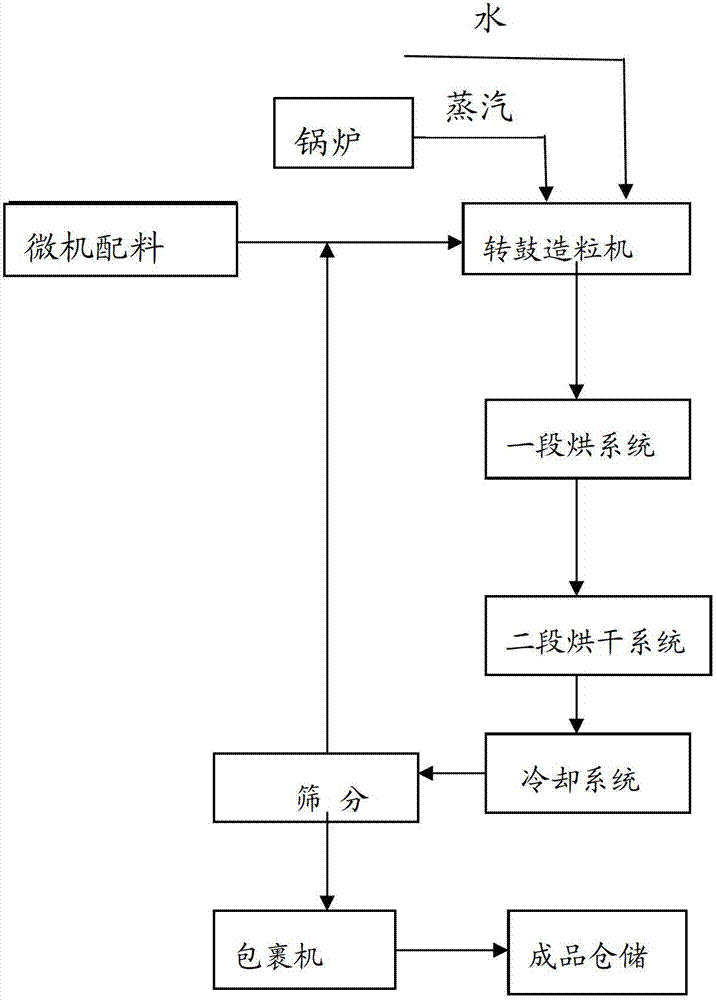

Production method of drying-free compound fertilizer

A technology of compound fertilizer and production method, applied in fertilizer mixture, fertilization device, application, etc., to achieve the effect of white color, flexible adjustment of product formula, and diverse production varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

