Device and method for testing low-permeability core starting pressure gradient at high temperature and high pressure with unsteady state method

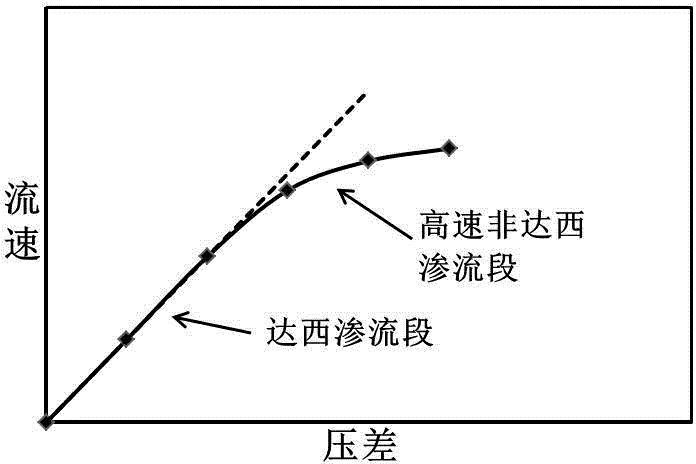

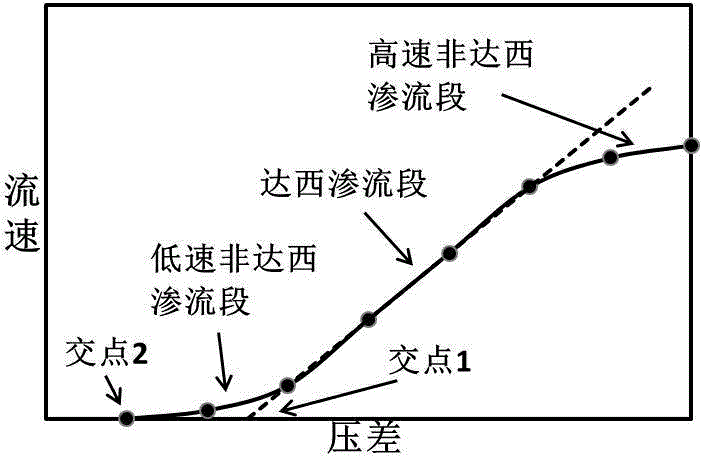

A technology of starting pressure gradient, high temperature and high pressure, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of starting pressure gradient that cannot effectively reflect the phenomenon of low-speed non-Darcy seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

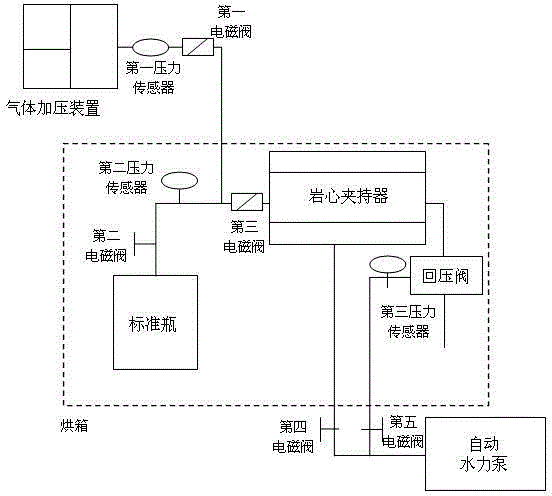

[0127] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0128] like image 3 As shown, a device for testing the starting pressure gradient of low-permeability cores with unsteady high temperature and high pressure, which includes core holders, gas pressurization devices, standard bottles, back pressure valves, automatic hydraulic pumps and controllers:

[0129] The core holder is used to hold the low-permeability core sample to be tested;

[0130] The gas pressurization device is used to provide the required pressure for the standard bottle;

[0131] The automatic hydraulic pump is used to provide the initial set back pressure for the back pressure valve and provide stable confining pressure for the core holder;

[0132] One outlet of the automatic hydraulic pump is connected to the confining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com