Patents

Literature

30 results about "Potassium product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

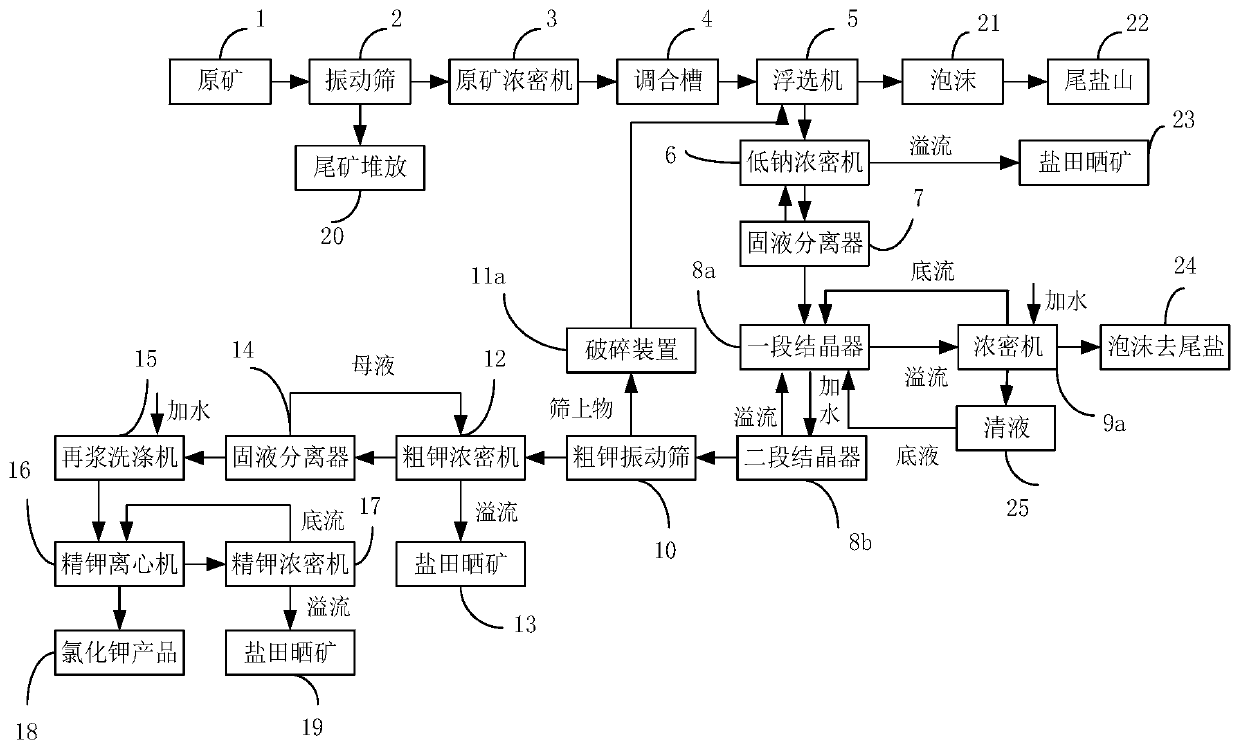

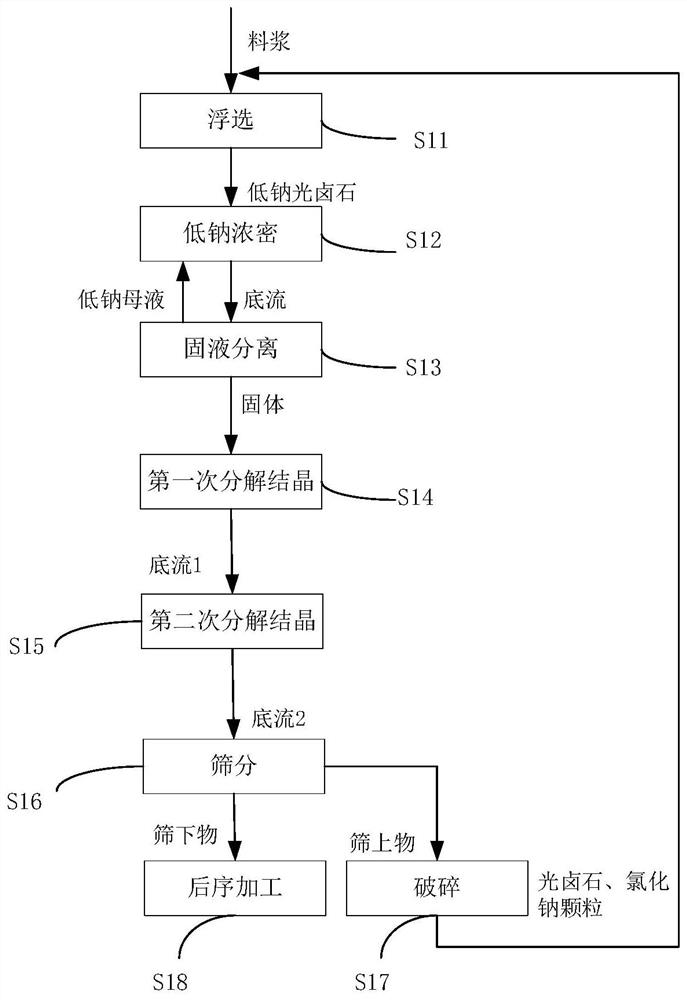

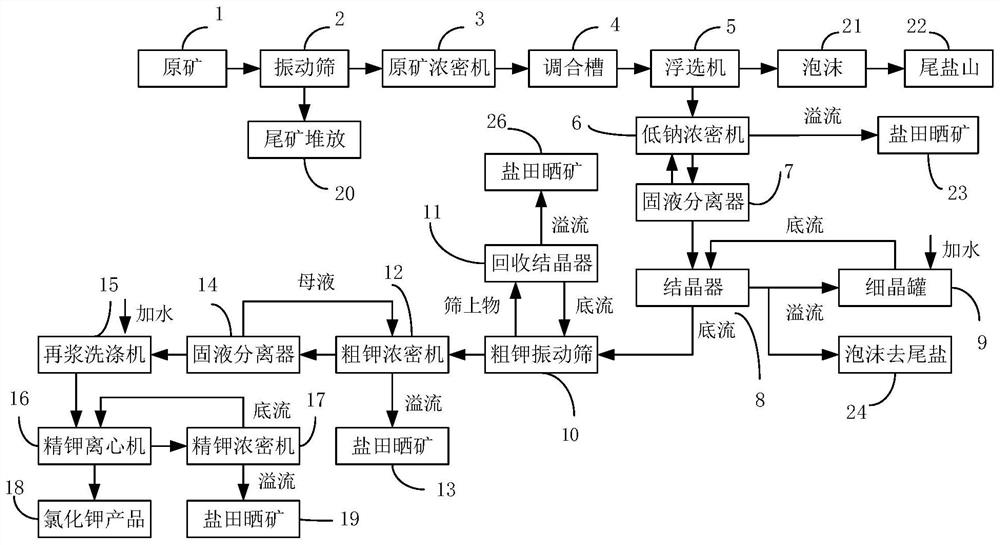

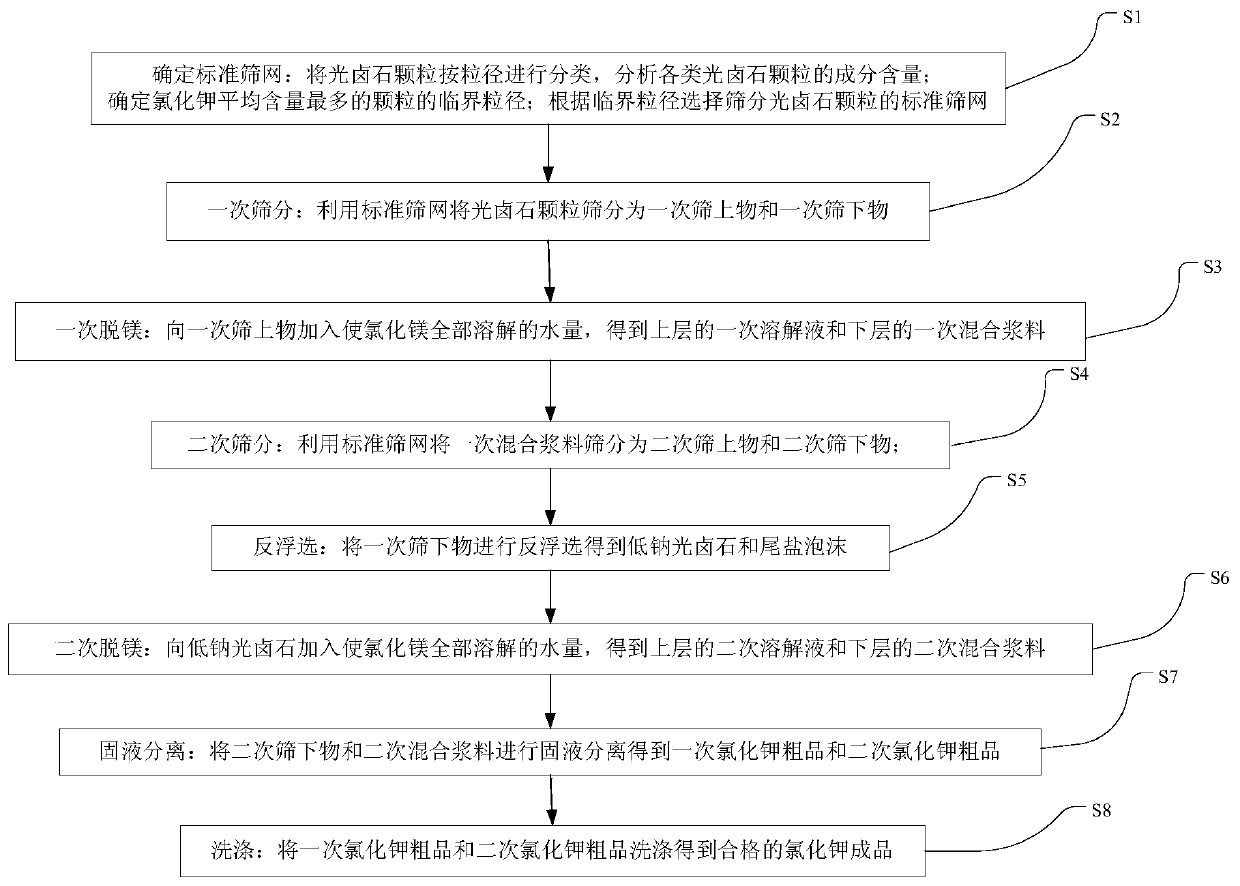

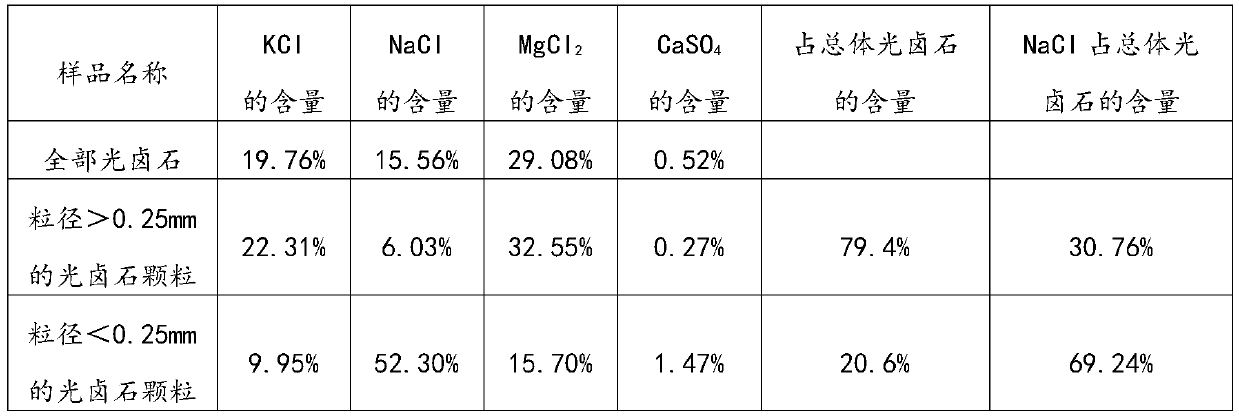

Technology for producing potassium chloride from carnallite

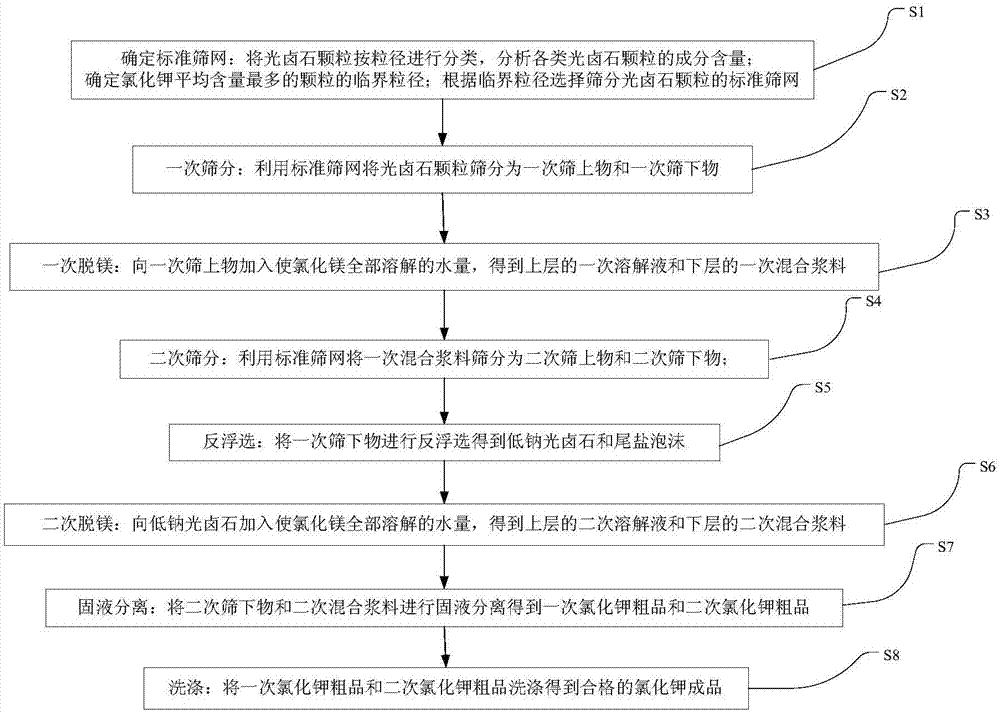

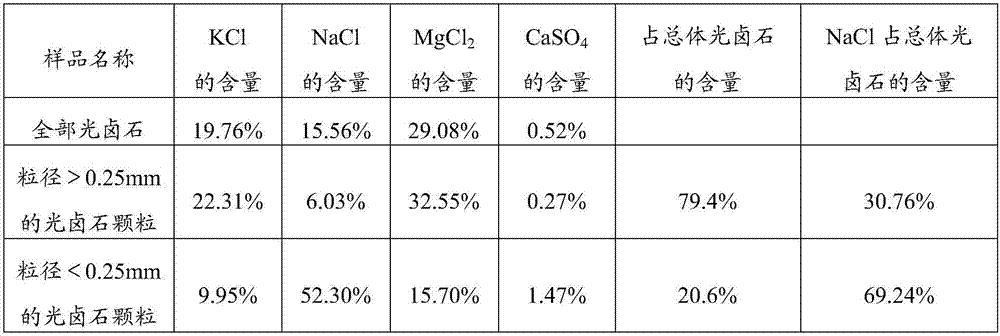

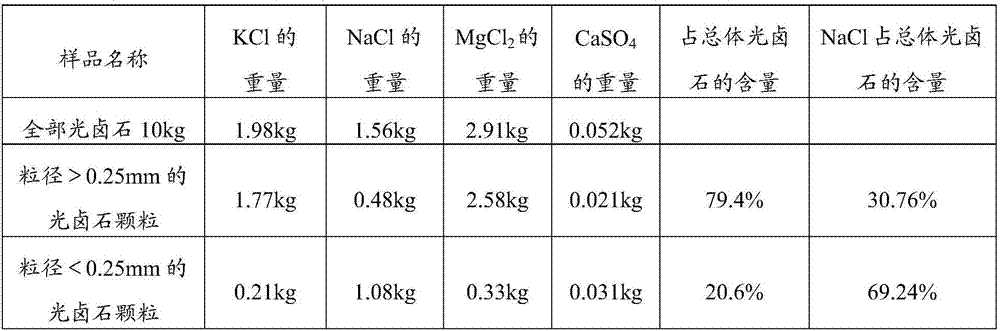

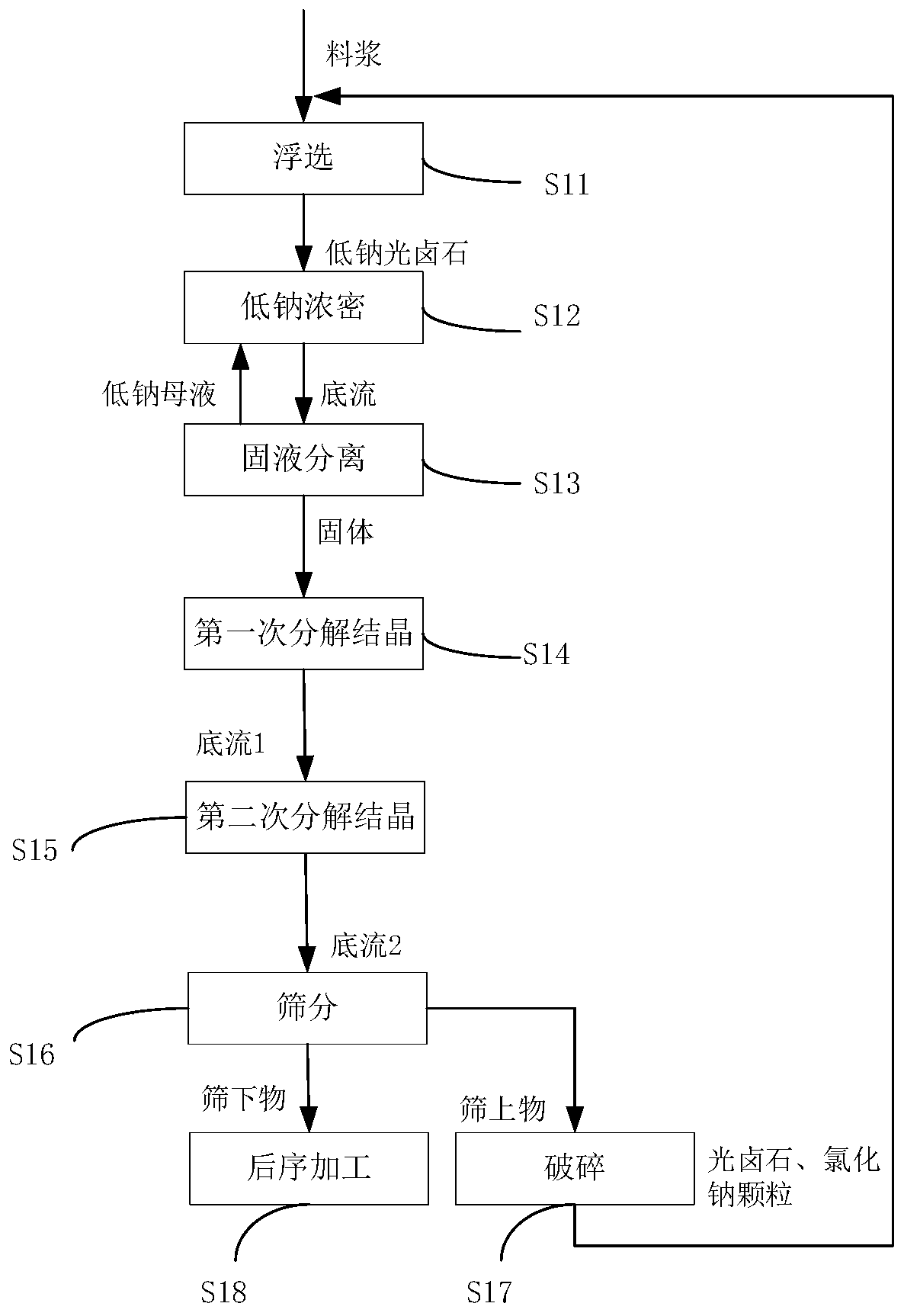

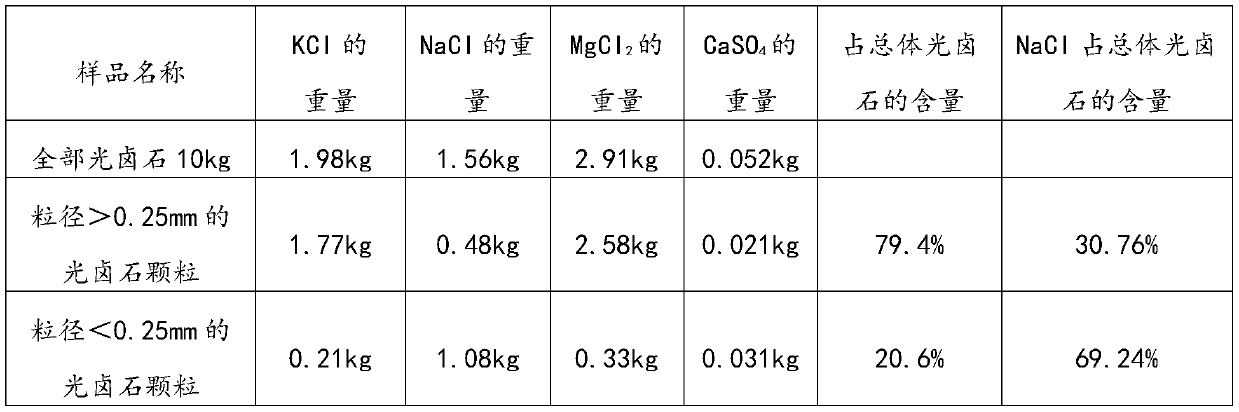

The invention discloses a technology for producing potassium chloride from carnallite. The technology comprises the following steps: determining a critical particle diameter of particles with the mostaverage content of the potassium chloride and selecting a standard screen mesh for sieving carnallite particles; sieving the carnallite particles into a primary oversize material and a primary undersize material by utilizing the standard screen mesh; adding a water amount for completely dissolving magnesium chloride into the primary oversize material to obtain a primary dissolving solution and primary mixed slurry; sieving the primary mixed slurry into a secondary oversize material and a secondary undersize material by utilizing the standard screen mesh; carrying out reverse flotation to obtain low-sodium carnallite and tail salt foam; adding the water amount for completely dissolving the magnesium chloride into the low-sodium carnallite to obtain a secondary dissolving solution