Patents

Literature

134results about How to "Risk of damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

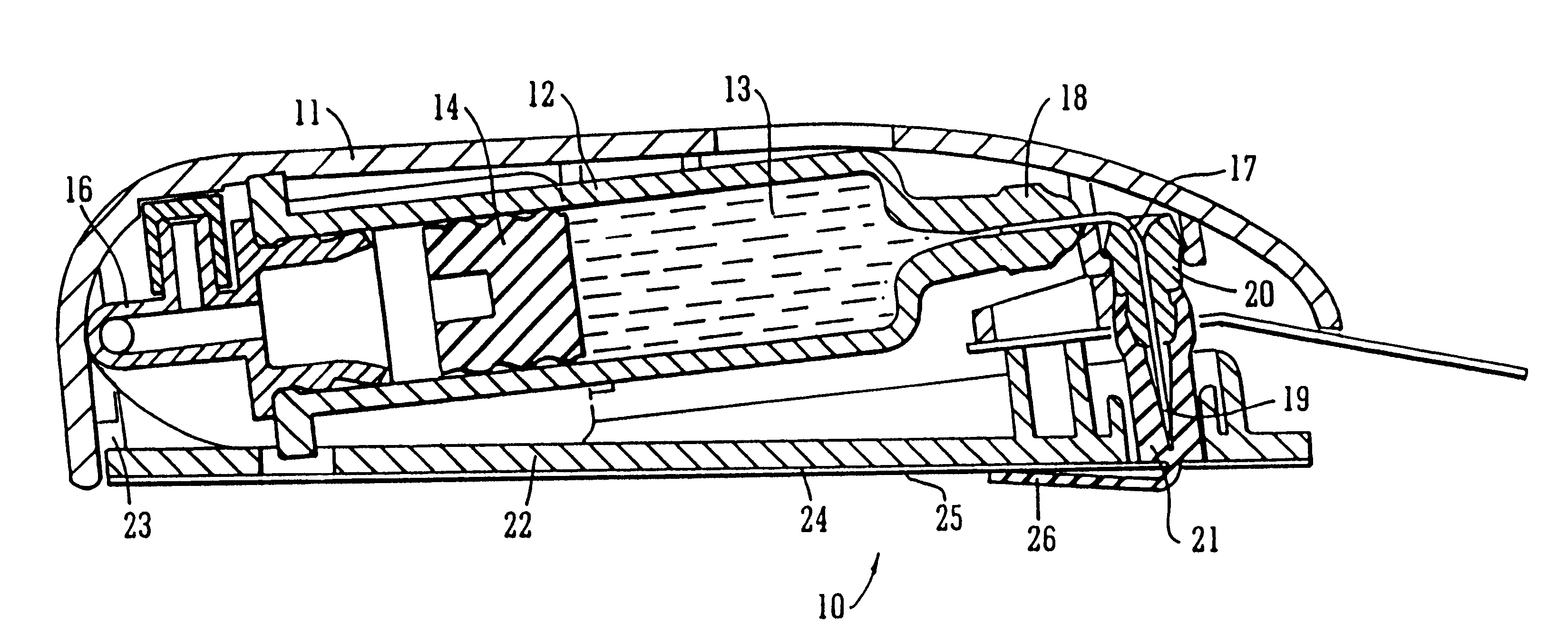

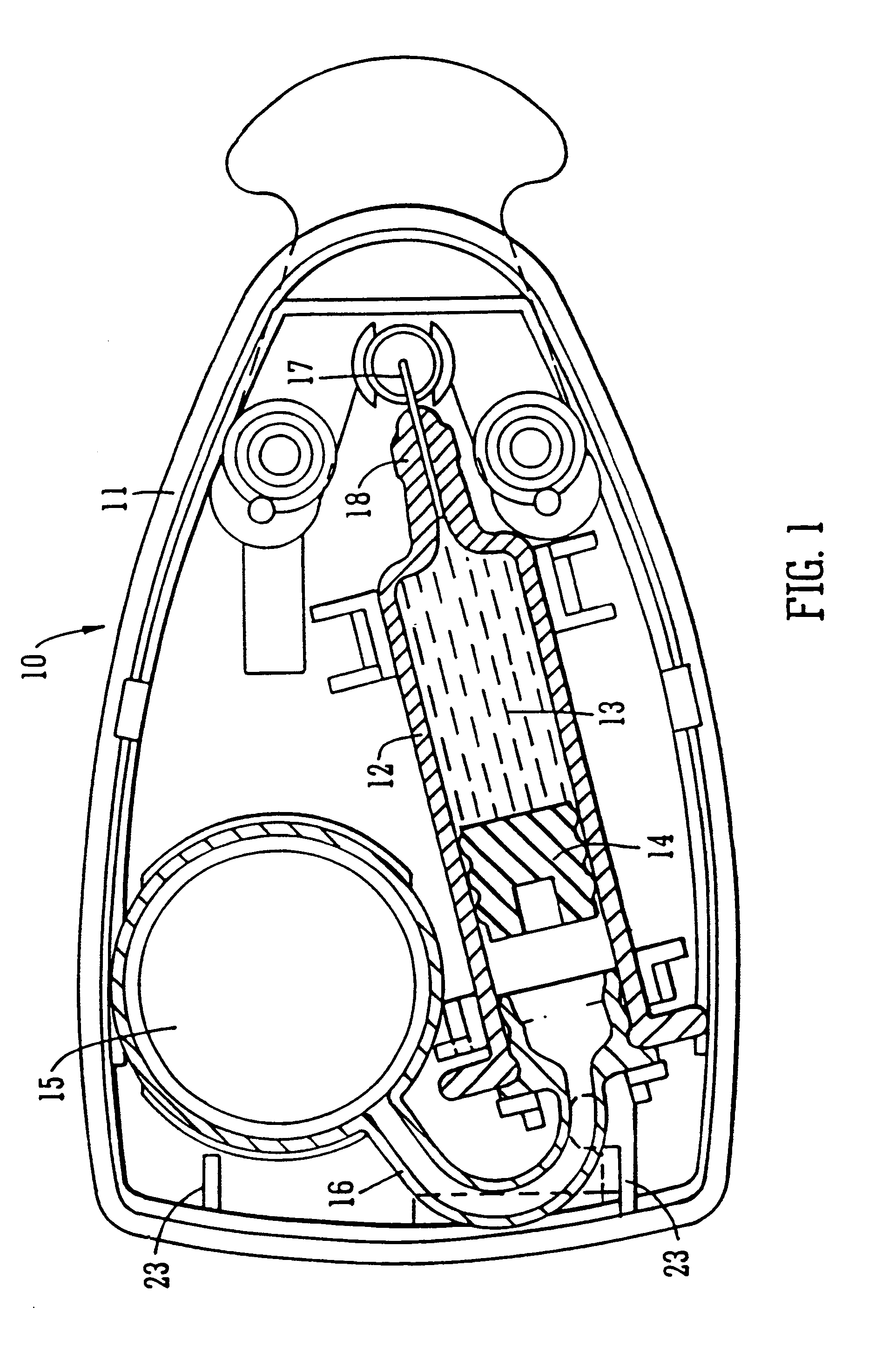

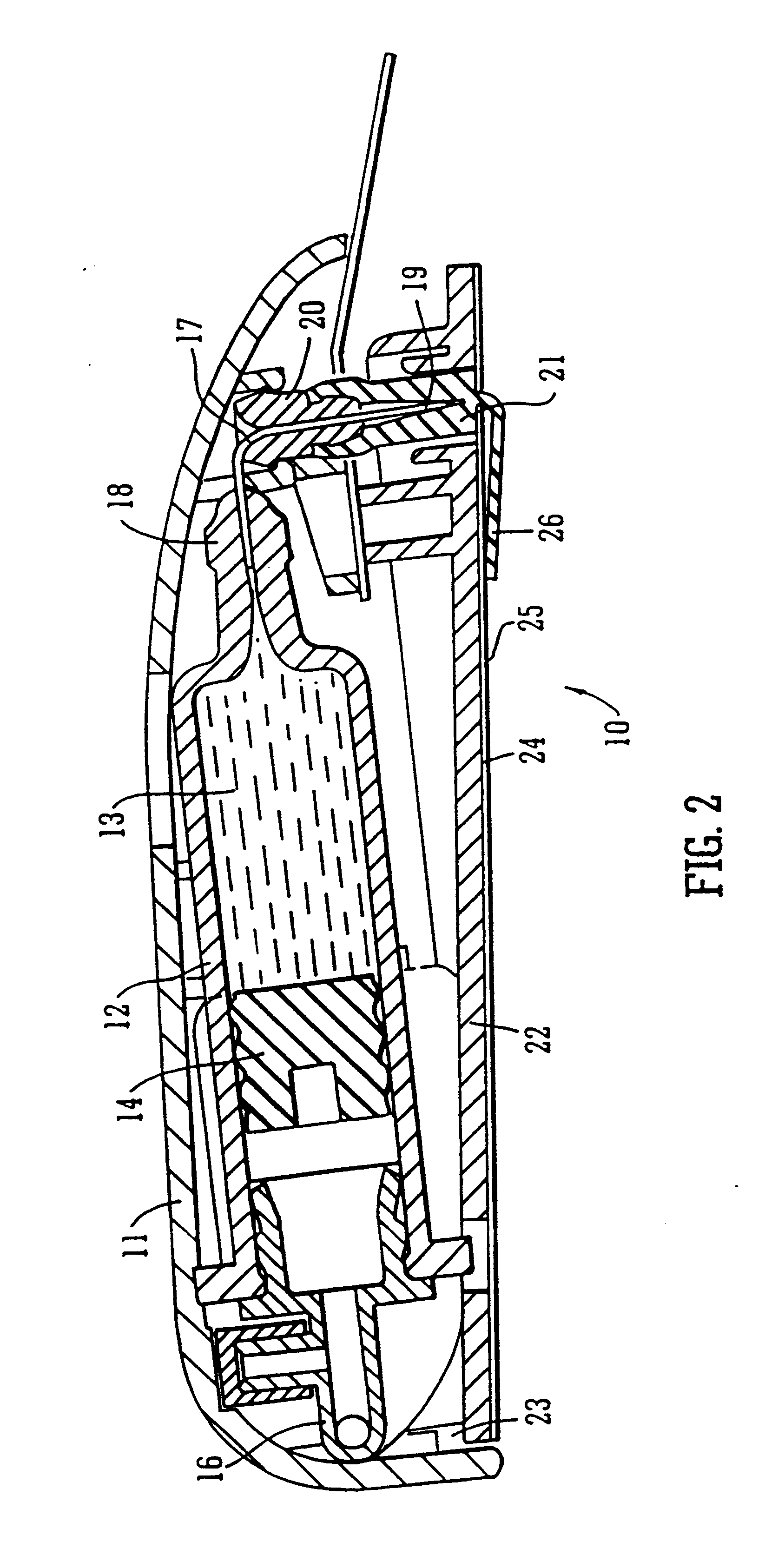

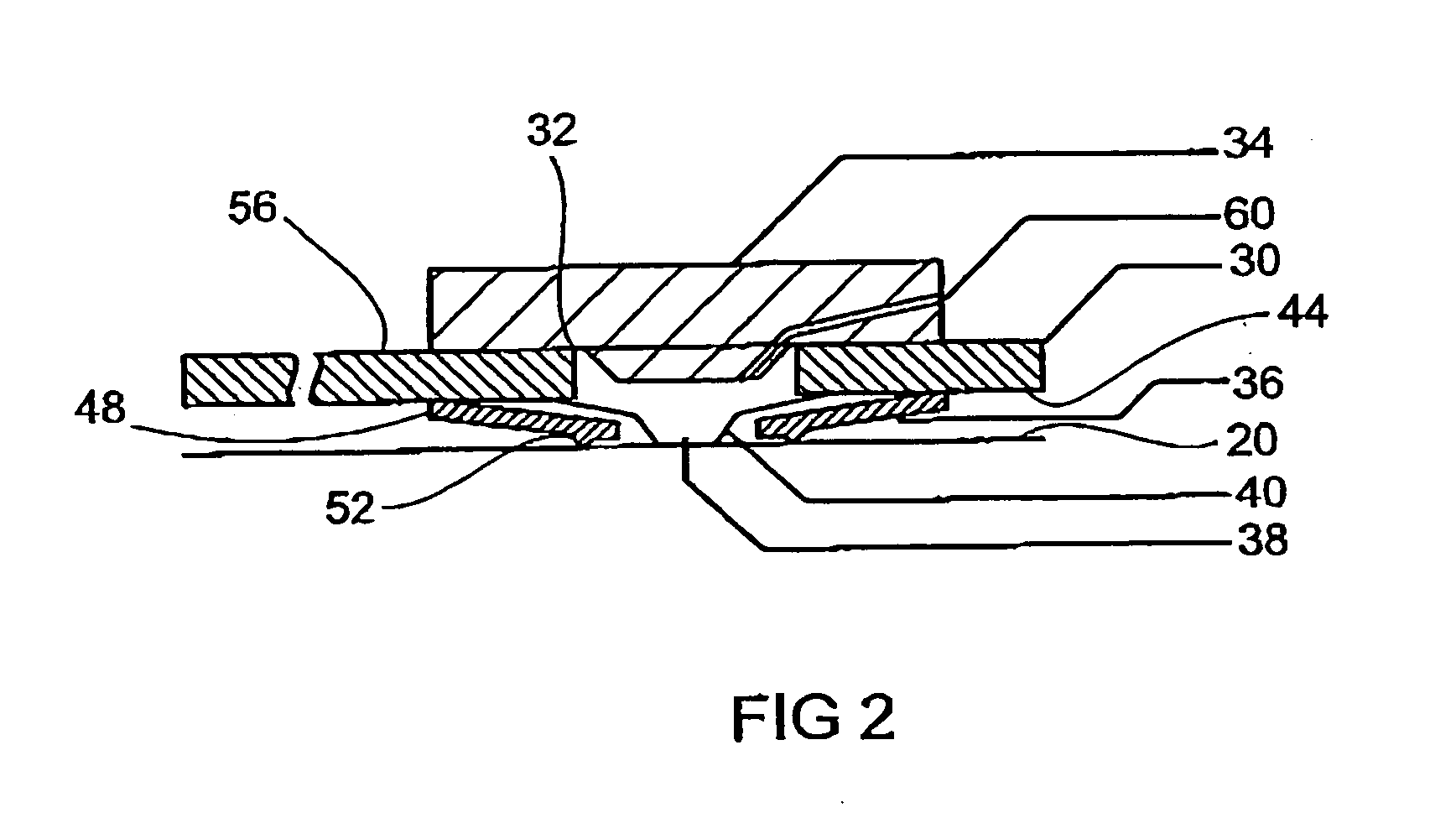

Pre-filled drug-delivery device and method of manufacture and assembly of same

A drug delivery device having a base member defining a skin-contacting surface, a syringe serving as a reservoir for the drug, and means for expelling drug from the syringe. The syringe is connected to the base member such that the longitudinal axis of the syringe is substantially parallel to the skin surface. A delivery needle is in communication with the syringe. The needle has an angled bend which directs the tip of the needle substantially perpendicular to the skin-contacting surface. In use, the tip of the needle is adapted to penetrate the skin of the subject.

Owner:ELAN PHRMA INT LTD

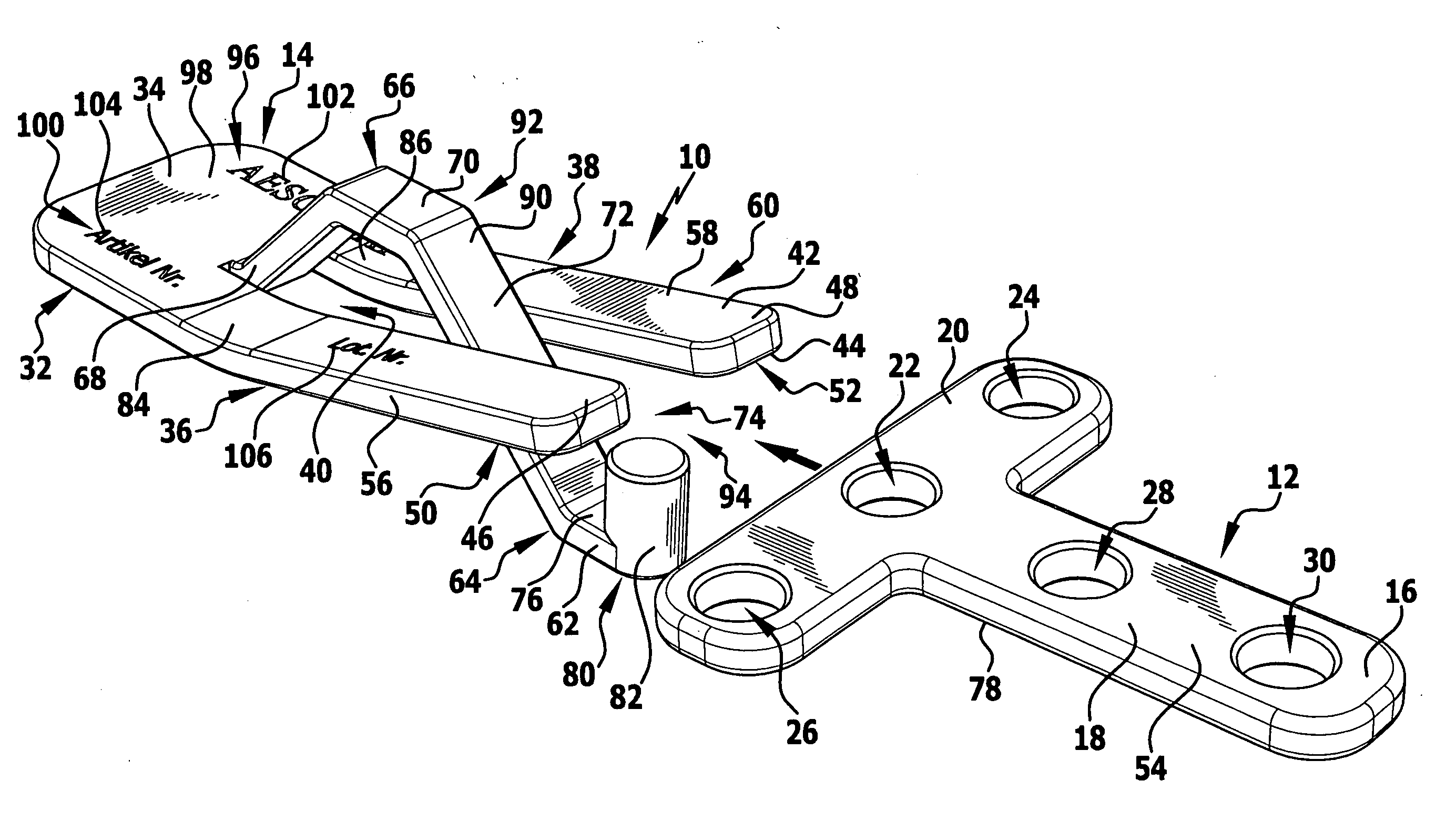

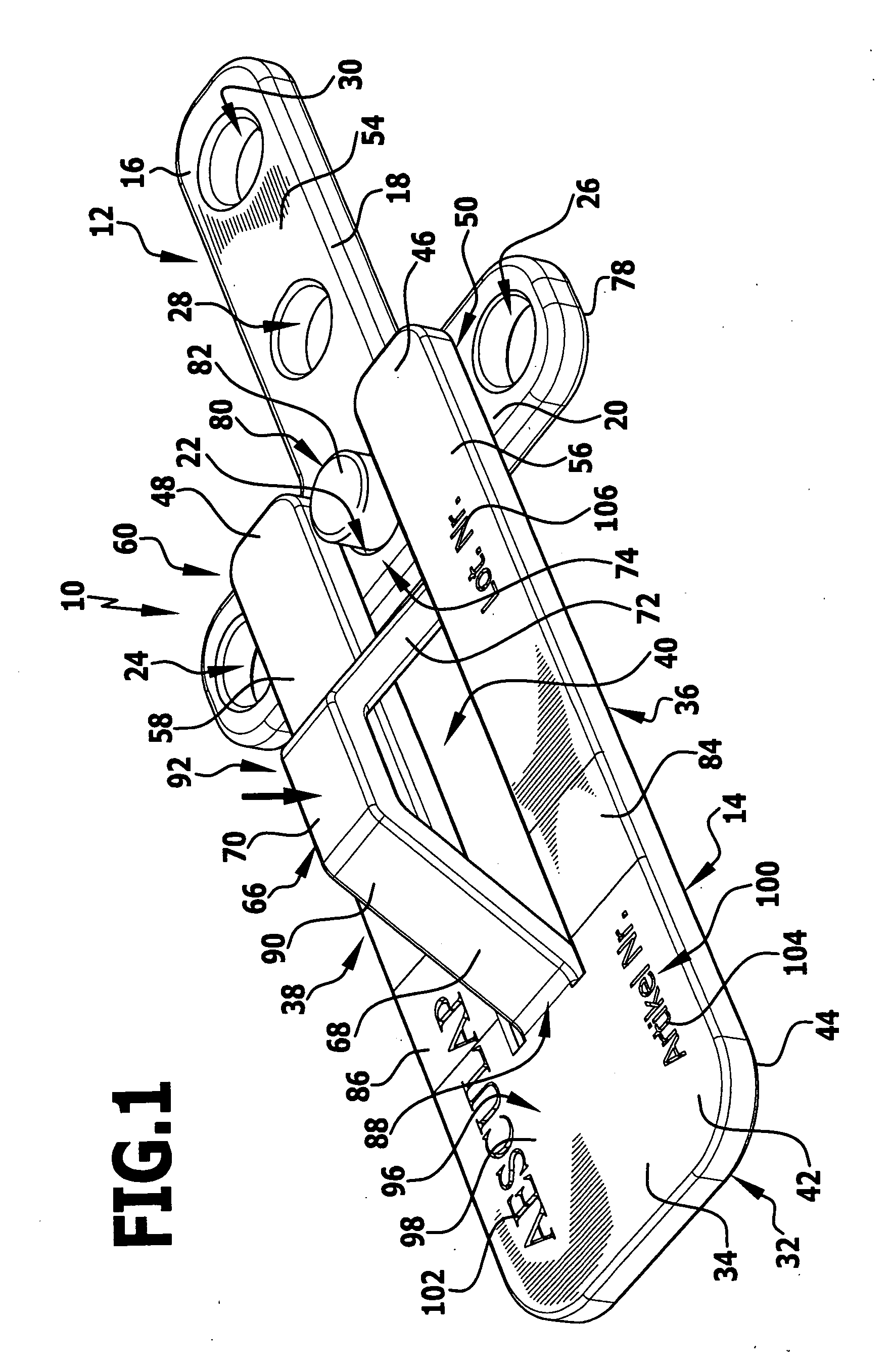

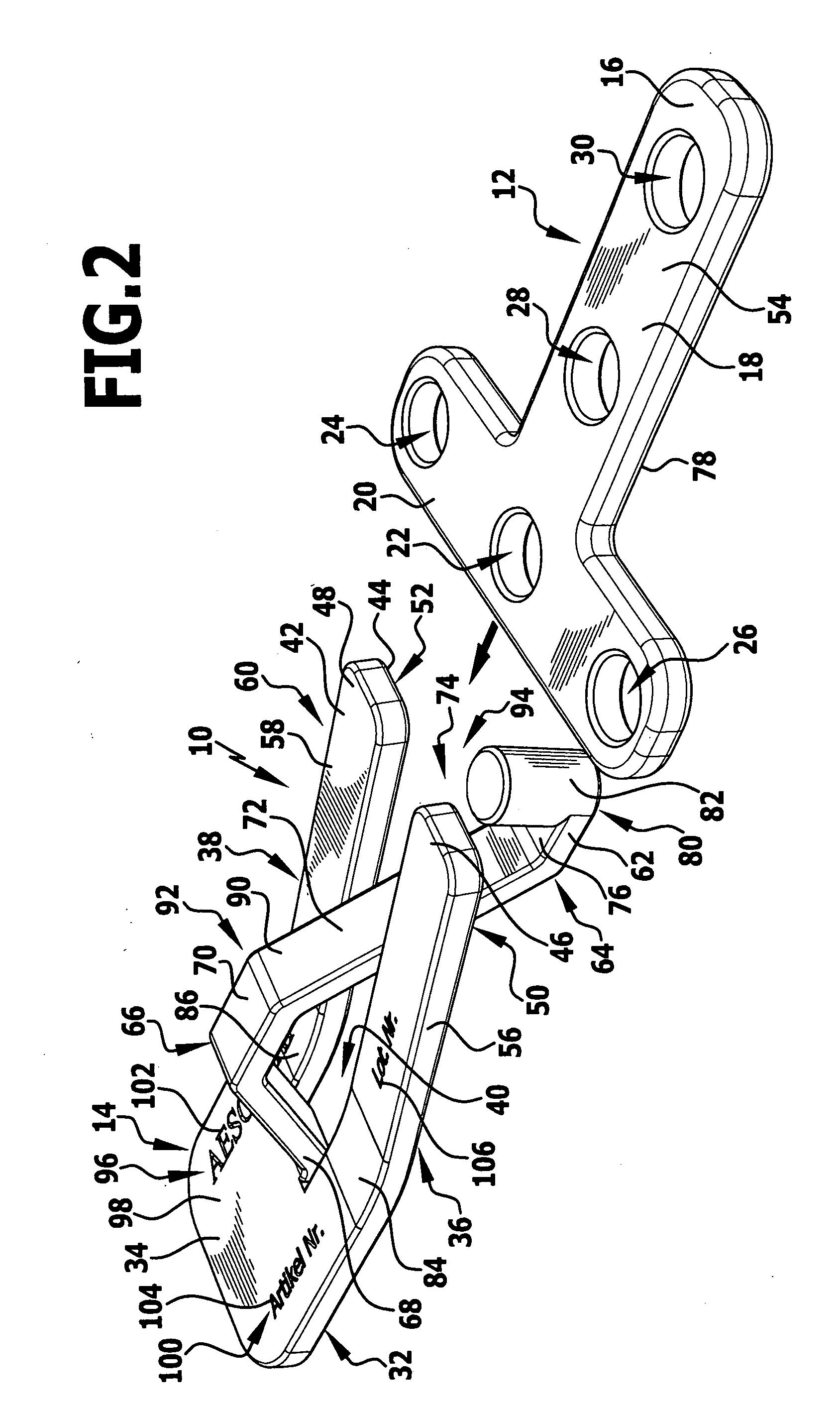

Surgical data carrier

InactiveUS20080230422A1Risk of infectionAdvantageously producedDiagnosticsSurgical needlesBone fragmentBiomedical engineering

The invention relates to a surgical data carrier for the identification of a medical implant, in particular, a surgical plate for the fixing of bones or bone fragments, wherein the data carrier has a carrier element and a connecting device which comprises a receptacle for the insertion of at least part of the implant. In order to make such a surgical data carrier available which has an improved handling capability, it is suggested in accordance with the invention that the data carrier have an actuating device which can be actuated by a user and with which the connecting device can be transferred from a connecting position, in which the implant is held in the receptacle, into a release position, in which the data carrier can be detached from the implant. The invention relates, in addition, to a surgical implantation system.

Owner:AESCULAP AG

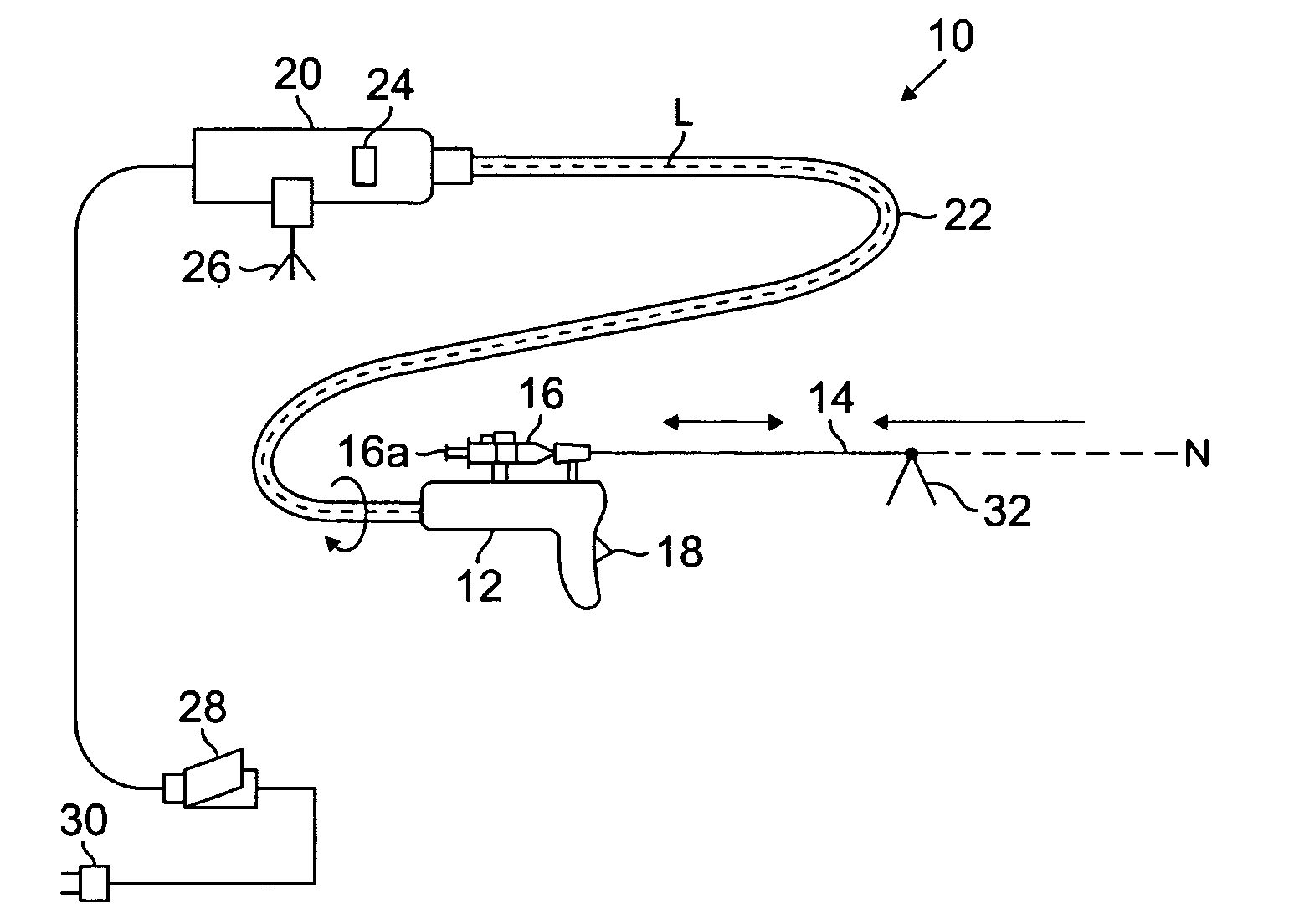

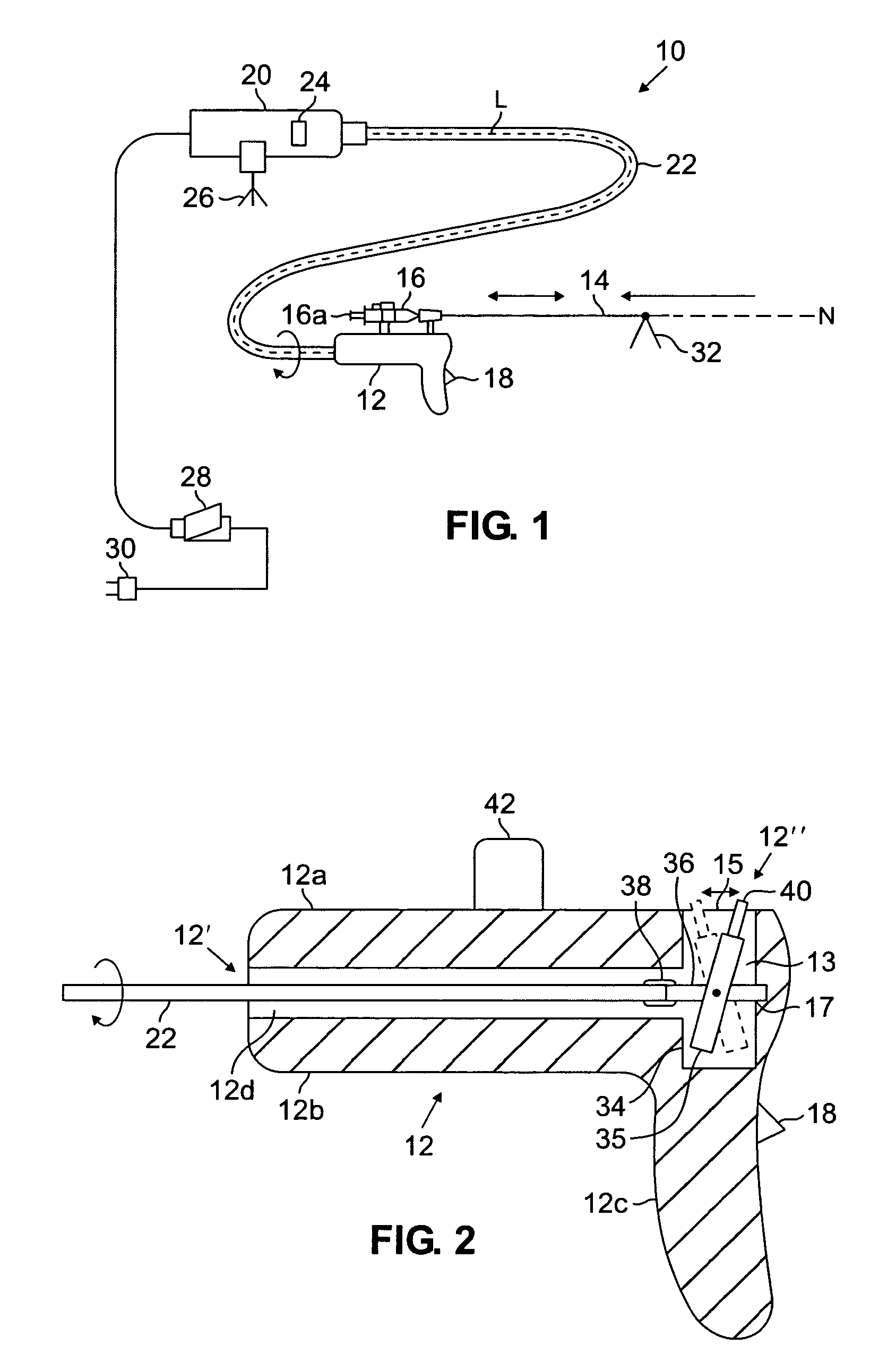

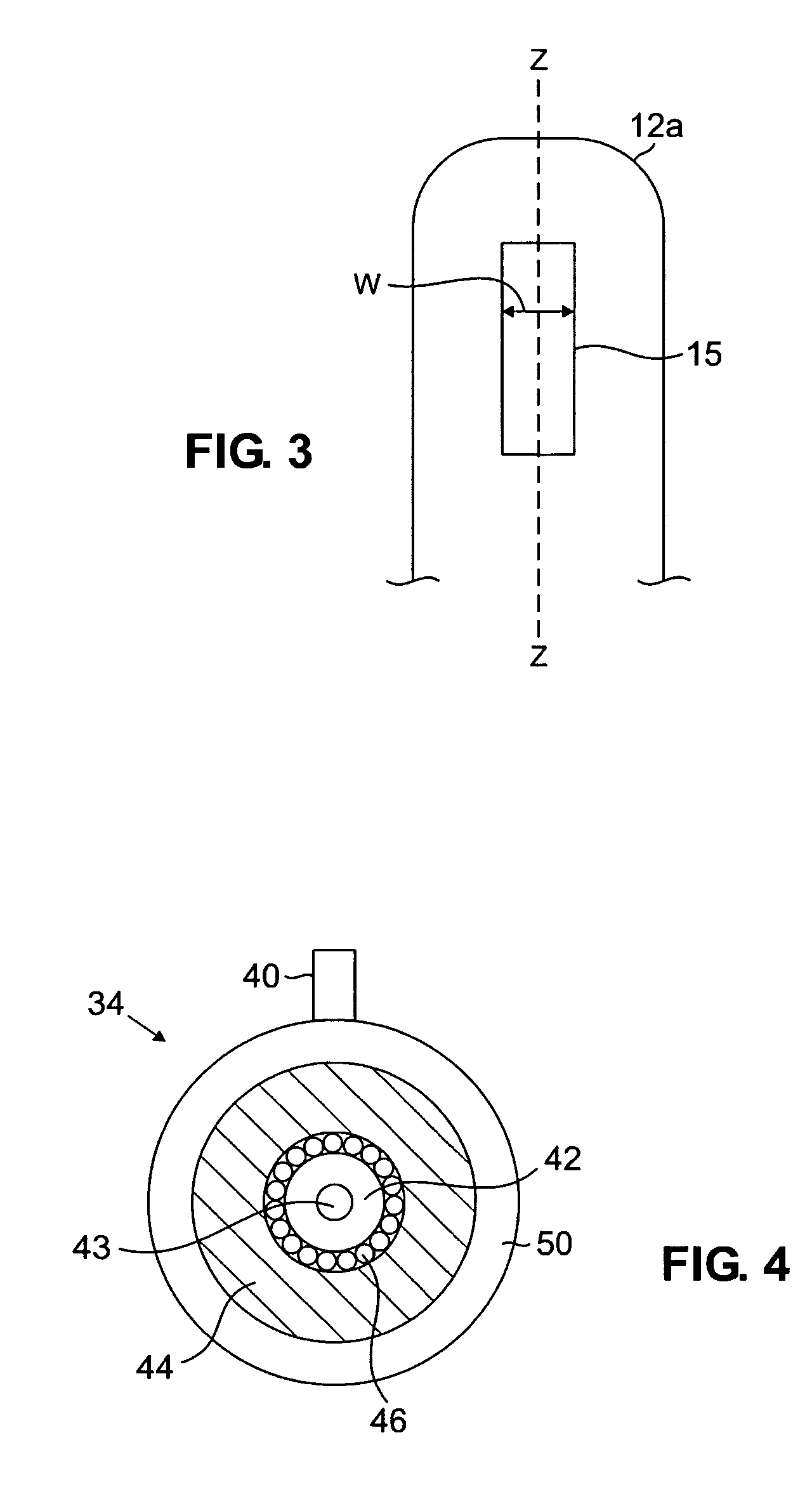

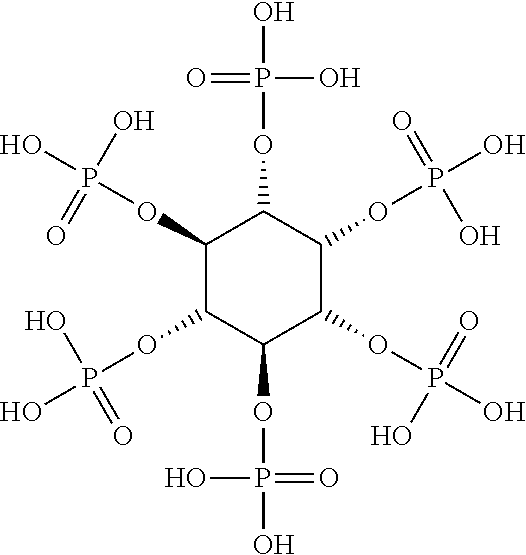

Method of conducting a needle biopsy procedure

InactiveUS7008383B1Reduce harmReduce frictionSurgical needlesVaccination/ovulation diagnosticsBiopsy procedureReciprocating motion

A vibration assisted needle device is disclosed for use in medical procedures such as needle aspiration biopsies. Reciprocation of the needle, such as a biopsy needle, eases the advance of the needle through tissue, penetration of the site of interest and the collection of sample at a site of interest. The device comprises a housing defining a chamber, a needle support external to the chamber for supporting a needle and a mechanism in the chamber for causing reciprocatory motion of the needle support. The needle support is preferably external to the housing. A syringe support may be connected to the housing for supporting a syringe. The reciprocatory mechanism may comprise means for converting rotational motion into reciprocating motion, such as a bearing or a rotor with a circumferential, angled groove on its surface, coupled to the needle support. The bearing or the rotor may be driven by a rotational motor, preferably located outside of the housing, or by a hydraulically driven turbine within the housing. Alternatively, the reciprocatory mechanism means may comprise a stationary solenoid and a movable solenoid for being coupled to the needle. Preferably, a second stationary solenoid is provided and the moving solenoid is between the two stationary solenoids. Energization of the stationary solenoid or solenoids by an alternating current for example, and energization of the movable solenoid by a direct current, or vice versa, attracts and repulses the movable solenoid, causing reciprocation of the needle. Methods and systems using the vibration assisted needle device are also disclosed.

