Patents

Literature

31results about How to "Minimal displacement" patented technology

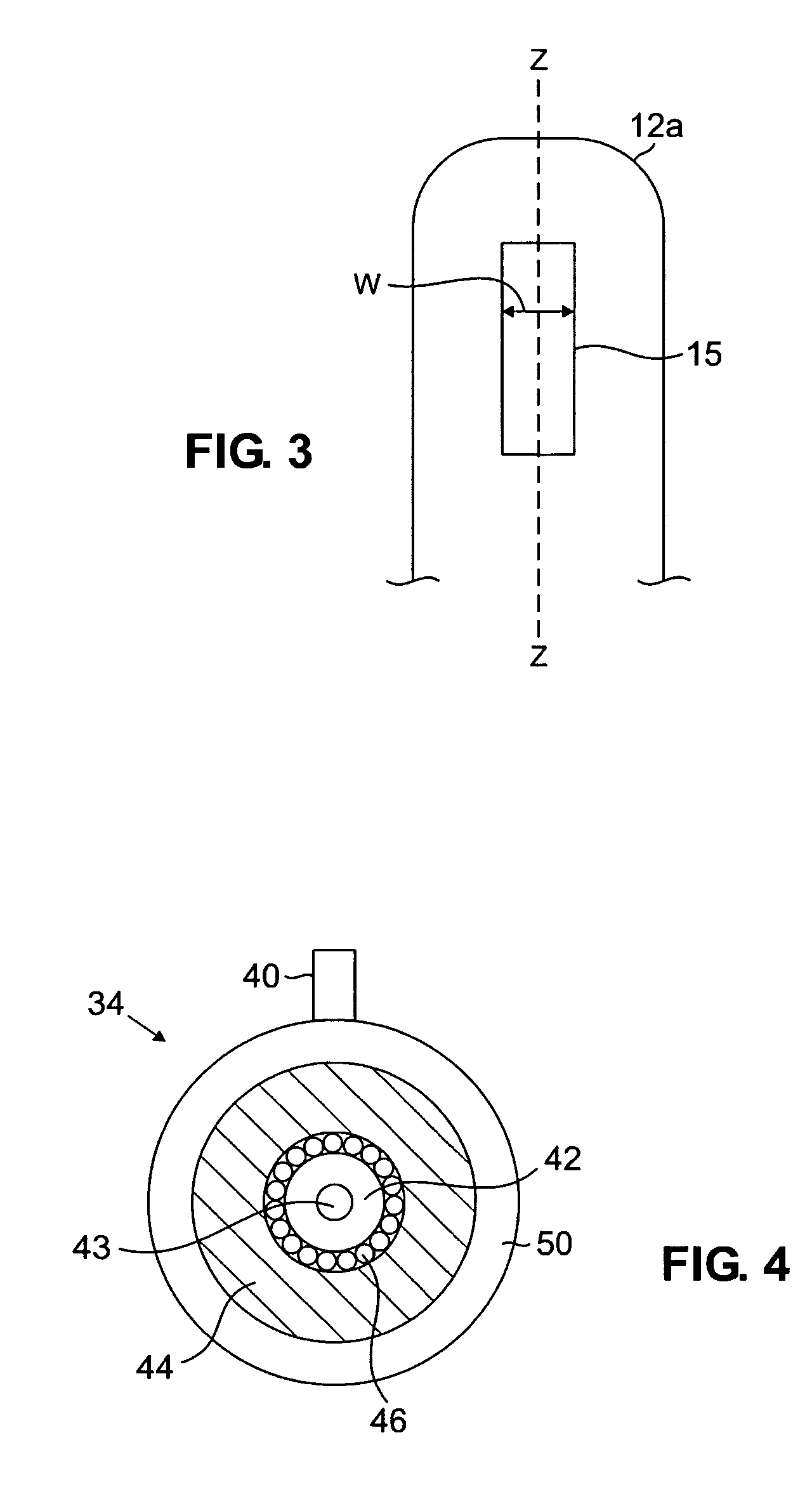

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

