Patents

Literature

39results about How to "The progress of the project is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

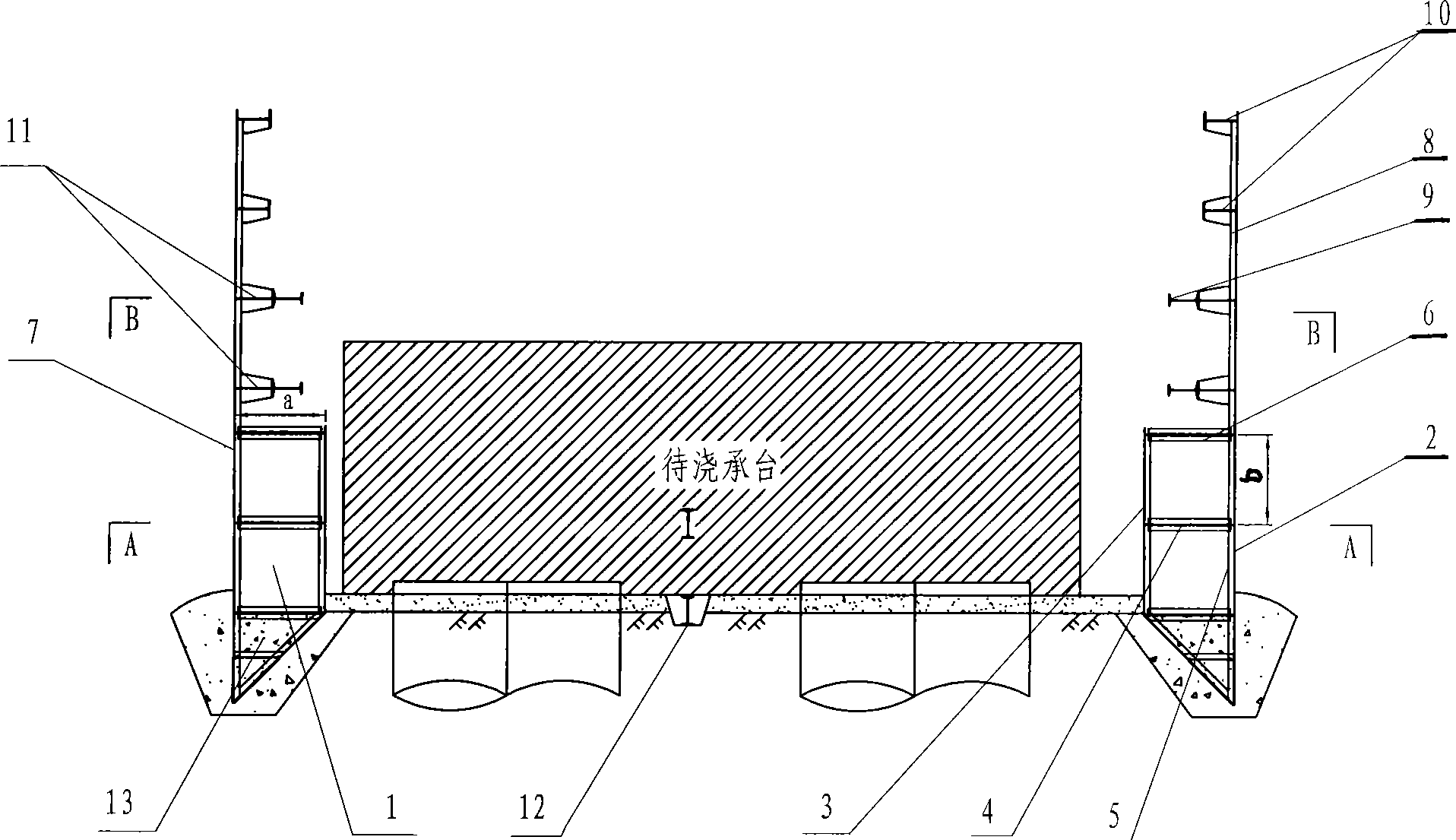

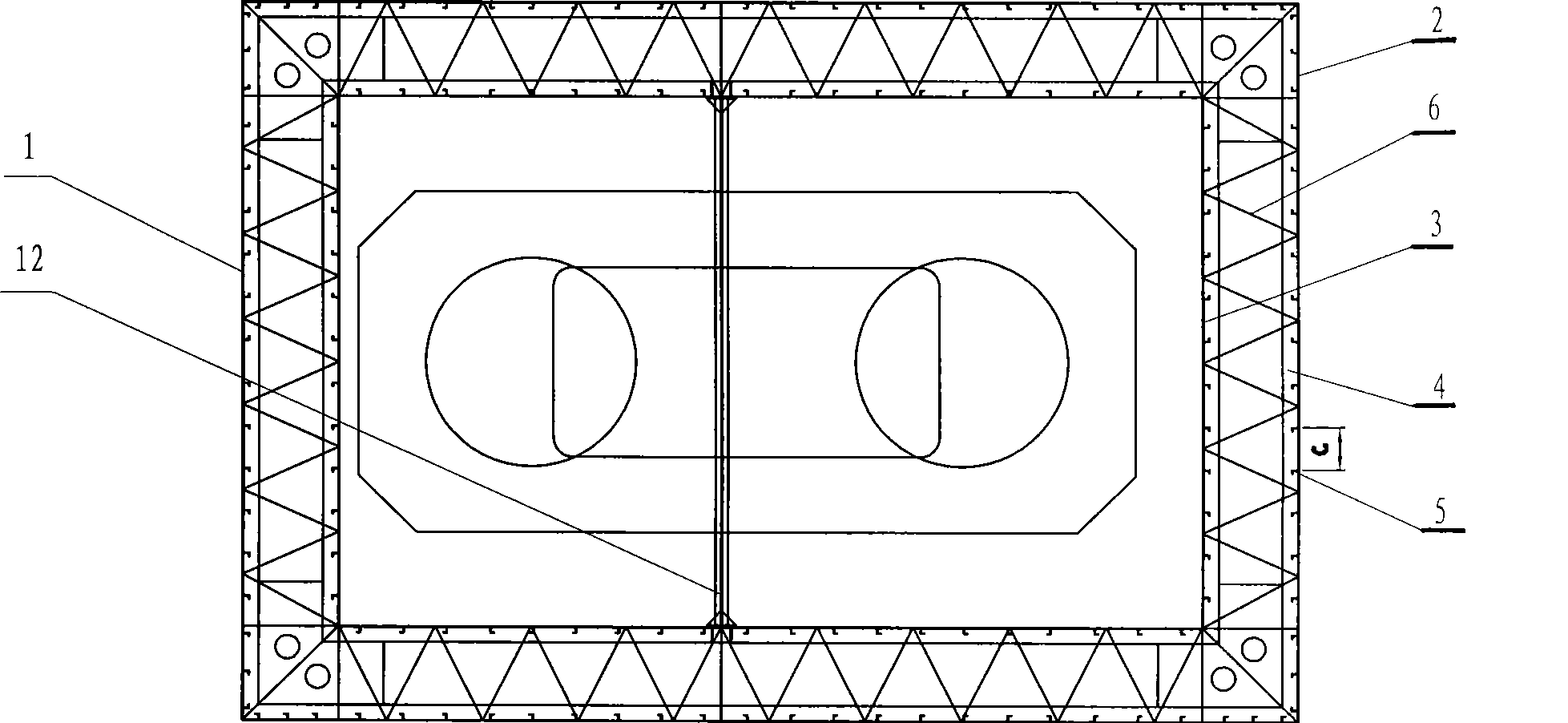

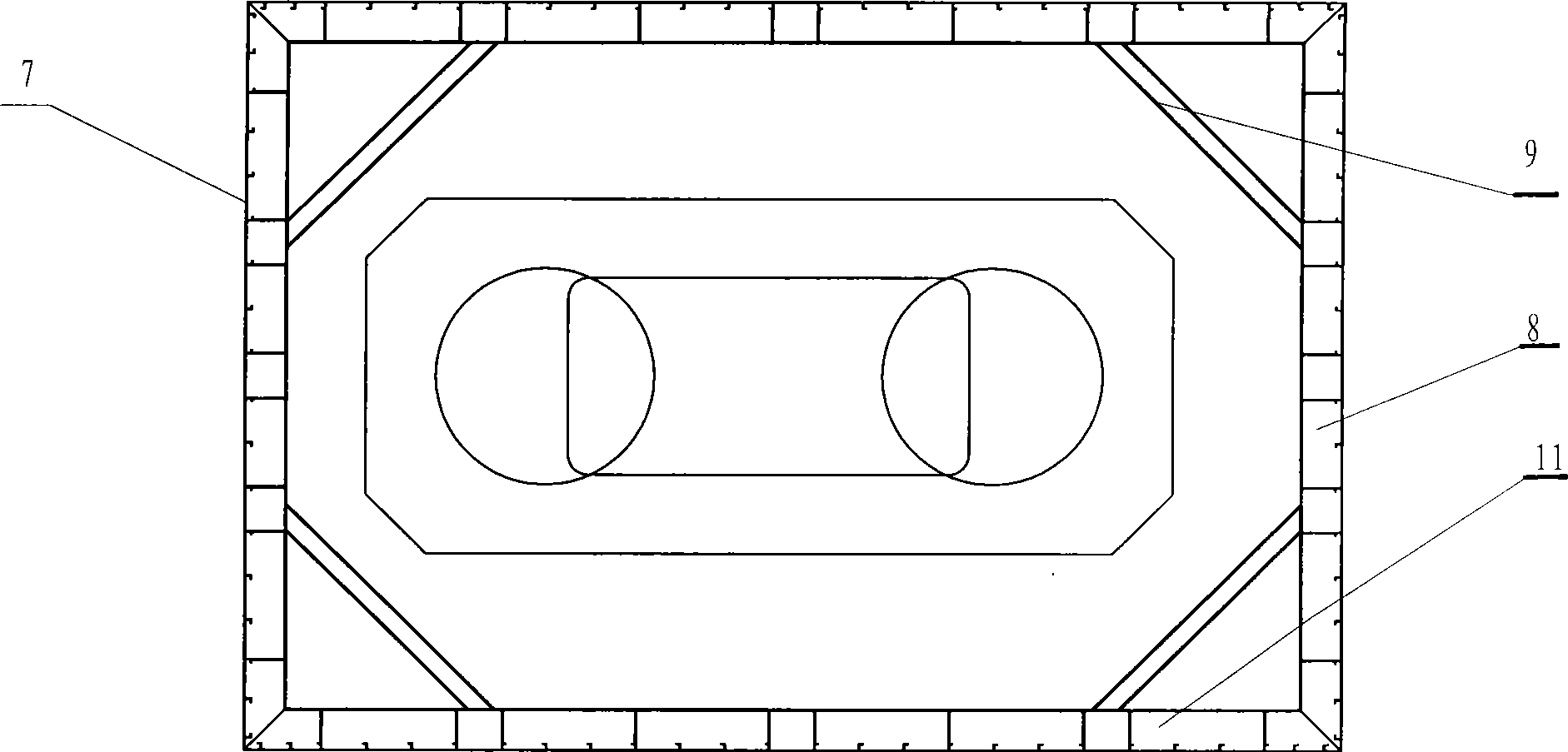

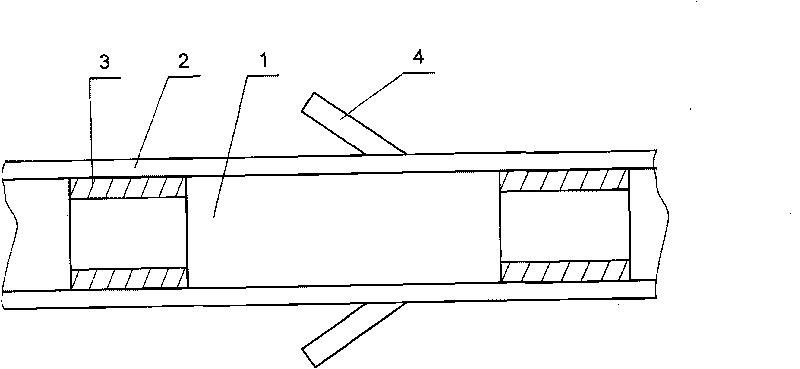

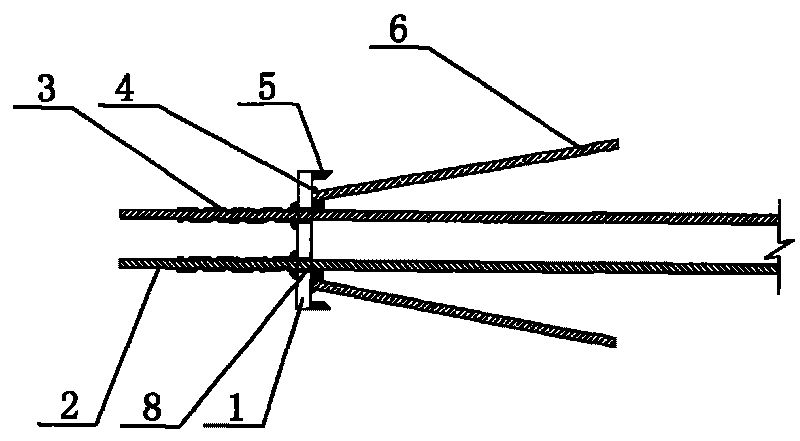

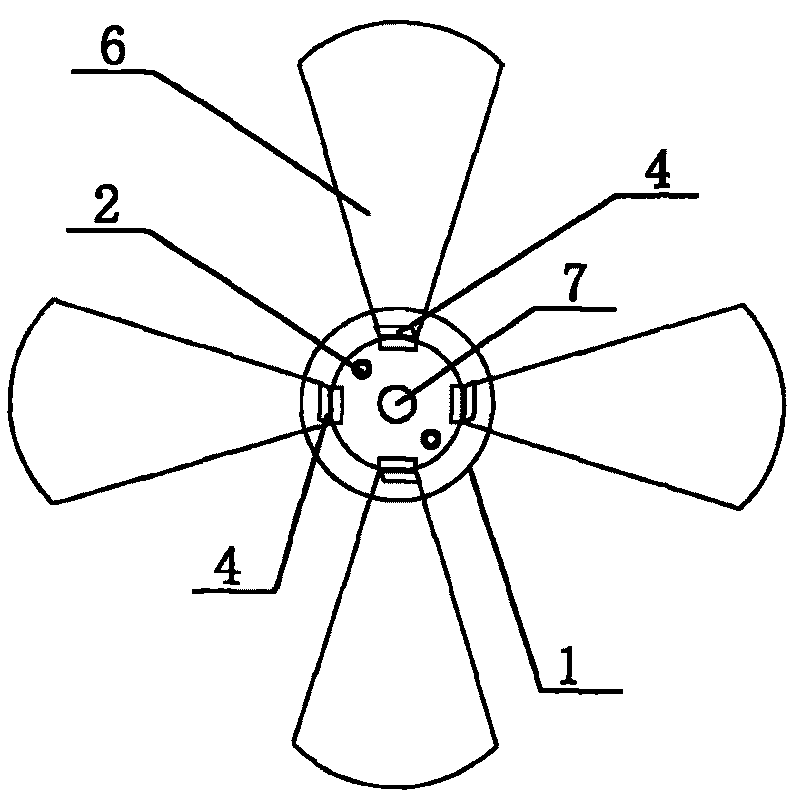

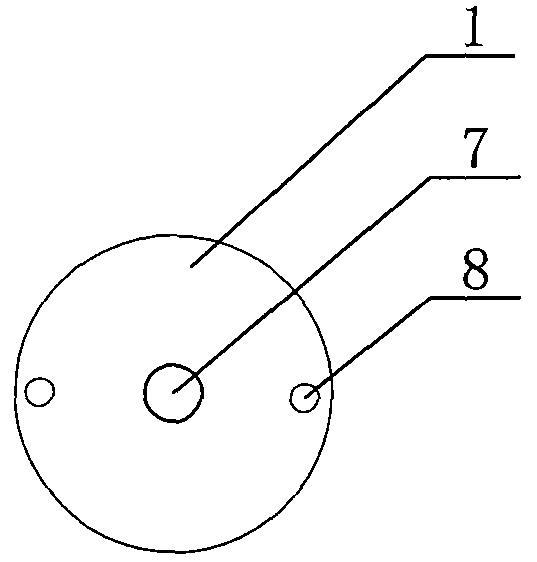

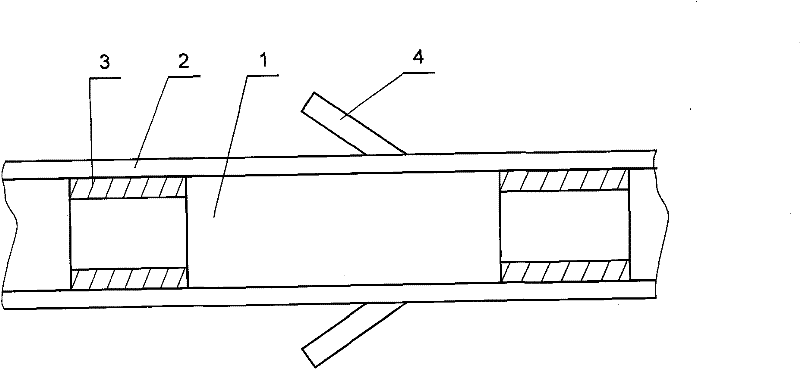

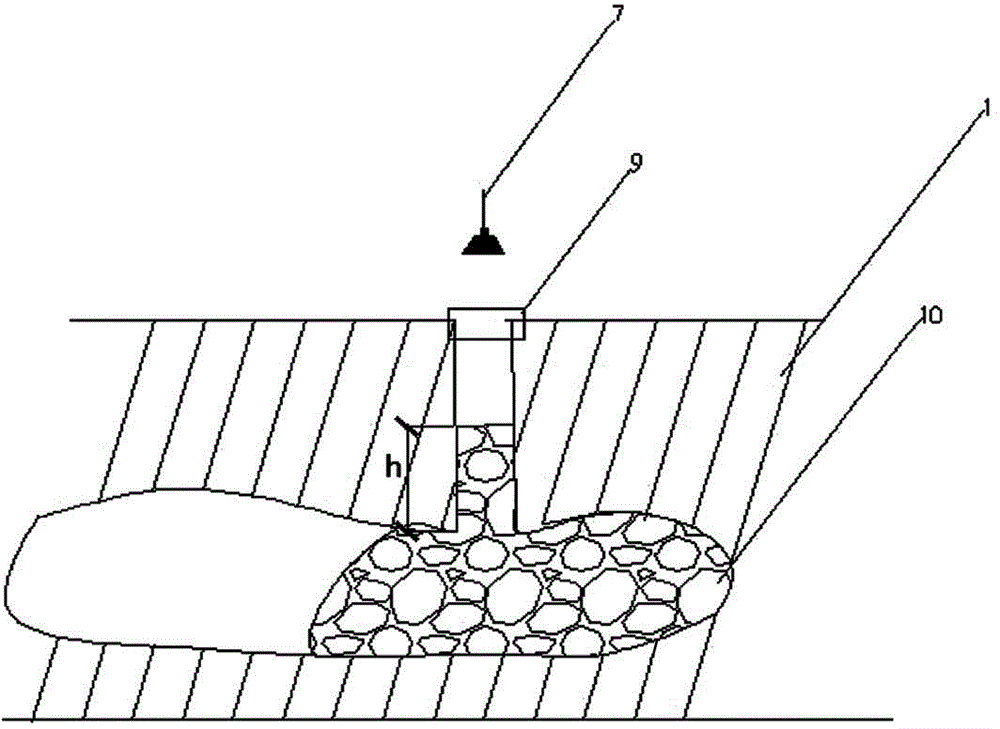

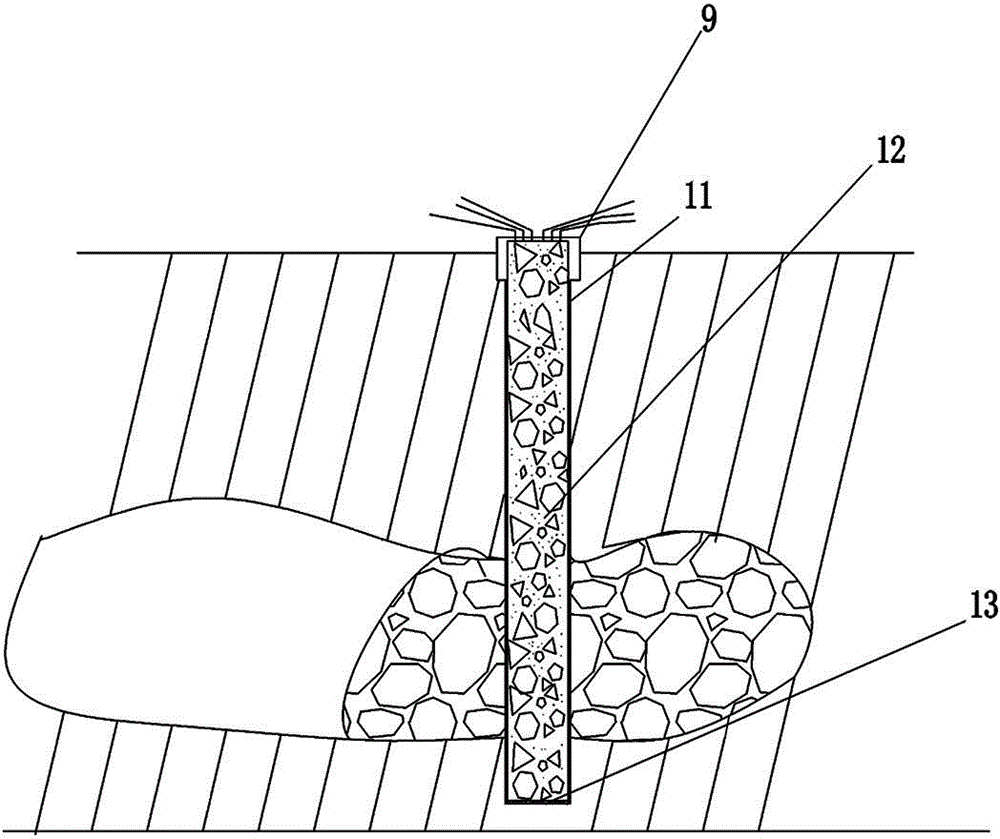

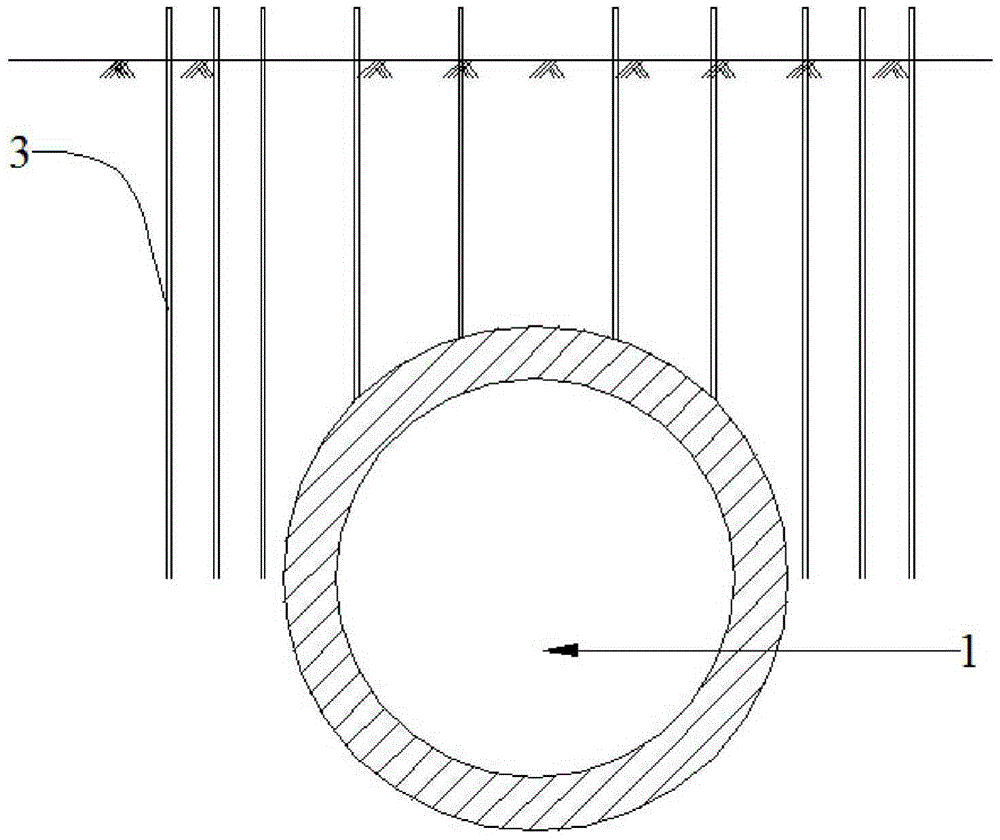

Single and double-wall combined steel cofferdam construction method and its single and double-wall combined steel cofferdam

ActiveCN101368389AThe progress of the project is fastReduce construction difficultyFoundation engineeringDouble wallCofferdam

The invention discloses a single-wall and double-wall combined steel cofferdam construction method and a single-wall and double-wall combined steel cofferdam. The single-wall and double-wall combined steel cofferdam construction method includes the following steps: firstly, assembling the bottom segment side plate of the cofferdam at an assembly field; then floating to the position of a pier; after that, injecting concrete into the foot blade and assembling the top segment of cofferdam and the top segment inclined strut; then positioning, cleaning up the pedestal, building a boring platform, installing a steel casing and stacking the sandbags sequentially; after that, injecting bottom seal concrete, and boring the pier for injection; finally, after the pier pedestal is constructed, pumping the water, cutting off the steel casing, chiseling off the laitance at the head of the pier and beginning the construction of a bearing board. The bottom segment side plate of the cofferdam is composed of circular external and internal wall panels, and the top segment side plate