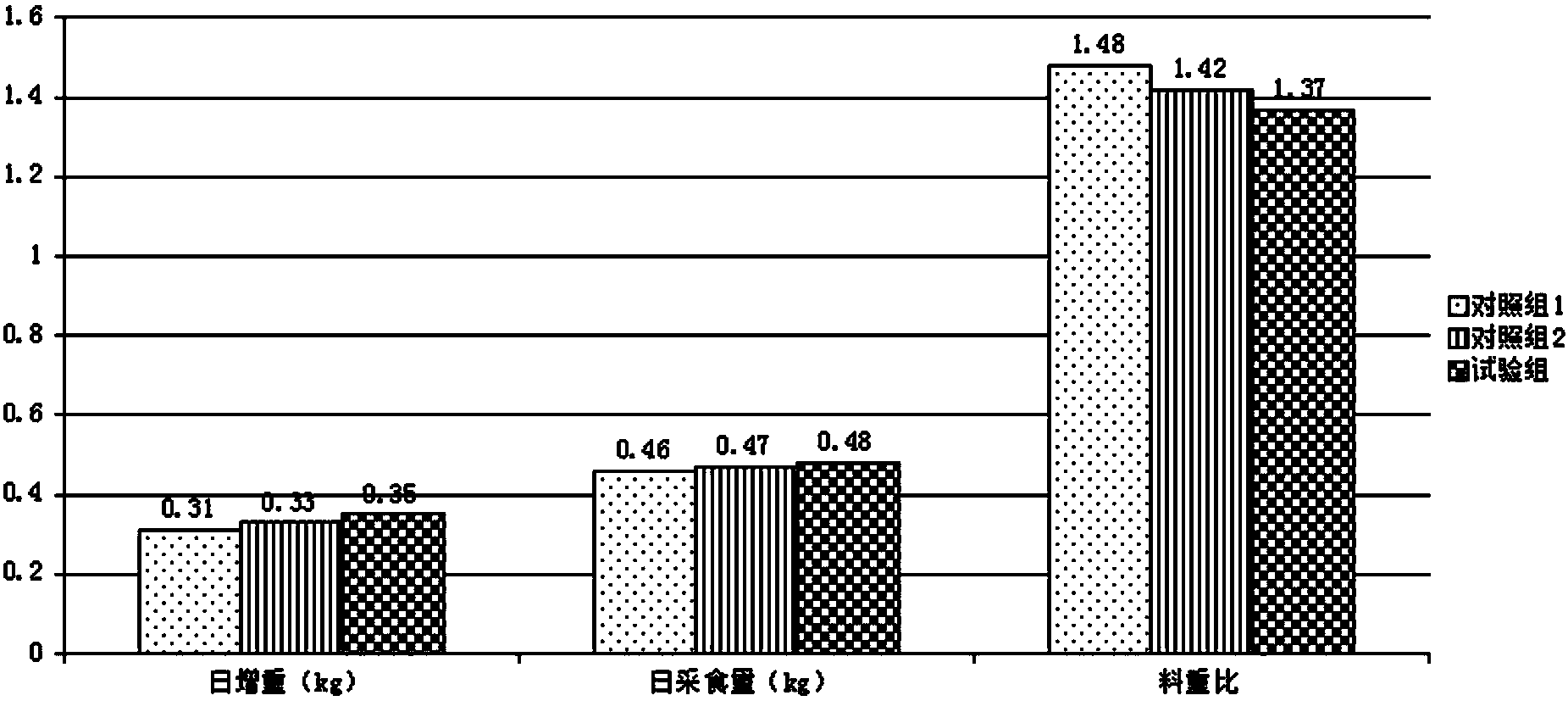

Enteric coated fodder acidifying agent and preparation method thereof

The invention discloses an enteric coated fodder acidifying agent which comprises the following ingredients by weight: 8 to 20 parts of a citric acid, 8 to 20 parts of a fumaric acid, 7 to 15 parts of a benzoic acid, 5 to 20 parts of a malic acid, 3 to 15 parts of a formic acid, 2 to 10 parts of an acetic acid, 6 to 15 parts of a propanoic acid, 2 to 5 parts of a butyric acid, 10 to 20 parts of an emulsifier, and 15 to 50 parts of an enteric slow-release coating material. Meanwhile, the invention discloses a preparation method of the enteric coated fodder acidifying agent. The preparation method comprises the following steps: preparation of an acidifying agent suspending liquid, preparation of an acidifying agent emulsion liquid, fluidization of the acidifying agent emulsion liquid, atomization of the enteric slow-release coating material, preparation of the enteric coated fodder acidifying agent, and the like. The enteric coated fodder acidifying agent prepared according to the preparation method has the advantages that the product purity is high; the enteric coated fodder acidifying agent is released slowly only after arriving the rear segment of an animal intestinal canal, so as to effectively play the bacteriostatic role and improve animal alimentary canal micro-ecology.

Owner:MAILUN ZHANGZHOU BIOTECH CO LTD

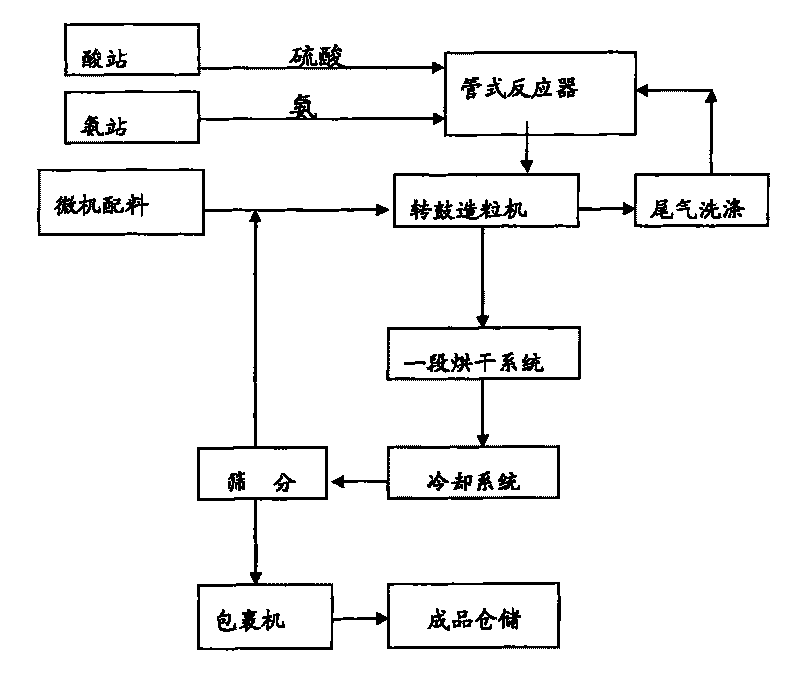

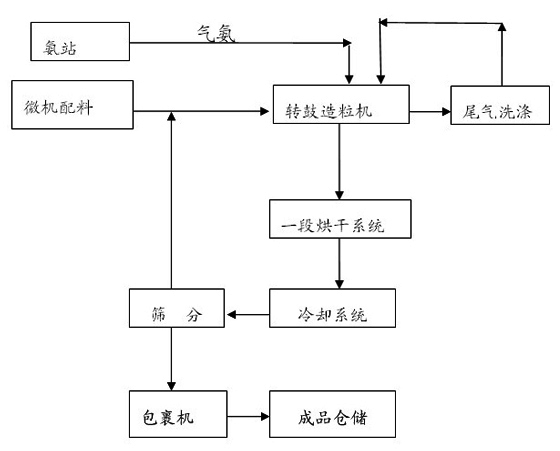

Production method of readily available and controlled release composite fertilizer containing three nitrogen elements

The invention discloses a production method of a readily available and controlled release composite fertilizer containing three nitrogen elements. The production method is as follows: raw materials containing nitric nitrogen, ammonium nitrogen and amido nitrogen are added in materials; in order to prevent that urea reacts with nitro phosphate fertilizer to generate too much urea nitrate and the production can not performed, ammonia gas is introduced in the granulation process according to different proportions to ammonify nitro phosphate fertilizer, reduce the generation of urea nitrate and increase the neutralization degree of monoammonium phosphate; and powdery fundamental fertilizers containing nitrogen, phosphorous and potassium are added to granulate, and then the composite fertilizer can be obtained through drying, cooling, screening and coating. In the production method of the invention, a lot of heat generated in the thermolysis of the nitro phosphate fertilizer and the neutralization heat of the reaction of ammonia gas and monoammonium phosphate are fully utilized to heat materials and increase the granulation temperature; and the viscosity of urea nitrate is utilized, the solubility of ammonium phosphate salt is increased, the quantity of the liquid phase for granulation can be satisfied, higher granulation rate can be realized without using other adhesive, the cost is reduced, the water content of the granulation material is significantly reduced, the drying energy consumption can be reduced and a large amount of energy consumption can be saved.