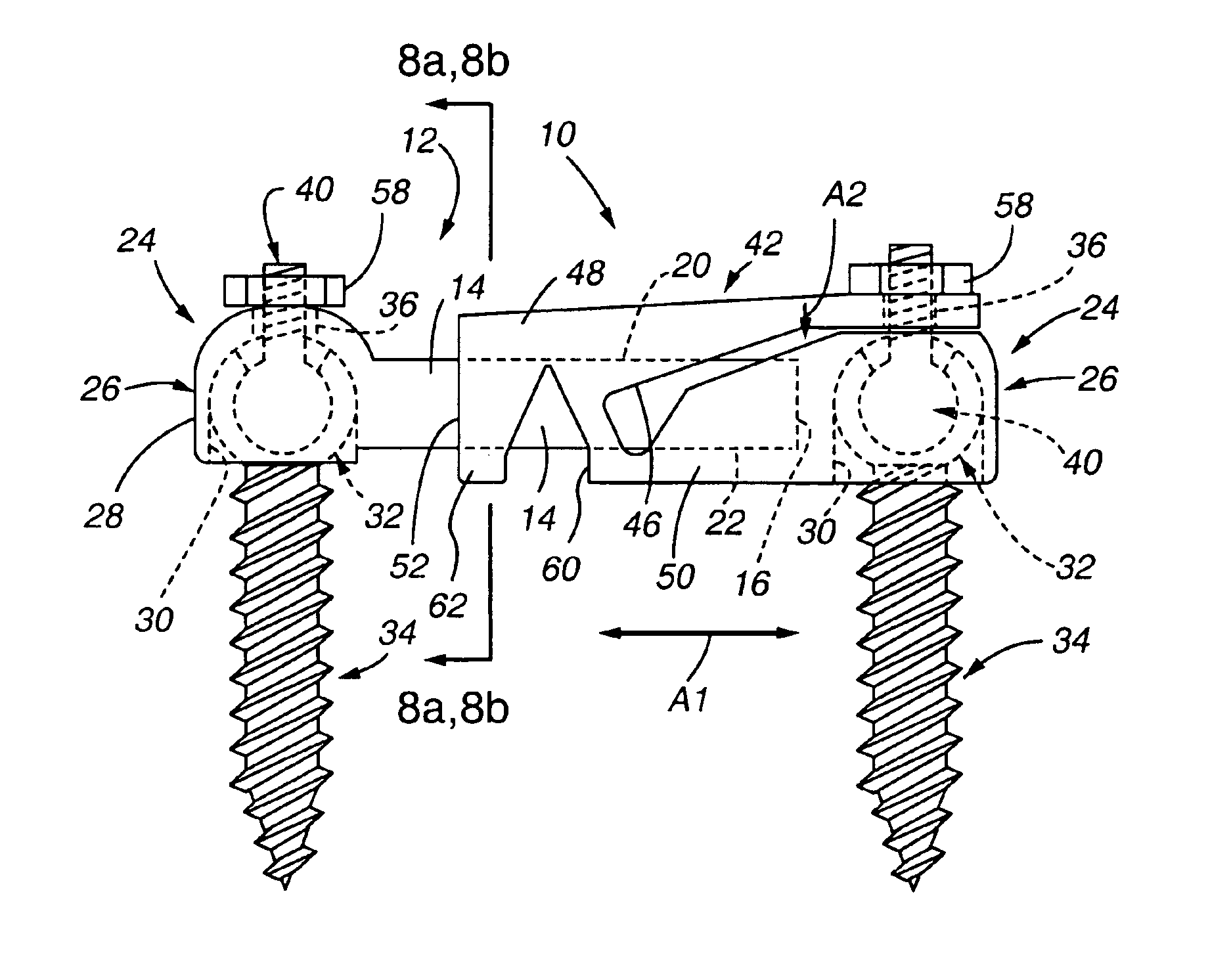

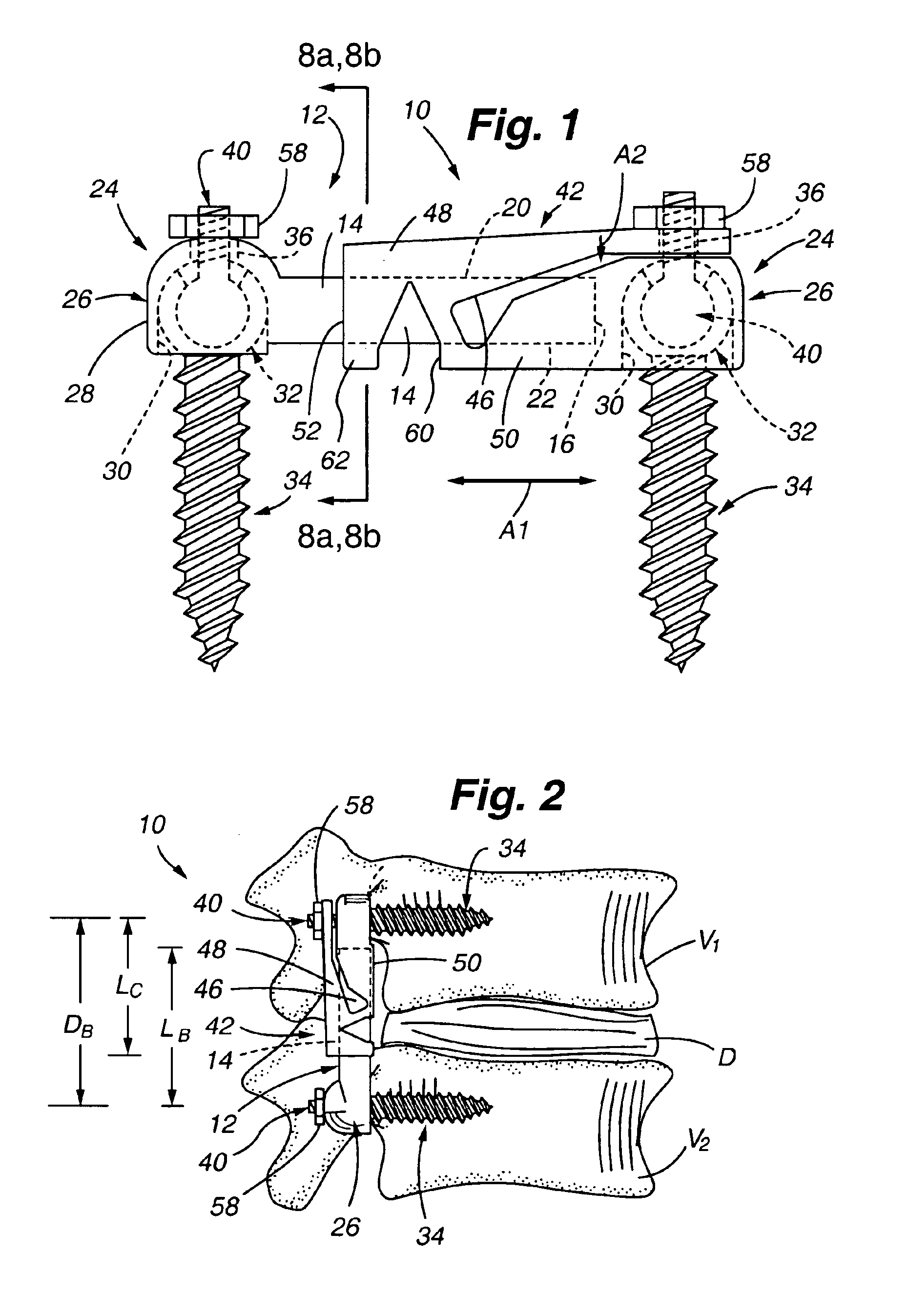

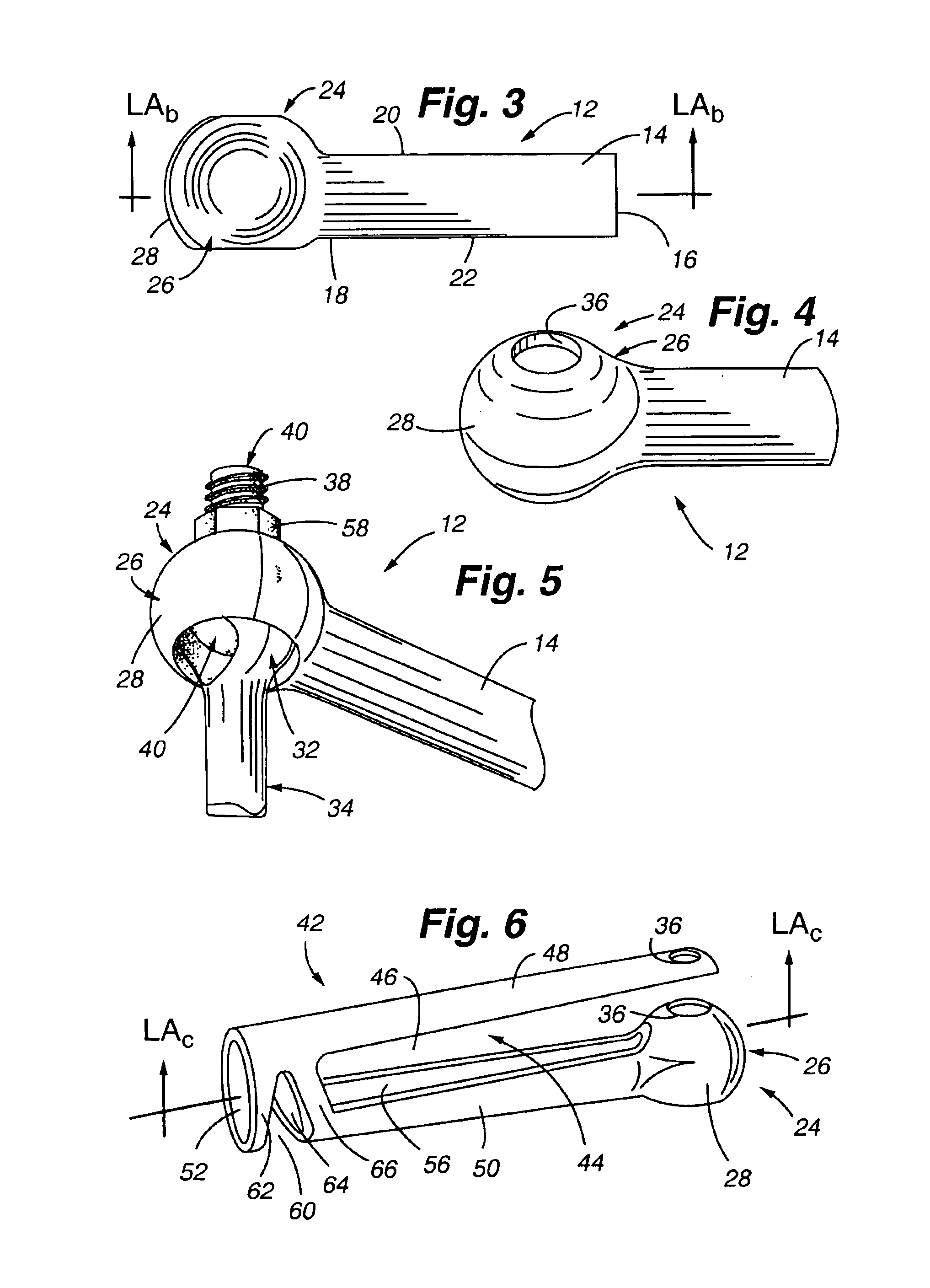

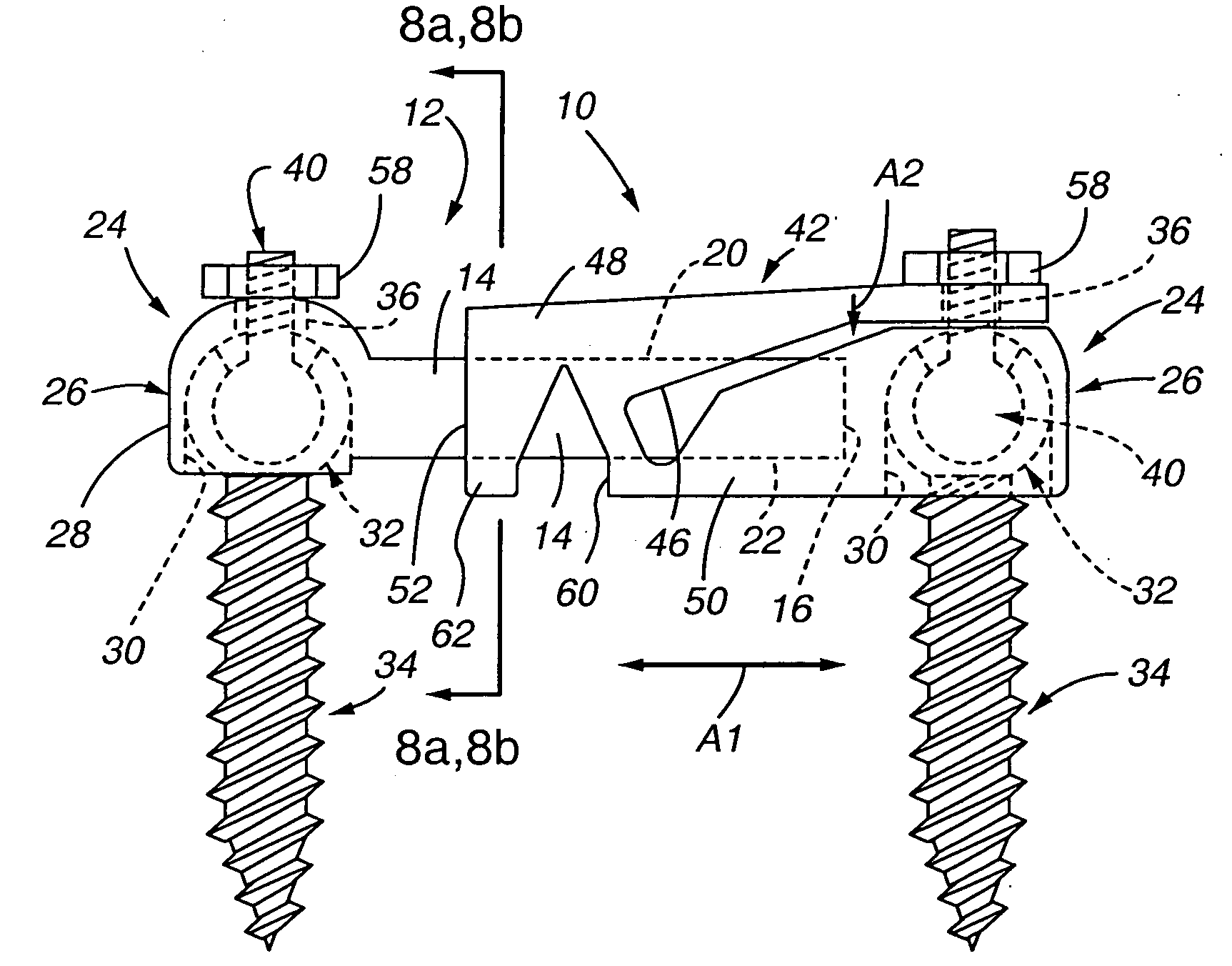

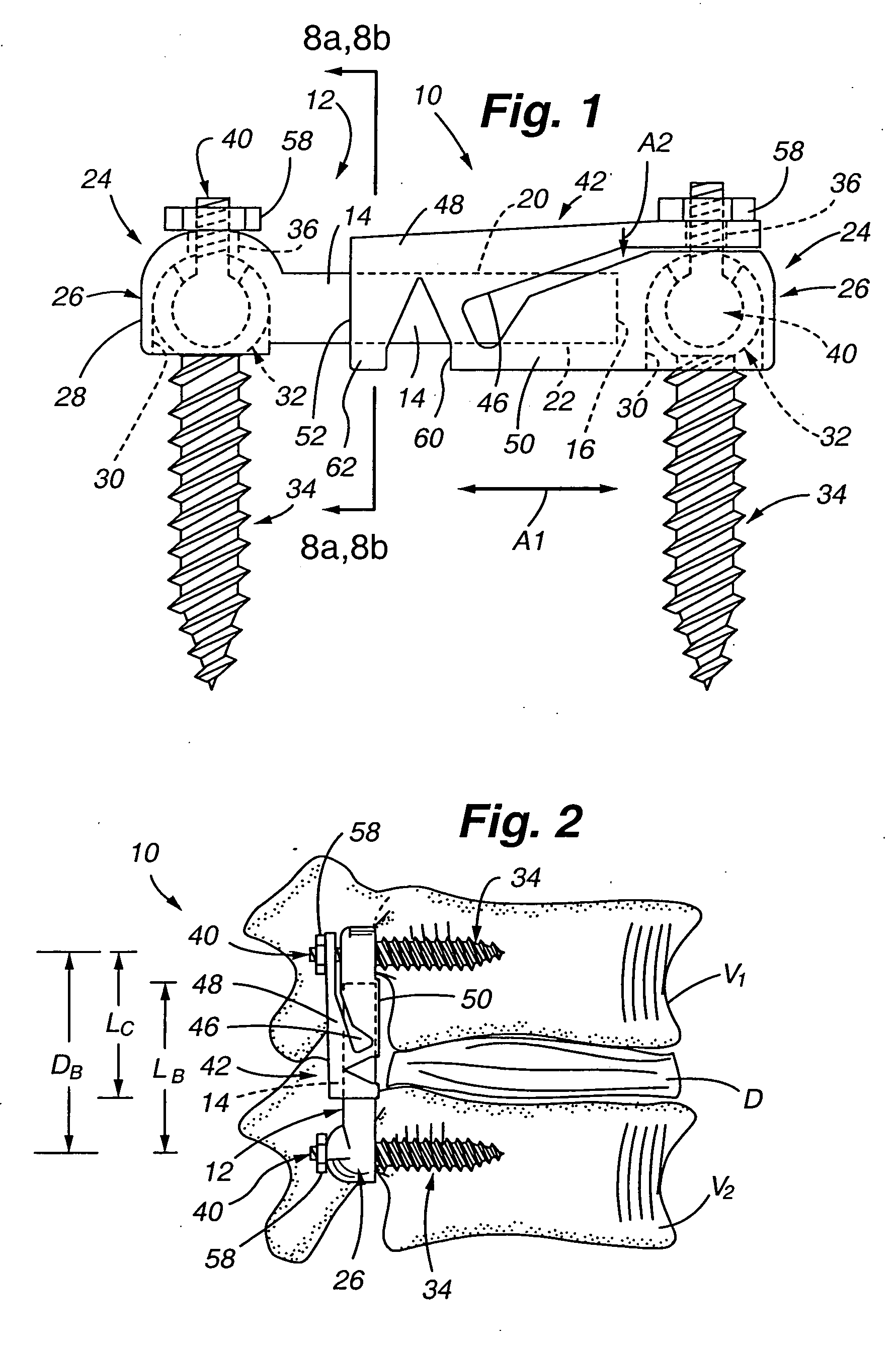