of the cofferdam is fixed on the circular external wall panel. The invention has the advantages of fast engineering speed, small construction difficulty and small cost investment, and the top segment side plate can be used repeatedly and is high in recovery rate; the invention overcomes the difficulties at the time of no bottoming concrete thickness; the circular sealing concrete between the bearing board and the cofferdam also has the effect of resisting water.

Owner:THE 5TH ENG MBEC

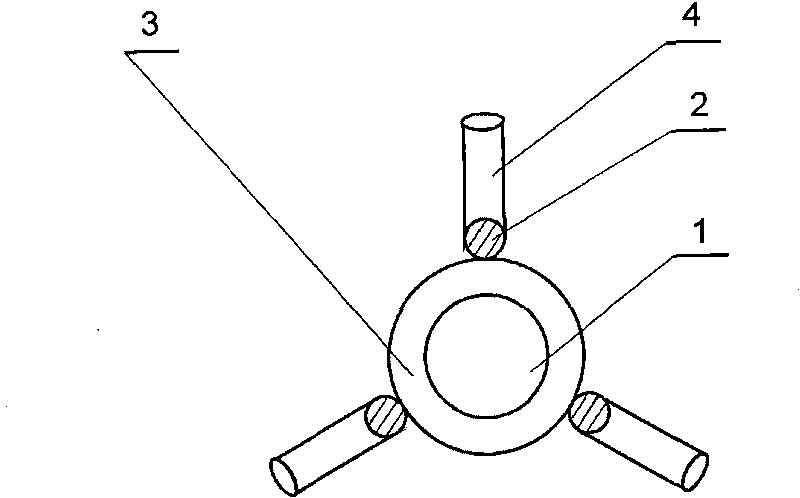

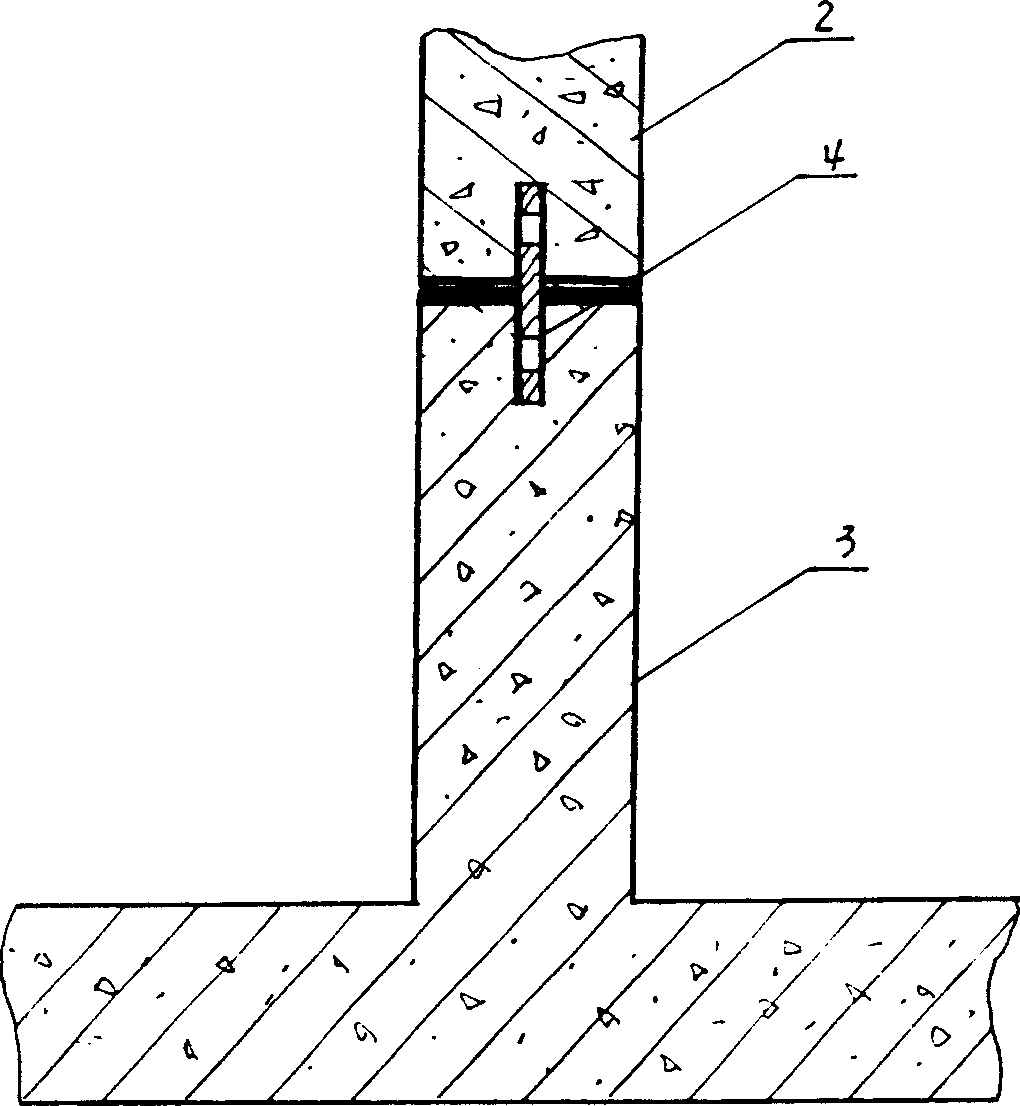

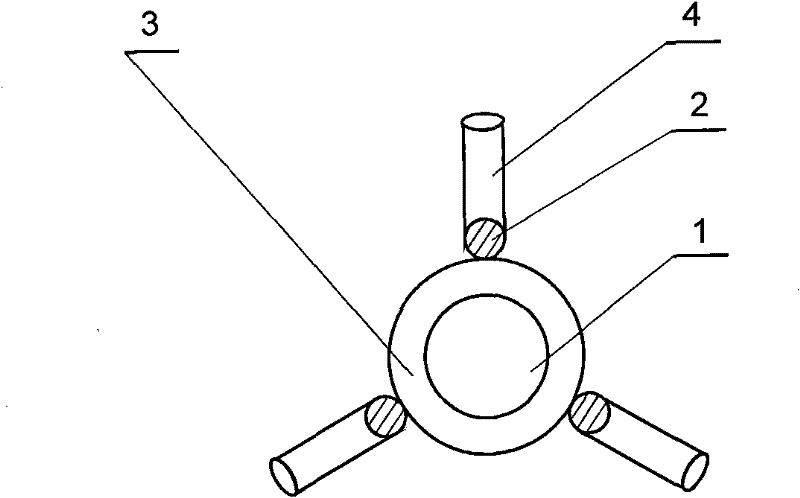

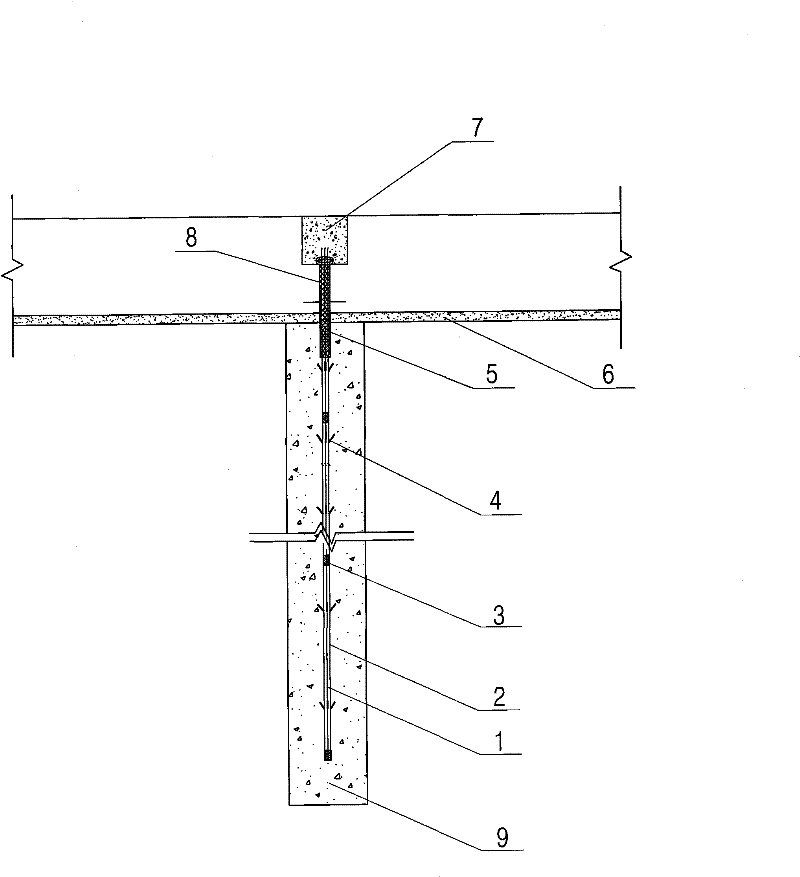

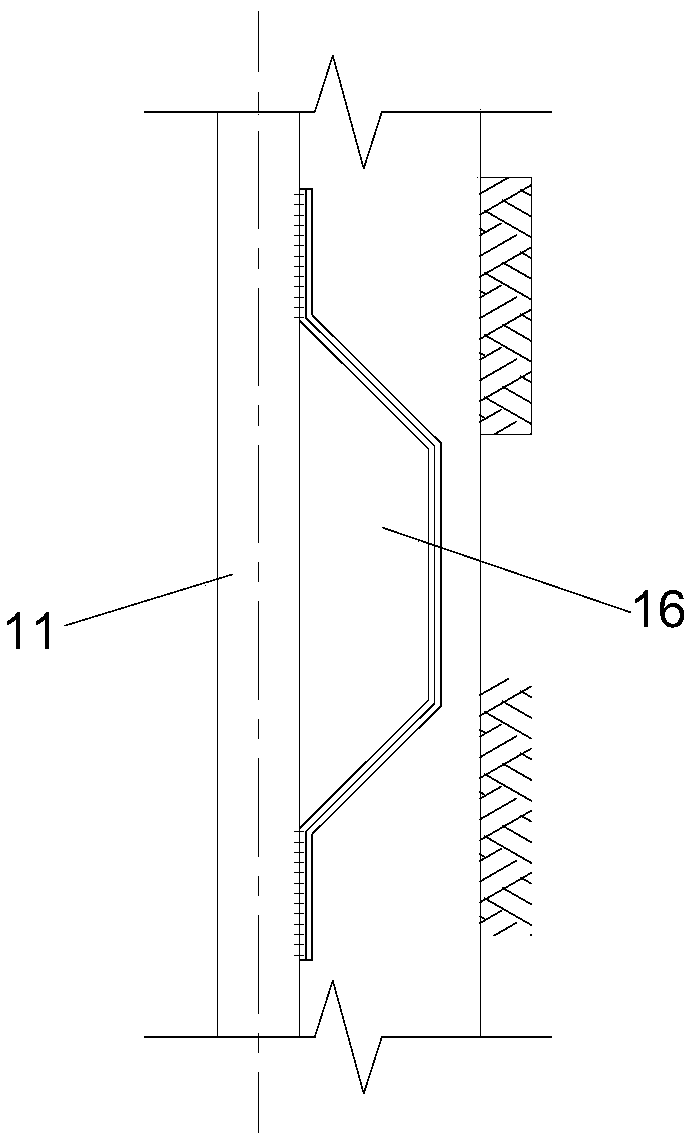

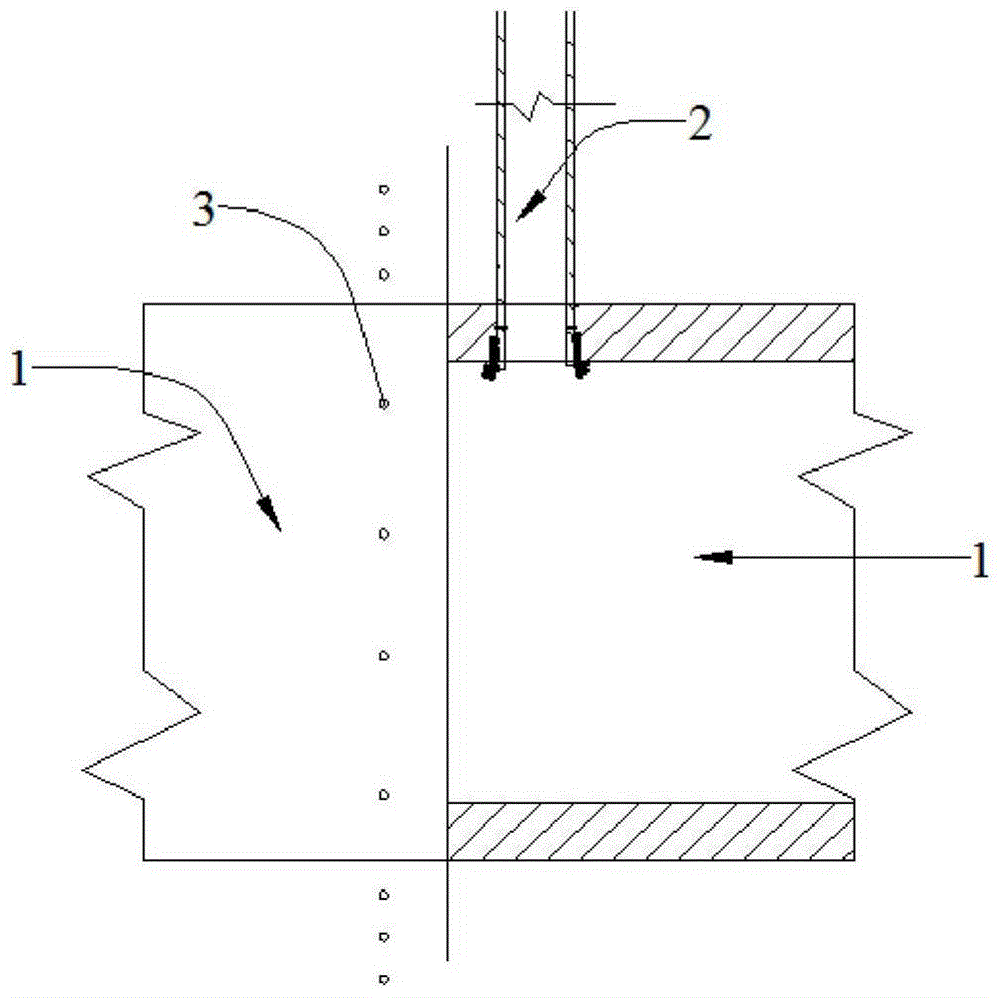

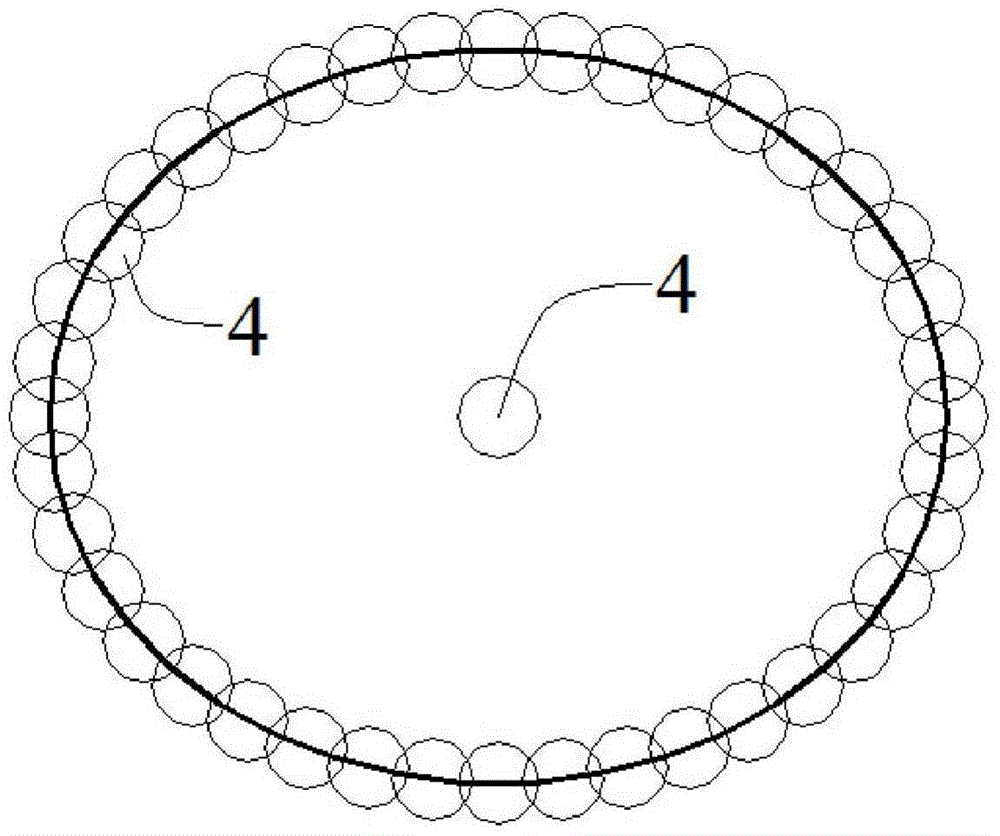

Prestressed anti-floating anchor rod and construction method thereof

ActiveCN101736760AIncrease frictionImprove anti-floating effectProtective foundationBuilding material handlingPre stressConfined water

The invention discloses a prestressed anti-floating anchor rod and a construction method thereof. The invention is characterized in that alignment steel tubes are arranged in an anchor rod body which is formed by a plurality of steel bars uniformly distributed along the circle, the steel bars are provided with a plurality of barbs, the alignment steel tubes are arranged at intervals along the axis of the anchor rod body and are fixedly connected with the steel bars, the barbs are welded with the steel bars. The construction method comprises the following steps: grouting into piles; arranging the anchor rod; locking the anchor rod; and sealing the anchor. Compared with the prior art, the invention has the advantages of simple structure, convenient construction, good anti-floating effect and low cost, especially being applicable to the reconstruction of old buildings with built underground structures and confined water.