and secondary mixed slurry; carrying out solid-liquid separation on the secondary undersize material and the secondary mixed slurry to obtain a crude potassium product; washing an obtained potassium chloride crude product to obtain a qualified potassium chloride finished product. The technology disclosed by the invention has the advantages of simplicity in operation, less investment, low energy consumptionand high yield and the quality of the prepared potassium chloride finished product is good.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

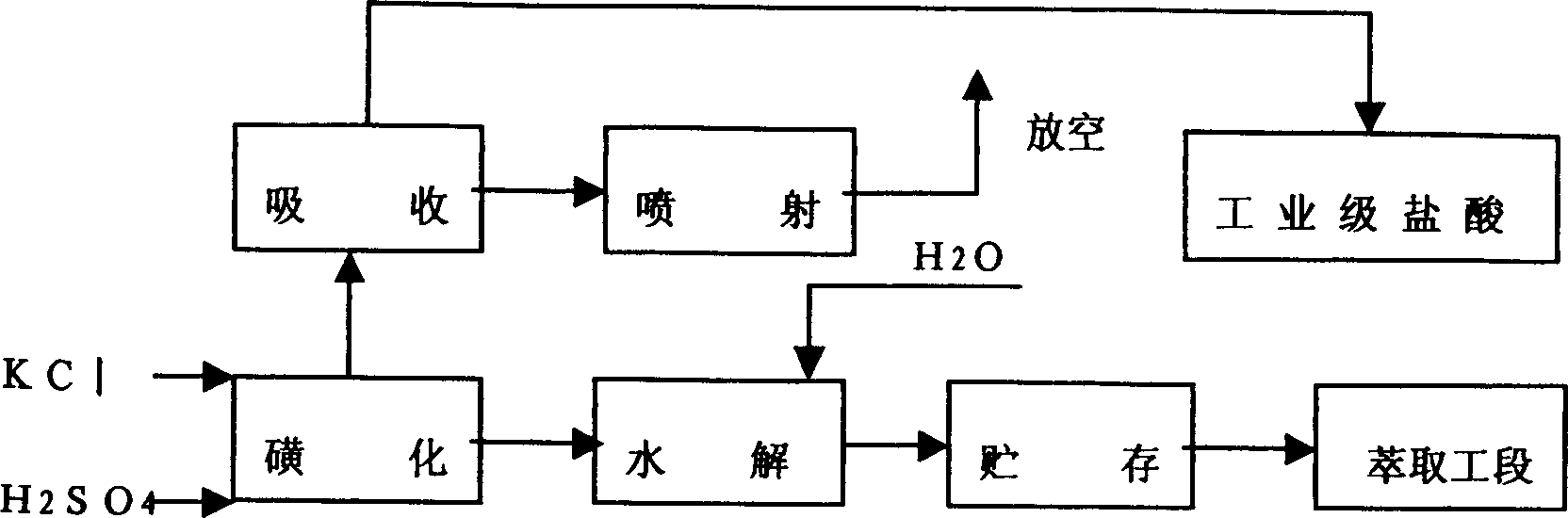

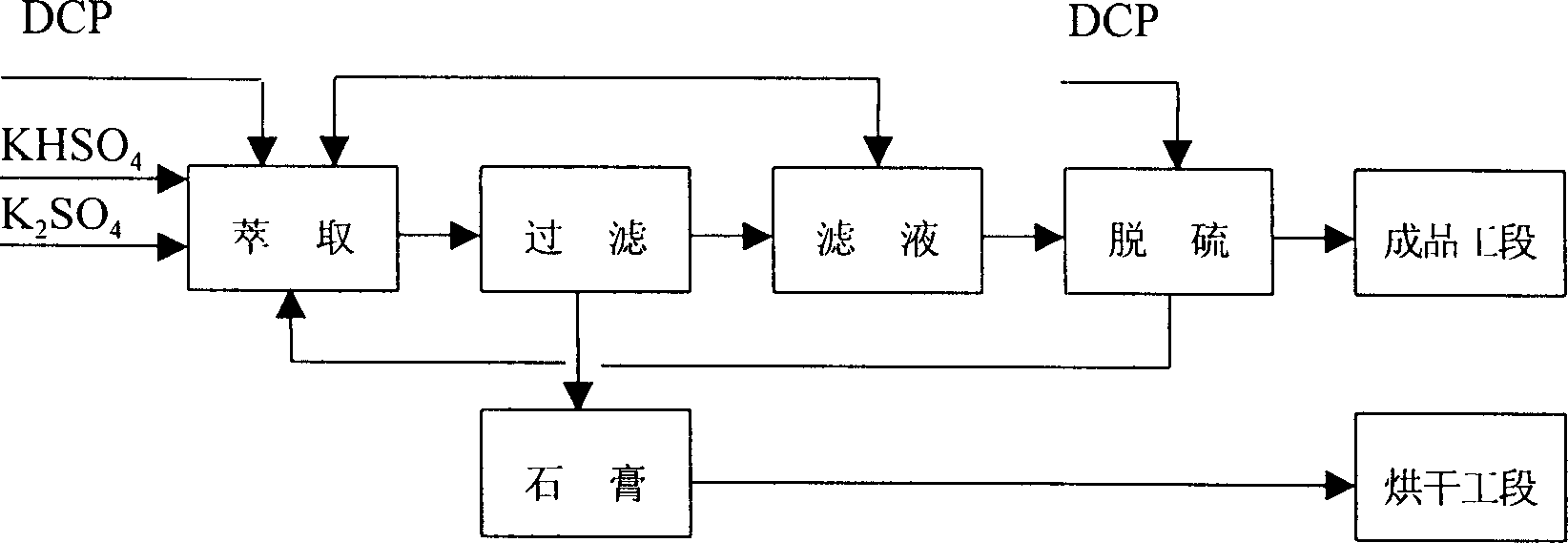

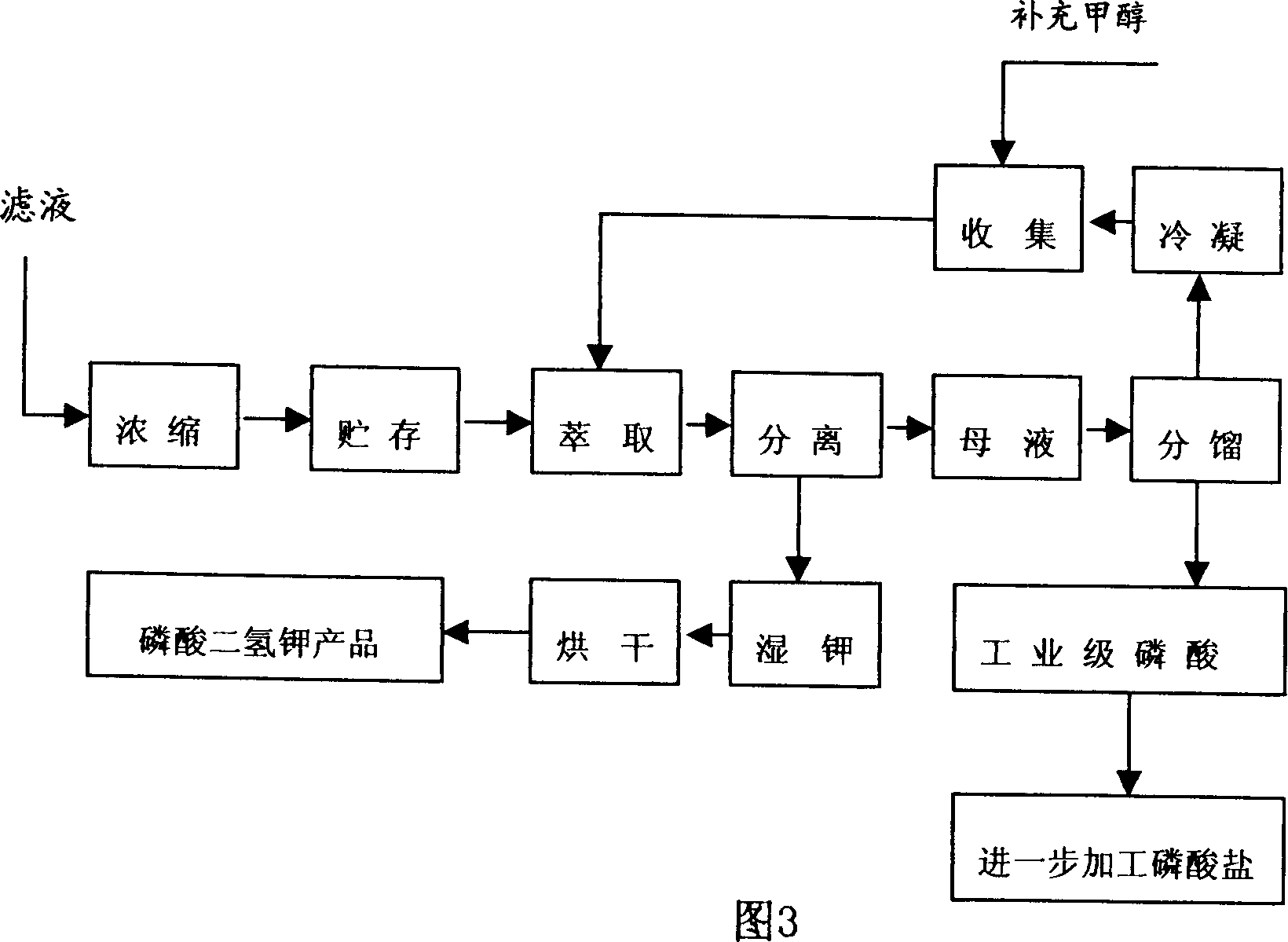

Production method of potassium dihydrogen phosphate

InactiveCN1412107AImprove qualityReliable technologySulfate/bisulfate preparationLiquid solutions solvent extractionHydrogen SulfateFiltration

The production method of potassium dihydrogen phosphate uses the calcium hydrogen phosphate whose impurities of iron, aluminium, fluorine and sulfur are low as raw material, and is implemented by adopting technological processes of potassium hydrogen sulfate preparation, solution extraction, potassium dihydrogen phosphate crystallization and separation ,and its operation includes the following steps: fulfonation, hydrolysis, extraction, filtration, filtrate concentration, crystallization and separation, drying and fractionation. Its reaction condition is moderate, its potassium yield is high,at the same time the quality of potassium dihydrogen phosphate and phosphoric acid can be ensured.

