Instrument and method for detecting density of numeral textile fabric

A fabric density and detector technology, applied in textile testing, instruments, measuring devices, etc., can solve the problems of difficulty in determining the actual density of fabrics, inability to store, transmit, and difficulty in comparing multiple people, and achieve rapid and accurate determination of fabric density, Avoid observing differences and improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

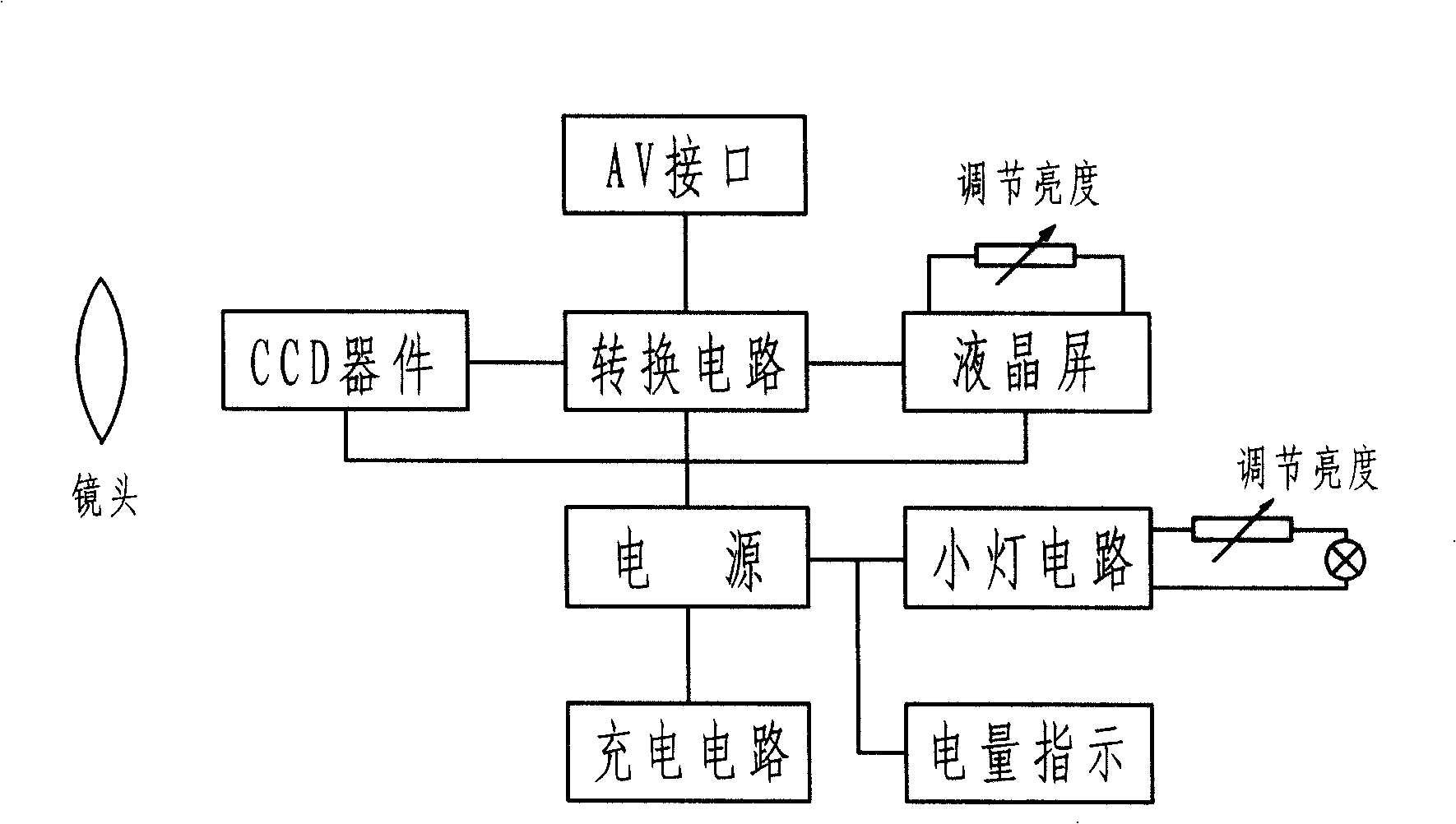

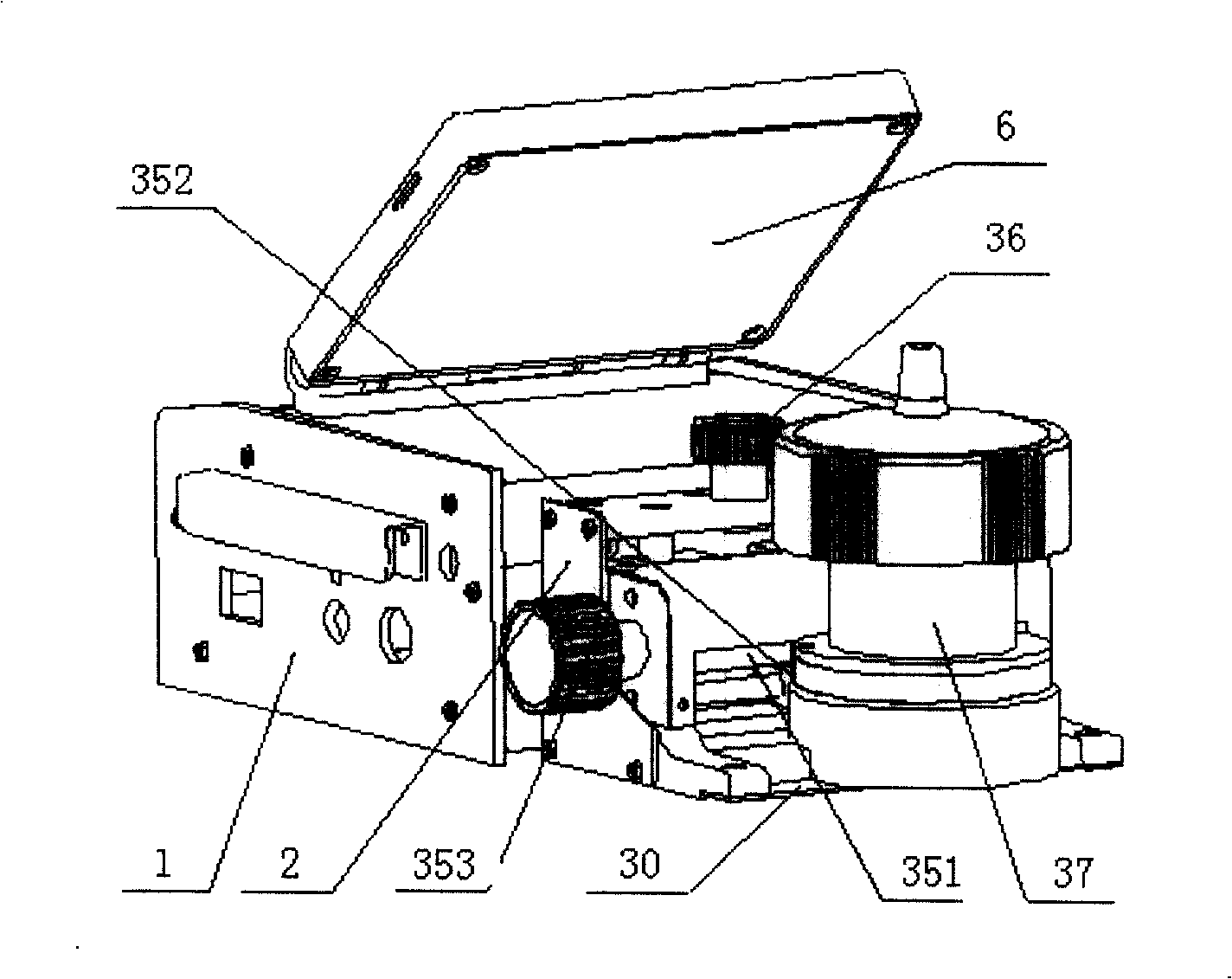

[0043] Embodiment 1: Tested by a single machine of a digital fabric density detector. Testing by one tester or by a tester and a retester at the same time. During the test, the test inspector or / and the retest inspector randomly select five test areas on the fabric at the same time, after measuring the value in each test area, take the average value of the value as the final determined value. The test results can be compared and determined by the re-examination inspector after performing the same method test. Pass if the difference is within the allowable range.

[0044] The fabric density image captured by the above stand-alone machine can also be connected to other display media for enlarged display, image storage, print display, and projection display.

Embodiment 2

[0045] Embodiment 2: Test by connecting a computer with a digital fabric density detector

[0046] It is tested by a test inspector, and a test inspector and a re-examination inspector can also be used to test at the same time. The host computer can choose CPU above P2. The operating system uses WINDOW 9X, WINDOW2000, WINDOW XP, etc. The screen resolution is above 800×600. The host computer also needs to be equipped with an AV interface card. During operation, the AV output port on the stand-alone machine of the present invention is connected to the input port of the AV interface card of the host computer. The connecting wire is a commonly used shielded cable. After the host computer is turned on, the AV interface card driver software is executed on the desktop of the operating system. During the test, the test inspector randomly selects five test areas on the fabric, and after measuring the values in each test area, the average value of the values is taken as the fin...

Embodiment 3

[0048] Embodiment three: connect computer and printer by digital fabric density detector. The fabric density image determined and displayed on the computer screen can be printed on a paper carrier by connecting a printer, as a test report document drawing or a test report paper document archive. The printer can choose a color inkjet printer or a color laser printer with a resolution of 600×600, 1200×1200, 1200×2400. The paper carrier can be 80g copy paper, ordinary photo paper, glossy photo paper, high-quality glossy photo paper, matte paper, drawing paper, color machine paper and other glossy photo paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com