Owner:FONAR

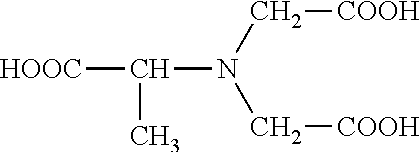

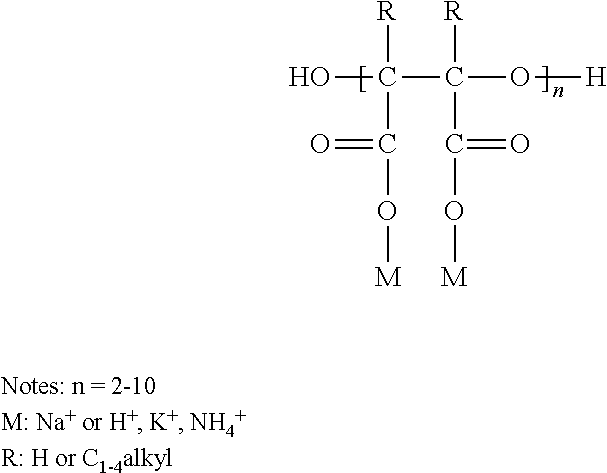

Biodegradable activators to gel silica sol for blocking permeability

ActiveUS20130292120A1Risk of damageDrilling compositionSealing/packingButanedioic acidSalicylic acid

A method of treating a treatment zone in a well to reduce the permeability of the treatment zone including the steps of: introducing into the treatment zone a water-based treatment fluid comprising: an aqueous silica sol; and a water-soluble chemical activator for gelling the silica sol, wherein the chemical activator is selected from the group consisting of: phytic acid, methylglycinediacetic acid, a water-soluble polyepoxysuccinic acid, salicylic acid, ascorbic acid, tannic acid, and an alkali metal salt or ammonium salt of any of the foregoing; and shutting in treatment zone for at least a sufficient time to allow the treatment fluid to in-situ form a solid gel at a design temperature for the method. Alternatively, a first treatment fluid including the aqueous silica sol and a second treatment fluid including the chemical activator can be introduced into the treatment zone separately, in any order.

Owner:HALLIBURTON ENERGY SERVICES INC

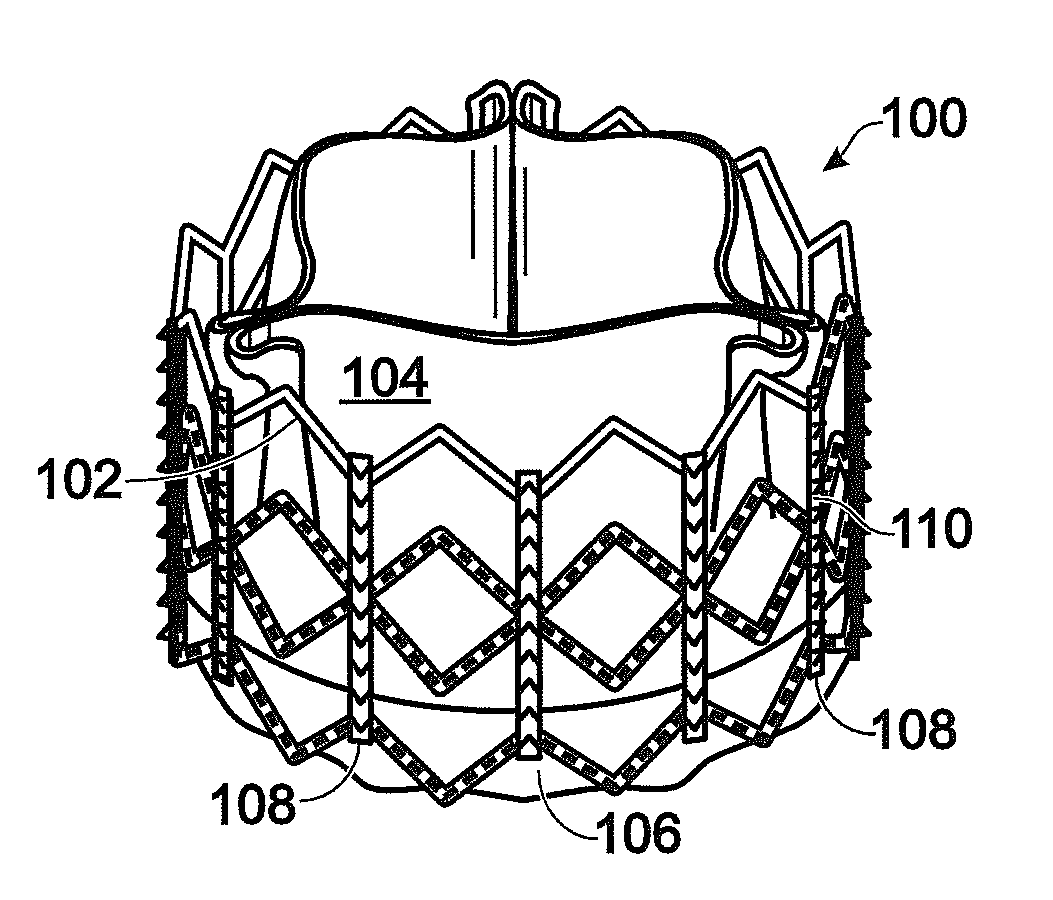

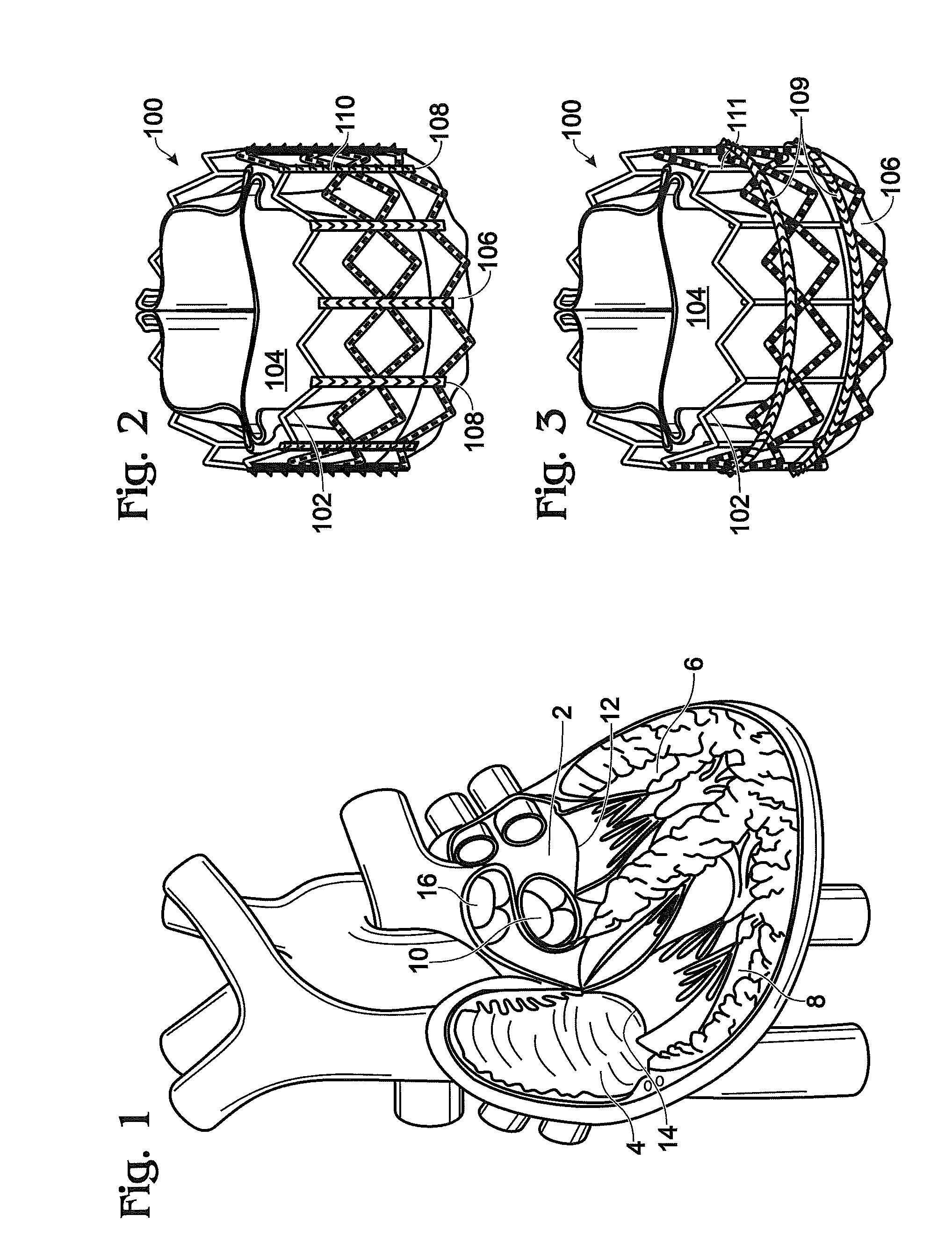

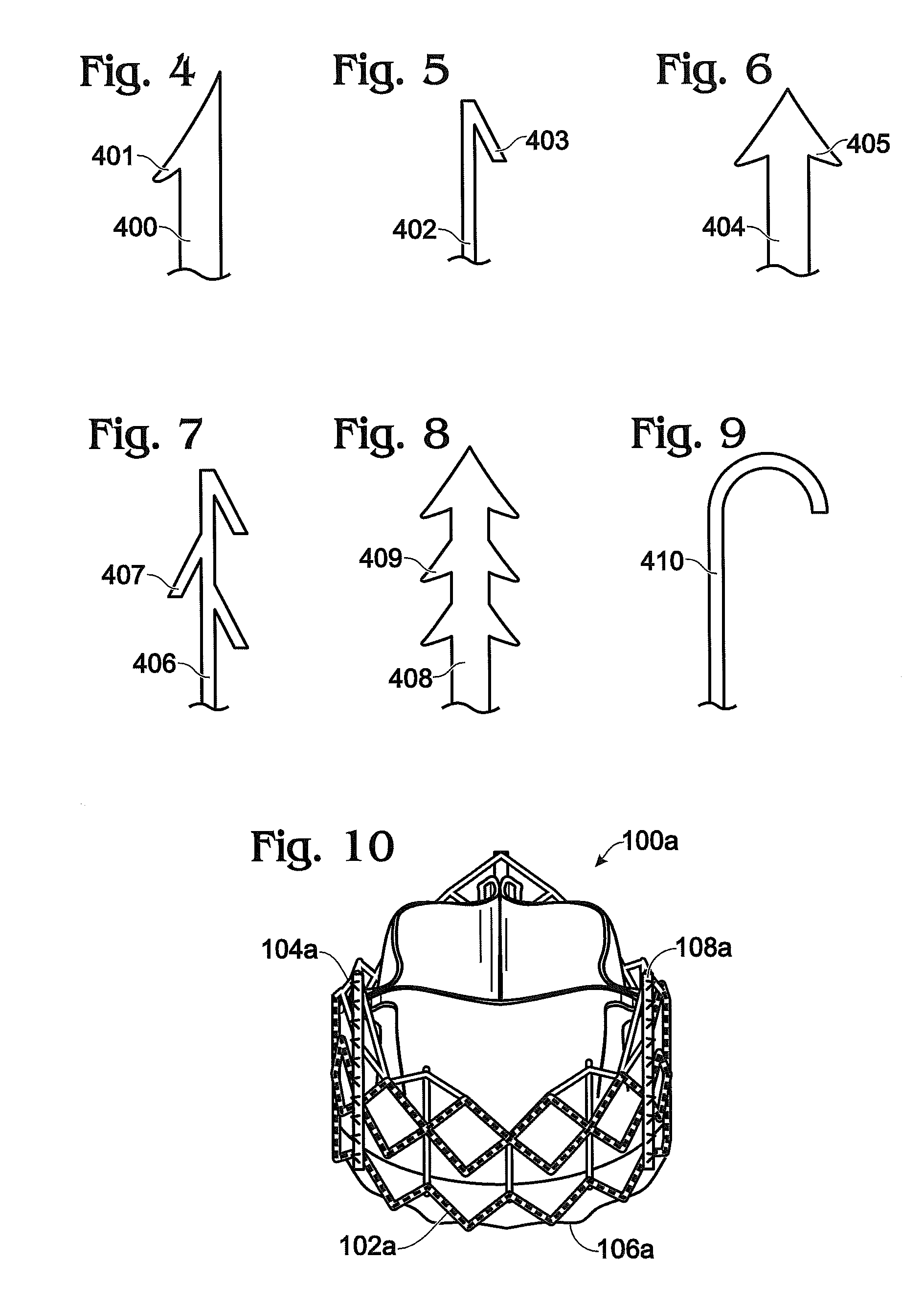

Transcatheter heart valve with micro-anchors

ActiveUS20130268066A1Risk of damageOption very attractiveStentsBalloon catheterHeart valveNative tissue

Methods and devices for treating defective heart valves are disclosed herein. In one exemplary embodiment, a transcatheter heart valve includes an expandable shape memory stent and a valve member supported by the stent. A plurality of micro-anchors can be disposed along an outer surface of the stent for engaging native tissue. The transcatheter heart valve can be configured to be advanced into a dilated valve annulus via a balloon catheter. The balloon can be inflated to expand the transcatheter heart valve from a collapsed diameter to an over-expanded diameter such that the micro-anchors engage tissue along the surrounding valve annulus. After engaging the tissue, the balloon can be deflated and the shape memory stent can retract or recoil toward its predetermined recoil diameter. As the stent recoils, the surrounding tissue is pulled inward by the stent such that the diameter of the valve annulus is reduced.

Owner:EDWARDS LIFESCIENCES CORP

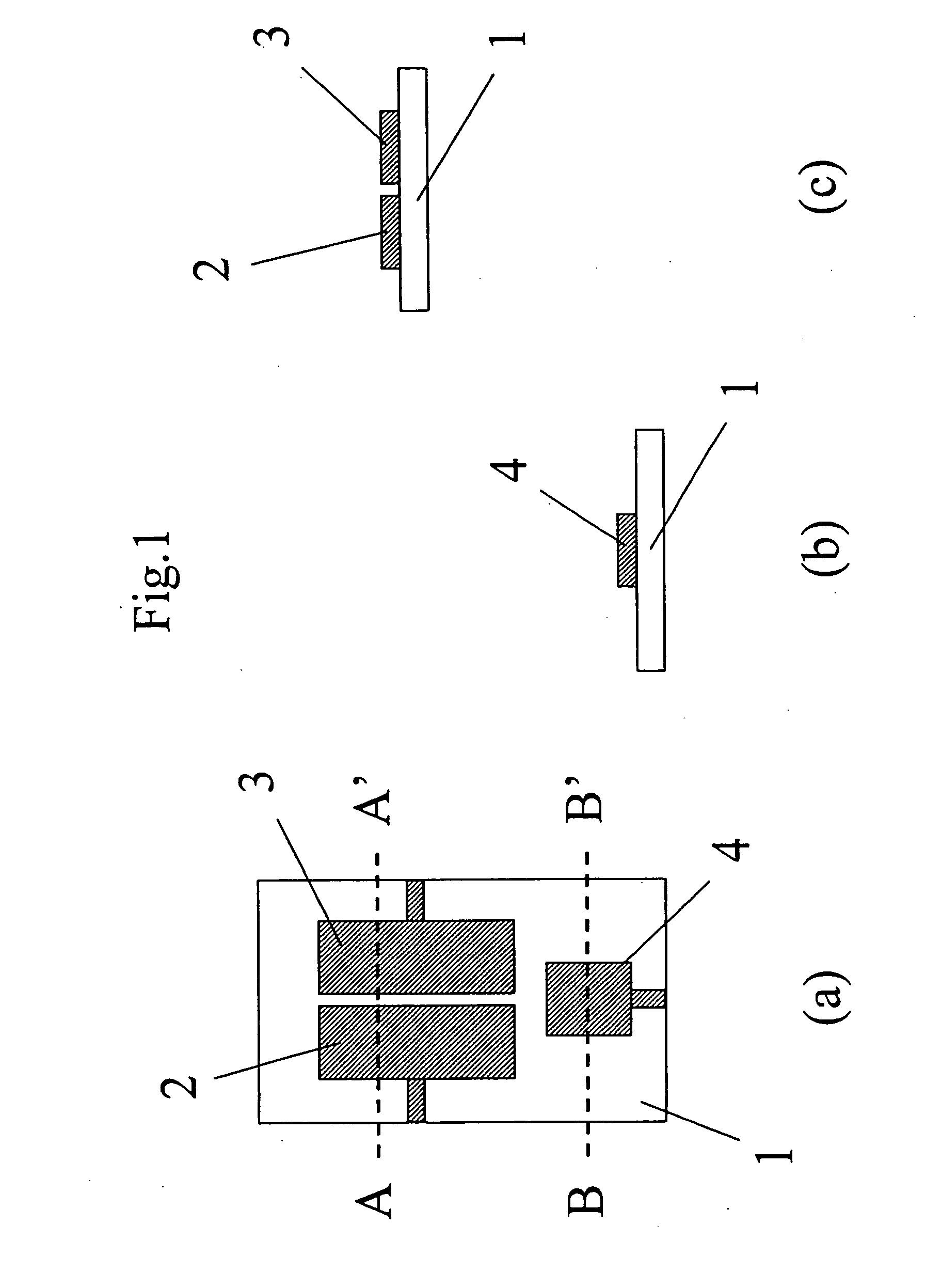

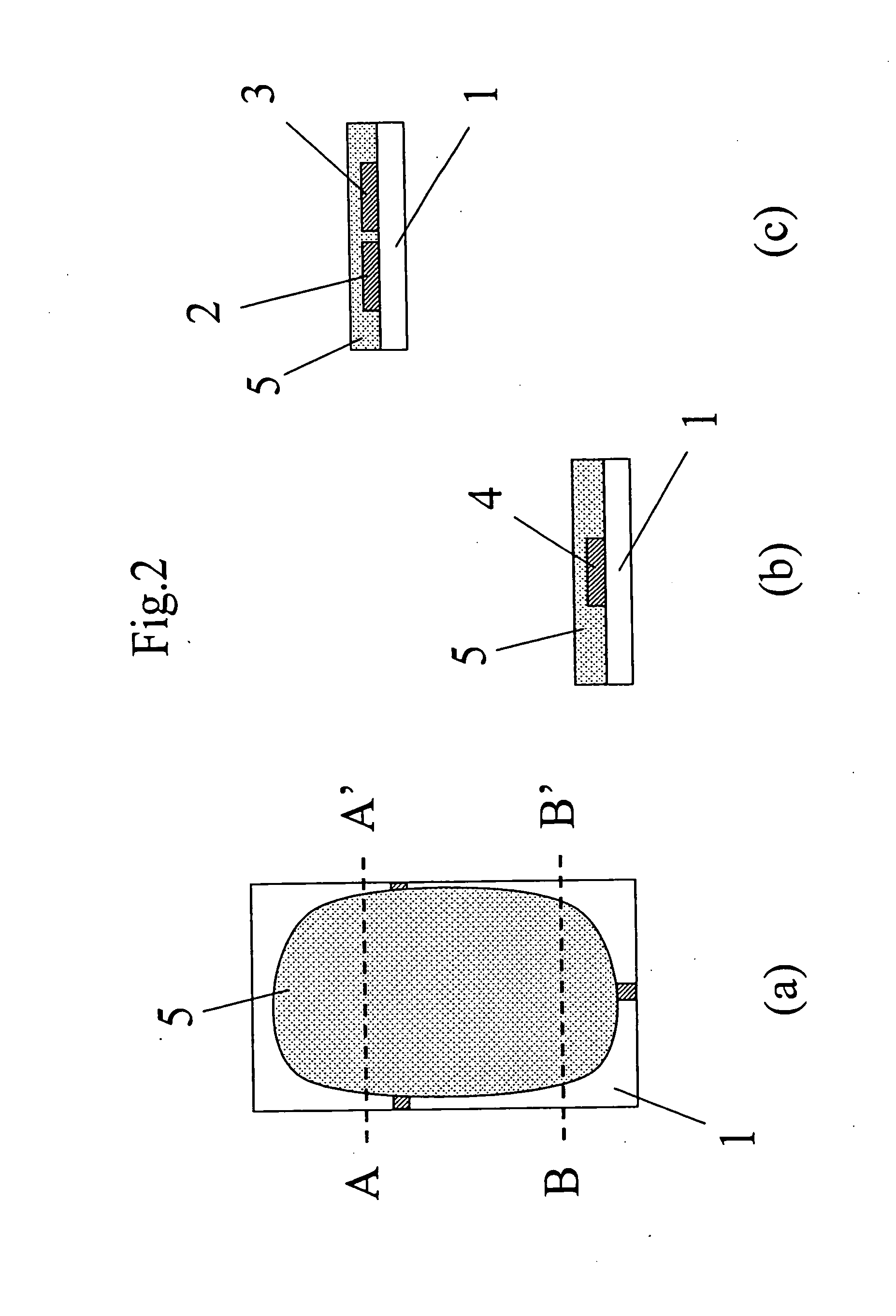

Electrolyte pattern and method for manufacturing an electrolyte pattern

InactiveUS20090042346A1Reduce riskPrevents leakage and diffusionSolid-state devicesSemiconductor/solid-state device manufacturingInkjet printingElectrolyte

A method for manufacturing a gel electrolyte pattern is disclosed, the method comprising depositing an electrolyte precursor by inkjet printing onto a gelling agent layer. A gel electrolyte pattern is also disclosed, the gel electrolyte pattern comprising either a mixture of a gelling agent and an electrolyte precursor or the products of a chemical reaction between a gelling agent and an electrolyte precursor.

Owner:SEIKO EPSON CORP

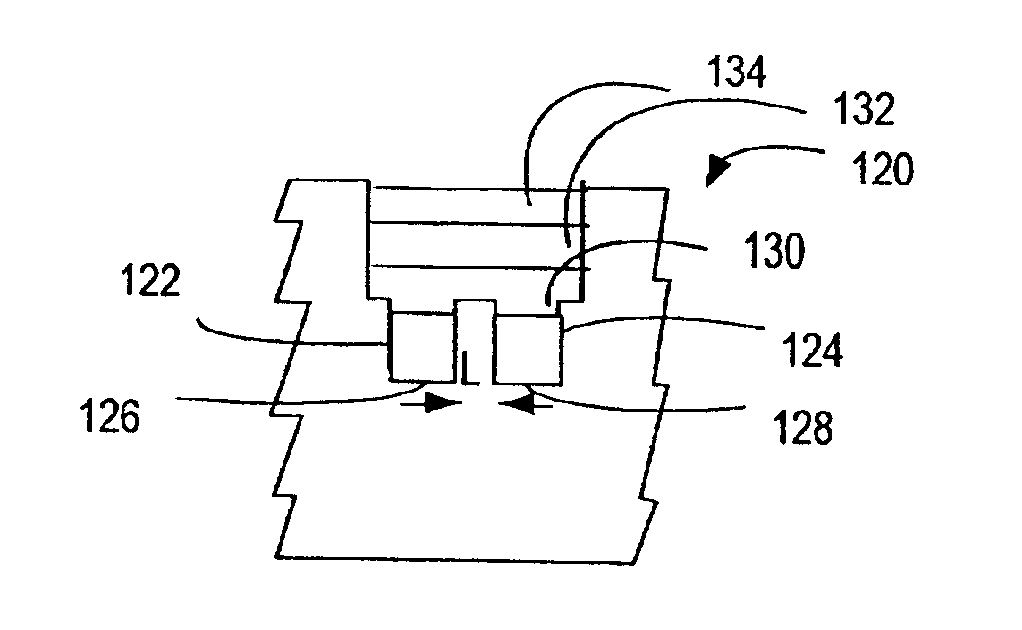

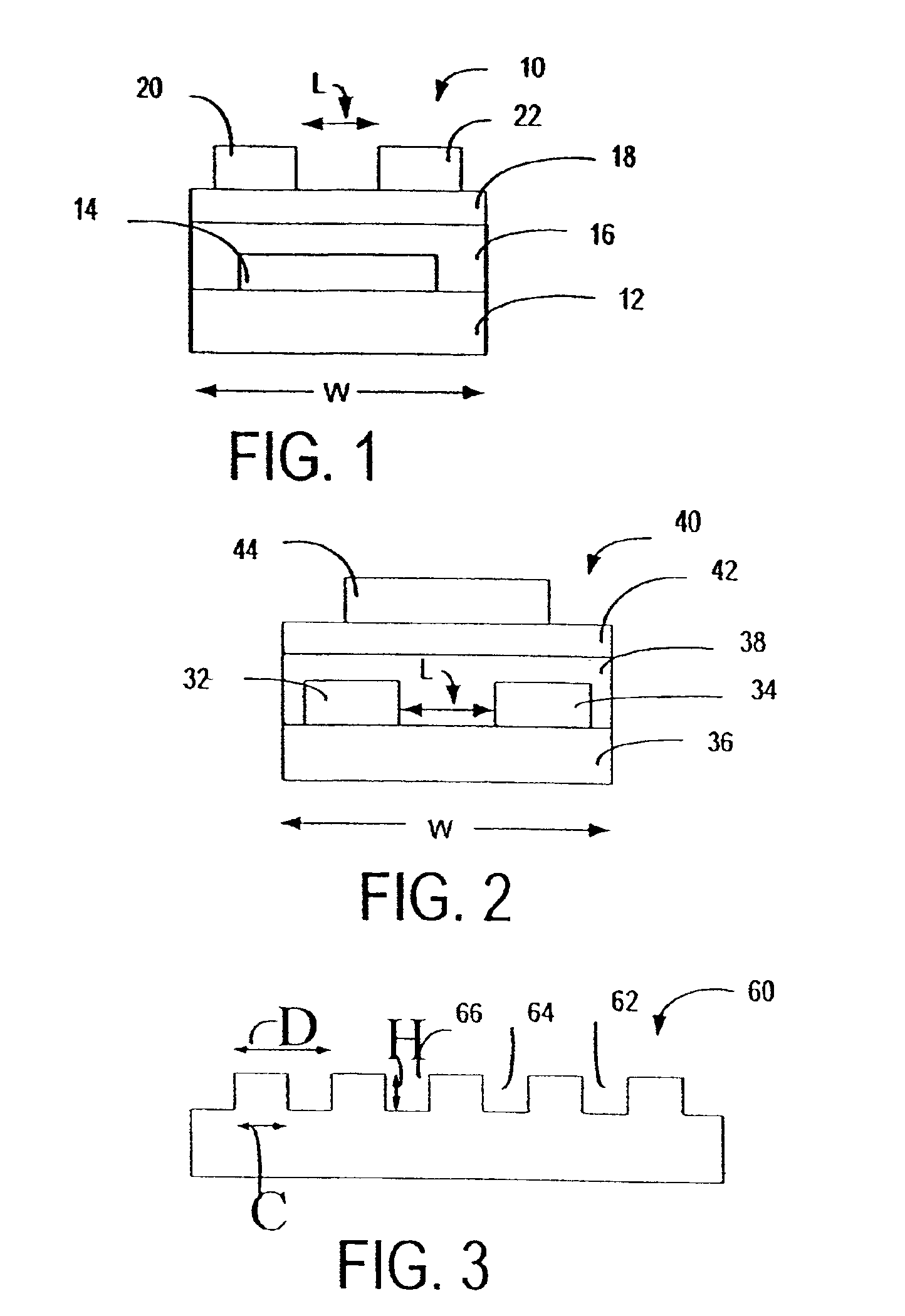

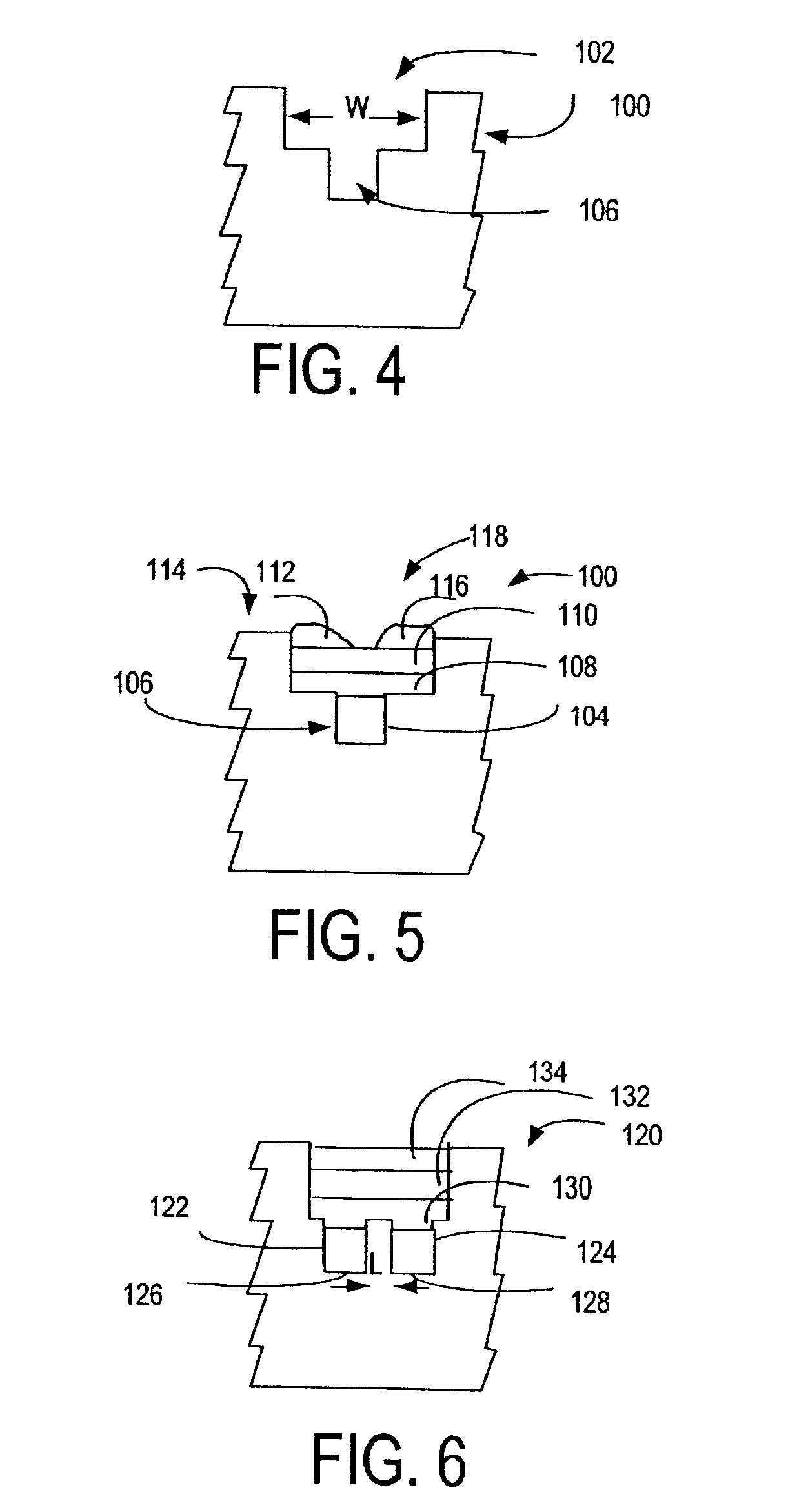

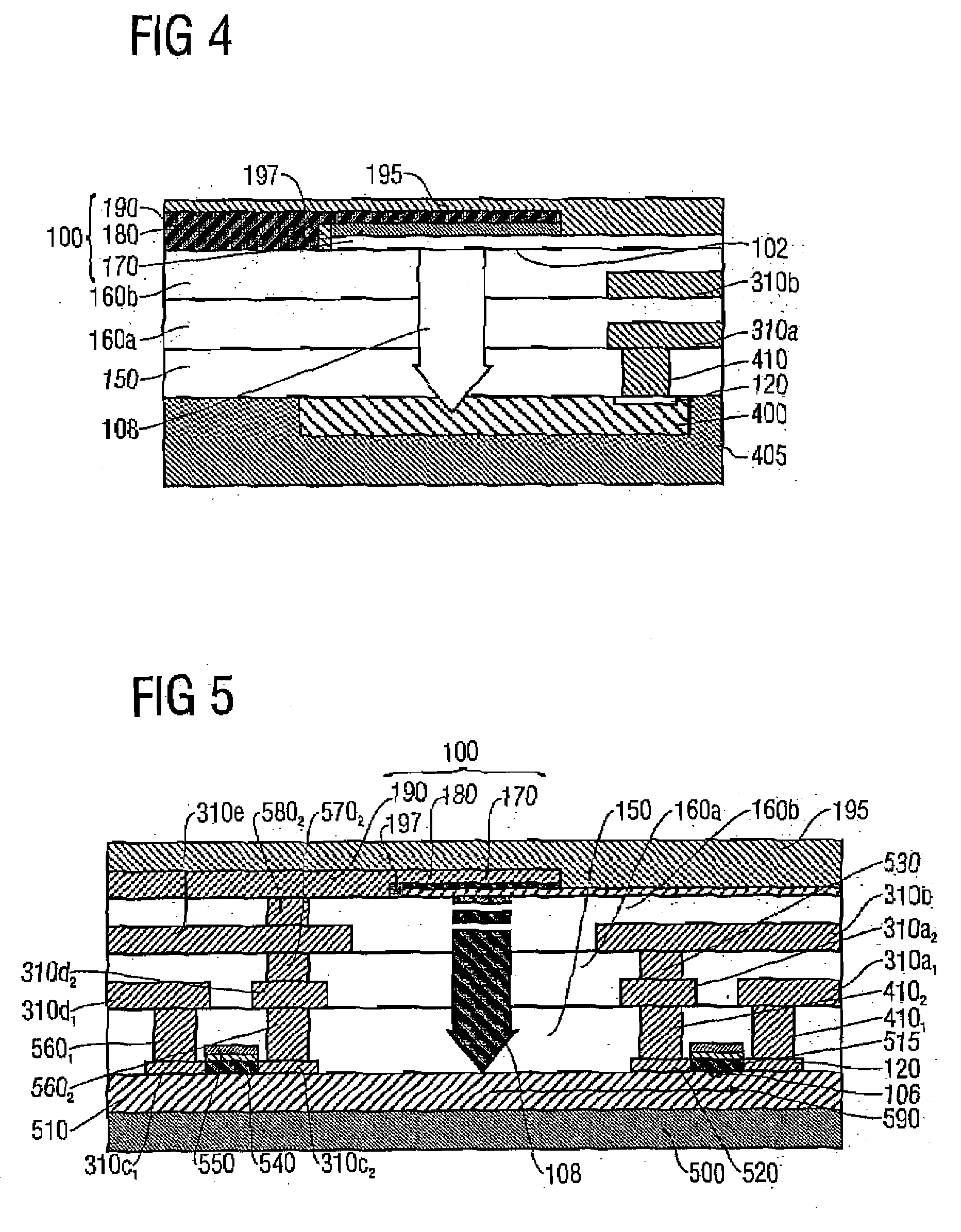

Pre-patterned substrate for organic thin film transistor structures and circuits and related method for making same

InactiveUS6946677B2Low costShort time frameSolid-state devicesSemiconductor/solid-state device manufacturingInjection molding processEngineering

Grooves in a desired circuit configuration are formed in the surface of a substrate to pre-pattern the area to receive material forming an organic thin film transistor (OTFT) structure and interconnecting conductive paths. The OTFT material is deposited in the pre-patterned area using printing techniques such as ink jet printing. In one embodiment, the grooves are formed in the surface substrate during the injection molding process of the substrate. Inter-exchangeable device covers carry different substrates to provide different functionalities of an electronic device with which the covers are used.