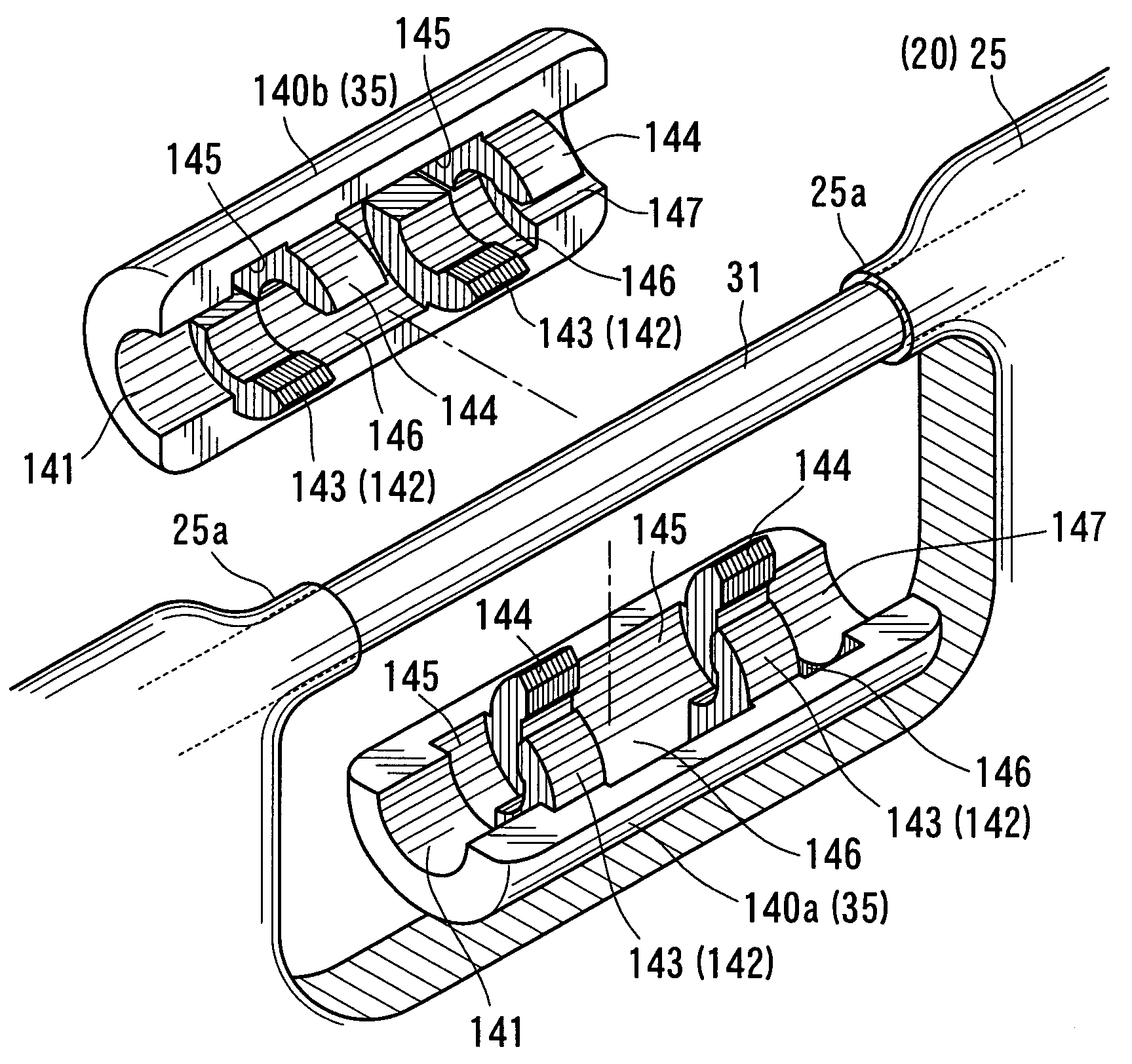

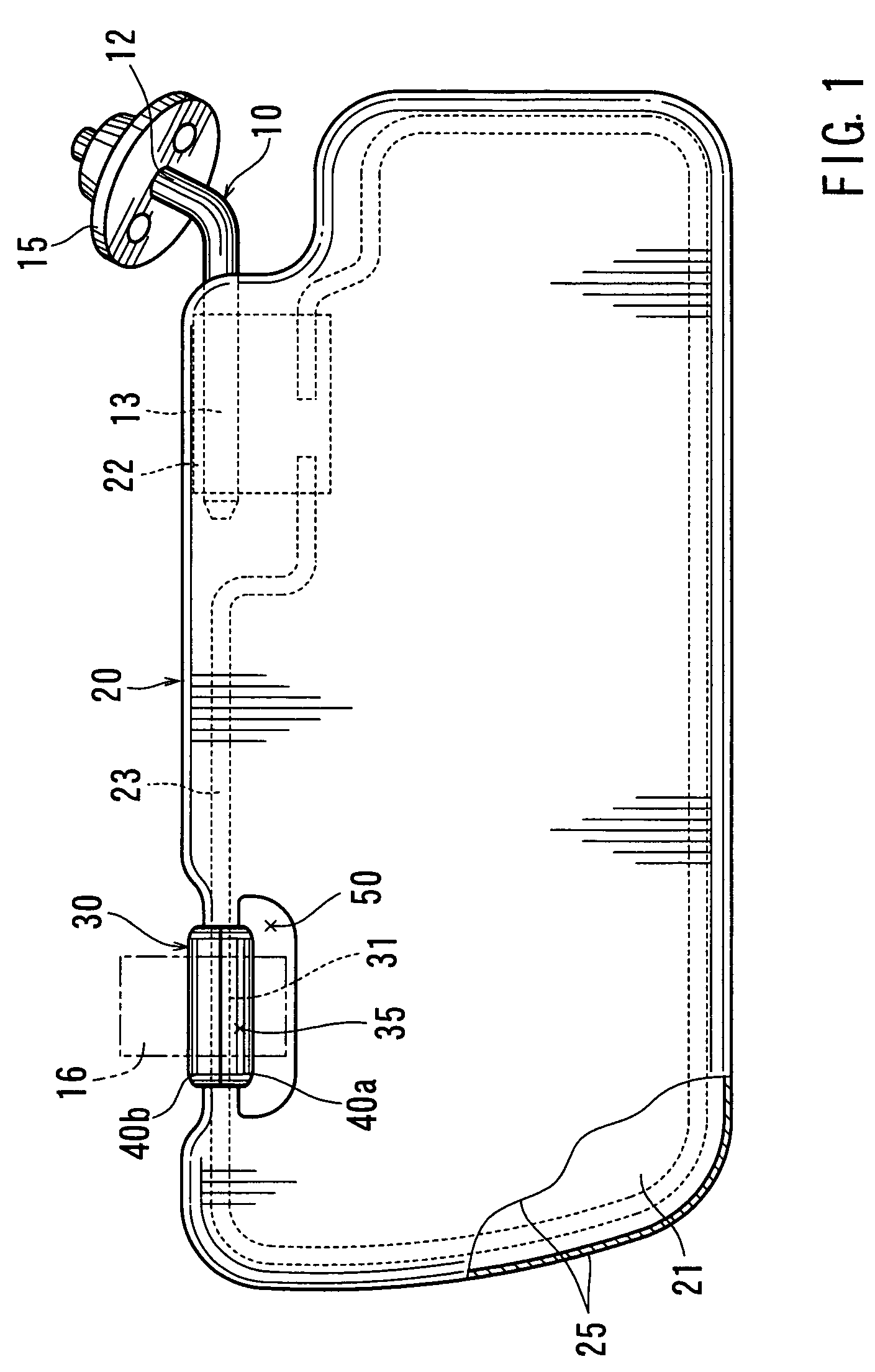

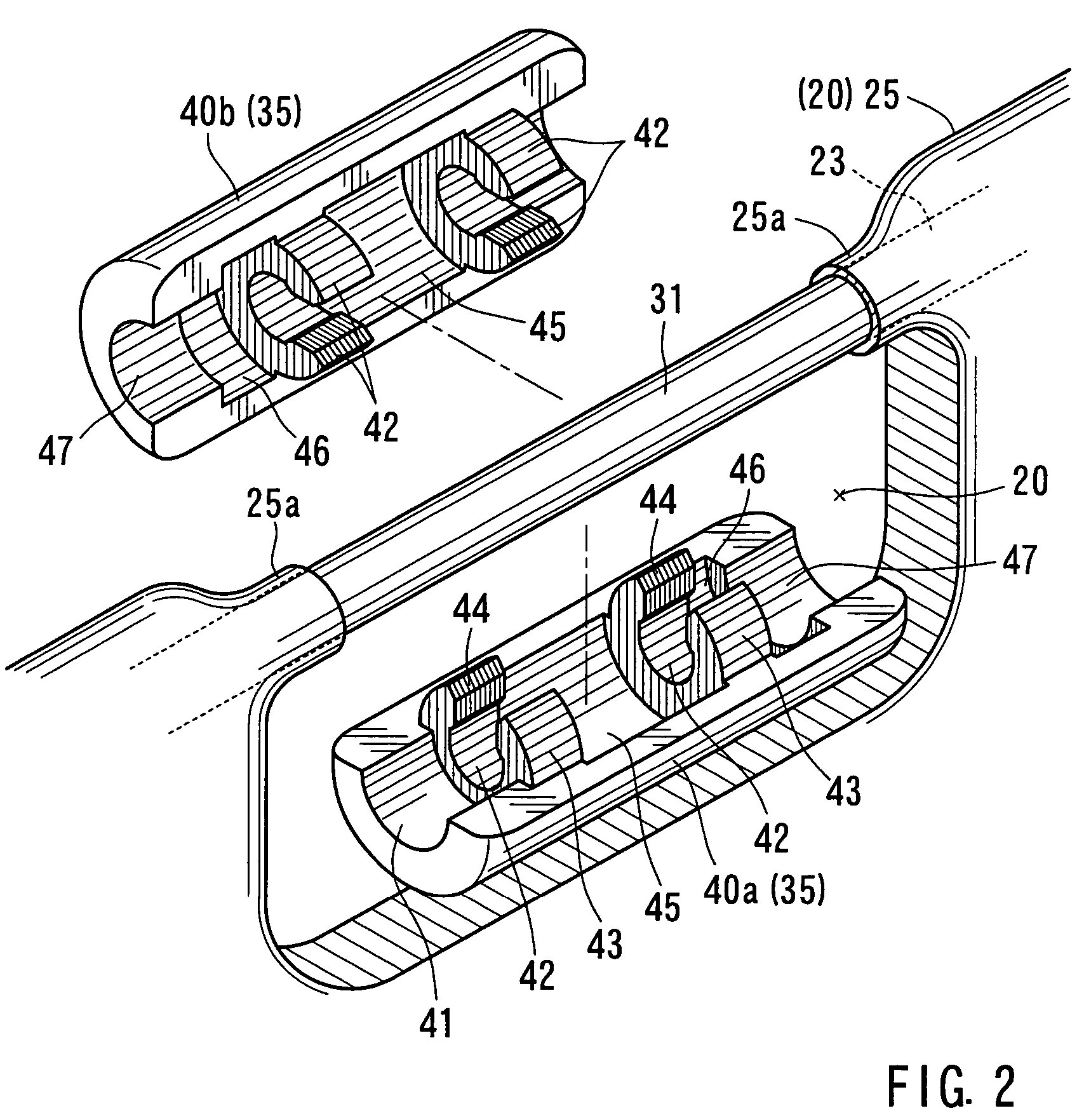

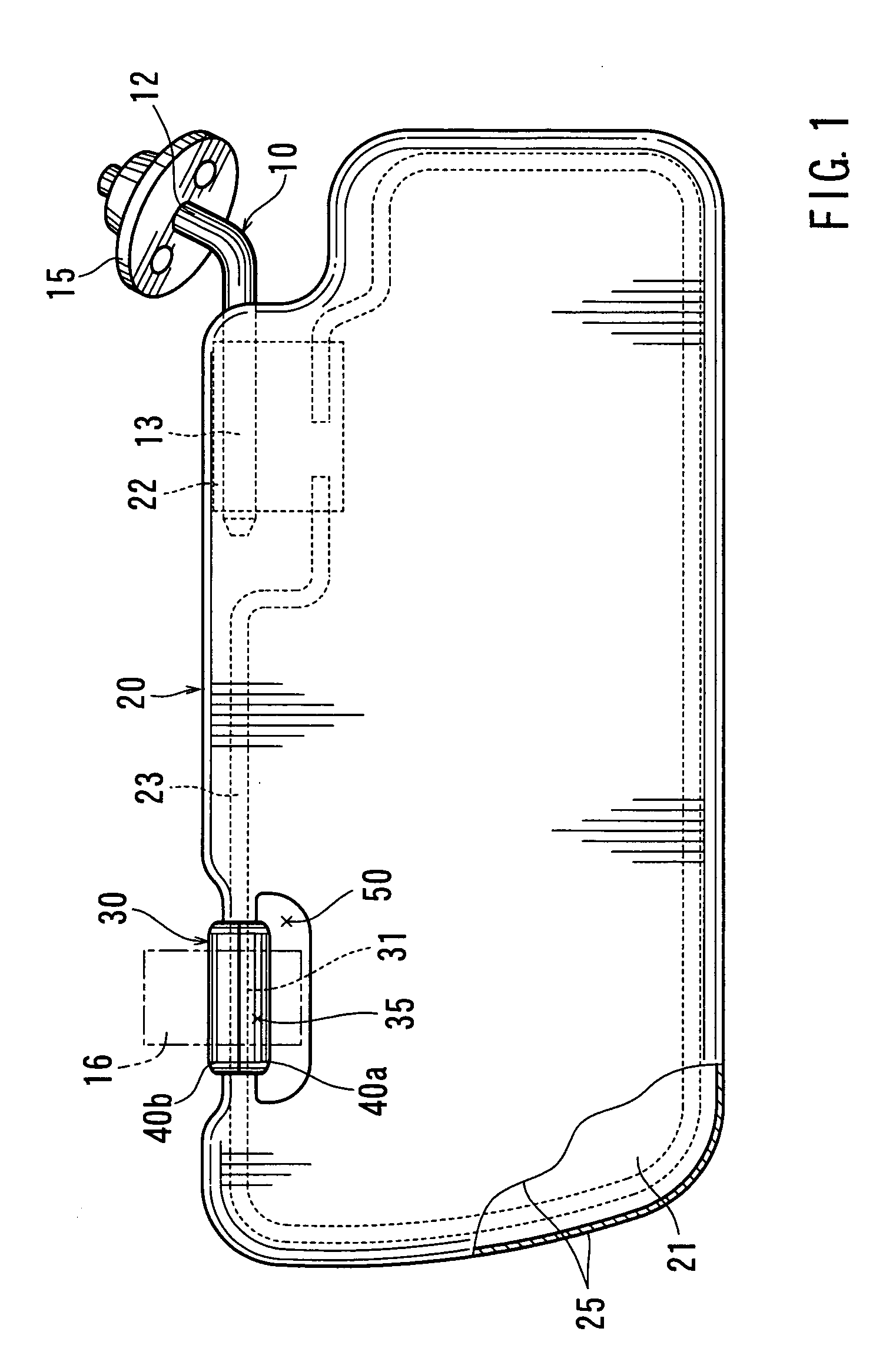