Owner:天津芦阳肥业股份有限公司

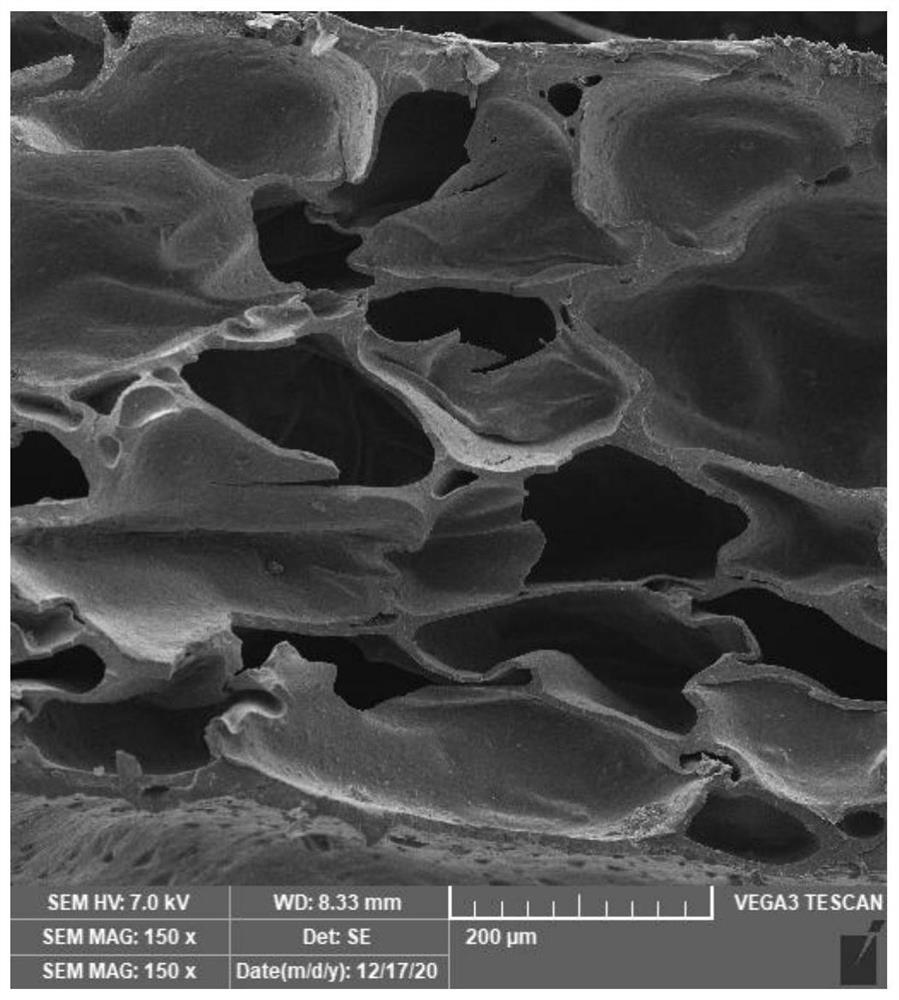

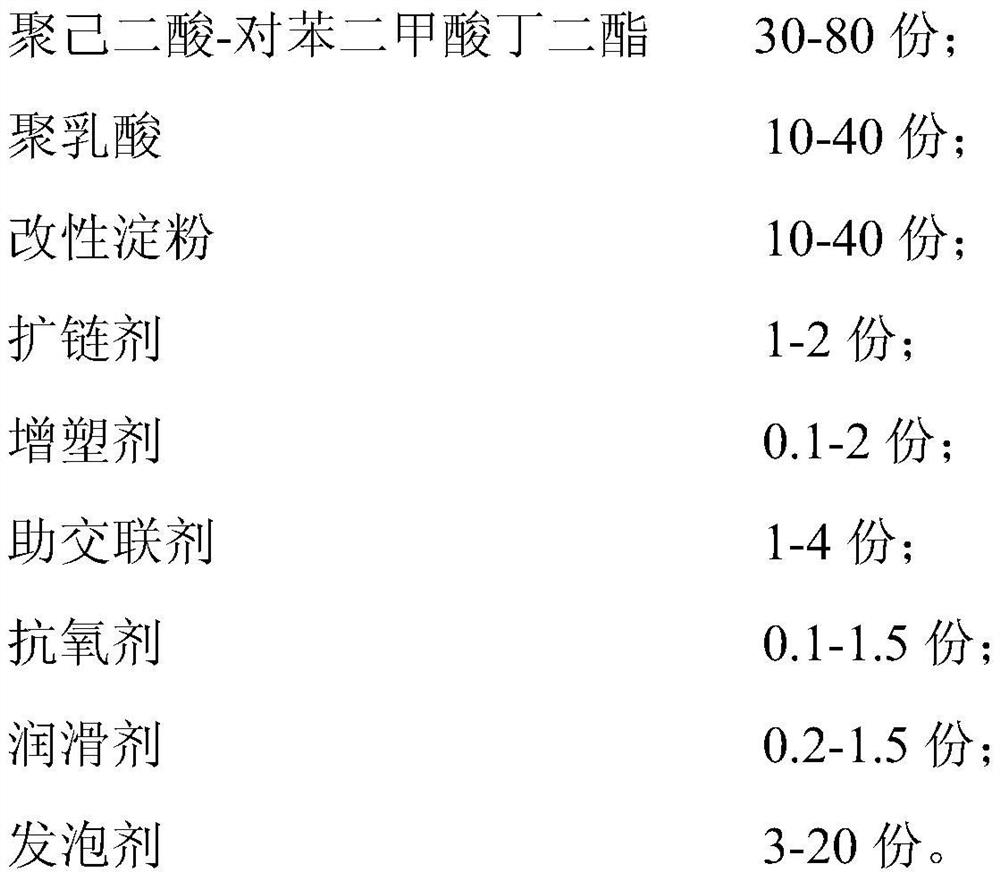

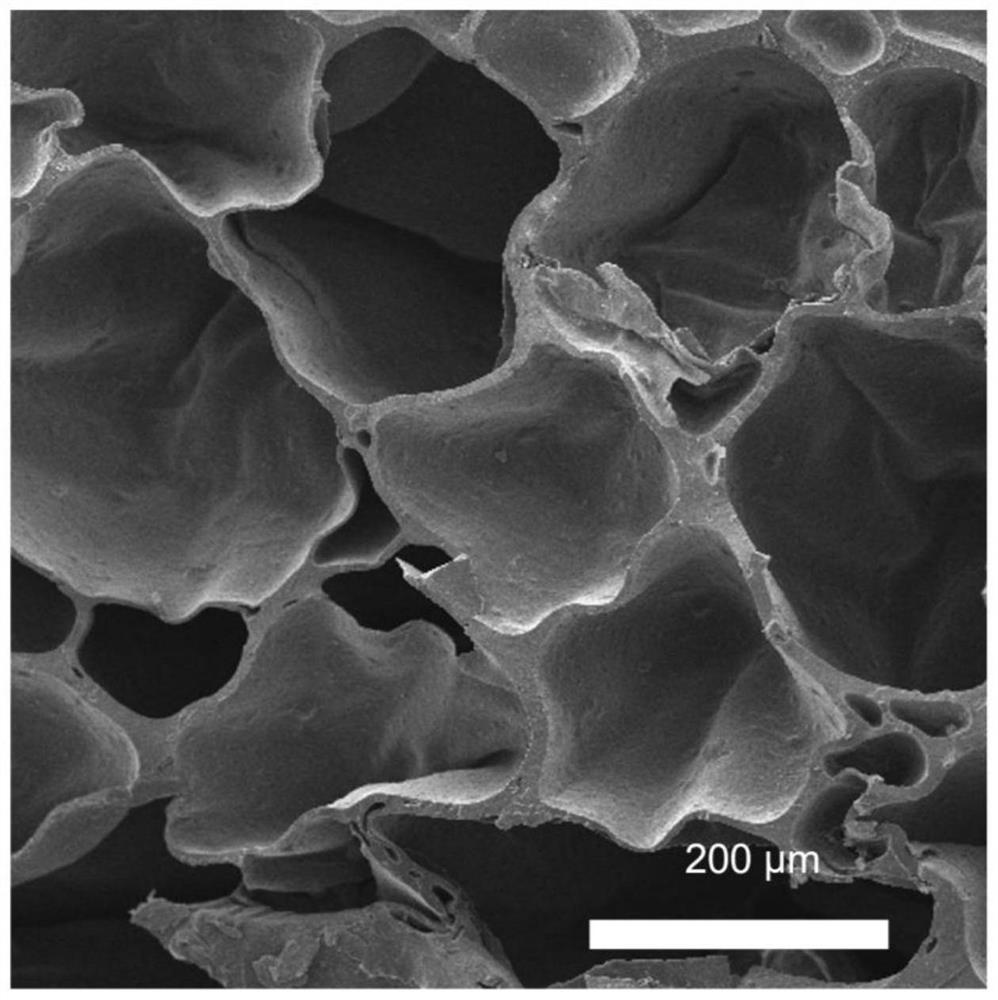

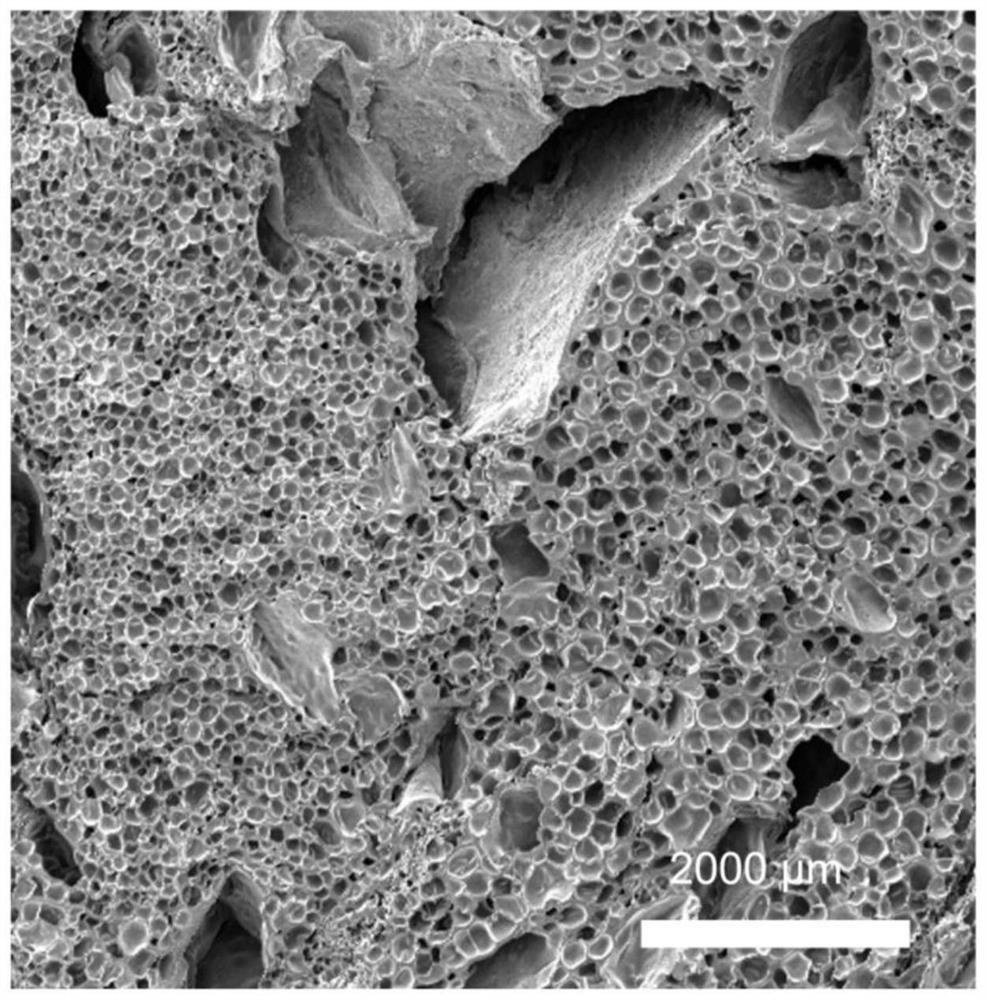

Degradable foaming material and preparation method thereof

The invention relates to the technical field of foaming materials, and discloses a degradable foaming material and a preparation method thereof. The degradable foaming material is prepared from, by mass, 30-80 parts of poly(butylene adipate-co-terephthalate); 10-40 parts of polylactic acid; 10-40 parts of modified starch; 1-2 parts of a chain extender; 0.1-2 parts of a plasticizer; 1-4 parts of an assistant crosslinker; 0.1-1.5 parts of an antioxidant; 0.1-1.5 parts of a lubricant and 3-20 parts of a foaming agent. By blending and modifying PLA through PBAT, on one hand, the melting point of PLA can be remarkably reduced, the melt extrusion temperature during subsequent coiled material extrusion is further reduced, decomposition of a chemical foaming agent is inhibited, and decomposition of the foaming agent is completely controlled in the foaming stage of a high-temperature foaming furnace; and on the other hand, the advantages and disadvantages of PBAT and PLA materials are combined, and the degradable foaming material with excellent ductility, tensile strength and comprehensive performance is obtained.

Owner:ZHEJIANG UNIV OF TECH

Method for producing nitrogen-fixing potassium slow-release compound fertilizer with mesh inner membrane by using ammonia-acid method

The invention discloses a method for producing nitrogen-fixing potassium slow-release compound fertilizer with mesh inner membranes by using an ammonia-acid method. The compound fertilizer comprises the following added raw materials: natural minerals capable of fixing and absorbing nutrients, and raw materials capable of forming shells with porous multiple layers of mesh inner membranes; and calcium salt is used to form a packaging skeleton and fix nutrients. The added concentrated sulfuric acid is divided into two parts, wherein one part is prepared into an ammonium sulfate solution of 180-220 DEG C with ammonia and water, amino acid reaction heat is controlled through controlling the added amount of water, and then the ammonium sulfate solution is sprayed into a granulator to granulate with powdery basic materials which contain nitrogen, phosphorus, potassium and natural minerals and are capable of forming shells with mesh inner membranes; and the other part is diluted and then directly added into the granulator to react with urea to generate thiocarbamide, and then drying, cooling, screening and enveloping are carried out on thiocarbamide after granulating to obtain the slow-release compound fertilizer containing nitrogen, phosphorus and potassium. In addition, two-section drying is changed to one-section drying, which can meet the requirements of production.

Owner:天津芦阳肥业股份有限公司

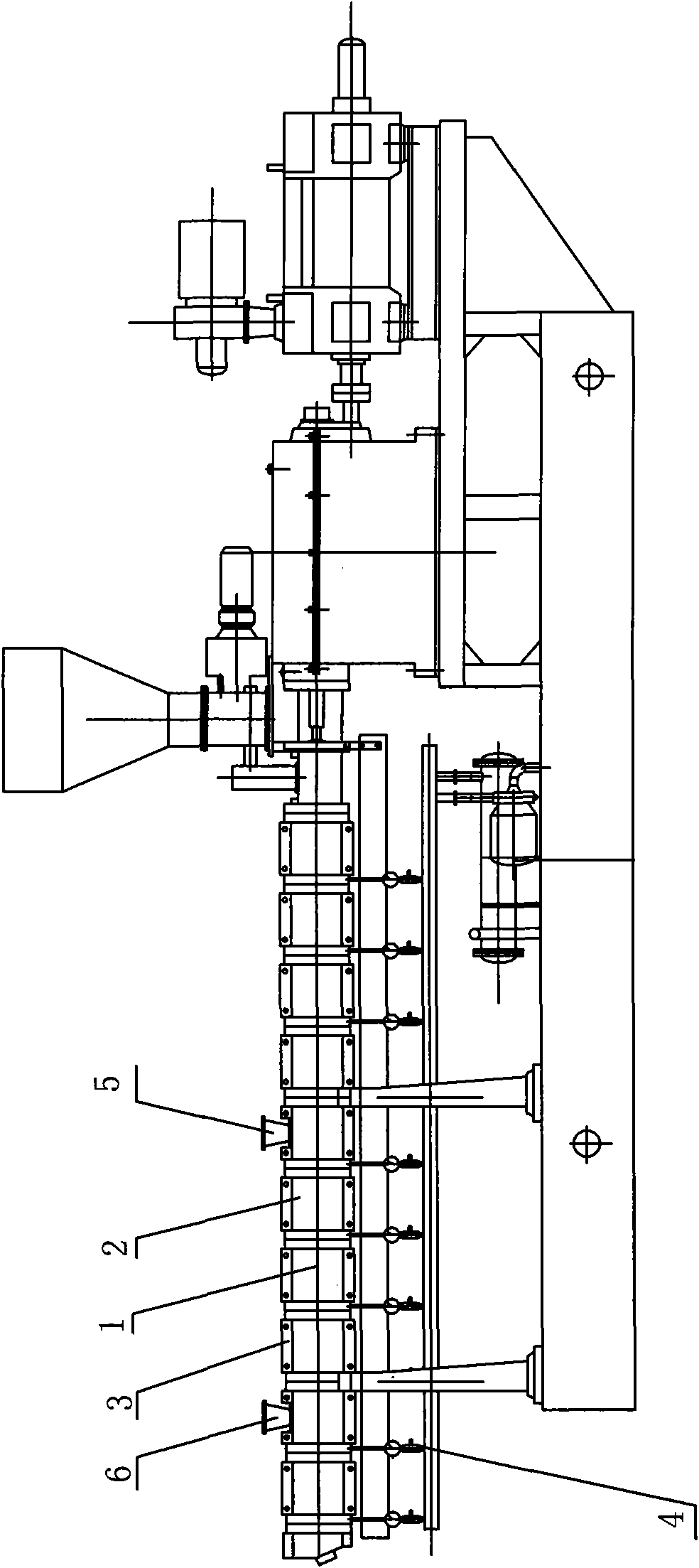

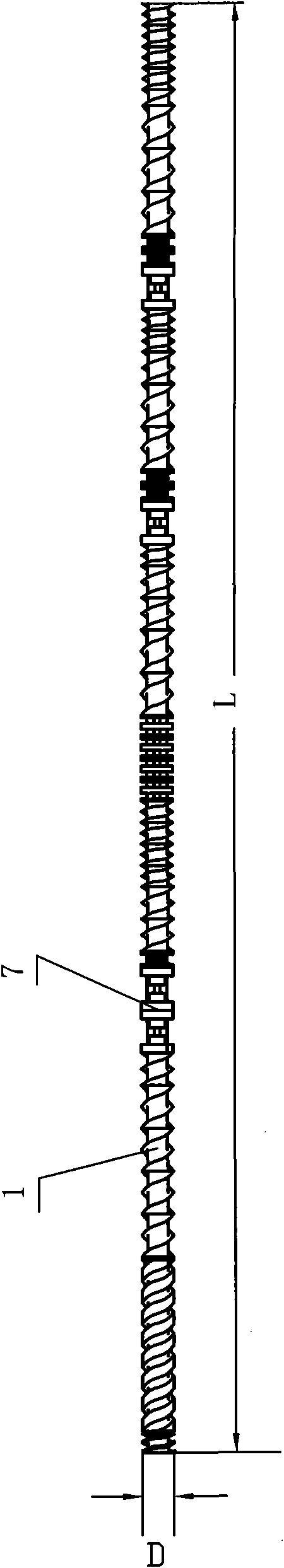

Pelleting extruder for FEP powder

The invention discloses a pelleting extruder for FEP powder, which comprises two parallel screws, a machine barrel which is arranged outside the screws, a heating system, a cooling system and a vacuumizing and de-volatilizing system, wherein a fluorine gas charging port is formed on the machine barrel. The invention aims to provide the dual-screw extruder for the FEP powders, which can shorten anFEP production and processing flow, simply and efficiently remove unstable end groups in products, control volatile matters of the products and has the advantages of high-temperature resistance, corrosion resistance and long service period. The double-screw extruder of the invention can efficiently remove the unstable end groups in molecular links and control the volatile matters of the products;and meanwhile, the machine barrel has corrosion resistance and high-temperature formation resistance and is very suitable for processing the FEP powder.