Owner:RPX CORP

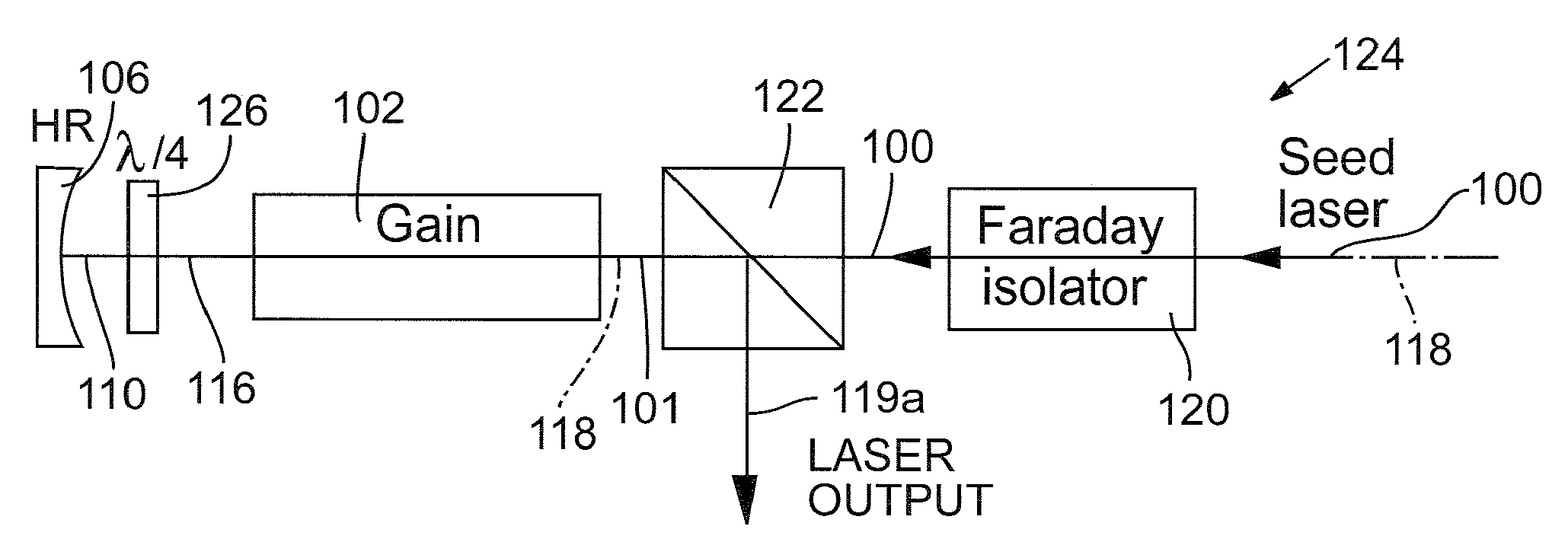

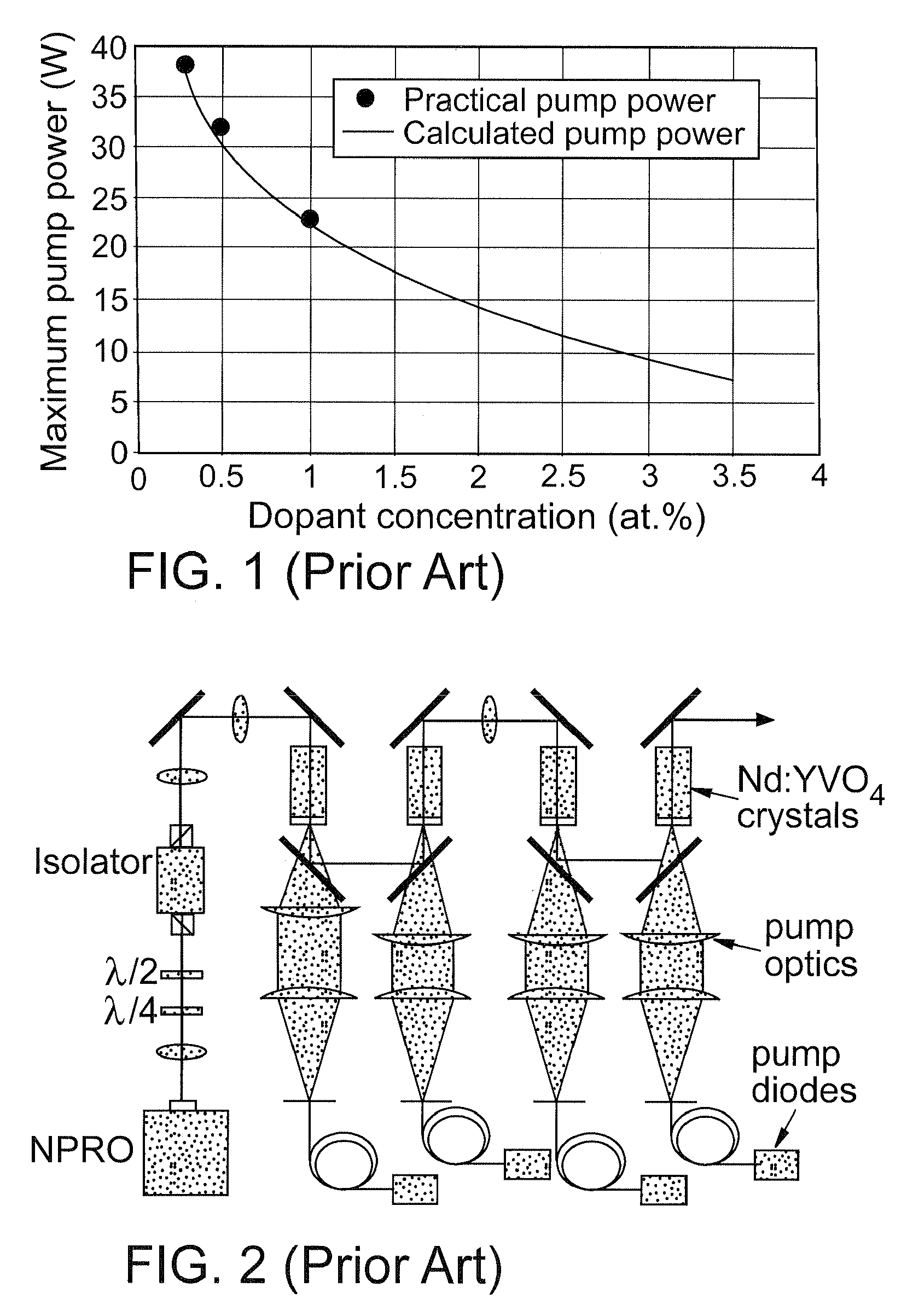

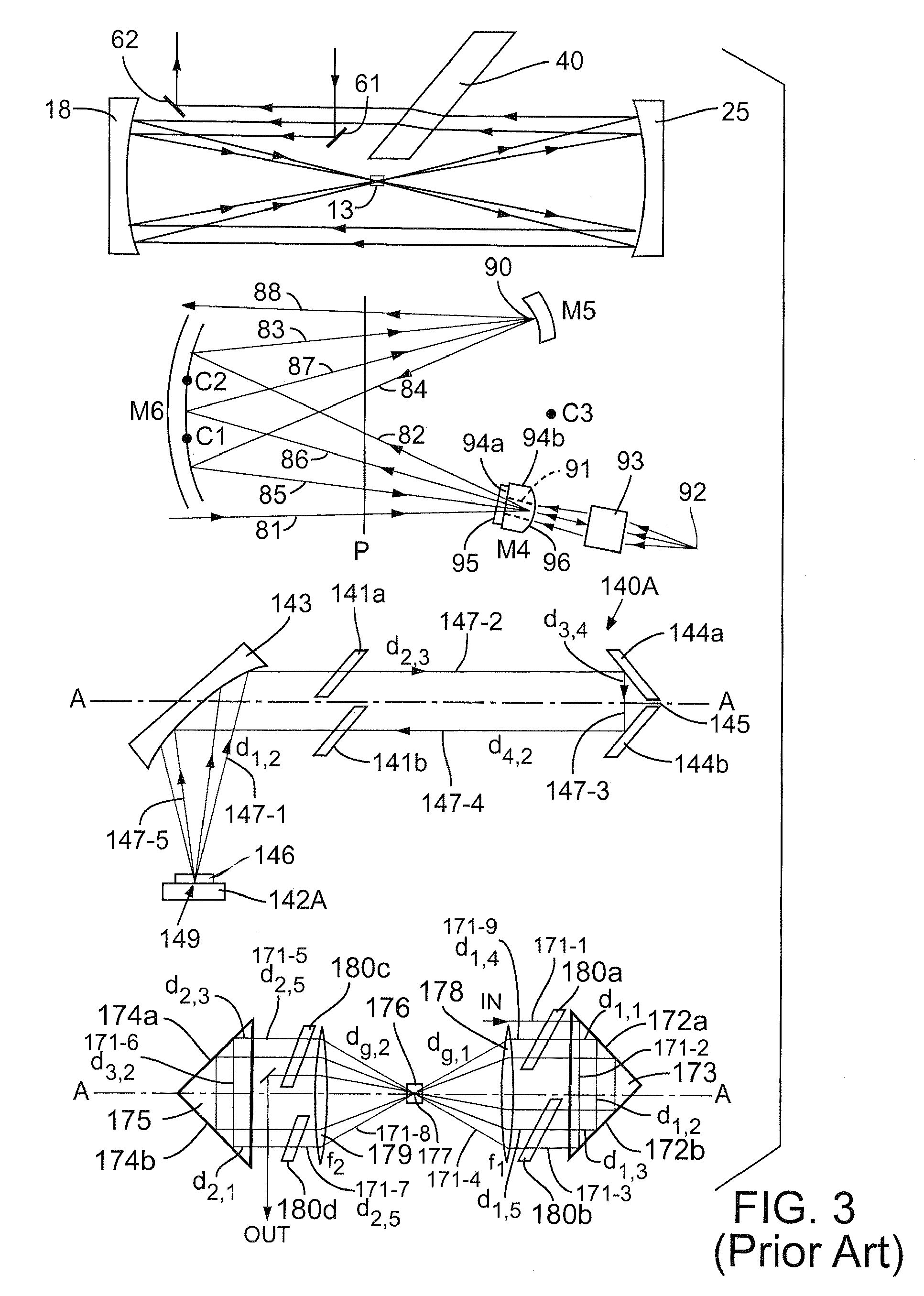

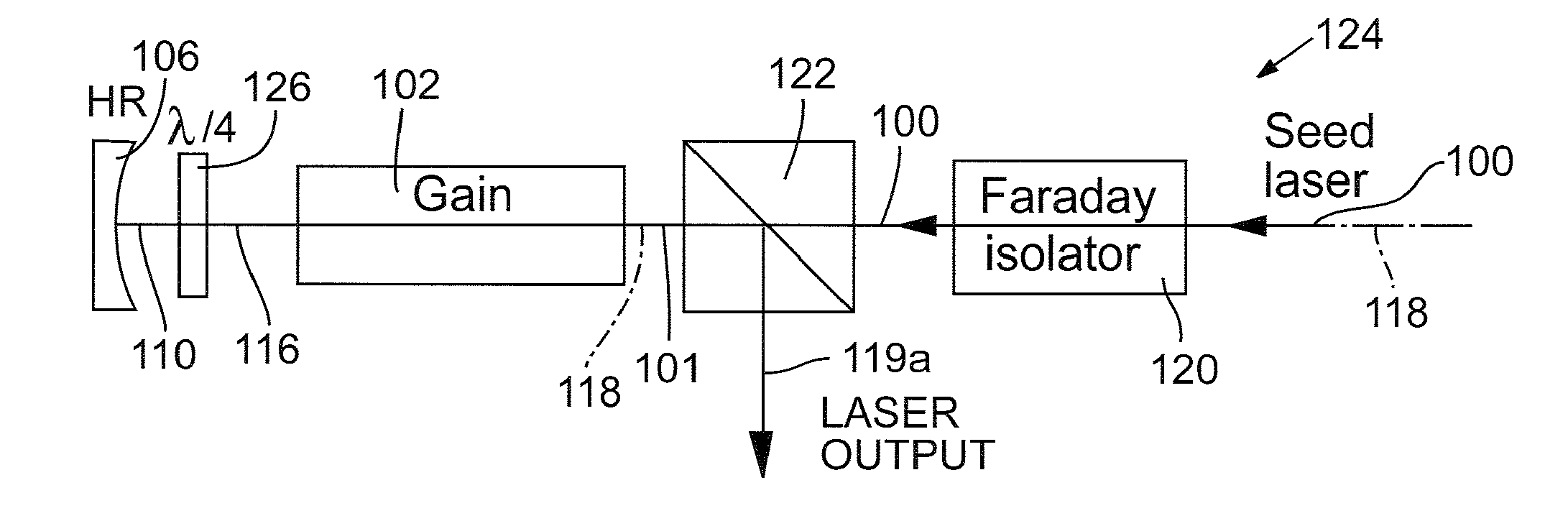

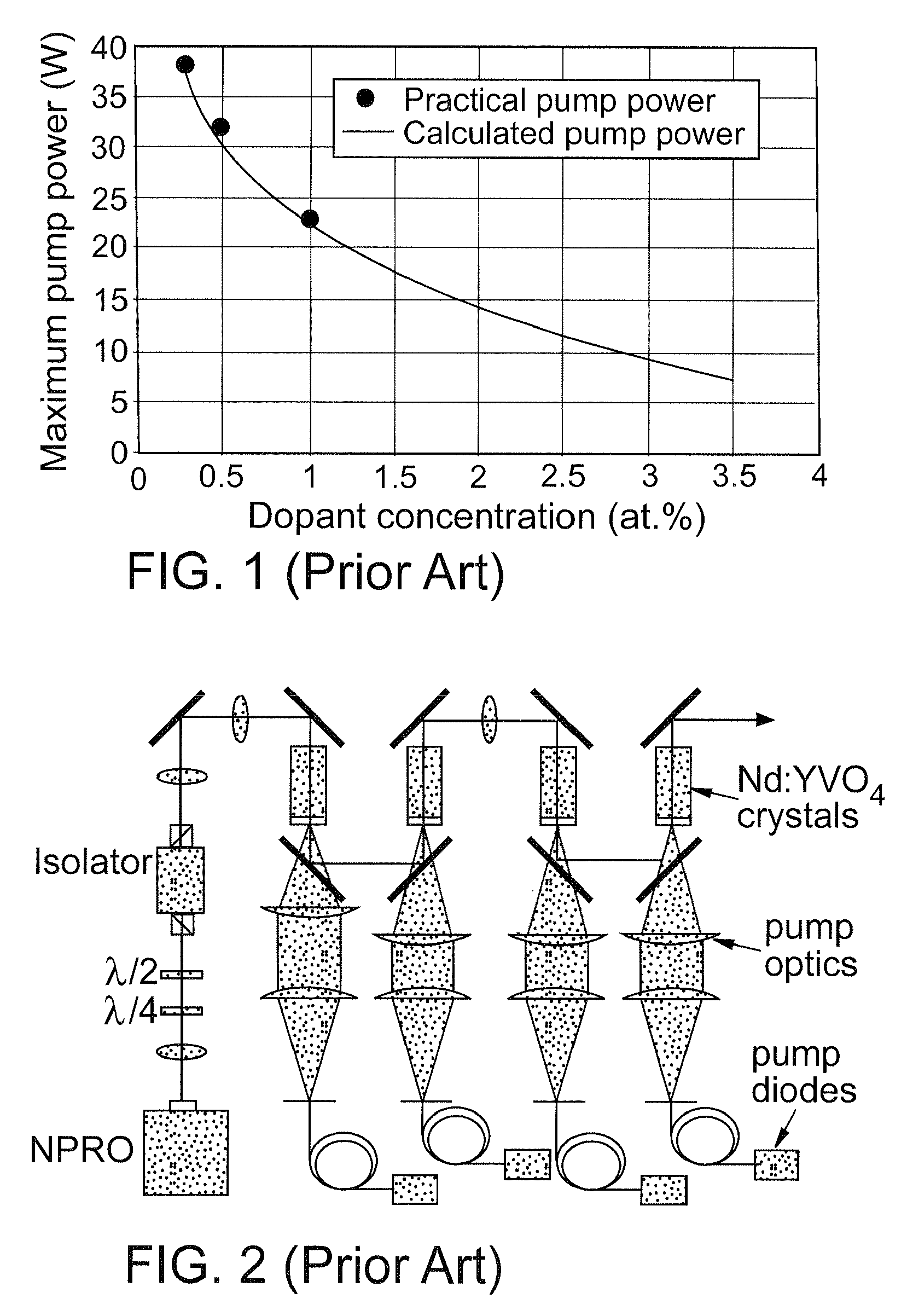

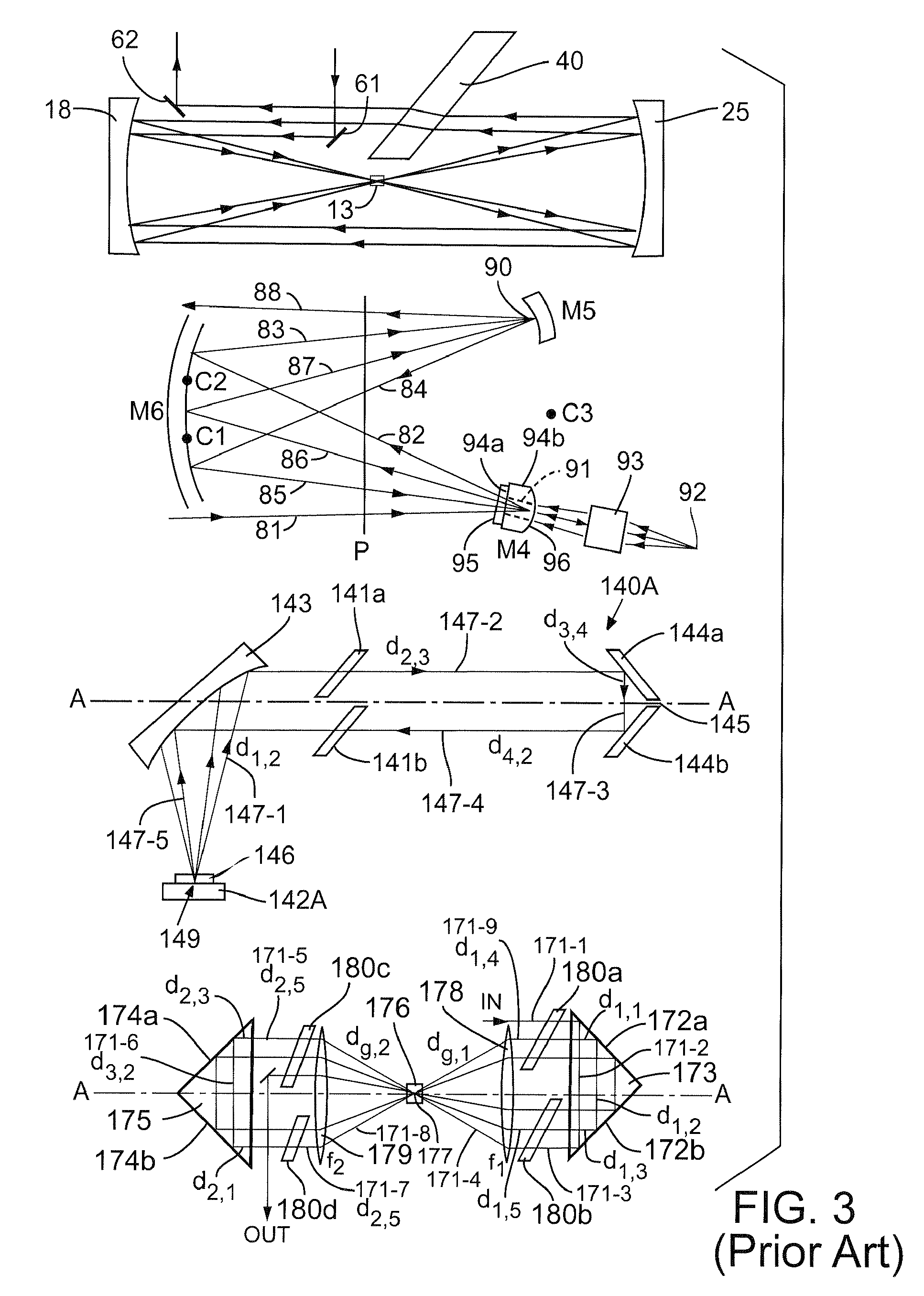

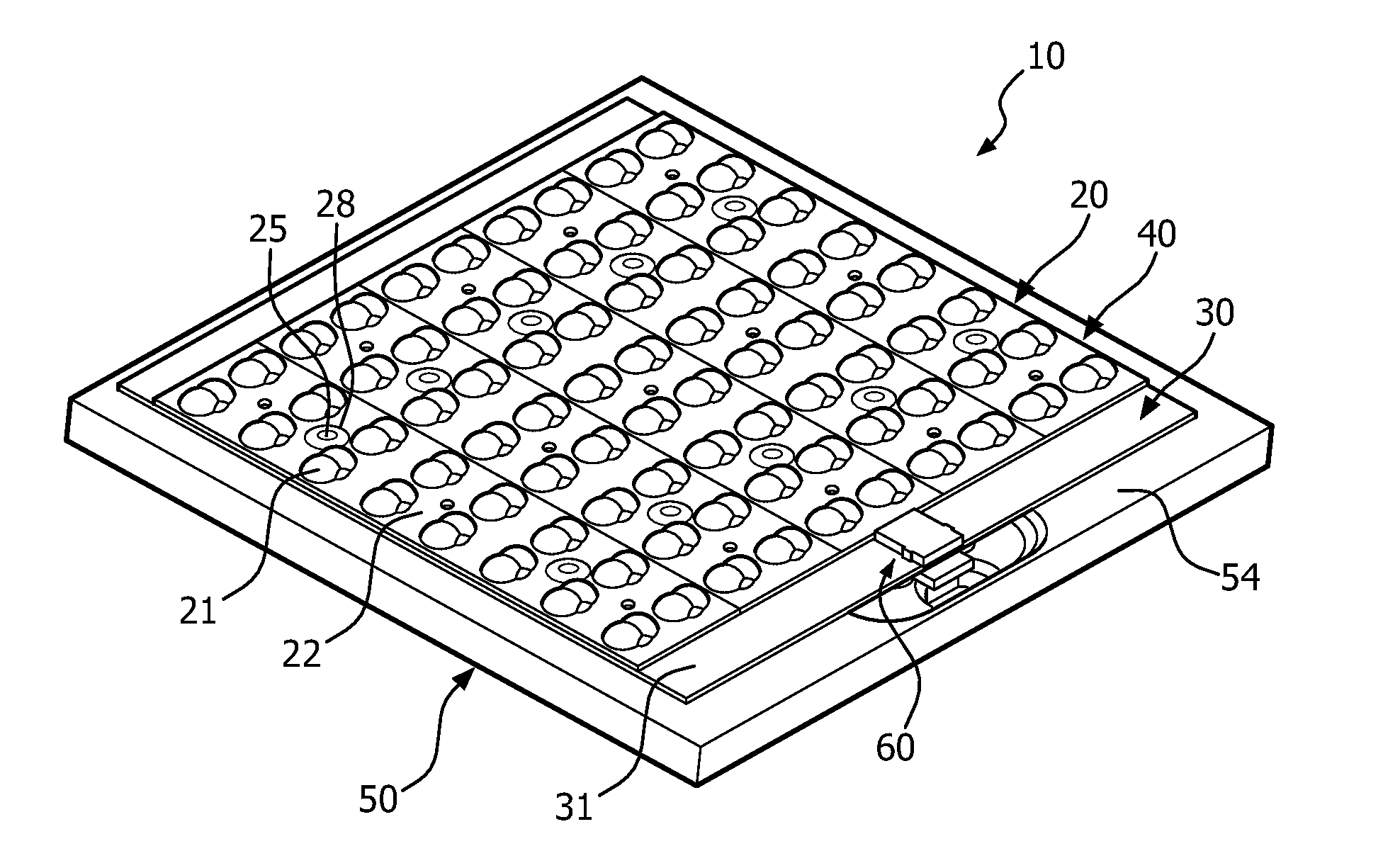

Multi-pass optical power amplifier

InactiveUS20090245304A1Quality improvementEffect of depolarization is negligibleOptical resonator shape and constructionOptical devices for laserOptical powerAnisotropic crystal

Anisotropic crystals such as Nd:YVO4, Nd:YLF, and Nd:GdVO4 have become preferred gain materials for many laser applications. The anisotropic gain medium without ancillary compensation ensures there is no degradation of laser modes when passing through the gain medium. An optical power amplifier that incorporates an anisotropic gain medium achieves power scaling with multiple passes while also maintaining good mode matching between the laser and the pump during each pass. Preferred embodiments implement for multiple passes of a seed laser beam through an anisotropic gain medium with substantially zero angular beam displacement during each pass. The multi-pass system provides an economical, reliable method of achieving high TEM00 power to meet the demands of micromachining, via drilling, and harmonic conversion applications.

Owner:ELECTRO SCI IND INC

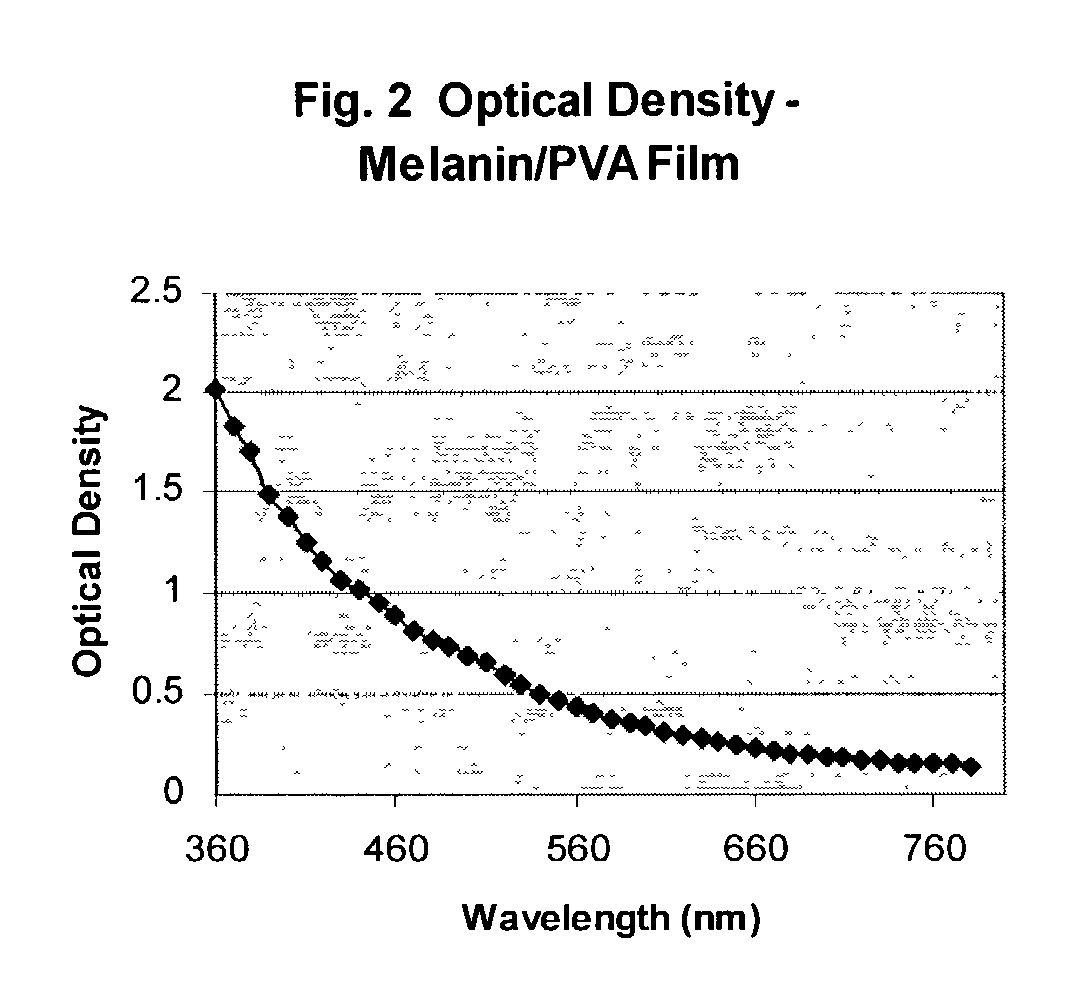

Melanin polyvinyl alcohol plastic laminates for optical applications

InactiveUS7029758B2Great riskReduce risk of damagePhotosensitive materialsDiffusing elementsWater solublePlastic film

The present invention relates to the use of water soluble melanin in solid plastic films of polyvinyl alcohol to be used in conjunction with other plastics to make laminated sheets or lenses. Such laminates will be used as filters to protect against photochemical damage from electromagnetic radiation.

Owner:PHOTOPROTECTIVE TECH

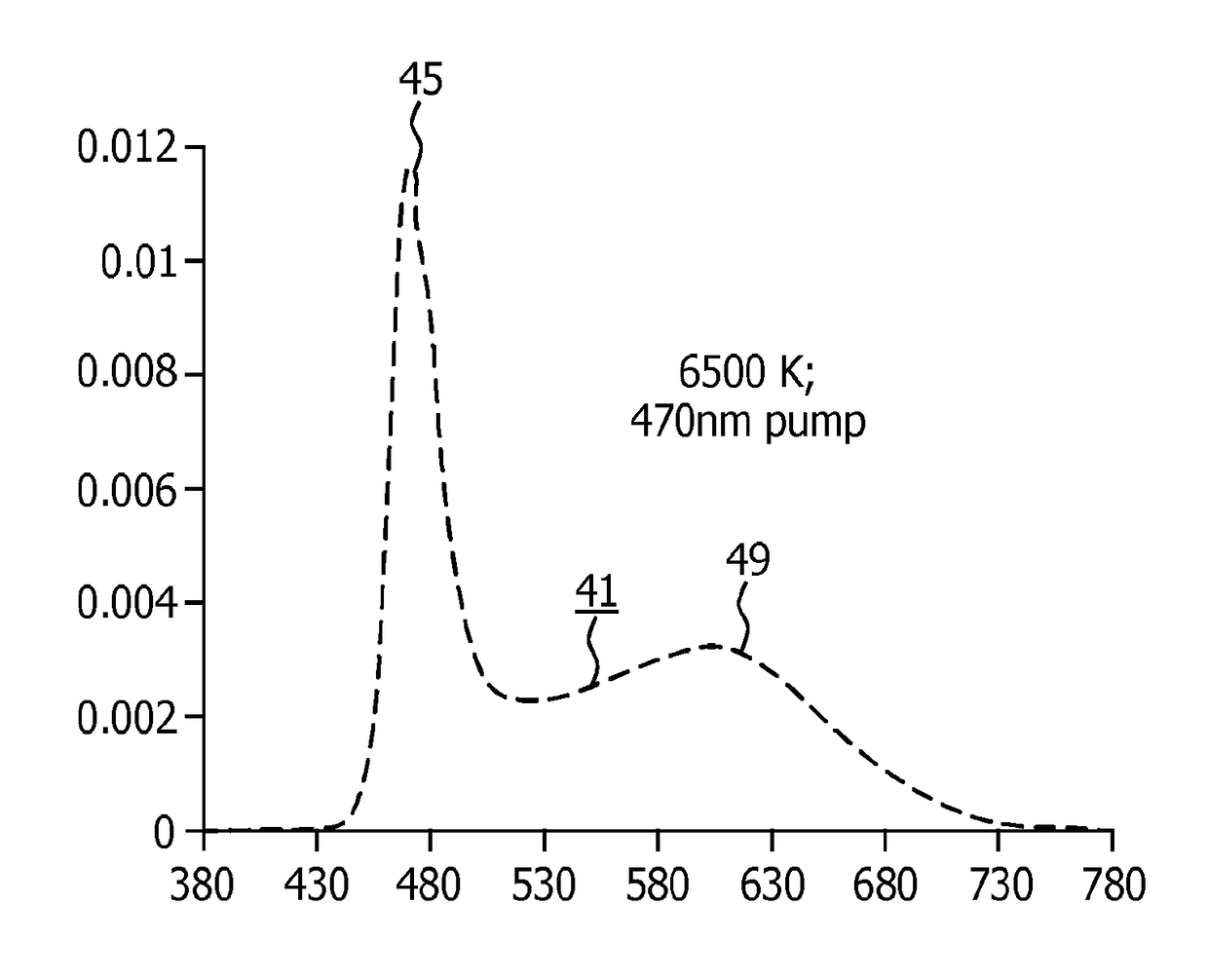

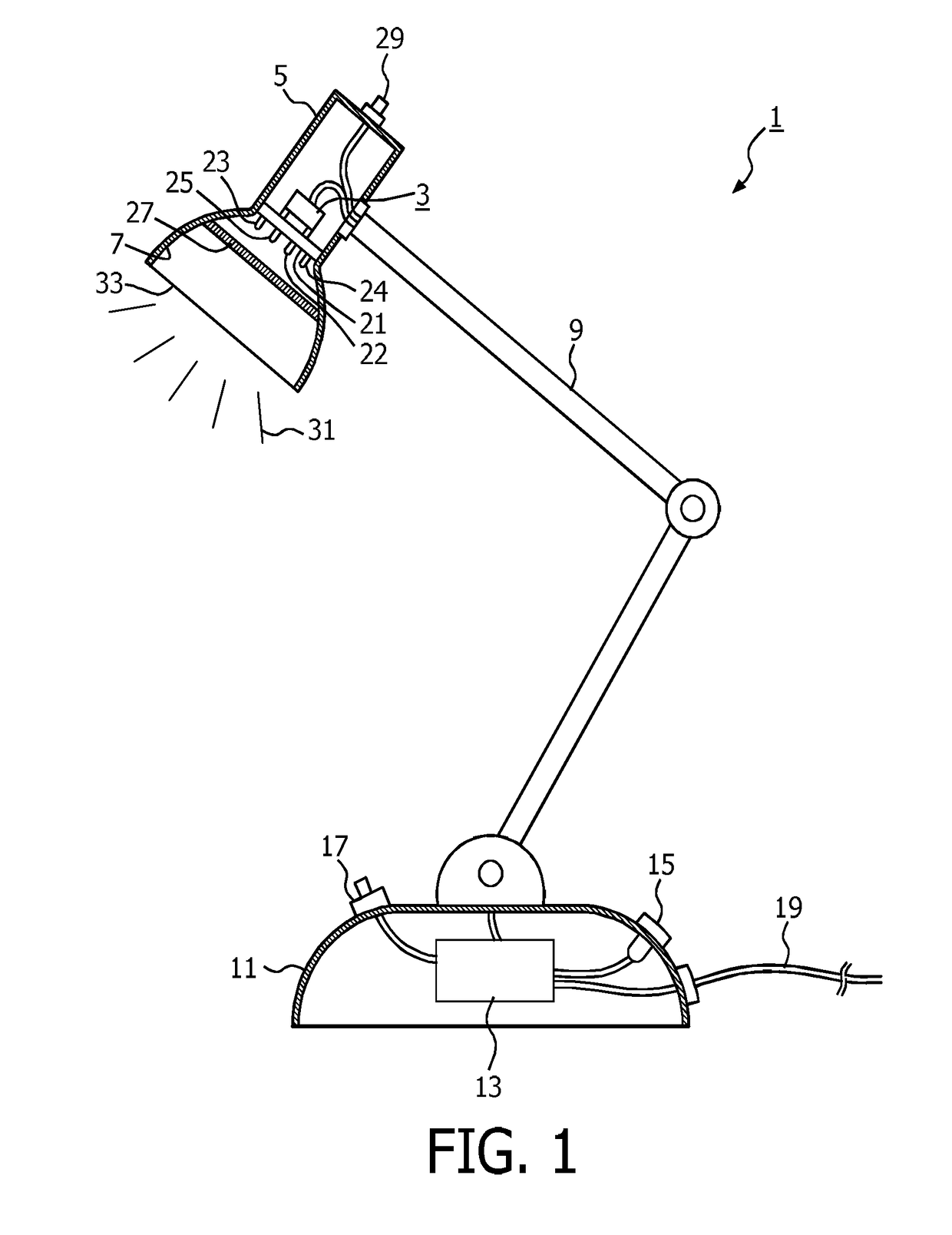

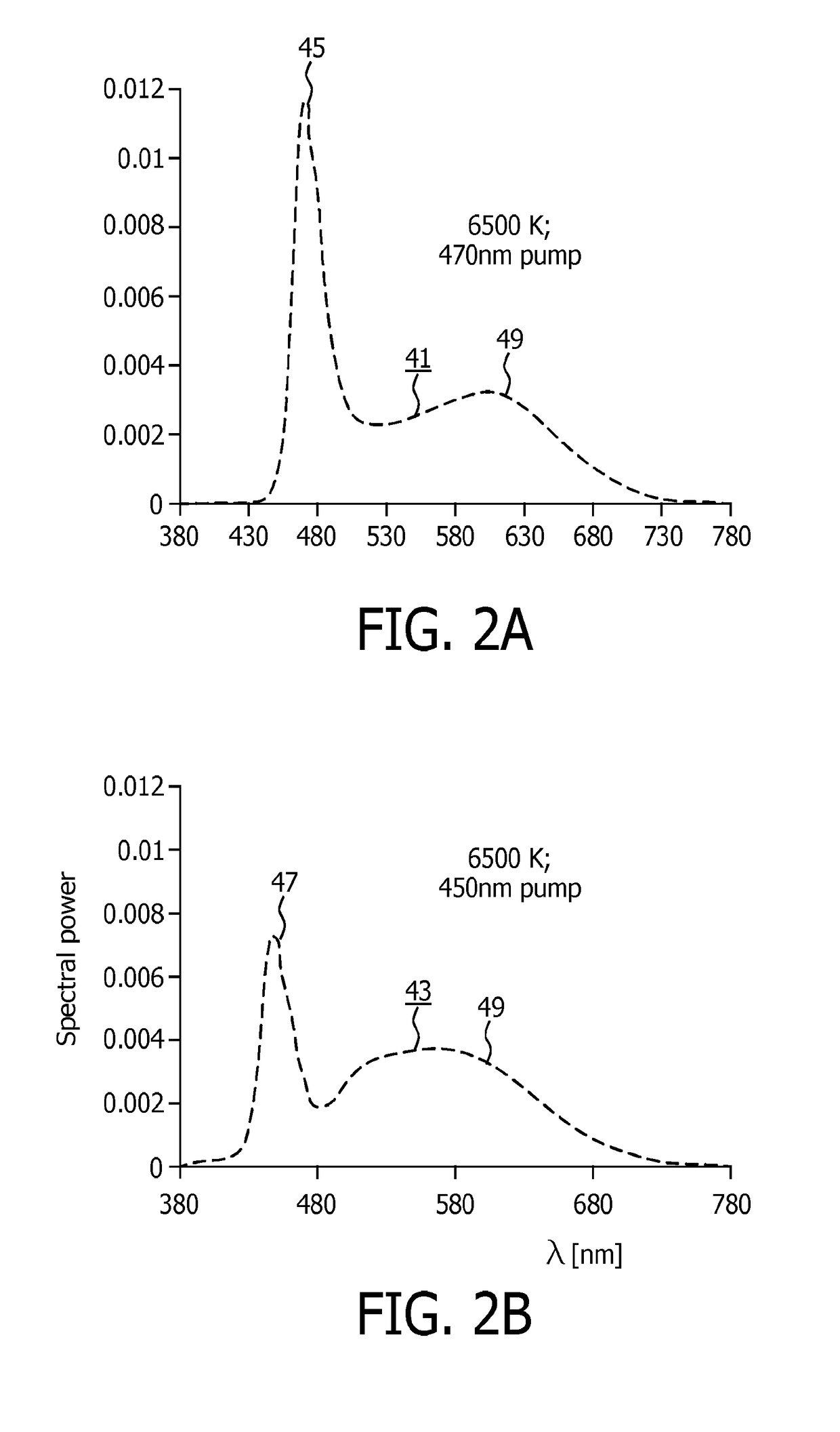

Lighting device, lighting system and use thereof

PendingUS20180073712A1Risk of damageIncrease illuminationLight source combinationsElectrical apparatusEffect lightPeak value

A lighting device comprising a light source being configured to generate source light of a white light emission spectrum having a color correlated temperature (CCT) in a range of 2500-20000K and comprising a control unit being configured to control a lighting element for tuning of the source light with respect to a ratio between a first emission peak in a wavelength range of 460-490 nm and a second emission peak in a wavelength range of 430-460 nm. Thus a lighting device with a tunable / adjustable spectrum is provided that can switch between a first operation state of energy efficiency lighting with a blue peak in the second wavelength range of 430-460 nm, but with blue hazard risk, and a second operation state of less efficient but safe, healthy lighting with a biological stimulant having a blue peak in the first wavelength range of 460-490 nm.

