Technology for producing potassium chloride from carnallite

A production process and potassium chloride technology, applied in the direction of alkali metal chloride and the like, can solve the problems of low environmental friendliness, difficult to obtain raw materials, low product quality, etc., and achieve the advantages of reducing environmental pollution, mature production technology, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

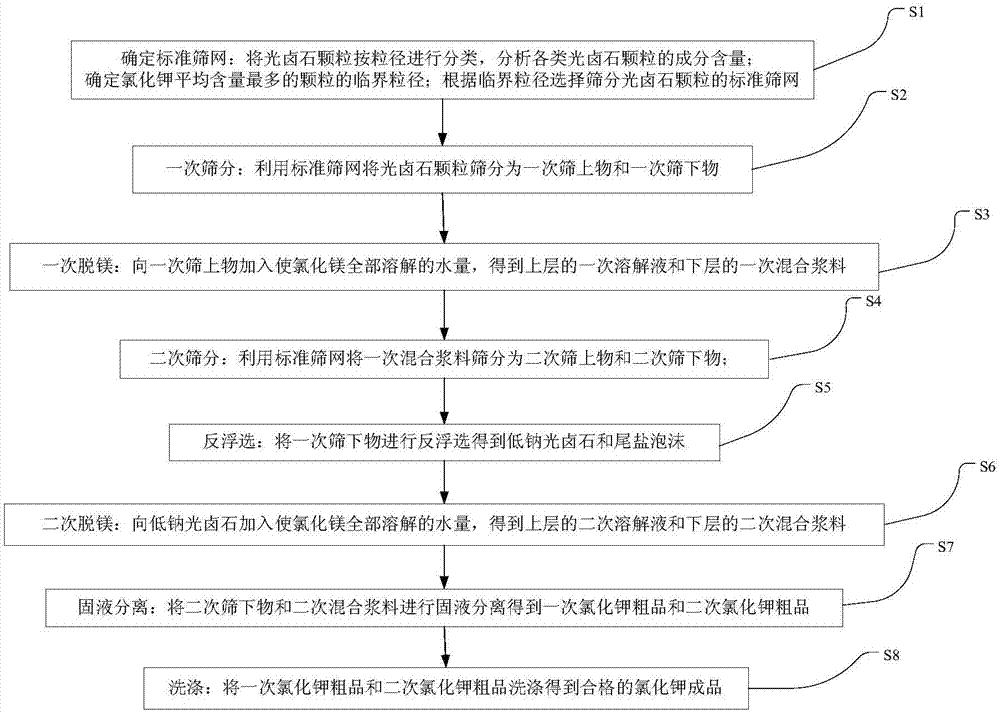

Method used

Image

Examples

specific Embodiment

[0045] The production process for preparing potassium chloride from carnallite of the present invention will be described in detail below through several specific examples.

[0046] The present invention is implemented according to the physical characteristics of carnallite. Carnallite is a stable double salt at a temperature ranging from -21 to 167.5°C. It is a heterogeneous double salt, which can be decomposed into another solid phase when dissolved in water. The composition of pure carnallite is: KCl MgCl 2 ·6H 2 O, in actual production, the most important thing in carnallite ore is sodium chloride containing impurity salt. No matter what kind of potassium chloride production process is, how to remove sodium chloride is the main means. The present invention first separates the sodium chloride with large particles and small particles through the particle size analysis of carnallite, and then divides them into two processes for processing, and finally obtains qualified pota...

Embodiment 1

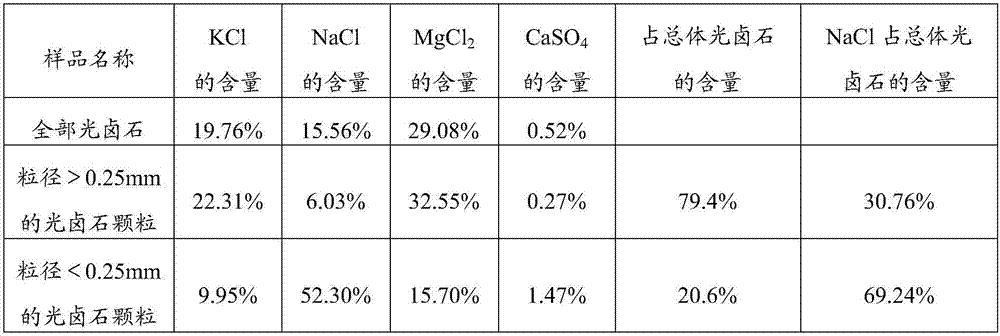

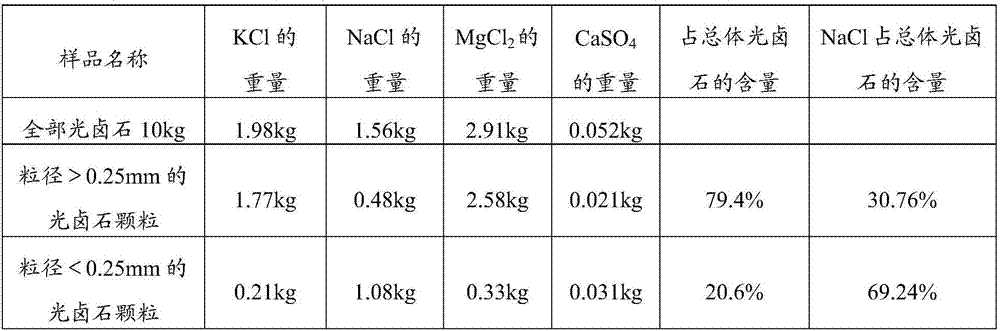

[0048] In the experiment, 10kg of carnallite particles were used as the raw material, and a 60-mesh screen was selected with 0.25mm as the critical particle size, and then the carnallite particles were sieved once to obtain 7.94kg of primary sieve material and 2.06kg of primary sieve material . Analyze the content of each component of carnallite, the composition content analysis is shown in Table 7-1:

[0049] The critical particle size in Table 7-1 embodiment 1 is the weight of each component of the carnallite particles in the particle size range determined by 0.25mm

[0050]

[0051] After the 7.94kg primary sieve was subjected to primary demagnesization, the primary solution obtained and the primary mixed slurry were obtained. Then the primary mixed slurry is subjected to secondary screening to obtain secondary oversize and secondary undersize, and the secondary undersize can be split into primary solution and primary crude potassium. After secondary screening, the con...

Embodiment 2

[0067] In the experiment, 10kg of carnallite particles were used as the raw material, and a 60-mesh screen was selected with 0.25mm as the critical particle size, and then the carnallite particles were sieved once to obtain 6.36kg of primary sieve material and 3.64kg of primary sieve material . Analyze the content of each component of carnallite, the composition content analysis is shown in Table 8-1:

[0068] The critical particle size in Table 8-1 embodiment 1 is the weight of each component of the carnallite particles in the particle size range determined by 0.25mm

[0069]

[0070] After 6.36kg of primary sieve material is demagnesified once, the primary solution and the primary mixed slurry obtained are obtained. Then the primary mixed slurry is subjected to secondary screening to obtain the secondary oversize and the secondary undersize, and the secondary undersize is divided into the primary solution and the crude potassium. After secondary sieving, the content ana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com