Dielectric-coating structure reflecting mirror used for chirp pulse amplification optical spectrum shaping

A spectral shaping, chirped pulse technology, applied in mirrors, lasers, laser parts and other directions, can solve the problems of inapplicability, complex adjustment, unsuitable neodymium glass system, etc., to achieve the effect of strong versatility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

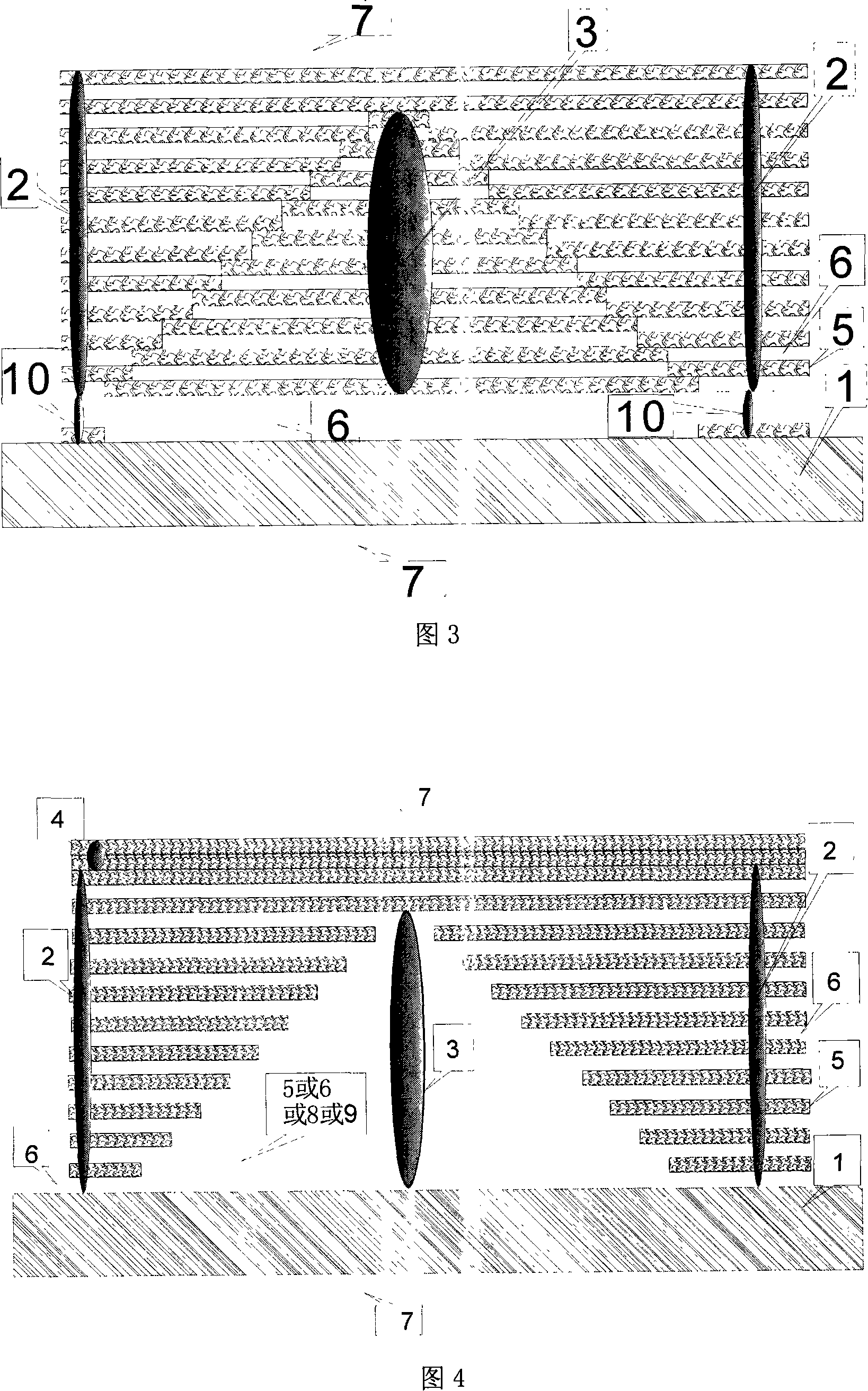

[0054] Under the outer protective layer 4 provided on the transparent substrate 1, and the high-reflection medium film system 2 composed of high-refractive-index medium film layers 5 and low-refractive-index medium film layers 6 alternately, a high-transmittance film system is buried, and the Specially designed anti-reflection coatings, such as λ 0 / 4 anti-reflection standard film system. Then etch and polish the micro-relief structure on the anti-reflection film system or film stack. Using mask technology, then plate high reflective dielectric film system 2 as the standard λ 0 / 4 high reflection film system, since the reflection phase is required to be unchanged, the coating steps are required to be accurately aligned vertically and horizontally. The role of the outer guiding protective layer is mainly to protect against scratches and the influence of atmospheric water vapor. At the same time, the outer guiding protective layer is thick because the λ / 2 layer is actually a ...