Owner:SIGNIFY HLDG BV

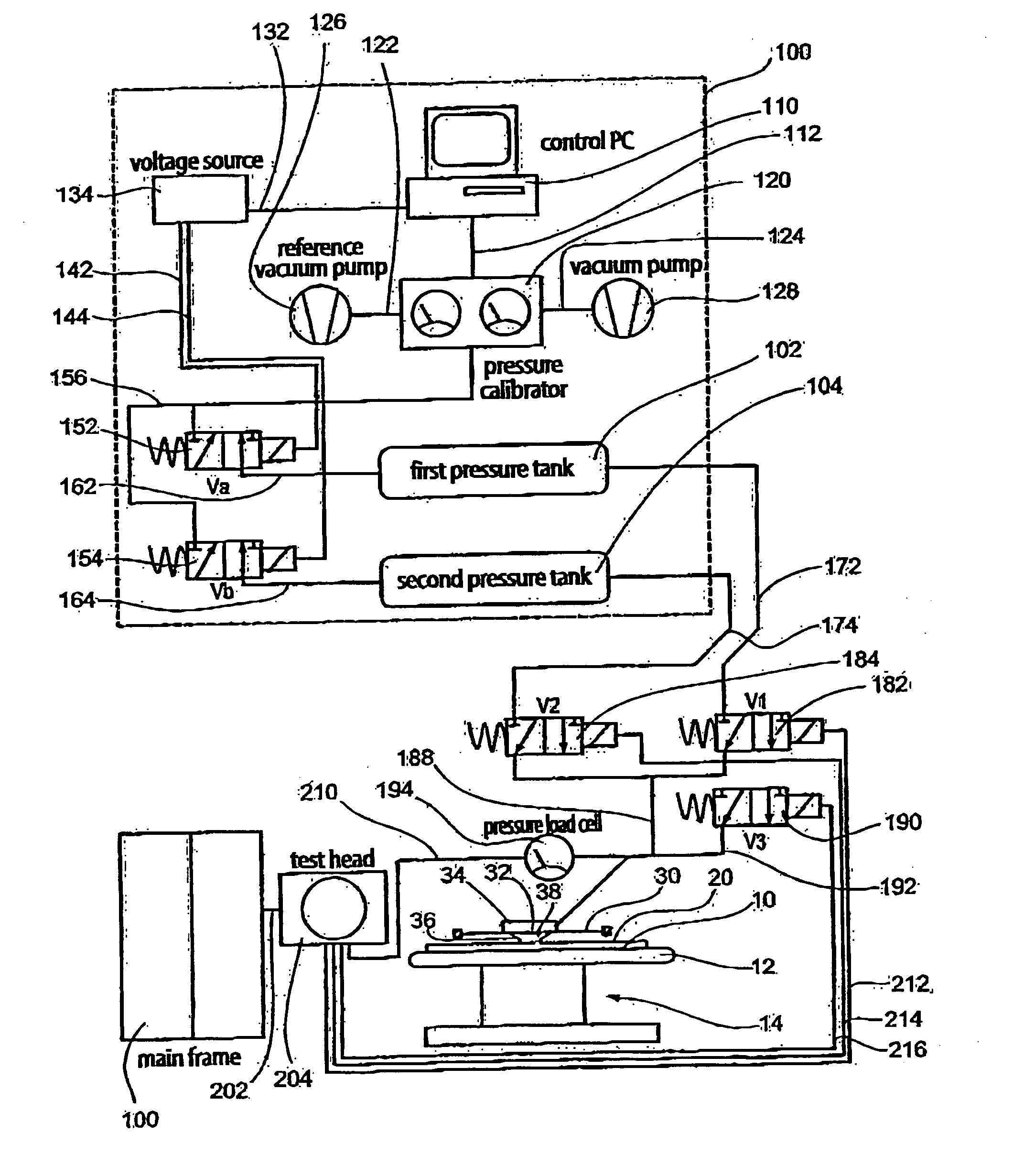

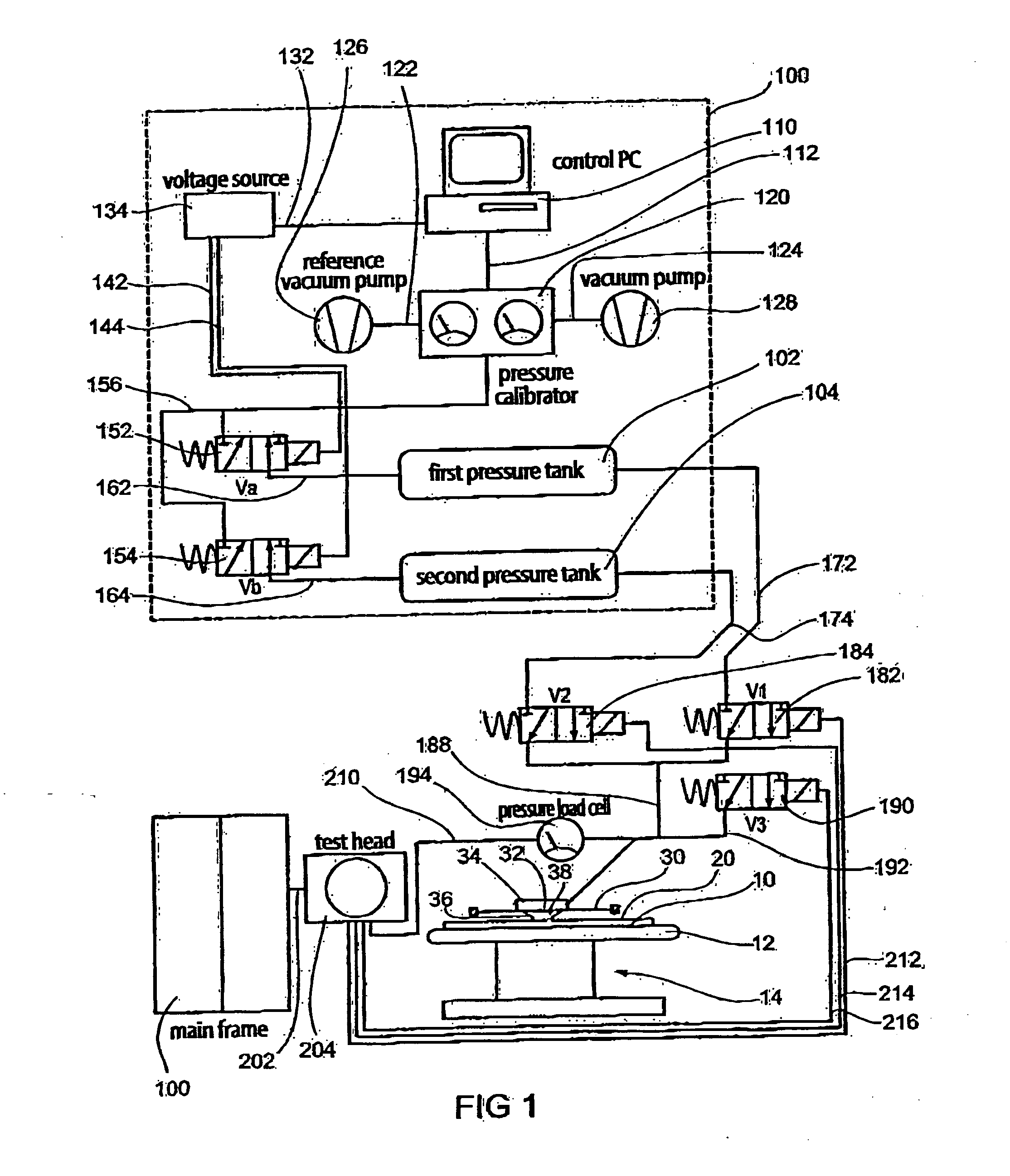

Method and device for testing or calibrating a pressure sensor on a wafer

InactiveUS20050116729A1Reduce production processCost be producedFluid pressure measurementIndividual semiconductor device testingForce sensorBiomedical engineering

A method is provided for testing or calibrating a pressure sensor of a plurality of pressure sensors formed in a wafer, wherein the pressure sensor has a pressure-sensitive portion and a signal output. The method includes a step of connecting the pressure-sensitive portion of the pressure sensor to a fluid line in a pressure-tight way, a step of applying a predetermined pressure to the pressure-sensitive portion of the pressure sensor via the fluid line and a step of receiving a signal from the signal output of the pressure sensor.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

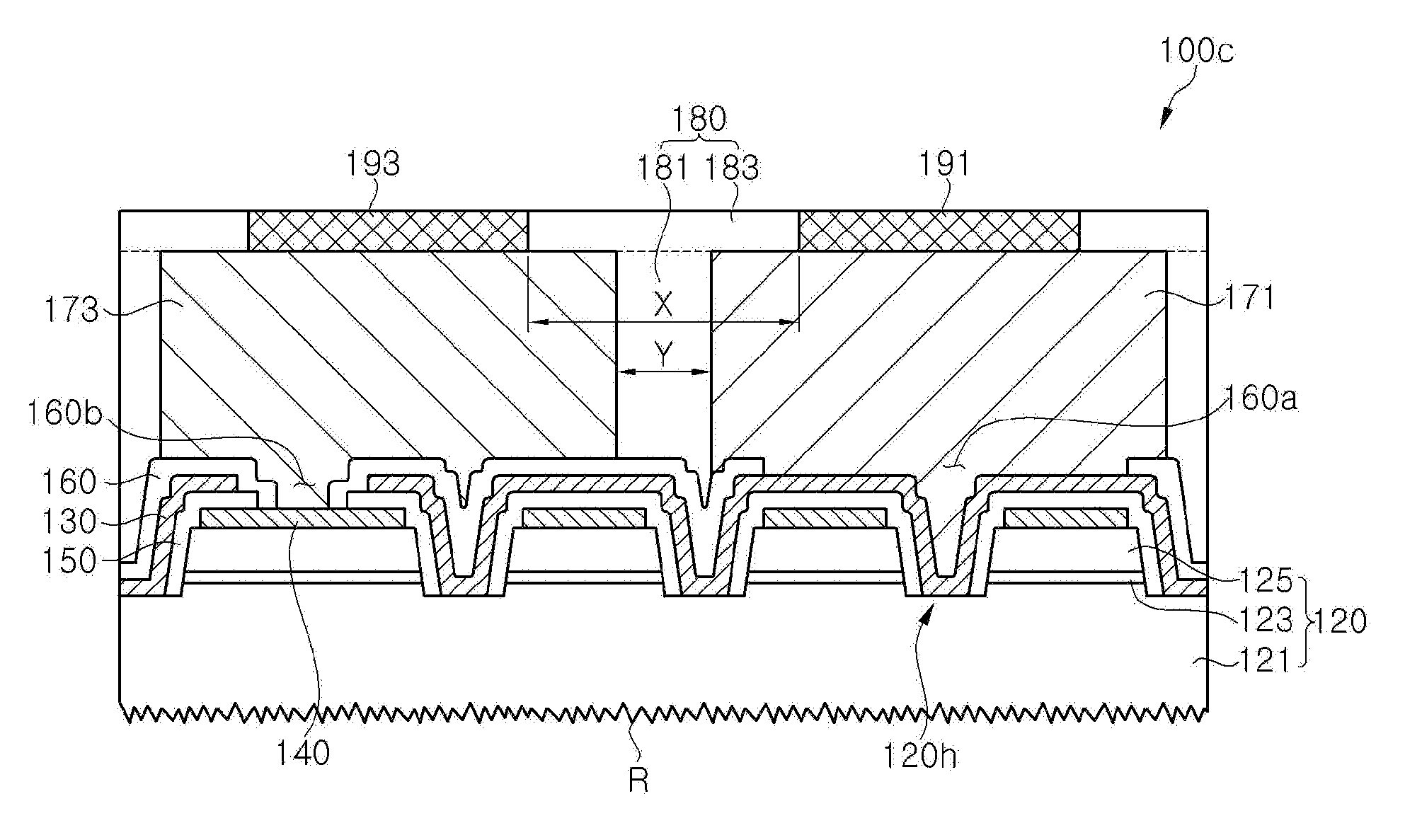

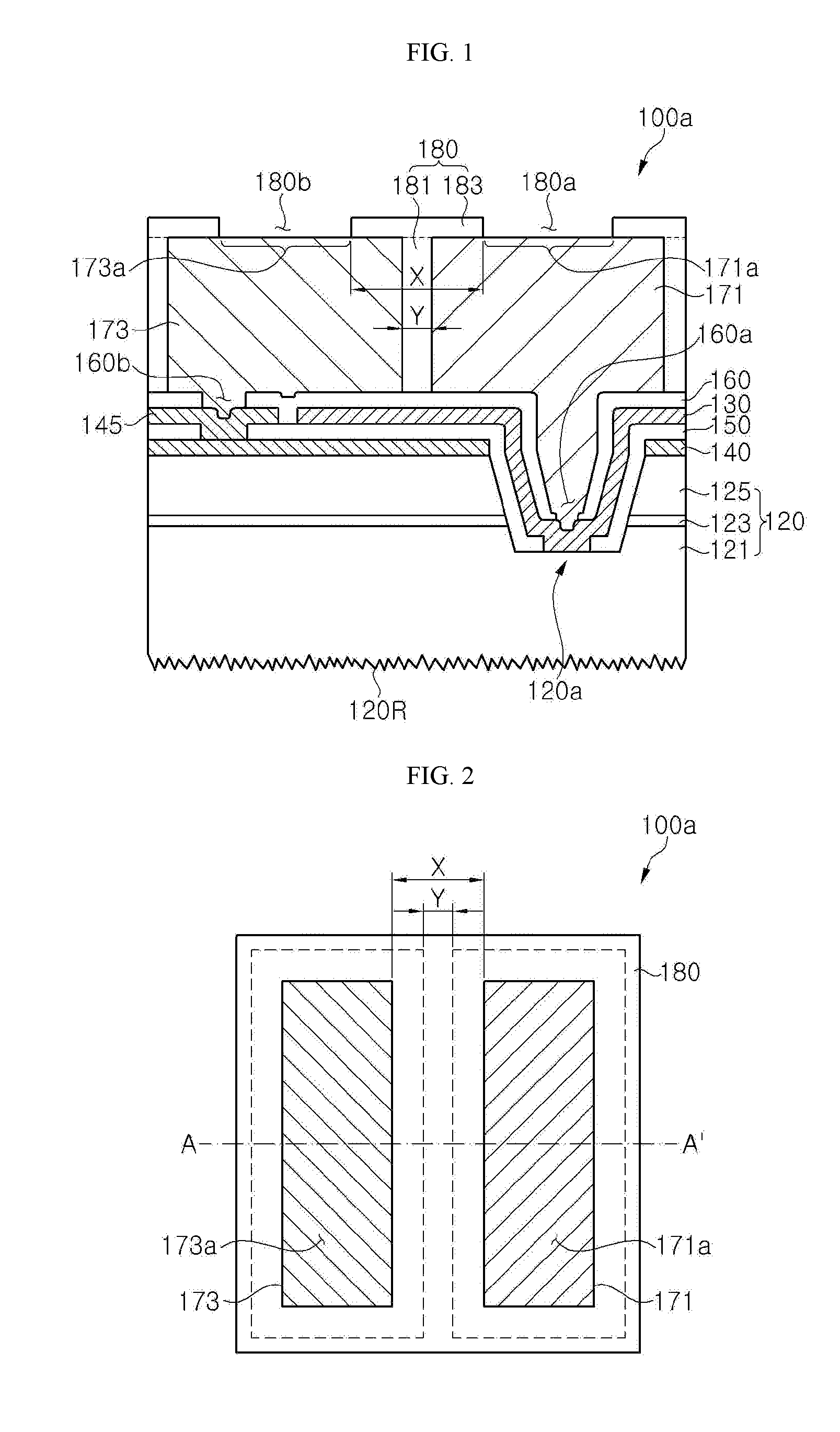

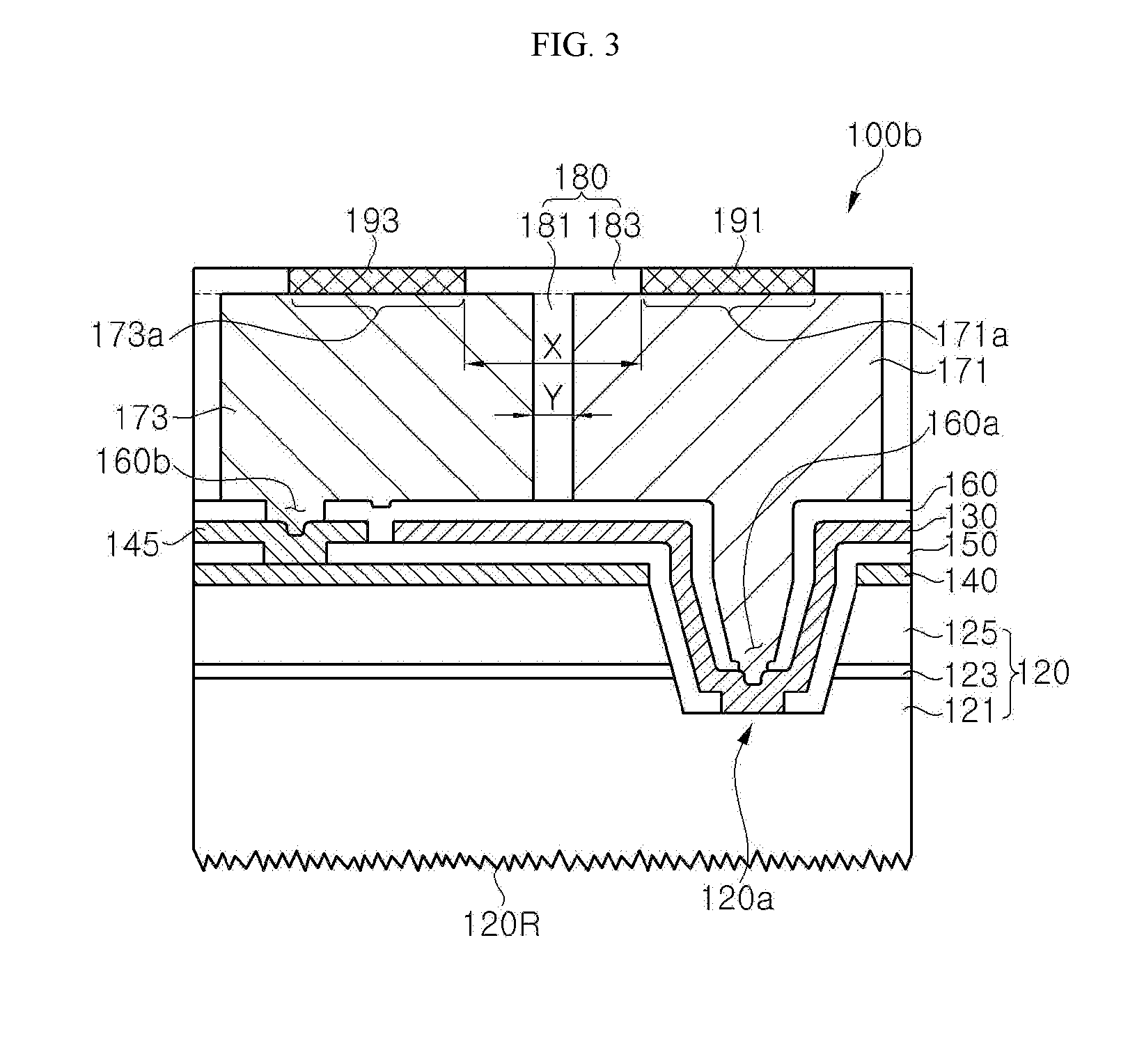

Light emitting device

ActiveUS20160365486A1Solve the low heat dissipation efficiencyUniform luminance characteristicSolid-state devicesSemiconductor devicesInterconnectionLight emitting device

A light emitting device includes a light emitting structure including a support structure including a first bulk electrode a second bulk electrode disposed on and electrically connected to the first electrode and the second electrode, respectively. A substrate is disposed adjacent to the support structure, wherein each of the first and second bulk electrodes includes an upper region and a lower region with the upper regions of the first and second bulk electrodes being separated from each other by a first distance. The substrate includes a first interconnection portion and a second interconnection portion electrically connected to the first bulk electrode and the second bulk electrode, respectively, and separated from each other by a second distance. The second distance is greater than the first distance.

Owner:SEOUL VIOSYS CO LTD

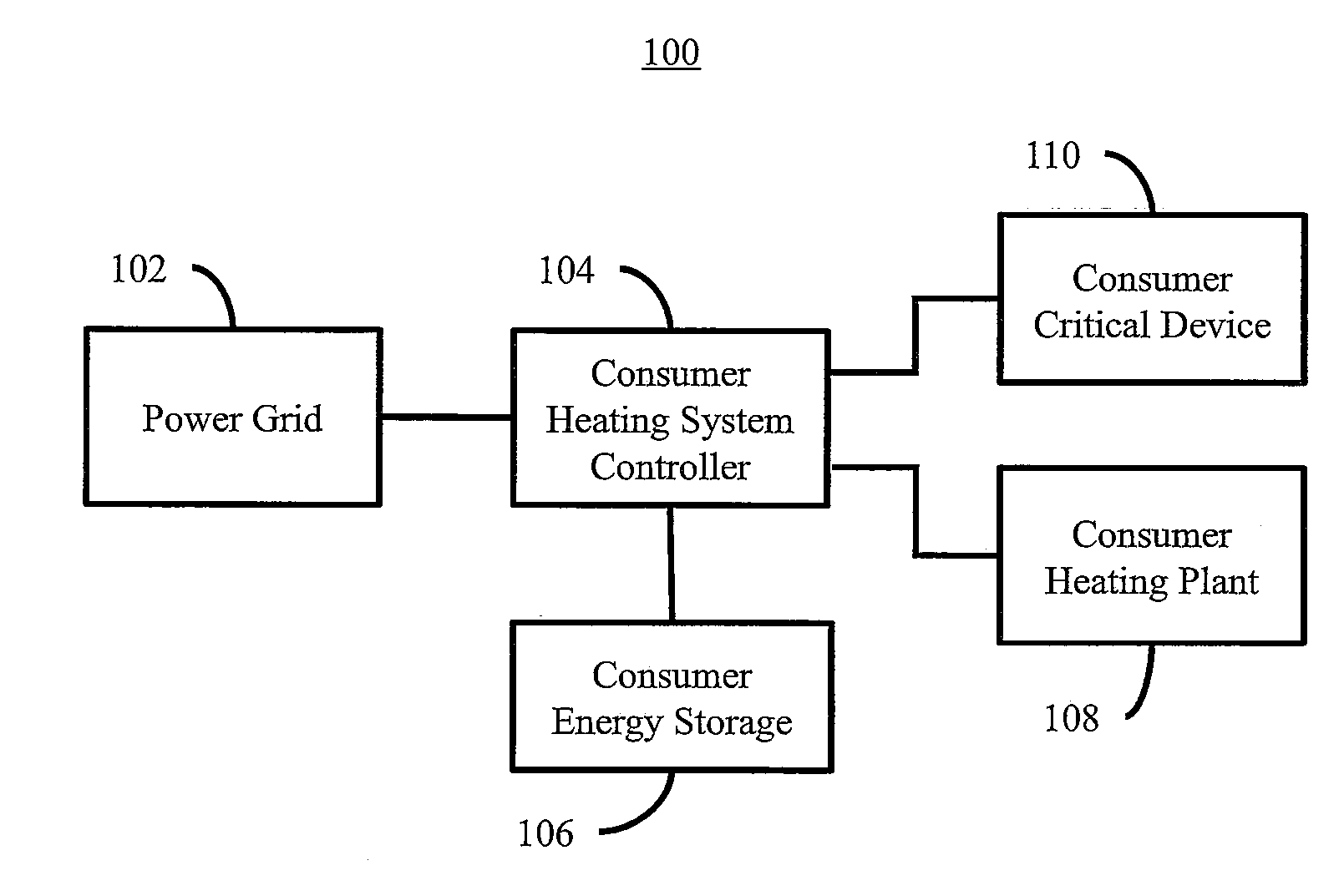

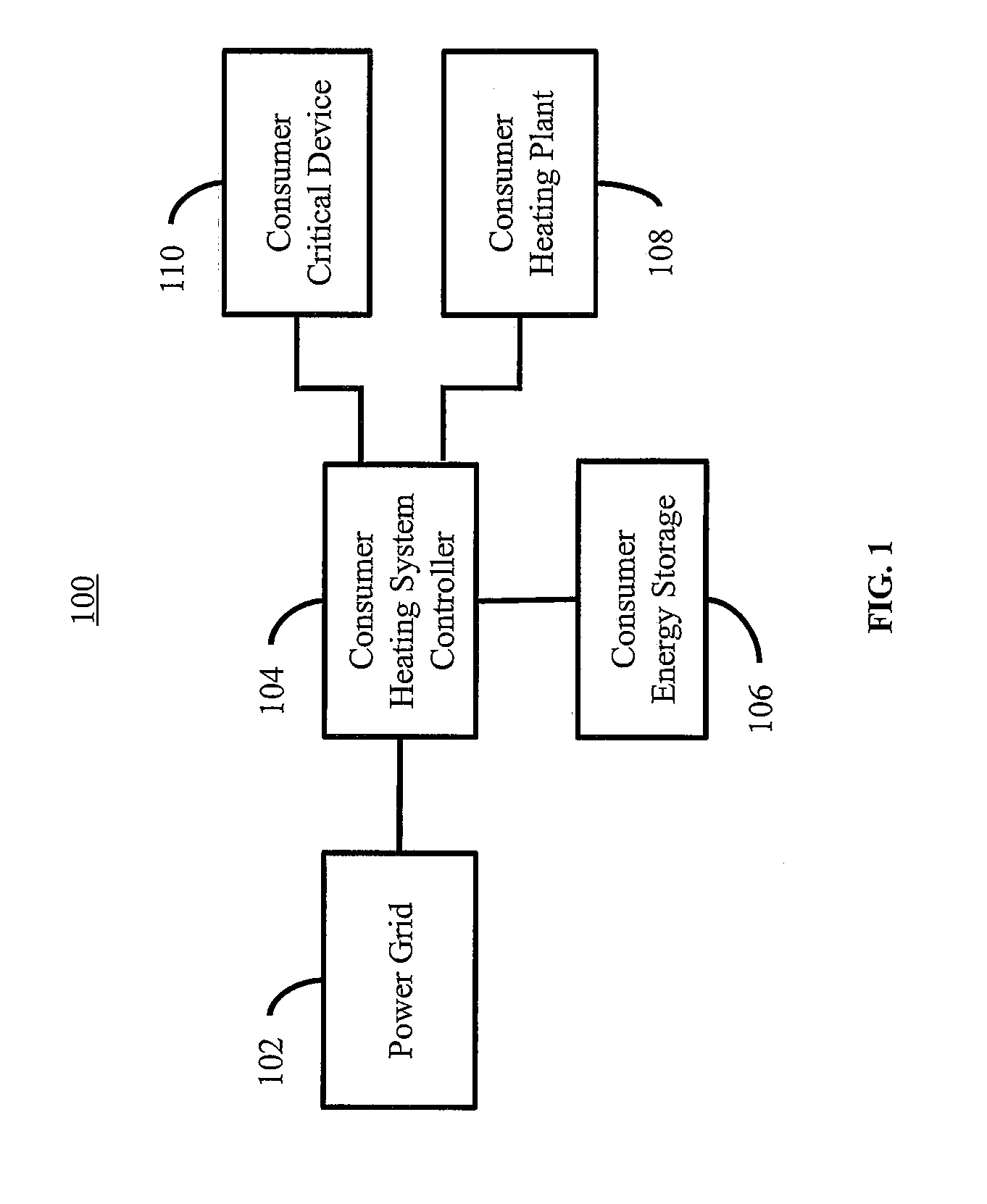

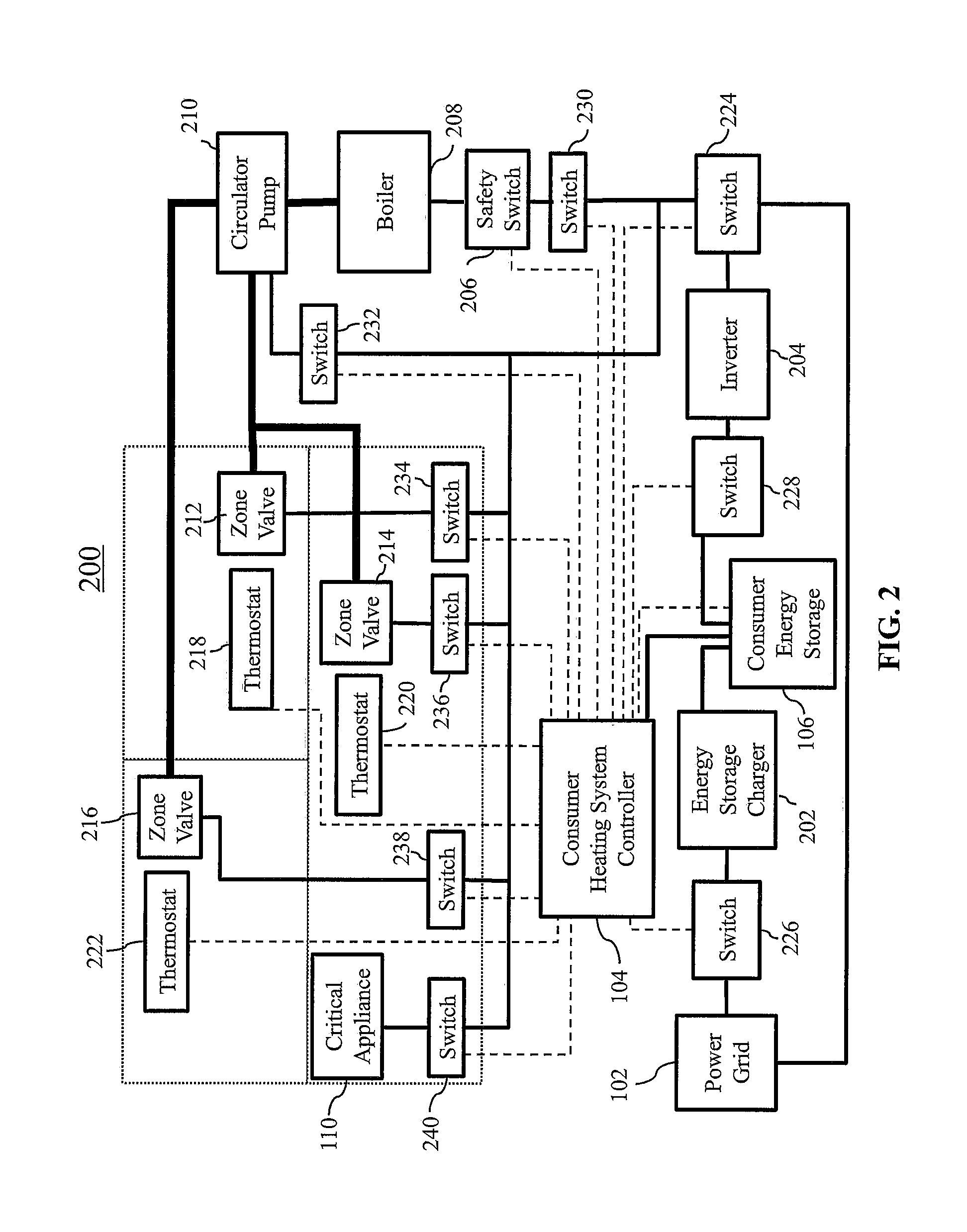

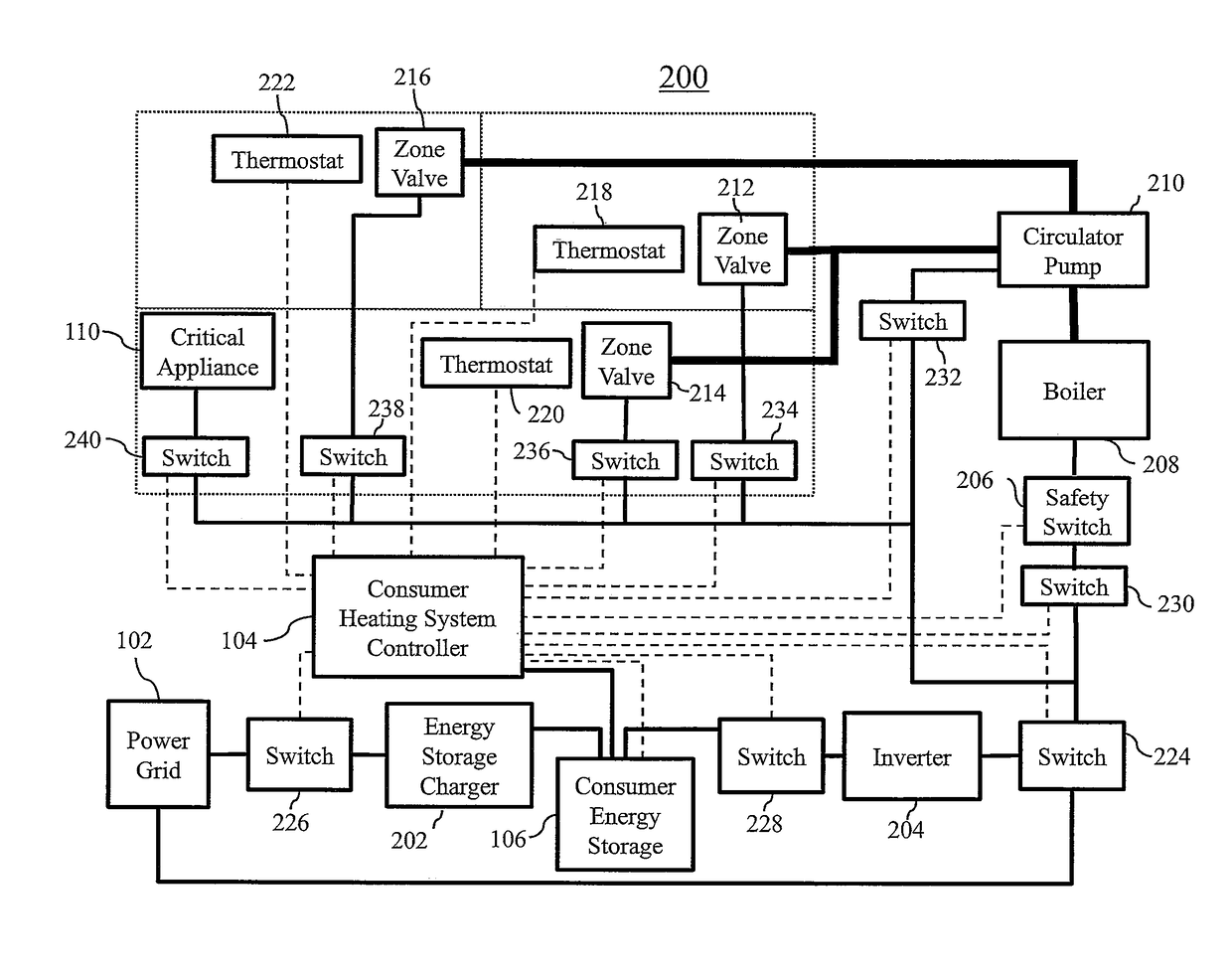

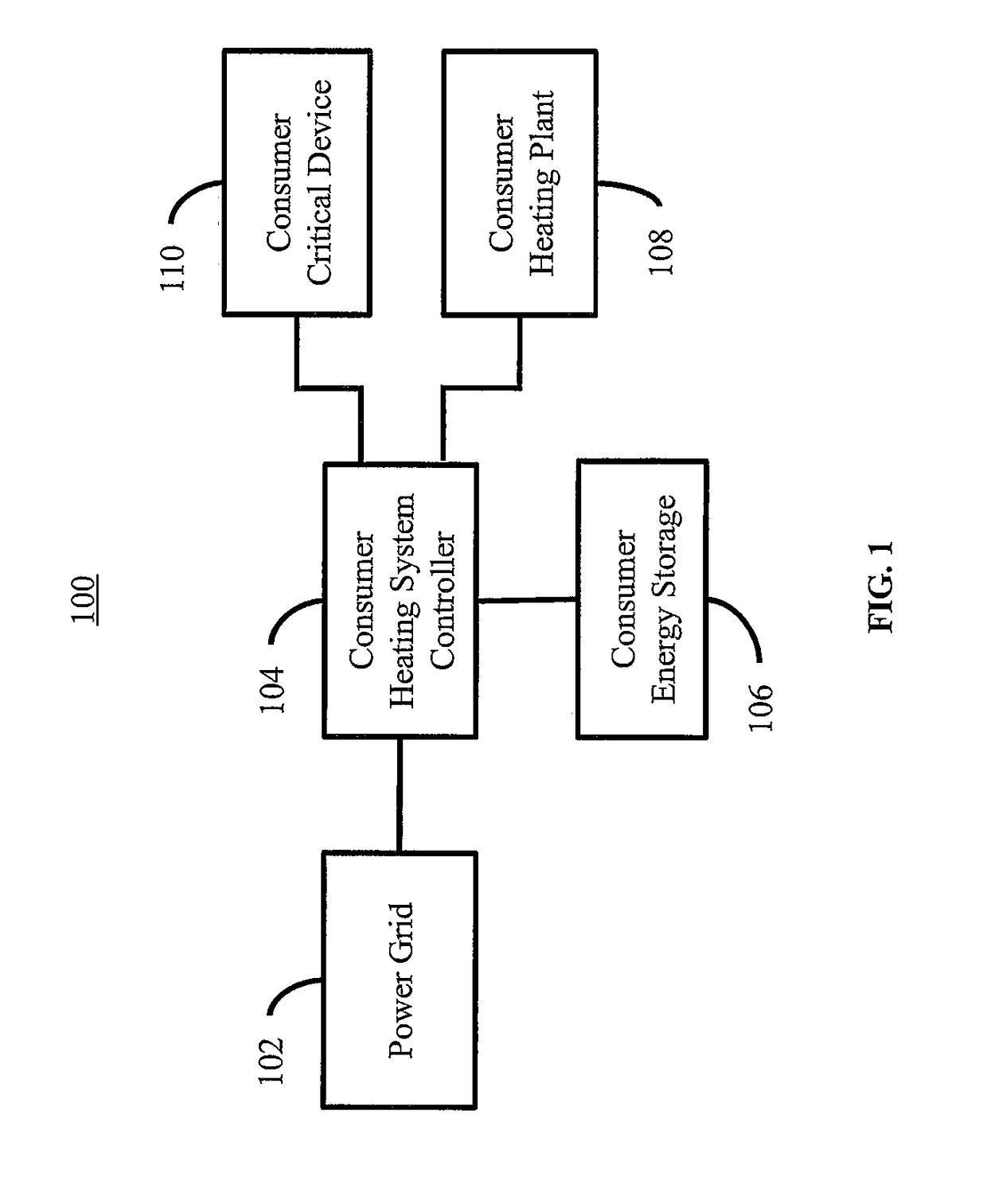

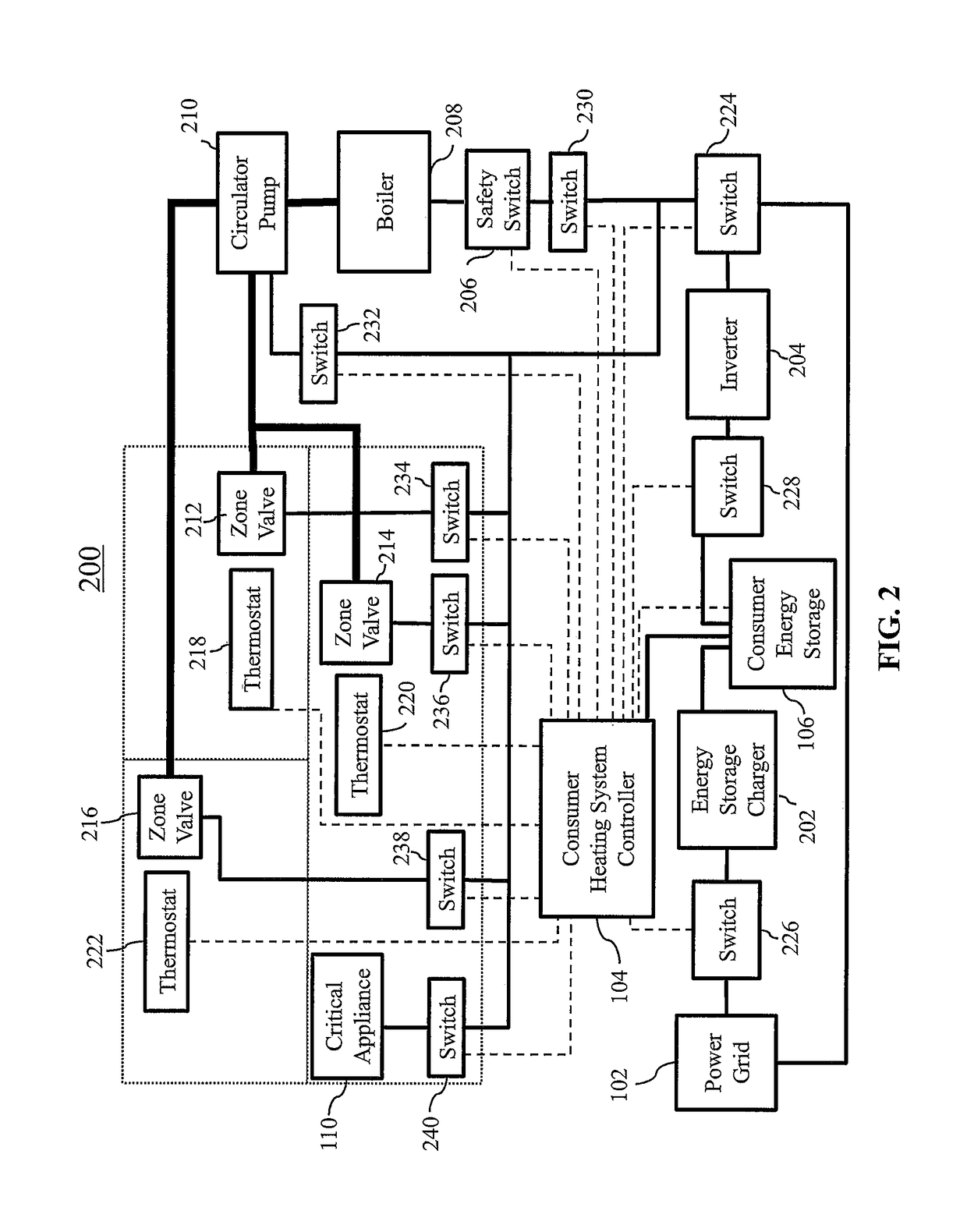

System and Methods for Controlling a Supply of Electric Energy

ActiveUS20150270743A1Health and safetyNot compromise safety and integrityBatteries circuit arrangementsTemperatue controlStored energyEngineering

A system and methods for controlling the supply and distribution of backup electrical power determine when backup power is needed and allocates available backup power among connected devices in a power outage. Batteries may be used as an energy storage subsystem, and may backup a home heating plant and other devices based on a dual set of user-established priorities that may change during power blackouts and brownouts as the amount of stored energy decreases.