Owner:SICHUAN HONGDA (GRP) CO LTD

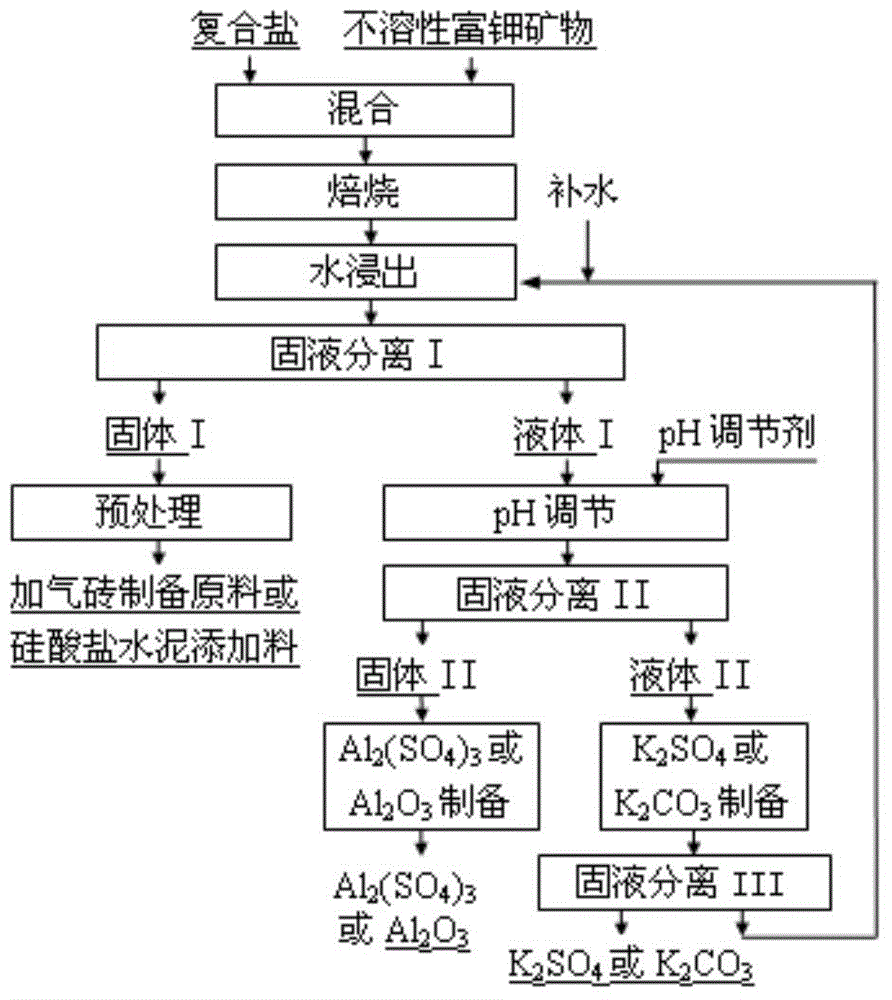

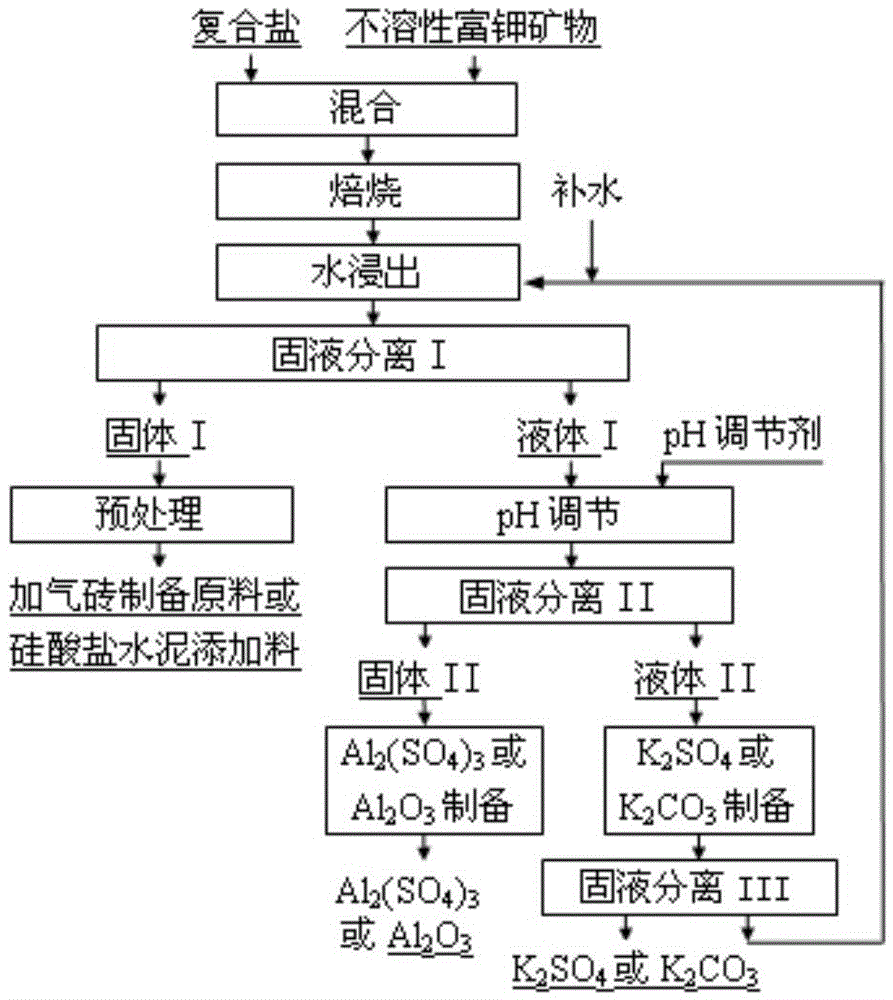

Composite salt treatment and comprehensive utilization process of insoluble potassium-enriched minerals

InactiveCN104445320ARealize comprehensive utilizationEfficient separationSulfate/bisulfate preparationCarbonate preparationBrickPortland cement

The invention discloses a composite salt treatment and comprehensive utilization process of insoluble potassium-enriched minerals. The process comprises the following steps: mixing insoluble potassium-enriched minerals with composite salt containing calcium salt and sodium salt, and then roasting at high temperature; performing water leaching on a roasted product, and then performing solid-liquid separation I to obtain a solid I and a liquid I, wherein the solid I is used for preparing aerated bricks or Portland cement additives, the liquid I is used for separating out precipitates by adjusting a pH value and is subjected to solid-liquid separation II to obtain a solid II and a liquid II, and the solid II is further prepared into Al2(SO4)3 or Al2O3; and preparing K2SO4 or K2CO3 by performing condensation crystallization or salt precipitation on the liquid II. According to the process disclosed by the invention, the insoluble potassium-enriched minerals are subjected to roasting treatment by the composite salt containing the calcium salt and sodium salt, and water leaching is combined to ensure that potassium, aluminum and silicon in the insoluble potassium-enriched minerals are fully separated, and meanwhile, aluminum products and potassium products with relatively high purity can be obtained; and by adopting the process, the comprehensive recovery and utilization of insoluble potassium-enriched mineral resources can be achieved.

Owner:CENT SOUTH UNIV

Oxydant of potassium perchlorate type special for fireworks and method for preparing same

The invention relates to a special potassium perchlorate oxidant for fireworks, particularly to an oxidant for producing fireworks and a preparation method thereof. The oxidant contains potassium perchlorate as the main component and no potassium chlorate as well as banned substances prescribed by the state. The key point of the invention is that a surfactant is used for modifying the potassium perchlorate and that other functional materials are added to improve the use and the storage properties of the potassium perchlorate. The oxidant solves the problems such as agglomeration of potassium perchlorate product after long-term storage, difficulty in firing the prepared oxidant, the need of a special high-potassium lead, easy extinguishing of the lead and less loading amount of powder cake. The oxidant comprises 70 to 90 parts of potassium perchlorate, 2 to 8 parts of nitrate, 5 to 8 parts of sulfate, 0 to 8 parts of carbonate, 5 to 8 parts of a density regulator, and 0.1 to 0.3 parts of the surfactant (external application). The oxidant has the advantages that (1) the product has low moisture absorption rate and good looseness and flowability by surface modification; (2) the powder mixed with a reducer has good firing property, and the fireworks are superior to the high-potassium product in ignition rate, paper shredding rate and sound intensity level value; and (3) the produce has lower cost than the high-potassium product and more powder loading amount.

Owner:湖南金能科技实业有限公司

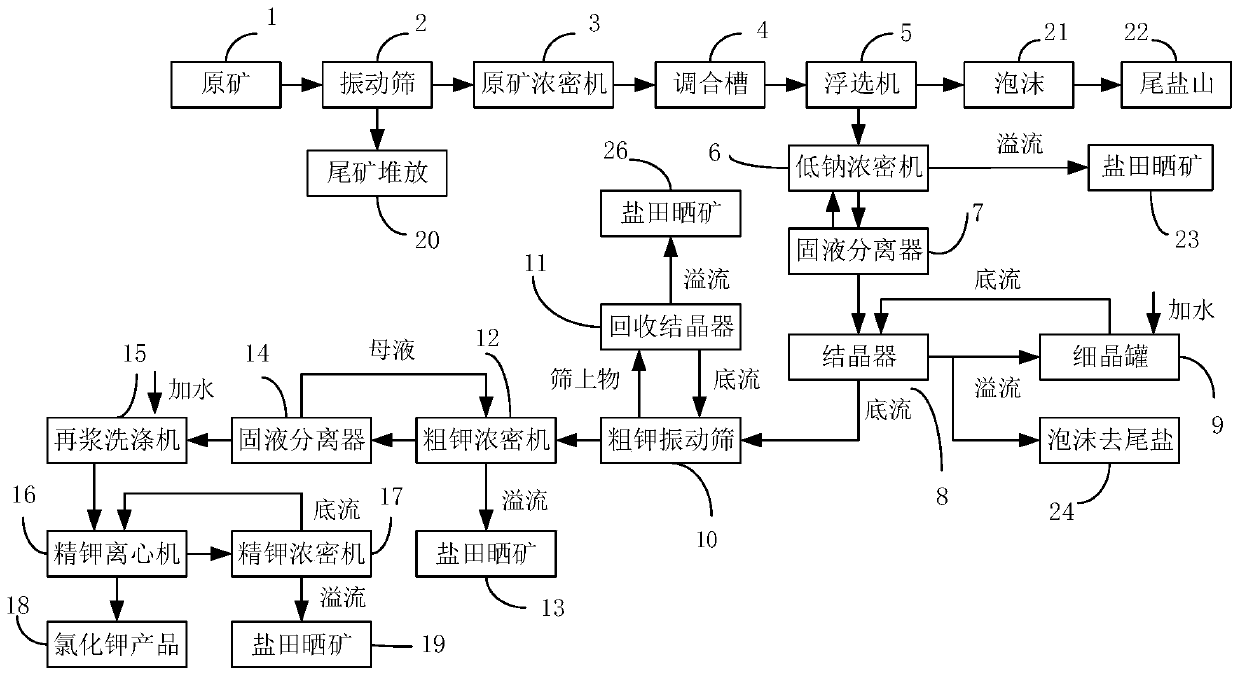

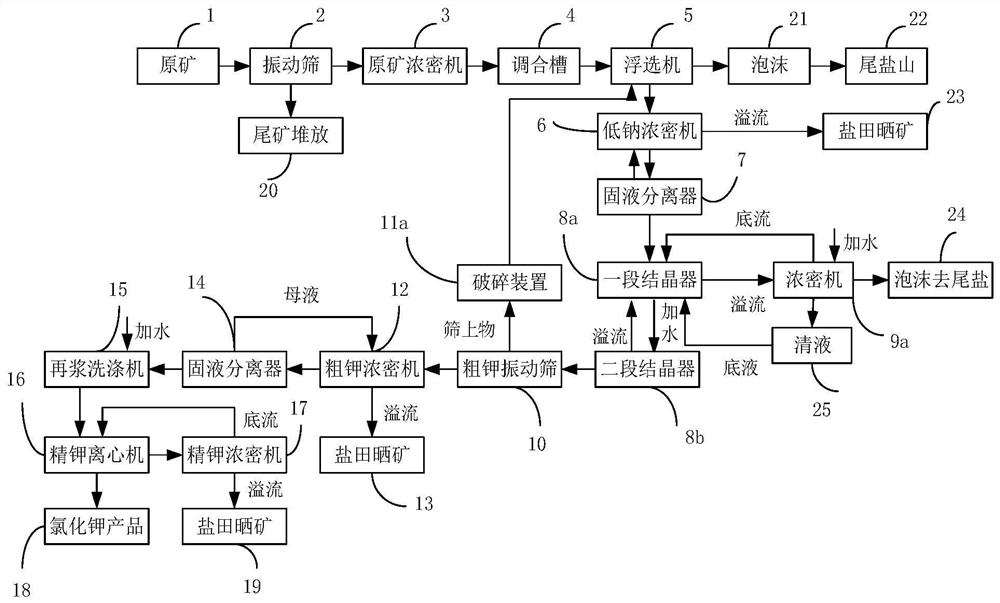

Method for preparing potassium chloride from carnallite raw ore

The invention provides a method for preparing potassium chloride from carnallite. The low-sodium carnallite slurry is decomposed and crystallized for the first time in a first crystallizer 8a, magnesium chloride in carnallite is transferred into a liquid phase, part of potassium chloride transferred into the liquid phase is crystallized and separated out, and underflow of the first crystallizer 8acontains separated-out potassium chloride and undecomposed carnallite and sodium chloride particles. The underflow of the first crystallizer 8a is decomposed and crystallized in a second crystallizer8b, sodium chloride in carnallite is transferred into a liquid phase, part of potassium chloride transferred into the liquid phase is crystallized and separated out, and the underflow of the second crystallizer 8b contains separated potassium chloride and undecomposed carnallite and sodium chloride particles. The underflow of the second crystallizer 8b is screened, the oversize product comprisesundecomposed carnallite and sodium chloride particles, and a potassium chloride product is generated from the undersize product. The oversize product is crushed, wherein the crushed oversize product is used for generating the low-sodium carnallite slurry. The grade of potassium chloride is guaranteed, and meanwhile, the recovery rate of carnallite is greatly increased.