Owner:SHANGHAI ZHIPING FOUNDATION ENG CO LTD

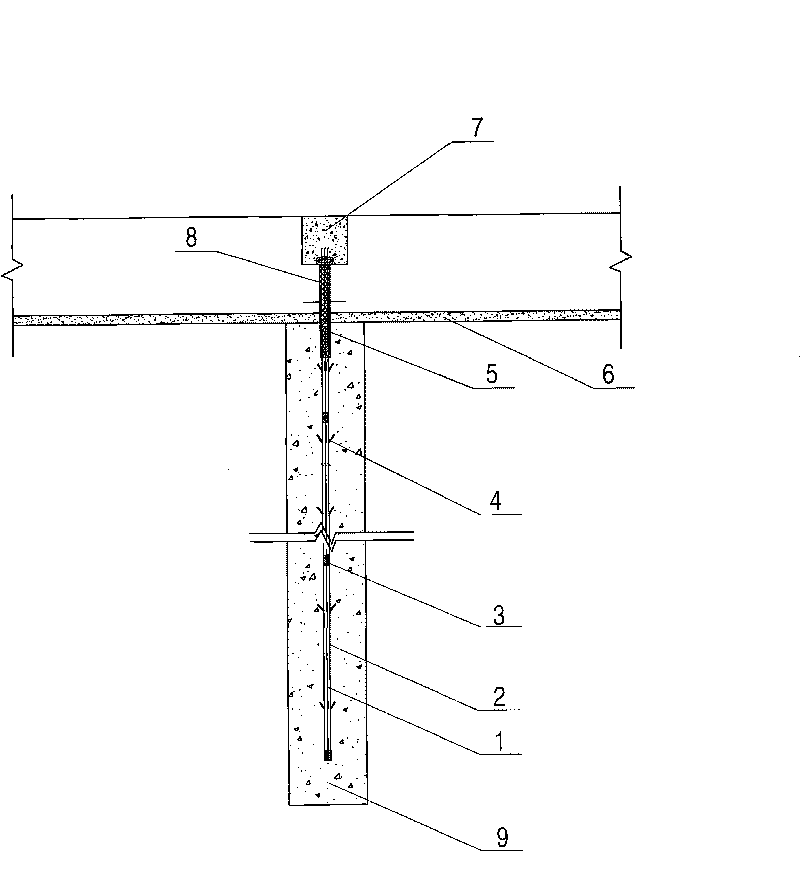

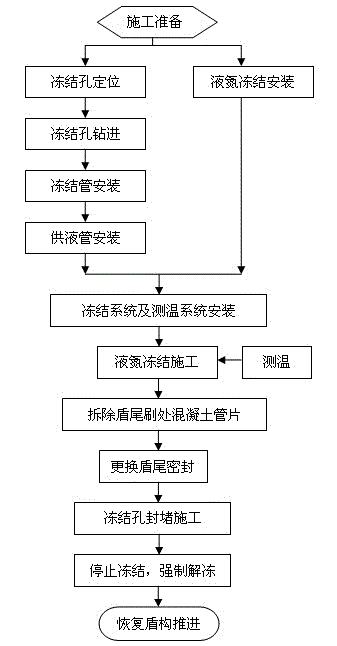

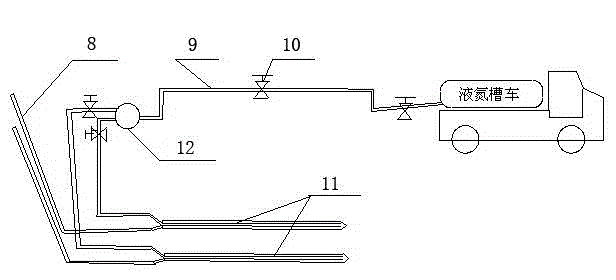

Method for replacing tail brush in shield tunnel through liquid nitrogen freezing

The invention relates to a maintenance method for shield equipment and discloses a method for replacing a tail brush in a shield tunnel through liquid nitrogen freezing. The method comprises the following processing steps: 1, preparation of construction; 2, construction of freezing holes; 3, installation of a freezing system and a temperature measuring system; 4, construction of liquid nitrogen freezing; 5, construction of sealing maintenance of a shield tail; 6, construction of formation sealing of the freezing holes; 7, construction of forced thawing; and 8, construction of propulsion of shield recovery. According to the invention, stratum is frozen through a liquid nitrogen freezing method to form a frozen curtain, so that the defect of indeterminacy of a traditional grouting method for carrying out the treatment of stratum consolidation and water sealing to bearing pressure permeable stratum can be avoided; and the method has the advantages of high strength, good uniformity, good water-resisting property and the like.

Owner:CHINA RAILWAY TUNNEL

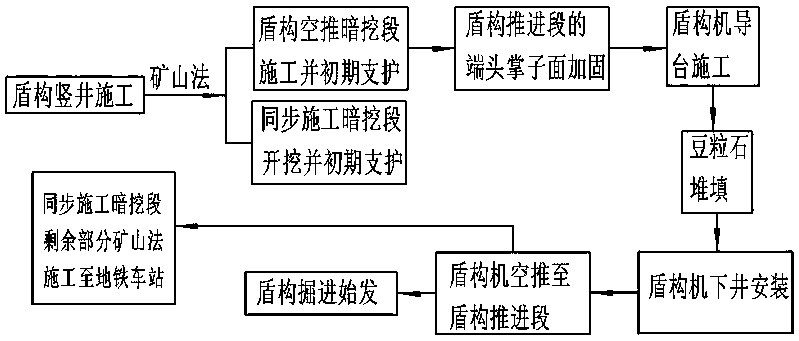

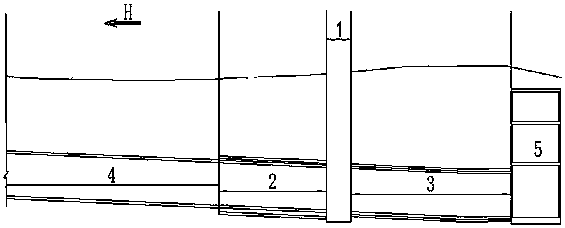

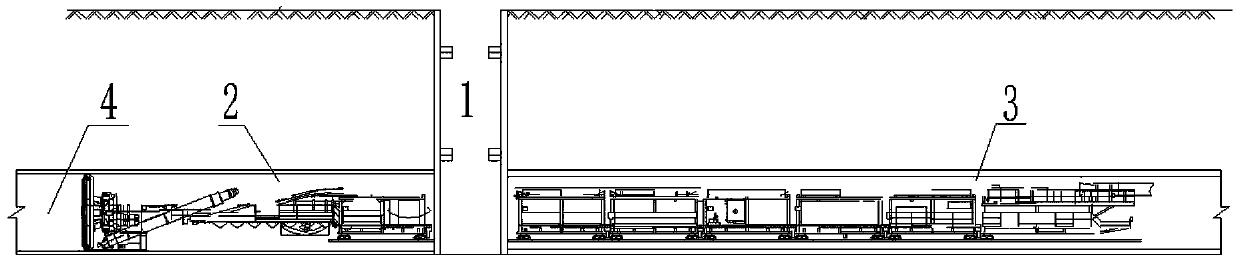

Method for constructing subway tunnel with complicated geology and without shield launching site

PendingCN107725060AReduce wearSpeed up the progress of the projectUnderground chambersTunnel liningEngineeringSubway station

The invention relates to the technical field of subway construction, in particular to a method for constructing subway tunnel with complicated geology and without shield launching site, which solves the problems of complicated geology in the subway section and failure to provide shield launching site on time in the exiting subway construction process. The method comprises the following steps of arranging a shield inclined shaft in a preset tunnel section; respectively constructing a shield empty-push hidden excavation section and a synchronous-construction hidden excavation section at both ends of the shield inclined shaft by a mine method, and timely applying primary support; connecting the shield empty-push hidden excavation section to a shield tunneling section; enabling a shield body and subsequent auxiliary equipment which are lowered and assembled by the shield inclined shaft to respectively adopt the splitting launching type to arrive at the shield pushing section via the shieldempty-push hidden excavation section, and performing shield tunneling launching; excavating the synchronous-construction hidden excavation section to a subway station by the mine method. The subway tunnel construction method has the advantages that compared with single shield construction method, the advantages of various working methods are fully played; the abrasion of a tool disc is reduced, the condition of frequent bin opening for tool replacing is avoided, the safety risk is decreased, the construction progress is quick, and the like.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

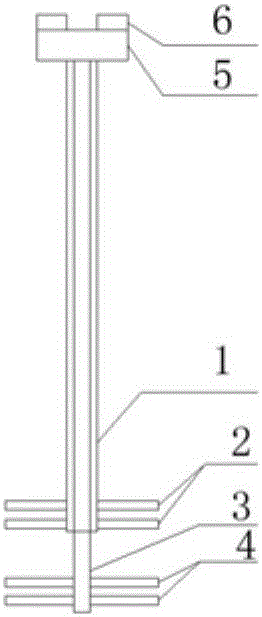

Recyclable prestressed tendon for soft oil support and construction method thereof

The invention discloses a recyclable prestressed tendon for soft oil support and a construction method thereof. The prestressed tendon comprises: an anchor plate, a steel strand, an anchor end lock and loaded plates, wherein the anchor plate is circular and one side of the plate is provided with a plurality of loaded plate and strand holes evenly along the periphery, and the circle center of the plate is provided with a grouting hole; the anchor end lock is tubular and fixedly arranged on the strand hole at one side of the anchor plate; the loaded plate takes the shape of a vane and is movably connected with the anchor by a hinge; two sides of the hinge are provided with a limit plate fixedly connected with the anchor plate; and the steel strand penetrates into the strand hole to be compressed and connected with the anchor end lock fixedly arranged on the anchor plate. The construction method includes the following steps: digging a base pit and forming pores; arranging the tendon; locking the tendon; and recovering the steel strand. The prestressed tendon and the method are simple in structure and convenient for construction and compared with the prior art, have the advantages of no support structure in the base pit, convenience for digging soil body, no problems that underground barriers appear and building construction crosses the building line, the recyclable tendon for support, fast progress of works and high work efficiency.

Owner:SHANGHAI ZHIPING FOUNDATION ENG CO LTD

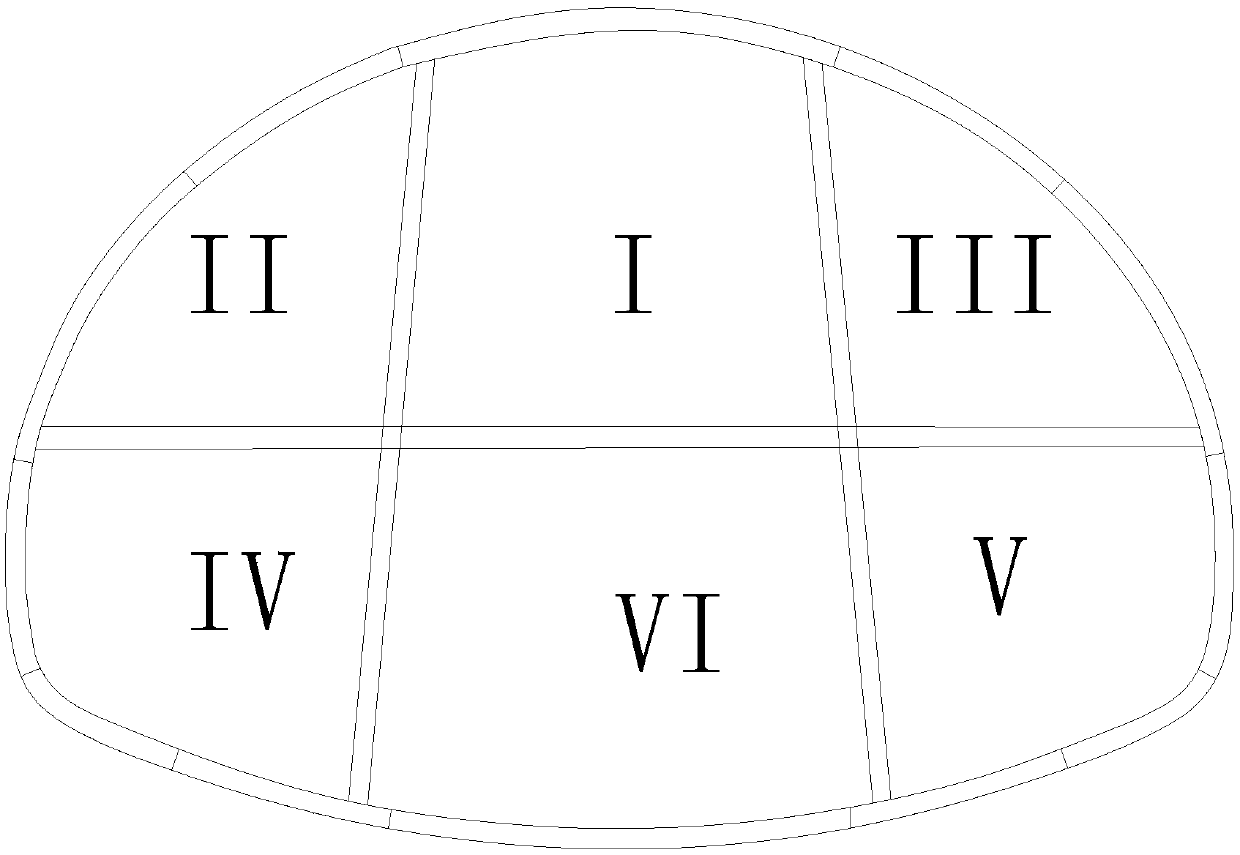

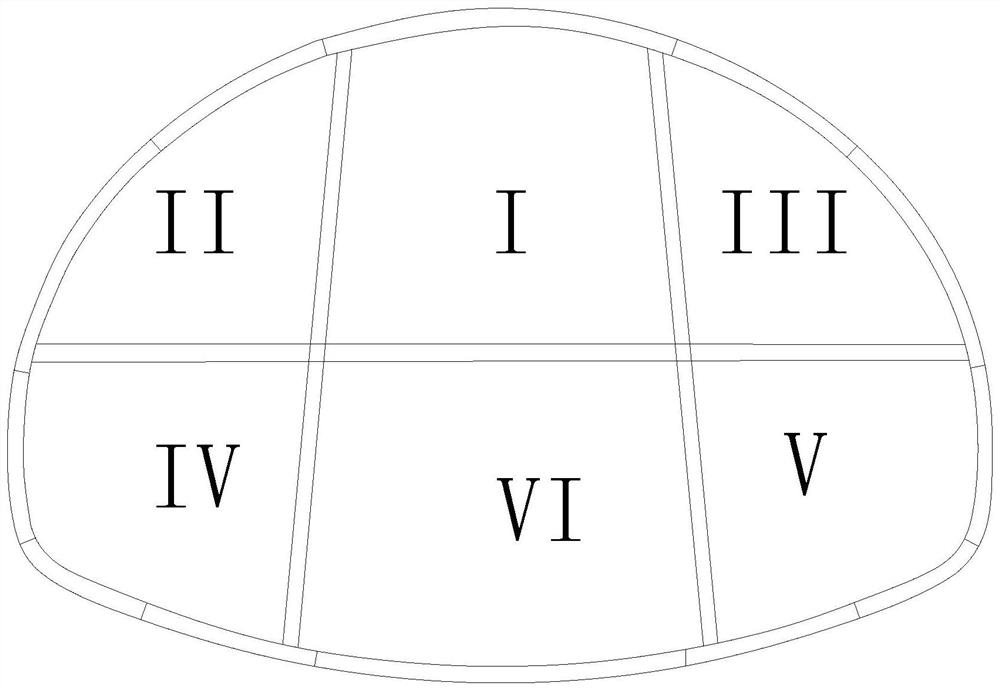

Tunnel two-expansion four-expansion excavation method

ActiveCN109595004AWide adaptability to terrainReduce sinkingUnderground chambersTunnel liningArchitectural engineeringRock tunnel

The invention relates to the field of tunnel excavation. The invention relates to a tunnel expanding excavation method. The method comprises IV-level and V-level surrounding rock tunnel construction methods and further includes an III-level surrounding rock tunnel construction method. The IV-level surrounding rock tunnel and the V-level surrounding rock tunnel construction methods comprise the following construction steps that an excavated tunnel is partitioned, and the excavation tunnel comprises a first part in the middle of an arch crown, a second part on the left side of the first part, athird part on the right side of the first part, a fourth part on the lower side of the second part, a V part on the lower portion of the third part and a VI part on the first part. According to the construction methods, double-side-wall partial excavation is adopted, and the excavation mode of first arching and then wall excavation has the advantages that the arch crown sinking is minimum, the horizontal displacement is small, the temporary supporting axial force is minimum, supporting is reliable, and the project progress is fast. And the scheme is very suitable for expanding excavation construction of tunnels with ultra-large spans, ultra-large sections and small intervals, the construction safety is high, and the phenomena of collapse and the like are avoided.