Owner:REDLINE INNOVATIONS GRP +1

System and methods for controlling a supply of electric energy

ActiveUS9735613B2Health and safetyNot compromise safety and integrityElectric signal transmission systemsBatteries circuit arrangementsStored energyConnected device

A system and methods for controlling the supply and distribution of backup electrical power determine when backup power is needed and allocates available backup power among connected devices in a power outage. Batteries may be used as an energy storage subsystem, and may backup a home heating plant and other devices based on a dual set of user-established priorities that may change during power blackouts and brownouts as the amount of stored energy decreases.

Owner:REDLINE INNOVATIONS GRP +1

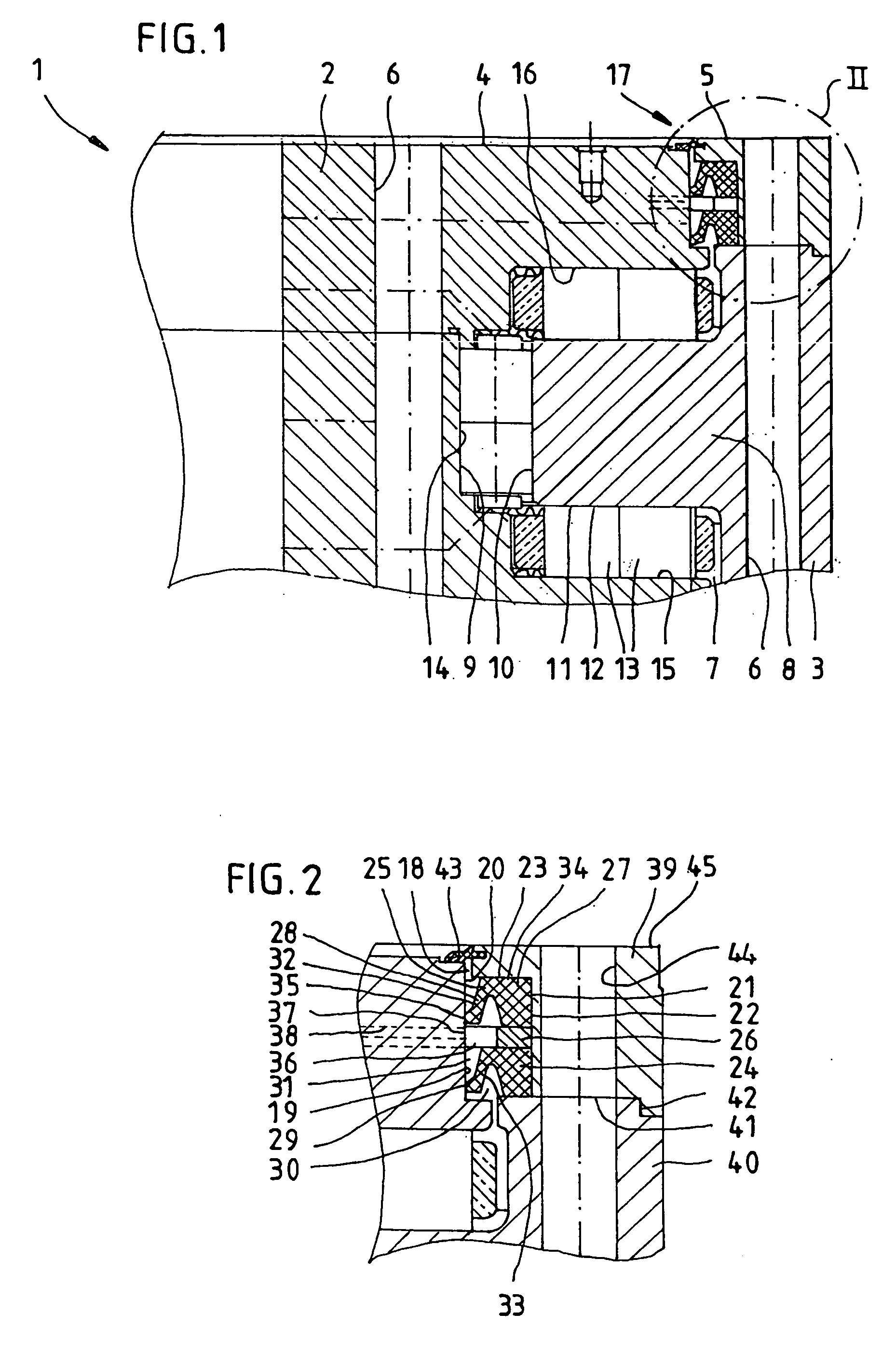

Sealing assembly for a rolling bearing

InactiveUS20130039611A1Easy to insertNot at risk being damagedRolling contact bearingsShaftsRolling-element bearingEngineering

The invention relates to a sealing assembly for a rolling bearing having two mutually concentric rings spaced apart from each other by a fully circumferential gap in which one or more rows of revolving rolling elements are disposed, such that the two rings are rotatable relative to each other about their common axis, wherein the gap is sealed in the region of at least one of its two mouths, and wherein provided in the region of a gap seal are at least two seal rings, each having at least one sealing lip and an anchoring region on a surface region of the particular seal ring that faces away from the sealing lip, the seal rings being fixed to the same rolling bearing ring, whereas their respective sealing lips bear against the other rolling bearing ring, specifically against surface regions having identical or similar cross section.

Owner:IMO HOLDING GMBH

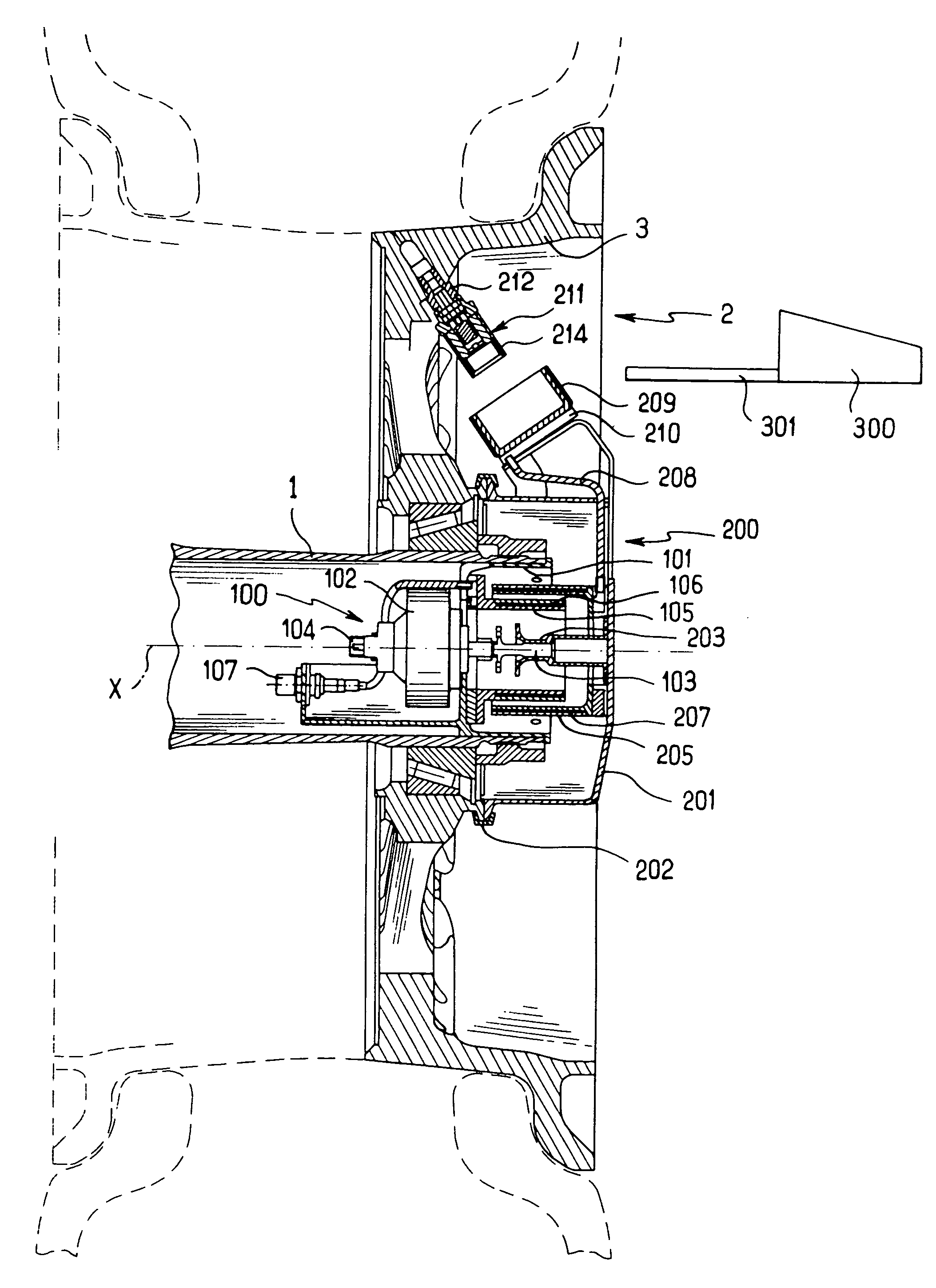

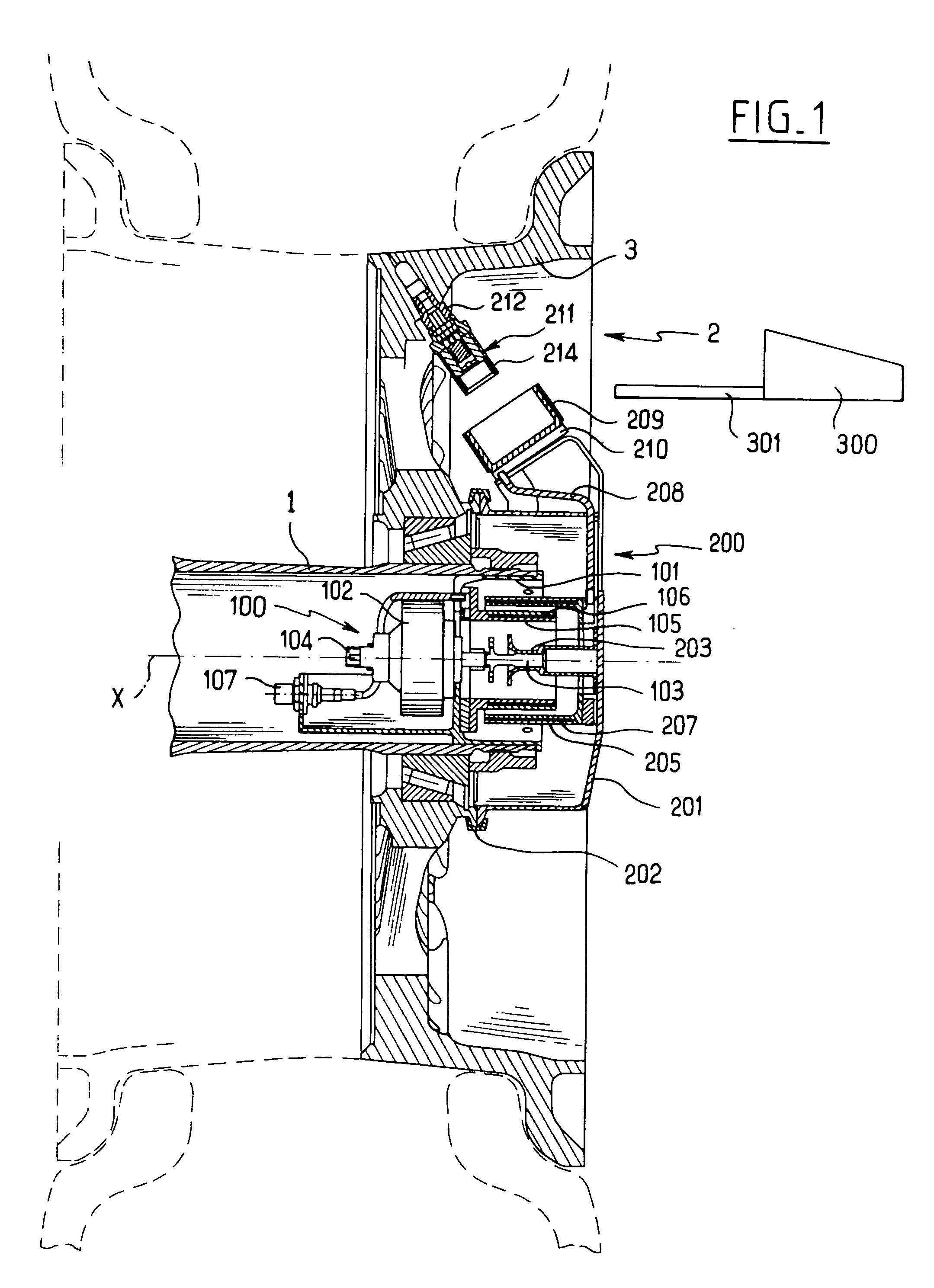

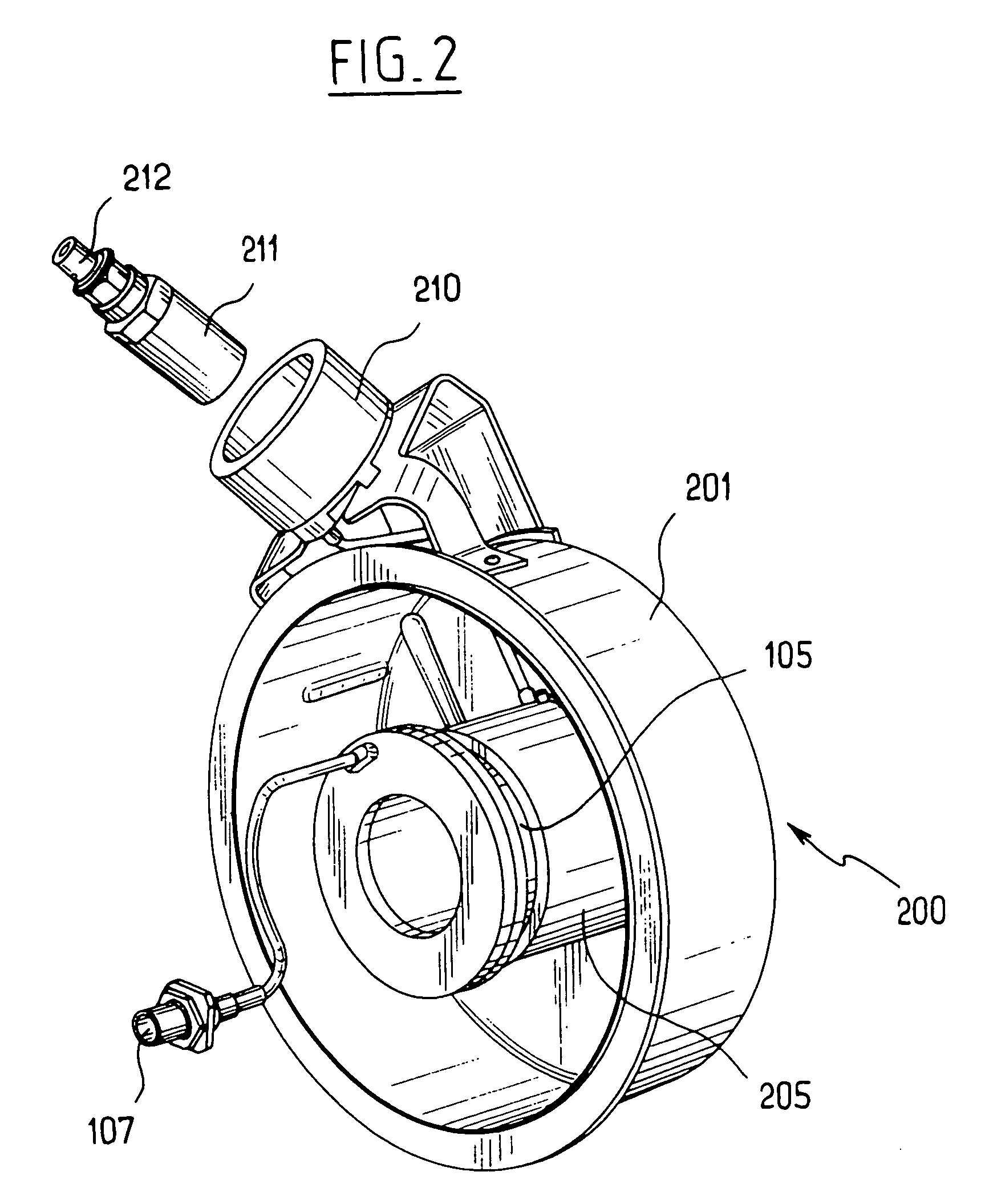

Axle end equipment for a vehicle, in particular an aircraft

Owner:SAGEM DEFENSE SECURITE SA

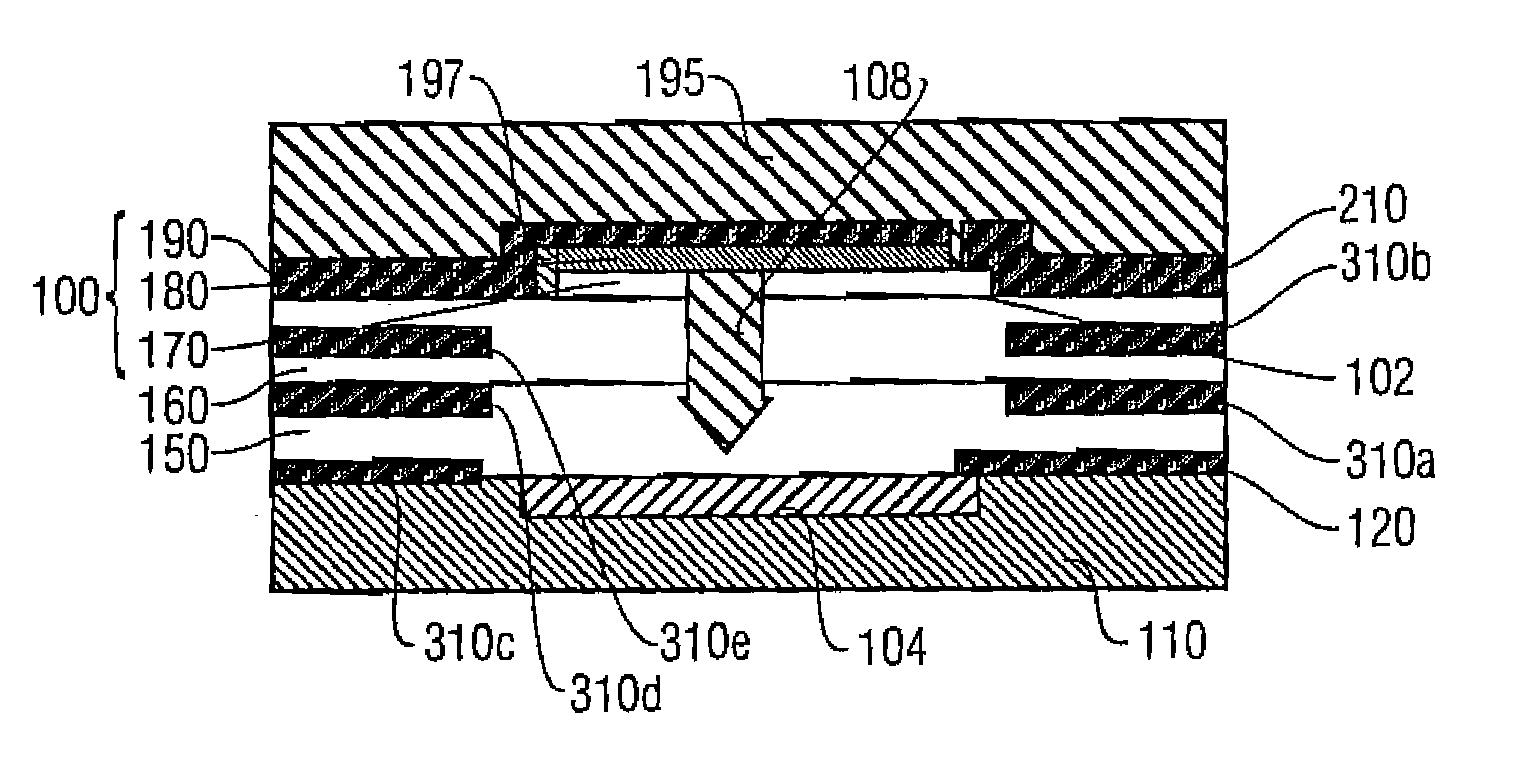

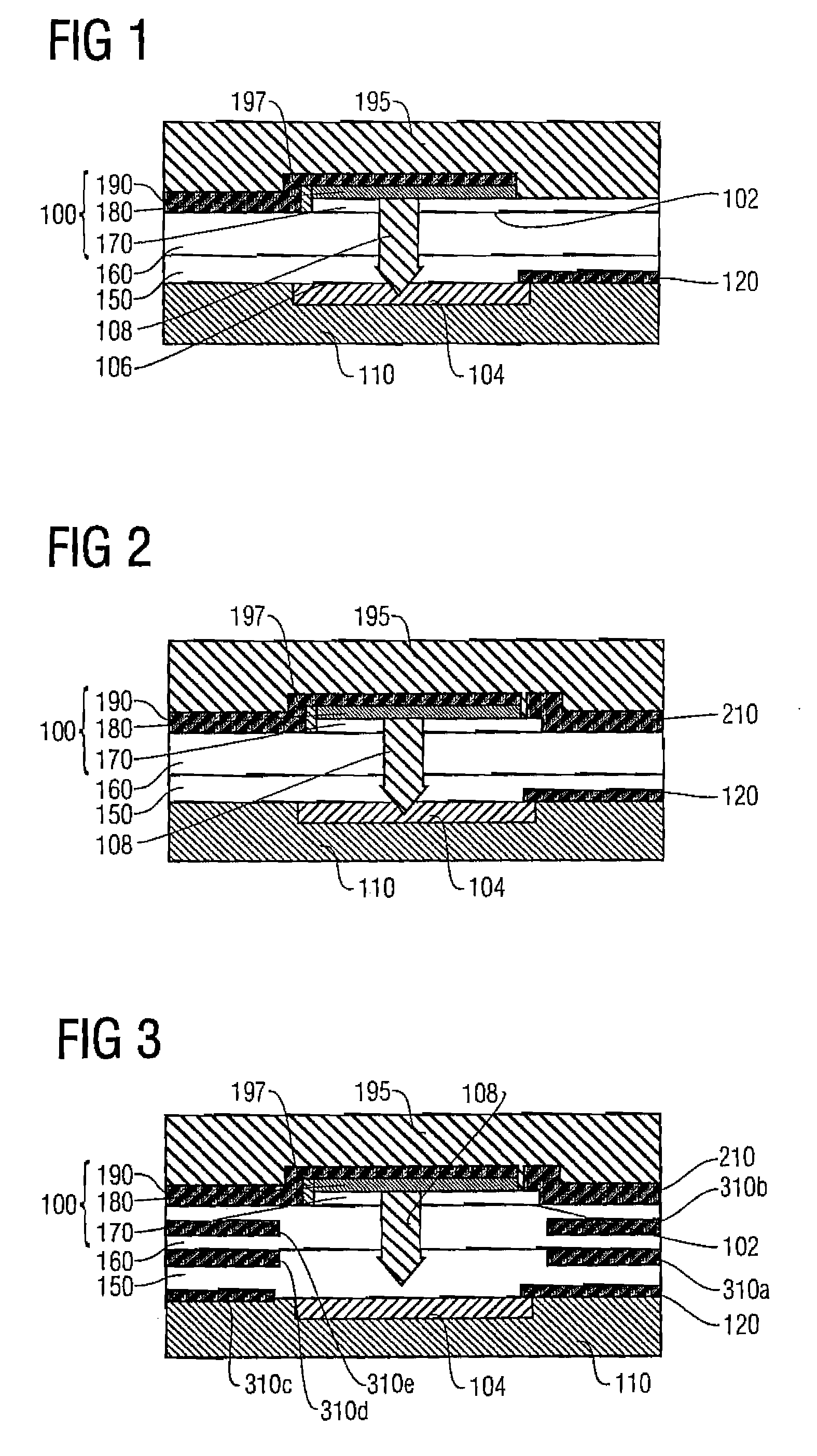

Integrated optocoupler with organic light emitter and inorganic photodetector

InactiveUS20080054275A1Optimized optical signal transmissionReduce areaSolid-state devicesMaterial analysis by optical meansPhotovoltaic detectorsPhotodetector

An optocoupler has an organic light emitter and an inorganic photodetector with a detector area, the detector area being optically coupled to the organic light emitter. The organic light emitter converts an electrical input signal into a light signal and the inorganic photodetector converts the light signal into an electrical output signal, the organic light emitter and the inorganic photodetector being integrated in a component and galvanically separated.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

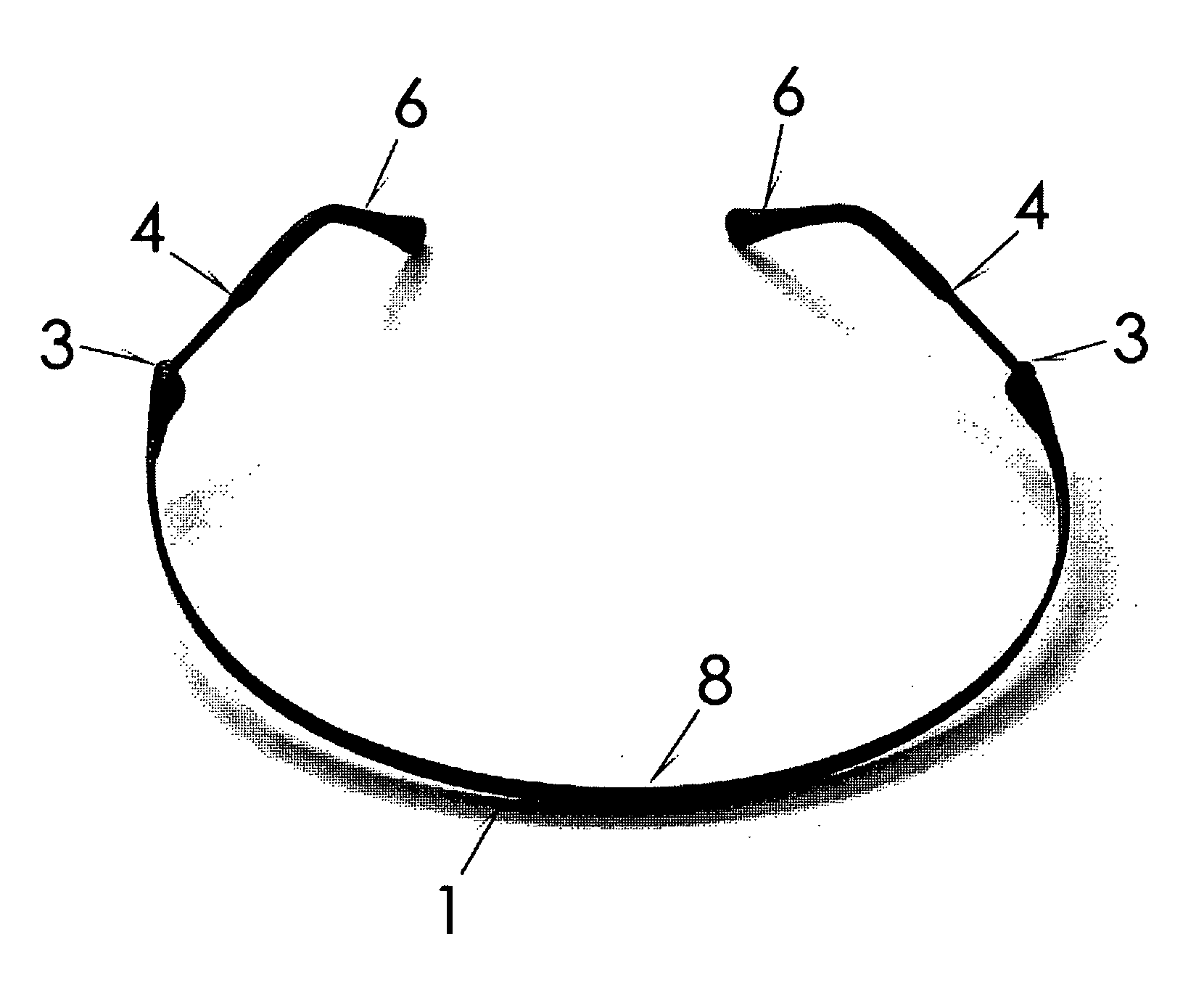

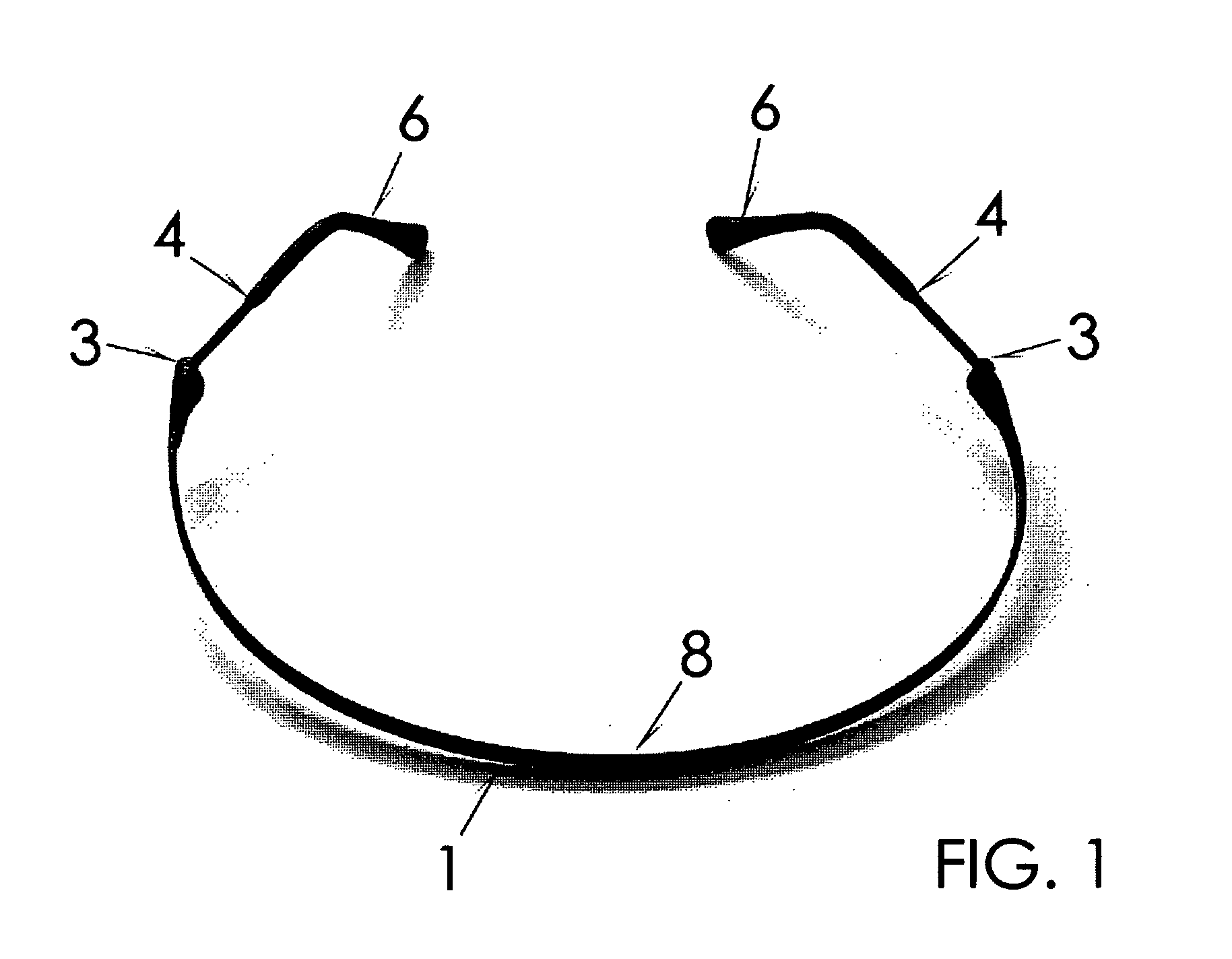

Foldable headband

Owner:ALLGOOD MELANIE PAINE

Double-patterned magneto-resistive random access memory (MRAM) for reducing magnetic tunnel junction (MTJ) pitch for increased MRAM bit cell density

ActiveUS20190214554A1Reduce sizeFacilitates MTJsMagnetic-field-controlled resistorsSolid-state devicesStatic random-access memoryRandom access memory

Double-patterned magneto-resistive random access memory (MRAM) for reducing magnetic tunnel junction (MTJ) pitch for increased MRAM bit cell density is disclosed. In one aspect, to fabricate MTJs in an MRAM array with reduced MTJ row pitch, a first patterning process is performed to provide separation areas in an MTJ layer between what will become rows of fabricated MTJs, which facilitates MTJs in a given row sharing a common bottom electrode. This reduces the etch depth and etching time needed to etch the individual MTJs in a subsequent step, can reduce lateral projections of sidewalls of the MTJs, thereby relaxing the pitch between adjacent MTJs, and may allow an initial MTJ hard mask layer to be reduced in height. A subsequent second patterning process is performed to fabricate individual MTJs. Additional separation areas are etched between free layers of adjacent MTJs in a given row to fabricate the individual MTJs.