Embodiment 2

[0056] There may also be no outer guiding protective layer 4 on the transparent substrate 1, and a specially designed anti-reflection film system may be directly plated in advance, and the anti-reflection film system is λ 0 / 4 anti-reflection standard film system, and then etch and polish the micro-relief structure on the anti-reflection film system or film stack. Utilize the mask technology, and then plate the highly reflective dielectric film system 2 as the usual standard λ 0 / 4 High reflection film system, because the reflection phase is required to be unchanged, so the coating steps are required to be accurately aligned vertically and horizontally. The guiding film layer 10 is a λ / 2 transparent layer composed of the low-refractive-index dielectric film layer 6, but it has a selective effect on other wavelengths and can be used to improve the bandwidth characteristics of the dielectric film. As shown in Figure 3. When the high-power laser chirped pulse of the plane wave ...

Embodiment 3

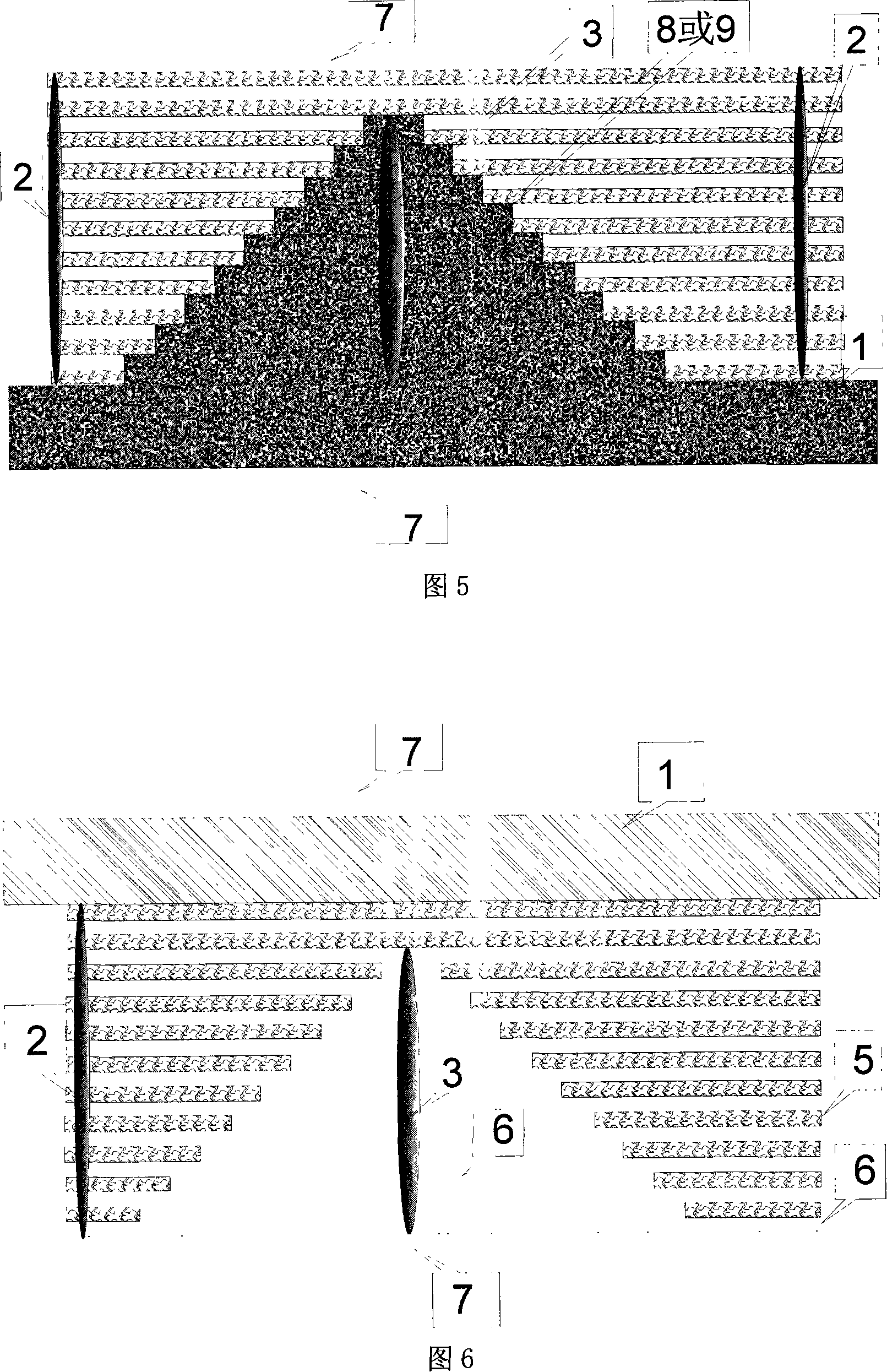

[0058] On the transparent substrate 1 , there is an outer guide protection layer 4 , and a high-reflection medium film system 2 composed of alternating high-refractive-index medium film layers 5 and low-refractive-index medium film layers 6 , and a transparent medium micro-relief structure 3 is embedded. The transparent medium is specially designed by pre-plating, and the material can be a high refractive index medium 5, or a low refractive index medium 6, or a glass medium 8, or a semiconductor medium 9, or an air medium 7, but due to the thermal coefficient of the gas, it is generally not in the film Use 7 in layer. Then etch and polish the micro-relief structure 3 on the transparent medium. Utilize the mask technology, and then plate the highly reflective dielectric film system 2, such as the usual standard λ 0 / 4 High reflection film system, because the reflection phase is required to be unchanged, so the coating steps are required to be accurately aligned vertically and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com