Owner:ZHEJIANG JUHUA CO LTD

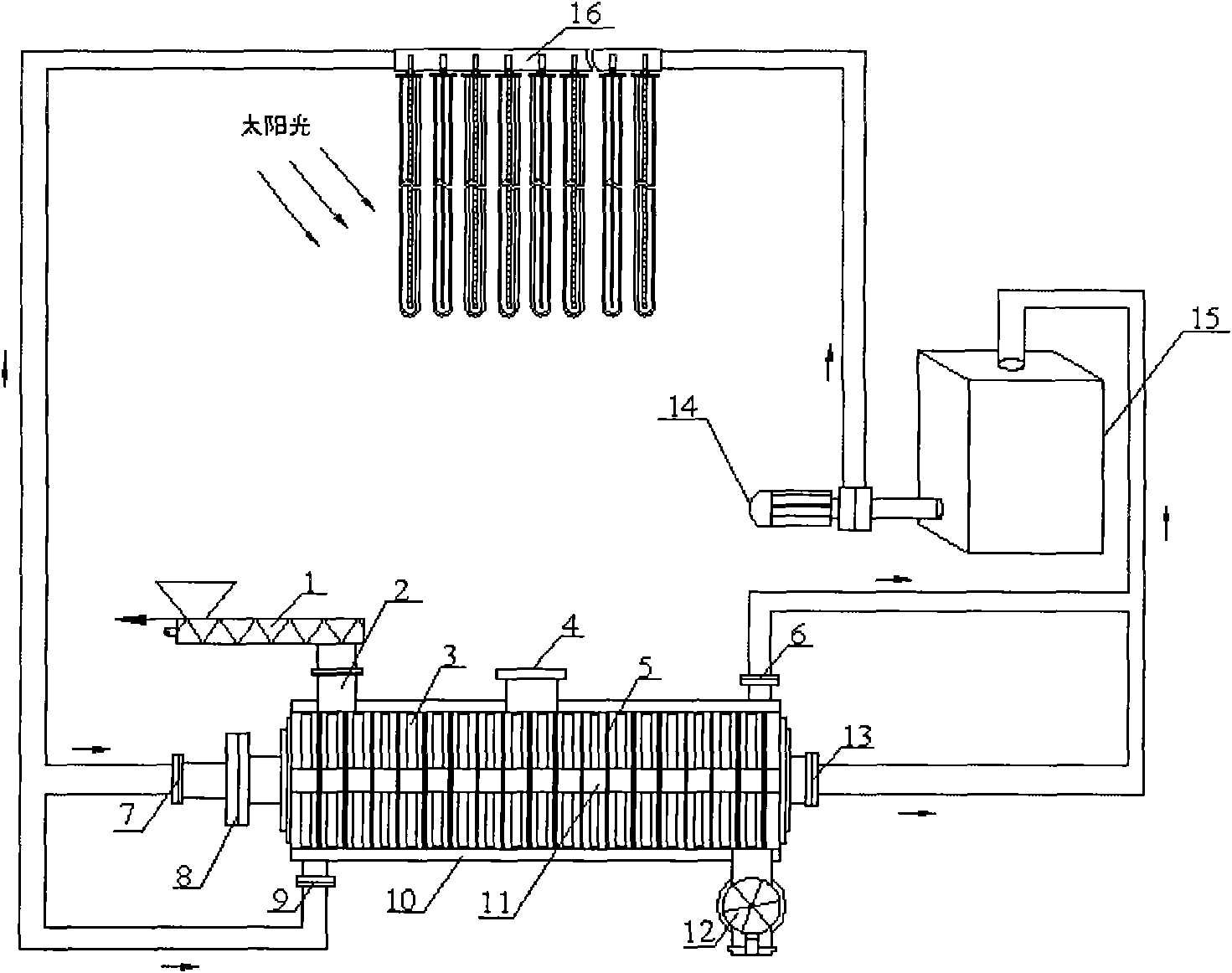

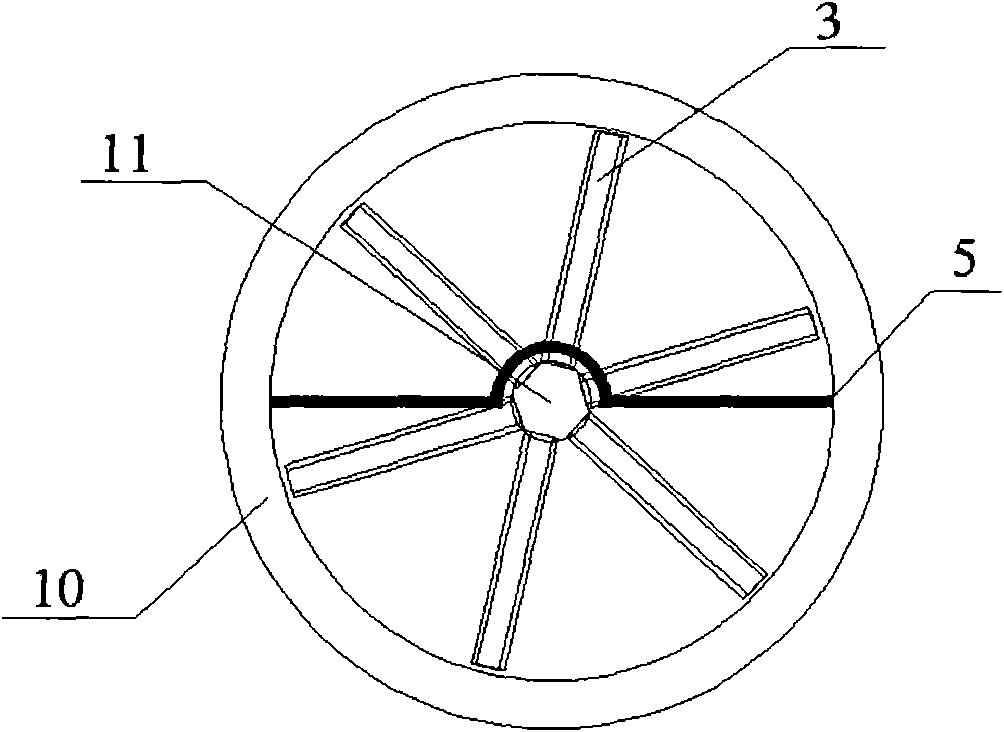

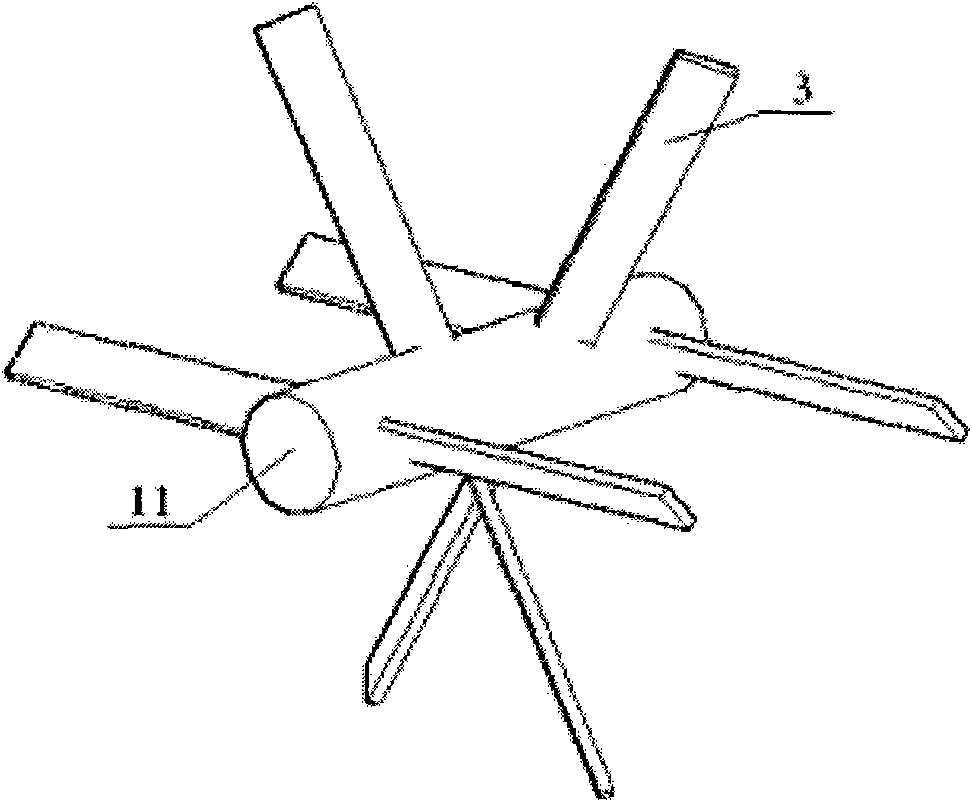

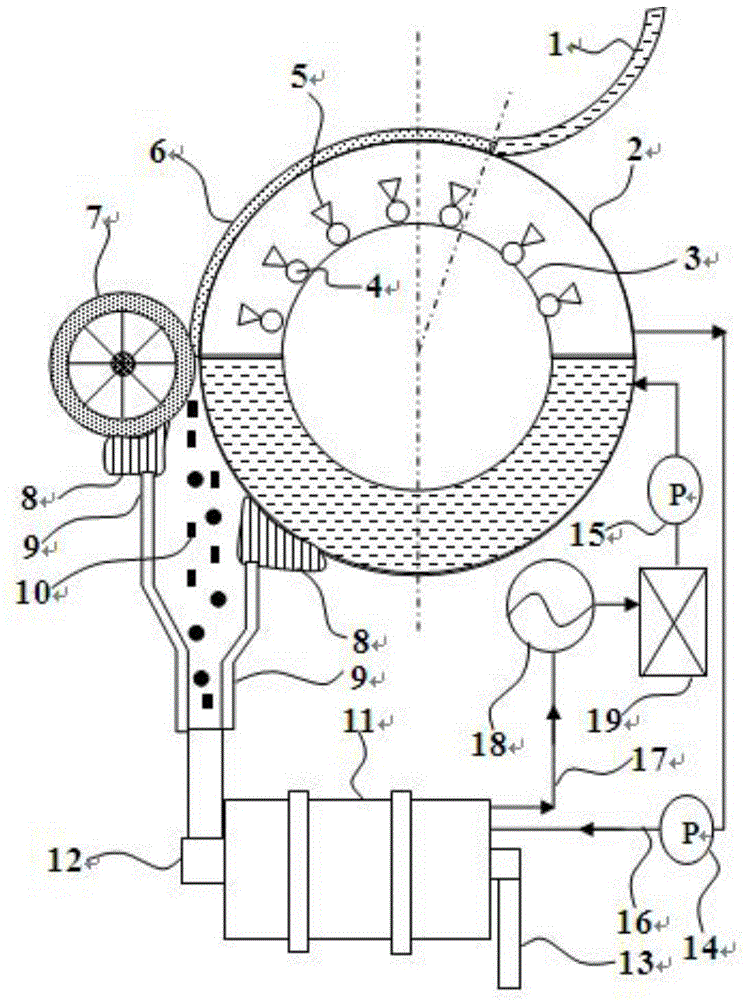

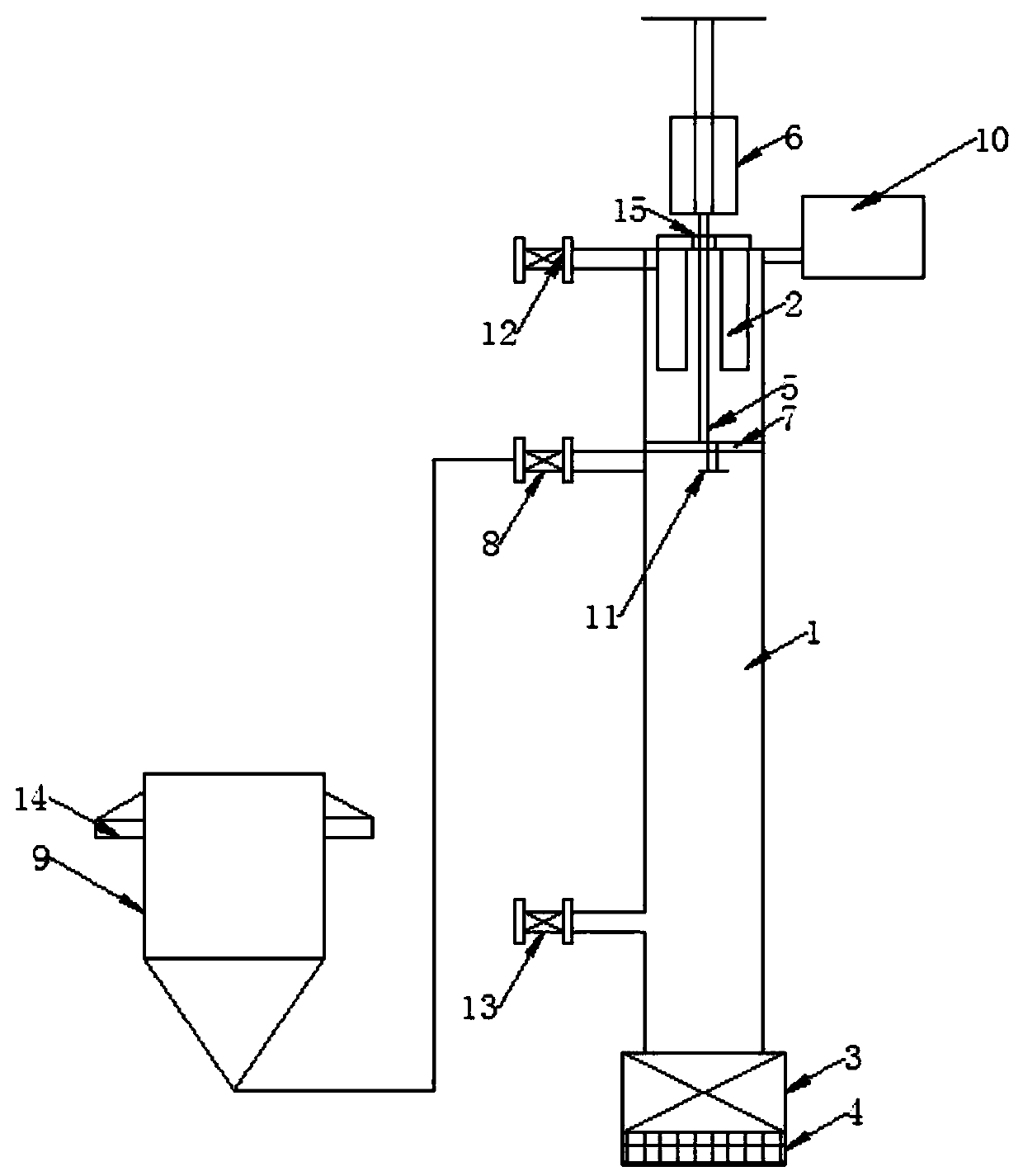

System for vacuum drying sludge by adopting solar energy

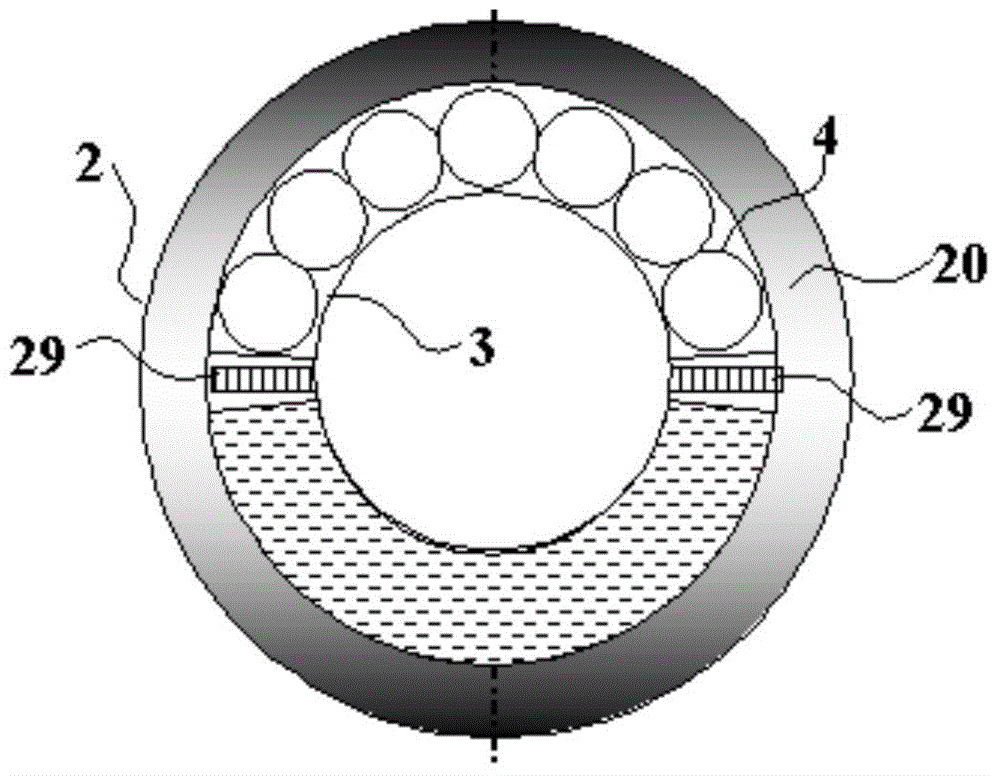

InactiveCN101781077AReduce consumptionSave energySludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentHeat conductingSludge

The invention relates to a system for vacuum drying sludge by adopting solar energy, comprising a self-cleaning sludge continuous vacuum drier with inclined two blades, a solar thermal collector, a heat conducting oil tank and a heat conducting oil pump. A cylindrical vacuum casing of the drier is internally provided with a vacuum thermal axis connected to a gearing. The vacuum thermal axis is provided with multiple sets of blades which are arranged in the inclined double blades manner. Both heat conducting oil outlets of the vacuum thermal axis and the casing are connected to the heat conducting oil tank through pipelines. Both heat conducting oil inlets and the outlets of the vacuum thermal axis and the casing are connected to the solar thermal collector through the pipelines. The heat conducting oil tank and the heat conducting oil pump are connected to the solar thermal collector through the pipelines. The invention realizes the drying of the sludge by adopting the solar energy, greatly reduces energy consumption during the sludge drying and saves energy by utilizing the self-cleaning vacuum sludge drier with inclined double blades.

Owner:DONGHUA UNIV

Waste plastic pulverizing and collecting device

InactiveCN108357026AExpedited screeningImprove crushing collection efficiencySievingScreeningPulp and paper industryProduction quality

The invention discloses a waste plastic pulverizing and collecting device and relates to the technical field of resources. The device comprises an outer frame. The bottom end of the interior of the outer frame is fixedly connected with a shaking device. The middle of the interior of the outer frame is fixedly connected with a limit slide bar, and a limit slide block is connected to the limit slidebar in a sliding mode. The end, away from a first motor, of an output connecting rod is rotationally connected with a transmission rod. The bottom end of the limit slide block is fixedly connected with a hanging rod. The bottom end of the hanging rod is rotationally connected with a stirring rotating wheel. The top end of the exterior of the outer frame is fixedly connected with a fixing rod. Pulverizing gears are rotationally connected into a pulverizing frame. The middle position of the bottom end of the pulverizing frame communicates with a communication pipeline. A pulverizing outlet is formed in the end, away from the pulverizing frame, of the communication pipeline. According to the waste plastic pulverizing and collecting device, the purposes that screening of plastic particles isaccelerated, the pulverizing and collecting efficiency is improved, cyclic pulverizing and pelleting are achieved, the production quality is improved, and the production labor is reduced are achieved.