Owner:QINGHAI SALT LAKE IND

Method for extracting potassium co-production liquid salt from concentrated seawater

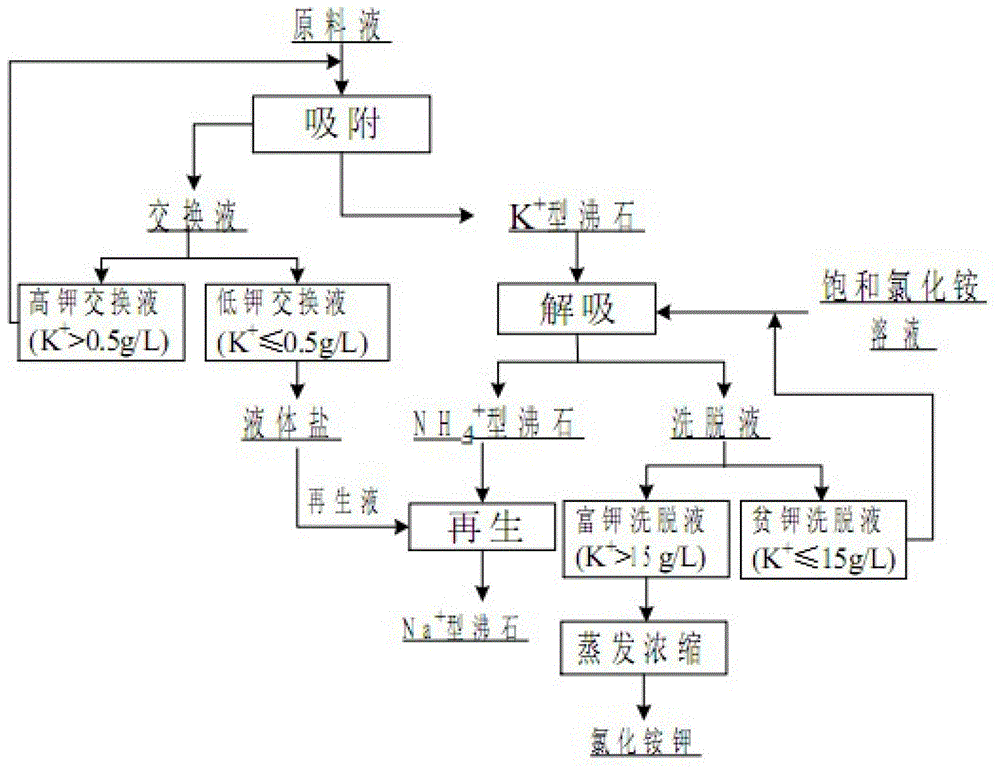

InactiveCN102976797AIncrease profitHigh market demandAlkali metal chloridesPotassium fertilisersDesorptionIon exchange

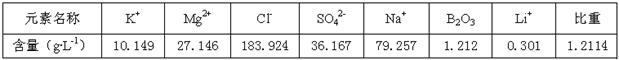

The invention discloses a method for extracting a potassium co-production liquid salt from concentrated seawater, and the method comprises the following steps of: taking natural clinoptilolite as an ion exchanger, and absorbing potassium in concentrated seawater of which the elements, namely bromine, magnesium, calcium and the like, are extracted, wherein the flow speed that the seawater passes into the natural clinoptilolite is 15-20mL / min, and the low-potassium exchange fluid in the obtained exchange fluid is a liquid salt product; taking saturated ammonium chloride solvating as a desorption solution, flowing into potassium-absorbed zeolite at the flow speed of 10-15mL / min, eluting to obtain a potassium-enriched eluant, and evaporating and concentrating the potassium-enriched eluant to obtain an ammonium chloride potassium product; and eluting potassium ion-absorbed zeolite, regenerating by liquid salt, and recycling. According to the method, the seawater of which the elements, namely bromine, magnesium, calcium and the like, are extracted is taken as a raw material liquid, so that the high-quality ammonium chloride potash fertilizer with large market demand can be obtained, the comprehensive utilization rate of the concentrated seawater can be improved, and the low-potassium production cost can be reduced.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

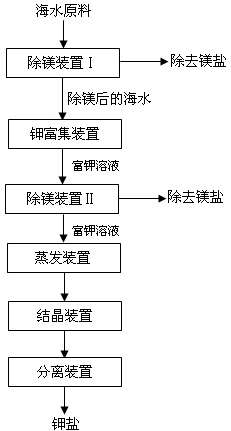

Method for removing magnesium in seawater potassium extraction process

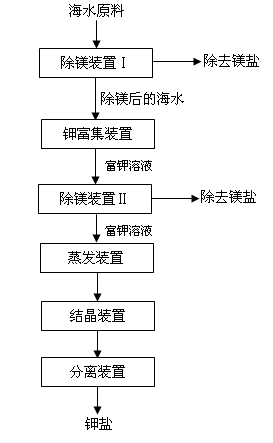

ActiveCN102642849AAddressing quality degradationEasy to get equipmentAlkali metal halide purificationIon exchangeIon-exchange resin

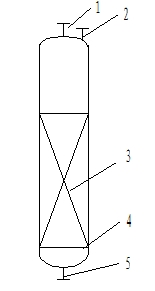

The invention relates to an ion-exchange method for treating seawater, particularly a method for removing magnesium in a seawater potassium extraction process. The devices for removing magnesium are as follows: a magnesium removing device I is arranged before a potassium enriching device, wherein an ion exchange resin in a bed form is filled in the magnesium removing device I; and a magnesium removing device II is arranged before an evaporator, wherein an ion exchange resin in a bed form is filled in the magnesium removing device II. The method comprises the following steps: introducing seawater into the magnesium removing device I to contact the ion exchange resin in the magnesium removing device I, wherein 90% of magnesium in the seawater is removed; introducing the seawater subjected to magnesium removal into the potassium enriching device; introducing the potassium-enriched solution produced by the potassium enriching device into the magnesium removing device II to contact the ion exchange resin in the magnesium removing device II, wherein 90% of magnesium in the potassium-enriched solution is removed; and sequentially sending the potassium-enriched solution subjected to magnesium removal into the evaporator, a crystallizing device and a separation device to finally obtain the potassium salt product. The method provided by the invention solves the problem that magnesium in the potassium-enriched solution can lower the quality of the finally prepared potassium product.

Owner:金盛海洋科技股份有限公司

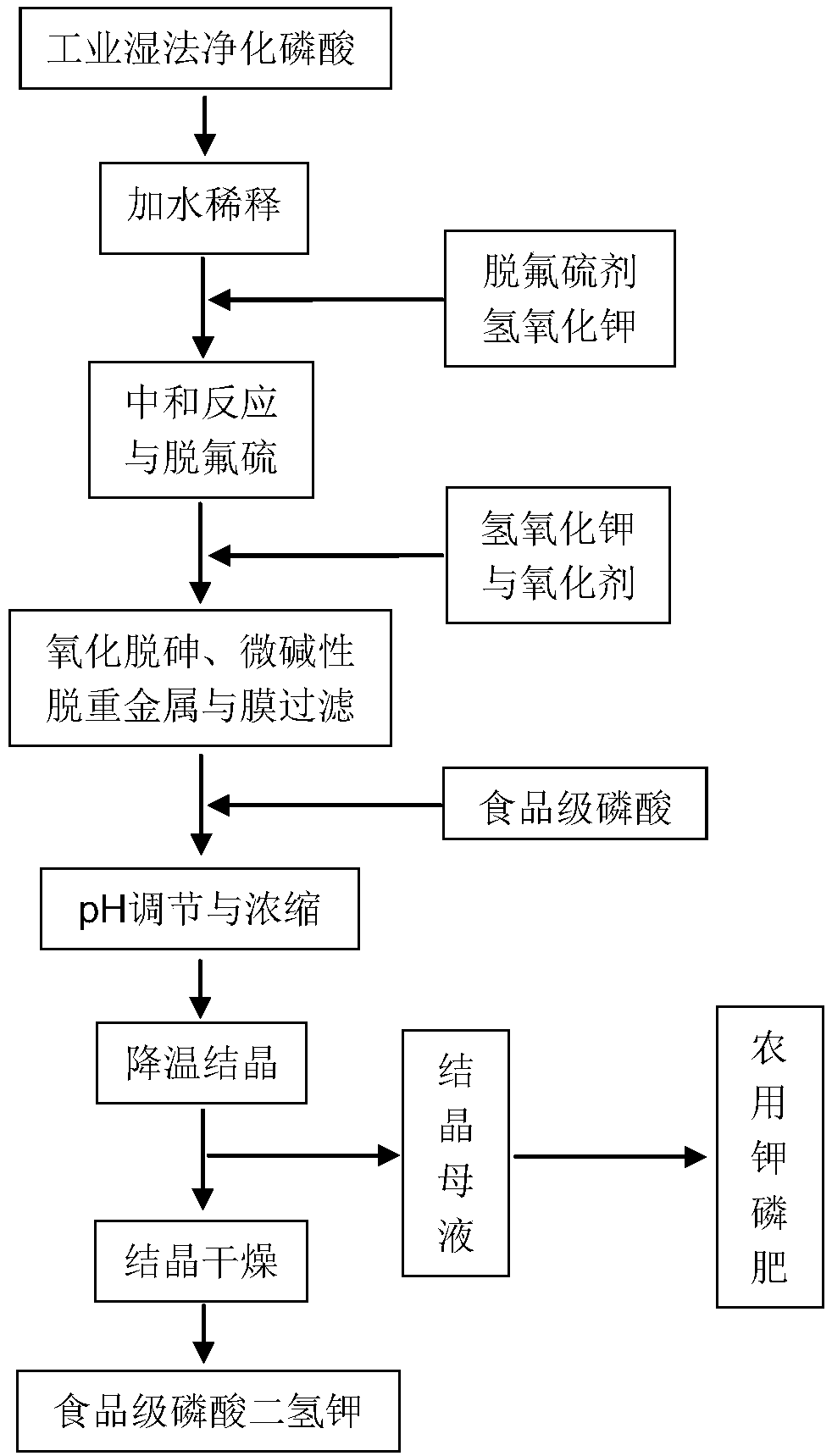

Method for preparing food grade potassium dihydrogen phosphate by using industrial wet-process purified phosphoric acid

Owner:HUBEI UNIV OF TECH

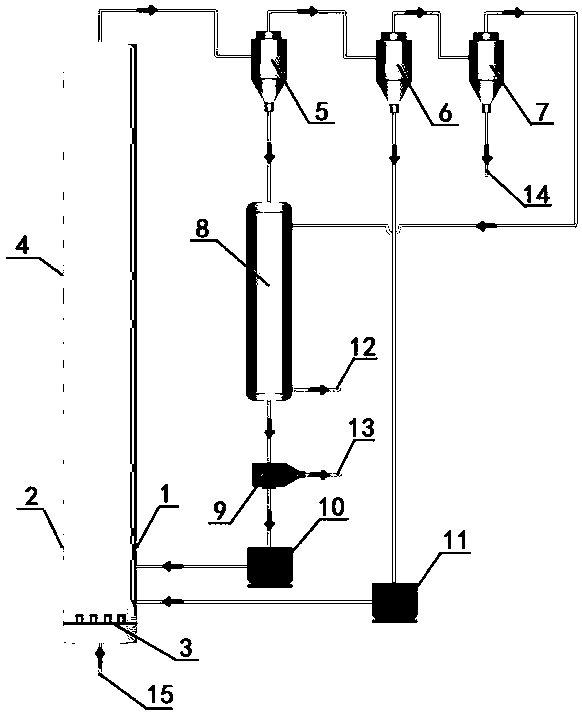

Gasification and high-temperature tar removal and dust removal integrated technology of biomass circulating fluidized bed

ActiveCN109609197ARealize integrationImprove thermal efficiencyGasification processes detailsGranular/pulverulent flues gasificationCatalytic pyrolysisHeat carrier

The invention discloses a gasification and high-temperature tar removal and dust removal integrated technology of a biomass circulating fluidized bed. Biomass particles which are smaller than 5 mm andsupplemented heat carriers enter the bottom of the circulating fluidized bed, pyrolysis, combustion and gasification reactions occur at the temperature of 750-900 DEG C, and residual semi-coke and heat carriers are carried at high speed, go upward along with synthesized gas to reach the top of the circulating fluidized bed, and then are subjected to four-stage gas-solid separation; in the first stage of separation, the large-particle carriers and the semi-coke are used as a fuel gas pyrolysis catalyst and a filtering material for filtering and dust removing, enter a movable bed filter device,and then return to a turbulence fluidized bed for a gasification reaction after super-thin dust is separated out, and the super-thin dust is delivered out as silicon-potassium products; in the secondstage of separation, the medium-small particle carriers and the semi-coke are directly circulated back to the turbulence fluidized bed, in the third stage of separation, fine particles are dischargedas silicon-potassium products, in the fourth stage, the movable bed filter device conducts secondary catalytic pyrolysis on a small amount of tar in fuel gas at the temperature of 700-850 DEG C through synergism of the high-temperature carriers and semi-coke to obtain methane, ethylene and others, meanwhile, the super-thin dust is removed, and purified fuel gas is delivered out as products.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