Owner:QUALCOMM INC

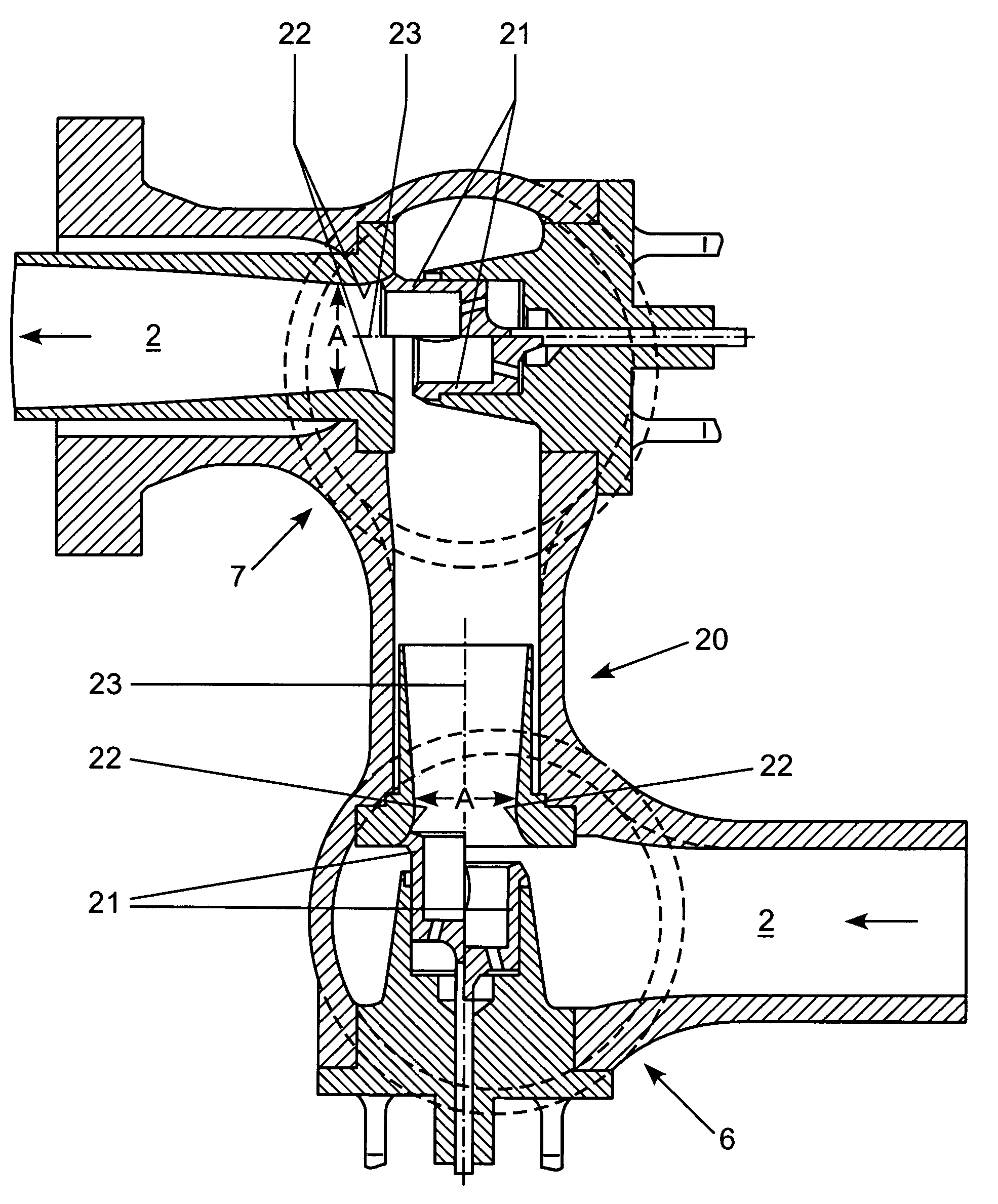

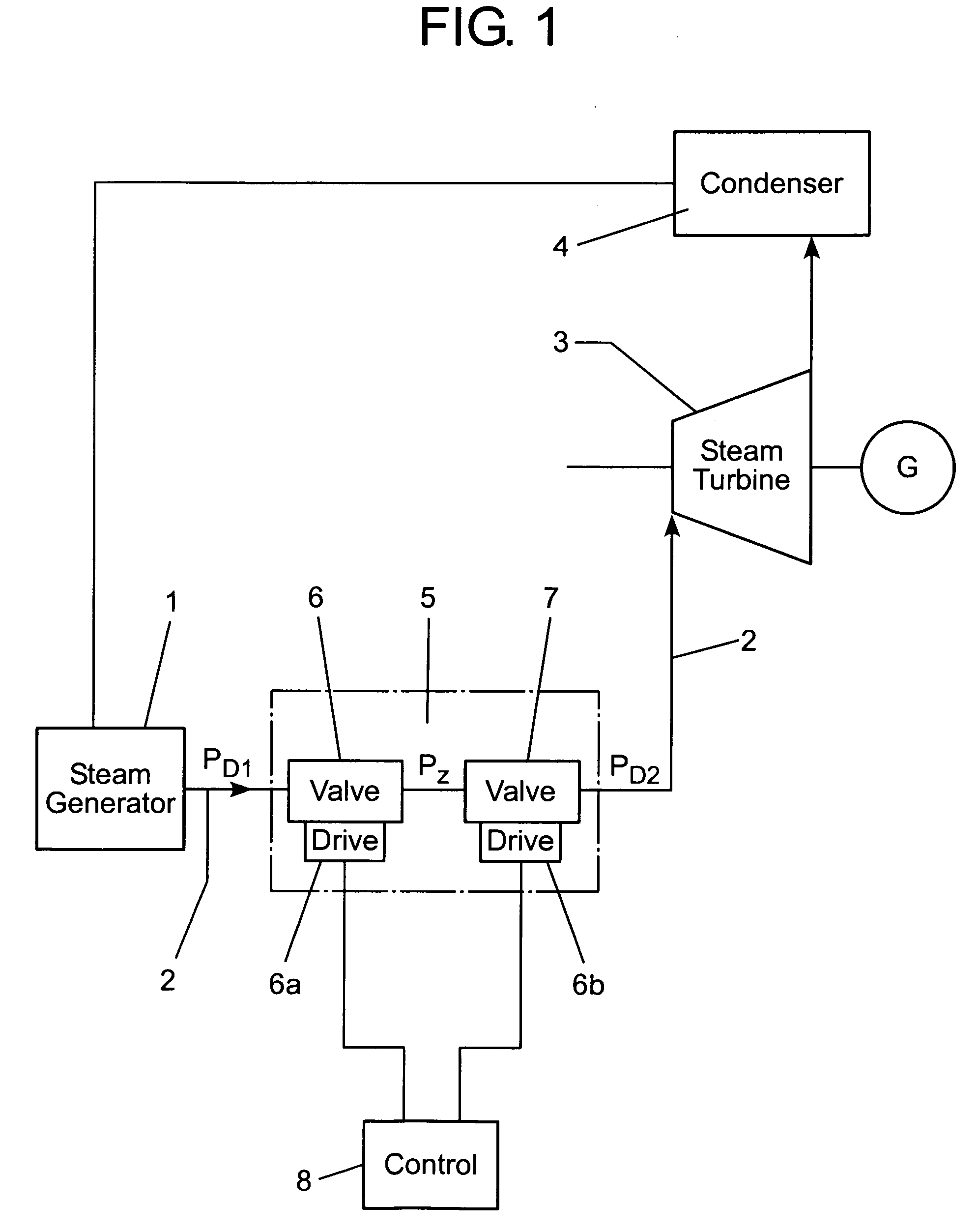

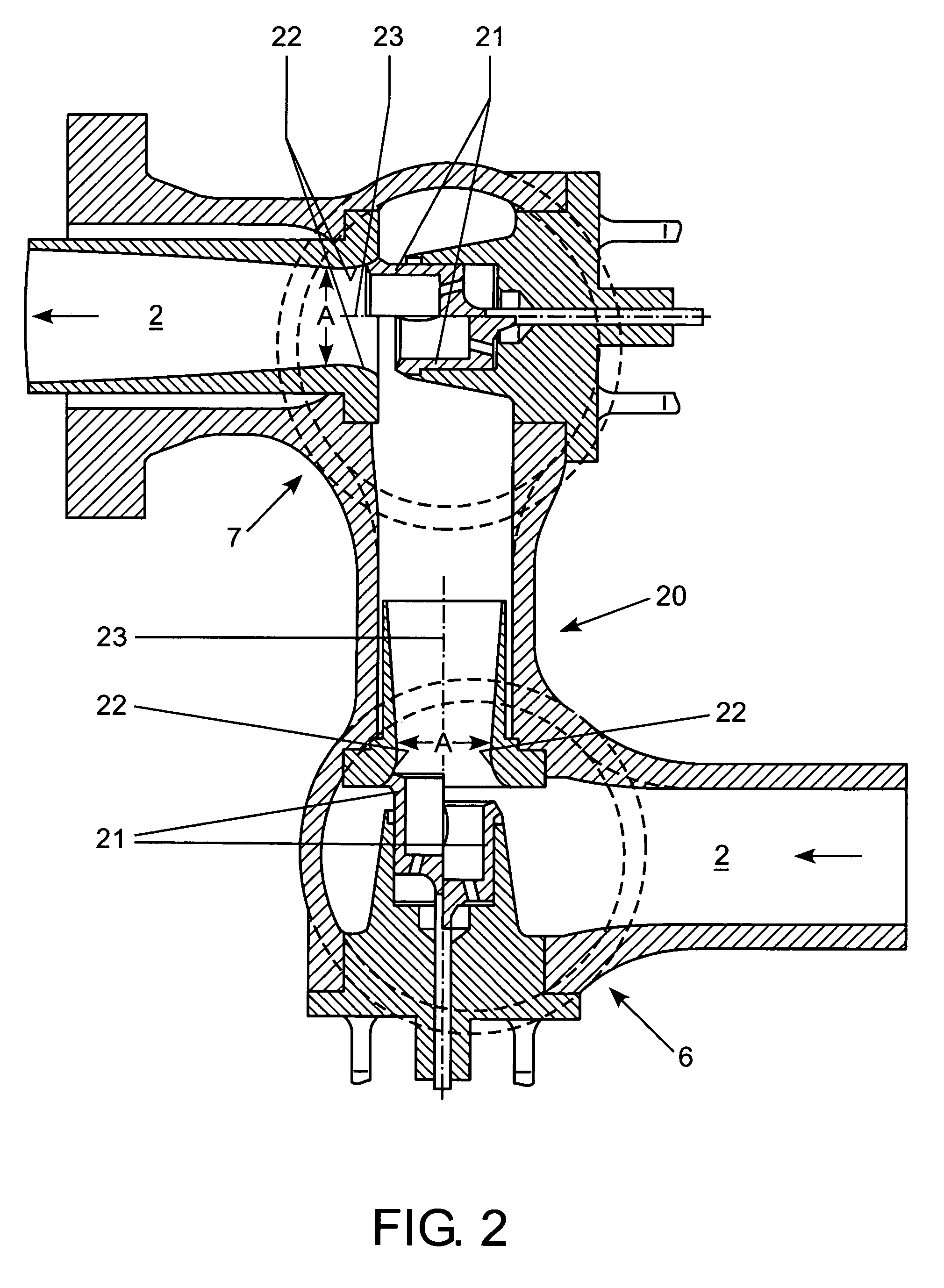

Steam turbine

InactiveUS7223065B2Reduce risk of damageReduce controlPump componentsWind motor controlOperation modeEngineering

The invention relates to a steam turbine comprising a valve arrangement for regulating the admission of live steam into the turbine consisting of two serially connected regulating valves. The two regulating valves enable a step-by-step separation of the live steam and ensure operational security in the case of a partial load operation of the turbine. Said valve arrangement is particularly suitable for steam turbines devoid of regulating steps in a fixed-pressure operation mode.

Owner:ALSTOM TECH LTD

Multi-pass optical power amplifier

InactiveUS7796671B2Quality improvementEffect of depolarization is negligibleExcitation process/apparatusOptical resonator shape and constructionAudio power amplifierHarmonic

Anisotropic crystals such as Nd:YVO4, Nd:YLF, and Nd:GdVO4 have become preferred gain materials for many laser applications. The anisotropic gain medium without ancillary compensation ensures there is no degradation of laser modes when passing through the gain medium. An optical power amplifier that incorporates an anisotropic gain medium achieves power scaling with multiple passes while also maintaining good mode matching between the laser and the pump during each pass. Preferred embodiments implement for multiple passes of a seed laser beam through an anisotropic gain medium with substantially zero angular beam displacement during each pass. The multi-pass system provides an economical, reliable method of achieving high TEM00 power to meet the demands of micromachining, via drilling, and harmonic conversion applications.

Owner:ELECTRO SCI IND INC

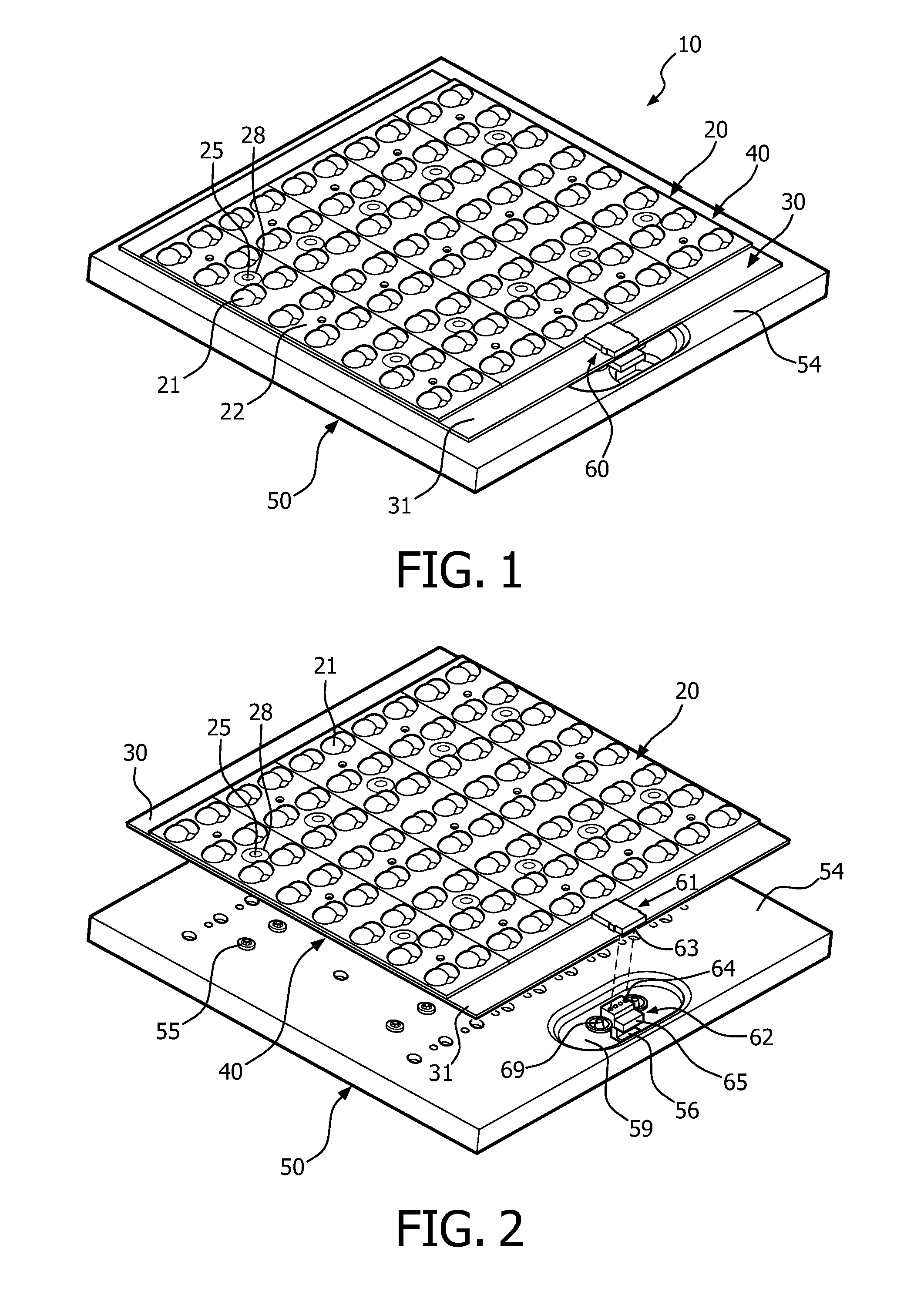

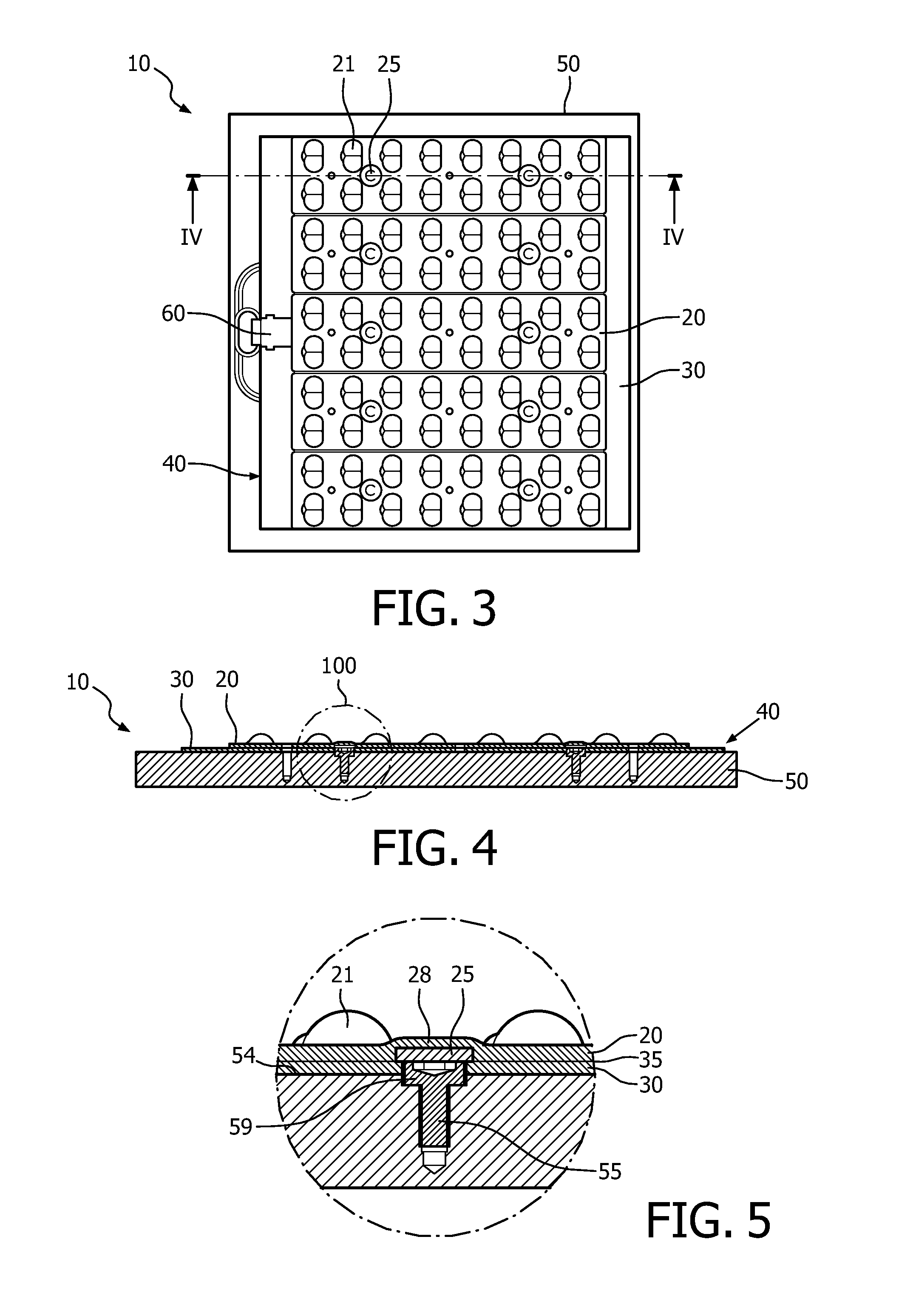

Removable light engine

ActiveUS20120293998A1Risk of damageMinimize damageNon-electric lightingPlanar light sourcesEngineeringLight emitting device

The invention relates to a light engine (40) comprising: a light-emitting device (30) comprising at least one light source; an optical device (20) attached to the light-emitting device (30); and at least one first magnetic element (25) between the light-emitting device (30) and the optical device (20). The invention relates also to a light device (10) comprising: said light engine (40); and a support holder (50) arranged to bear the light engine (40), comprising a magnetic material adapted such that the at least one first magnetic element (25) of the light engine (40) and this magnetic material are magnetically attracted one to the other to magnetically attach the light engine (40) to the support holder (50).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

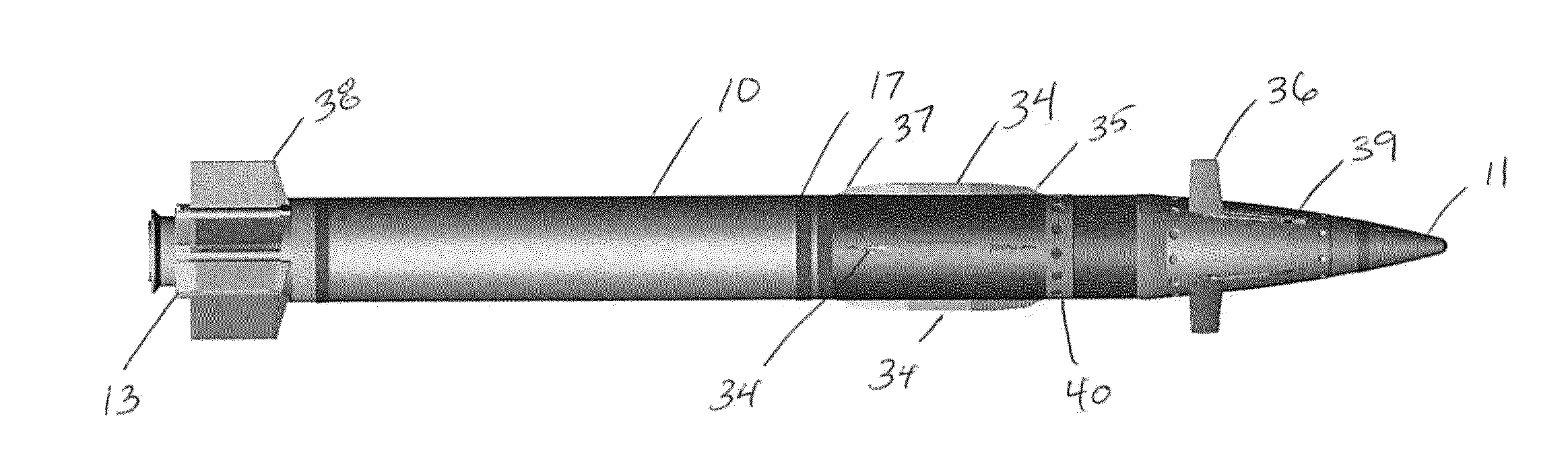

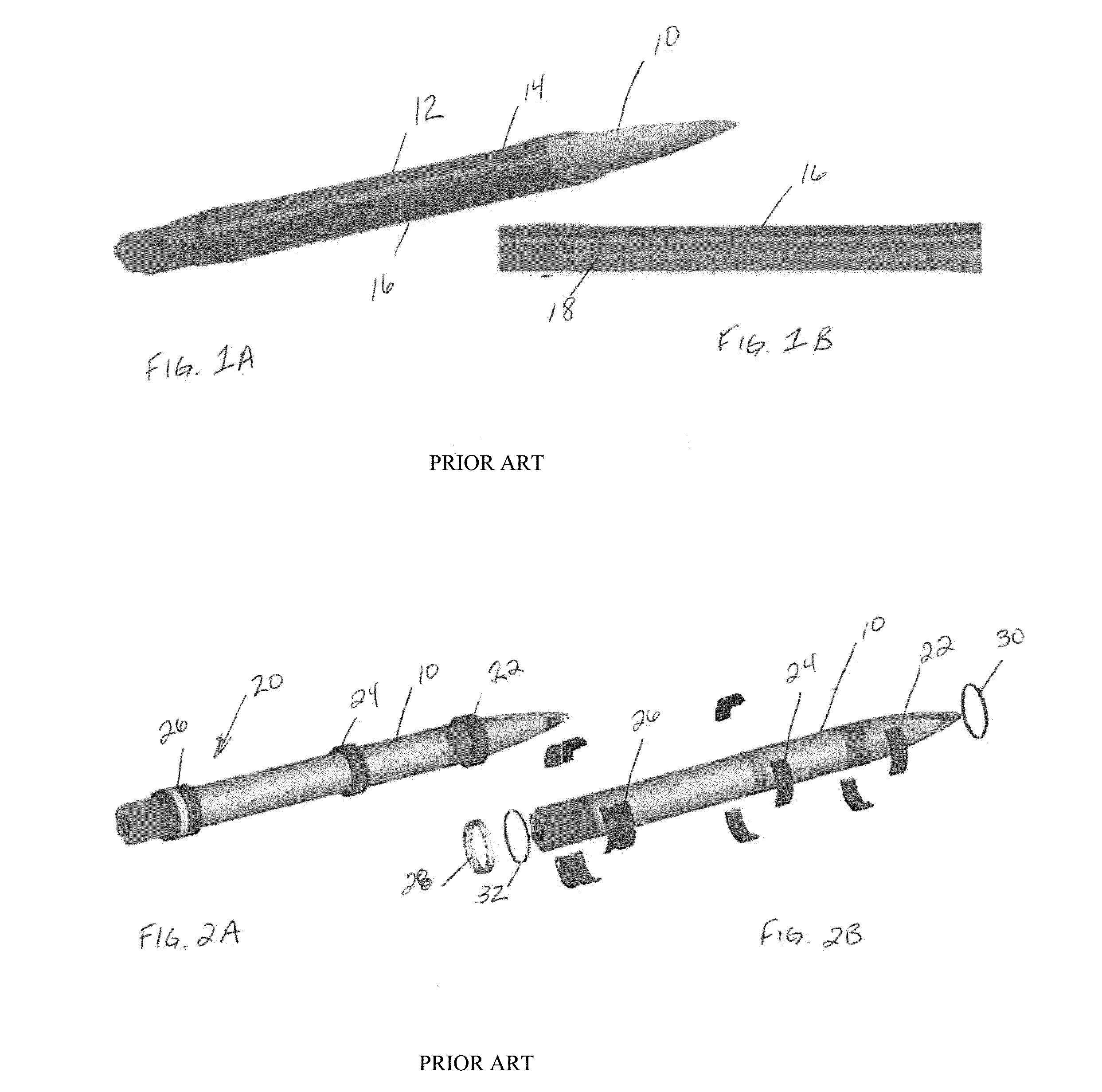

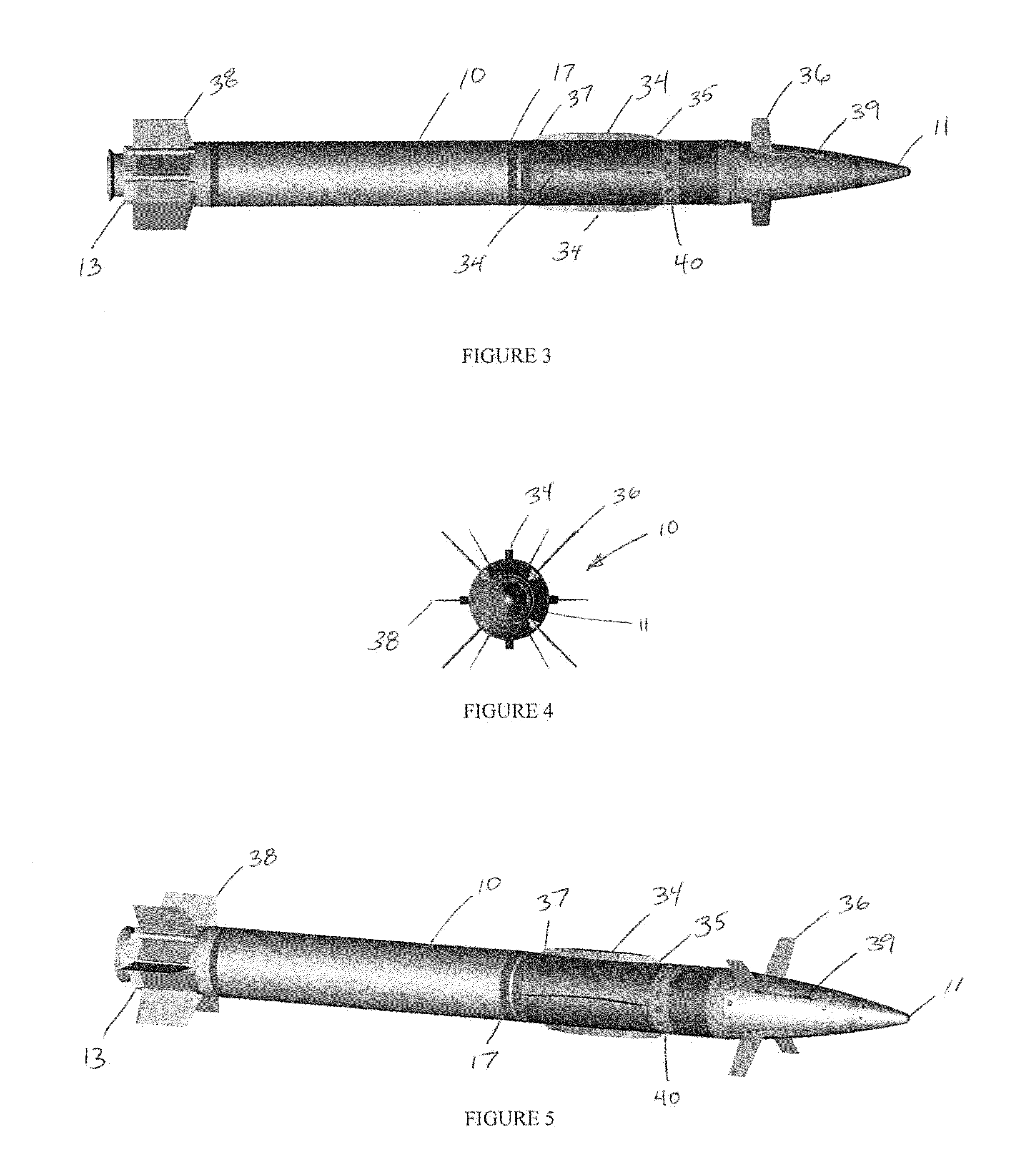

Gun launched munition with strakes

ActiveUS20150330755A1Not create a risk of harming personnel or damaging the gunRisk minimizationAmmunition projectilesTraining ammunitionCentral line placementEngineering

Owner:BAE SYSTEMS LAND & ARMAMENTS LP

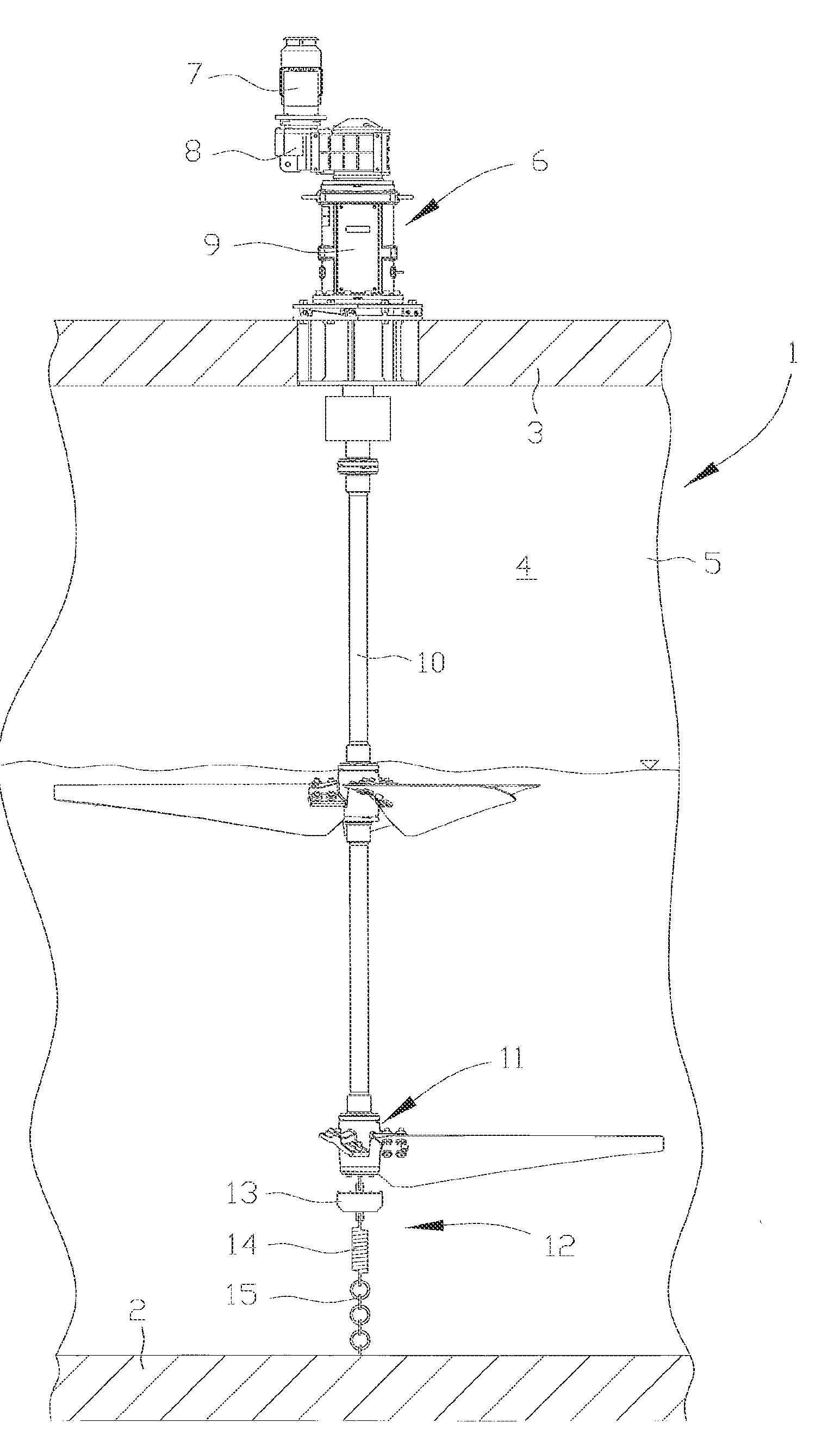

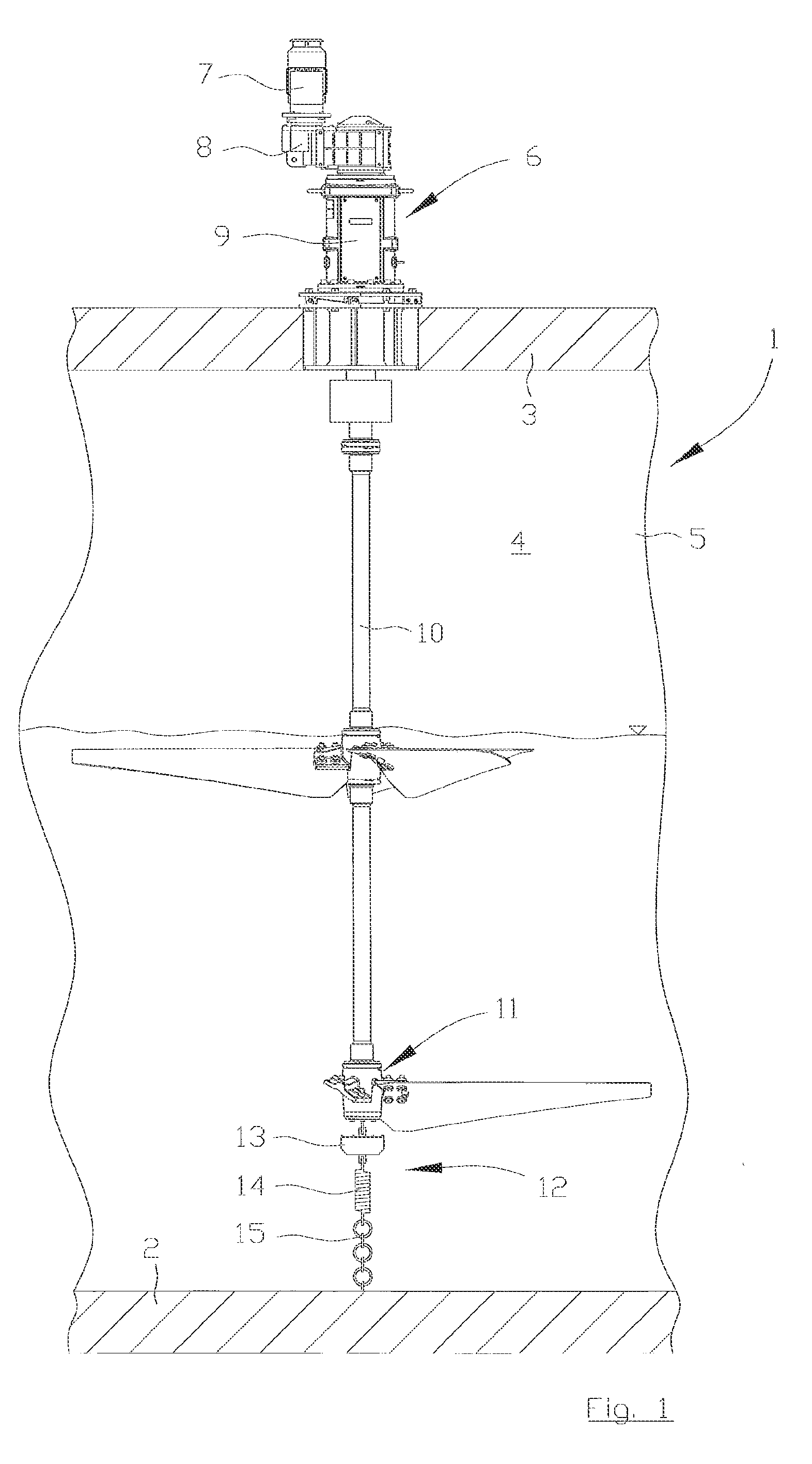

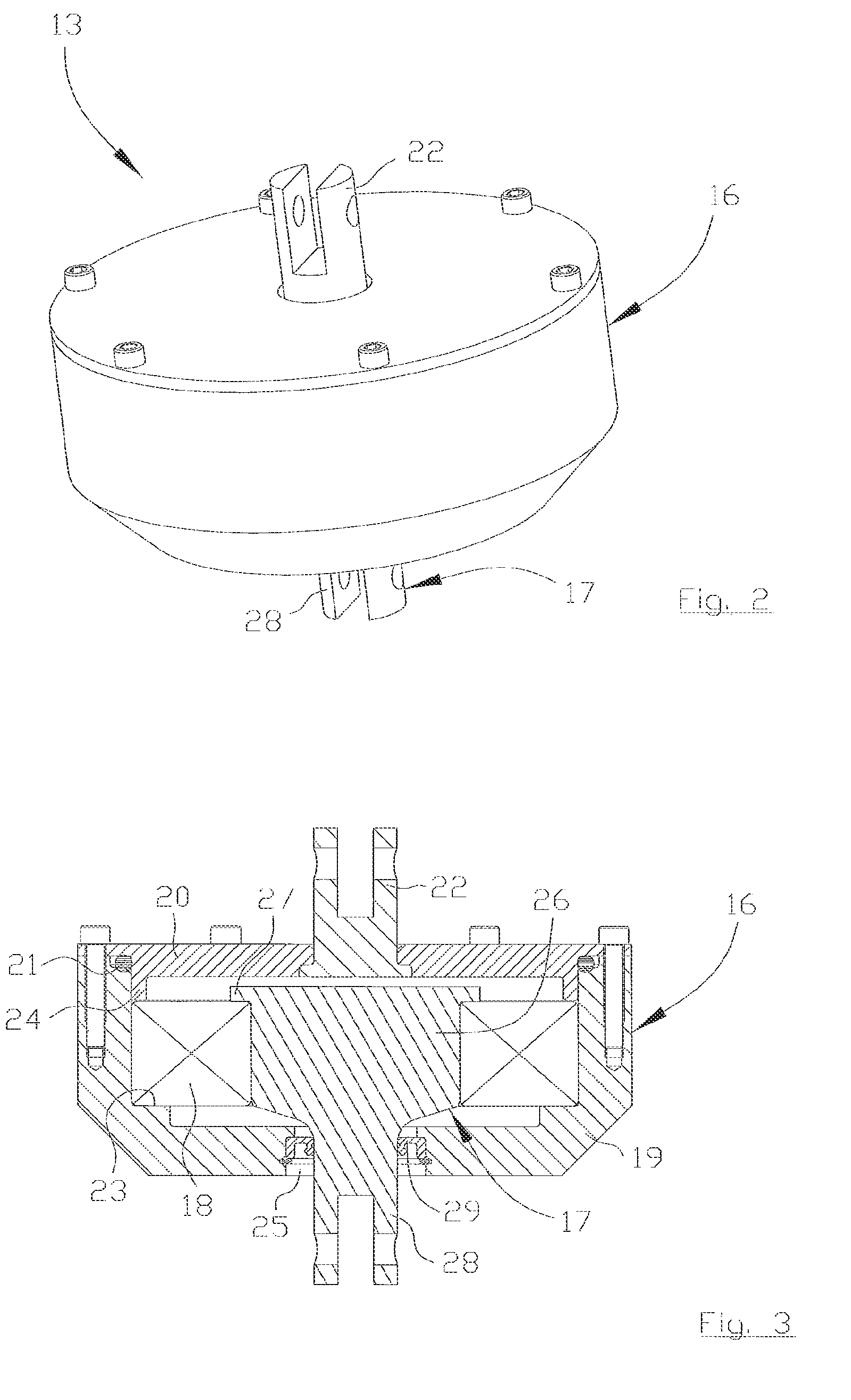

Mixer assembly for digestion tank

The invention relates to a mixer assembly for agitating material in a digestion tank (1), comprising a drive unit (7, 8, 9) and an output shaft (10) extending from said drive unit, which output shaft is arranged to hang down into said digestion tank (1) rotatably suspended from the drive unit. According to the invention the mixer assembly (6) furthermore comprises a stabilizer (12) comprising a swivel (13) and at least one resilient element (14) connected to said swivel (13), the stabilizer (12) being connected to the lower end of the output shaft (10) of the mixer assembly (6) and being arranged to be connected to a floor (2) of said digestion tank.