Owner:浙江省隧道工程集团有限公司

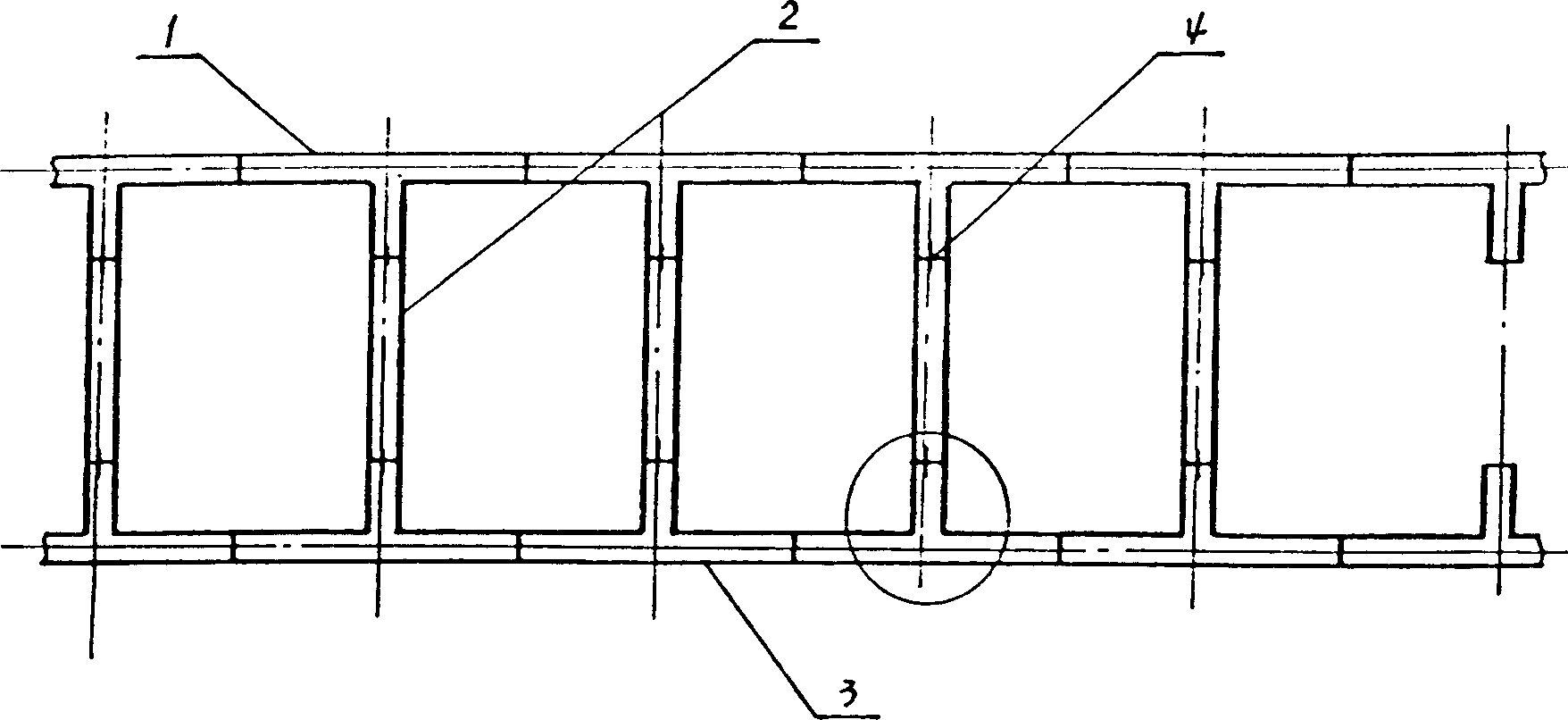

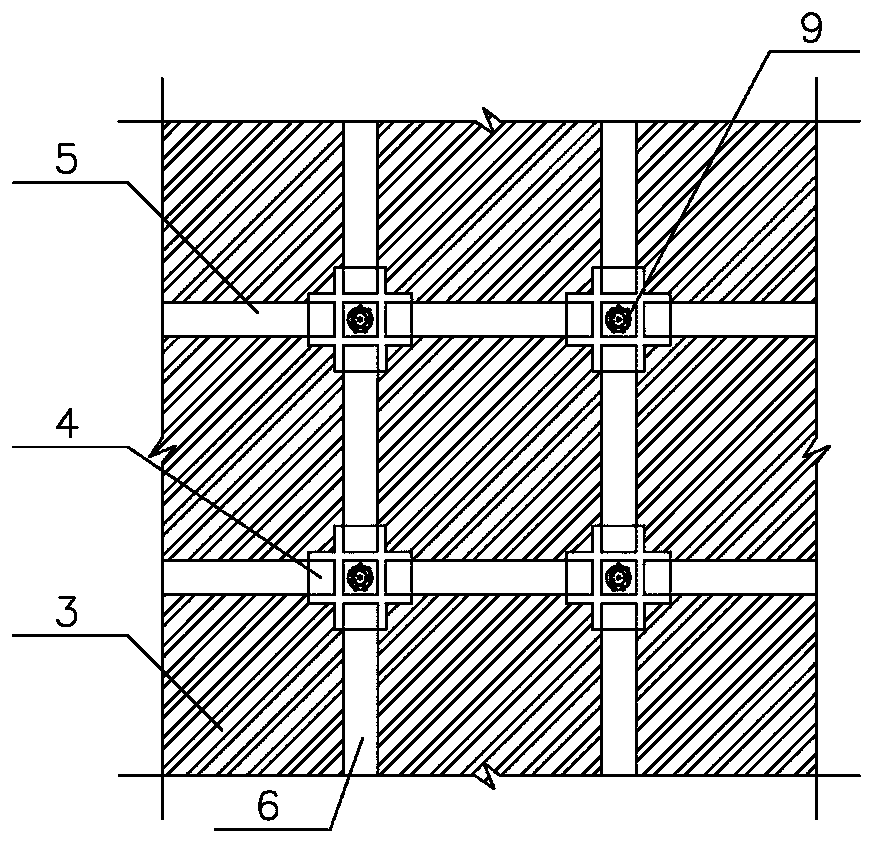

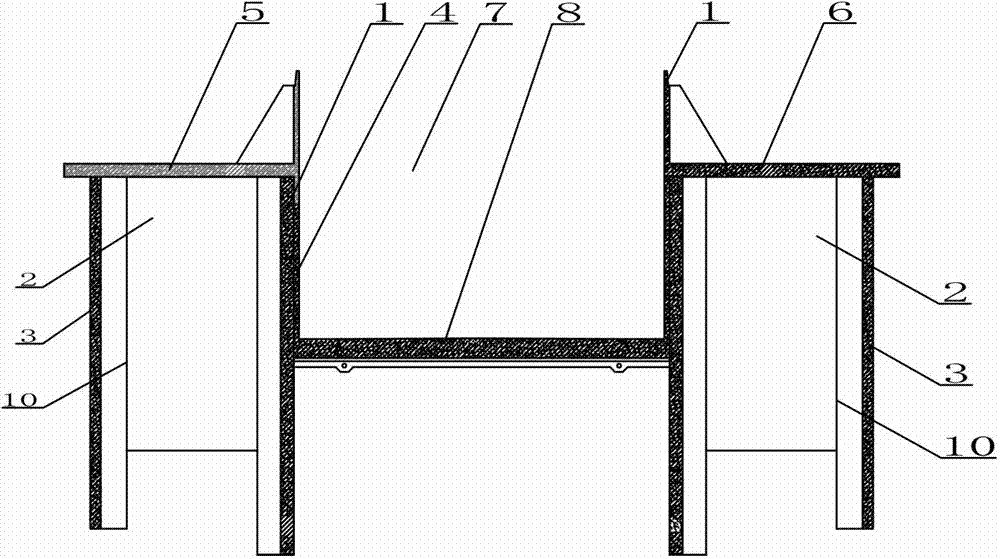

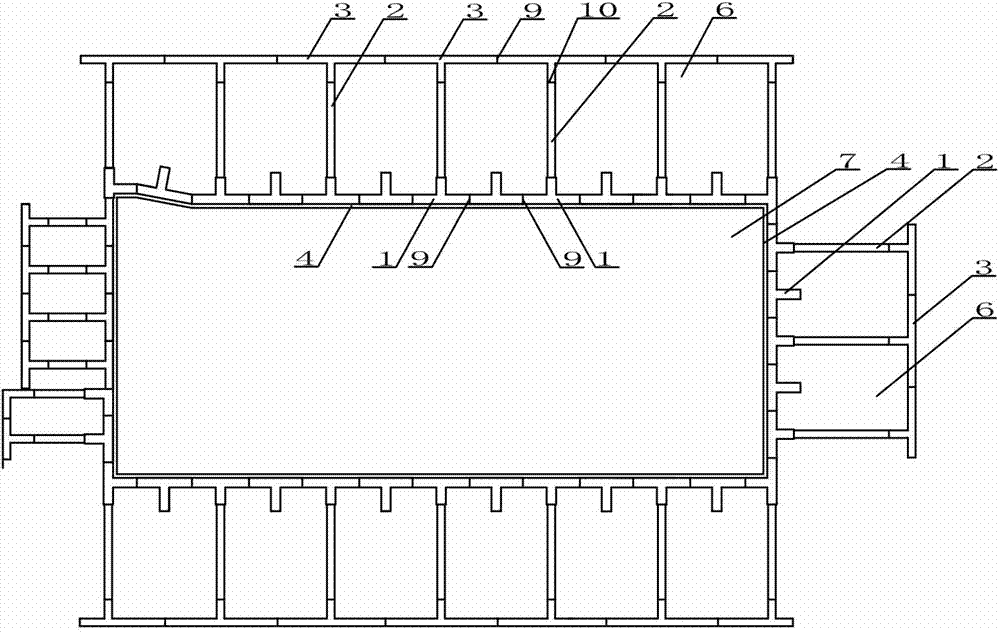

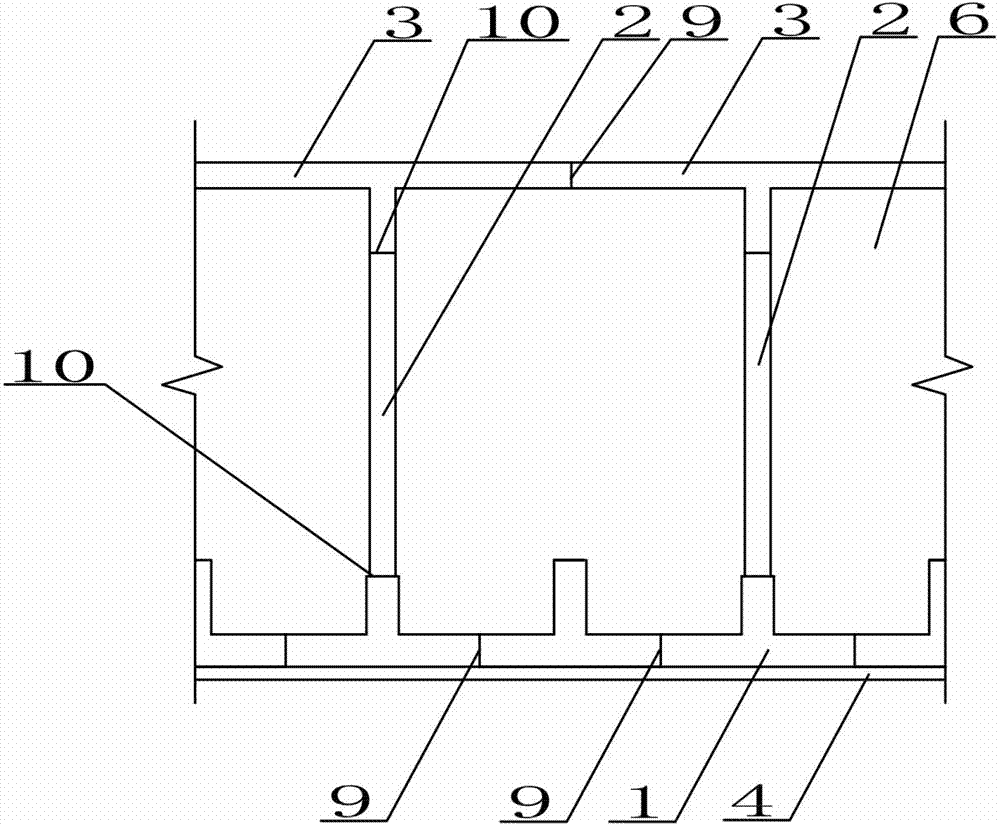

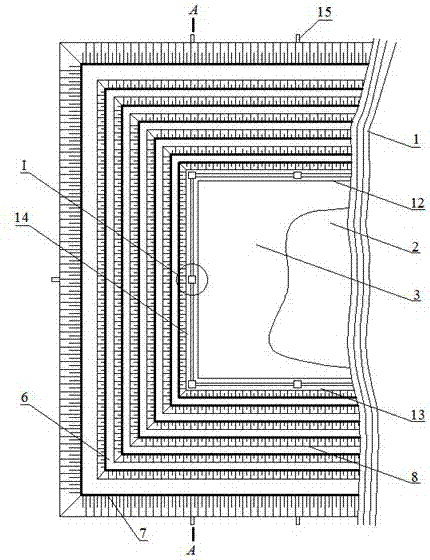

Self-erecting guard wall structure of grid underground wall

InactiveCN1896384AReduce the impactStrong anti-seepage abilityArtificial islandsUnderwater structuresEngineeringStructural engineering

The present invention discloses a free-standing encasing structure of grid ground wall that consists of inner ground wall, middle ground wall, outer ground wall, punched steel plates and top plates. The section of the inner ground wall is of a serial T-shapes, the section of the outer ground wall is also a series of T shapes and is corresponding to the T-shaped sections of the inner ground wall. Between corresponding T sections is traverse I-shaped middle ground wall that is connected to corresponding T sections via punched steel plates. The top plates are positioned on the top of the inner, middle and outer ground wall. This invention has strong resistance to incline, slide and seepage, meets the needs of structural and environmental safety, and has the advantages of holistic stability, strong resistance to apophysis, little distortion on digging, slight effects on the environment and wide application range.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Construction method of prestressed anti-floating anchor rod

ActiveCN101736760BIncrease frictionImprove anti-floating effectProtective foundationBuilding material handlingConfined waterPre stress

The invention discloses a prestressed anti-floating anchor rod and a construction method thereof. The invention is characterized in that alignment steel tubes are arranged in an anchor rod body which is formed by a plurality of steel bars uniformly distributed along the circle, the steel bars are provided with a plurality of barbs, the alignment steel tubes are arranged at intervals along the axis of the anchor rod body and are fixedly connected with the steel bars, the barbs are welded with the steel bars. The construction method comprises the following steps: grouting into piles; arranging the anchor rod; locking the anchor rod; and sealing the anchor. Compared with the prior art, the invention has the advantages of simple structure, convenient construction, good anti-floating effect and low cost, especially being applicable to the reconstruction of old buildings with built underground structures and confined water.

Owner:SHANGHAI ZHIPING FOUNDATION ENG CO LTD

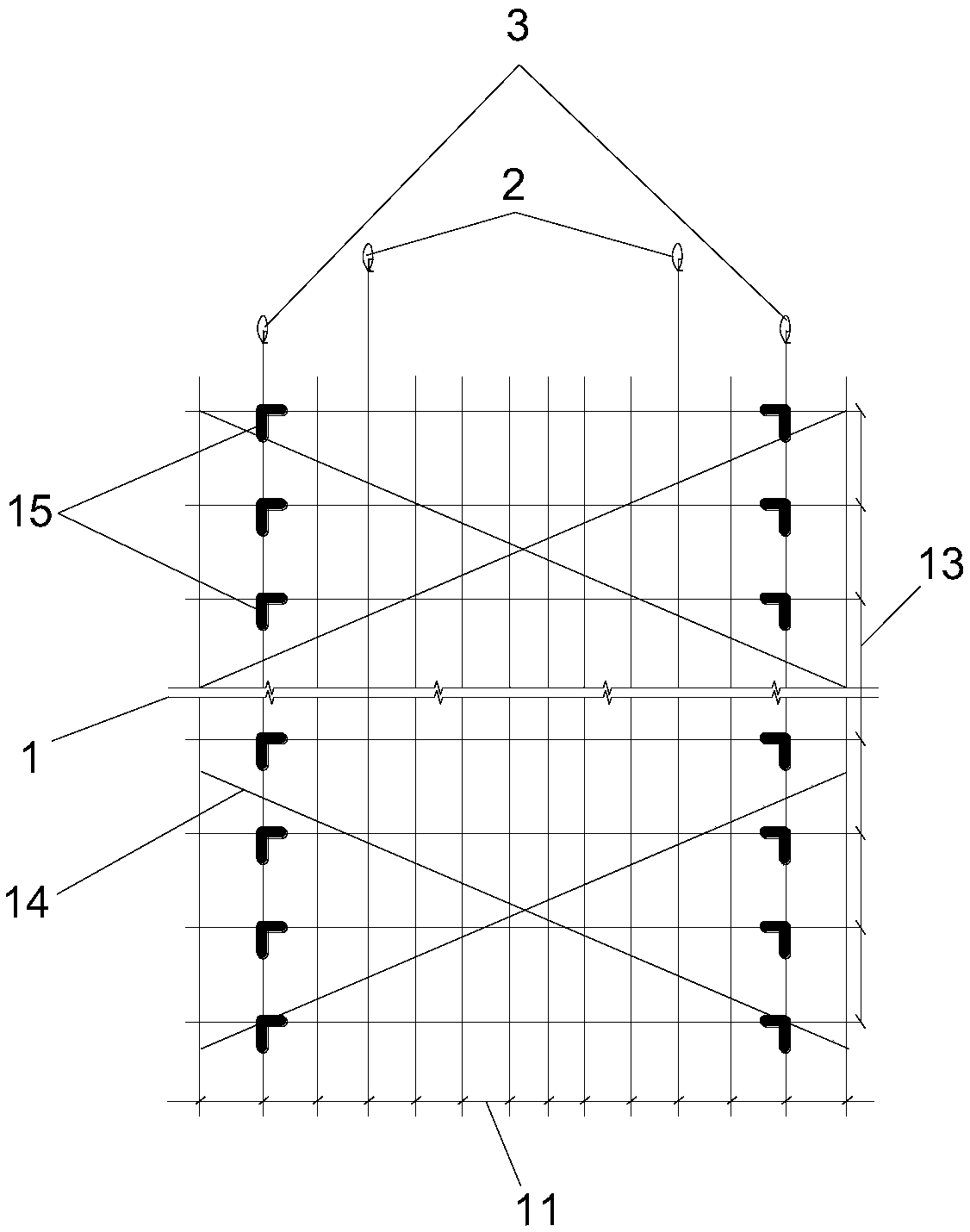

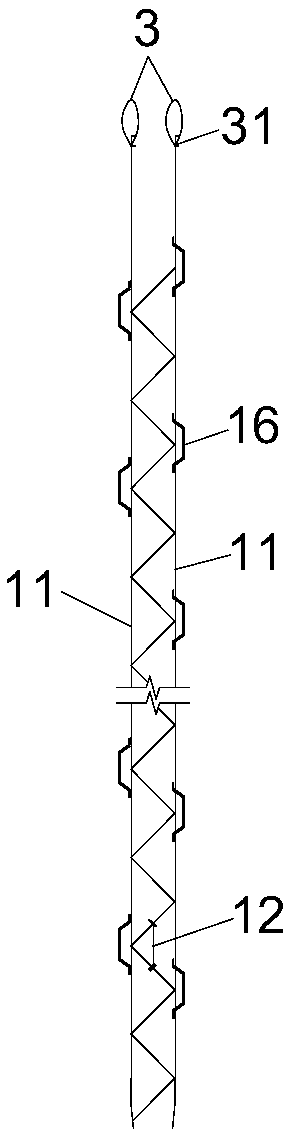

Retaining-wall reinforcement cage for traversing underground pipelines and construction method thereof

ActiveCN108867622ASolve construction difficultiesAvoids the need to span pipelinesBulkheads/pilesInterference factorSmall footprint

The invention discloses a retaining-wall reinforcement cage for traversing underground pipelines and a construction method thereof. The retaining-wall reinforcement cage comprises a reinforcement cageframework, primary suspension point groups and secondary suspension point groups, wherein the secondary suspension point groups are arranged on two sides of one end of the reinforcement cage framework; and the primary suspension point groups are arranged at an end of the reinforcement cage framework between the secondary suspension point groups. The construction method comprises the steps of slotting, suspending movement by use of the primary suspension point groups, suspending movement by use of the secondary suspension point groups and final accomplishment of construction. Owing to variations of positions of suspension points and transverse swinging movement in a slot, the retaining-wall reinforcement cage is prevented from stretching across the underground pipelines. The problem that aretaining wall is difficult to construct in a pipeline dense area can be effectively solved. The retaining-wall reinforcement cage has the advantages that an occupied area is small, a site is easy toarrange, the progress of works is high, interference factors are less and exiting facilities around are guaranteed to be in a perfect condition.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD +1