Owner:佛山杰致信息科技有限公司

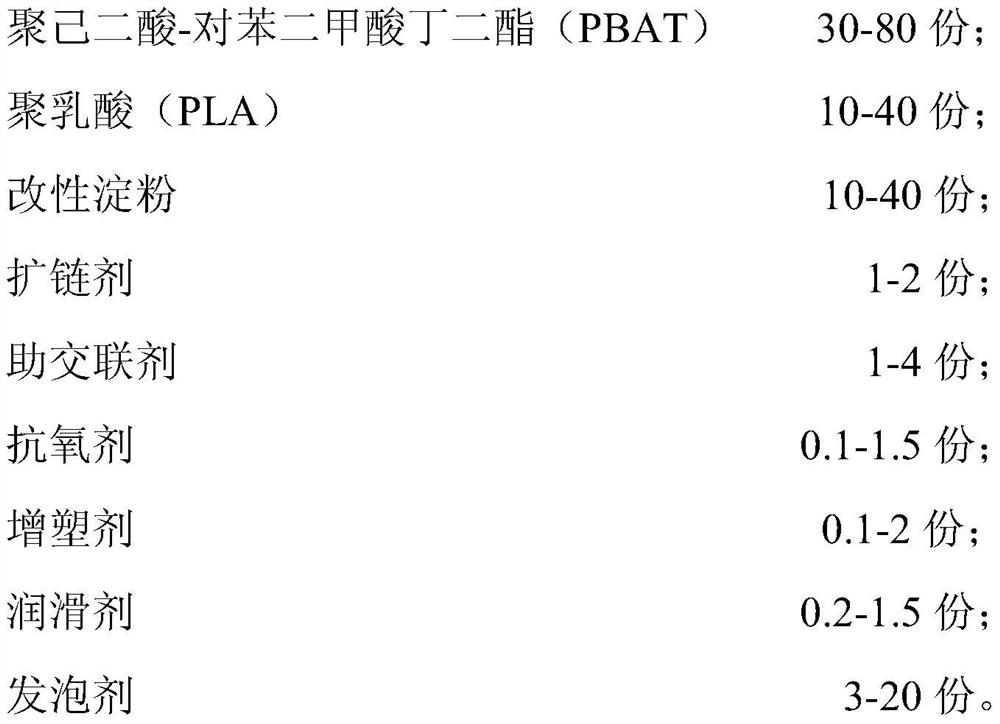

Degradable foam material and preparation method thereof

The invention discloses a degradable foam material and a preparation method thereof, and relates to the technical field of foam materials. The degradable foam material comprises the following components by mass: 40-80 parts of poly(butylene adipate-co-terephthalate); 20-40 parts of polylactic acid; 1-5 parts of a photosensitizer; and 3-20 parts of a foaming agent. The PBAT and the PLA are adopted as matrixes, the prepared foam material is degradable, environmentally friendly and high in ductility and comprehensive mechanical property, meanwhile, the processing temperature is reduced, advanced decomposition of a chemical foaming agent is inhibited, and the cell uniformity and foaming stability of the foaming material are improved. Meanwhile, the photosensitizer is added, after irradiation, the overall melt strength of the material can be improved, then the foaming ratio and the foam structure stability in the foaming process are increased, and the temperature resistance and the mechanical property of the foaming material can be further improved.

Owner:ZHEJIANG UNIV OF TECH

Treatment method for blast furnace melting slag

InactiveCN104357606AMeet the requirements of rapid coolingNo high temperature creepWater vaporOrganic matter

The invention relates to the technical field of treating furnace slag during pig iron melting, and particularly provides a treatment method for blast furnace melting slag. According to the treatment method, a blast furnace melting slag treatment device is utilized and controlled. Through utilizing the treatment method, not only can the treatment requirements on shock cooling, granulation and residual heat utilization of the blast furnace slag be met, but also the use of high-pressure vapor or inflammable organic matters can be avoided.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

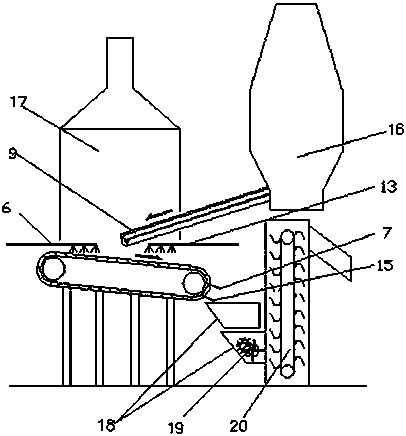

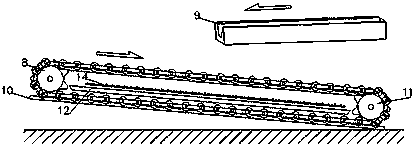

Dry granulation apparatus of blast furnace slag using continuous thin single-layer hot sprinkling and application method thereof

ActiveCN108441590AHighlight the effective effectPromote fragmentationRecycling and recovery technologiesBlast furnace smeltingCrusher

The invention relates to a treatment method of blast furnace slag from blast furnace smelting production, in particular to a dry granulation apparatus of blast furnace slag using continuous thin single-layer hot sprinkling and an application method thereof. The apparatus comprises a grate unit, a cooler, a slag trough, a crusher and a conveying lifter and is characterized in that the grate unit isarranged below the head of the slag trough, the grate unit is mounted at a positive angle of 2-5 degrees relative to a horizontal flowing direction of liquid slag, a condensing column is arranged above the grate unit, a grate plate of the grate unit is composed of a plurality of chain plate groups connected together, a water distributor and an upper cooler are arranged above the grate unit, the crusher is arranged below a head scraper of the grate unit, and a guide plate and the conveying lifter are arranged below a collection channel. Blast furnace slag can be quickly set and can be granulated and loosened via multiple pores, the high temperature is still retained which helps recycle subsequent heat, and the apparatus has the advantages of high efficiency, low energy consumption, and good convenience of arrangement.

Owner:吕艳

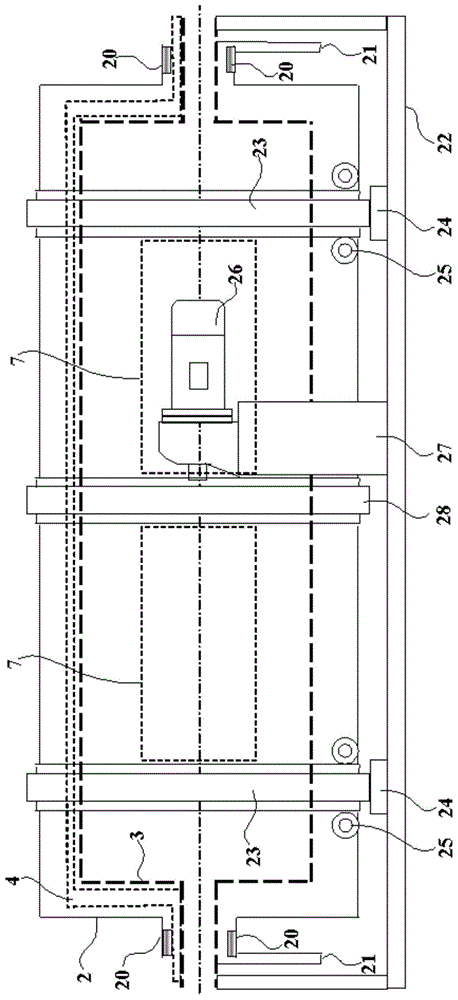

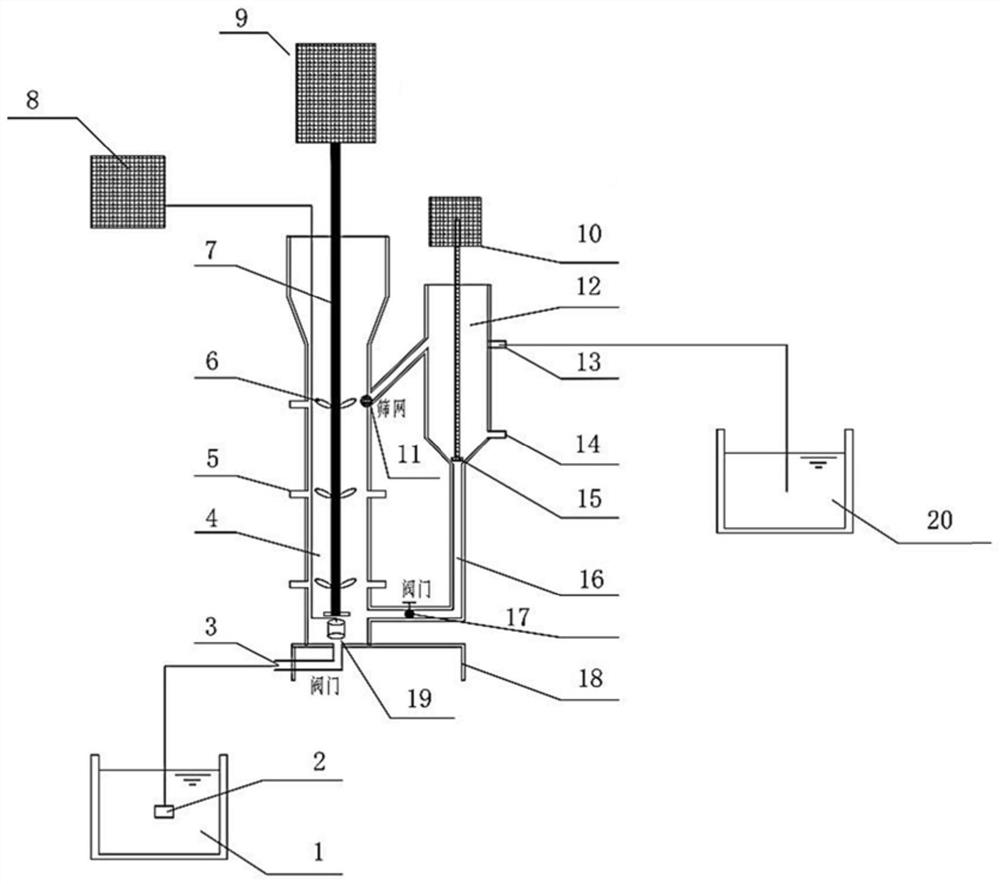

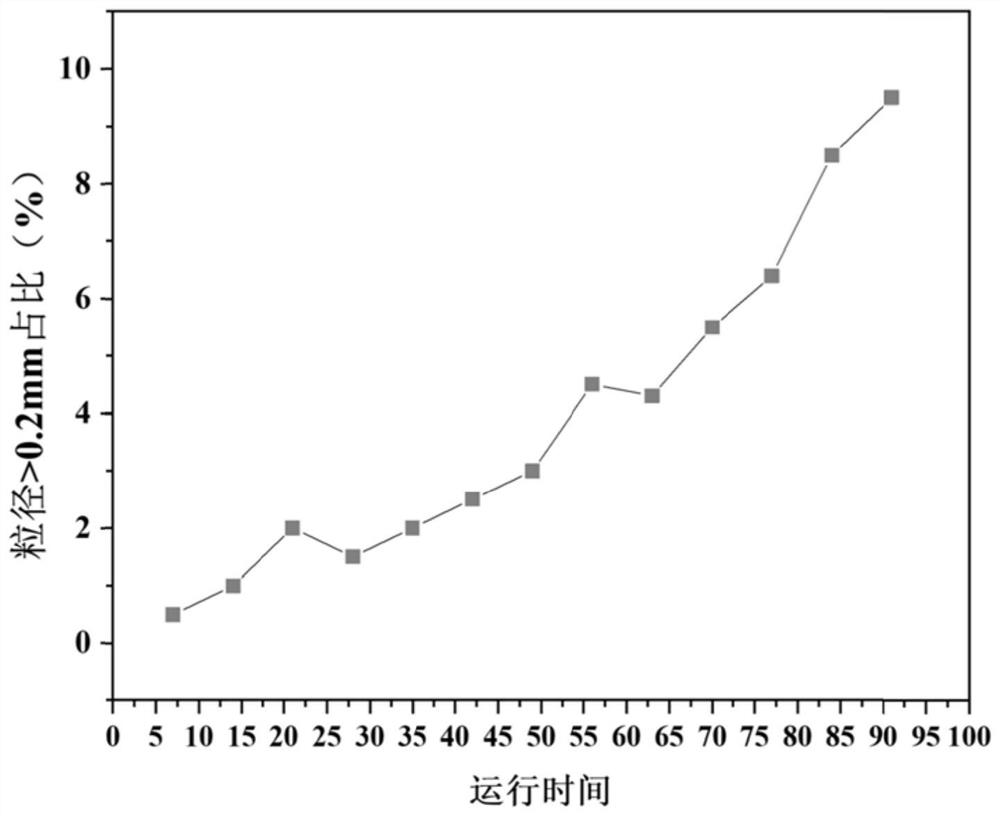

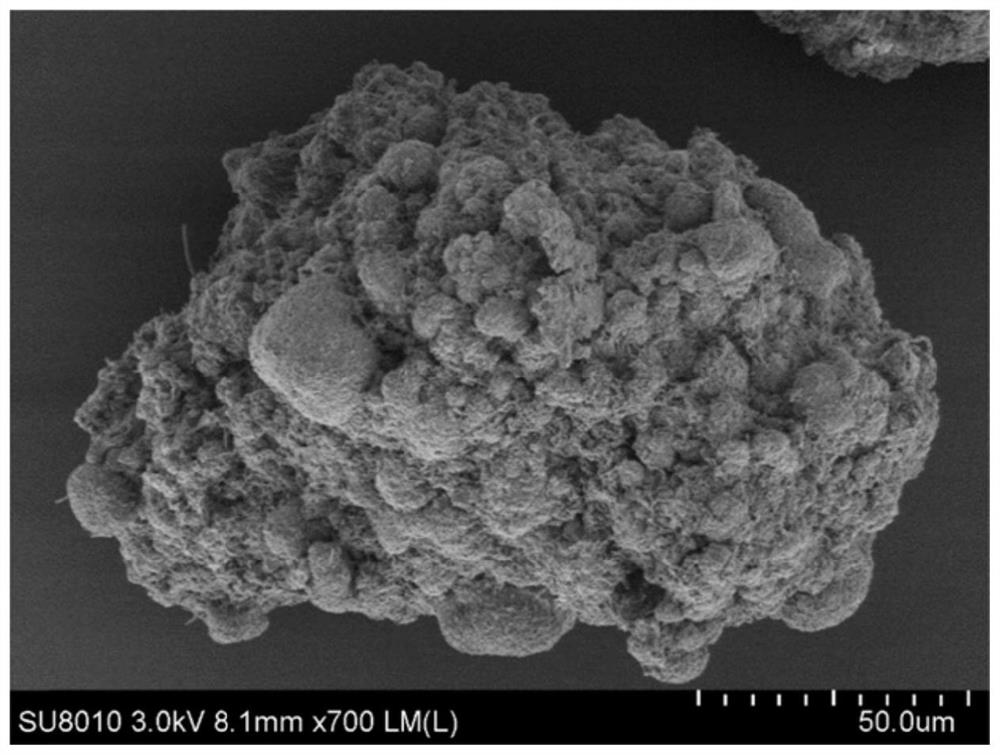

Continuous flow aerobic granular sludge reaction device provided with stirring paddle internal components and method

InactiveCN113304685AReasonable structureSimple structureSludge treatmentBiological treatment apparatusSludgeWater flow

The invention discloses a continuous flow aerobic granular sludge reaction device provided with stirring paddle internal components and a method, and belongs to the field of water pollution control. The device comprises an aerobic bioreactor, a precipitation reactor and a sludge return pipe, a stirring device for fully stirring mud-water mixed liquid is arranged in an inner cavity of the aerobic bioreactor, and an aerating device for aerating and oxygenating is arranged at the bottom of the aerobic bioreactor; sewage treated by the aerobic bioreactor passes through a screen and then enters the precipitation reactor; a reflux inlet is formed in the bottom of the precipitation reactor, is communicated with the lower part of the aerobic bioreactor through the sludge return pipe, and is used for returning sludge in the precipitation reactor into the aerobic bioreactor; and an electromagnetic valve externally connected with a magnetic device is arranged at the reflux inlet. The stirring device provides a rotational flow water flow state for the aerobic bioreactor, provides directional hydraulic shearing force for sludge particles, promotes granulation of aerobic sludge, and shortens the starting time of the system.