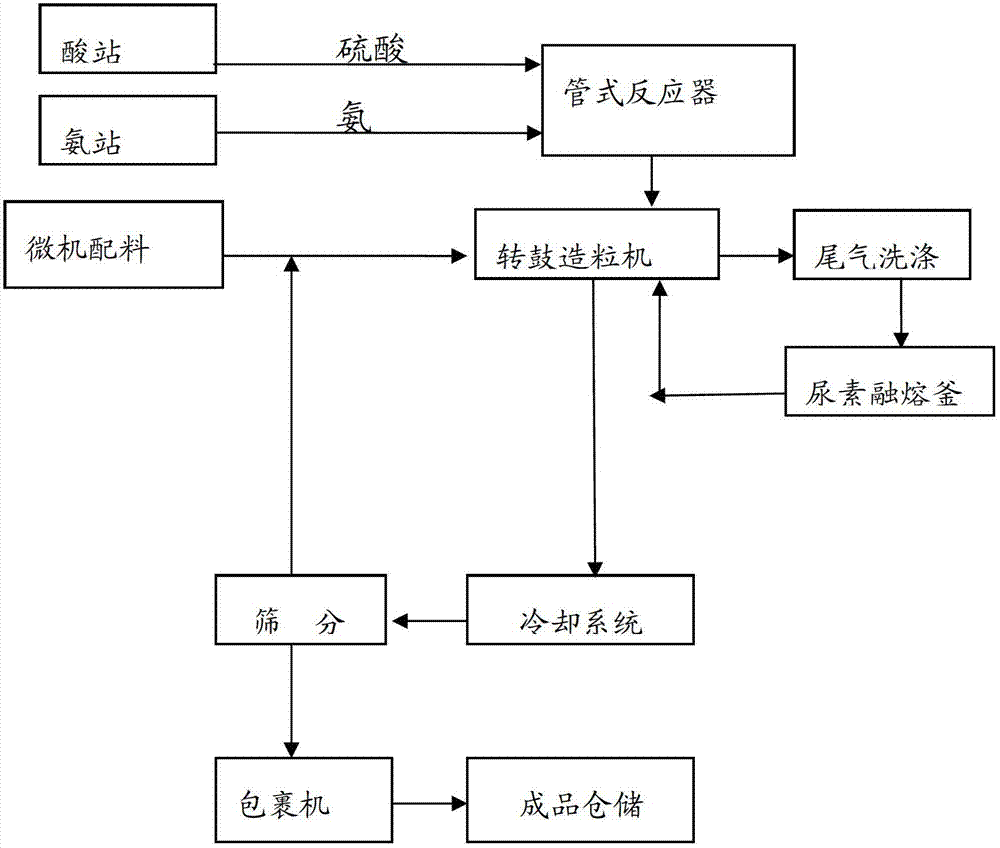

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: 17-17-17 Nitrogen Phosphorus Potassium Balanced Product

[0050] 55 kg of concentrated sulfuric acid (mass percentage, the same below) with a concentration of 98% is pumped into the tubular reactor after metering, and 40 kg of gaseous ammonia (containing 82.3% N) is metered and added to the tubular reactor. After the washing water is metered, it is added to the urea melting tank and the metered urea is made into a urea solution with a concentration of about 95% by mass. The temperature of the solution is controlled between 115-125°C. The amount of urea solution added is 0.088 cubic meters, which is converted into 100 kg of solid urea (including N 46.2), and at the same time, 70 kg of urea (including N 46.2), 60 kg of ammonium chloride (including N 25.1), and powdered phosphoric acid Monoammonium (containing N 11%, P2O 545%) 385 kg, potassium chloride (containing K2O 60%) 285 kg, the above-mentioned powdery materials, ammonium sulfate solution and urea solu...

Embodiment 2

[0051] Embodiment 2: 25-13-10 high nitrogen product

[0052] 65 kg of concentrated sulfuric acid (mass percentage, the same below) with a concentration of 98% is pumped into the tubular reactor after metering, and 40 kg of gaseous ammonia (containing 82.3% N) is metered and added to the tubular reactor. After the washing water is metered, it is added to the urea melting tank and the metered urea is made into a urea solution with a concentration of about 95% by mass. The temperature of the solution is controlled between 115-125°C. The amount of urea solution added is 0.132 cubic meters, which is converted into 150 kg of solid urea (including N 46.2). At the same time, 200 kg of urea (including N 46.2), 90 kg of ammonium chloride (including N 25.1) and powdered phosphoric acid are added through computer metering. Monoammonium (containing N 11%, P2O 545%) 290 kg, potassium chloride (containing K2O 60%) 170 kg, the above powder materials are mixed with the ammonium sulfate solutio...

Embodiment 3

[0053] Embodiment 3: 18-10-20 high potassium product

[0054] 70 kg of concentrated sulfuric acid (mass percentage, the same below) with a concentration of 98% is pumped into the tubular reactor after metering, and 45 kg of gaseous ammonia (containing 82.3% N) is metered and added to the tubular reactor. After the washing water is metered, it is added to the urea melting tank and the metered urea is made into a urea solution with a concentration of about 95% by mass. The temperature of the solution is controlled between 115-125°C. The amount of urea solution added is 0.132 cubic meters, which is converted into 150 kg of solid urea (including N 46.2), and at the same time, 30 kg of urea (including N 46.2), 140 kg of ammonium chloride (including N 25.1), and powdered phosphoric acid Monoammonium (containing N 11%, P2O5 45%) 225 kg, potassium chloride (containing K2O 60%) 335 kg, the above powder materials and the ammonium sulfate solution and urea solution sprayed from the tubul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com