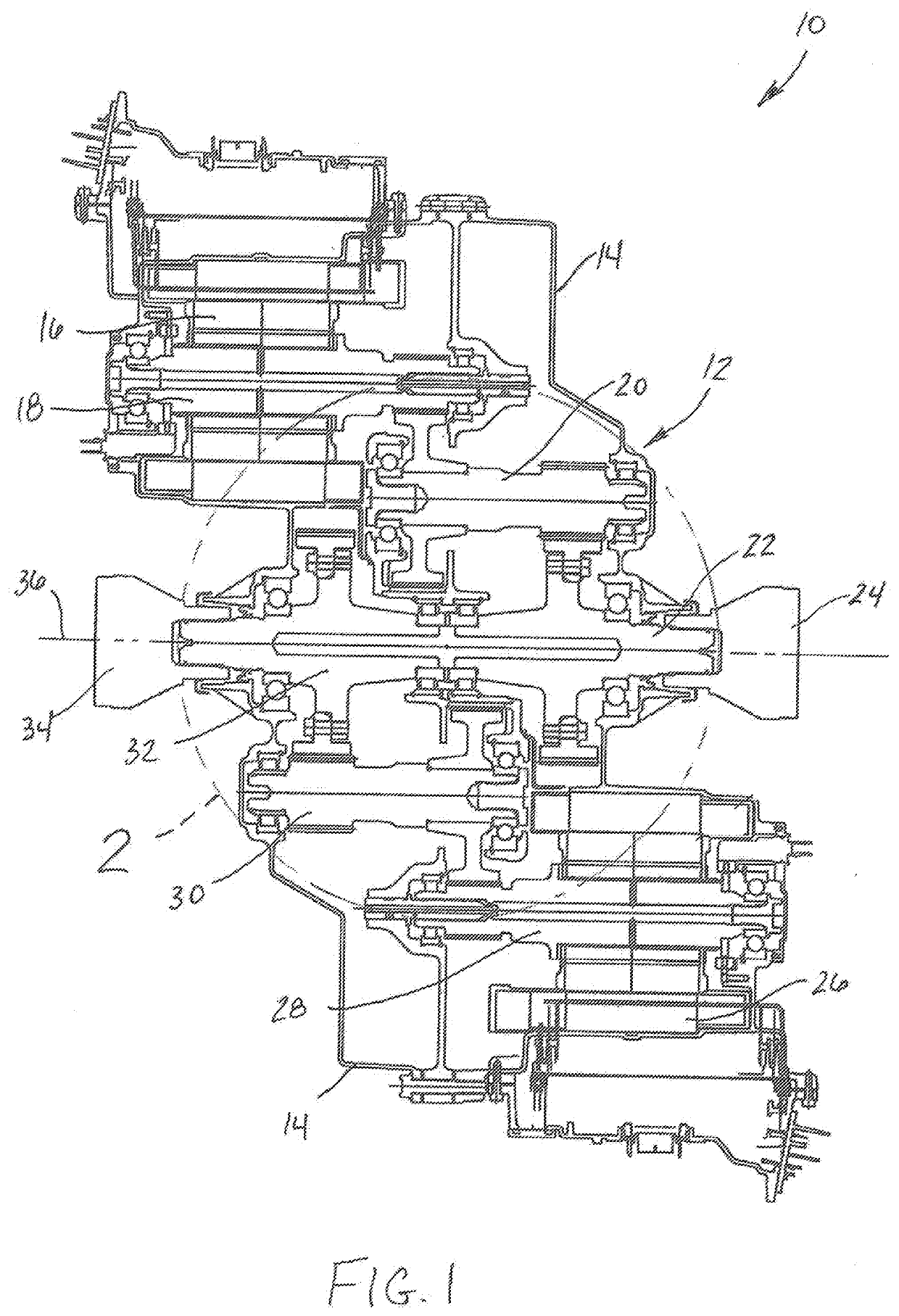

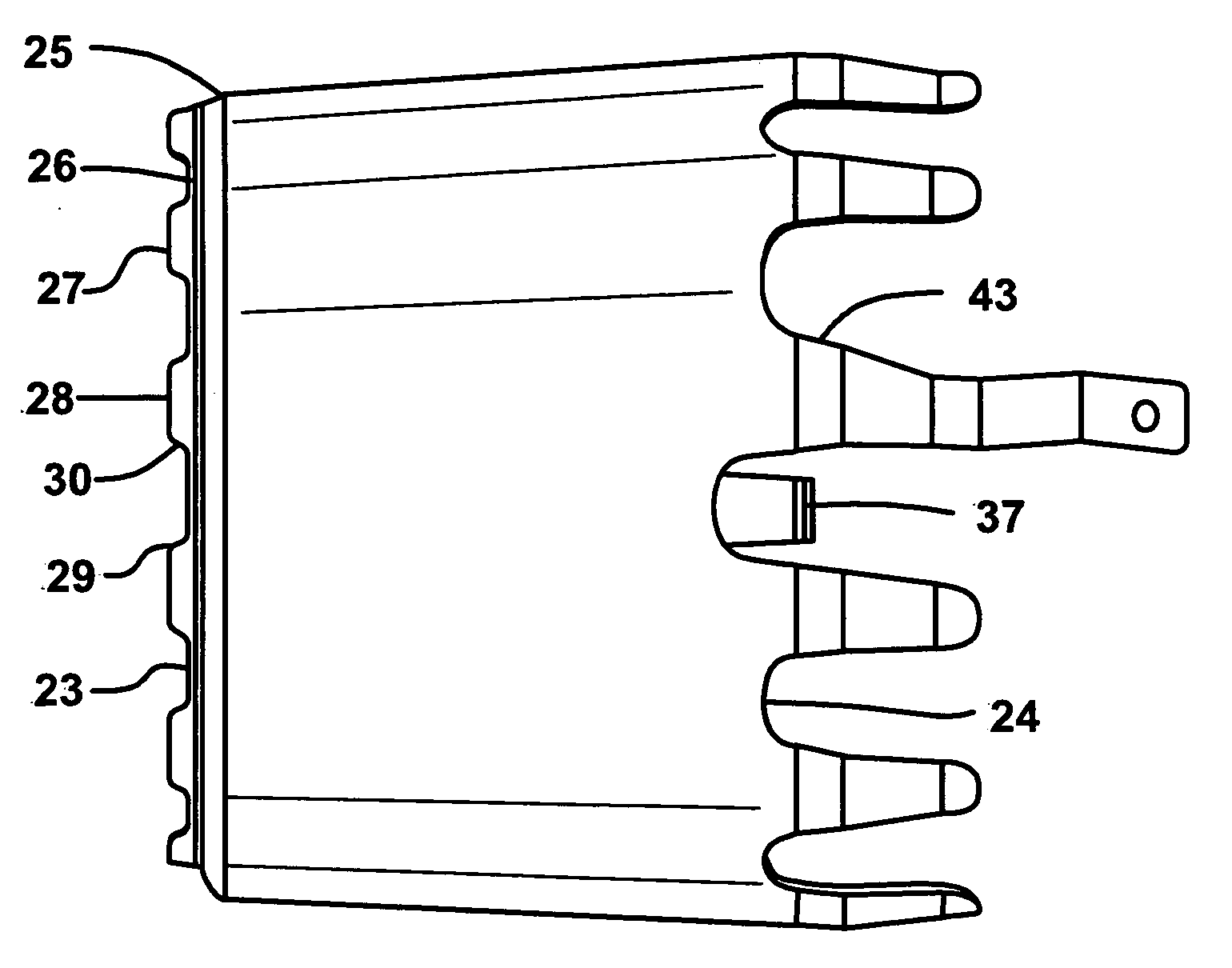

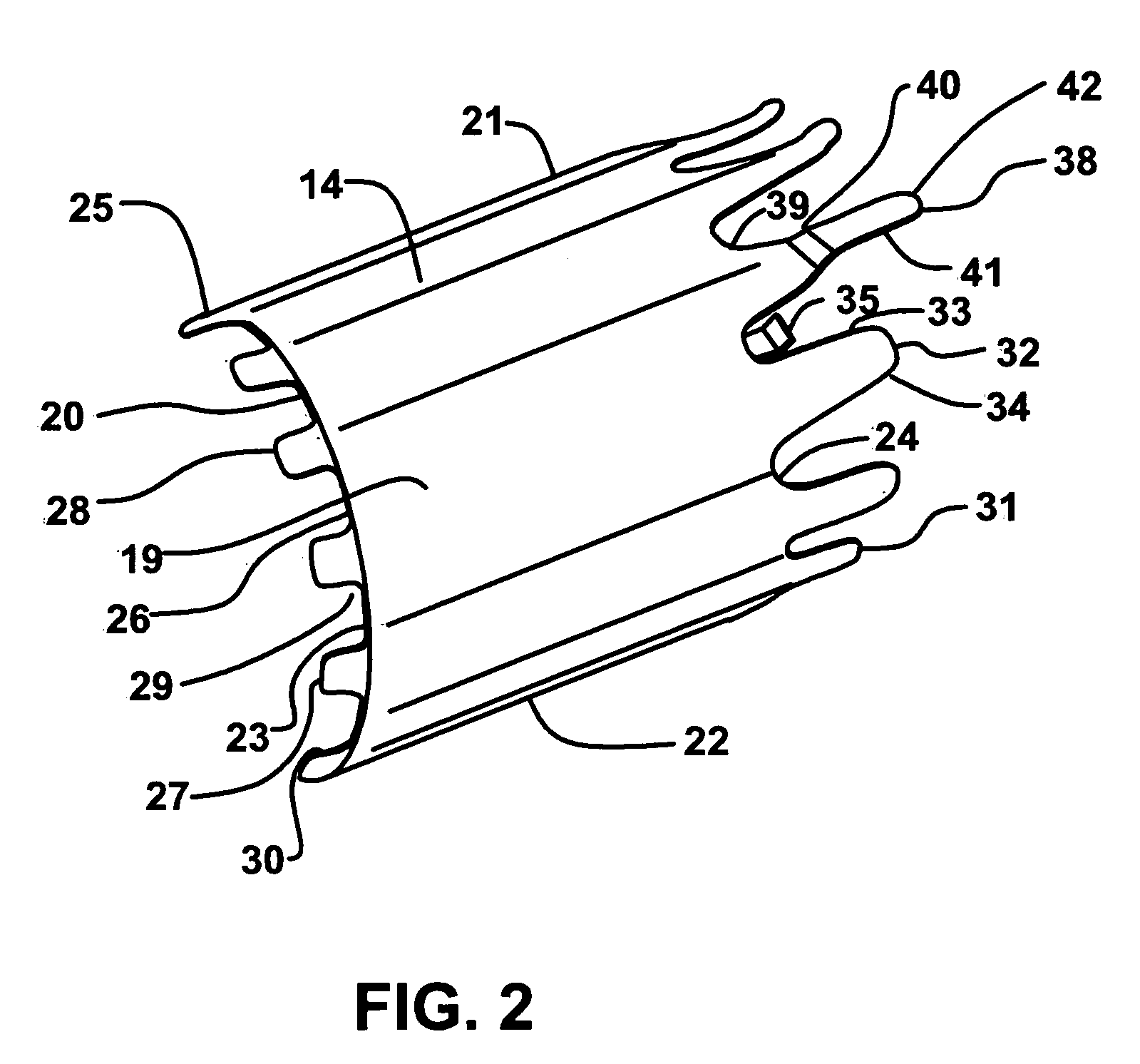

Adjustable rod and connector device and method of use