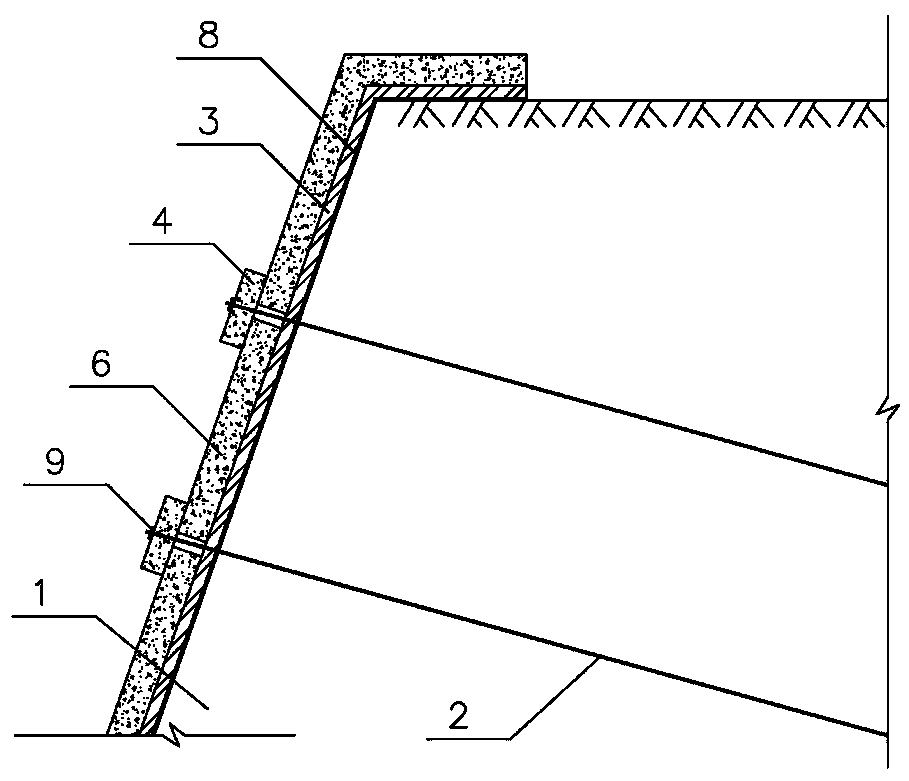

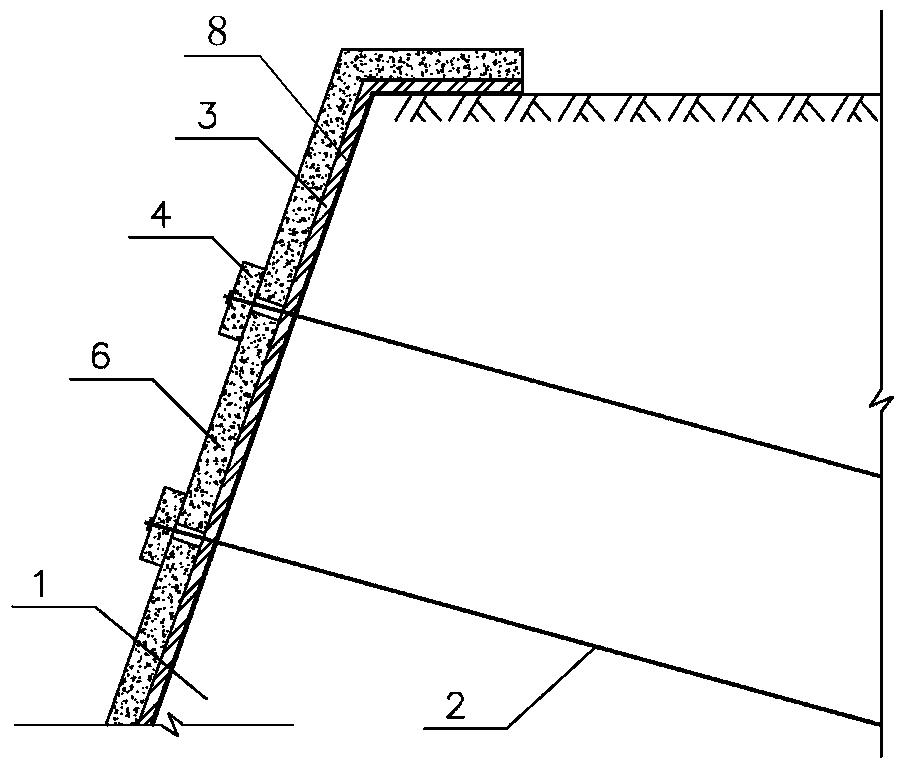

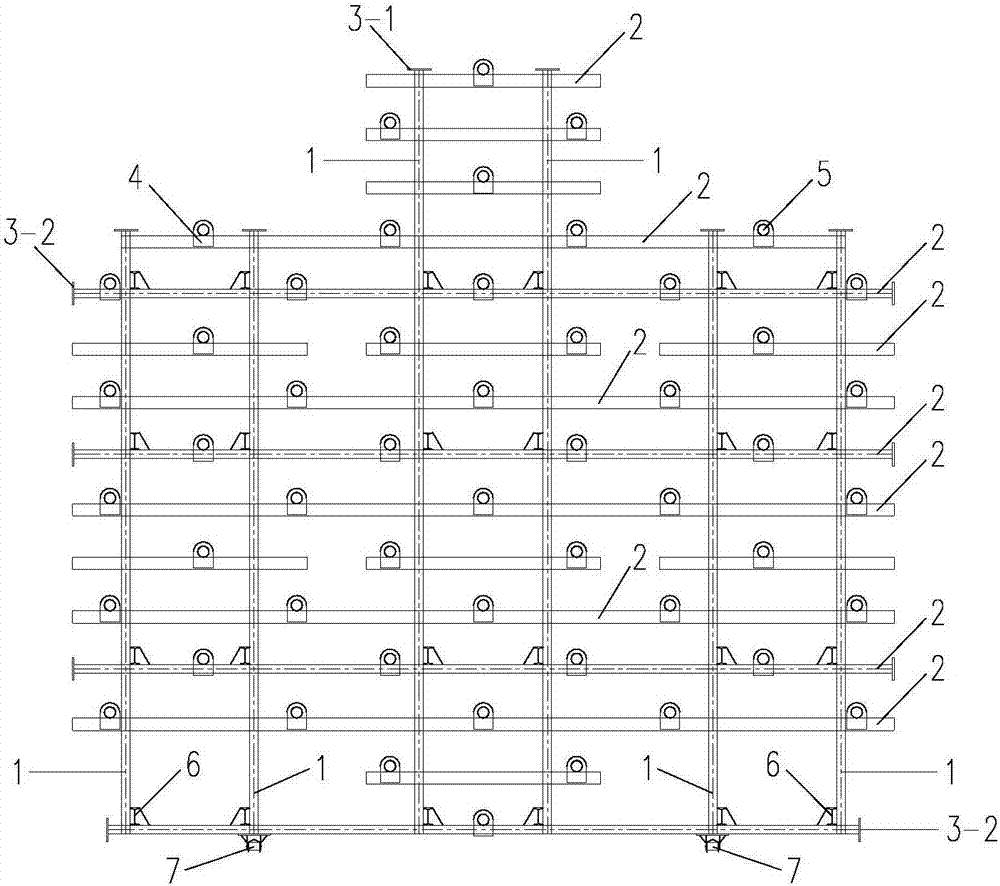

Flexible surface layer fabricated soil nail wall structure for foundation pit slope and construction method of flexible surface layer fabricated soil nail wall structure

The invention provides a flexible surface layer fabricated soil nail wall structure for a foundation pit slope and a construction method of the flexible surface layer fabricated soil nail wall structure. Soil nails, flexible surface layers, prefabricated connecting pieces, horizontal beams and inclined beams are included; the flexible surface layers are laid on the side slope; the prefabricated connecting pieces comprise pressing plates and convex blocks; the pressing plates comprise horizontal edges and vertical edges; the convex blocks are arranged at the cross points of the pressing plates,and the vertical sections of the convex blocks are square or rectangular; the prefabricated connecting pieces are arranged in a matrix mode; the convex blocks are vertically pressed on the flexible surface layers; at least one positioning installation hole passage is arranged on the middle part of each prefabricated connecting piece, the horizontal beams are correspondingly arranged between the adjacent prefabricated connecting pieces in the horizontal direction, two ends of the horizontal edges of the pressing plates are pressed on the horizontal beams on both sides; the inclined beams are correspondingly arranged between the adjacent prefabricated connecting pieces in the inclined direction, two ends of the vertical edges of the pressing plates are pressed on the inclined beams on two sides, and the soil nails are correspondingly arranged in the positioning installation hole passages of the prefabricated connecting pieces in a penetrating mode. The technical problems of unclear force mechanism, weak force at joints, waste of building materials, poor environmental protection and low construction efficiency of a traditional soil nail wall structure are solved.

Owner:JIAN YAN FOUND ENG

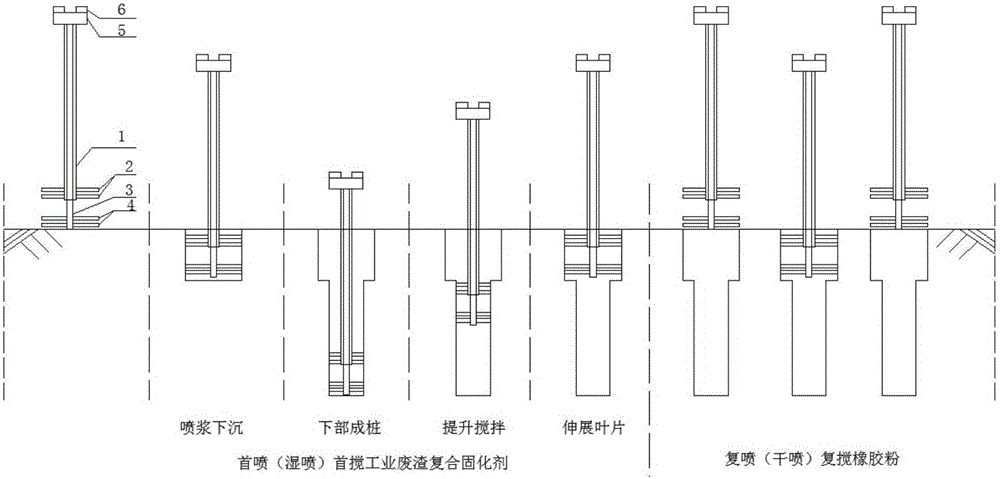

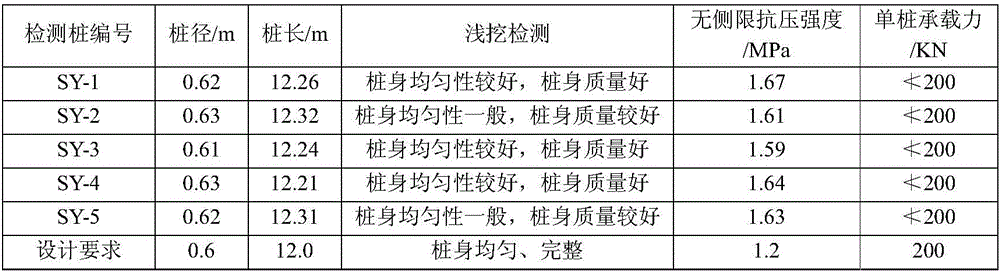

Method for treating soft coastal salty foundations by jetting industrial waste residues to bi-direction T-shaped deep mixing columns

InactiveCN105970922AAchieve reuseSolve land occupationBulkheads/pilesSoil preservationEngineeringSlurry

The invention provides a method for treating coastal saline soft ground by jetting industrial waste slag into two-way nail-shaped mixing piles. The method comprises the steps of: removing sundries on the surface of the site to be treated, and leveling the site; Identify each pile position and mark it; according to the pile position identification, move the two-way nail-shaped pile mixer into place and align the specified pile position; first spray and first stir the composite curing agent slurry; second spray and second stir waste tire rubber powder; The invention uses a variety of industrial waste residues to prepare a composite curing agent, which can not only treat the coastal salt-stained soft foundation formed by tidal flat reclamation on a large scale, but also solve the problems of land occupation and environmental pollution by various wastes, and achieve good economic and social benefits. And environmental benefits, has a relatively broad engineering application prospects.

Owner:ZHEJIANG UNIV OF TECH

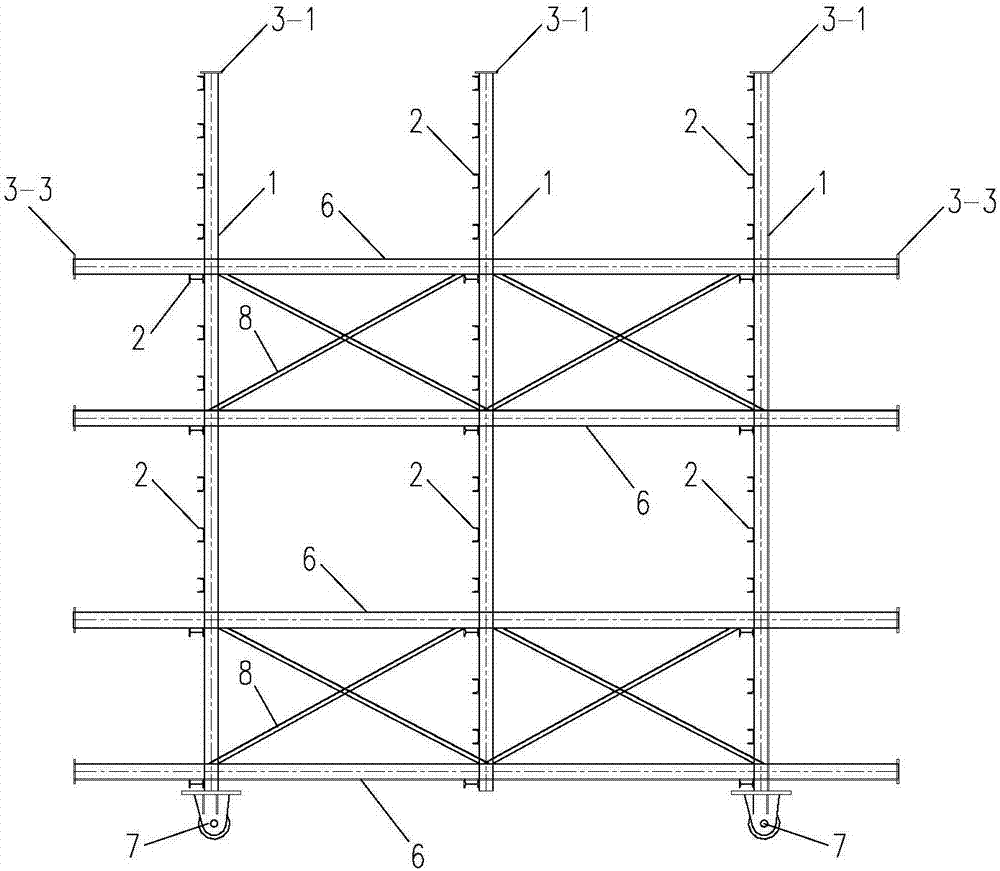

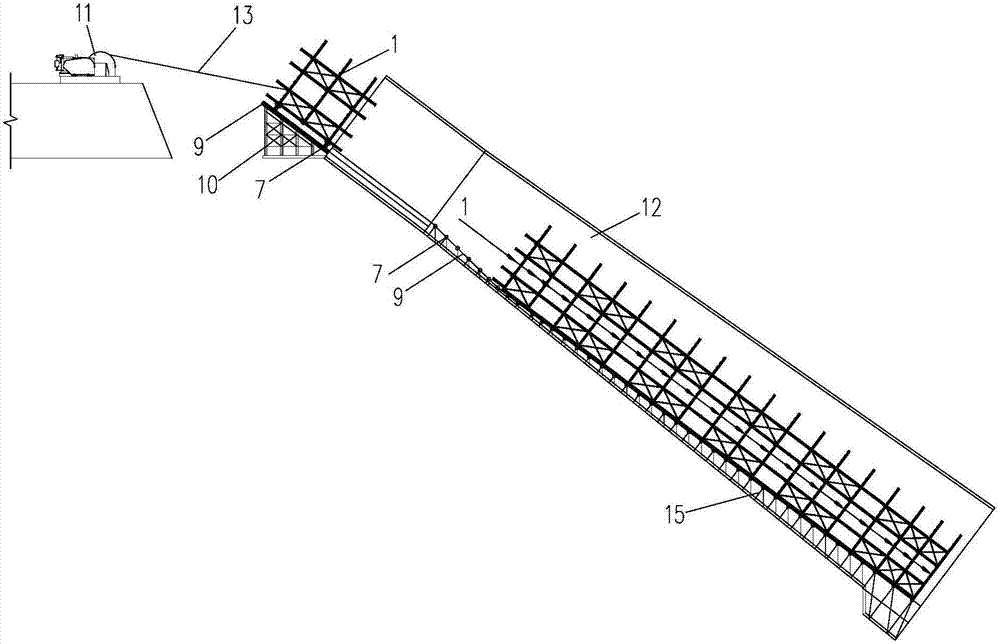

Construction method for locating bracket of tunnel anchorage prestressed system

InactiveCN107227686ASimple processThe progress of the project is fastBridge structural detailsBridge erection/assemblyPre stressWinch

The present invention discloses a construction method for a locating bracket of a tunnel anchorage prestressed system, comprising the following steps: manufacturing locating bracket racks outside a tunnel, assembling the racks into segmented locating bracket steel trusses, and installing rolling wheels at the bottoms of the trusses, and temporarily fixing prestressed pipes on the trusses; laying a slip track at the bottom of the interior of the tunnel, putting the steel trusses onto the slip track through hoisting in a segmented manner, and slowly lowering the steel truss by a winch; when the steel truss slides to the design positions, removing the rolling wheels from the steel truss for sliding of the next segment of section truss; and adjusting and fixing the positions of the steel trusses and the prestressed pipes. Through the method, the prestressed locating bracket is subjected to assembly construction, the process is simple and the project progress is fast, accordingly the construction period is greatly shortened, construction costs are reduced, and the economic efficiency is very obvious.

Owner:CHINA CONSTR SIXTH ENG DIV CORP +1

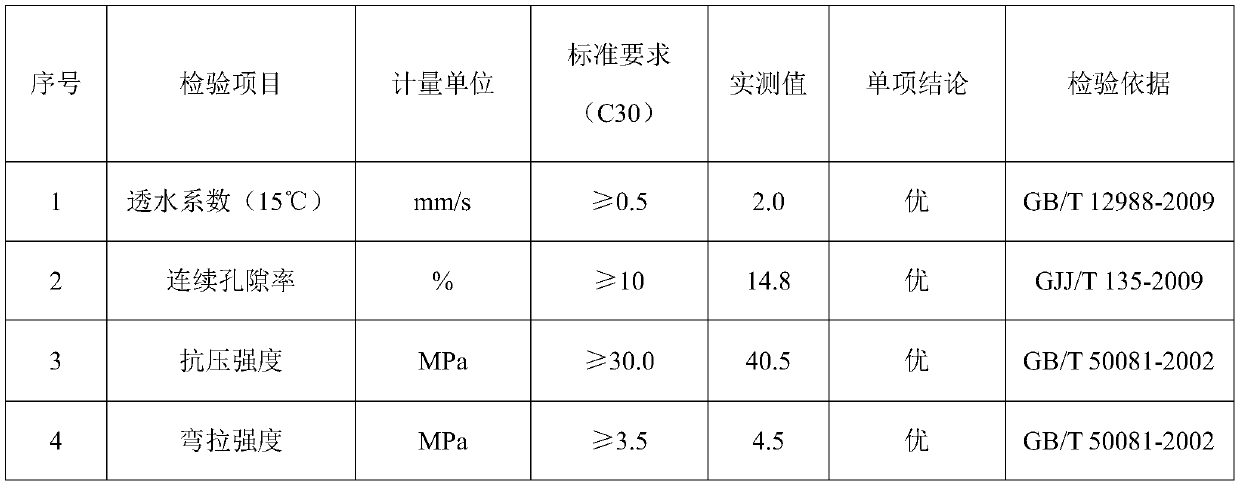

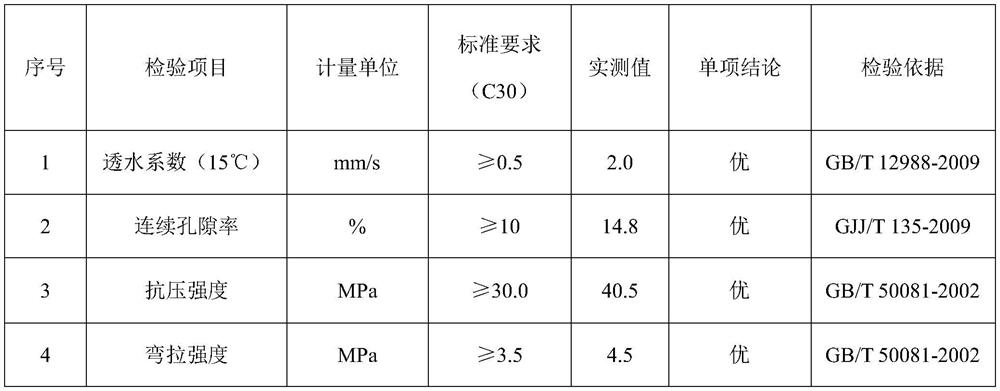

Reinforcing agent for pervious concrete as well as preparation method and construction process of reinforcing agent

The invention discloses a reinforcing agent for previous concrete as well as a preparation method and a construction process of the reinforcing agent. The reinforcing agent is prepared from the following components in parts by weight: 50 to 80 parts of nano-grade silicon powder, 10 to 15 parts of water reducing agent, 2 to 4 parts of cellulose, 8 to 10 parts of calcium sulfate whisker, 5 to 8 parts of trisodium phosphate, 1.5 to 5 parts of calcium carboxylate, 2 to 6 parts of alkali carbonate and 0.5 to 2 parts of formamide. According to the reinforcing agent, the bonding effect of cement canbe enhanced; meanwhile, the compressive strength and service life of a previous concrete pavement are respectively enhanced and prolonged, and the construction process is simplified; the process flowis short, the project progress is quick, and remarkable economic benefit and social benefit are realized.

Owner:南京海牛科技有限公司

Karst stratum stabilization structure

The invention provides a karst stratum stabilization structure used for constructing a punch filling pile. The punch filling pile penetrates through at least one cave in a karst stratum from top to bottom; a hole-wall treatment structure comprises a casing, a pile hole of the punch filling pile, a hole-wall crack water neutralization layer of the pile hole and a mud protection layer, wherein the casing is embedded into the karst stratum at a pile position of the constructed punch filling pile before the punch construction of a top plate of the cave for a certain depth and is far away from the surface of the karst stratum for a certain height; the pile hole is concentric to the casing, and the diameter of the pile hole is smaller than that of the casing; the mud protection layer punctures a cave wall and a pile hole wall behind the top plate of the cave and is sealed, tight and waterproof. Due to the fact that a karst area is treated by using flagstones, clay, straws, cement and the like, the engineering progress is rapid, the engineering quality is reliable, the construction is safe, general resources can be better utilized, and a great number of concrete materials are saved.