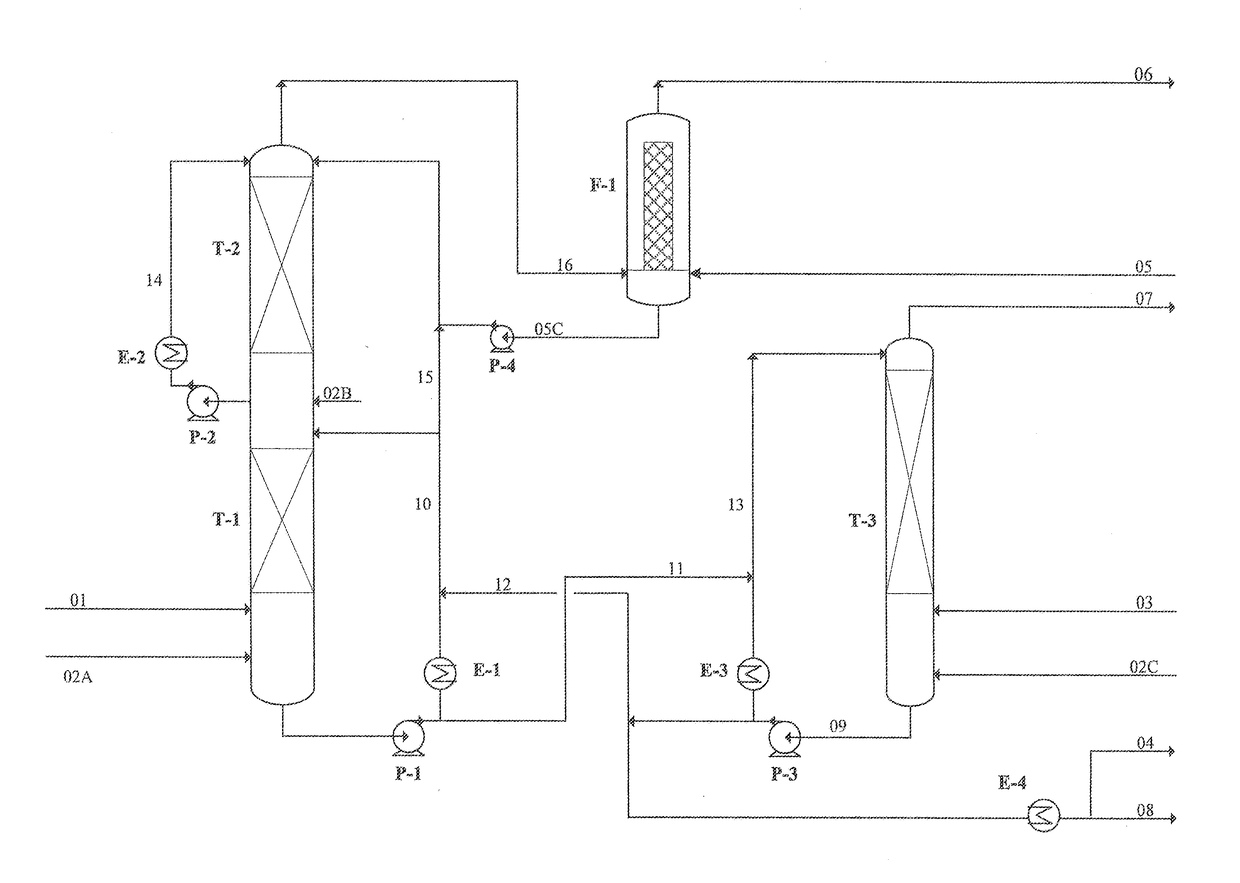

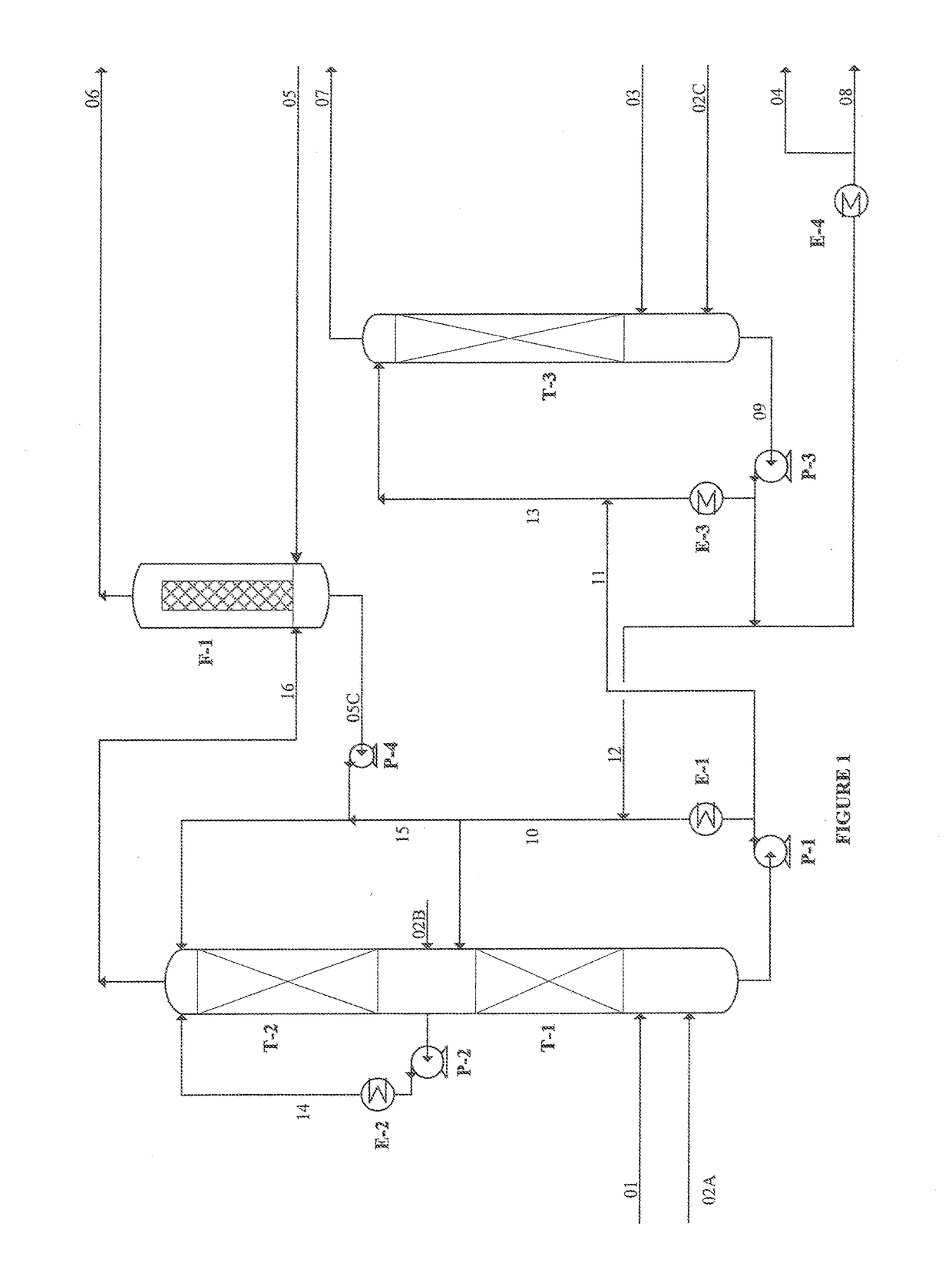

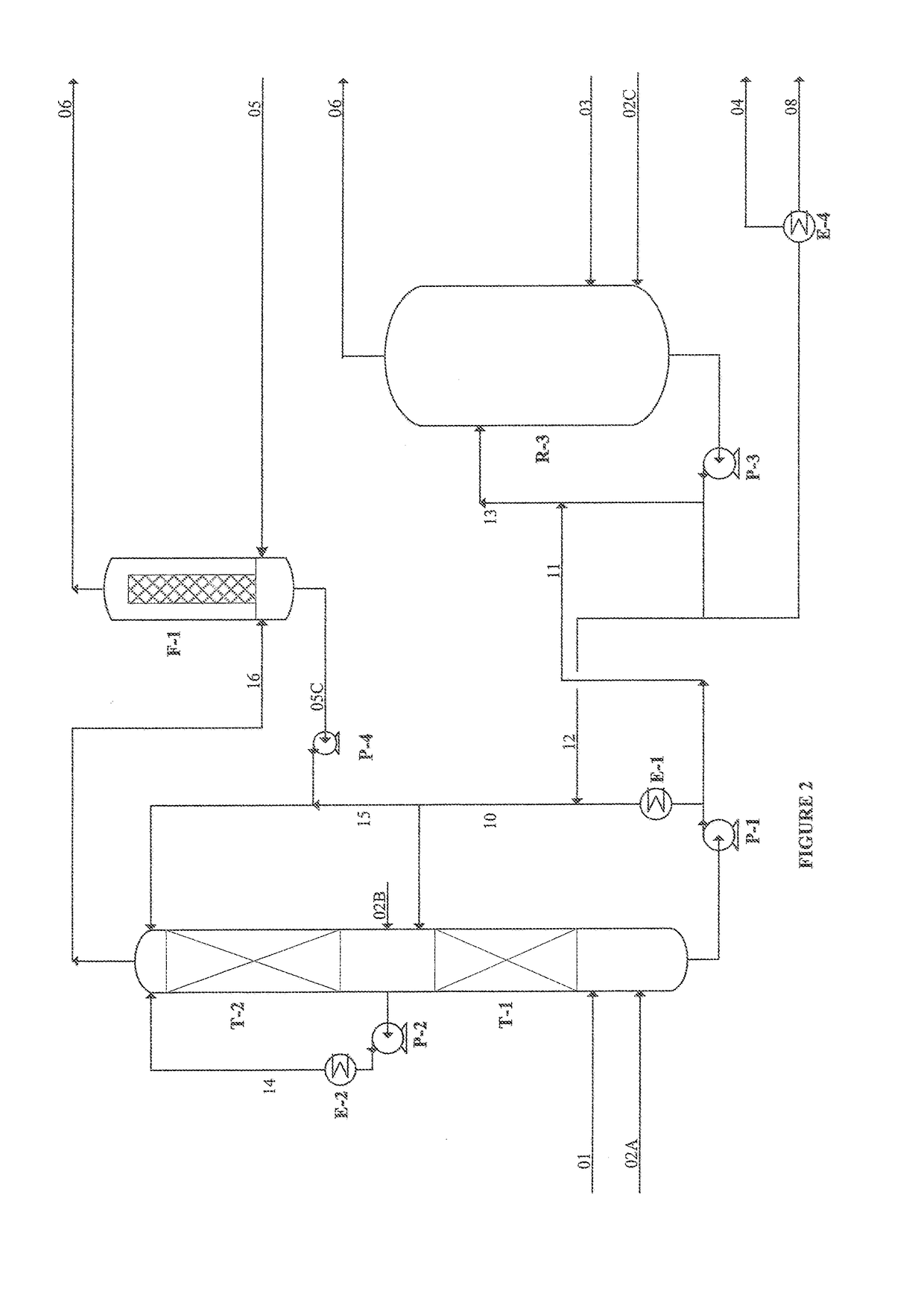

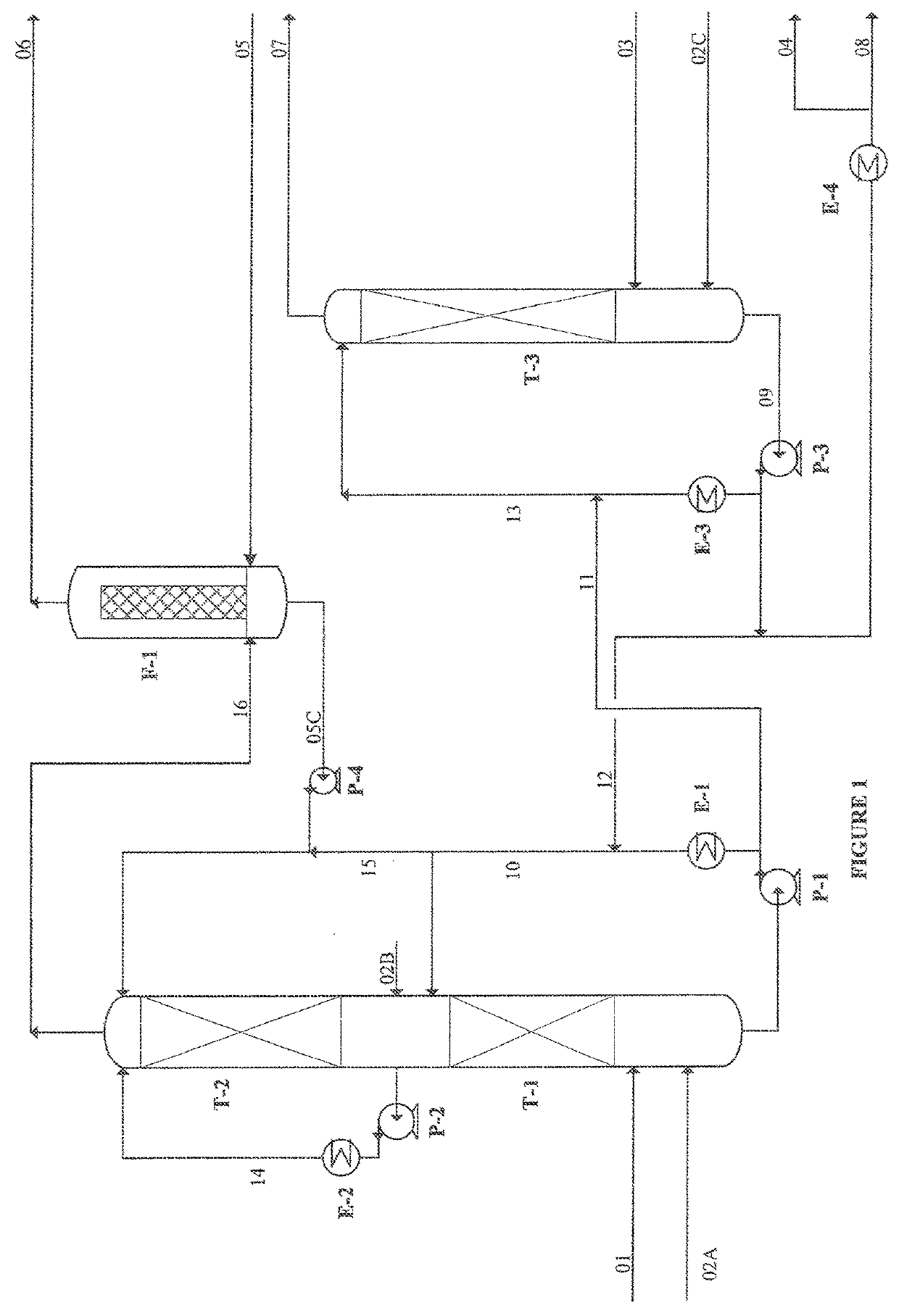

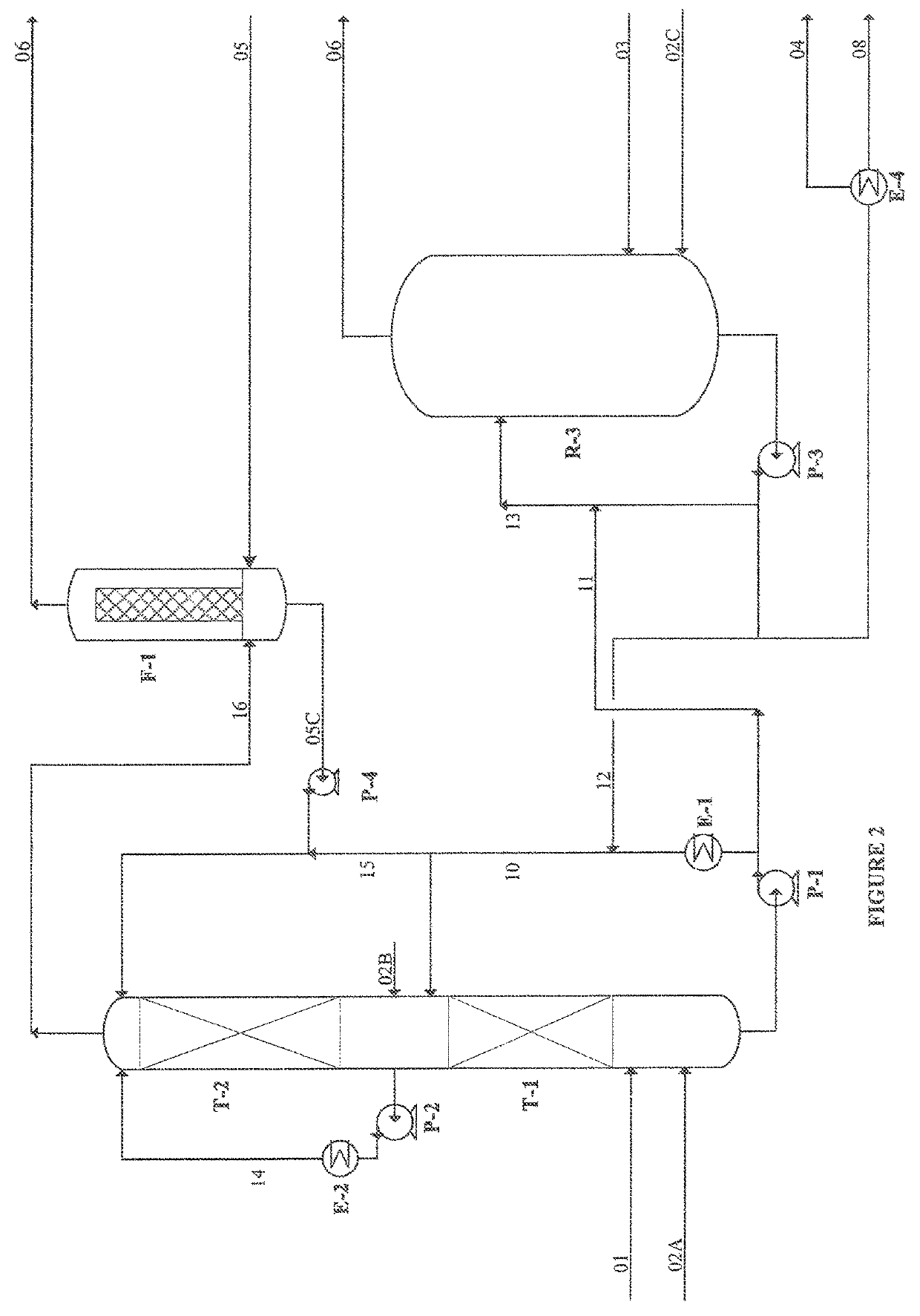

Sulfur dioxide scrubbing system and process for producing potassium products

ActiveUS20170190575A1Gas treatmentThiosulfates/dithionites/polythionitesPotassium peroxideOxidation state

The invention relates to a process for preparing potassium thiosulfate, potassium sulfite or potassium bisulfite comprising the following steps:Step (1a): providing a potassium hydroxide or potassium carbonate solution for neutralizing acid forming components such as dissolving SO2 or H2S;Step (1b): providing an SO2 contacting solution, containing at least some potassium sulfite or potassium bisulfite or potassium thiosulfate;Step (2): providing SO2 gas;Step (3): reacting these to absorb the SO2 gas and to form an intermediate reaction mixture comprising potassium sulfite, or potassium bisulfite or a mixture thereof, and optionally recovering the potassium sulfite, or potassium bisulfite or a mixture thereof, and / or optionally using steps 4 and 5;Step (4): adding sulfur or sulfide containing compound containing sulfur having the oxidation state of 0, −2 or of between 0 and −2 to the reaction mixture and optionally potassium hydroxide or potassium carbonate, and reacting the mixture under suitable conditions to form potassium thiosulfate; andStep (5): recovering the potassium thiosulfate, and optionally concentrating the potassium thiosulfate.

Owner:TESSENDERLO KERLEY INC

Vermicelli powder opening agent

The invention relates to a vermicelli powder opening agent which comprises the following components by weight percent: high-efficiency compound emulsifier 0.1-0.3, cellulose sodium carboxymethyl 0.7-2, sodium tripolyphosphate 2-6, tartaric acid 10-13, potassium hydrogen tartrate 7-10, sodium bicarbonate 12-16, paraffin 12-18, salt 7-10 and acid-modified potato starch 35-43, wherein the high-efficiency compound emulsifier mainly contains distilled monoglyceride, sodium carboxymethylcellulose and the like. The vermicelli powder opening agent does not contain alum or A13K, has the ion concentration reaching 331ppm, and satisfies the demand of people on high potassium products. The tartaric acid, taken as an acidity regulator, also can be synthetized by a chemical method, so that the difficulty in purchasing the tartaric acid is solved. The vermicelli powder opening agent contains no alum, and is used for producing the vermicelli containing no alum, so that the performance of a finished product is obviously improved, and the vermicelli powder opening agent has no toxic and side effects.

Owner:许兆宏

Control method for granularity of potassium nitrate product produced through double decomposition

InactiveCN104843745AReduce entryGuaranteed qualityAlkali metal nitrate preparationPotassium nitrateCentrifugation

The invention relates to a control method for the granularity of a potassium nitrate product produced through double decomposition. The control method comprises the following steps: (1) adding potassium chloride, ammonium nitrate and mother liquor into a double decomposition tank for double decomposition so as to obtain reaction slurry; (2) delivering the reaction slurry into a potassium nitrate cooling crystallization reaction vessel and carrying out cooling crystallization in two steps so as to obtain potassium nitrate crystallizer underflow slurry; (3) introducing the potassium nitrate crystallizer underflow slurry into a cyclone so as to separately obtain coarse-grain potassium nitrate crystal underflow and a feed liquid containing fine potassium nitrate crystal and allowing the feed liquid containing fine potassium nitrate crystal to return to the potassium nitrate cooling crystallization reaction vessel in the step (2); (4) separating the coarse-grain potassium nitrate crystal underflow from a lower outlet of the cyclone and carrying out centrifugation, washing and drying so as to separately obtain crystallization mother liquor and a large-granule potassium nitrate product with crystal granularity stabilized in a range of 1.0 to 1.5 mm and uniform particle sizes; and (5) evaporating the crystallization mother liquor according to a conventional method so as to separately obtain a byproduct--ammonium chloride and circulating mother liquor. The method provided by the invention is simple and reliable, is convenient to operate and has obvious effect.