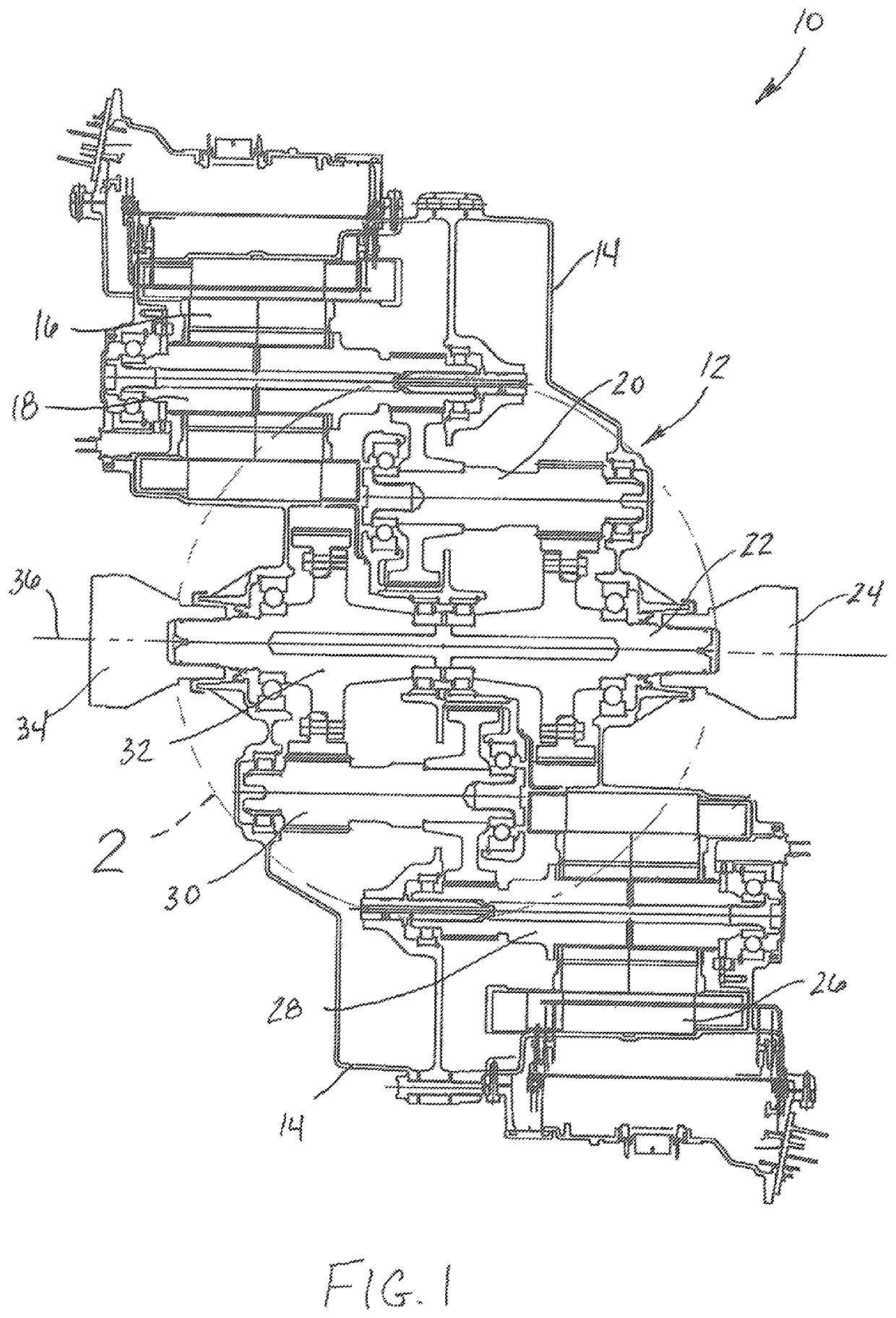

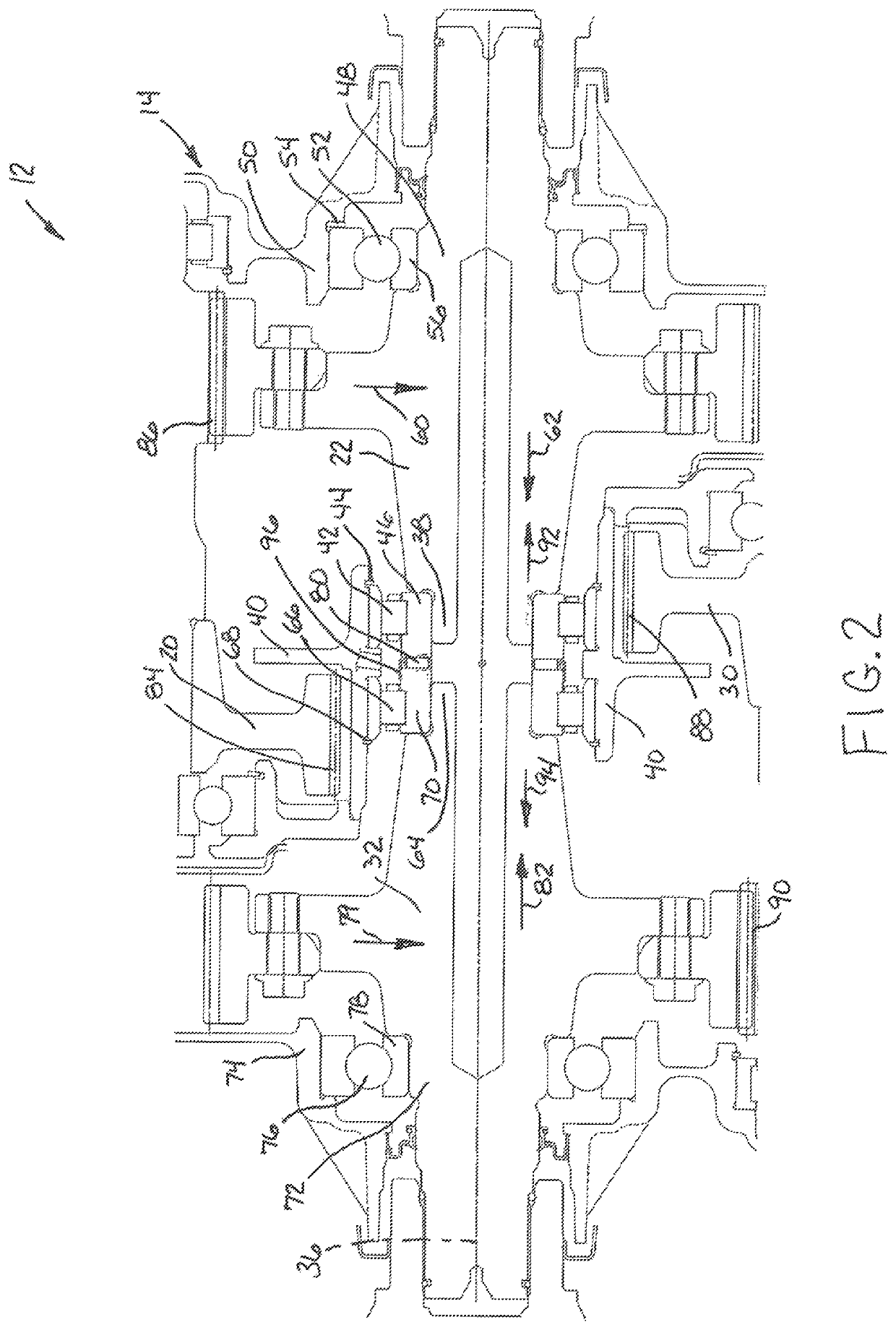

InactiveUS6991632B2Minimal displacementEasy to useInternal osteosythesisJoint implantsImplanted deviceIliac screw