Owner:ZHONGDING INT ENG

Deeply-buried pool construction method for gridded underground continuous-wall foundation pit support

InactiveCN104846842AAvoid causingSimplify the construction processArtificial islandsExcavationsSlurry wallSoft layer

The invention discloses a deeply-buried pool construction method for a gridded underground continuous-wall foundation pit support. The method includes construction of a gridded underground continuous wall and a deeply-buried pool structure, and is characterized in that a deeply-buried pool takes the gridded underground continuous wall as a lateral force resistant soil retaining structure, and vertical earth excavation of an inner-support free structure is performed in the foundation pit support formed by the gridded underground continuous wall. The construction method specially includes the steps of building of the underground continuous wall and construction of the main pool structure. Compared with the prior art, the deeply-buried pool construction method has the advantages that the construction process is simple, progress of the construction is fast, construction waste caused by subsequent dismantling of a temporary foundation pit structure is avoided, energy conservation and emission reduction are achieved, the process is green and environment friendly, and the method is especially suitable for construction of pool structures with soft layers deeply buried by less than 15 meters.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Support free construction method for super large diameter circular deep foundation ditch

The invention discloses a method for processing super-large-diameter round hole without supports, which comprises following steps: building underground continuous wall; setting filling posts and supports; setting strengthen element; excavating and setting purlin. Compared to traditional method, the invention has strong stability, less excavating deformation, less rebound of hole-bottom, and less effect on around environment. The invention has no inner support structure; therefore, it has less cost with simple operation, quick time and high working efficiency.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

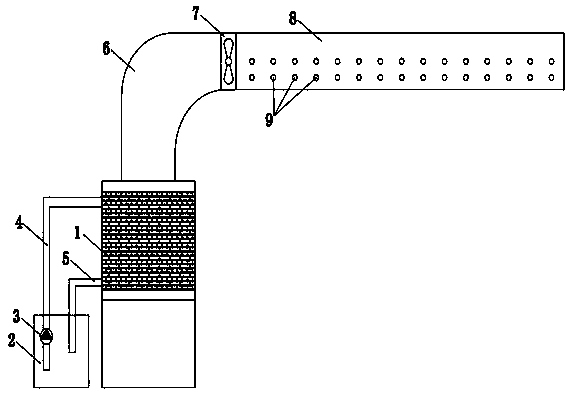

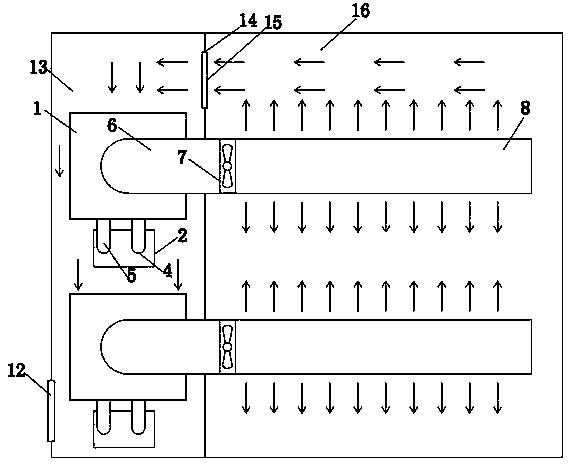

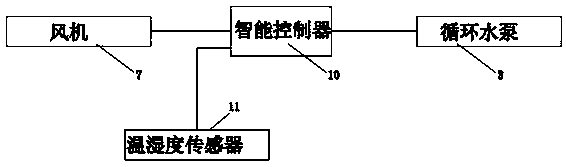

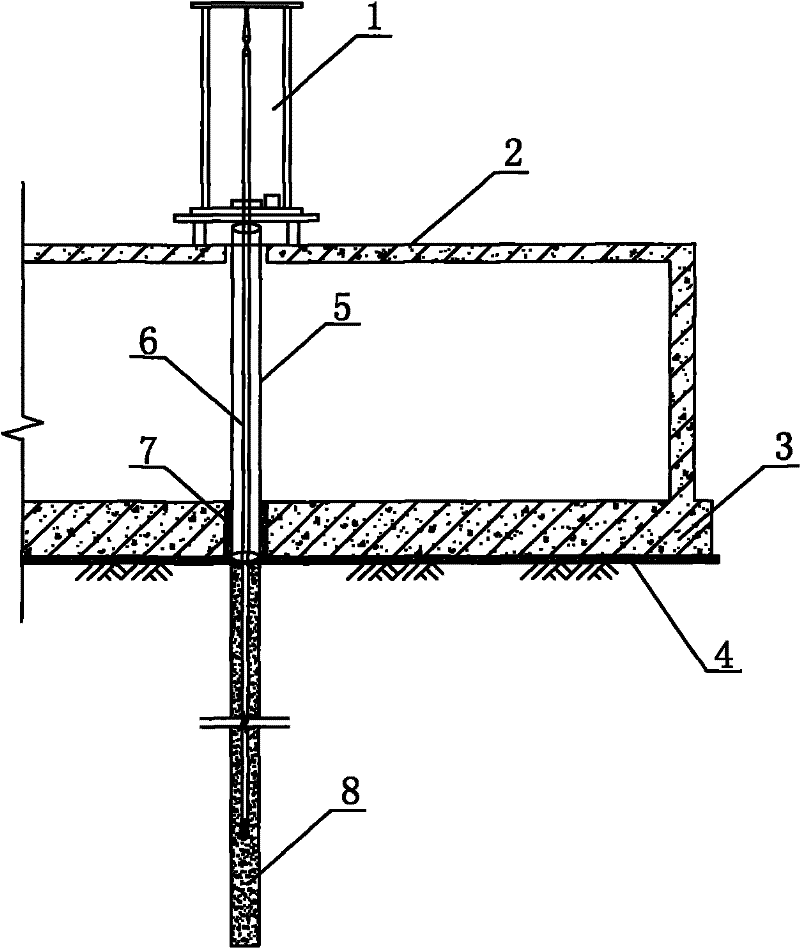

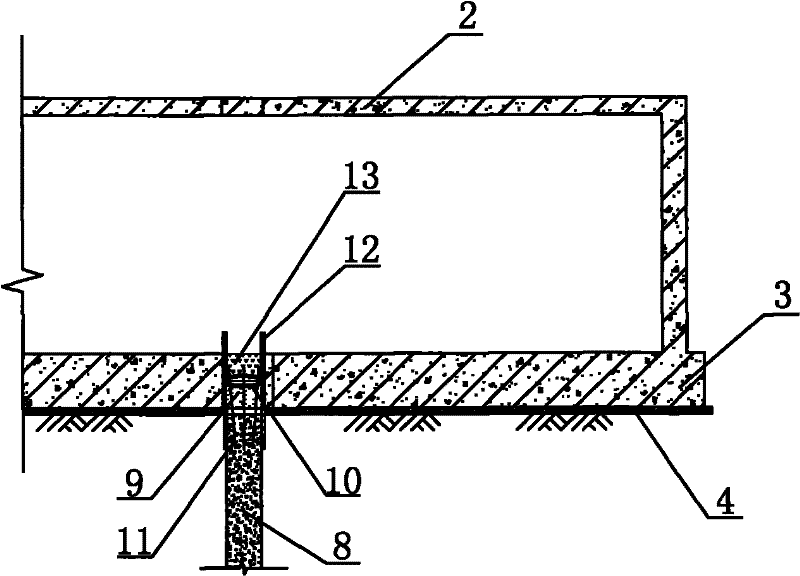

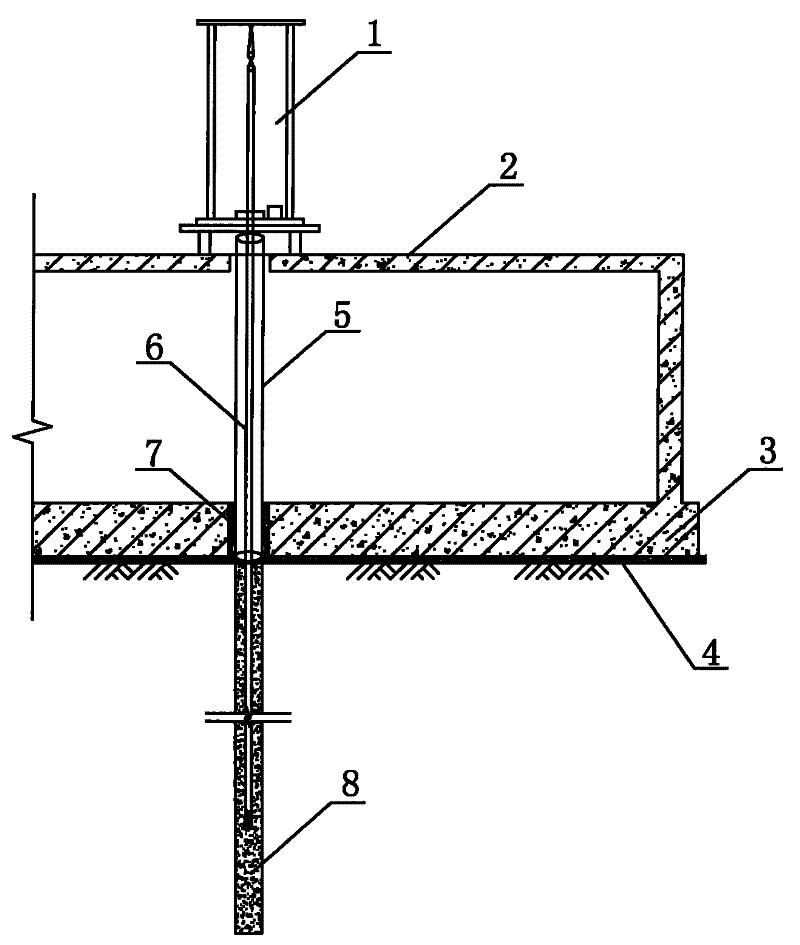

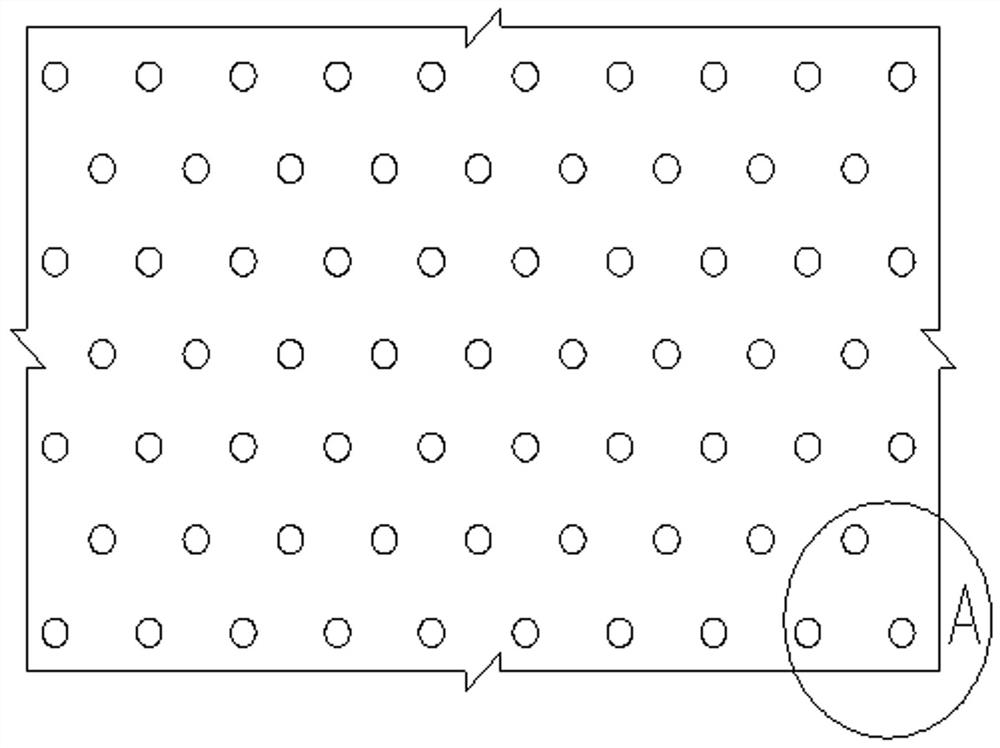

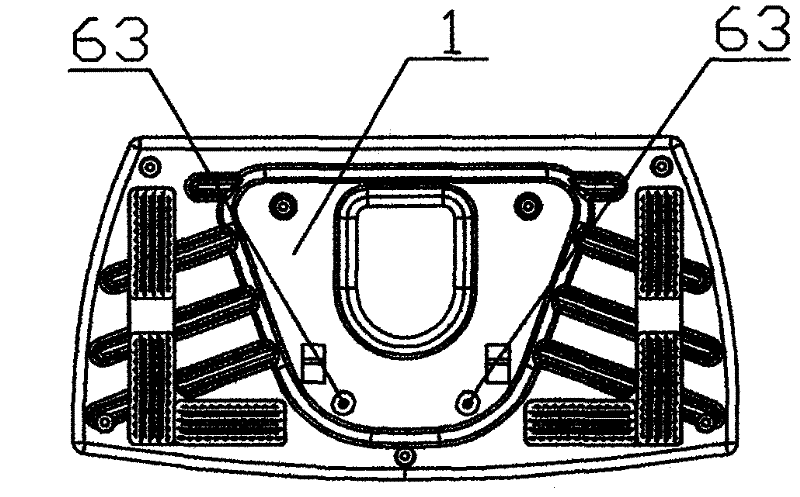

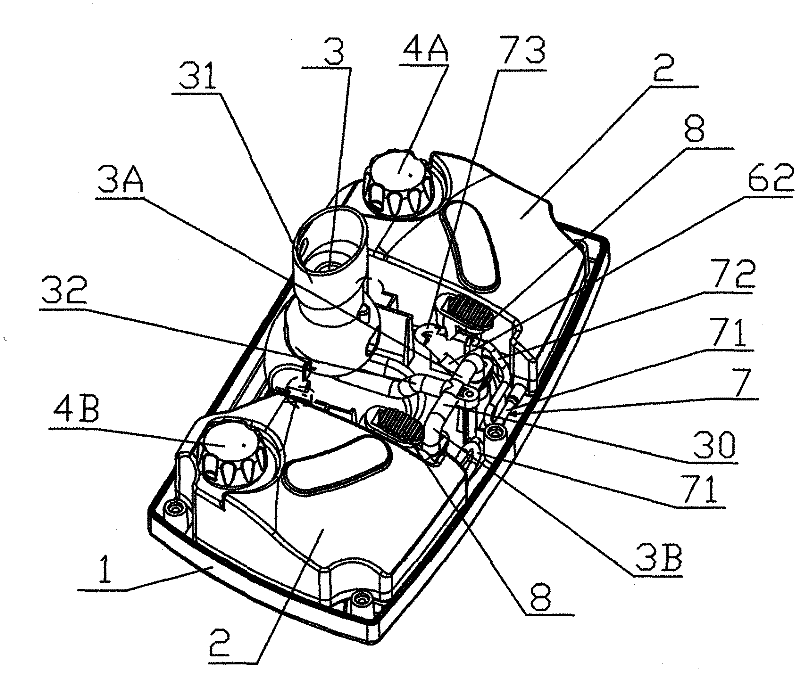

Efficient energy-saving wet curtain humidifying and cooling system for textile workshop and control method of efficient energy-saving wet curtain humidifying and cooling system

PendingCN111520851AEasy to installEasy maintenanceDucting arrangementsMechanical apparatusEngineeringProcess engineering

The invention belongs to the technical field of textile workshop humidification, and particularly relates to an efficient energy-saving wet curtain humidifying and cooling system for a textile workshop and a control method of the efficient energy-saving wet curtain humidifying and cooling system. The efficient energy-saving wet curtain humidifying and cooling system comprises a wet curtain, a water tank, a circulating water pump, a water supply pipe and a water return pipe, wherein the wet curtain is mounted in an air duct; an indoor air adjusting window communicating with the workshop is arranged on the air duct; the water supply pipe and the water return pipe are arranged between the wet curtain and the water tank; the circulating water pump is arranged on the water supply pipe; circulating water is supplied into the wet curtain through the circulating water pump; the wet curtain is connected with a main air pipe; a fan is arranged in the main air pipe; the main air pipe is connectedwith an air pipe; a plurality of air holes are uniformly distributed in the air pipe; and the air pipe is distributed in the workshop. The efficient energy-saving wet curtain humidifying and coolingsystem has the advantages of low cost, low energy consumption, good humidifying effect and the like, and can save energy by 50% or above.

Owner:SHANDONG XIANGRUIXIANG TEXTILE CO LTD

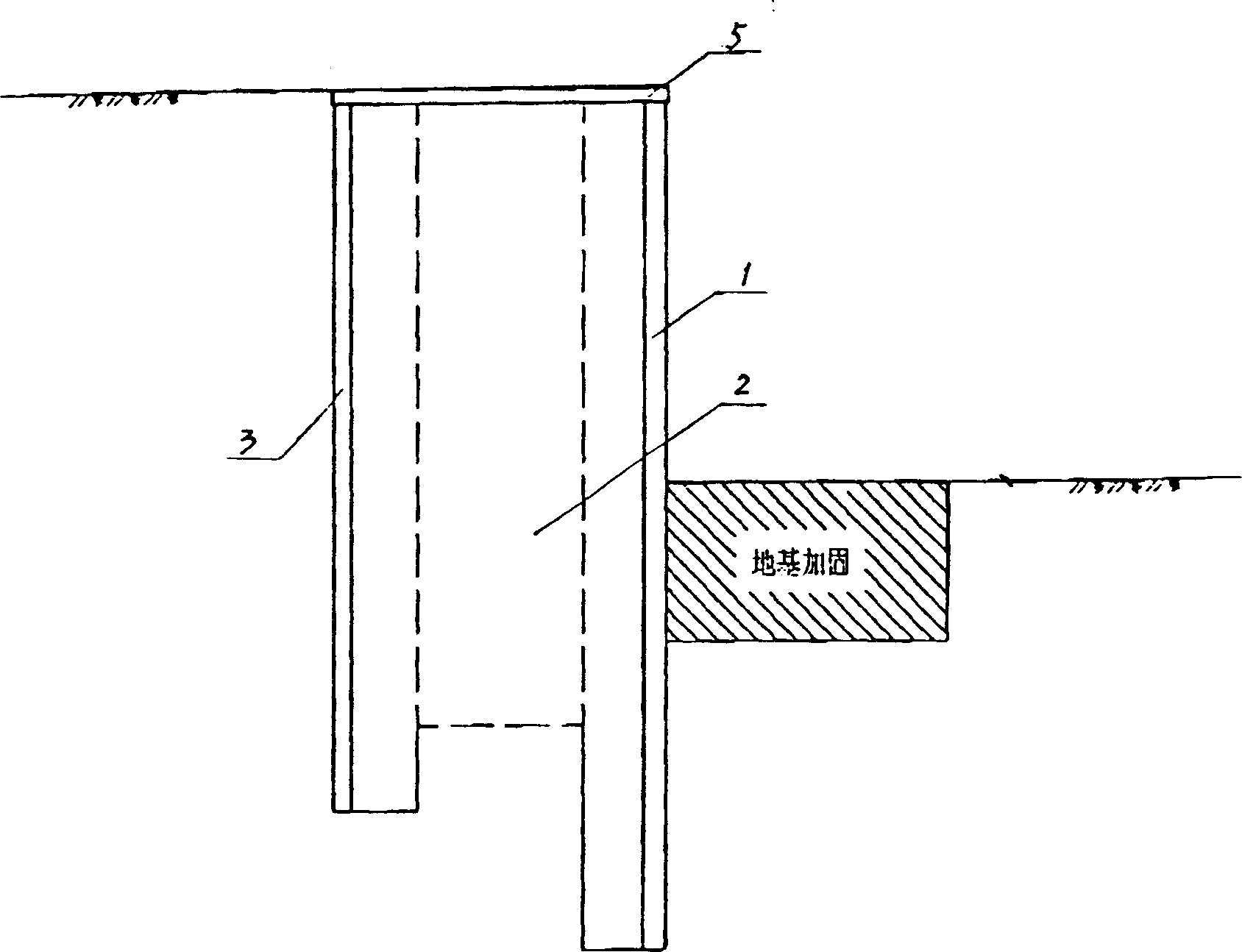

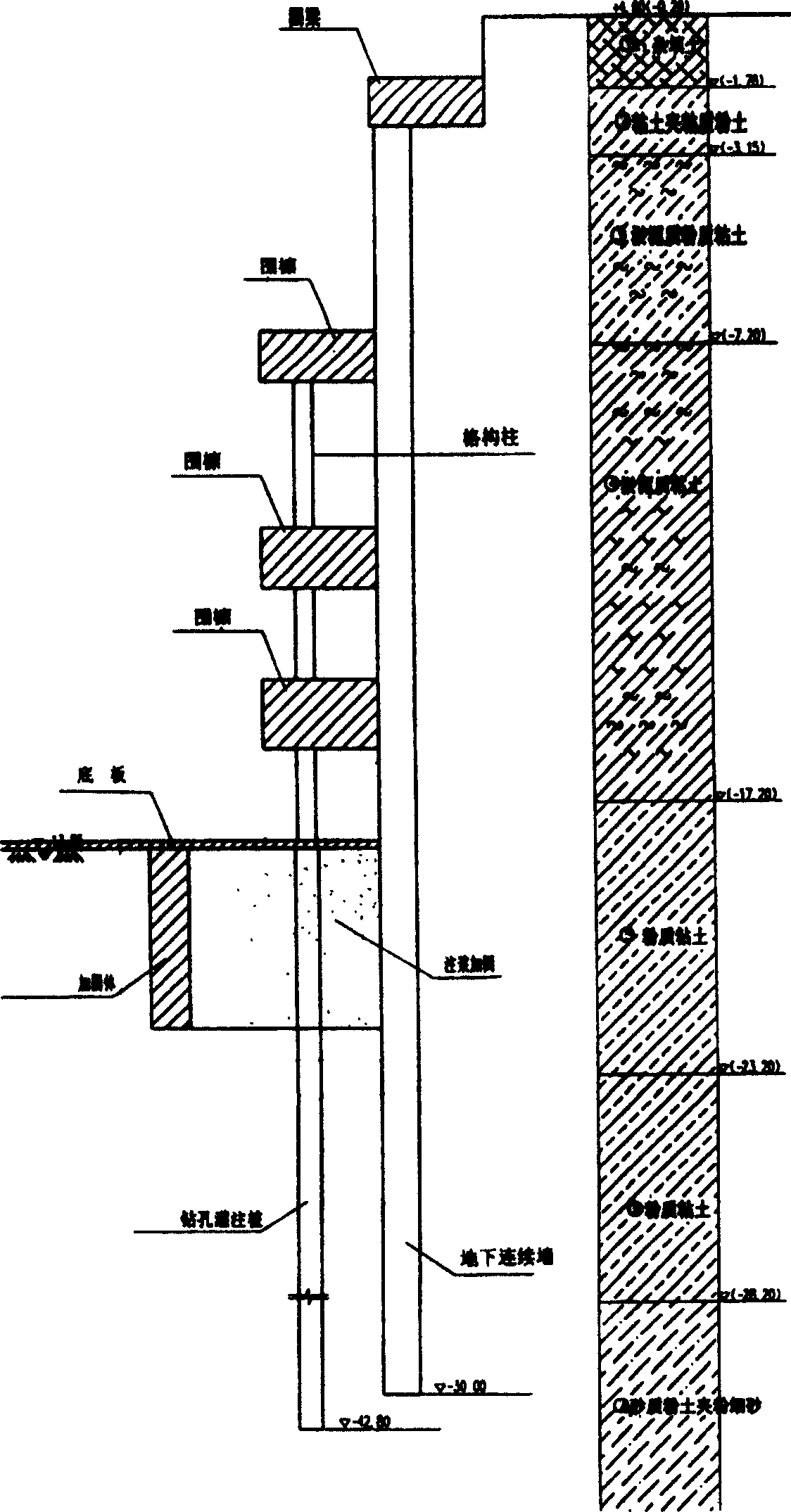

Casing construction method for reinforcing underground building and structure foundation

ActiveCN101787718BPrevent sprayingPrevent spillageFoundation repairBulkheads/pilesBasementEngineering

Owner:SHANGHAI ZHIPING FOUNDATION ENG CO LTD

Pre-consolidation construction method for completely weathered stratum

The invention discloses a pre-consolidation construction method for a completely weathered stratum. The pre-consolidation construction method is characterized in that cement grout materials are filled in gaps among particles of the completely weathered stratum, an intensely weathered stratum or a covering layer under certain pressure, and after solidification of the cement grout materials, consolidated bodies are formed by mixing the particles with grout. The pre-consolidation construction method particularly includes steps of trimming slopes so that the ratio of the slopes ranges from 1:1 to 1:1.3; measuring and setting out hole positions; performing drilling with casing in a non-irrigation section and embedding orifice pipes in the non-irrigation section; forming a hole in a first section by means of drilling with casing; mounting a grouting shock pipe; pulling up the orifice pipe; grouting; waiting for solidification of the cement grout materials, and cleaning the drilled hole; and performing acceptance check. The pre-consolidation construction method is high in pertinence and reliable in technology, construction procedures are simple, operation is simple and convenient, cost is low, and steel materials are saved as compared with other supporting measures such as steel tubular piles. Besides, as compared with the other supporting measures, a ground for implementing the pre-consolidation construction method is easy to arrange, project progress is fast, and the pre-consolidation construction method is favorable for providing operation conditions for follow-up working procedures in time.