Owner:XYLEM IP HLDG

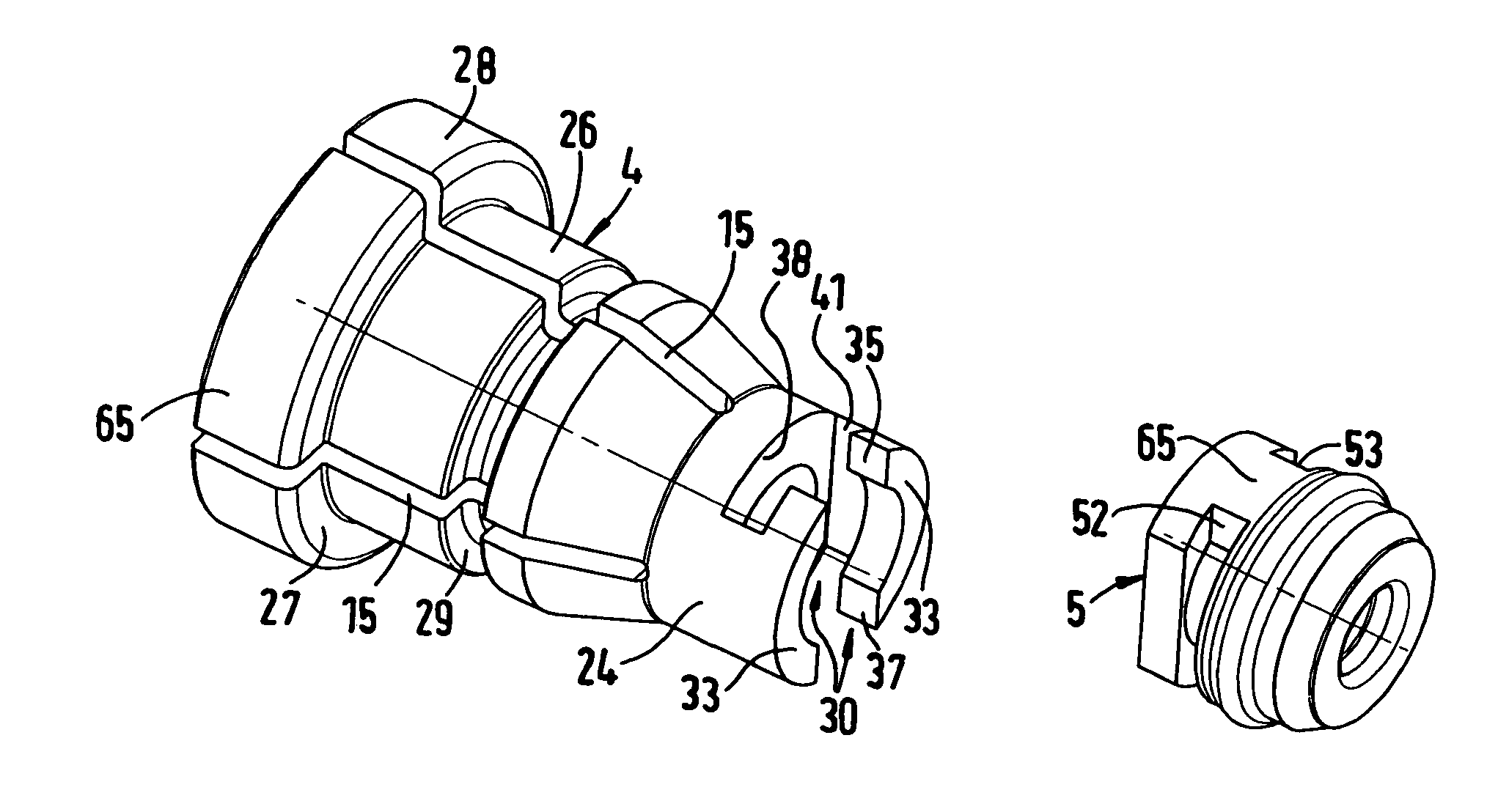

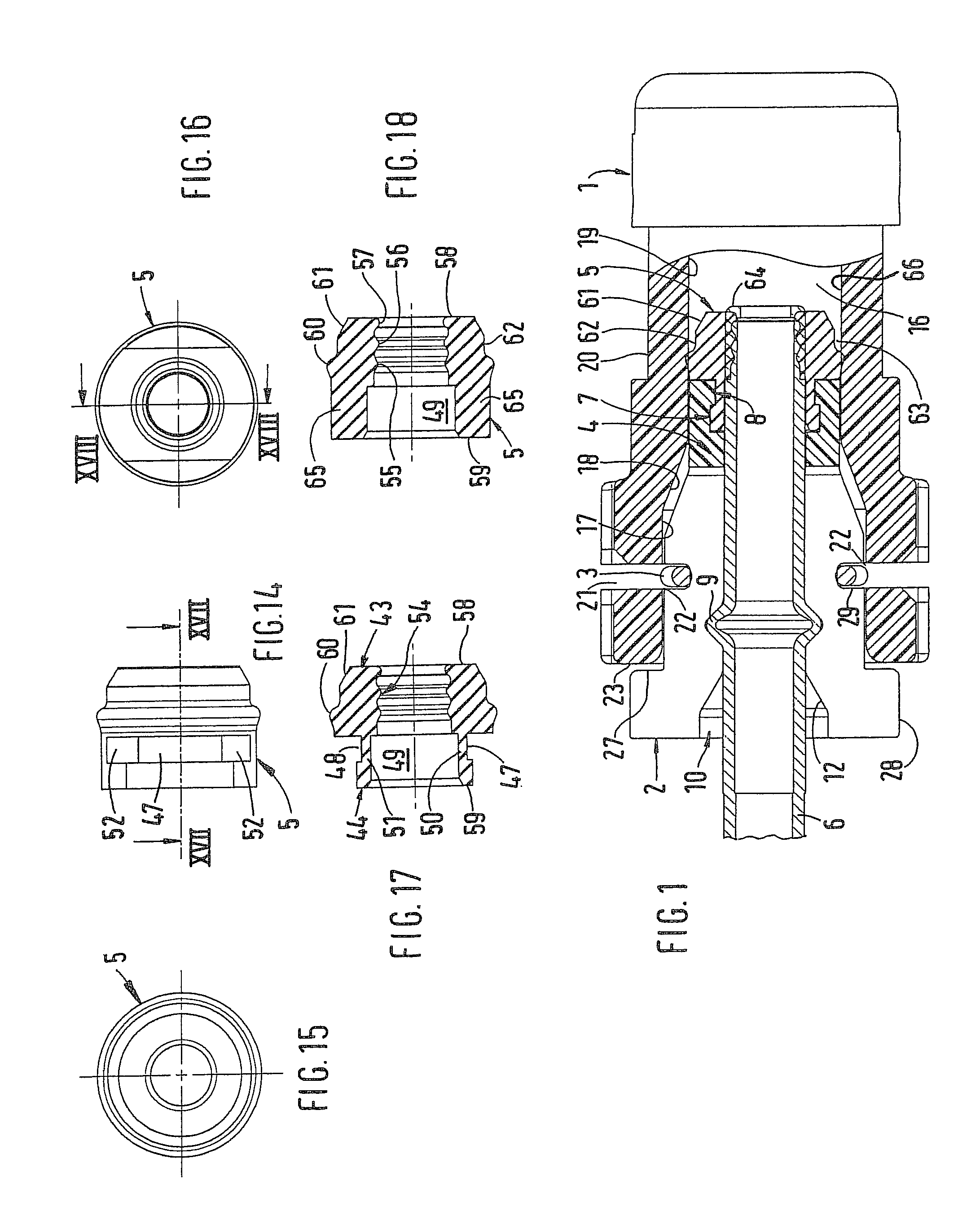

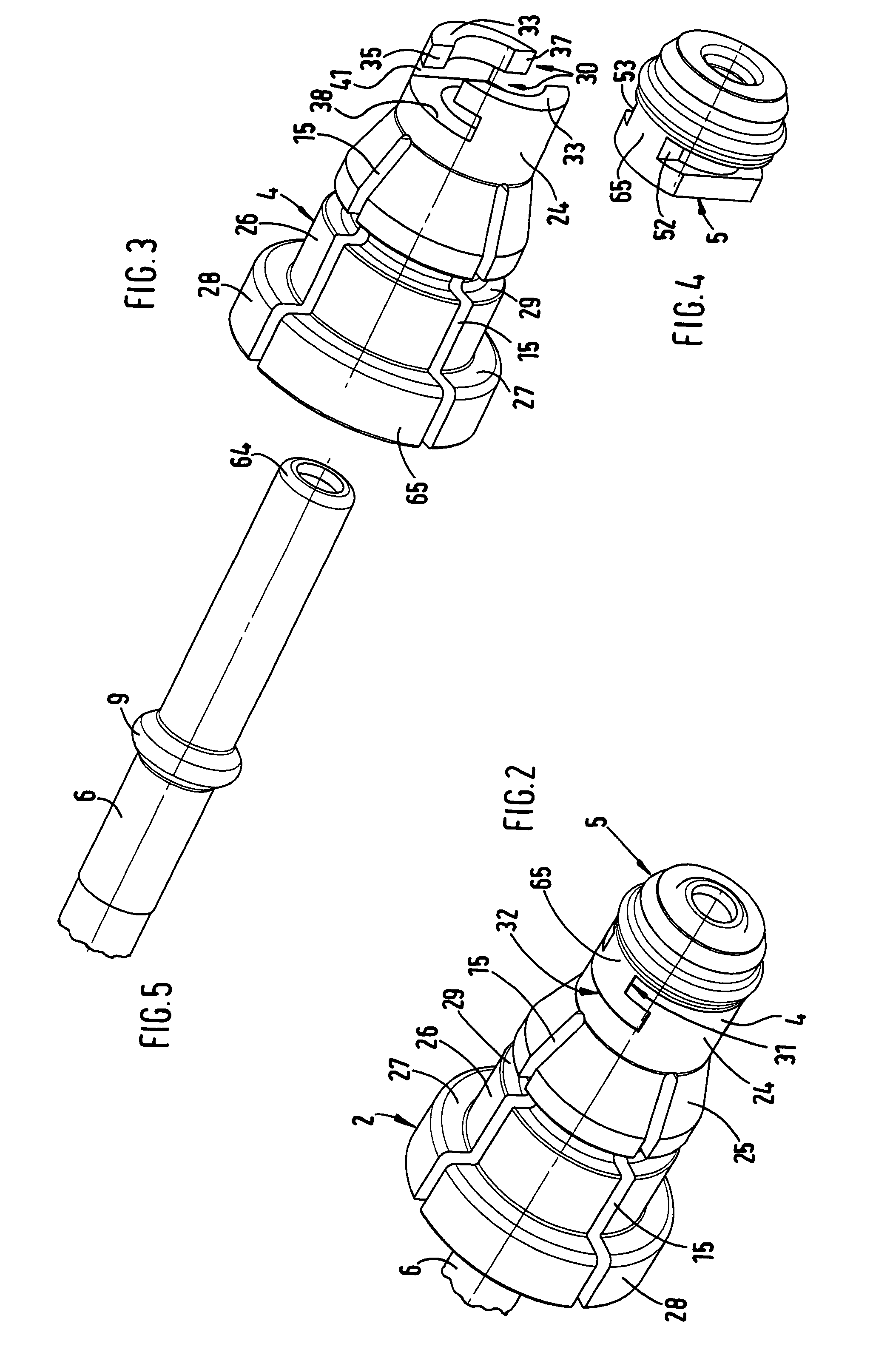

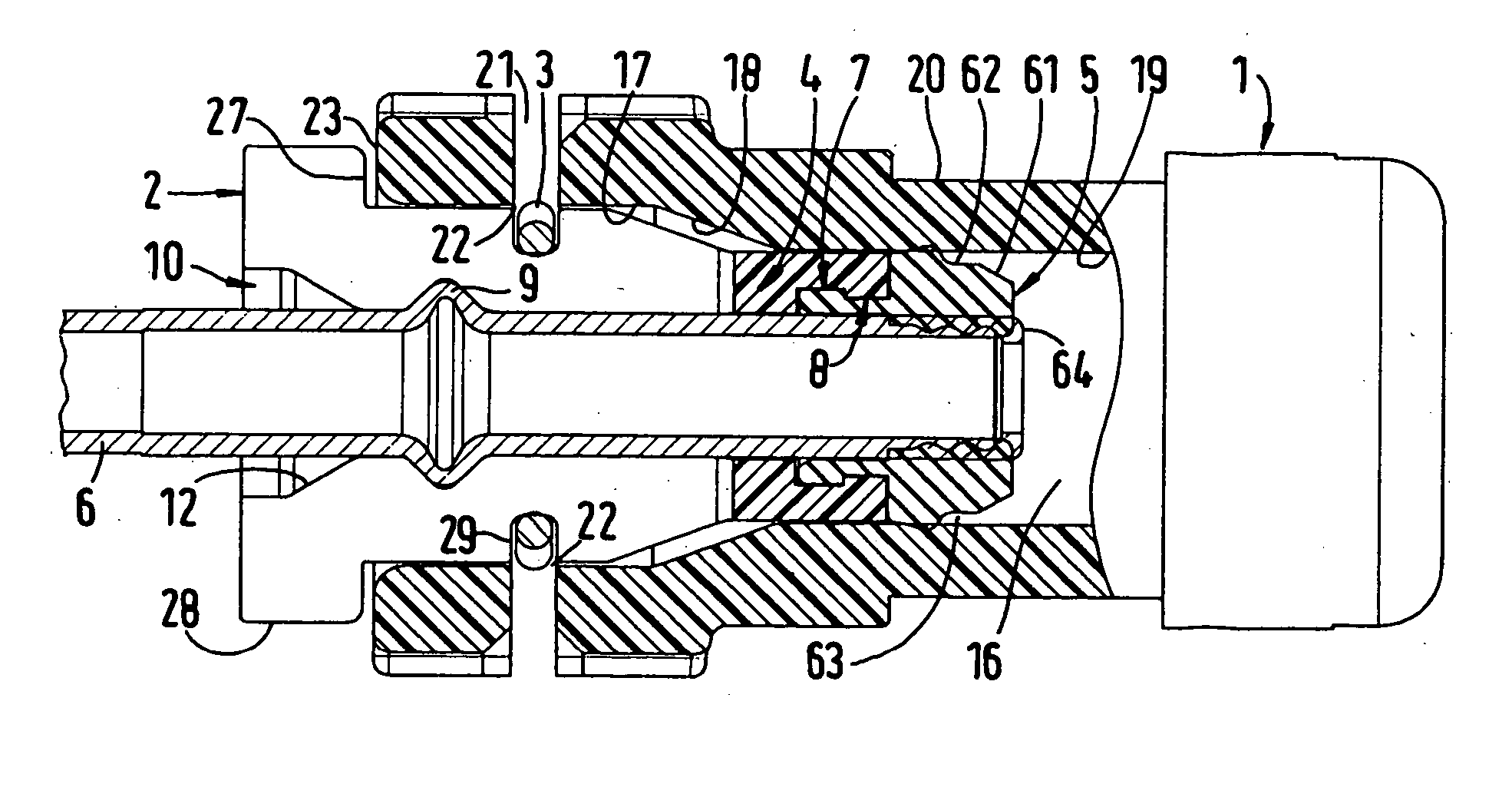

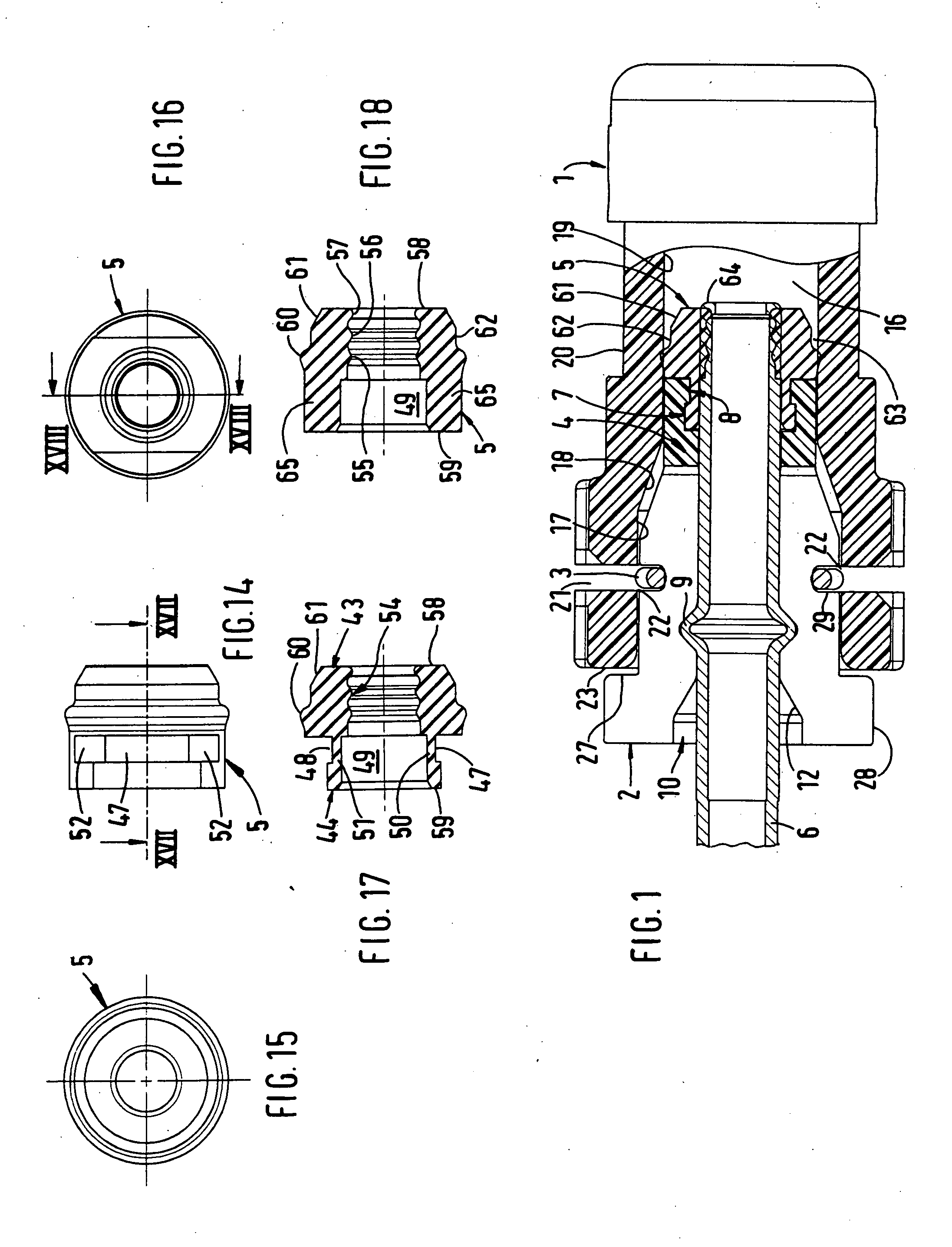

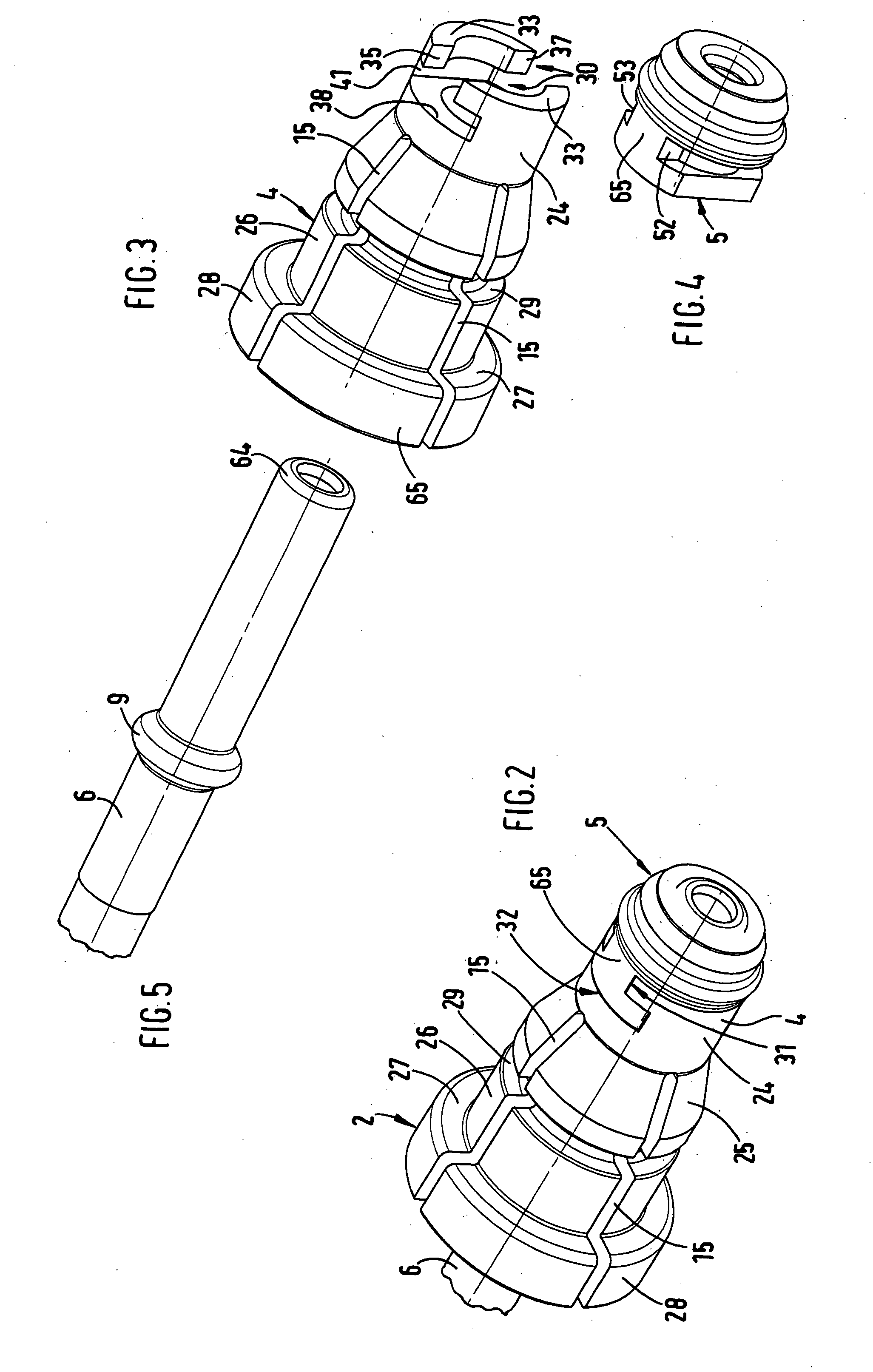

Sealing arrangement for a hydraulic plug-in connection

A sealing arrangement for a hydraulic plug-in connection for use in particular in the motor vehicle industry for hydraulic clutch and brake systems is fitted on a hydraulic plug-in connection and has a socket and a plug-in fitting which can be connected thereto. The plug-in fitting is attached to a hydraulic tube. The plug-in fitting has a sleeve and a sealing element fixed thereto, which seals off the plug-in connection both from the hydraulic tube and from the exterior of the socket. The sealing element and the end of the sleeve which receives the sealing element are designed so as to be able to install the sealing arrangement without it being possible for the sealing element to be separated axially from the sleeve when the plug-in connection is released.

Owner:FTE AUTOMOTIVE GMBH & CO KG

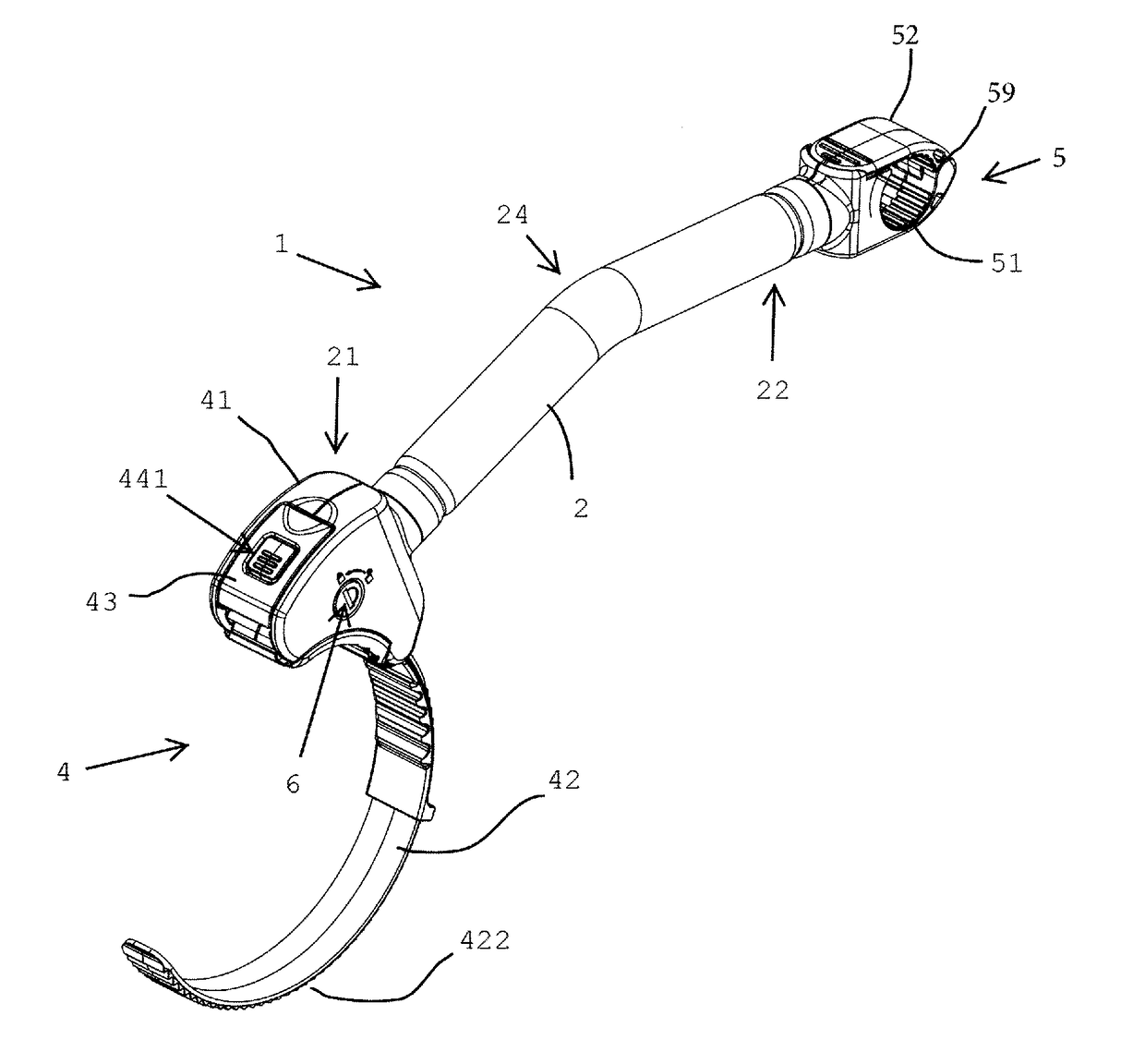

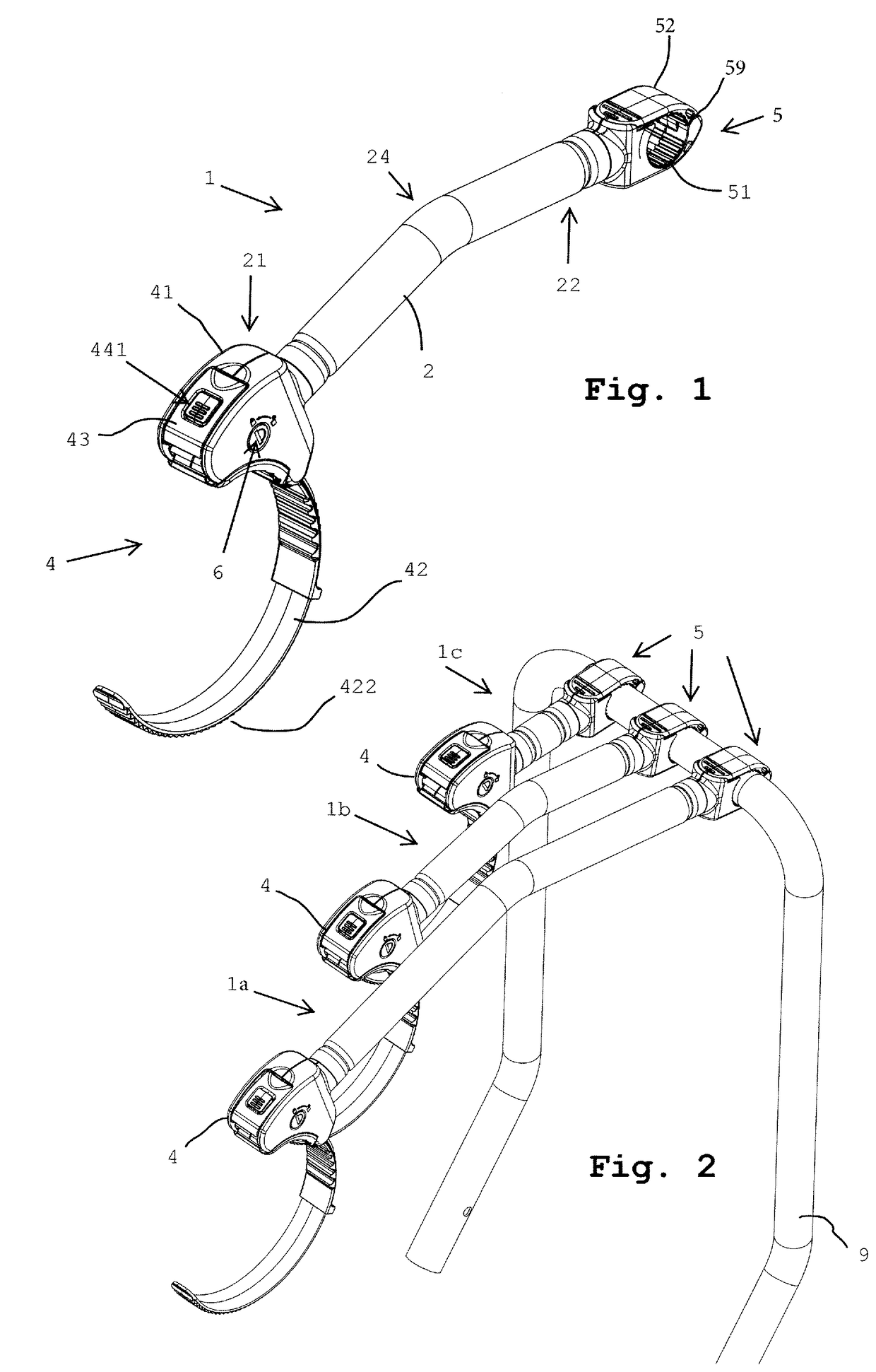

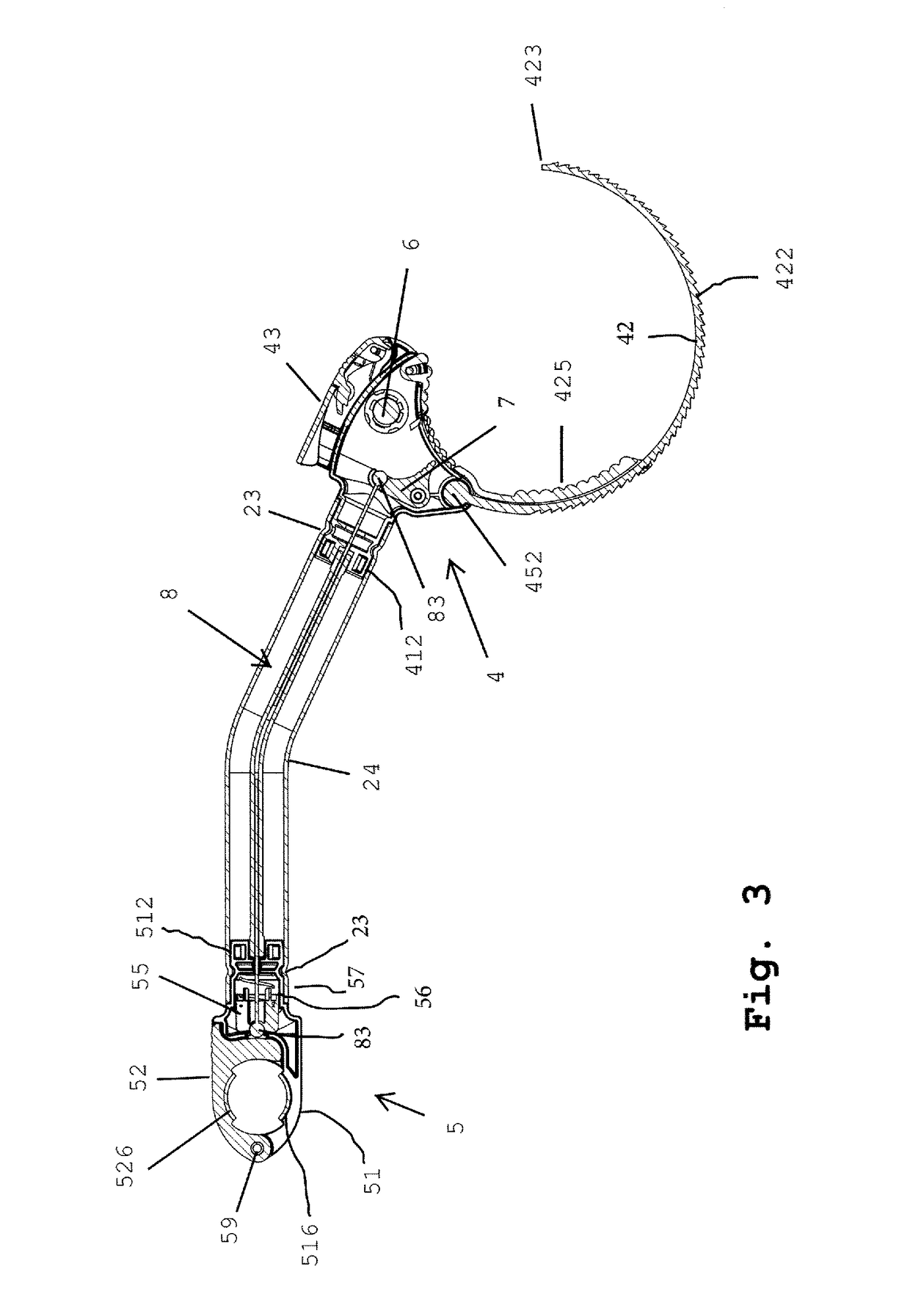

Support bars and cycle carriers

InactiveUS20170066385A1Increased Design FreedomEffective protectionSupplementary fittingsFriction grip releasable fasteningsEngineeringBowden cable

A cycle carrier support bar has a cycle end grip device (4) at a first end of a tubular spacer bar (2) and a carrier end grip device (5) at the second end. The cycle end grip device can be a flexible strap (42) with a tensioning lever (43) and a key-operated lock (6). The carrier end grip device (5) can be a rigid clamp with opposed jaws (51,52) connected at a pivot (54) and closed releasably by a latch mechanism operated by a longitudinally-slidable carrier shuttle (55) carrying a detent of the latch. The latch is released to open the carrier end grip device (5) by pulling on the wire of a Bowden cable (8) which extends along the middle of the tubular spacer bar, and has an actuating lever (7) exposed through a window in the cycle end grip (4), so as to be accessible only when the cycle end grip (4) is open.

Owner:C P WITTER

Sealing arrangement for a hydraulic plug-in connection

ActiveUS20070228731A1Large inner diameterFacilitate transverse insertionSleeve/socket jointsClutchesBraking systemClutch

A sealing arrangement for a hydraulic plug-in connection for use in particular in the motor vehicle industry for hydraulic clutch and brake systems is fitted on a hydraulic plug-in connection and has a socket and a plug-in fitting which can be connected thereto. The plug-in fitting is attached to a hydraulic tube. The plug-in fitting has a sleeve and a sealing element fixed thereto, which seals off the plug-in connection both from the hydraulic tube and from the exterior of the socket. The sealing element and the end of the sleeve which receives the sealing element are designed so as to be able to install the sealing arrangement without it being possible for the sealing element to be separated axially from the sleeve when the plug-in connection is released.

