Construction method for large-dip-angle tunnel type anchorage secondary lining support

A construction method and tunnel-like technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of uneven secondary lining thickness, inability to adjust the height accurately, heavy bracket quality, etc., and achieve reliable decision-making basis and technical indicators , Promote the progress of construction technology and the effect of fast project progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

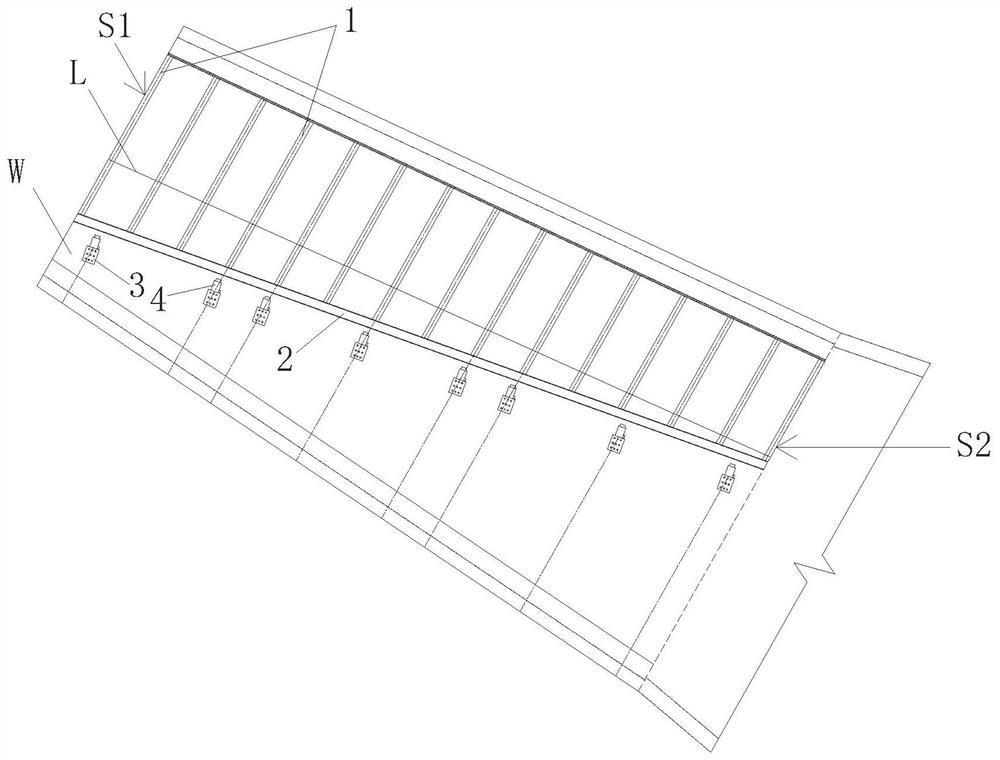

[0053] as attached Figure 1 to Figure 6 As shown, a construction method for the second lining support of large-inclination tunnel anchorage includes the following steps:

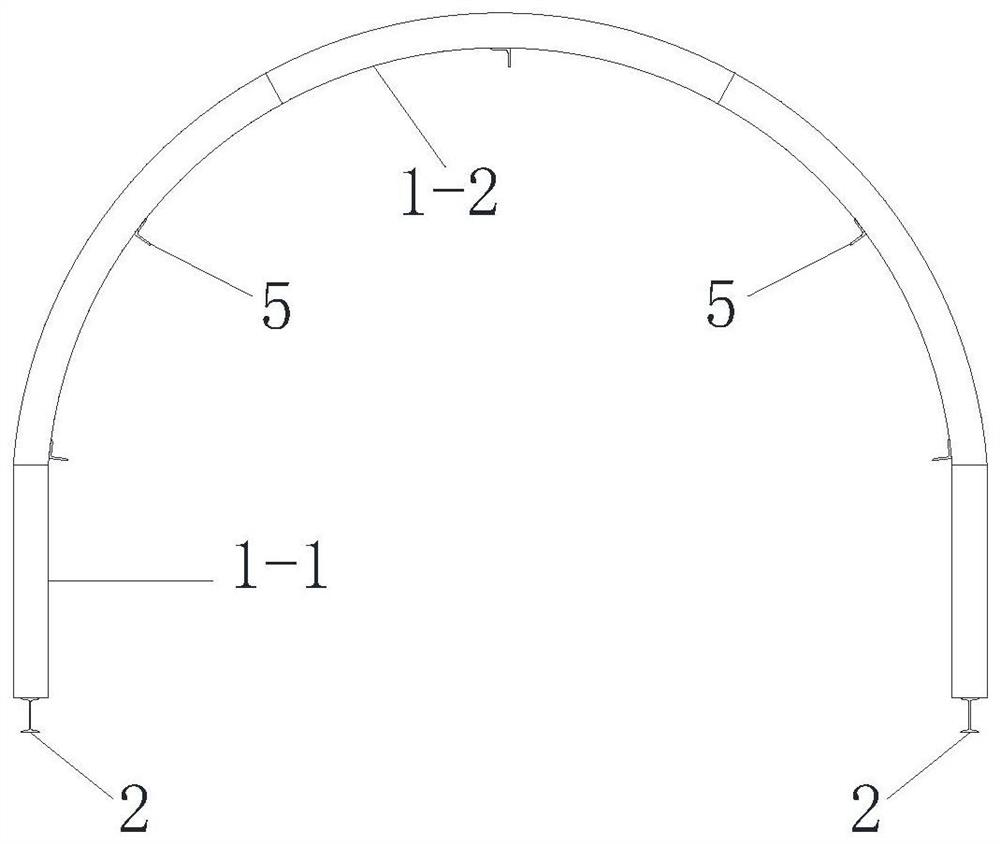

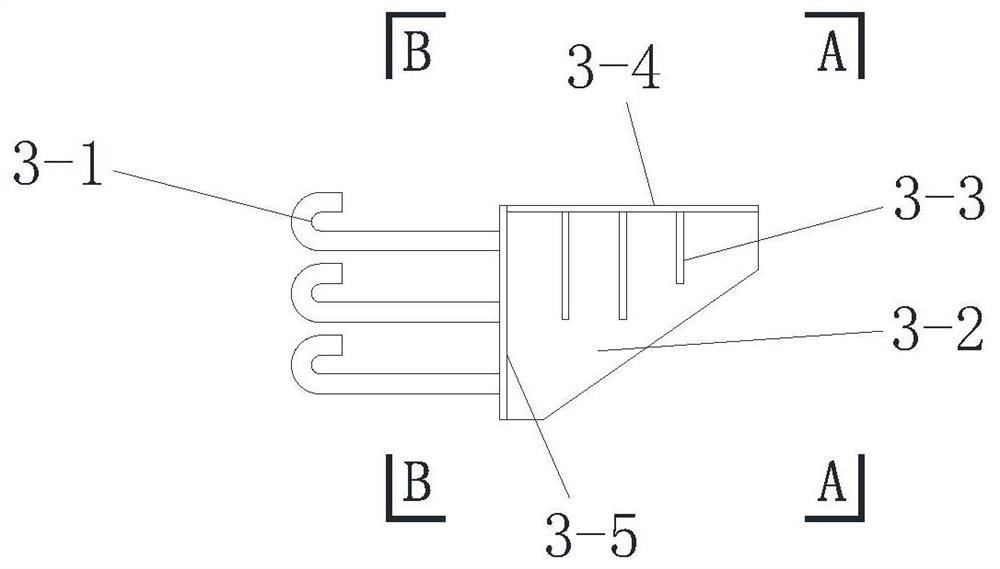

[0054] Step 1, manufacturing a plurality of two-liner frame units 1, each of which is an arched structure, including two vertical supports 1-1 and a steel arch 1-2, the steel Both ends of the arch 1-2 are respectively fixedly connected to the two vertical supports 1-1. Among them, the steel arch 1-2 is divided into 3 sections, which are formed by connecting the 3 steel arch monomers in sequence, and the two ends of the steel arch monomers in each section are provided with flange plates for adjacent The connection between the single steel arches is described, which not on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com