Owner:中国安能集团第三工程局有限公司

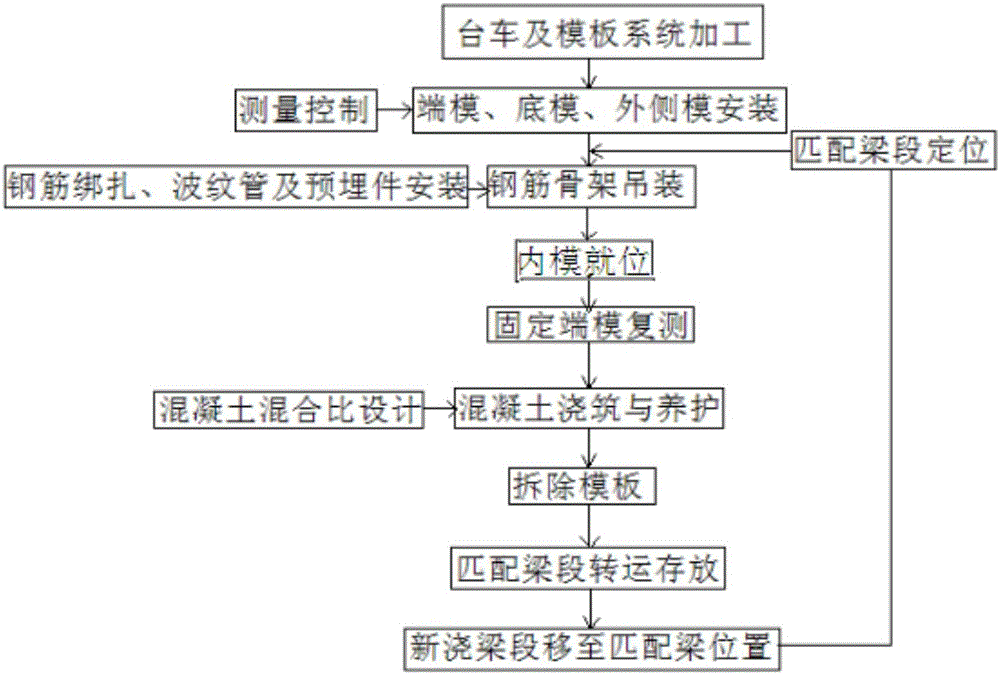

Construction method of industrialized short-line prefabrication and assembly of urban overpass

The invention discloses an urban overpass industrial short-line prefabricating and splicing construction method. The method includes the first step of calculating the deflection aggregate value in each construction stage by considering the structure dead load of an overpass, the construction live load of the over pass and the load, based on the concrete shrinkage, creep, prestressed tendon relaxation and wind load influences, of the overpass, and dividing a whole box girder into multiple sections with the deflection aggregate value in the construction complete stage as the camber during cast-in-place beam construction; the sixth step of symmetrically splicing the box girder bodies in pairs in a suspended mode after the box girder bodies poured block by block are set finally and stacked and stored for a certain time period, and finally forming a multi-span continuous girder bridge. By means of the urban overpass industrial short-line prefabricating and splicing construction method, social resources are reasonably utilized, the input amount of steel and mechanical devices for the support system is lowered, construction cost is reduced, the land requisition and demolishing area is reduced, and the construction cycle is shortened.

Owner:NANTONG ROAD & BRIDGE ENG CO LTD

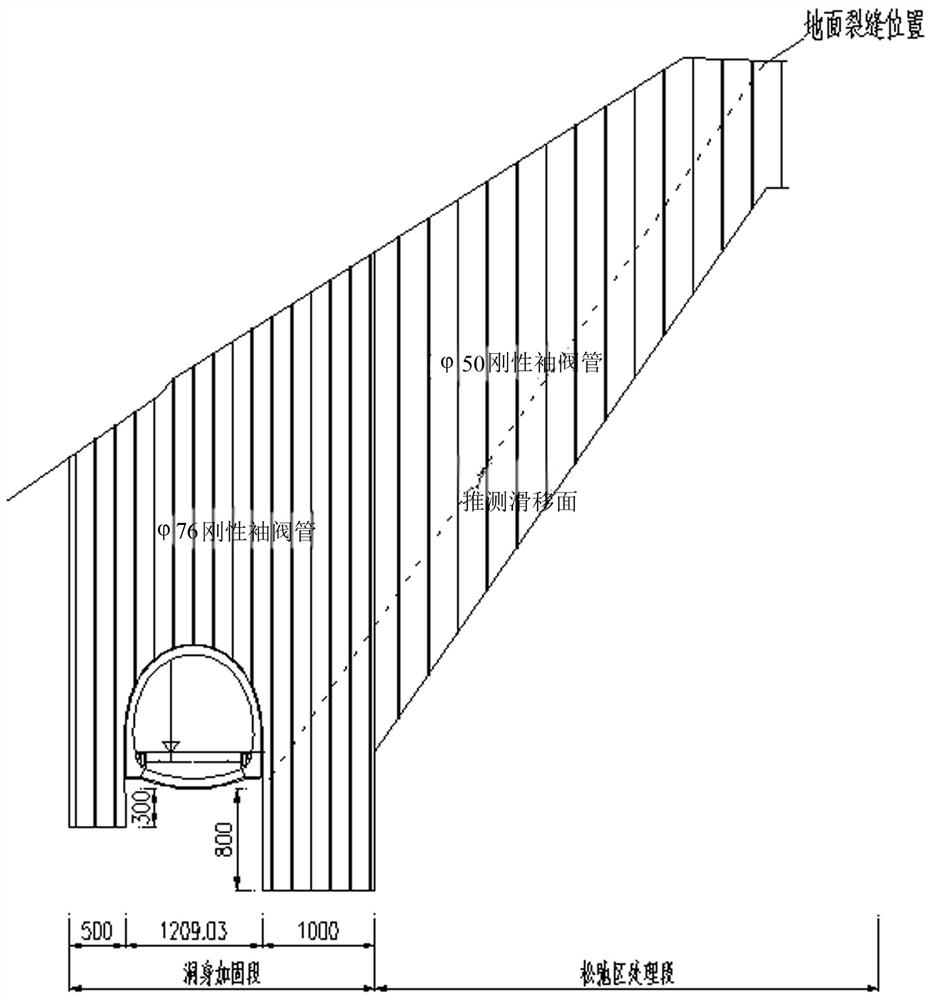

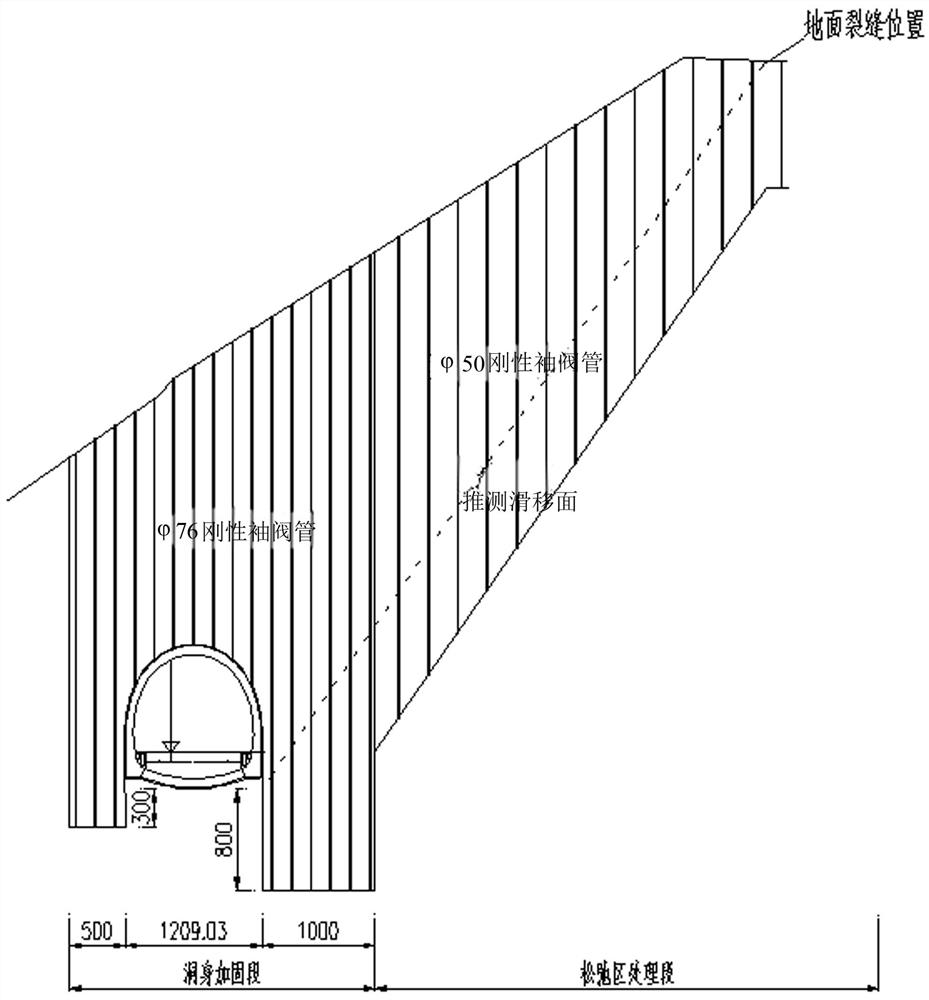

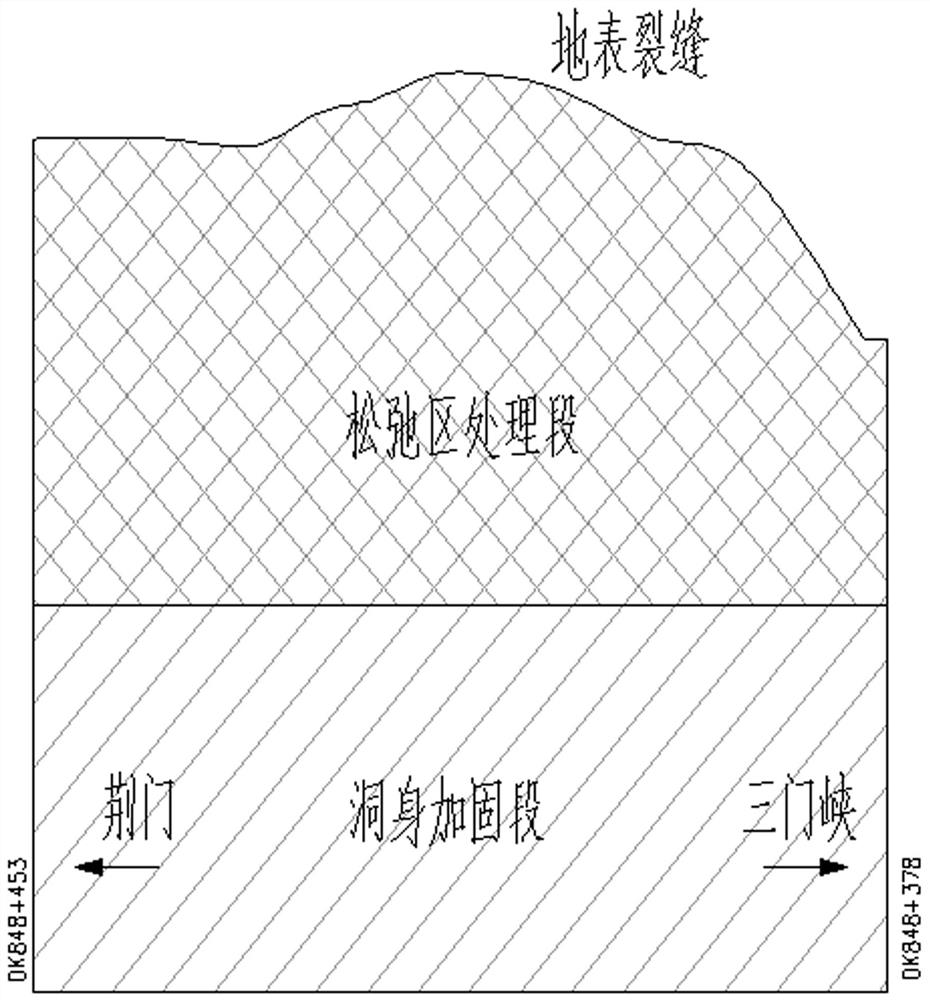

Construction Method of Reinforcing Sleeve Valve Pipe in Mountain Body

ActiveCN113217020BThe impact of shortening the durationLow costUnderground chambersHydro energy generationSleeve valveSteel frame

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

A kind of reinforcing agent for permeable concrete and its preparation method and construction technology

The invention discloses a reinforcing agent for permeable concrete and its preparation method and construction process, wherein the reinforcing agent comprises the following components in parts by weight: 50-80 parts of nano-scale silicon powder, 10-15 parts of water reducer, 2~4 parts of cellulose, 8~10 parts of calcium sulfate whiskers, 5~8 parts of trisodium phosphate, 1.5~5 parts of calcium carboxylate, 2~6 parts of alkali metal carbonate and 0.5~2 parts of formamide. The reinforcing agent can improve the bonding effect of cement, improve the compressive strength and service life of the permeable concrete pavement at the same time, and can also simplify the construction process, the process flow is short and the project progress is fast, and has significant economic and social benefits.

Owner:南京海牛科技有限公司

A method for excavating tunnels with two expansions and four expansions

ActiveCN109595004BWide adaptability to terrainReduce sinkingUnderground chambersTunnel liningRock tunnelAxial force

The present invention relates to the field of tunnel excavation, in particular to a method for expanding tunnels, including the construction methods for tunnels in Class IV and V surrounding rocks, and the construction methods for tunnels in Class III surrounding rocks, wherein the construction methods for tunnels in Class IV and V surrounding rocks include The construction steps are as follows: divide the excavated tunnel, including Part I in the middle of the vault, Part II on the left side of Part I, Part III on the right side of Part I, Part IV on the lower side of Part II, and Part V on the lower part of Part III and Part VI of the lower part of I. This construction method adopts double-side wall excavation in sections, and the excavation method of the arch first and the wall later has the following advantages: the vault sinks the least, the horizontal displacement is small, the axial force of the temporary support is the smallest, and the support is reliable, and the project progress is fast . Moreover, this scheme is very suitable for the expansion and excavation construction of ultra-large-span, ultra-large-section, and small-spacing tunnels. The construction safety is high and there will be no collapse.

Owner:浙江省隧道工程集团有限公司

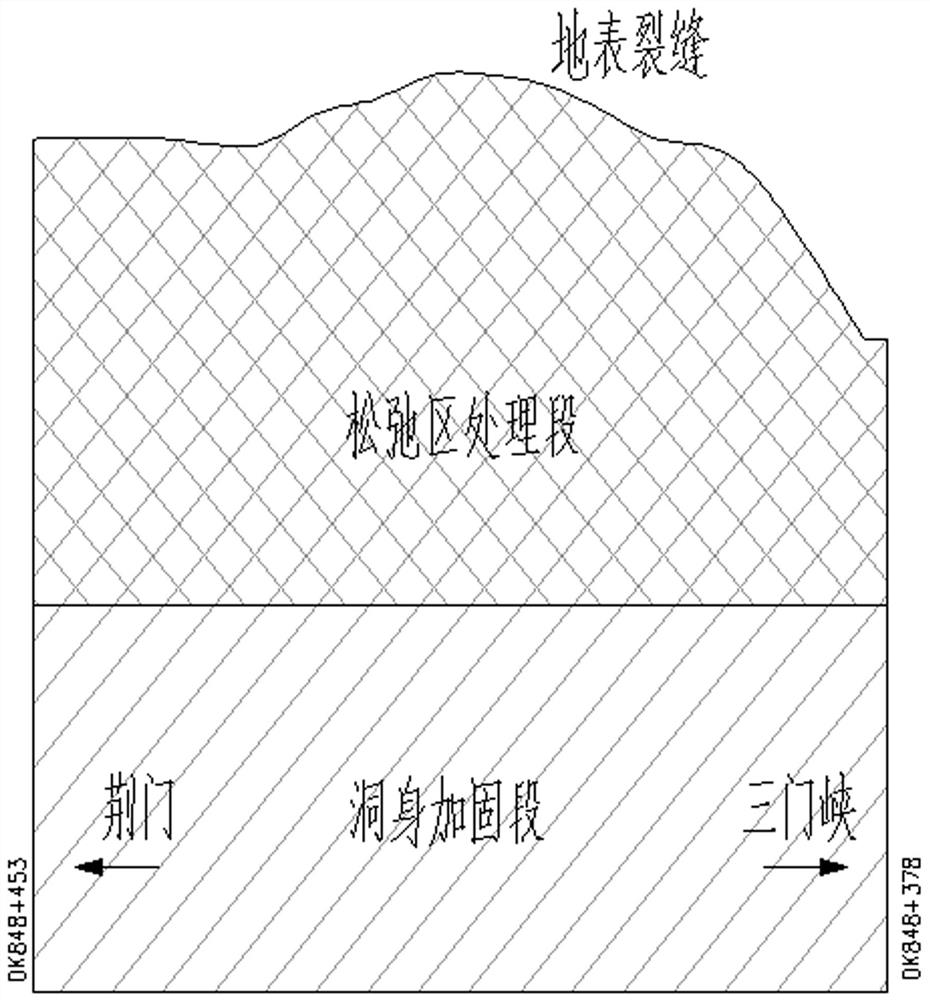

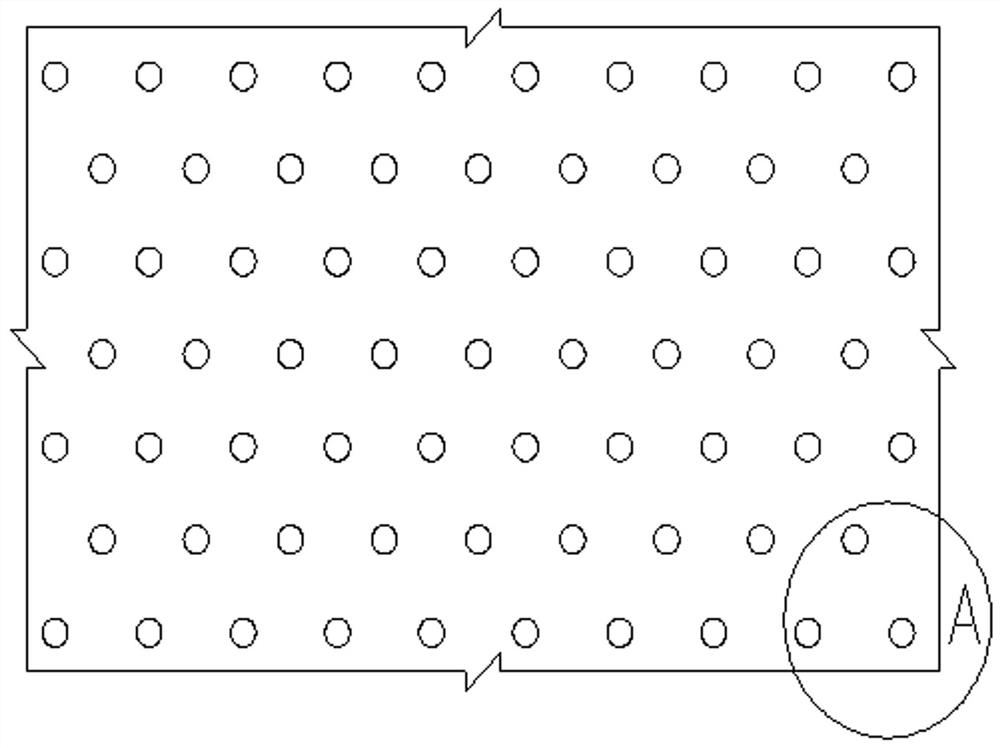

Sleeve valve pipe reinforcing construction method for mountain

ActiveCN113217020AThe impact of shortening the durationLow costUnderground chambersHydro energy generationSteel frameEarth surface

The invention relates to tunnel mountain unsymmetrical pressure section and underground excavation underground engineering construction, in particular to a sleeve valve pipe reinforcing construction method for a mountain. The technical problems that in existing tunnel construction, due to influence of rock mass crushing, structural face steep inclination, steep terrain and engineering activities, primary support cracking in a tunnel is caused, a local steel frame is distorted and deformed, and arc-shaped cracks are generated on the earth surface are solved. Rigid sleeve valve pipe grouting is conducted within a certain range on two sides of a tunnel section with cracks. Through high-pressure grouting, grout permeates into rock stratum cracks, the compactness and uniformity of a stratum are improved by repeatedly compacting the stratum, and the rigid sleeve valve pipe micro pile effect is combined, so that a rigid composite stratum is formed, and the stability of the stratum is effectively improved.