Owner:ZHEJIANG UNIV

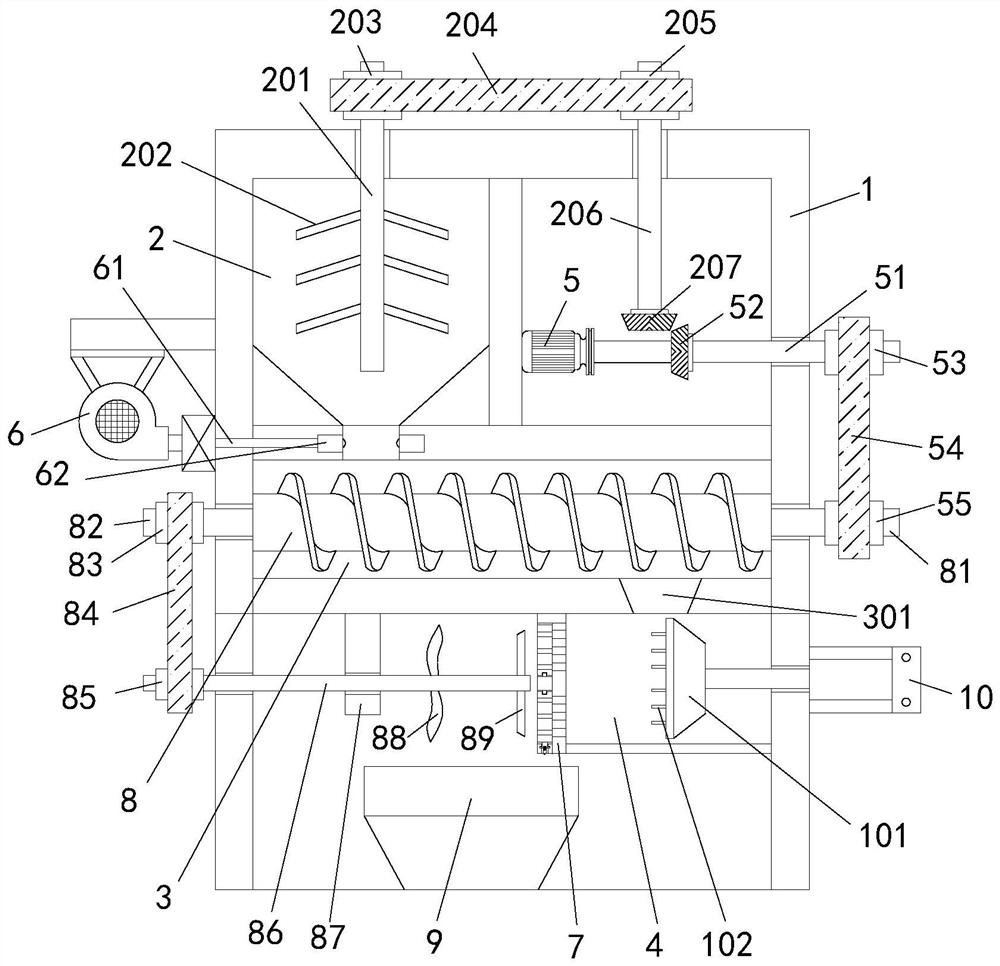

Adjustable granulation device for modified plastic production and processing

The invention discloses an adjustable granulation device for modified plastic production and processing. The adjustable granulation device comprises a device body shell, a stirring chamber, a spiral feeding chamber and a granulation chamber, the stirring chamber, the spiral feeding chamber and the granulation chamber are arranged in the device body shell and sequentially communicate from top to bottom, and a spiral rod is horizontally arranged in the spiral feeding chamber. A first main shaft and a second main shaft are arranged at two ends of the spiral rod correspondingly, and the spiral feeding chamber communicates with the granulation chamber through a discharging opening. An air cylinder is arranged on the outer wall of the granulation chamber, the output end of the air cylinder is connected with a push plate through a piston rod, a plurality of ejector pins are arranged on the side wall of the push plate, and an extrusion adjusting device is arranged at the end, opposite to the air cylinder, of the granulation chamber. According to the device, the defects in the prior art are overcome, the design is reasonable, the granulation of particles with different particle sizes can be achieved by adjusting the extrusion adjusting device under the condition that the device is not disassembled, the production and processing efficiency is greatly improved, and the social use value and the application prospect are relatively high.

Owner:合肥市丽红塑胶材料有限公司

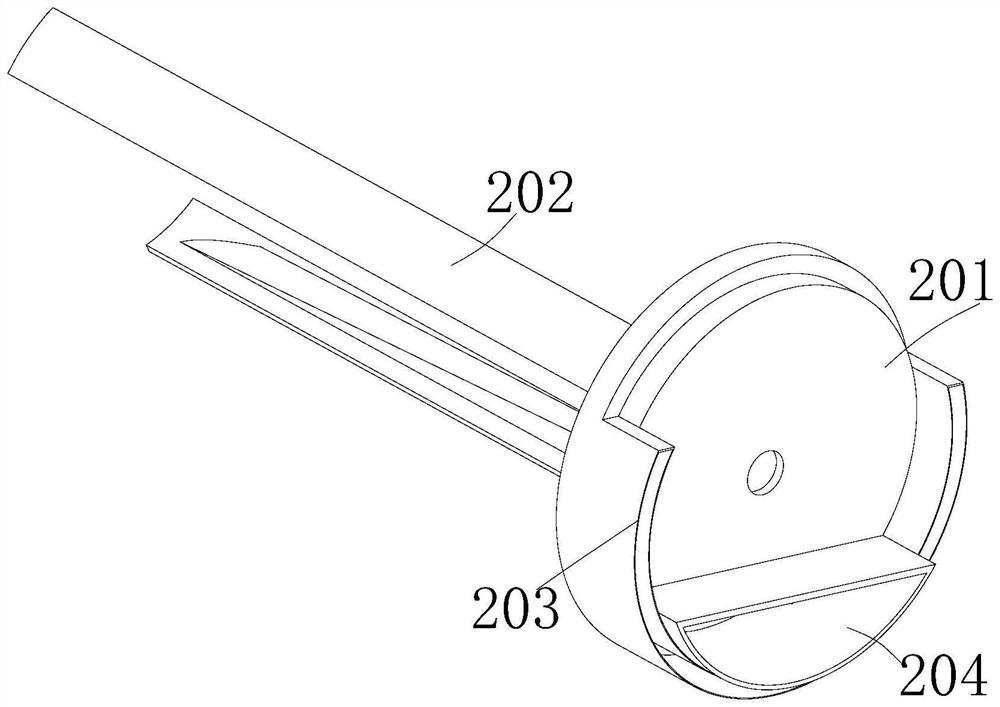

Plastic granulation device capable of conveniently adjusting particle size

The invention discloses a plastic granulation device capable of conveniently adjusting the particle size. The plastic granulation device comprises a compression cavity, wherein the compression cavityis of a pipe-shaped structure with through holes formed in two ends; a feeding hopper is arranged at the top end of the compression cavity; in an extrusion process, when a compression piston is used for pushing plastic to one end of a granulation disc, a heating pipe is used for heating the plastic in the compression piston and the plastic is convenient to extrude; when an extruded plastic strip passes through a through hole of the granulation disc, a motor drives a cutting-off disc and a cutting-off knife to rotate under the supporting of a motor retainer, and then the extruded plastic stripis cut off and plastic granulation is realized; the cutting-off knife and the cutting-off disc are tightly matched through a mounting groove and can be detached; when the length of cutting off the plastic strip needs to be adjusted, only the quantity of the cutting-off knives mounted on an outer ring of the cutting-off disc needs to be changed, the cutting-off frequency can be changed and the change of cutting-off length is realized; cut-off plastic falls into a collection cabin and the collection cabin is provided with a pull type cabin door and plastic grains are conveniently subjected to next-step treatment; the design of the device is more humanized and the device is easy to popularize and apply.

Owner:安徽泽泓塑业股份有限公司

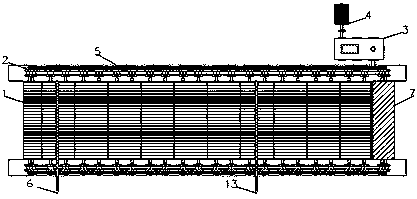

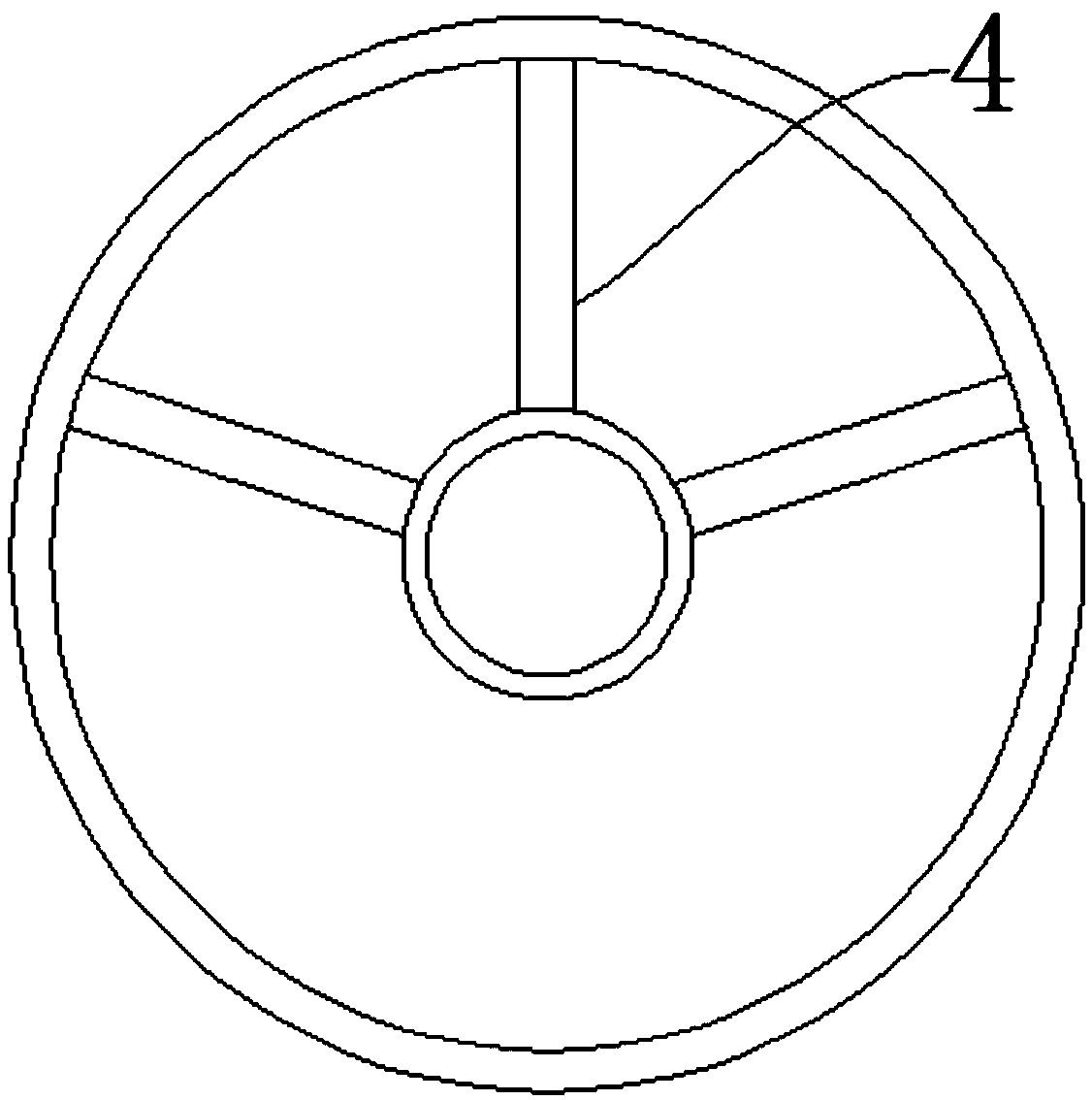

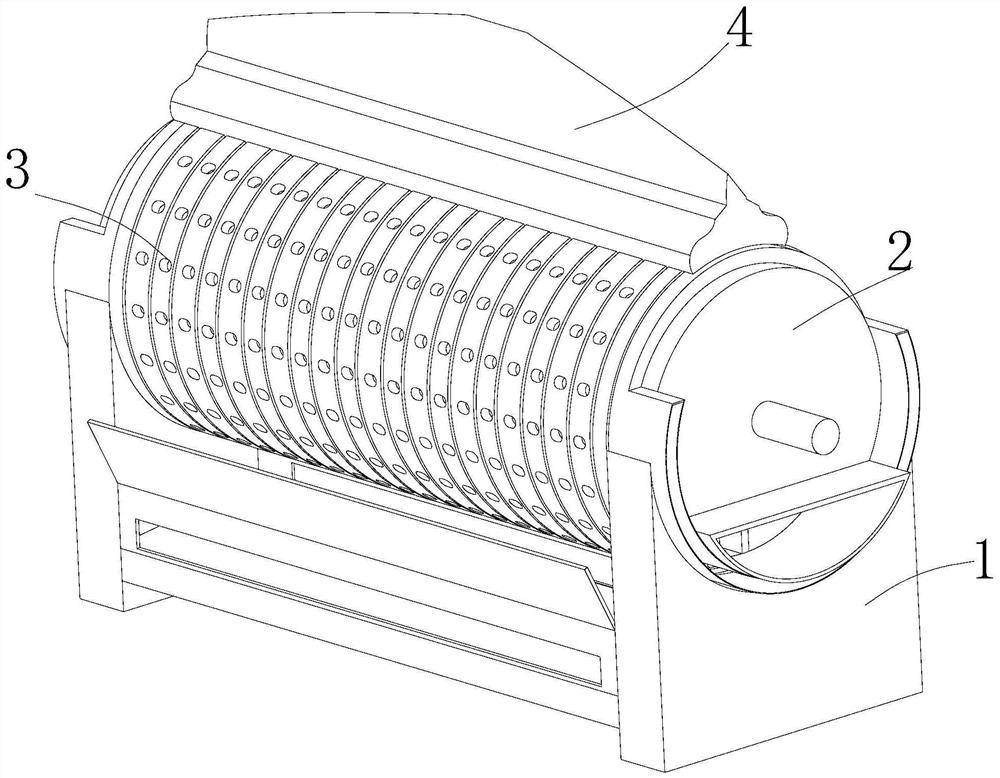

Automatic compound fertilizer granulation assembly system

ActiveCN103694064AAchieve granulationAchieve dryingGranulation in rotating drumsFertiliser formsEconomic benefitsAgricultural engineering

The invention discloses an automatic compound fertilizer granulation assembly system which comprises a granulator and a drier connected with the granulator. The system is characterized in that the granulator comprises a rotating drum, wherein the top of the rotating drum is provided with a feed port, the middle of the rotating drum is provided with a worm transmission part, the position with the same center of circle as the worm transmission part in the rotating drum is provided with a rotary sprayer, and the rotating drum and the rotary sprayer are driven to rotate by the same power source. The system has the advantages of ingenious and reasonable design and high systematicness; by arranging the multistage equipment, the system can effectively implement the functions of granulating, drying screening and assembling the compound fertilizer, has high degree of automation and superior performance; and compared with the existing split equipment, the efficiency is enhanced by more than 40%, and the economic benefit is enhanced by more than 30%.