Owner:FTE AUTOMOTIVE GMBH & CO KG

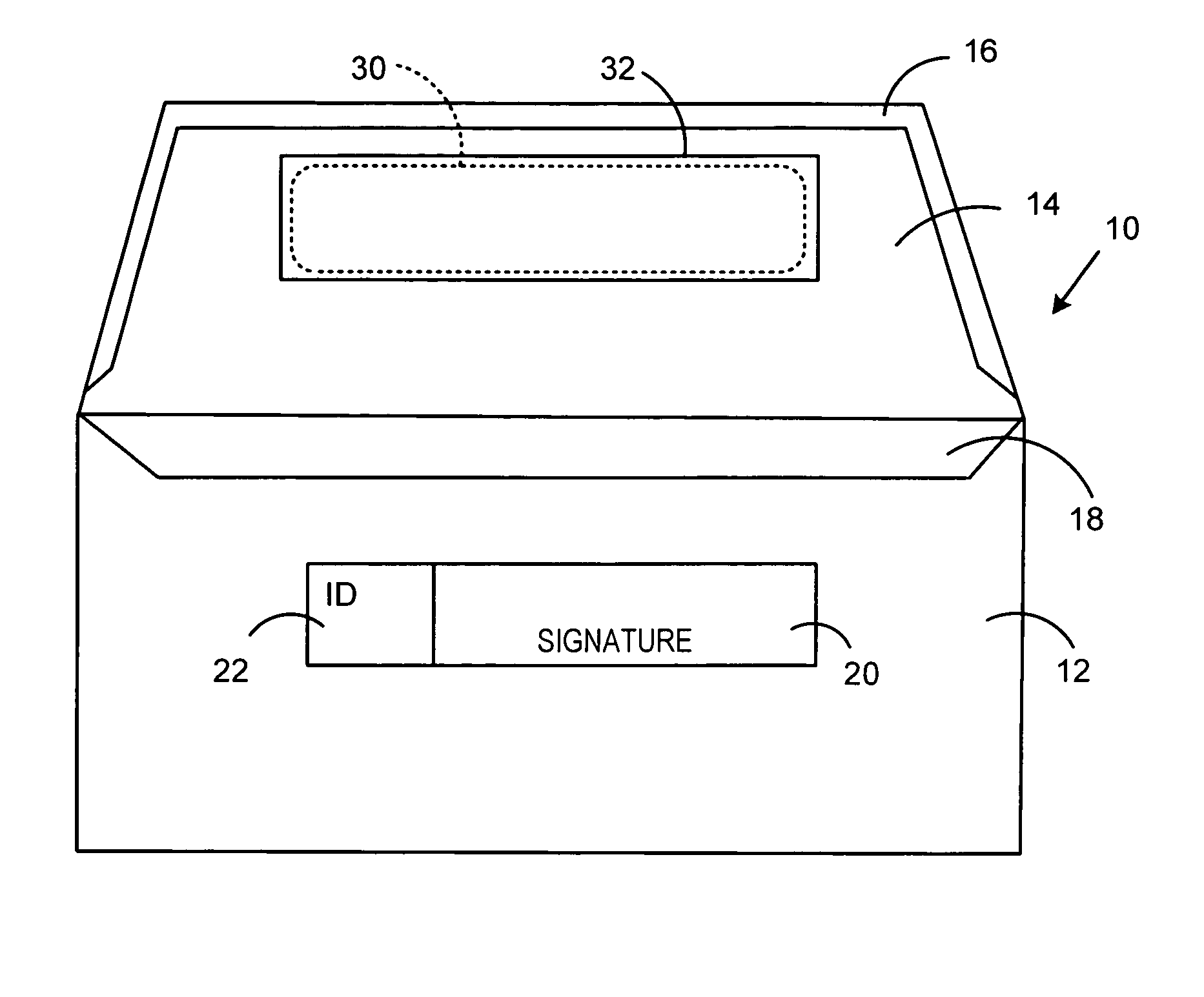

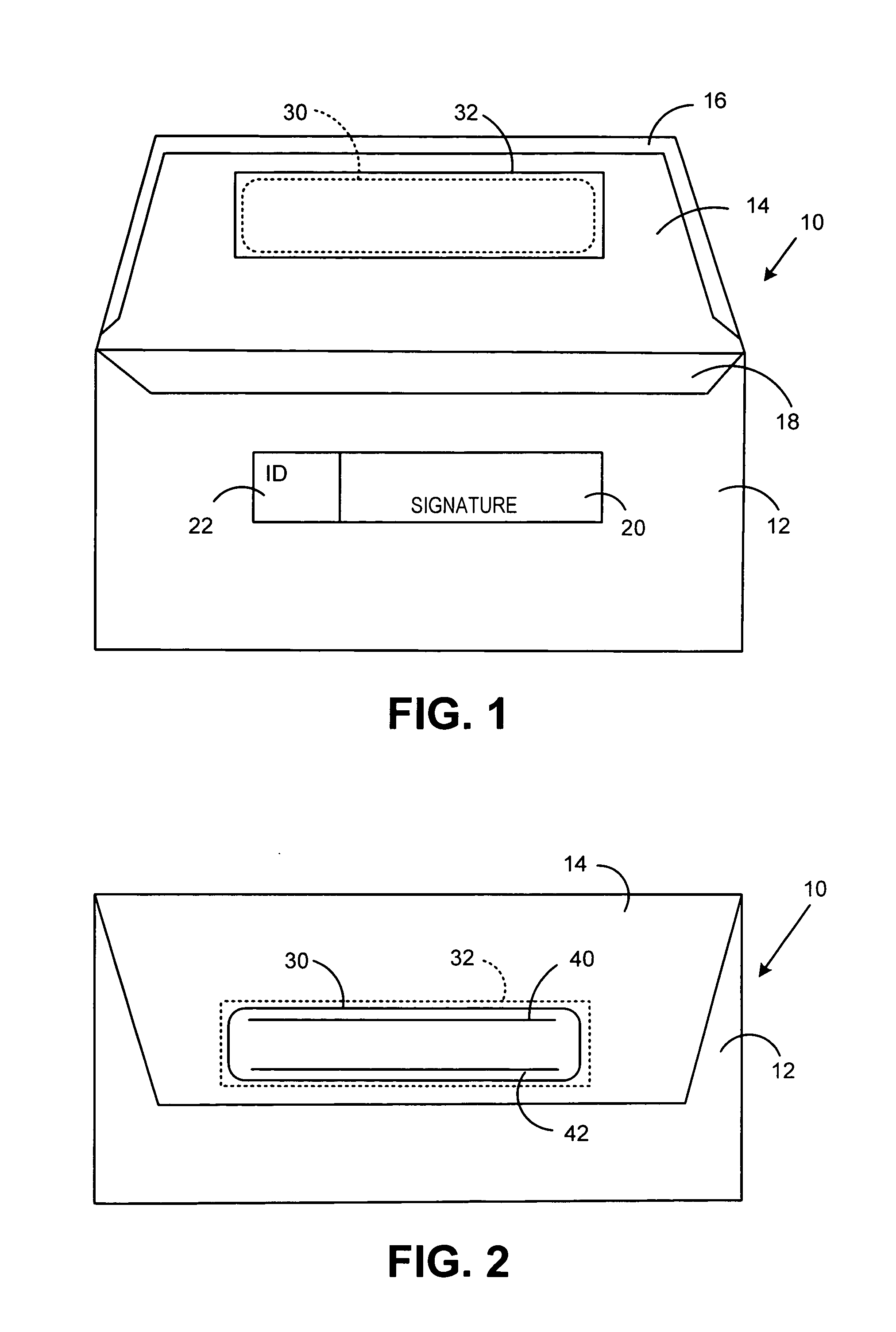

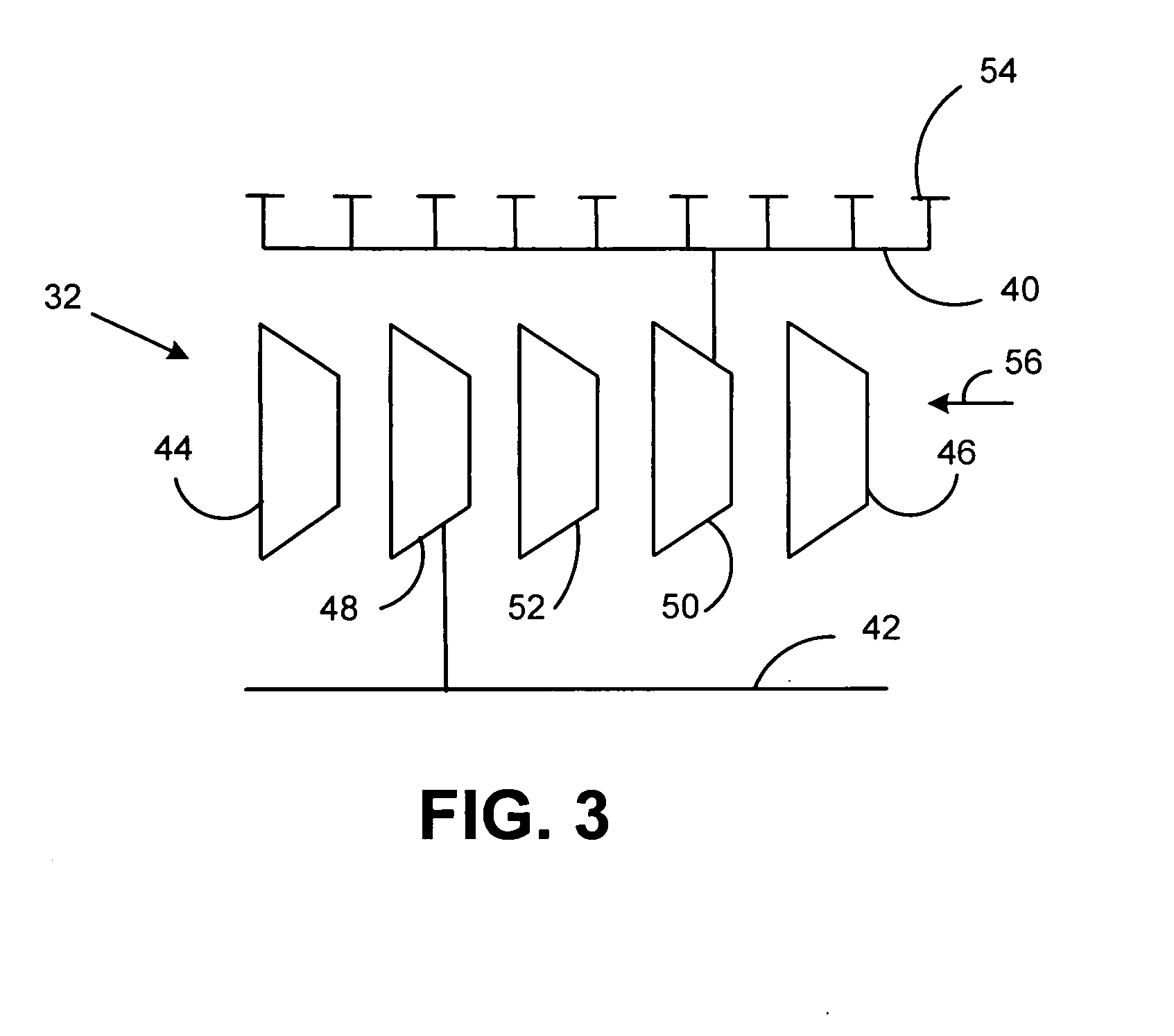

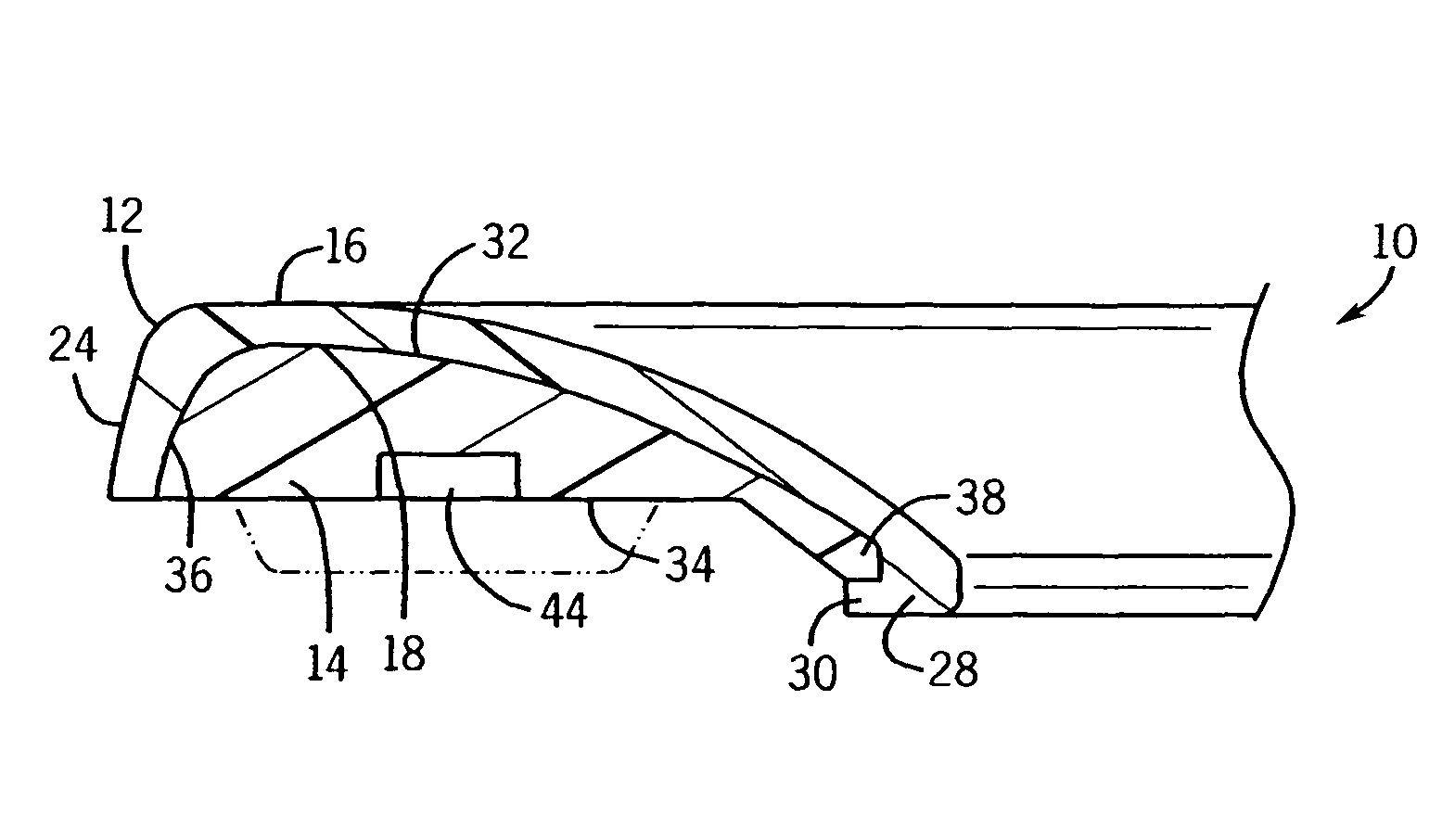

Method and system for protecting privacy of signature on mail ballot utilizing optical shutter

InactiveUS20080121680A1Reduce risk of damageCost of damageVoting apparatusEnvelopesEngineeringElectric power

Methods and systems that protect the privacy of signatures on envelopes containing ballots sent through the mail are provided. The envelope for returning ballots by mail includes an electronic optical shutter that covers an opening in the flap of the envelope. The voter signs the back of the envelope in an area that will be visible through the opening in the flap (covered by the optical shutter) when the envelope flap is sealed. The optical shutter is opaque under static conditions, but will become transparent when power is supplied to it. When the envelope flap is sealed and no power is applied to the optical shutter, the voter's signature will be concealed by the optical shutter. Upon receipt at the registrar's office, the optical shutter can be powered, thereby rendering the optical shutter transparent, and the voter's signature can be viewed.

Owner:PITNEY BOWES INC

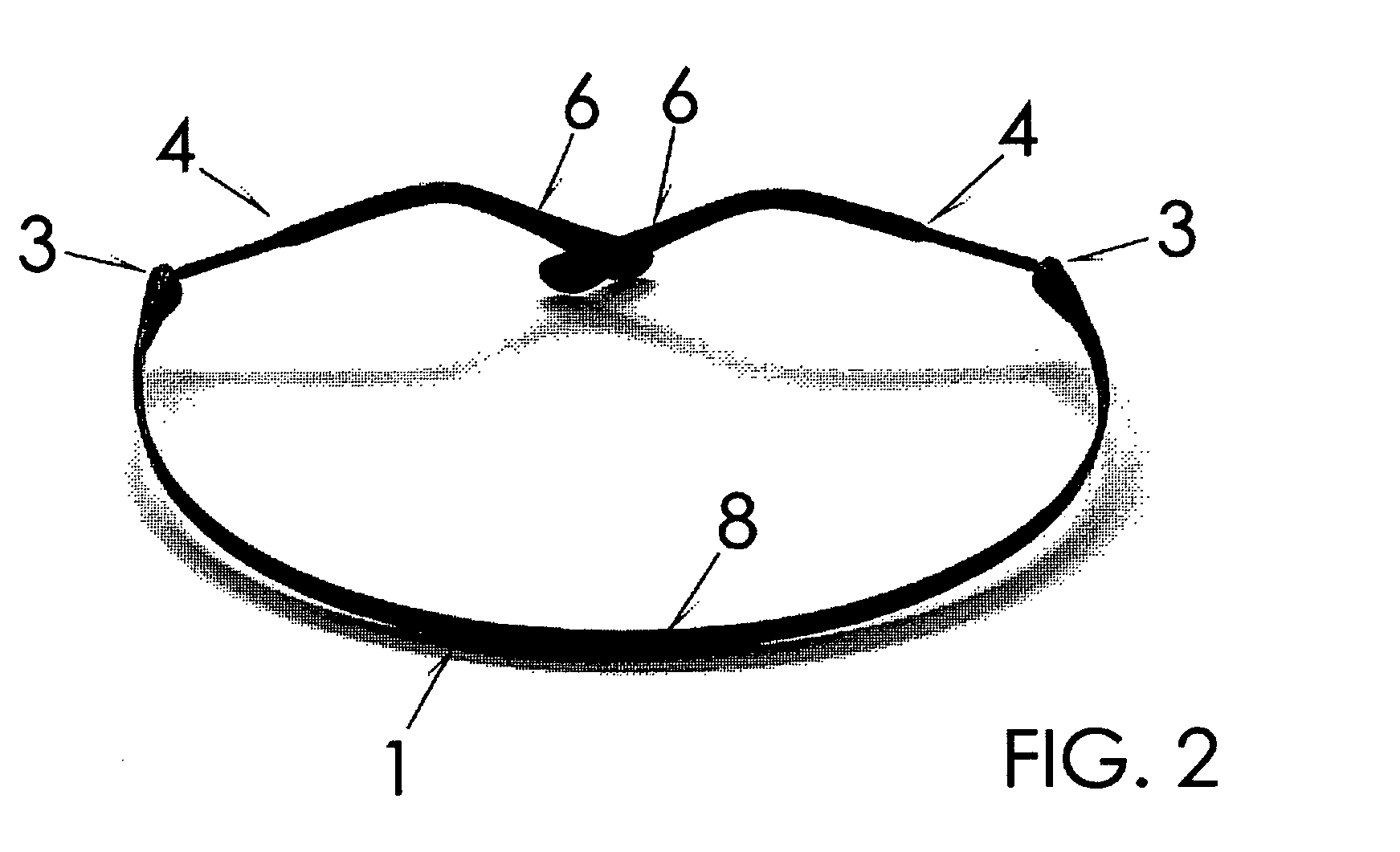

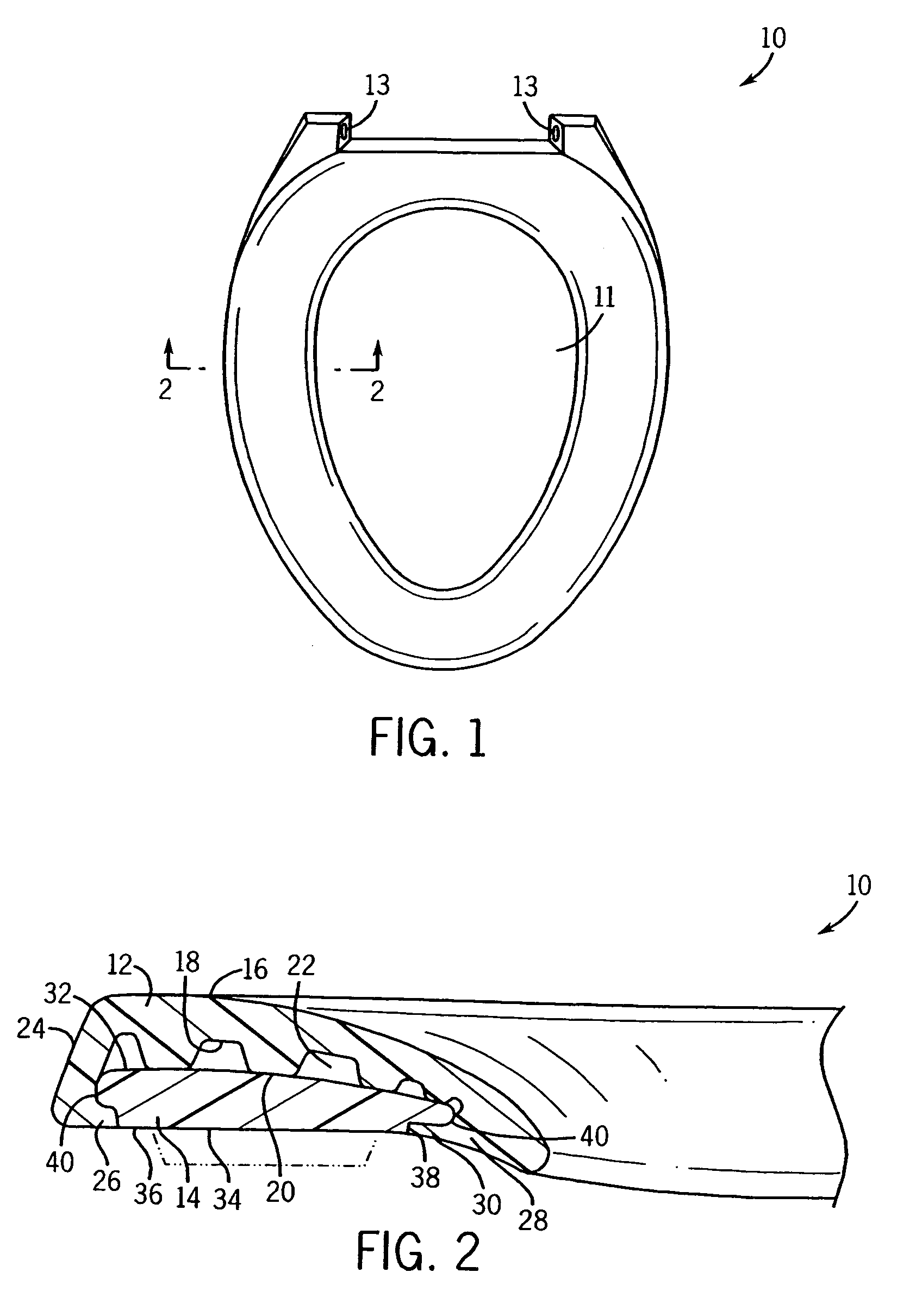

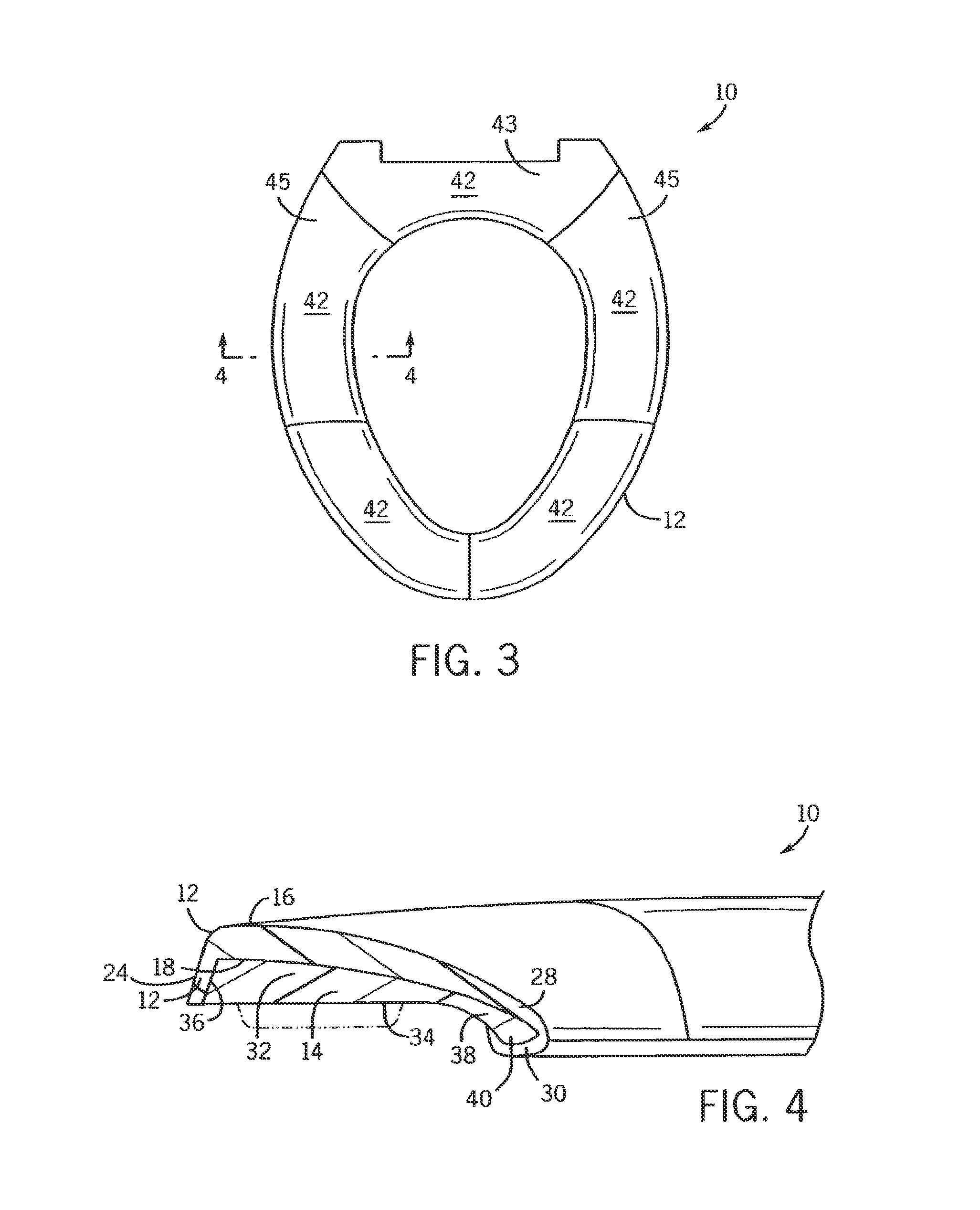

Plumbing fixture seat

Disclosed are cushioned toilet seats. They have an upper cushion supported on a more rigid base. The base may be removably connected to the cushion via a snap-fit connection, and the cushion can include zones having different durometers around its circumference. The upper cushion may have flexible support legs that extend into a cavity between the base and cushion. In other forms a kit is provided to allow the upper cushion of the seat to be customized by the consumer.

Owner:KOHLER CO

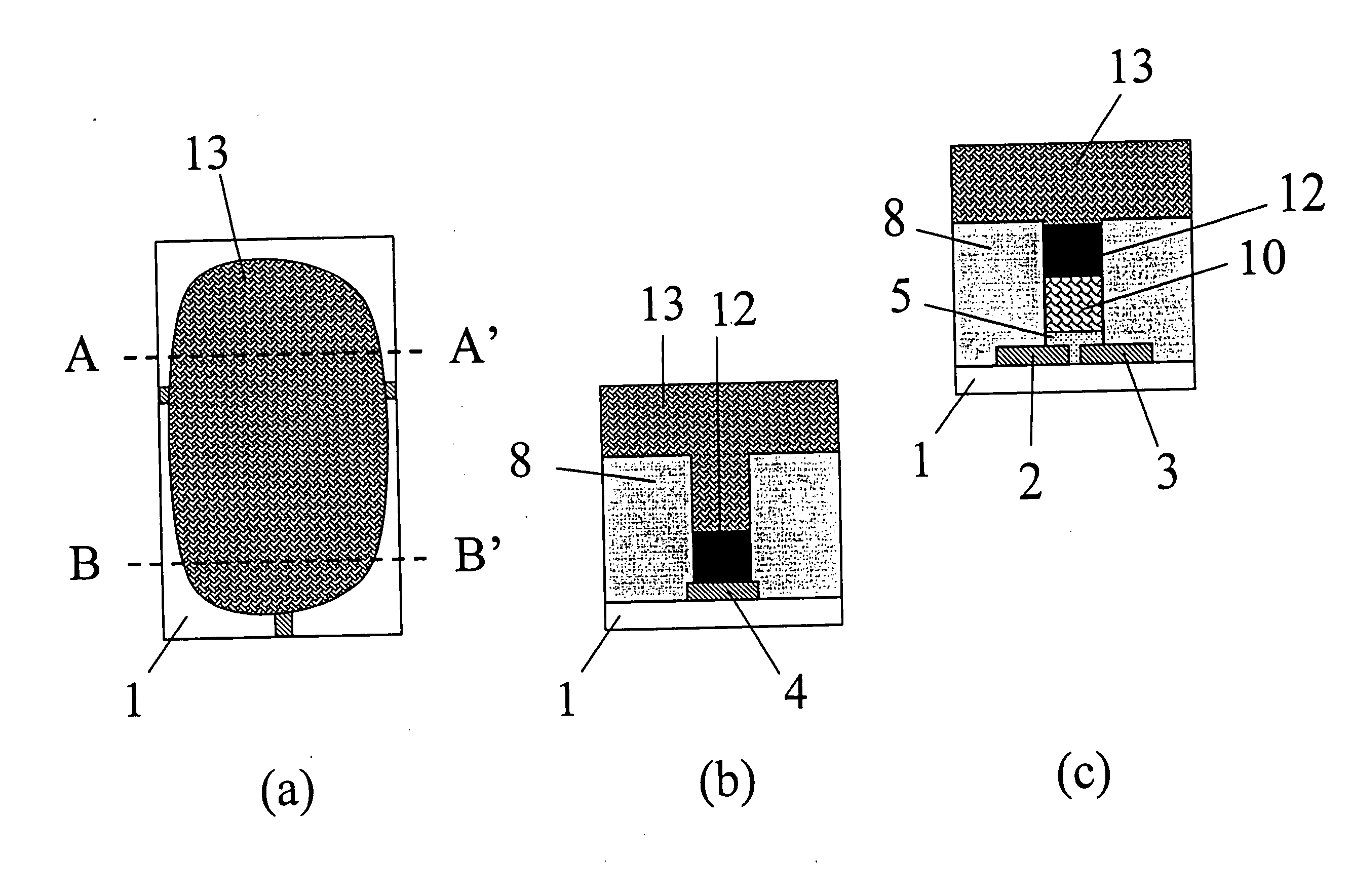

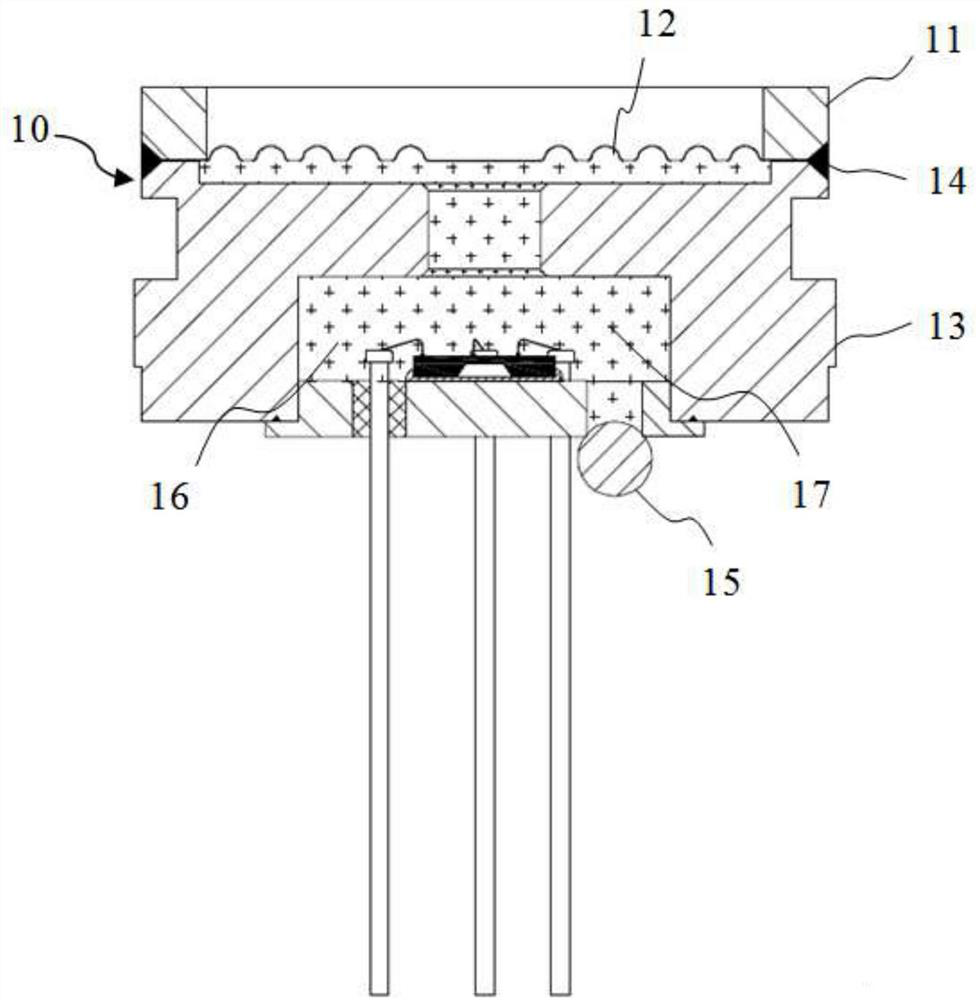

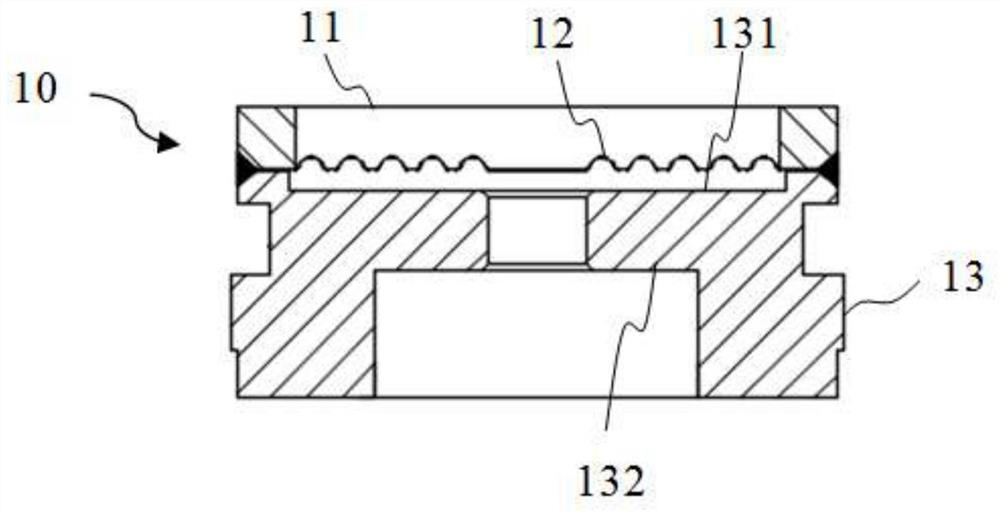

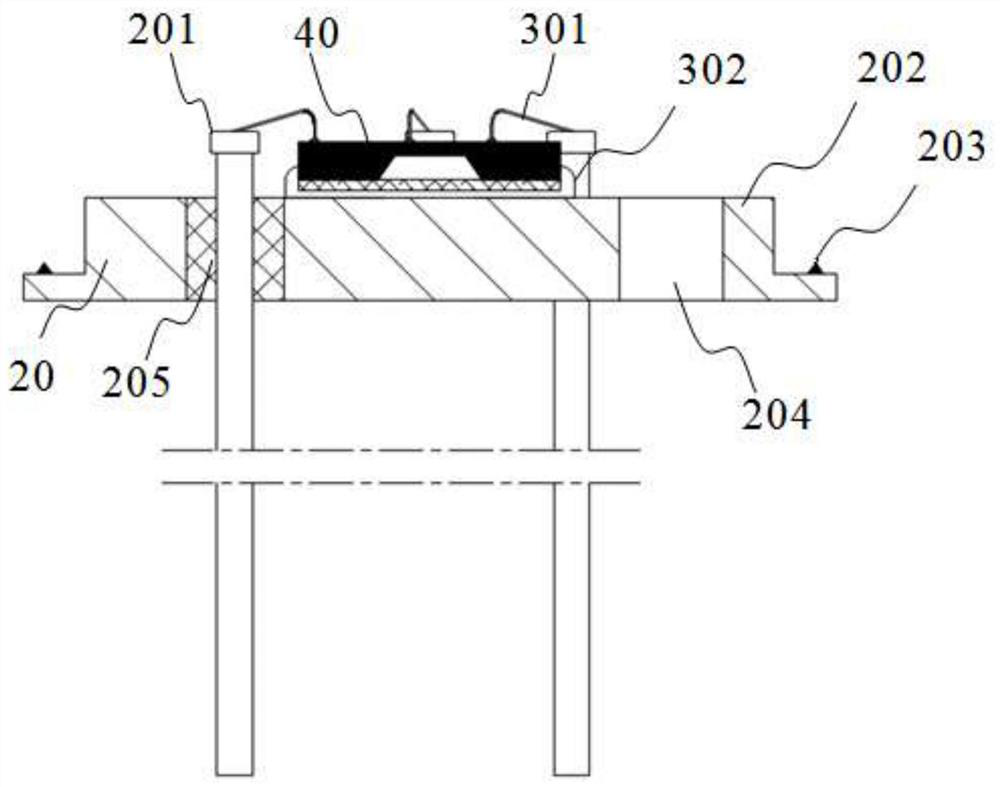

MEMS pressure sensor oil-filled core body and packaging method thereof

PendingCN111638002ALess interconnectionRisk of damageTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesSignal processing circuitsMems pressure sensor

The invention relates to the technical field of pressure sensors, and discloses an MEMS pressure sensor oil filling core which comprises an upper cover, a base and a sensitive assembly. A lower end ofthe upper cover is in sealed connection with the base, the base and the upper cover form a sealed cavity, and the sealed cavity is filled with a detection medium; a sensitive assembly is arranged onthe base and located in the sealed cavity. According to the MEMS pressure sensor oil-filled core and the packaging method thereof, a chip composed of a silicon elastic diaphragm, a semiconductor resistor and signal calibration modules is adopted; a signal processing circuit does not need to be arranged outside, and lead wire interconnection is reduced; the structure is simple, the cost is low, theproduct reliability is high, and convenience of production is achieved; the semiconductor resistor and the signal calibration module are located on different planes, the signal calibration modules are located on the periphery of the silicon elastic diaphragm, the risk that lines in the signal calibration module are damaged due to the fact that stress changes of the silicon elastic diaphragm influence the signal calibration module is prevented, and precision can be guaranteed.

Owner:WUHAN FINEMEMS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com