Owner:甘肃丰谷高科农业有限公司

Sulfur dioxide scrubbing system and process for producing potassium products

ActiveUS10005667B2Gas treatmentThiosulfates/dithionites/polythionitesOxidation statePotassium hydroxide

The invention relates to a process for preparing potassium thiosulfate, potassium sulfite or potassium bisulfite comprising the following steps:Step (1a): providing a potassium hydroxide or potassium carbonate solution for neutralizing acid forming components such as dissolving SO2 or H2S;Step (1b): providing an SO2 contacting solution, containing at least some potassium sulfite or potassium bisulfite or potassium thiosulfate;Step (2): providing SO2 gas;Step (3): reacting these to absorb the SO2 gas and to form an intermediate reaction mixture comprising potassium sulfite, or potassium bisulfite or a mixture thereof, and optionally recovering the potassium sulfite, or potassium bisulfite or a mixture thereof, and / or optionally using steps 4 and 5;Step (4): adding sulfur or sulfide containing compound containing sulfur having the oxidation state of 0, −2 or of between 0 and −2 to the reaction mixture and optionally potassium hydroxide or potassium carbonate, and reacting the mixture under suitable conditions to form potassium thiosulfate; andStep (5): recovering the potassium thiosulfate, and optionally concentrating the potassium thiosulfate.

Owner:TESSENDERLO KERLEY INC

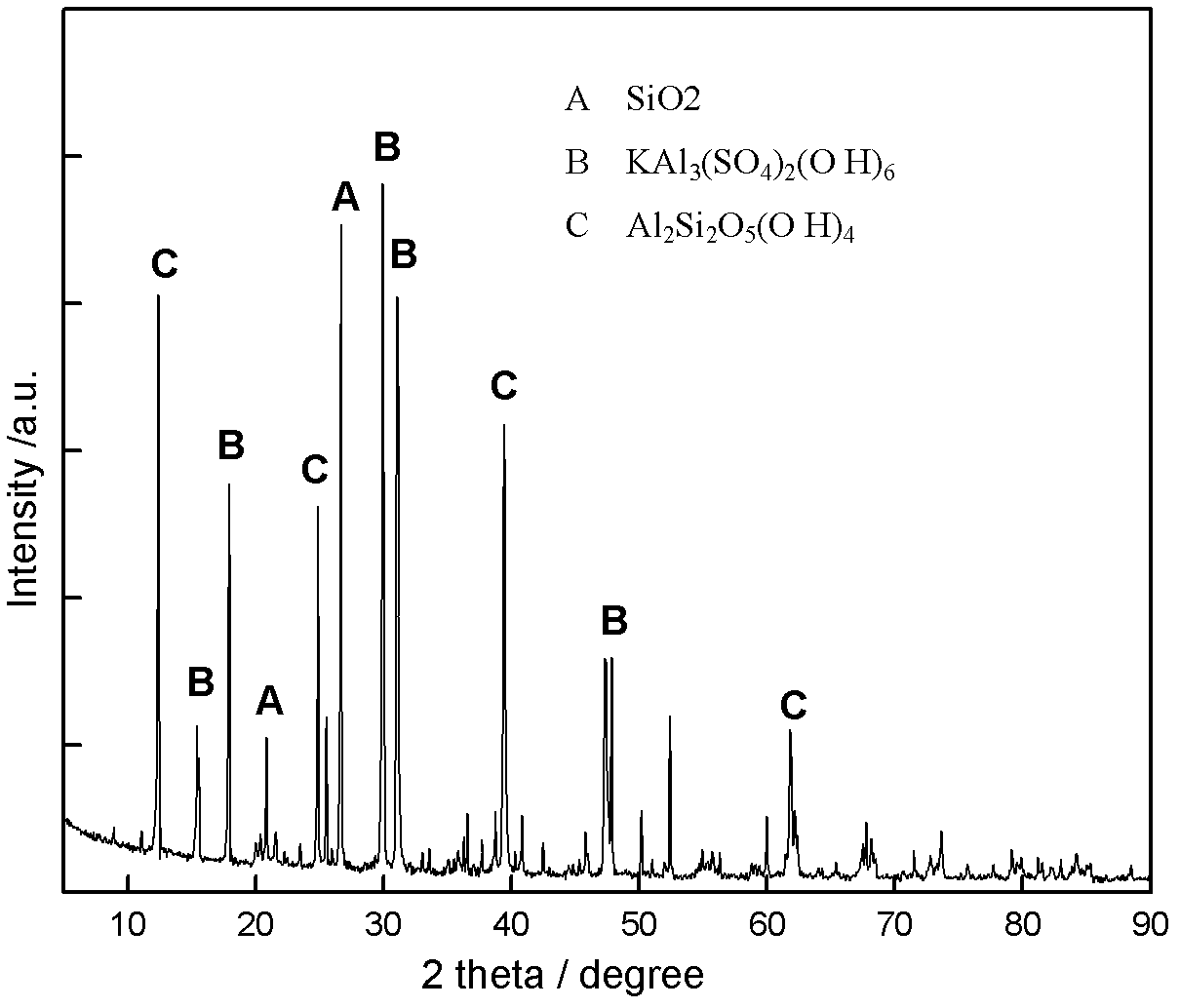

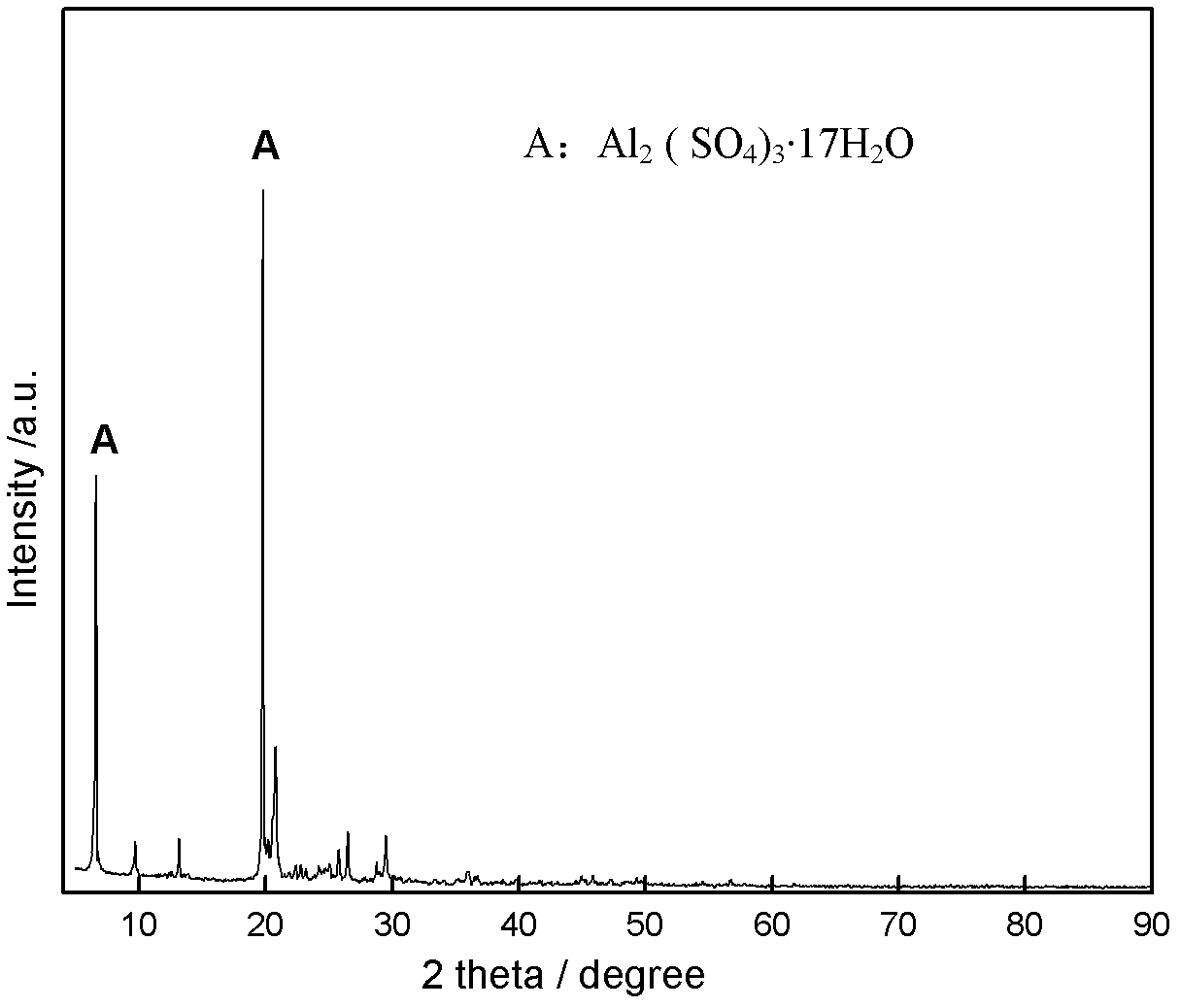

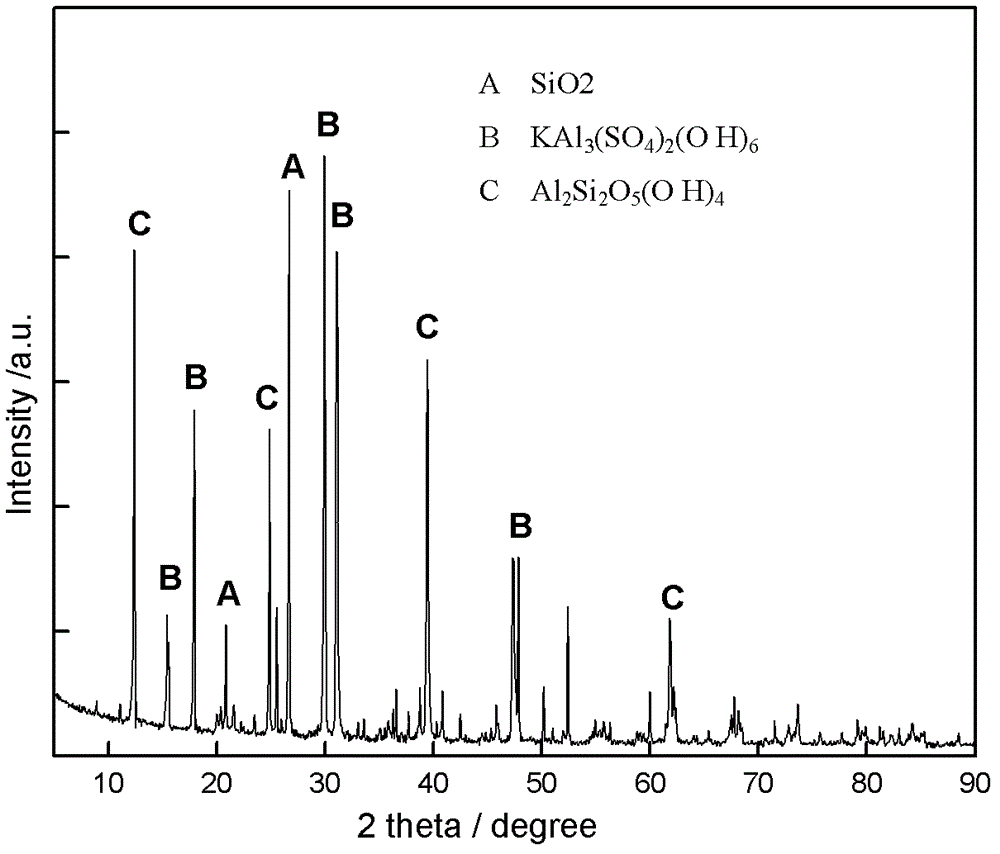

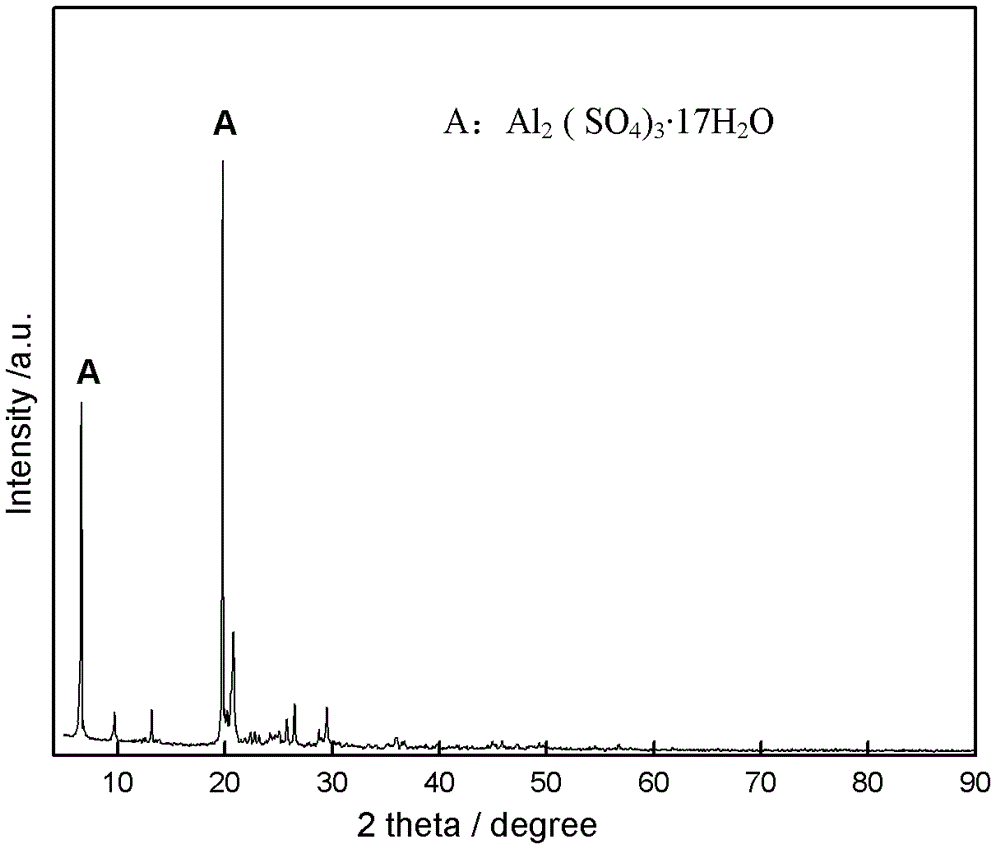

Method for extracting aluminum potassium product from associated alum quarry tailings

Aiming at the characteristic that associated alum quarry tailings in domestic enterprises are higher in aluminum potassium content and are simple in phase composition and contain main impurities, i.e. SIO2, the invention provides a novel acid fusion-water immersion method for treating the tailings to extract a high-value aluminum potassium product. After an ore sample is strengthened and roasted by low-temperature acid and is immersed into water with a temperature of 90 DEG C for treatment, the extraction rates of Al and K respectively reach 94.6 percent and 92.9 percent, which show better industrial application prospect. By adopting a fractional crystallization method, aluminum sulfate hydrate and alum crystals with higher purity are respectively obtained, and the preliminary separation of aluminum from potassium is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