Owner:河北百斗嘉肥料有限公司

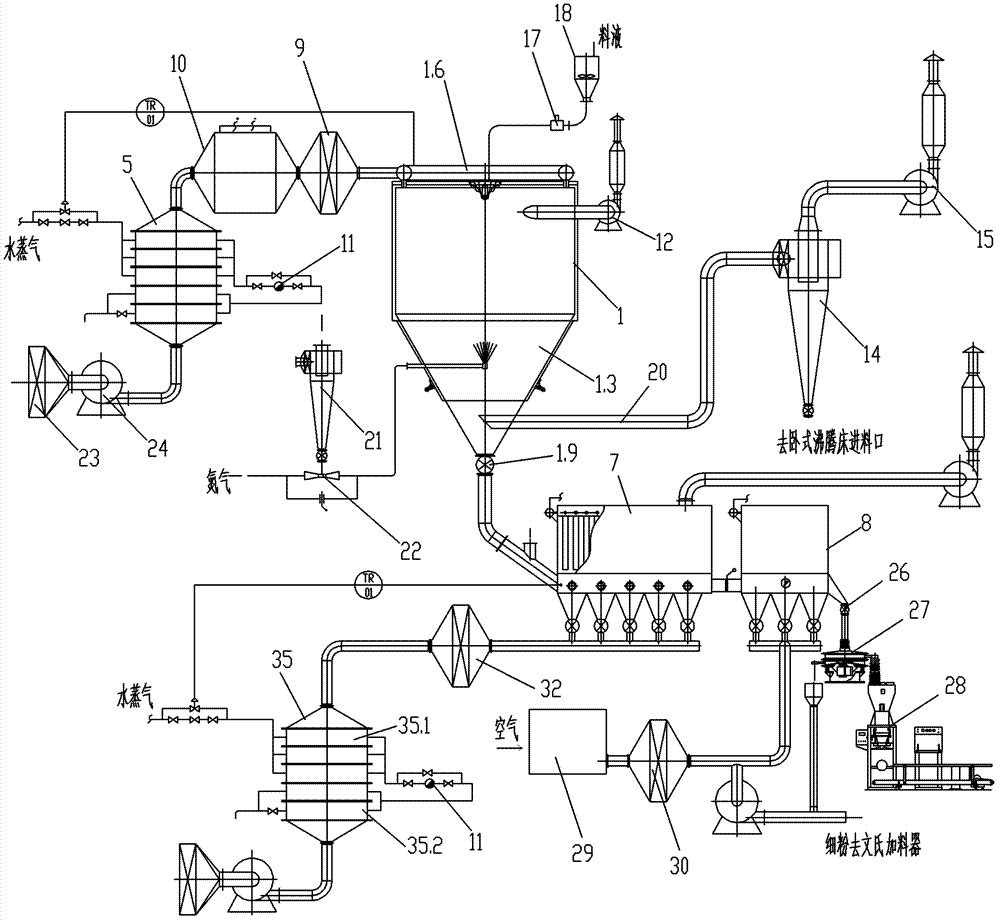

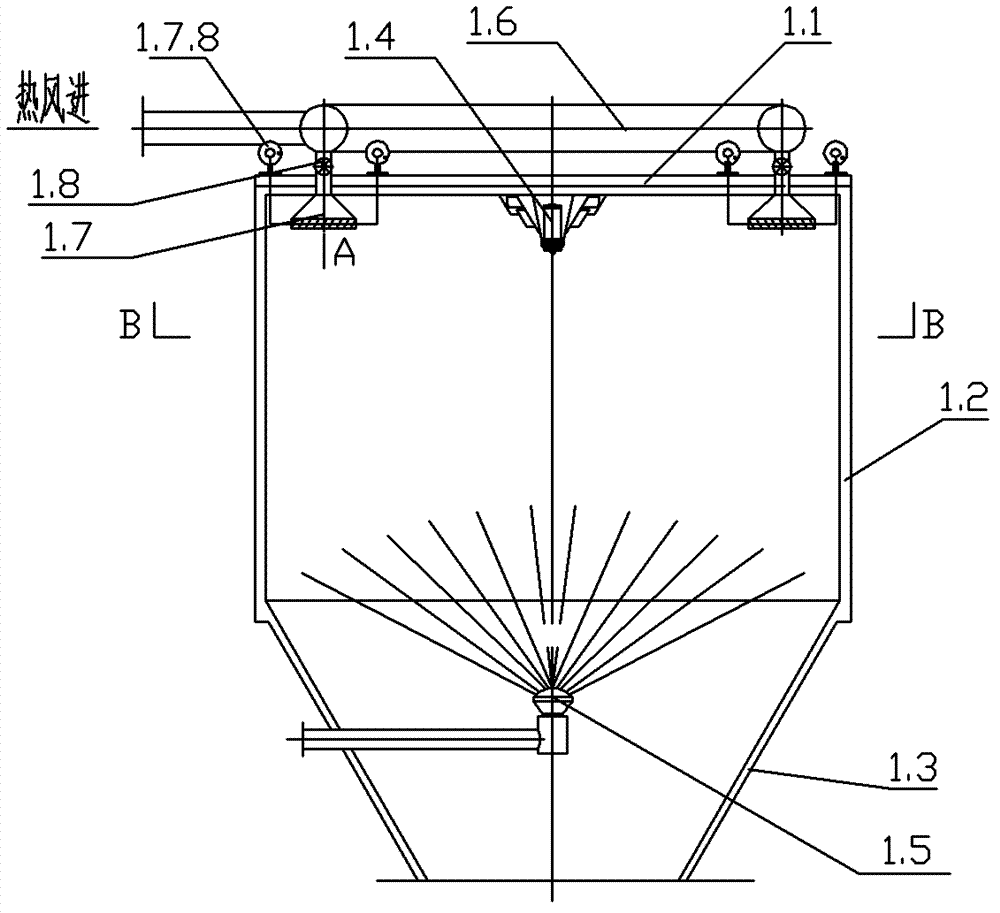

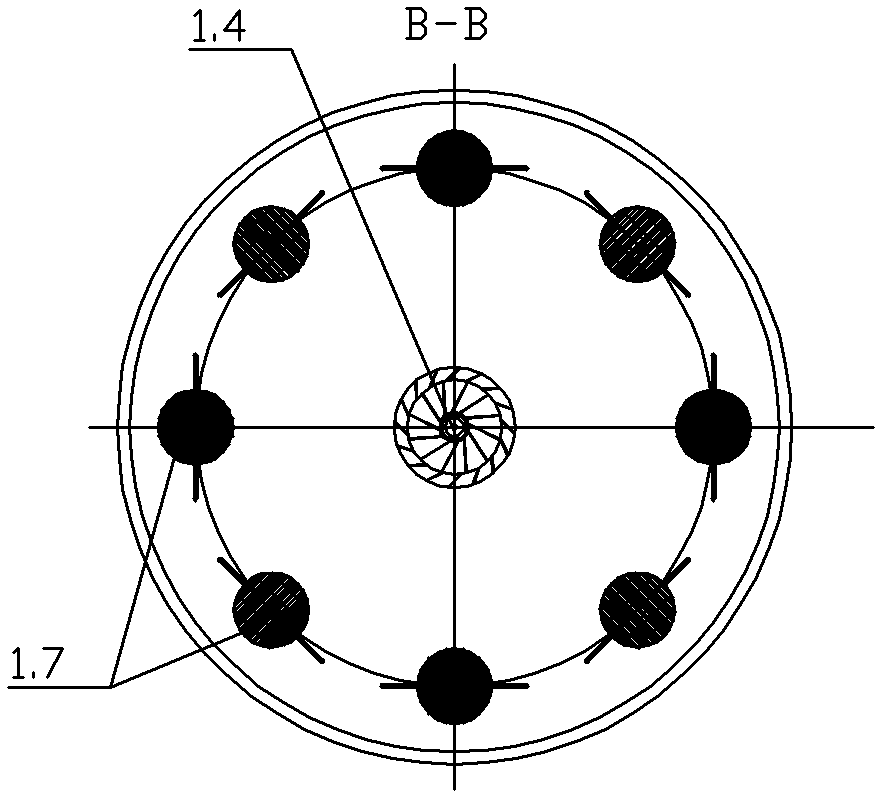

Centrifugal spray drying tower of spray granulation fluidized drying unit

ActiveCN102847329AHigh density contactHigh densityEvaporation by sprayingSpray GranulationHigh density

The invention relates to a spray granulation fluidized drying system of a spray granulation fluidized drying unit, comprising a centrifugal spray drying tower, wherein the centrifugal spray drying tower comprises a tower top, a tower body and a tapered tower bottom which have an upper and lower sealing connection in order; the center of the tower top is provided with an atomizer, and a pressure spray nozzle for spraying dry powder upwards is arranged in the spray drying tower and under the atomizer. According to the invention, by adopting the mode of spraying downwards from the top and spraying upwards from the bottom, relative to the upward spraying, the downward spraying is suitable for further fining fog drips and increasing the fog drip density to guarantee the full and high density contact between the fog drips and dry powder; in advance, in the descending process of the fog drips, fine particles in the fog drips rapidly become sticky semi-wet state and bonds with oncoming dry powder to form particles with low humidity, thus granulation and drying can be realized without a binder.

Owner:CHANGZHOU YUTONG DRYING EQUIP

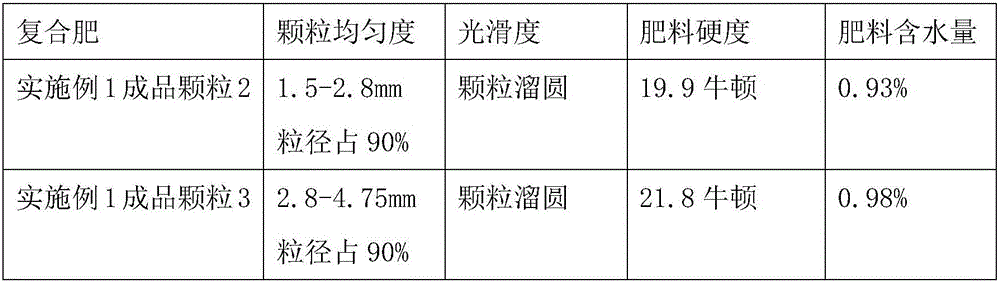

Combined ejection prilling tower compound fertilizer prilling method

InactiveCN106116991ALow costSmall footprintGranulation by liquid drop formationSolid/semi-solid fertilisersSlurryProduct gas

The invention relates to a combined ejection prilling tower compound fertilizer prilling method. The method comprises the following steps that small granules and melting slurry A are mixed to form feed liquid, the feed liquid is mixed with gas to form a gas-liquid mixture, the gas-liquid mixture is ejected into a first prilling tower, formed fertilizer granules enter a screening machine, and first-grade finished product granulated fertilizer and first-grade small granulated fertilizer are obtained; the first-grade finished product granulated fertilizer is mixed with melting slurry B to form feed liquid, the feed liquid is mixed with gas to form a gas-liquid mixture, the gas-liquid mixture is ejected into a second prilling tower, formed fertilizer granules enter the screening machine, and second-grade finished product granulated fertilizer and second-grade small granulated fertilizer are obtained. The angle between the ejection direction and a horizontal plane is 0-90 degrees, and the ejection direction is upward relative to the horizontal plane. According to the multilayer compound fertilizer prepared through the prilling method, uniformity, smoothness and other indexes of the fertilizer granules can meet requirements for composite fertilizer products, the prilling cost is low, and the cost performance of the fertilizer is improved.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

Composite potassium carbonate fertilizer and preparation process thereof

InactiveCN107141085AImprove molding rateIncrease productionCalcareous fertilisersAlkali orthophosphate fertiliserSulfatePhosphate

The invention discloses a composite potassium carbonate fertilizer and a preparation process thereof. The composite potassium carbonate fertilizer is prepared from, by weight, 25-30 parts of urea, 35-45 parts of monoammonium phosphate, 20-30 parts of potassium carbonate, 2-3 parts of ammonium bicarbonate and 2.5-3.5 parts of calcium sulfate. The preparation process comprises the steps that smashing is performed, wherein the urea, the monoammonium phosphate, the potassium carbonate, the ammonium bicarbonate and the calcium sulfate are smashed by a smashing machine according to the weight parts; stirring is performed, wherein the obtained mixed smashed materials are fed into a stirring tank through a conveying belt for stirring, and the materials are conveyed into a granulator after being evenly stirred; steam is introduced into the granulator, the viscidity of the monoammonium phosphate in the materials is increased through the effect of the steam, and mixed granulation is performed; the obtained granulated mixture is dried, screened and cooled, and finished product screening is performed to obtain finished product granules; the outer layers of the obtained finished product granules are coated with an anti-blocking substance through a coating machine, and then package is performed. A product forming period can be shortened by replacing the potassium carbonate with traditional potassium sulfate, and the yield of the compound fertilizer can be increased.