Owner:RITLAND STEPHEN

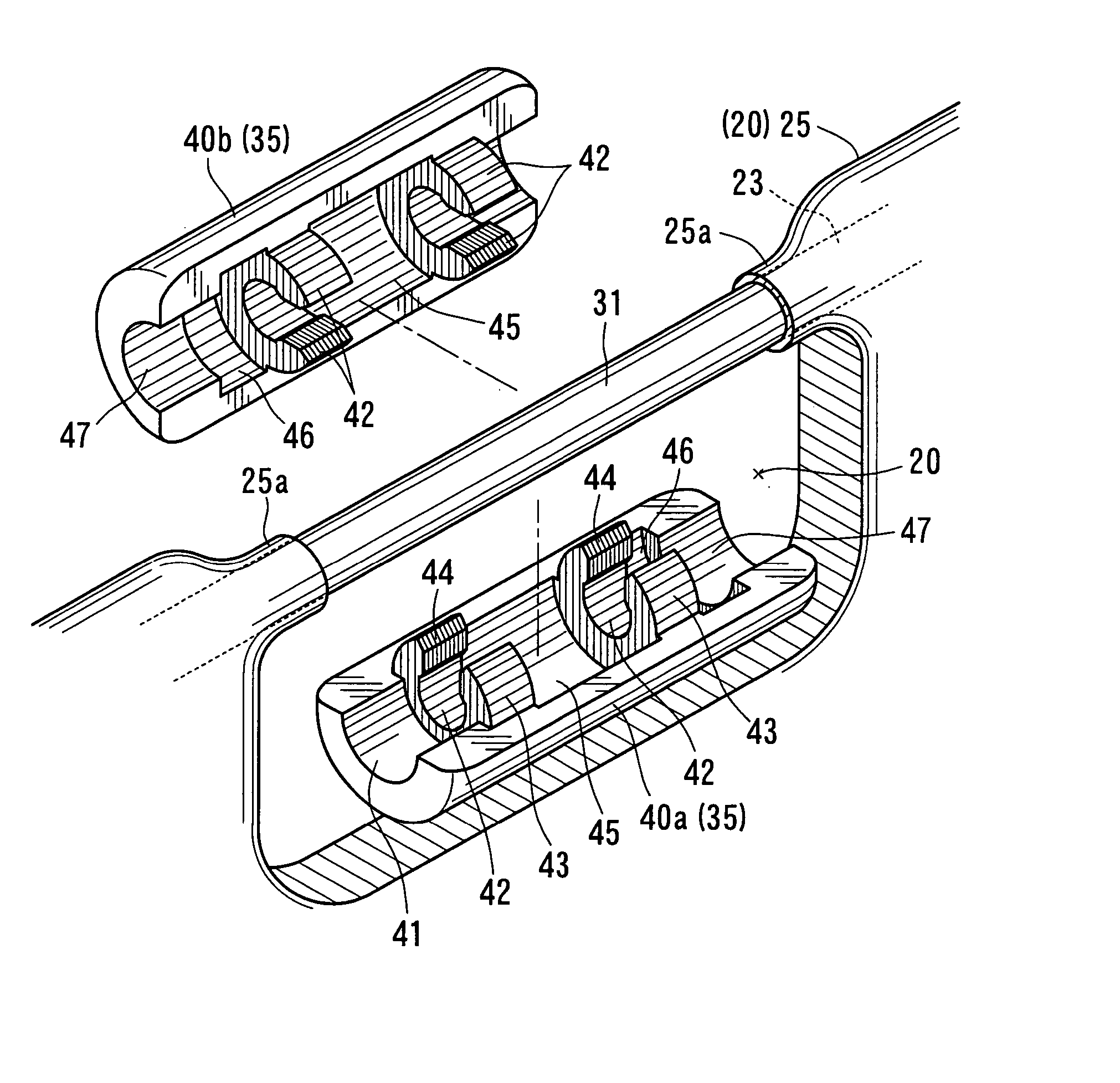

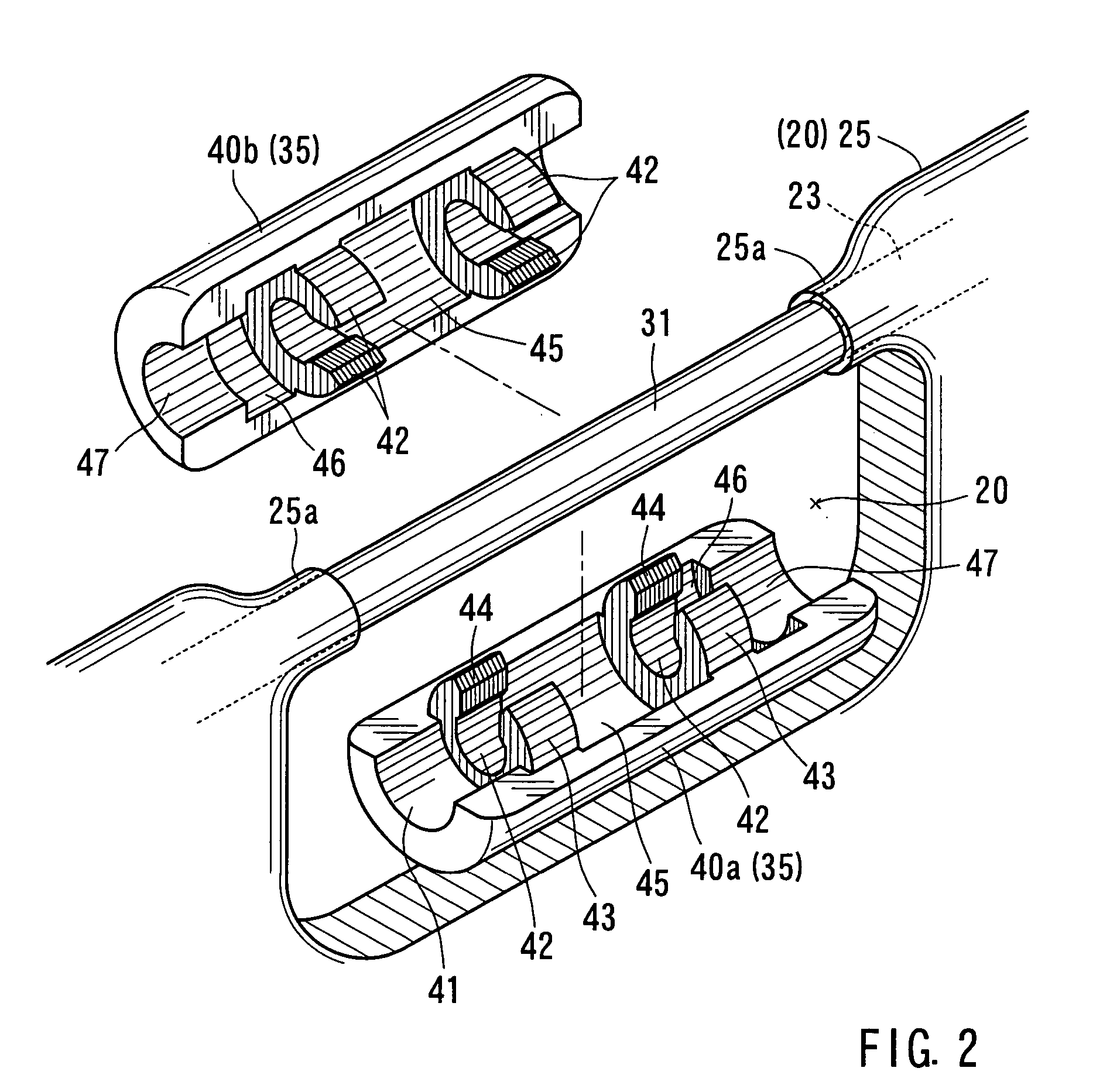

Adjustable rod and connector device and method of use

InactiveUS20050149023A1Minimal displacementLow-profileSuture equipmentsInternal osteosythesisImplanted deviceIliac screw

A low-profile surgical rod implant device is provided that allows the length of a rod spanning two bone screws to be adjusted at the time of implantation. In a separate aspect of the invention, the rod implant device can be secured by tightening and securing an end of the rod implant device at one of the bone screws. Embodiments are provided for use with polyaxial pedicle screws and substantially straight shank pedicle screws in spinal applications. In a separate aspect of the invention, a bone screw connector having an interference type fit is also provided. A method for implanting the device is also provided.

Owner:RITLAND STEPHEN

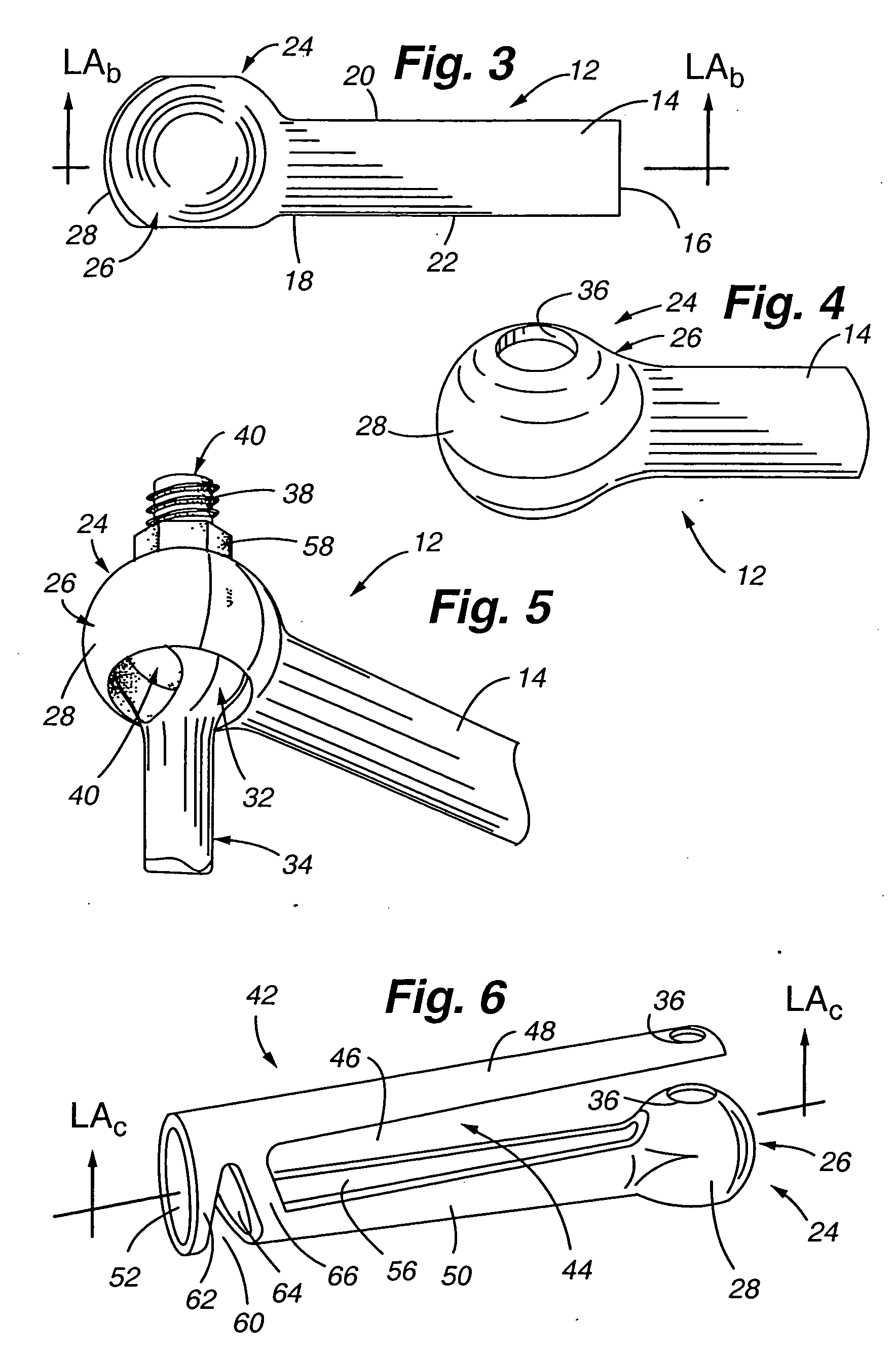

Method of conducting a needle biopsy procedure

InactiveUS7008383B1Reduce harmReduce frictionSurgical needlesVaccination/ovulation diagnosticsBiopsy procedureReciprocating motion

A vibration assisted needle device is disclosed for use in medical procedures such as needle aspiration biopsies. Reciprocation of the needle, such as a biopsy needle, eases the advance of the needle through tissue, penetration of the site of interest and the collection of sample at a site of interest. The device comprises a housing defining a chamber, a needle support external to the chamber for supporting a needle and a mechanism in the chamber for causing reciprocatory motion of the needle support. The needle support is preferably external to the housing. A syringe support may be connected to the housing for supporting a syringe. The reciprocatory mechanism may comprise means for converting rotational motion into reciprocating motion, such as a bearing or a rotor with a circumferential, angled groove on its surface, coupled to the needle support. The bearing or the rotor may be driven by a rotational motor, preferably located outside of the housing, or by a hydraulically driven turbine within the housing. Alternatively, the reciprocatory mechanism means may comprise a stationary solenoid and a movable solenoid for being coupled to the needle. Preferably, a second stationary solenoid is provided and the moving solenoid is between the two stationary solenoids. Energization of the stationary solenoid or solenoids by an alternating current for example, and energization of the movable solenoid by a direct current, or vice versa, attracts and repulses the movable solenoid, causing reciprocation of the needle. Methods and systems using the vibration assisted needle device are also disclosed.

