Method for replacing tail brush in shield tunnel through liquid nitrogen freezing

A technology of liquid nitrogen freezing and shield tunneling, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as complex geological conditions, achieve good water resistance, obvious social and environmental benefits, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

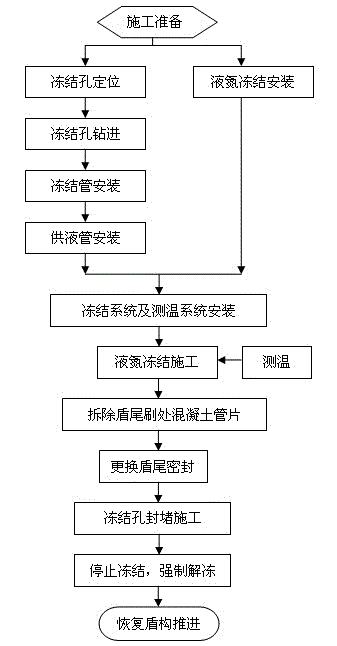

[0060] A method for freezing and replacing the tail brush with liquid nitrogen in a shield tunnel hole, such as Figure 1 to Figure 3 As shown, it includes the following process steps: 1. Construction preparation → 2. Freezing hole construction → 3. Installation of freezing system and temperature measurement system → 4. Liquid nitrogen freezing construction → 5. Shield tail seal maintenance construction → 6. Freezing hole plugging Construction → 7. Forced thaw construction → 8. Resume shield tunneling and advance construction.

[0061] The specific steps are as follows: 1. Construction preparation:

[0062] a. Make sure to replace the shield tail brush;

[0063] b. Grouting using shield tail synchronous grouting system;

[0064] Second, the freezing hole construction:

[0065] a. Frozen hole location: determine the location of the frozen hole according to the geographical location of the shield tail brush and the surrounding geological conditions;

[0066] b. Drilling ...

Embodiment 2

[0102] A method for freezing and replacing the tail brush with liquid nitrogen in a shield tunnel hole, such as Figure 1 to Figure 3 As shown, including 1. Construction preparation → 2. Freezing hole construction → 3. Installation of freezing system and temperature measurement system → 4. Liquid nitrogen freezing construction → 5. Shield tail seal maintenance construction → 6. Freezing hole plugging construction → 7. Forced thawing construction → 8. Resume shield tunneling and advance construction.

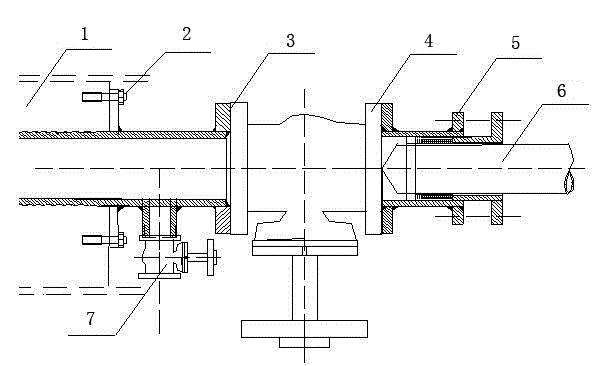

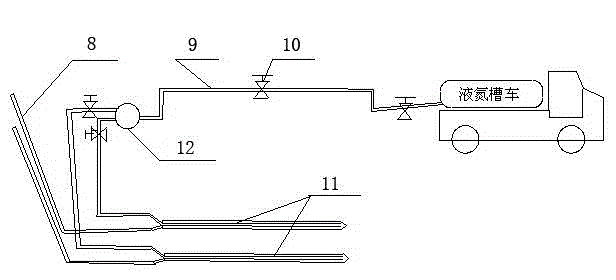

[0103] The construction process of the freezing hole is as follows: determine the hole position and orifice pipe installation according to the construction drawing of the freezing hole → install the orifice sealing device to ensure the safety of the opening → check and confirm that the orifice sealing device is firmly installed → perform the hole opening operation and drill Freezing hole → After the drilling of the freezing hole is completed, start the installation of the freezin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com