Owner:魏万辉

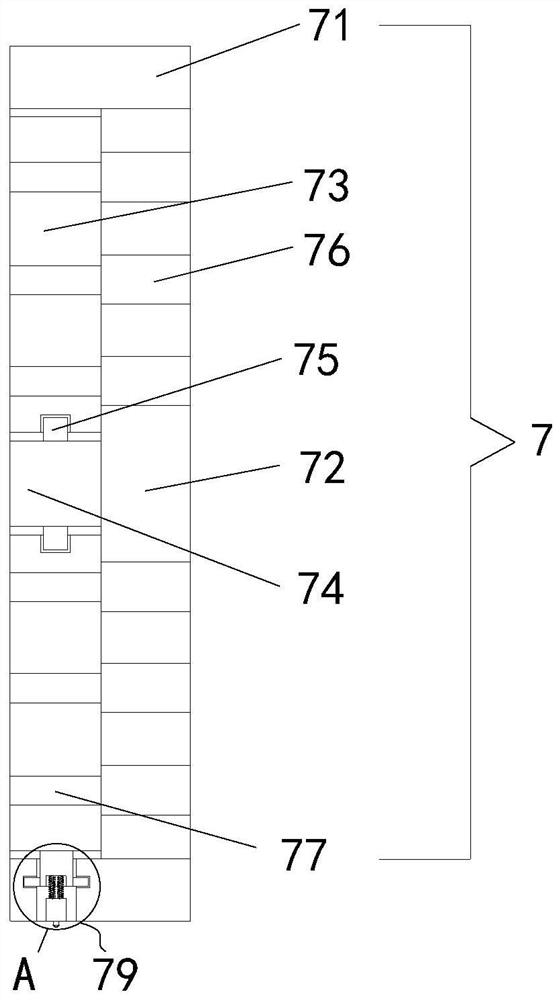

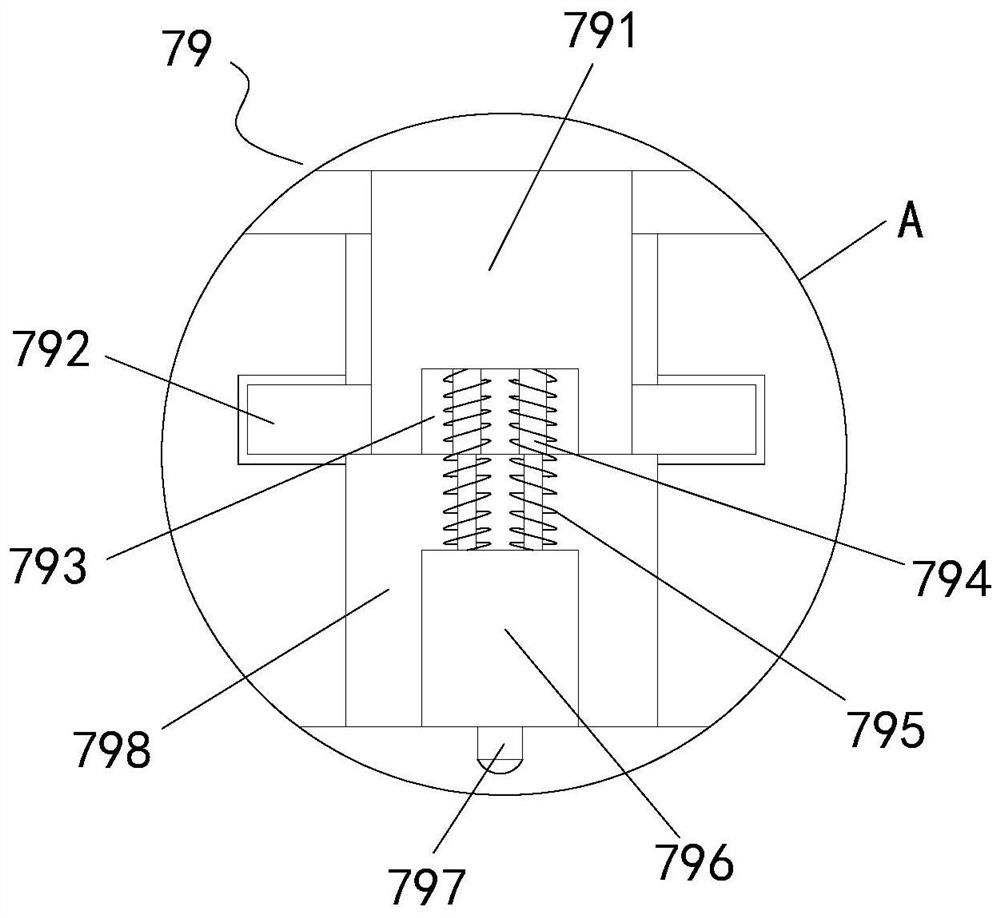

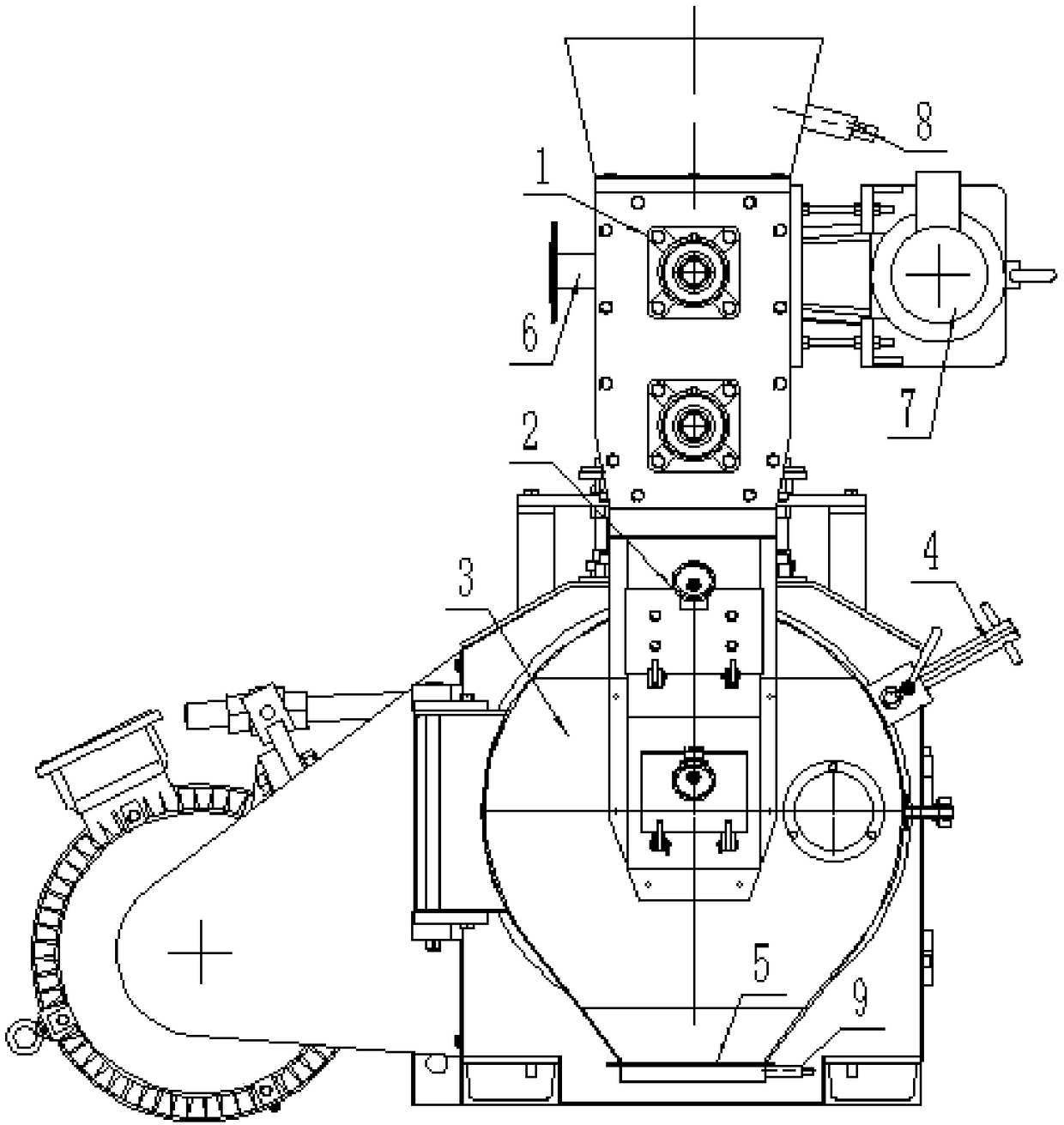

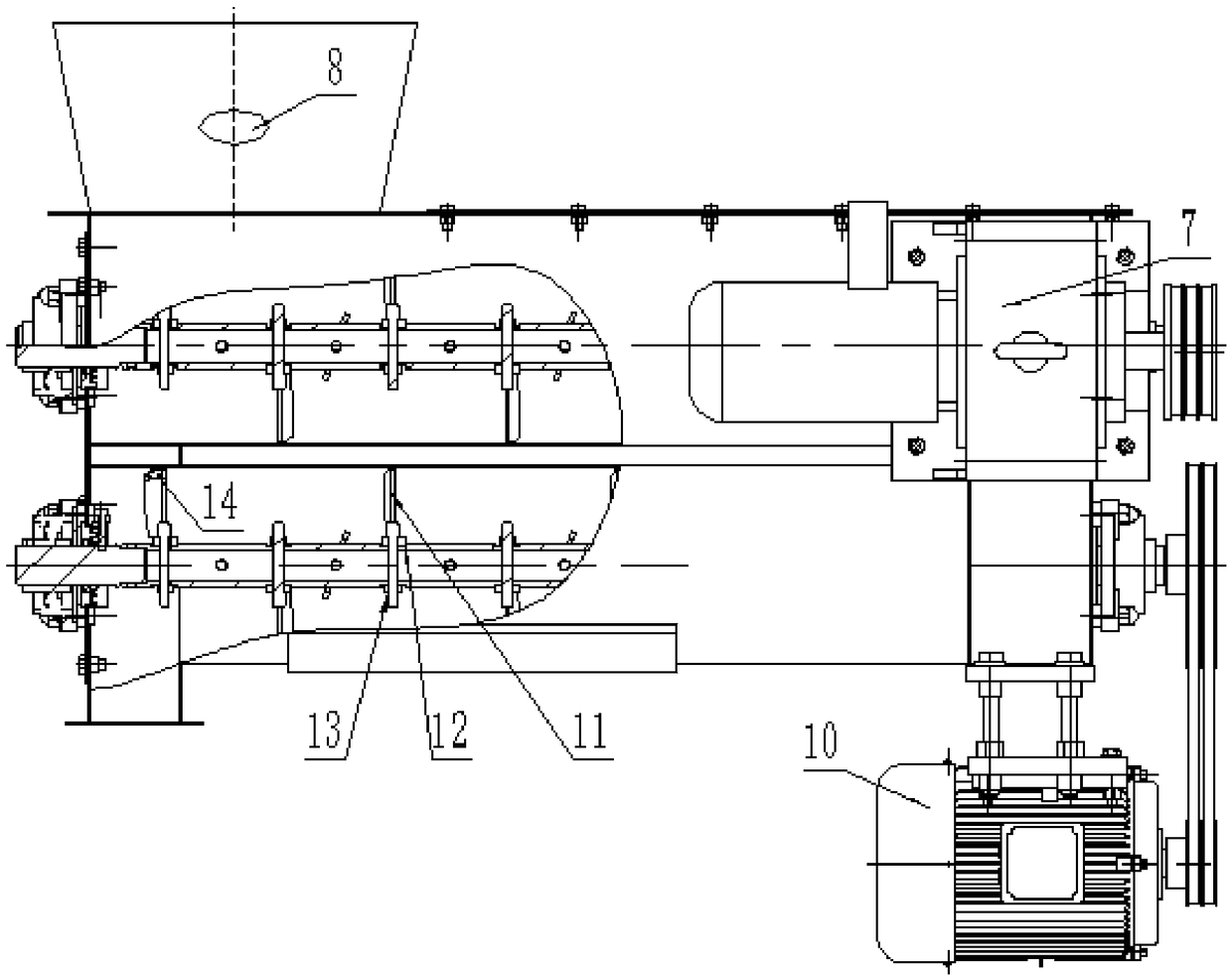

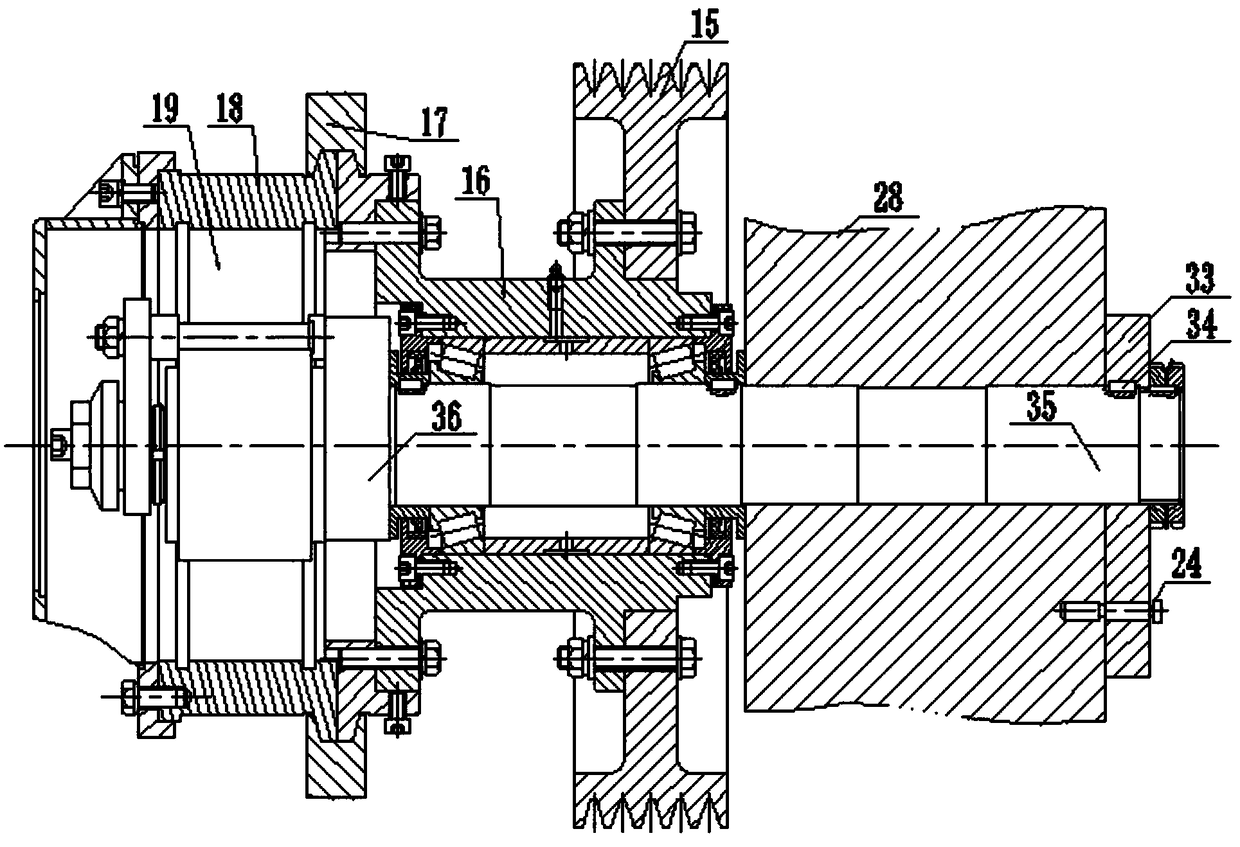

Feeding modulator and horizontal type circular mould straw granulator provided with feeding modulator

PendingCN108726109AAchieve granulationImprove efficiencyCleaningLarge containersEngineeringHigh pressure

The invention discloses a feeding modulator and a horizontal type circular mould straw granulator provided with the feeding modulator. The feeding modulator and the horizontal type circular mould straw granulator provided with the feeding modulator solve the problems of low automation level and low level of safety protection of a horizontal type circular mould straw granulator in the prior art, and the effects of being capable of realizing the automatic operation of the horizontal type circular mould straw granulator, accurately and reliably adjusting a pressure roller circular mould gap, andbeing high in safety factor of the equipment operation are achieved. According to the technical scheme, the feeding modulator includes a feeder and a modulator body, and both of the feeder and the modulator body include screw conveying devices with adjustable spiral angles. The feeder includes a feeding hopper, and an arch breaking air hammer for preventing straw arching is installed on the side face of the feeding hopper. The feeder is driven by a variable-frequency and variable-speed motor to realize the adjustment of feeding volume of materials. The modulator body is powered by a modulatingmotor, and the moisture content and temperature of the materials are adjusted by high pressure steam entering from a pipe joint installed on one side of the feeder.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Method for purifying hydrolyzed phytosterols by oxidase

InactiveCN109971816ASave raw materialsImprove purification efficiencySteroidsFermentationSterolVegetable oil

The present invention discloses a method for purifying hydrolyzed phytosterols by oxidase and relates to the technical field of phytosterols. The method comprises the following steps: hydrolyzing is conducted: vegetable oil is transferred into a hydrolysis kettle, sulfuric acid, sulfonic acid and water are added, and then refluxing is conducted for 1-4 hours; distillate deodorization is conducted:the hydrolyzed vegetable oil is subjected to distillate deodorization, a deodorized distillate is subjected to a methyl esterification reaction, vacuum dehydration is conducted, and then triglycerideis hydrolyzed into fatty acids and glycerol; and after a methyl esterification agent is added, sterol is separated and a filtrate is collected; enzyme catalyzed esterification is conducted; desolvation is conducted; vacuum distillation is conducted; sterol and VE extracting is conducted; separation is conducted; and waste granulation is conducted. The hydrolysis can be realized before the esterification, purification efficiency is improved, and a purification rate can reach 99.3-99.8%. Compared with the existing technology, 1-3 hours can be saved. The method is easy to protect environment effectively, then the waste granulation can be realized after the purification, waste is recycled, and the method is not liable to cause pollution; and at the same time, during the production, waste water is less and the method is conducive to production.

Owner:ZHEJIANG SHENZHOU PHARMA

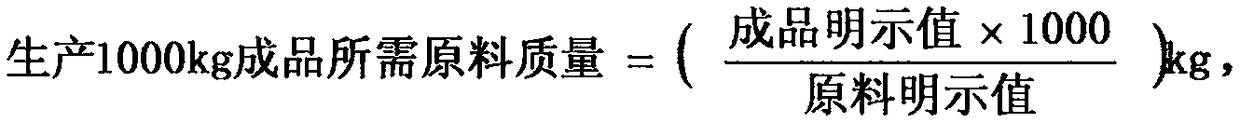

Compound fertilizer granulation assembly system

ActiveCN103694063AAchieve granulationAchieve dryingGranulation in rotating drumsFertiliser formsSprayerEconomic benefits

The invention discloses a compound fertilizer granulation assembly system which comprises a granulator and a drier connected with the granulator. The system is characterized in that the granulator comprises a rotating drum, wherein the top of the rotating drum is provided with a feed port, the middle of the rotating drum is provided with a worm transmission part, the position with the same center of circle as the worm transmission part in the rotating drum is provided with a rotary sprayer, and the rotating drum and the rotary sprayer are driven to rotate by the same power source. The system has the advantages of ingenious and reasonable design and high systematicness; by arranging the multistage equipment, the system can effectively implement the functions of granulating, drying screening and assembling the compound fertilizer, has high degree of automation and superior performance; and compared with the existing split equipment, the efficiency is enhanced by more than 40%, and the economic benefit is enhanced by more than 30%.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

Nano carbon material compression pelletizing device for rubber and process method

InactiveCN110180458ARealize compression granulationNo drying requiredGranulation by pressingMixed materialsSolvent

The invention relates to the technical field of nano carbon material pelletizing and in particular to a nano carbon material compression pelletizing device for rubber and a process method. The compression pelletizing device is internally of an upright hollow cylindrical structure with a compression cavity, and comprises a compression cavity, a hydraulic device, a feeding control device, a filtering device, a vacuum exhaust device, a back blowing device, a discharge device and a pelletizing device. The process method of compression pelletizing comprises the following steps: (1) uniformly mixinga nano carbon material with a rubber formula aid filler; (2) putting mixed materials into the inner cavity of the device; (3) performing vacuuming; (4) compacting the mixed materials; (5) dischargingand pelletizing compressed materials; (6) discharging materials; (7) performing back blowing; and (8) repeating the process, so as to achieve continuous compression pelletizing. A part of materials of a formula of rubber self are adopted to bond the nano carbon material, a solvent does not need to be removed at a later stage, the compact density of the nano carbon material pelletized by using thedevice and the method is remarkably increased, and continuous operation and high efficiency can be achieved.

Owner:甘海半导体材料(上海)有限公司

Production method of drying-free compound fertilizer

The invention discloses a production method of a drying-free compound fertilizer, which comprises the following steps: directly preparing concentrated sulfuric acid and ammonia into an ammonium sulfate solution of more than 400 DEG C; melting urea in a urea melting device to obtain a urea solution of which the temperature is 115-125 DEG C and the mass percentage is 95-98%; passing the ammonium sulfate solution through a purpose-made tubular reactor, atomizing and spraying the ammonium sulfate solution and the urea solution with a special sprayer into a granulator, and granulating with other powdery basic fertilizers containing nitrogen, phosphorus and potassium; and after the granulation, directly cooling, screening and coating to obtain the nitrogen-phosphorus-potassium compound fertilizer. The invention fully utilizes ammonia-acid reaction head and temperature of the urea solution to enhance the material temperature, and utilizes the ammonia sulfate solution generated by ammonia-acid reaction and the urea solution as the liquid phase, and has the advantages of high viscosity and high granulation rate. The invention does not need to add vapor and water to increase the water content of the granulated material, cancels the drying system and auxiliary facility, reduces the technical process, and saves about 30% of equipment investment and a great deal of energy consumption.