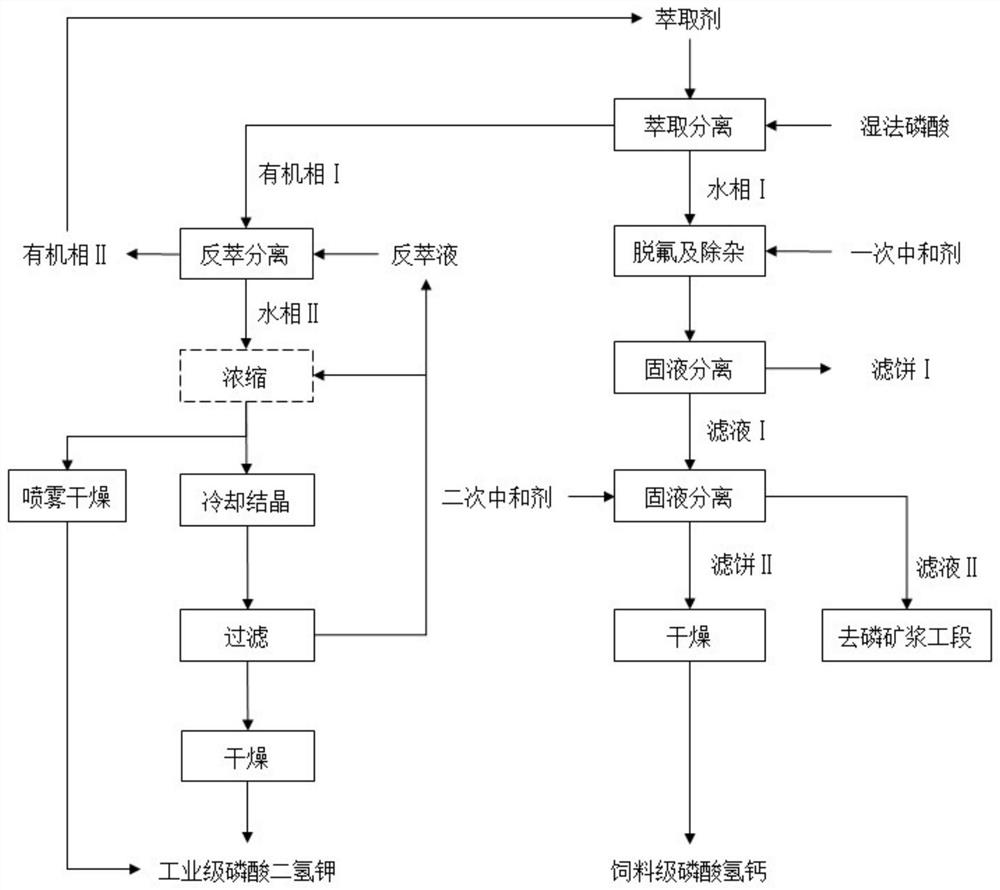

Method for joint production of industrial-grade potassium dihydrogen phosphate and feed-grade calcium hydrogen phosphate by wet-process phosphoric acid

ActiveCN110395704BLower quality requirementsReduce manufacturing costPhosphorus compoundsO-Phosphoric AcidHydrogen phosphate

The invention relates to a method for co-production of industrial-grade potassium dihydrogen phosphate and feed-grade dicalcium phosphate from wet-process phosphoric acid and belongs to the technicalfield of chemical production. The technical problem to be solved by the invention is to provide the method for co-production of the industrial-grade potassium dihydrogen phosphate and the feed-grade dicalcium phosphate from wet-process phosphoric acid. The method includes a) subjecting the wet-process phosphoric acid to extraction with an extractant to obtain an organic phase I and a water phase I; b) subjecting the organic phase I and a stripping agent to back extraction to obtain an organic phase II and a water phase II; c) purifying the water phase II to obtain an industrial-grade potassiumdihydrogen phosphate product; d) neutralizing the water phase I with a first neutralization agent and performing solid-liquid separation to obtain filter cake I and a filtrate I; e) neutralizing thefiltrate I with a second neutralization agent, performing solid-liquid separation to obtain filter cake II and a filtrate II, and drying the filtrate II to obtain a feed-grade dicalcium phosphate product. The method has advantages of a simple process, a low cost, a high phosphorus utilization rate and good social and economic benefits.

Owner:SICHUAN UNIV

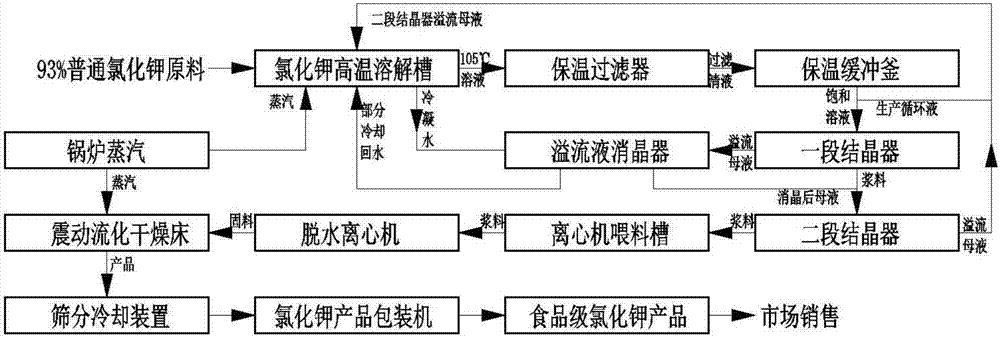

Method for producing food grade potassium chloride

InactiveCN107162020AReduce production processReduce production capacityAlkali metal halide purificationFood additiveFiltration

The invention discloses a method for producing food grade potassium chloride. The method mainly comprises high temperature dissolution, filtration and purification, continuous crystallization, dehydration separation, and drying. The prepared food-grade potassium chloride has large product particles, high particle uniformity and low impurity content, can be directly dried and packaged without washing, reduces process consumption and realizes a low production cost. The product has large particle sizes and high main content, does not easily cake after long term storage, and realizes production of low sodium salt through direct mixing of table salt or can be directly used as a food additive. The method utilizes a simple device, has a short production process, does not pollute the environment and has a high industrial application value.

Owner:天津长芦汉沽盐场有限责任公司

A kind of method of producing potassium chloride by carnallite raw ore

The invention provides a method for preparing potassium chloride from carnallite. The low-sodium carnallite slurry is decomposed and crystallized for the first time in the first crystallizer 8a, so that the magnesium chloride in the carnallite is transferred to the liquid phase, and the potassium chloride crystallization partly transferred to the liquid phase is separated out, and the crystallization of the first crystallizer 8a The underflow contains precipitated potassium chloride and undecomposed carnallite and sodium chloride particles. In the second crystallizer 8b, the underflow of the first crystallizer 8a is decomposed and crystallized, the sodium chloride in the carnallite is transferred to the liquid phase, and the potassium chloride crystallization partly transferred to the liquid phase is separated out, and the second crystallizer 8b The underflow contains precipitated potassium chloride and undecomposed carnallite and sodium chloride particles. The underflow of the second crystallizer 8b is sieved, and the oversize contains undecomposed carnallite and sodium chloride particles, and the undersize is used to generate potassium chloride product. The oversize is crushed, and the broken oversize is used to generate the low-sodium carnallite slurry. While ensuring the grade of potassium chloride, the recovery rate of carnallite is greatly increased.

Owner:QINGHAI SALT LAKE IND

Method for purifying potassium nitrate from waste potassium nitrate obtained from chemical toughened glass production

PendingCN114516647AHigh recovery rateHigh purityAlkali metal nitrate purificationPotassium nitratePhysical chemistry

The invention discloses a method for purifying potassium nitrate from waste potassium nitrate obtained by chemical toughened glass production. The method comprises the following steps: crushing waste potassium nitrate to obtain a raw material A; adding water into the raw material A, and stirring to obtain a potassium nitrate mixed solution B; repeatedly adding the raw material A into the potassium nitrate mixed solution B, stirring and filtering to obtain filtrate C and a semi-finished product potassium nitrate salt; heating the filtrate C, repeatedly adding the raw material A again, stirring and filtering to obtain filtrate D and a semi-finished product potassium nitrate salt; adding water into the filtrate D, cooling to normal temperature, stirring and filtering to obtain a semi-finished product potassium nitrate salt and filtrate E; and drying the obtained semi-finished product potassium nitrate salt, and removing ash in the semi-finished product potassium nitrate salt to obtain an industrial potassium nitrate product. The method can obtain a high-purity potassium nitrate product, and is high in potassium nitrate recovery rate, simple in process condition, energy-saving, environment-friendly and low in production cost.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

A compound salt treatment and comprehensive utilization process of insoluble potassium-rich minerals

InactiveCN104445320BRealize comprehensive utilizationEfficient separationSulfate/bisulfate preparationCarbonate preparationBrickSodium salt

The invention discloses a composite salt treatment and comprehensive utilization process of insoluble potassium-enriched minerals. The process comprises the following steps: mixing insoluble potassium-enriched minerals with composite salt containing calcium salt and sodium salt, and then roasting at high temperature; performing water leaching on a roasted product, and then performing solid-liquid separation I to obtain a solid I and a liquid I, wherein the solid I is used for preparing aerated bricks or Portland cement additives, the liquid I is used for separating out precipitates by adjusting a pH value and is subjected to solid-liquid separation II to obtain a solid II and a liquid II, and the solid II is further prepared into Al2(SO4)3 or Al2O3; and preparing K2SO4 or K2CO3 by performing condensation crystallization or salt precipitation on the liquid II. According to the process disclosed by the invention, the insoluble potassium-enriched minerals are subjected to roasting treatment by the composite salt containing the calcium salt and sodium salt, and water leaching is combined to ensure that potassium, aluminum and silicon in the insoluble potassium-enriched minerals are fully separated, and meanwhile, aluminum products and potassium products with relatively high purity can be obtained; and by adopting the process, the comprehensive recovery and utilization of insoluble potassium-enriched mineral resources can be achieved.

Owner:CENT SOUTH UNIV

Oxydant of potassium perchlorate type special for fireworks and method for preparing same

Owner:湖南金能科技实业有限公司

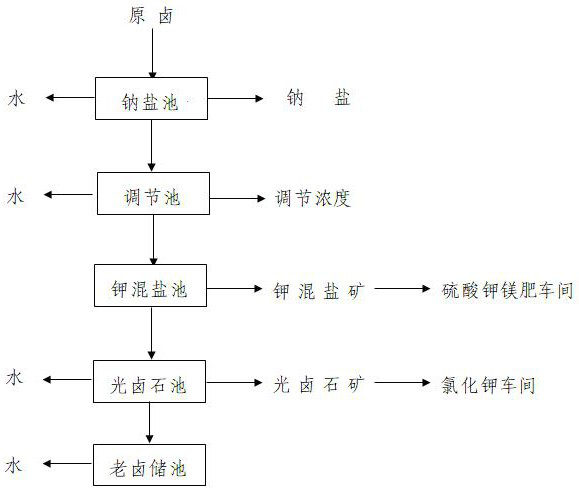

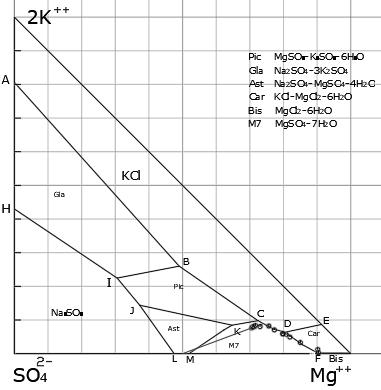

A kind of magnesium sulfate subtype salt lake brine salt field natural evaporation staged mineralization technology

ActiveCN110283001BReduce lossesReduce salt pan processAlkali metal sulfite/sulfate purificationAlkali metal chloridesCarnalliteSodium salt

The present invention relates to a sub-type magnesium sulfate subtype salt lake brine natural evaporation staged ore-forming process, comprising the following steps: (1) pumping brine from a magnesium sulfate subtype salt lake well into a sodium salt pool, naturally evaporating to precipitate sodium chloride, and then When the sharp salt is close to saturation, it is introduced into the adjustment pool, and when the brine point reaches the epsom salt and is about to be precipitated, it is imported into the potassium mixed salt pool; (2) in the potassium mixed salt pool, the brine obtained in step (1) continues to be evaporated naturally, and when the brine is close to light brine The stone is saturated and will be imported into the carnallite pool when it is about to be separated out, and the potassium mixed salt ore is separated out, and the potassium mixed salt ore is separated out, and the potassium mixed salt ore enters the potassium magnesium sulfate fertilizer workshop to produce langbeinite products; (3) in the carnallite In the pool, the brine obtained in step (2) continues to be evaporated naturally, and when the brine reaches the old brine point, it is introduced into the old brine storage tank, and carnallite ore is precipitated, and the carnallite ore enters the potassium chloride workshop to produce potassium chloride products . The invention has the advantages of simple process, low production cost and high sulfur-potassium ratio of potassium mixed salt ore.

Owner:青海中信国安锂业发展有限公司

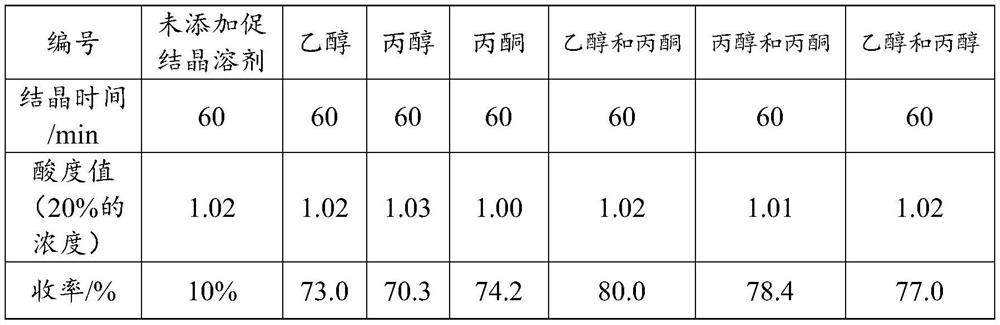

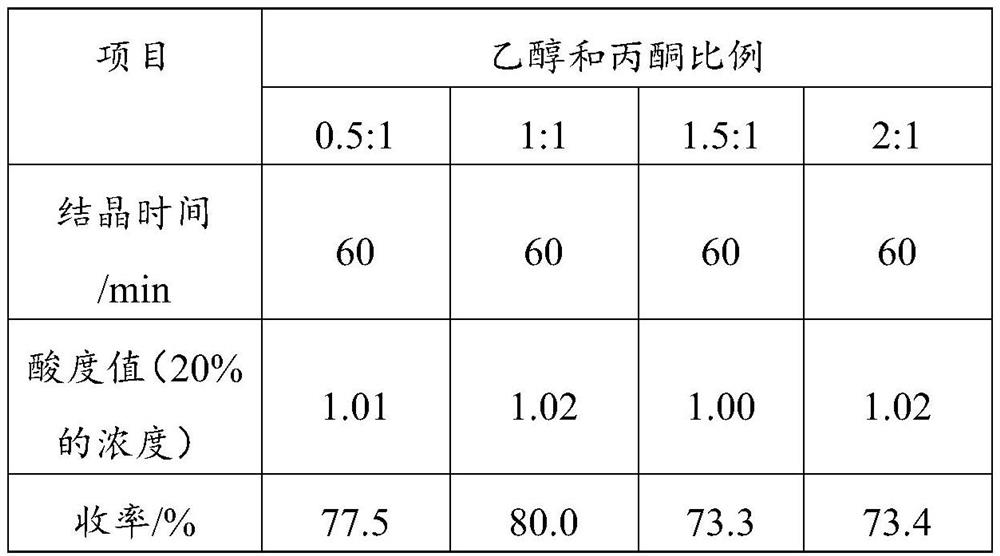

Preparation method of dipotassium malate

PendingCN114436812AConvenient amountIncrease productionOrganic compound preparationCarboxylic acid salt preparationPropanolAlcohol ethyl

The invention discloses a preparation method of dipotassium malate, which comprises the following steps: S1, mixing malic acid and potassium carbonate in a solution, reacting at 50-80 DEG C for 0.5-1 hour, and after the reaction is finished, carrying out solid-liquid separation to obtain filtrate; s2, the filtrate is concentrated, a crystallization promoting agent is added, the crystallization promoting agent is a combination of any two of propyl alcohol, ethyl alcohol and acetone, drying is conducted after crystallization, and a dipotassium malate product is obtained. The malic acid and the potassium carbonate are used as raw materials and react at the high temperature of 50-80 DEG C, the synthesis rate of the dipotassium malate is increased, the yield of the dipotassium malate is increased by optimizing the dosage of the malic acid and the potassium carbonate, crystallization of the dipotassium malate is promoted by adding a proper crystallization promoting agent, and then the yield is further increased. The dipotassium malate prepared by the method is white crystal or powder, the acidity value (20%) is 0.5-3.8, and the yield can reach 80%.