Owner:CHINA RAILWAY SIXTH GROUP +1

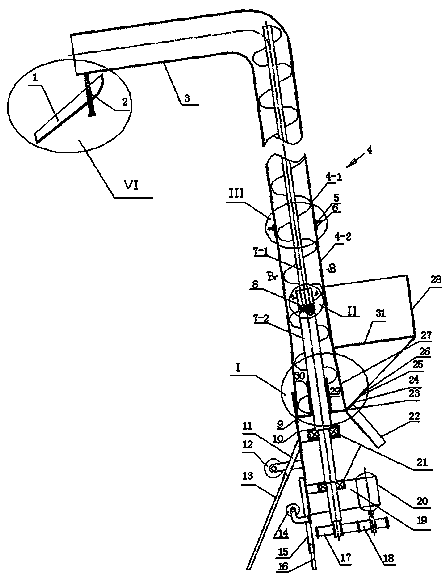

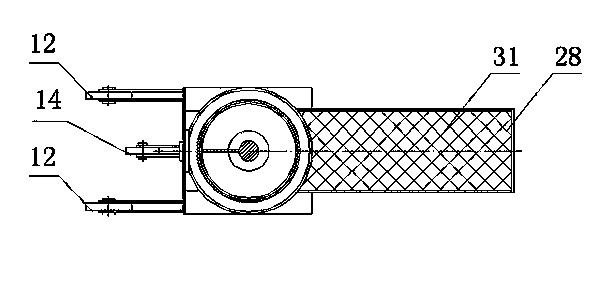

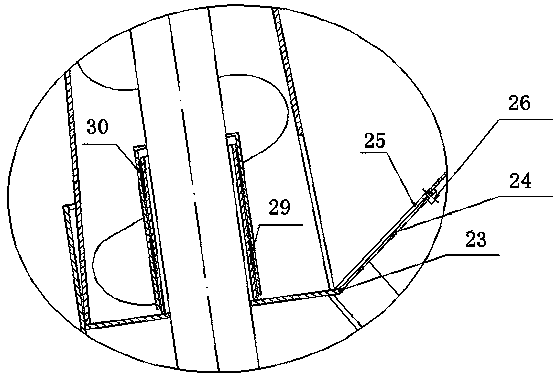

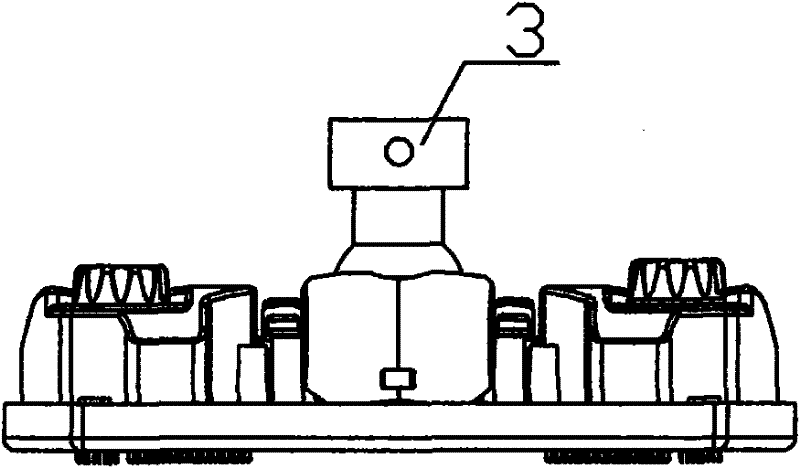

Pile filling machine for building secondary structure

InactiveCN102828512BReduce labor intensitySave human effortBuilding repairsPackagingPile driverHelix

The invention discloses a special pile-grouting machine for a secondary structure of a building. The special pile-grouting machine comprises a screw elevator and is characterized in that a discharging pipe (3) for changing the flow direction of concrete in a helix drum (4) is arranged at the upper end of the helix drum (4) of the screw elevator; a pouring chute (1) is arranged on the lower part at the front end of the discharging pipe (3); and the pouring chute (1) can swing around a shaft (2) fixed on the discharging pipe (3). Compared with the prior art, the special pile-grouting machine has the advantages that the never solved technical problem that the pile-grouting for the secondary structure of the building is manually finished is solved, and by utilizing the special pile-grouting machine for the secondary structure of the building provided by the invention to perform the pile-grouting construction for the secondary structure of the building, the labor intensity of workers is small, the manpower is saved, the construction progress is quick and the construction cost is low.

Owner:曹生然

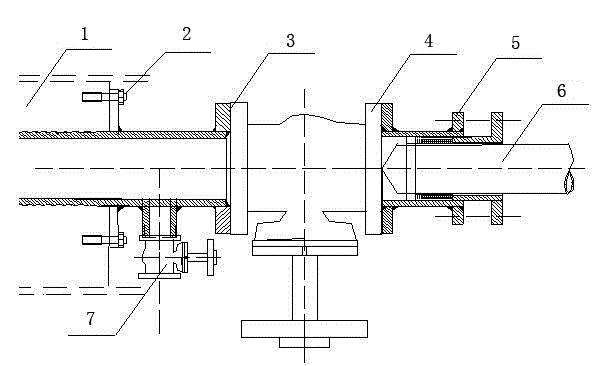

A kind of underground pipeline branch connection construction method

ActiveCN105065774BThe construction method is reliable and environmentally friendlyReduce vibrationPipe laying and repairLine tubingArchitectural engineering

The invention provides a branch connection construction method for an underground pipeline to enable an underground branch pipe to be connected with a main pipe. The branch connection construction method comprises the steps that the soil body on the outer portion of the part, where the branch pipe is connected into the main pipe, of the main pipe is strengthened; the branch pipe is ejected into the part close to the outer wall of the main pipe through a pipe ejecting construction technology; a hole is formed in pipe wall of the part, where the branch pipe is connected into, of the main pipe; and the branch pipe and the main pipe are connected. By means of the branch connection construction method, it is achieved that branch connection construction of the pipeline is transferred to an underground part from the ground, original pipeline relocation caused by construction is avoided, the defects that a road and the traffic are occupied by ground construction are overcome, the construction method is reliable and environmentally friendly, and generated public hazards such as vibration, noise and dust are reduced to the maximum.

Owner:TENGDA CONSTR GROUP CORP

Device for jetting liquid and usage thereof

InactiveCN101607238BSpray evenlyEasy to useLiquid spraying apparatusHigh pressureElectrical and Electronics engineering

The invention provides a device for jetting liquid and a usage thereof and relates to a device for jetting liquid, which is used for cleaning floors, walls, and the like. The device for jetting liquid comprises a box (2) containing liquid and a vacuum generating device (6), wherein an air intake pipe (61) of the vacuum generating device (6) is communicated with an air intake pipe (3) of the device for jetting liquid; and a liquid conveying pipes (7) and a flow control devices (8) which are communicated with each other are arranged between a pumping pipe (62) of the vacuum generating device (6) and the box (2). The device for jetting liquid is characterized by being provided with at least two sets of part assemblies comprising the vacuum generating device (6), the box (2) and the liquid conveying pipes (7); and the outer port of the air intake pipe (3) is communicated with a high-pressure air generator. The device for jetting liquid evenly jets detergent when cleaning floors or walls, and the like, has various functions, convenient use, rapid work process, reasonable structure and attractive appearance and can be used for jetting perfume.

Owner:何启烽

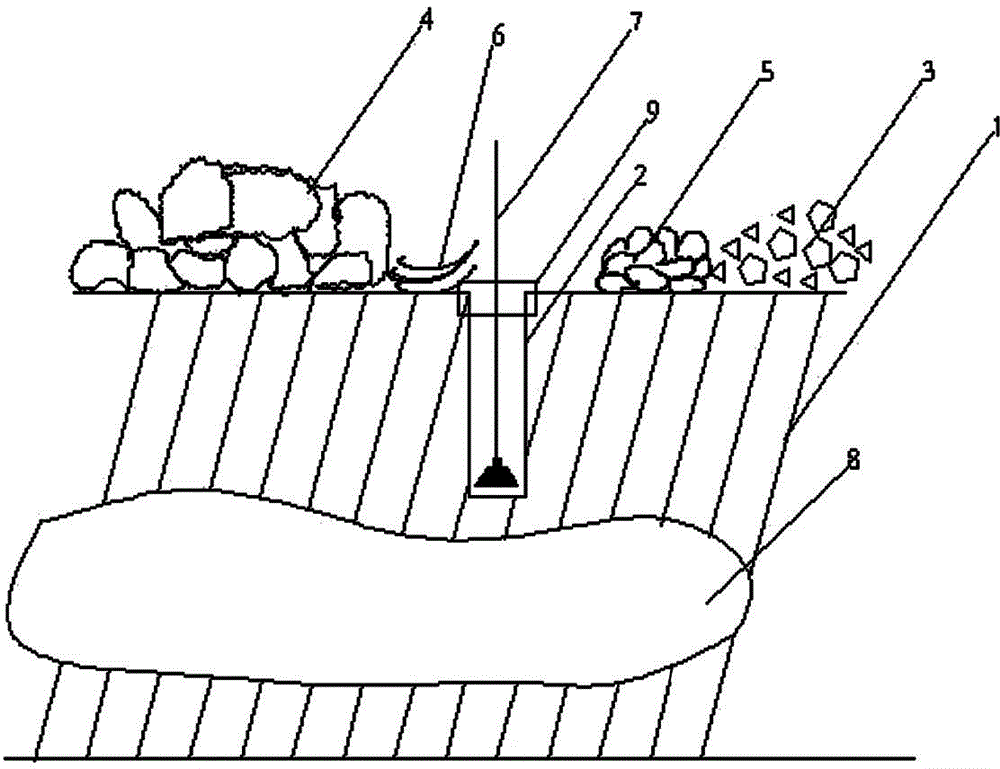

A filter wall for upstream tailings pond

ActiveCN106088108BPermeation barrierLower Wetting LineEmbankmentsSoil preservationIsosceles trapezoidChipseal

The invention relates to a water filtration wall for an upstream type tailing pond. According to the technical scheme, the water filtration wall is formed by a first water filtration wall body (12), a second water filtration wall body (13) and a third water filtration wall body (14) in an enclosed mode. The first water filtration wall body (12) and the second water filtration wall body (13) extend outwards from the two sides of a mountain slope (1) correspondingly and are correspondingly connected with the two ends of the third water filtration wall body (14). The main bodies of the water filtration wall bodies have the same cross-section shape which is a constant-section isosceles trapezoid. According to each isosceles trapezoid, a concrete interlayer (10) is arranged in the middle and located at the perpendicular bisector of the top edge of the isosceles trapezoid, 4-16 layers of water collecting plates (4) are symmetrically arranged on the two sides of the concrete interlayer (10), and a row of water filtration pipes (9) is arranged above each layer of water collecting plates (4). Each concrete interlayer (10) is uniformly provided with water collecting wells (16), gravel (5) is symmetrically laid on the two sides of each concrete interlayer (10), and geotechnical cloth (11) is laid on the inclined surface of the gravel (5). The water filtration wall for the upstream type tailing pond has the advantages that the seepage drainage and stopping effects are good, cost is low, a dam body is safe and steady and construction is easy and convenient.

Owner:武汉科技大学资产经营有限公司

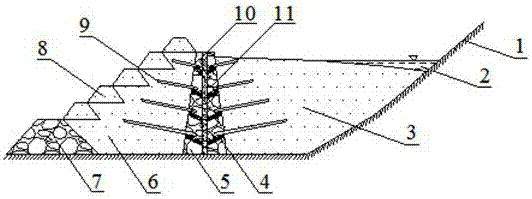

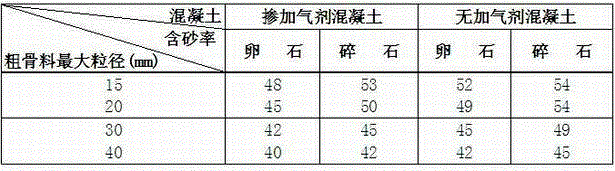

Application of Pumping Concrete Construction Method in Transmission Lines in Mountainous Areas

ActiveCN103669360BQuality requirements are not easyNot easy to segregateFoundation engineeringArchitectural engineeringEconomic benefits

The present invention relates to a foundation engineering concrete construction technology in power transmission lines in mountainous areas, in particular to the application of a pumping concrete construction method in power transmission lines in mountainous areas, which utilizes the pressure of a concrete pump to transport concrete mixture through pipelines to pouring construction point, and complete the horizontal transportation and vertical transportation of the concrete mixture at one time. Compared with the traditional self-mixing method for road foundation construction in mountainous areas, the application of the concrete pumping construction method of the present invention is very innovative, not only speeding up the construction progress and reducing construction costs, but also saving labor, reducing labor intensity, Improving the construction quality can obtain obvious technical and economic benefits in certain occasions, especially in the case of large-volume continuous pouring concrete projects, the superiority and economical efficiency of the concrete pumping construction method can be fully utilized.

Owner:STATE GRID CORP OF CHINA +2

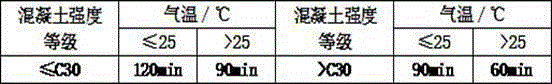

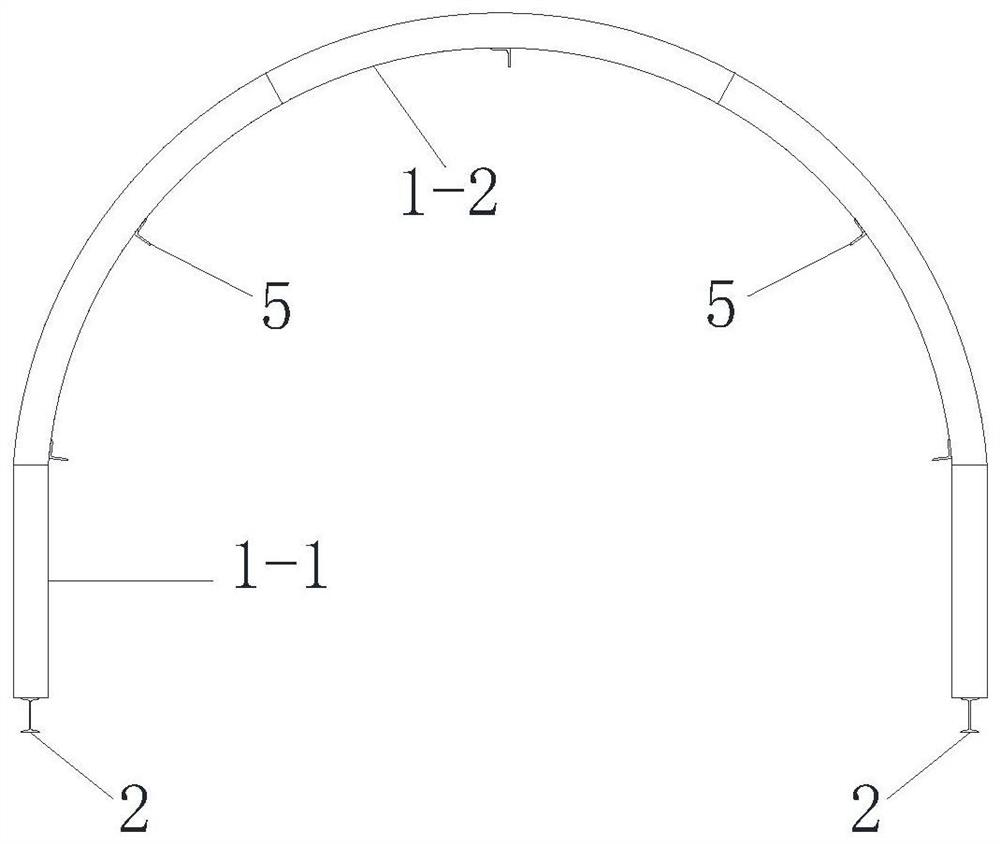

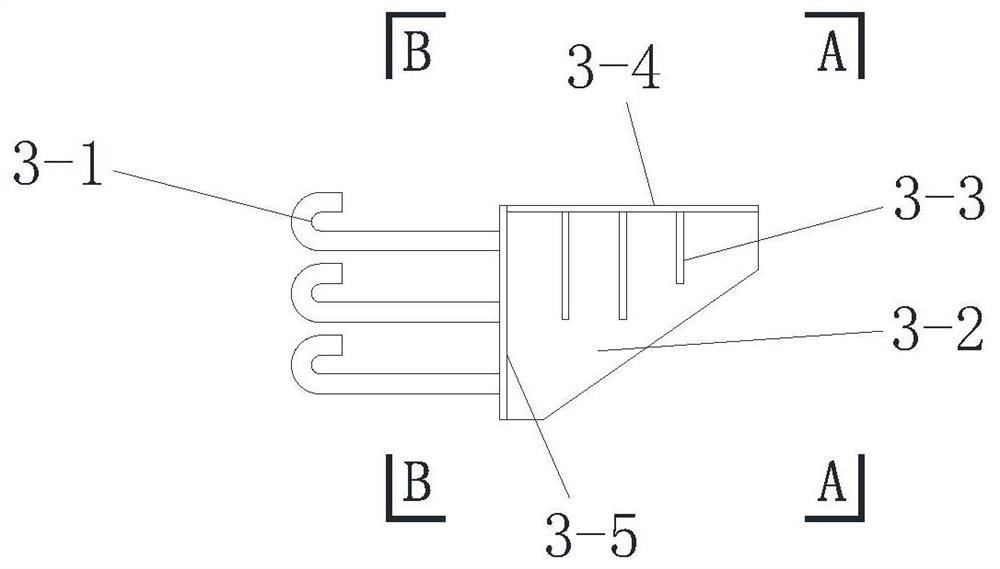

Construction method for large-dip-angle tunnel type anchorage secondary lining support

ActiveCN113668392AAdjust pour thicknessSolve the problem of uneven pouring thicknessHydro energy generationBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses a construction method for a large-dip-angle tunnel type anchorage secondary lining support. The construction method comprises the steps that (1) a plurality of secondary lining support piece units are manufactured, and each secondary lining support piece unit is of an arch structure; (2) secondary lining side walls are poured, a plurality of brackets are embedded in the secondary lining side wall on each side, and the brackets are located on the same straight line; a jack is arranged on each bracket, and multiple jacks jointly support a longitudinal adjusting beam arranged in the linear direction; (3) the secondary lining support is installed, specifically, a plurality of secondary lining support piece units are installed in sequence, the two ends of each secondary lining support piece unit are connected with longitudinal adjusting beams on the secondary lining side walls on the two sides of the tunnel respectively, and the secondary lining support piece units are arranged at intervals; and after the secondary lining support piece units on each construction section are installed, the elevations of the secondary lining support piece units are adjusted by adjusting the jacks, and installation of the secondary lining support is completed. According to the construction method, the construction quality is guaranteed, the construction efficiency is improved, and the construction cost is saved.

Owner:中建桥梁有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com