Owner:PANJIN STRONG FERTILIZER

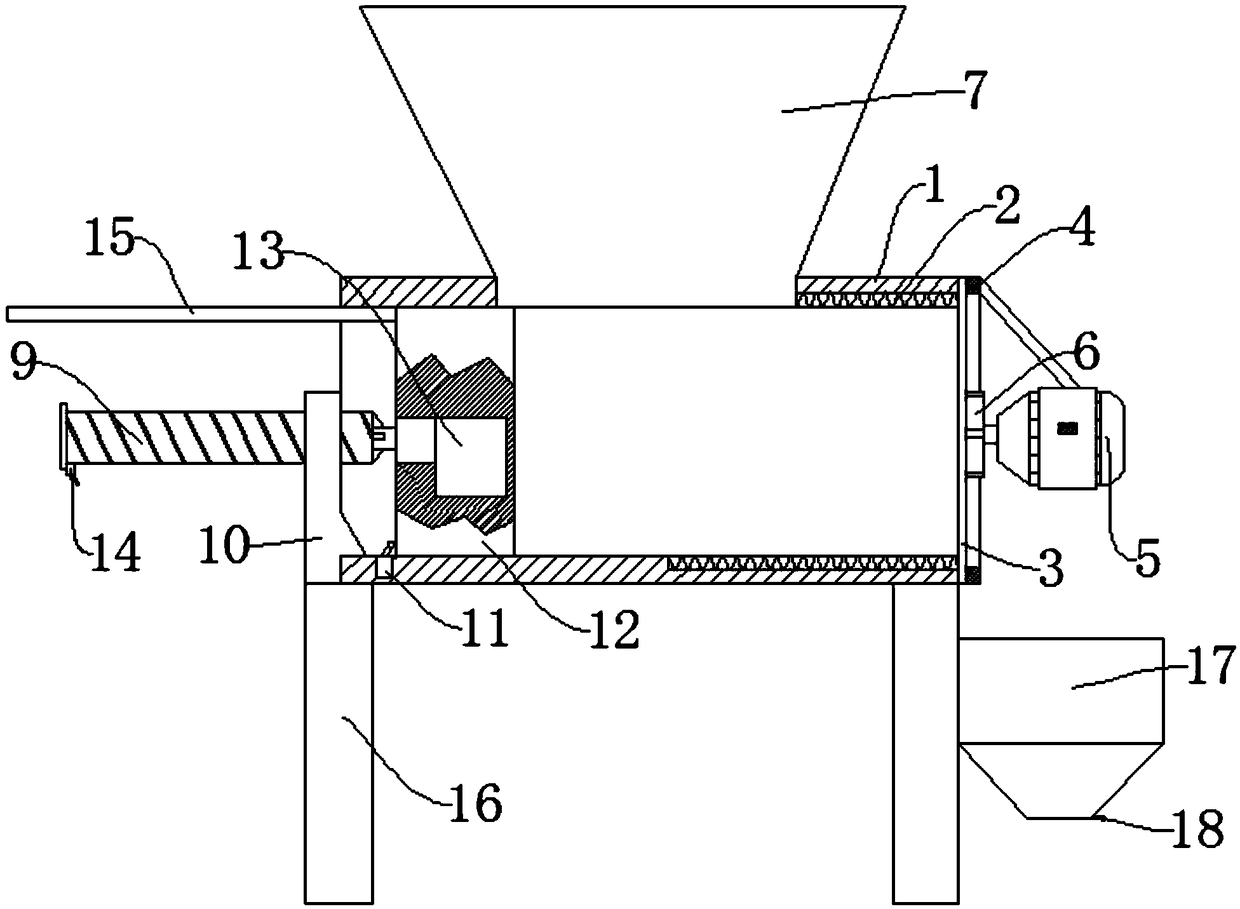

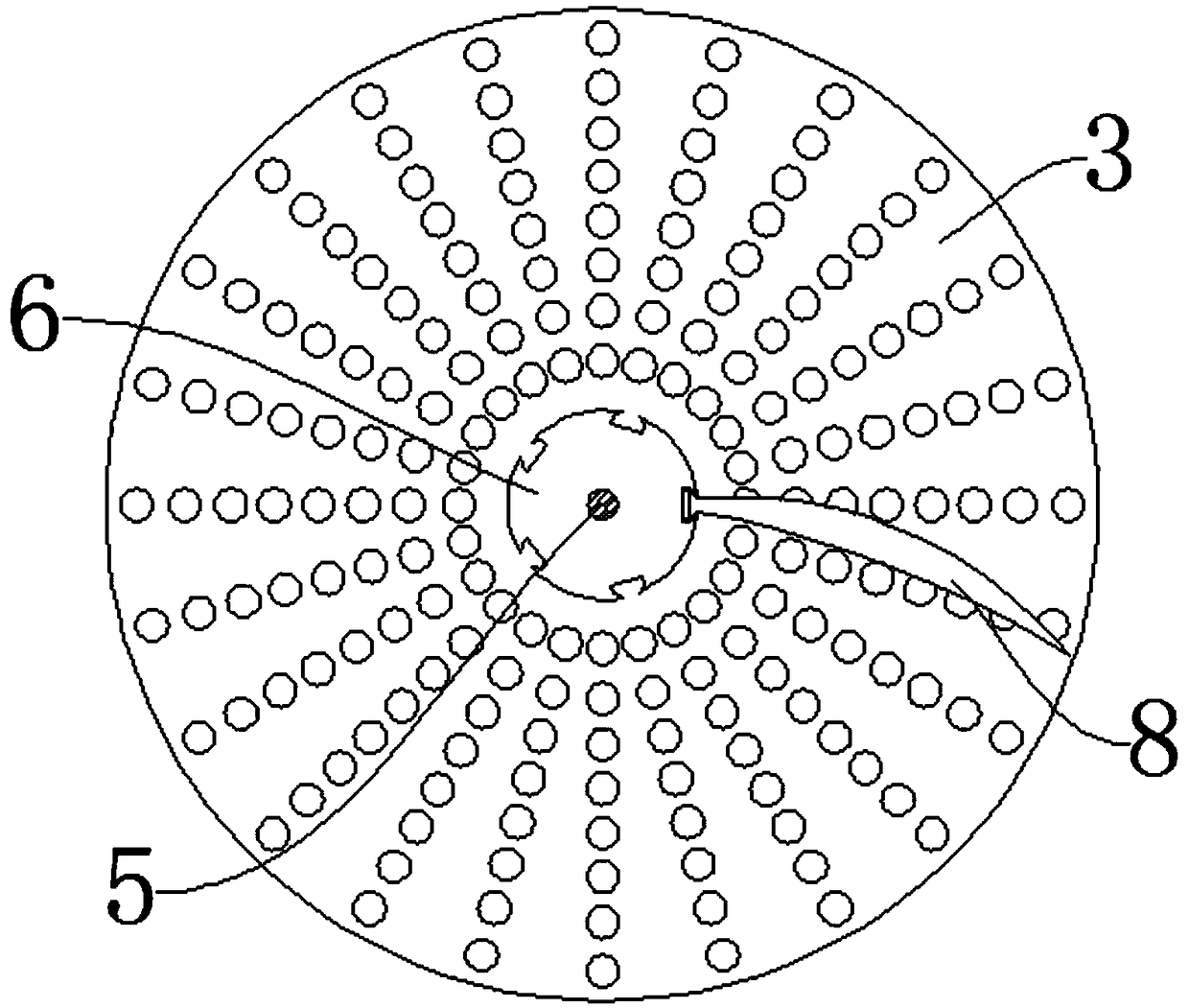

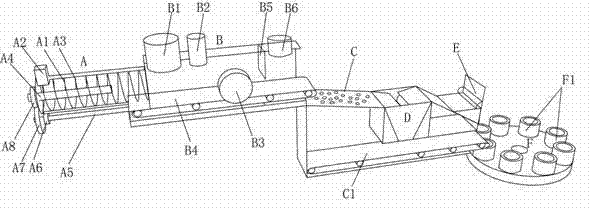

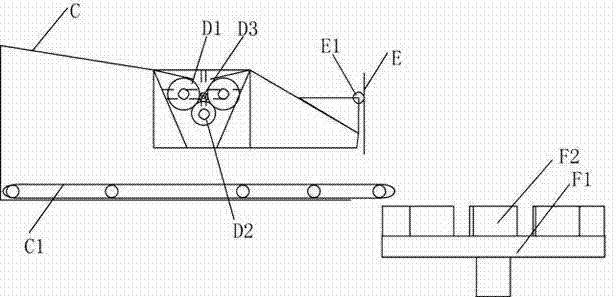

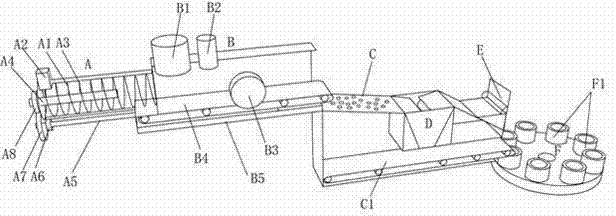

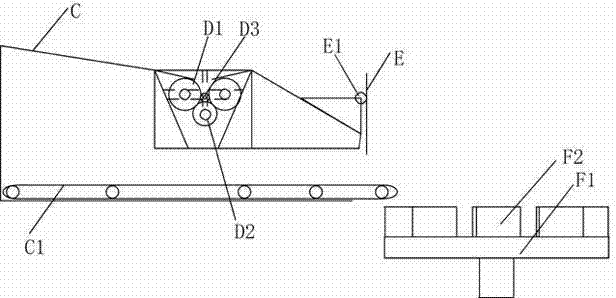

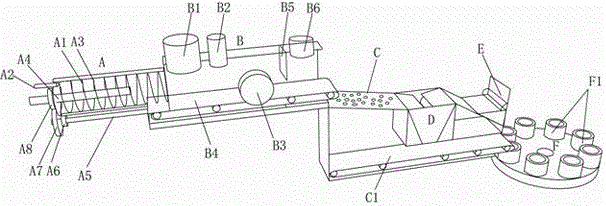

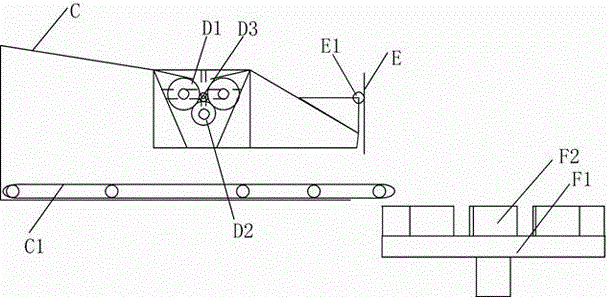

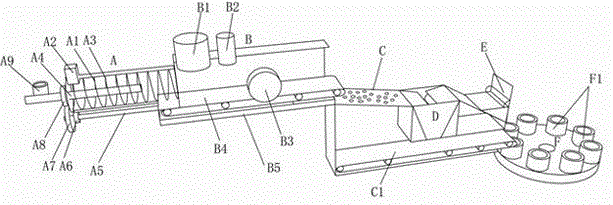

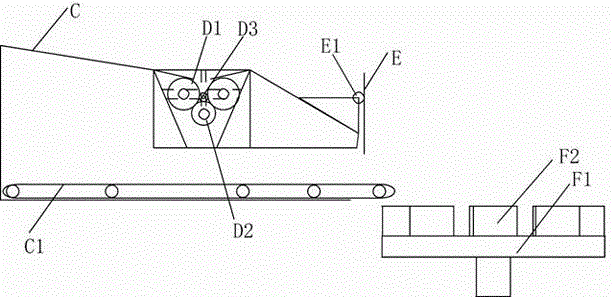

Compound fertilizer granulation continuous feeding assembly system

ActiveCN103694062BAchieve granulationAchieve dryingFertiliser formsFertilizer mixturesCooking & bakingEconomic benefits

The invention discloses a continuous feeding assembly system for pelletizing a compound fertilizer. The continuous feeding assembly system comprises a pelletizing device, and a baking device connected with the pelletizing device. The continuous feeding assembly system is characterized in that the pelletizing device comprises a drum, wherein two ends of the drum are hollow; a feeding hole pipeline is arranged at the end part of the drum; a worm transmission component is arranged at the middle part of the drum; a rotary shower nozzle is also arranged concentrically with the worm transmission component inside the drum; the drum and the rotary shower nozzle are driven to rotate through a same power source; the rotary shower nozzle is fixed outside the drum through a fixing element. The continuous feeding assembly system is clever and reasonable in design, strong in systematicness, high in automatic degree, and excellent in performance, can achieve a continuous feeding function, and can effectively achieve the function of pelletizing, baking, screening and assembling the compound fertilizer by providing multi-sectional equipment. Compared with the existing split-type equipment, the efficiency is improved by over 40%, and the economic benefits are improved by over 30%.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

Potassium nitrate compound fertilizer and preparation process thereof

InactiveCN108147898AImprove molding rateIncrease productionCalcareous fertilisersAlkali orthophosphate fertiliserPotassium nitrateSulfate

The invention discloses a potassium nitrate compound fertilizer and a preparation process thereof. The potassium nitrate compound fertilizer is prepared from various components in parts by weight: 35to 45 parts of urea, 20 to 25 parts of monoammonium phosphate, 30 to 35 parts of potassium nitrate, 2 to 3 parts of ammonium hydrogen carbonate, and 2 to 3 parts of calcium sulfate. The preparation process comprises the following steps: crushing: crushing the urea, the monoammonium phosphate, the potassium nitrate, the ammonium hydrogen carbonate and the calcium sulfate by virtue of a crushing machine according to the parts by weight; stirring: sending the obtained mixed crushed material into a stirring tank by virtue of a conveyor belt, stirring, and after uniformly stirring a mixed material,sending the material into a granulating machine; introducing steam into the granulating machine, improving the viscosity of the monoammonium phosphate in the material by virtue of the effect of the steam, and mixing and granulating; drying, screening and cooling the obtained particle mixture, and screening a finished product, thus obtaining finished product particles; and coating the outer layerof the obtained finished product particles with an anti-caking substance by virtue of a coating machine, and packaging. The potassium nitrate is used for substituting the traditional potassium sulfate, so that the molding period of the product can be shortened, and the yield of the compound fertilizer can be increased.

Owner:魏万辉

Double-waterway plastic particle extrusion device

ActiveCN114559587AReduce space consumptionAchieve granulationPlastic recyclingEngineeringMechanical engineering

The invention provides a double-waterway plastic particle extrusion device, and relates to the field of plastics. The double-water-path plastic particle extrusion device comprises a supporting mechanism, water supply mechanisms are fixedly installed on the two sides of the upper portion of the supporting mechanism, a cooling forming mechanism is rotationally connected between the two water supply mechanisms, an extrusion head is arranged above the cooling forming mechanism, and the supporting mechanism comprises two symmetrically-arranged supporting plates; the two supporting plates are fixedly connected through a collecting hopper, a discharging opening is formed in the lower portion of the front end of the collecting hopper, a scraping plate is fixedly installed in the middle of the collecting hopper, and the water supply mechanism comprises a water supply end cover. According to the double-water-path plastic particle extrusion device, the upper portion of the cooling cylinder can make contact with an extrusion head through rotation of the cooling cylinder, plastic is injected into a bearing groove, the plastic is cooled through water between the cooling cylinder and an inner cooling sleeve in the rotation process, formed plastic particles are discharged when the cooling cylinder rotates to the lowermost end, and occupied space is reduced; therefore, granulation can be realized in a limited space.

Owner:佛山市中丽新型材料科技有限公司

Anti-overpressure compound fertilizer granulation assembly system

ActiveCN103694061BAchieve granulationIngenious designGranulation in rotating drumsFertiliser formsEconomic benefitsEngineering

The invention discloses an anti-overpressure compound fertilizer granulation assembly system which comprises a granulator and a drier connected with the granulator. The system is characterized in that the granulator comprises a rotating drum, wherein the top of the rotating drum is provided with a feed port, the middle of the rotating drum is provided with a worm transmission part, the position with the same center of circle as the worm transmission part in the rotating drum is provided with a rotary sprayer, and the rotating drum and the rotary sprayer are driven to rotate by the same power source. The system has the advantages of ingenious and reasonable design and high systematicness; by arranging the multistage equipment, the system can effectively implement the functions of granulating, drying screening and assembling the compound fertilizer, has high degree of automation and superior performance; and compared with the existing split equipment, the efficiency is enhanced by more than 40%, and the economic benefit is enhanced by more than 30%.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com