Owner:河南瑞贝佳生物科技有限公司

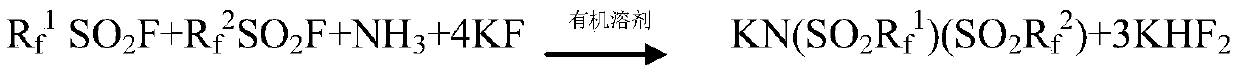

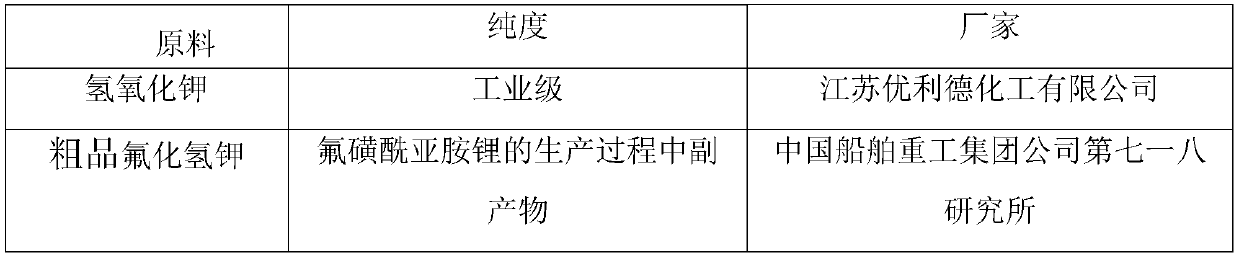

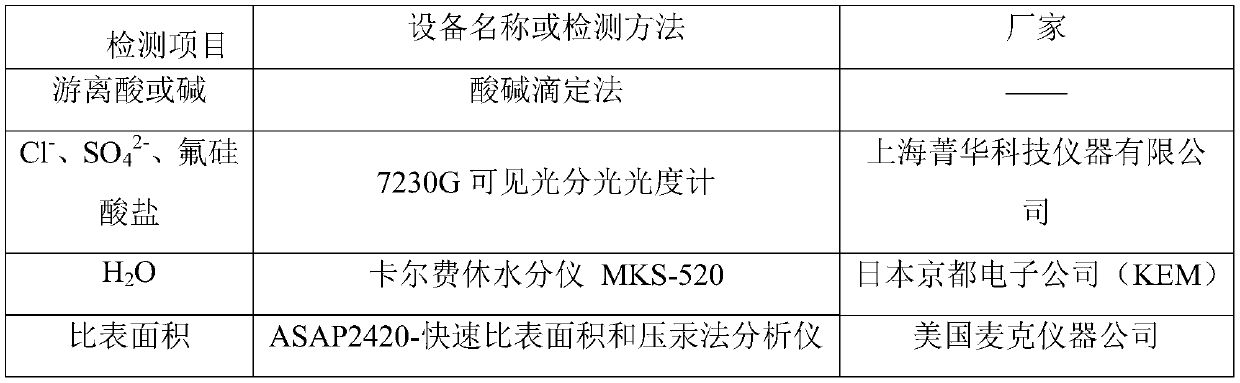

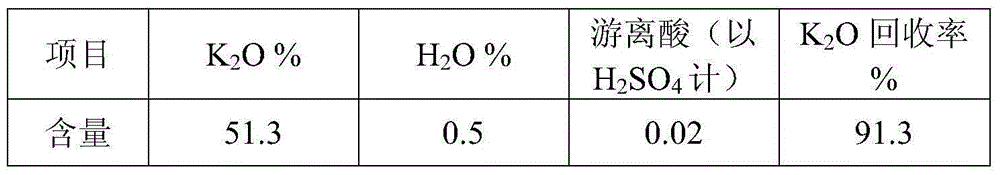

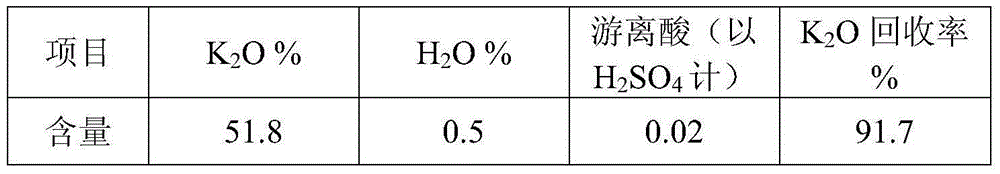

Method for preparing potassium fluoride from crude potassium bifluoride

PendingCN111217381AReduce pollutionReduce manufacturing costAlkali metal fluoridesHydrogen fluorideOrganic solvent

The invention relates to a method for preparing potassium fluoride from crude potassium bifluoride, and belongs to the technical field of fine chemical engineering. The method comprises the followingsteps: drying the crude potassium bifluoride while stirring; adding water into the dried crude potassium bifluoride to prepare turbid liquid; dropwise adding an alkaline solution into the turbid liquid while stirring for reaction, and ending the reaction when the pH value of the solution is 9-10.5; and carrying out spray drying on the reacted solution to obtain a potassium fluoride product. The crude potassium bifluoride is composed of potassium bifluoride, potassium fluoride and an organic solvent, wherein the mass fraction of potassium fluoride is less than or equal to 5%, and the mass fraction of the organic solvent is less than or equal to 2%. The method is simple in process, greatly reduces the production cost and is easy to popularize.

Owner:PERIC SPECIAL GASES CO LTD

A kind of processing technique of potassium stannate

The invention discloses a processing technology of potassium stannate. The process includes reaction preparation-dehydration treatment-pickling-high purification-finished product treatment. This process makes the potassium stannate The purity of the product is higher and the quality of the product is better.

Owner:赣州白塔金属材料有限公司

Potassium sulfate crystal growth promoter and application thereof

InactiveCN105217657AEfficient crystallizationImprove product qualityAlkali metal sulfites/sulfatesHydrogen phosphateAlcohol

The invention discloses a potassium sulfate crystal growth promoter and application thereof. The crystal growth promoter consists of sodium tripolyphosphate, diammonium hydrogen phosphate, magnesium sulfate, urea and sodium sulfate. The crystal growth promoter is simple, safe, and realizes efficient crystallization of potassium sulfate on the premise of no alcohol. The invention also provides application of the crystal growth promoter, which can obtain high quality potassium sulfate products, and is safe, efficient and low in cost.

Owner:莫红兵 +2

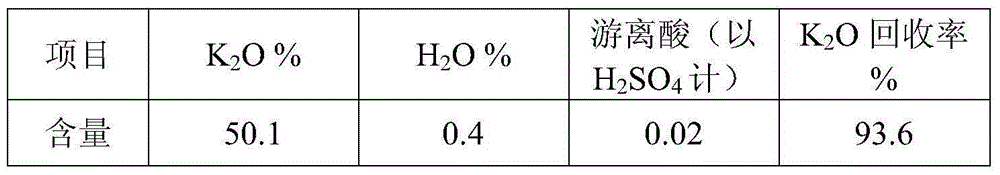

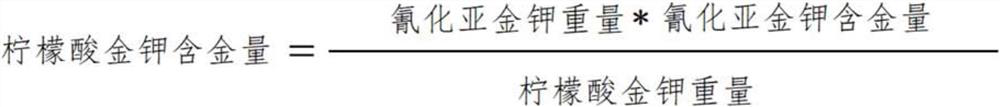

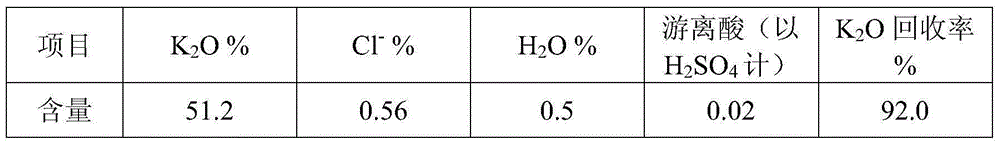

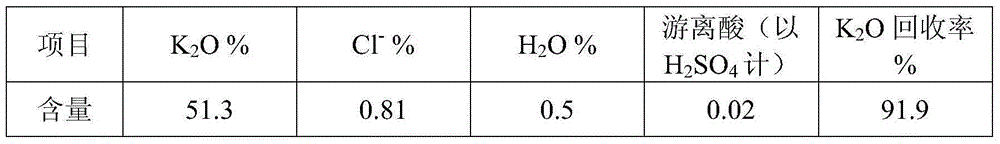

A kind of gold potassium citrate production technology

ActiveCN109553520BAdequate responseImprove product qualityOrganic compound preparationCarboxylic acid salt preparationCyanideEnvironmental engineering

The invention relates to a production process of gold potassium citrate. The production process first uses citric acid and potassium citrate as raw materials to prepare potassium dihydrogen citrate, then adds potassium aurous cyanide and potassium dihydrogen citrate, mixes them with water, and then dries them to prepare potassium gold citrate. The gold potassium citrate production process of the present invention has high production efficiency, low cost and environmental protection, and the prepared gold potassium citrate product has high quality and stable pH value, can meet the requirements of the gold plating process, and has great industrial production application value .

Owner:泰州市欣港电子材料有限公司

Potassium sulfate crystal growth accelerant and application thereof

InactiveCN105036156AEfficient crystallizationImprove product qualityAlkali metal sulfites/sulfatesHydrogen phosphateAlcohol

The invention discloses a potassium sulfate crystal growth accelerant and application thereof. The crystal growth accelerant is composed of sodium triphosphate, diammonium hydrogen phosphate, magnesium sulfate, urea and sodium chloride. The potassium sulfate crystal growth accelerant is simple, safe and capable of efficiently crystallizing potassium sulfate on the premise that no alcohol substances are used. The invention also provides application of the potassium sulfate crystal growth accelerant which is capable of obtaining high-quality potassium sulfate products, safe, efficient and low in cost.

Owner:莫红兵 +2

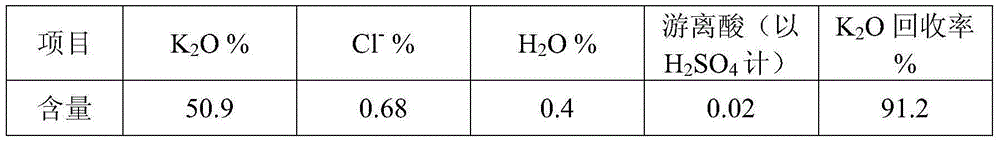

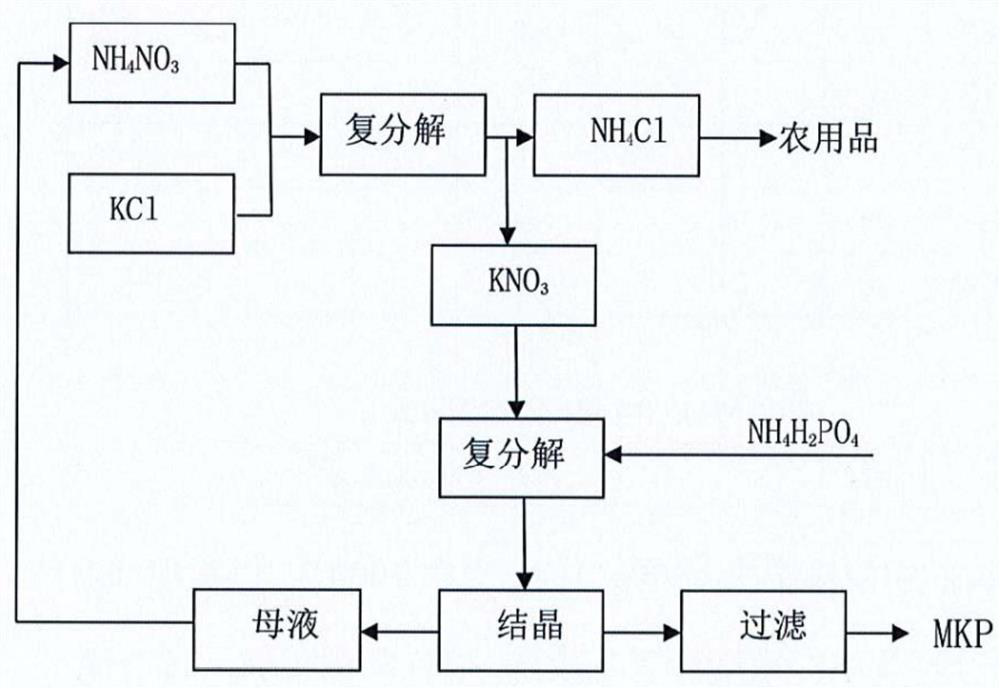

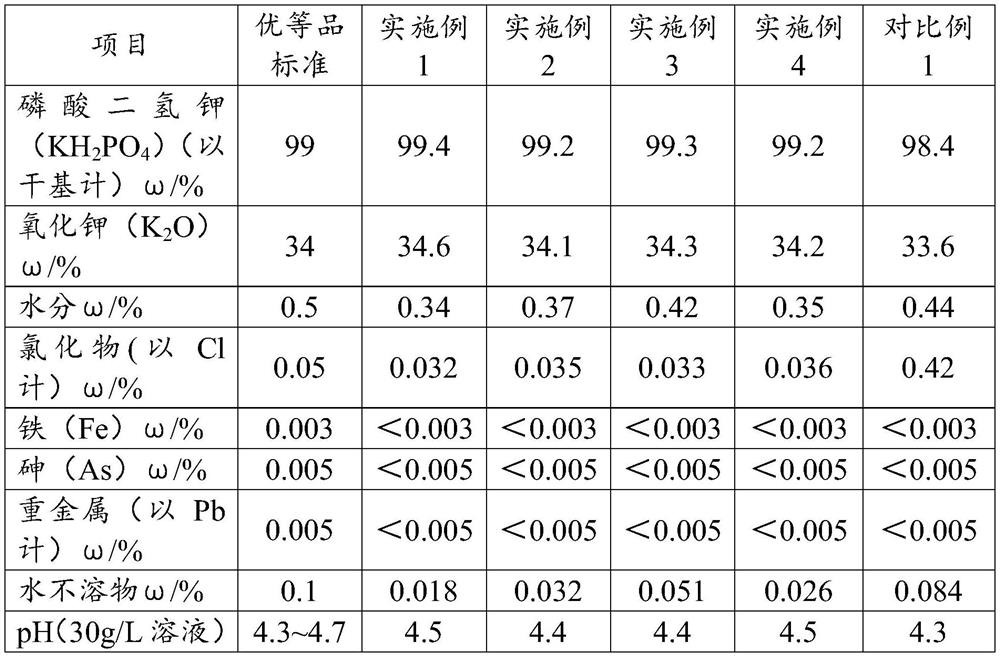

Process for producing monopotassium phosphate by taking potassium nitrate as raw material

InactiveCN112694075AReduce manufacturing costReduce contentPhosphorus compoundsPotassium nitratePhosphate

The invention provides a process for producing monopotassium phosphate by taking potassium nitrate as a raw material. The process comprises the following steps: S1, carrying out double decomposition reaction on ammonium nitrate and potassium chloride to prepare potassium nitrate and ammonium chloride; and S2, reacting the potassium nitrate obtained in the step S1 with ammonium dihydrogen phosphate to prepare potassium dihydrogen phosphate. According to the process, the content of chloride ions in the monopotassium phosphate product can be reduced, and the production cost can be reduced.

Owner:SICHUAN LOMON PHOSPHORUS CHEM

Method for extracting aluminum potassium product from associated alum quarry tailings

Aiming at the characteristic that associated alum quarry tailings in domestic enterprises are higher in aluminum potassium content and are simple in phase composition and contain main impurities, i.e. SIO2, the invention provides a novel acid fusion-water immersion method for treating the tailings to extract a high-value aluminum potassium product. After an ore sample is strengthened and roasted by low-temperature acid and is immersed into water with a temperature of 90 DEG C for treatment, the extraction rates of Al and K respectively reach 94.6 percent and 92.9 percent, which show better industrial application prospect. By adopting a fractional crystallization method, aluminum sulfate hydrate and alum crystals with higher purity are respectively obtained, and the preliminary separation of aluminum from potassium is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of production technology that prepares potassium chloride from carnallite

The invention discloses a technology for producing potassium chloride from carnallite. The technology comprises the following steps: determining a critical particle diameter of particles with the mostaverage content of the potassium chloride and selecting a standard screen mesh for sieving carnallite particles; sieving the carnallite particles into a primary oversize material and a primary undersize material by utilizing the standard screen mesh; adding a water amount for completely dissolving magnesium chloride into the primary oversize material to obtain a primary dissolving solution and primary mixed slurry; sieving the primary mixed slurry into a secondary oversize material and a secondary undersize material by utilizing the standard screen mesh; carrying out reverse flotation to obtain low-sodium carnallite and tail salt foam; adding the water amount for completely dissolving the magnesium chloride into the low-sodium carnallite to obtain a secondary dissolving solution and secondary mixed slurry; carrying out solid-liquid separation on the secondary undersize material and the secondary mixed slurry to obtain a crude potassium product; washing an obtained potassium chloride crude product to obtain a qualified potassium chloride finished product. The technology disclosed by the invention has the advantages of simplicity in operation, less investment, low energy consumptionand high yield and the quality of the prepared potassium chloride finished product is good.

Owner:QINGHAI SALT LAKE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com