Double-waterway plastic particle extrusion device

A technology of plastic pellets and extrusion devices, applied in the field of plastics, can solve the problems of large floor space and large cooling water consumption, and achieve the effect of reducing space occupation, realizing discharging and resetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

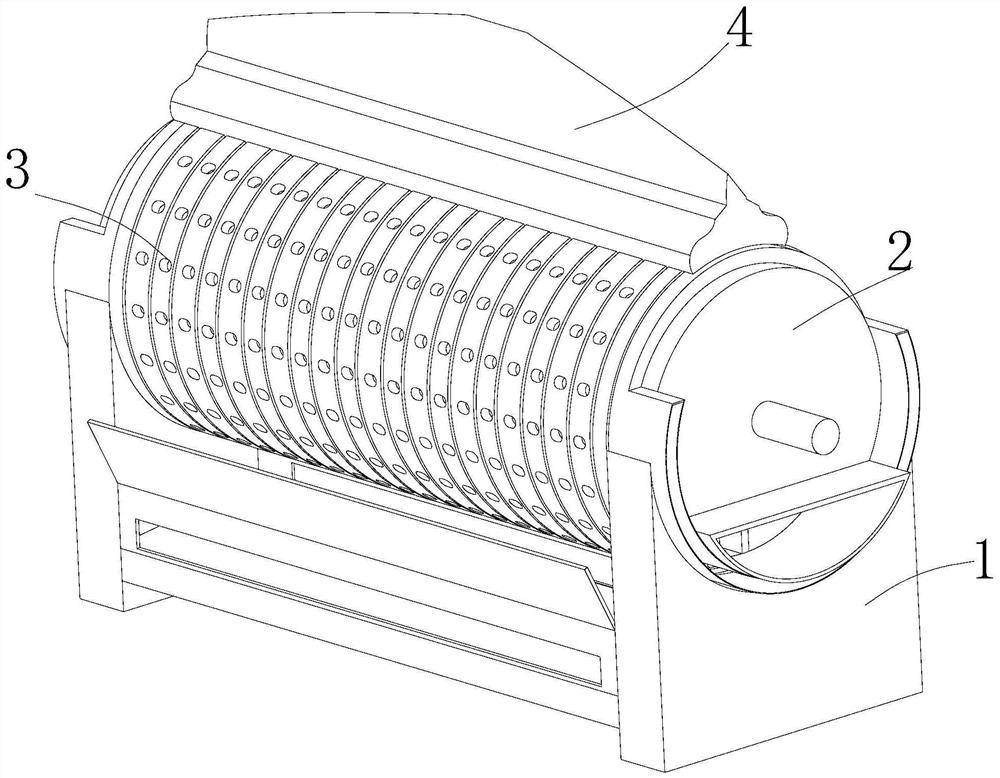

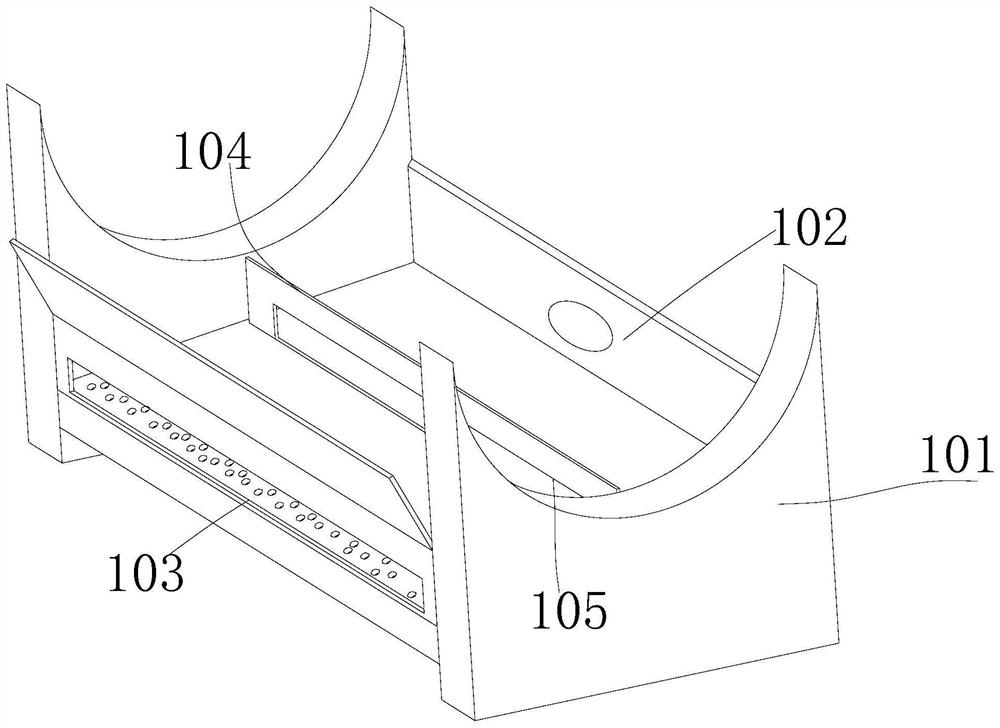

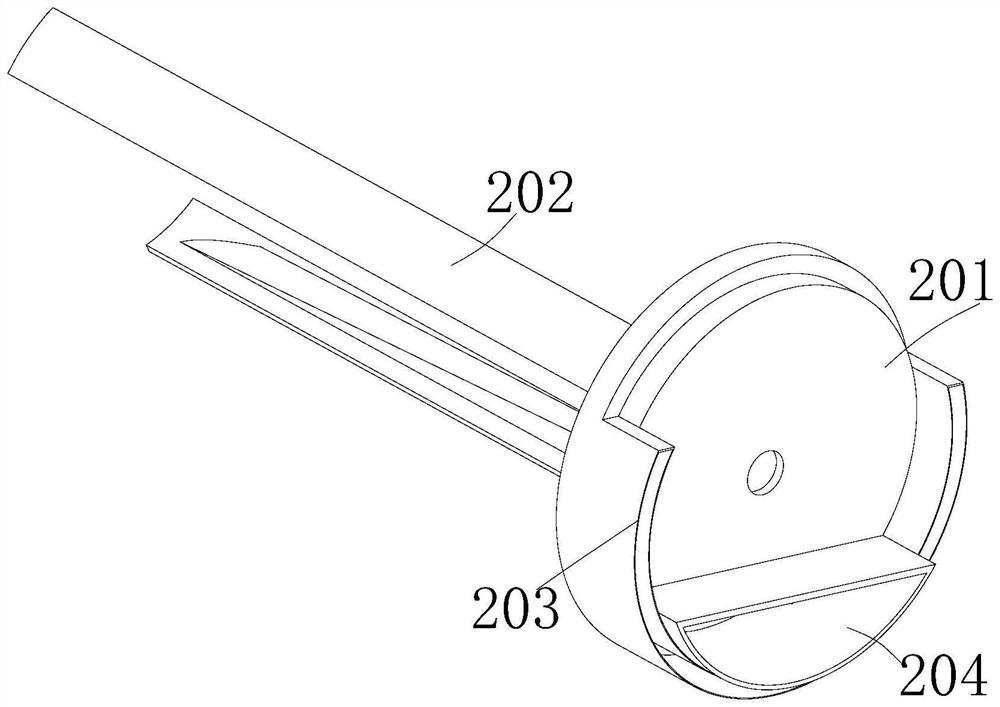

[0024] Embodiment one, such as Figure 1-6 As shown, it includes a support mechanism 1, a water supply mechanism 2 is fixedly installed on both sides above the support mechanism 1, a cooling forming mechanism 3 is rotatably connected between the two water supply mechanisms 2, and an extrusion head 4 is arranged above the cooling forming mechanism 3. The support mechanism 1 includes two symmetrically arranged support plates 101, and the two support plates 101 are fixedly connected by a collection bucket 102. A discharge port 103 is opened under the front end of the collection bucket 102, and a collecting bucket 103 is fixedly installed at the bottom of the collection bucket 102. In the water tank, the surface of the collecting bucket 102 is provided with a small through hole, the middle part of the collecting bucket 102 is fixedly equipped with a scraper 104, the water supply mechanism 2 includes a water supply end cover 201, and the water supply end cover 201 is fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com