Owner:FONAR

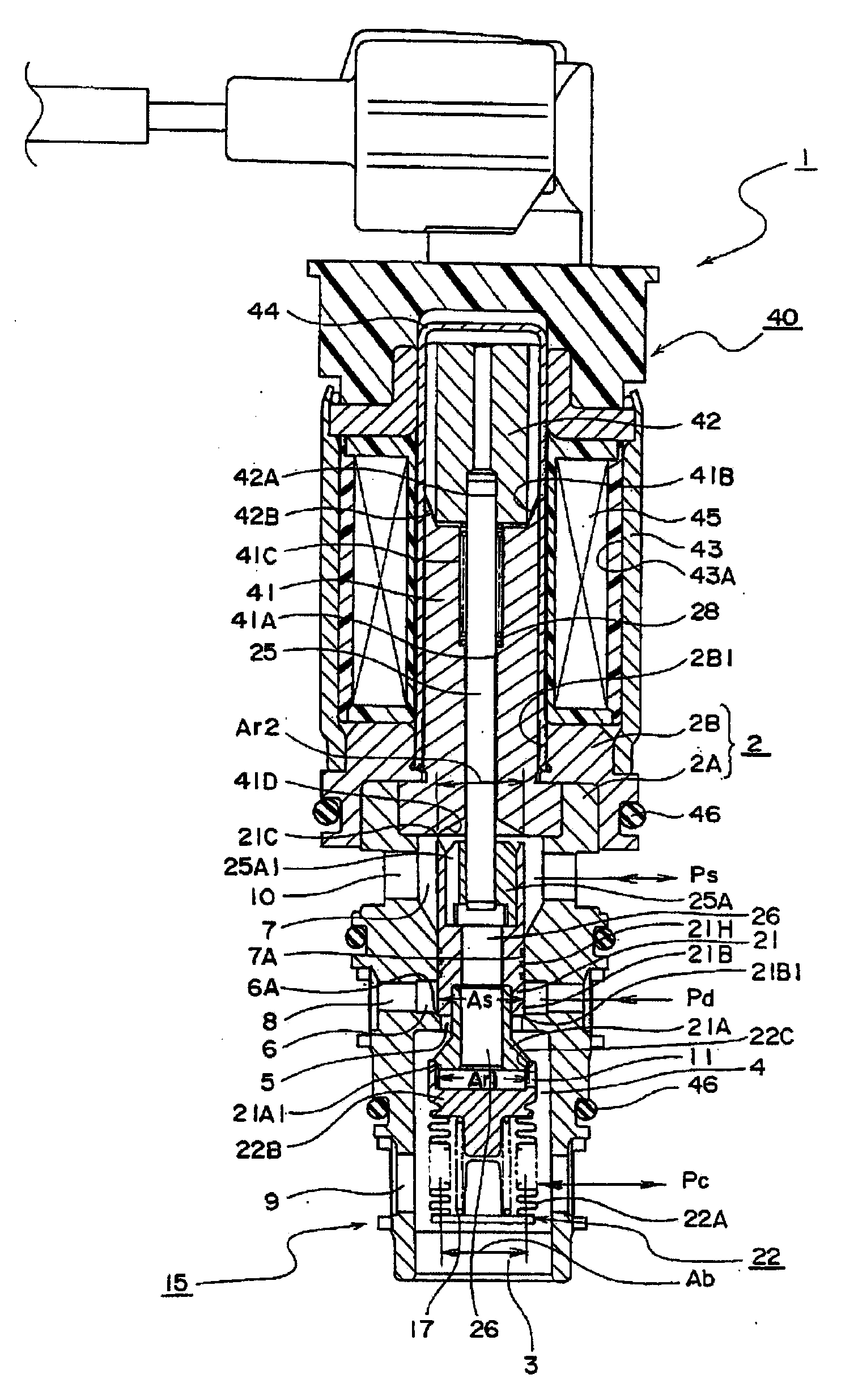

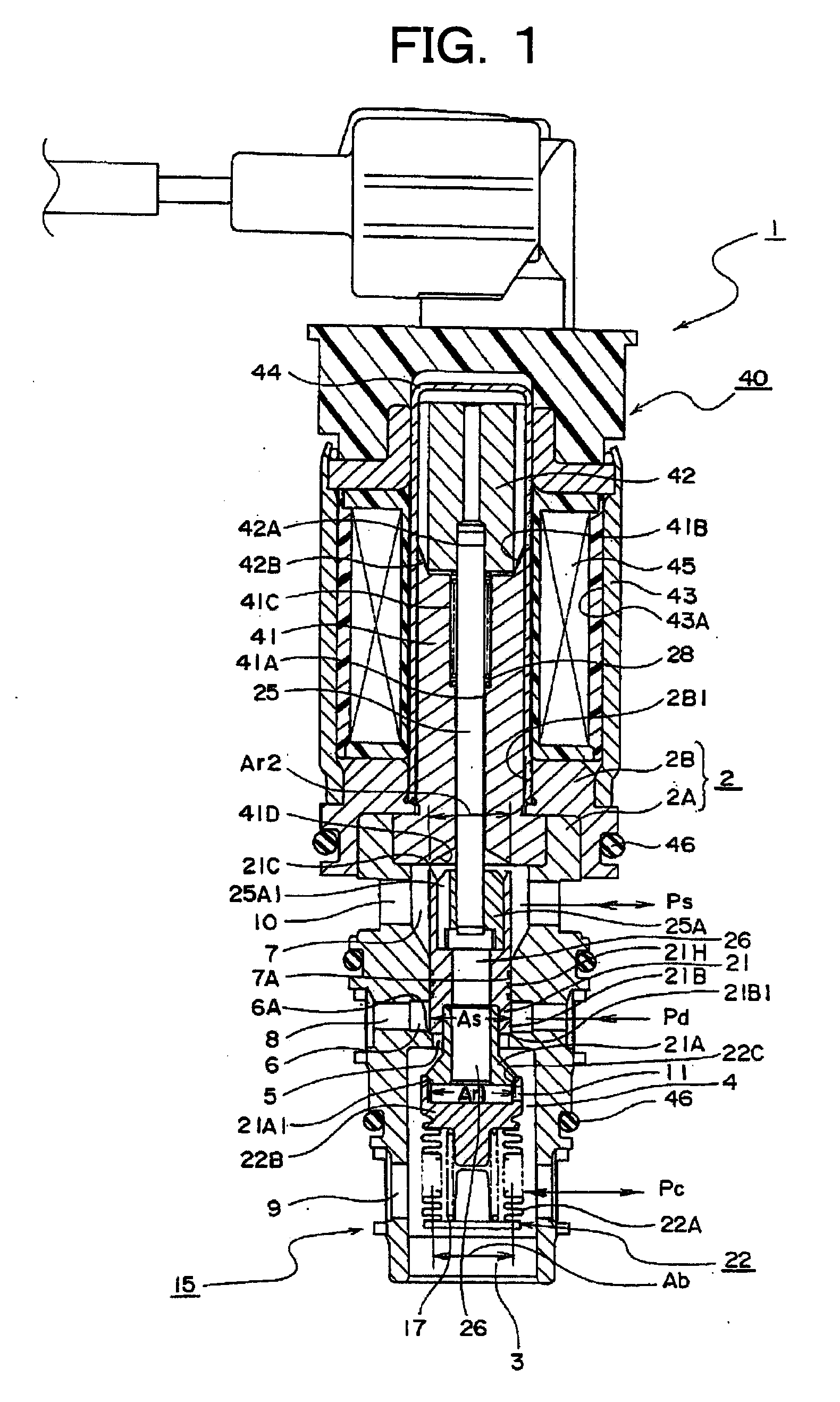

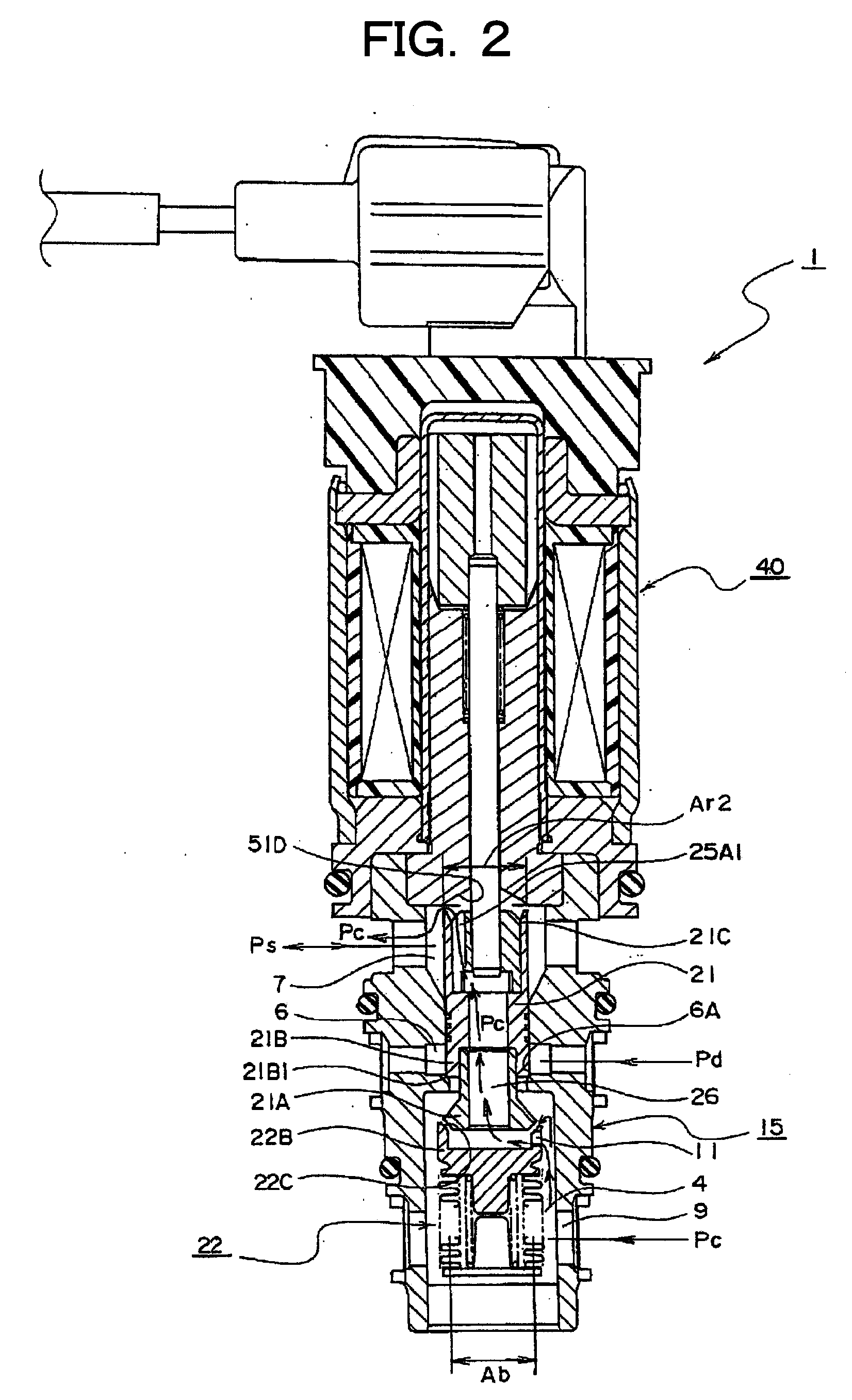

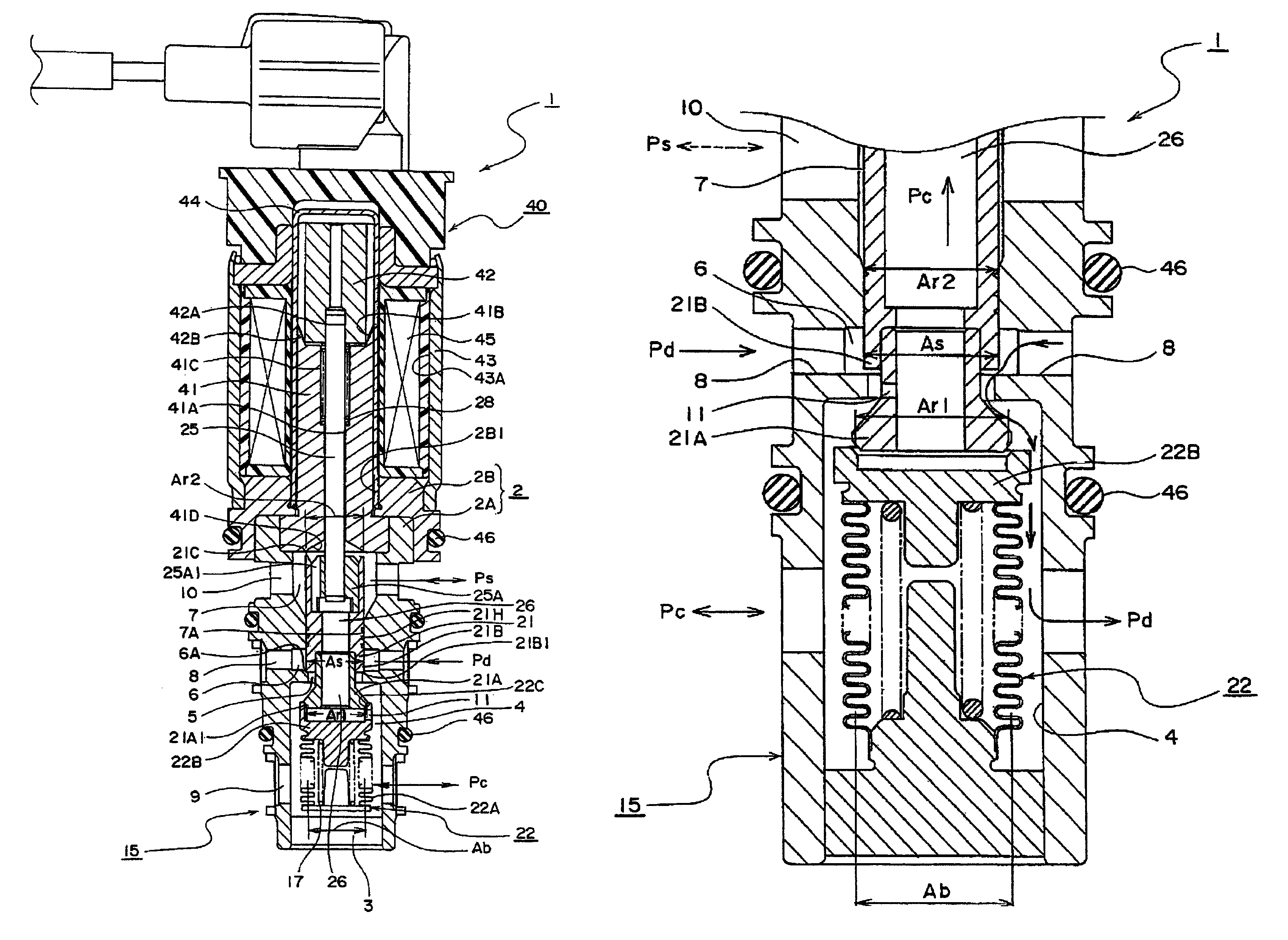

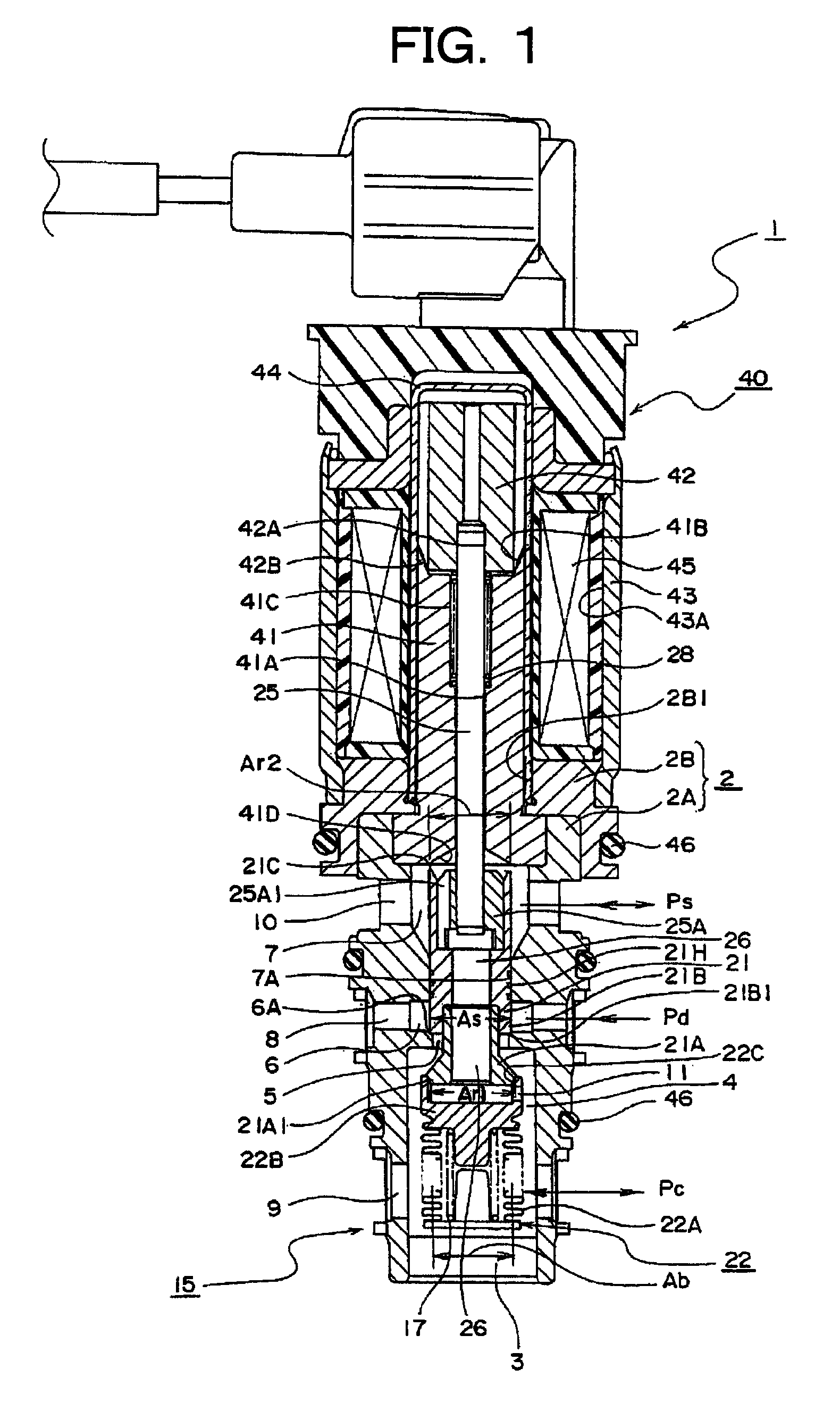

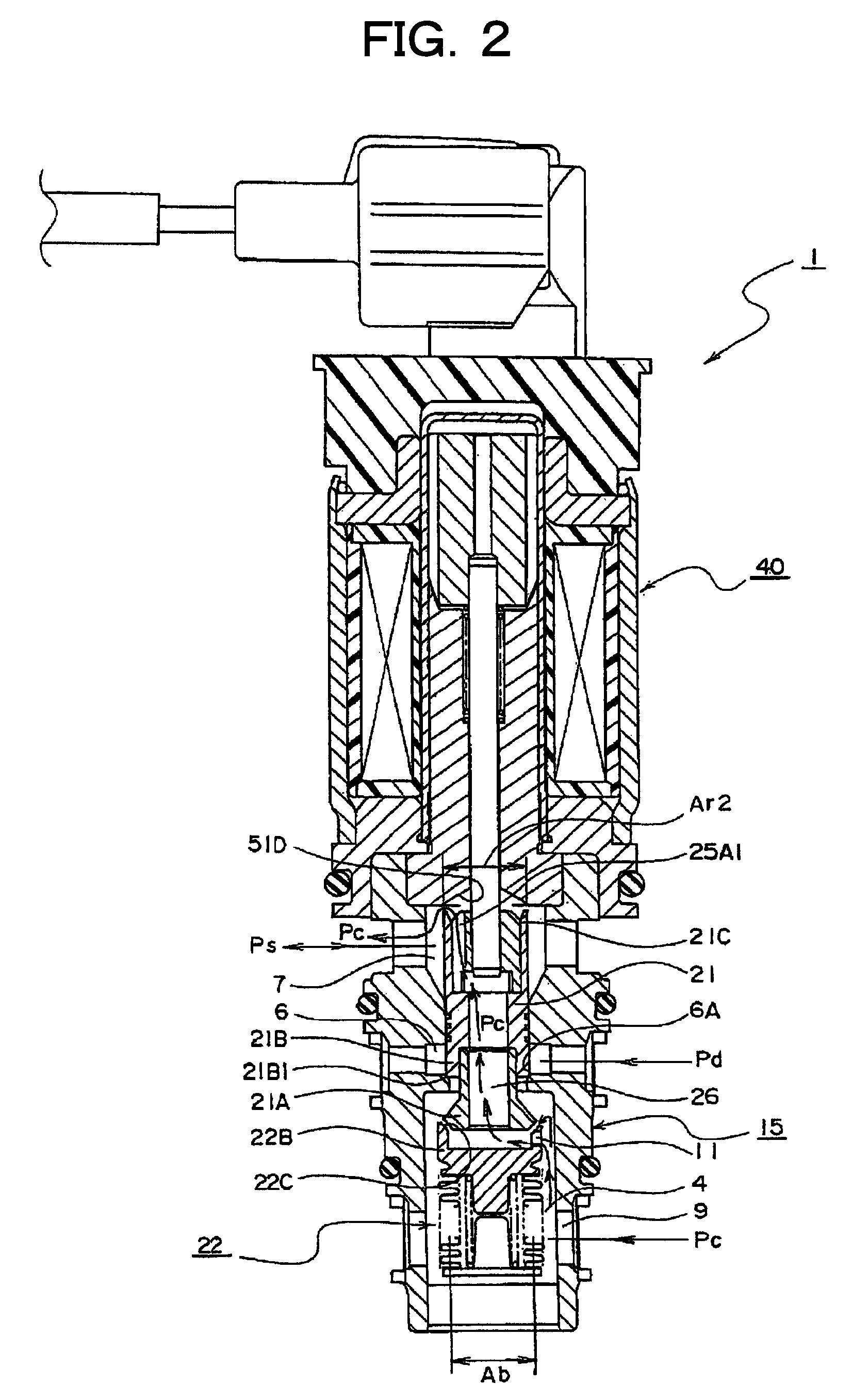

Displacement Control Valve

ActiveUS20090183786A1Reduce manufacturing costStart fastOperating means/releasing devices for valvesPipeline systemsPressure senseDisplacement control

The present invention comprising a valve main body having a first valve chamber, a second valve chamber and a third valve chamber, said first valve chamber communicating with a first communication passage, said second valve chamber having a second valve seat face for a valve hole and communicating with a second communication passage, said third valve chamber having a third valve seat face and communicating with a third communication passage; a valve body having a first valve member, a second valve member and a third valve member, said second valve member having a intermediate communication passage therein communicating with said first valve chamber and said third communication passage, said second valve member opening and closing a valve hole with respect to second valve seat face, thereby communicating with said first valve chamber and said second valve chamber, said third valve member performing a valve opening / closing action with respect to said third valve seat face in an reverse manner against said second valve member, thereby opening or closing the communication with said intermediate communication passage and said third communication passage, said first valve member performing a valve opening / closing action in the same direction to said second valve member; a pressure sensing member having a valve seat portion, said valve seat portion being disposed at a free end of said pressure sensing member, said valve seat portion performing a valve opening / closing action with respect to said first valve member, thereby opening or closing the communication with said first valve chamber and said intermediate communication passage; and a solenoid member driving said valve body in accordance with an electric current supplied thereto; and an auxiliary communication passage providing a communication between said first valve chamber and said intermediate communication passage.

Owner:MAHLE INT GMBH +1

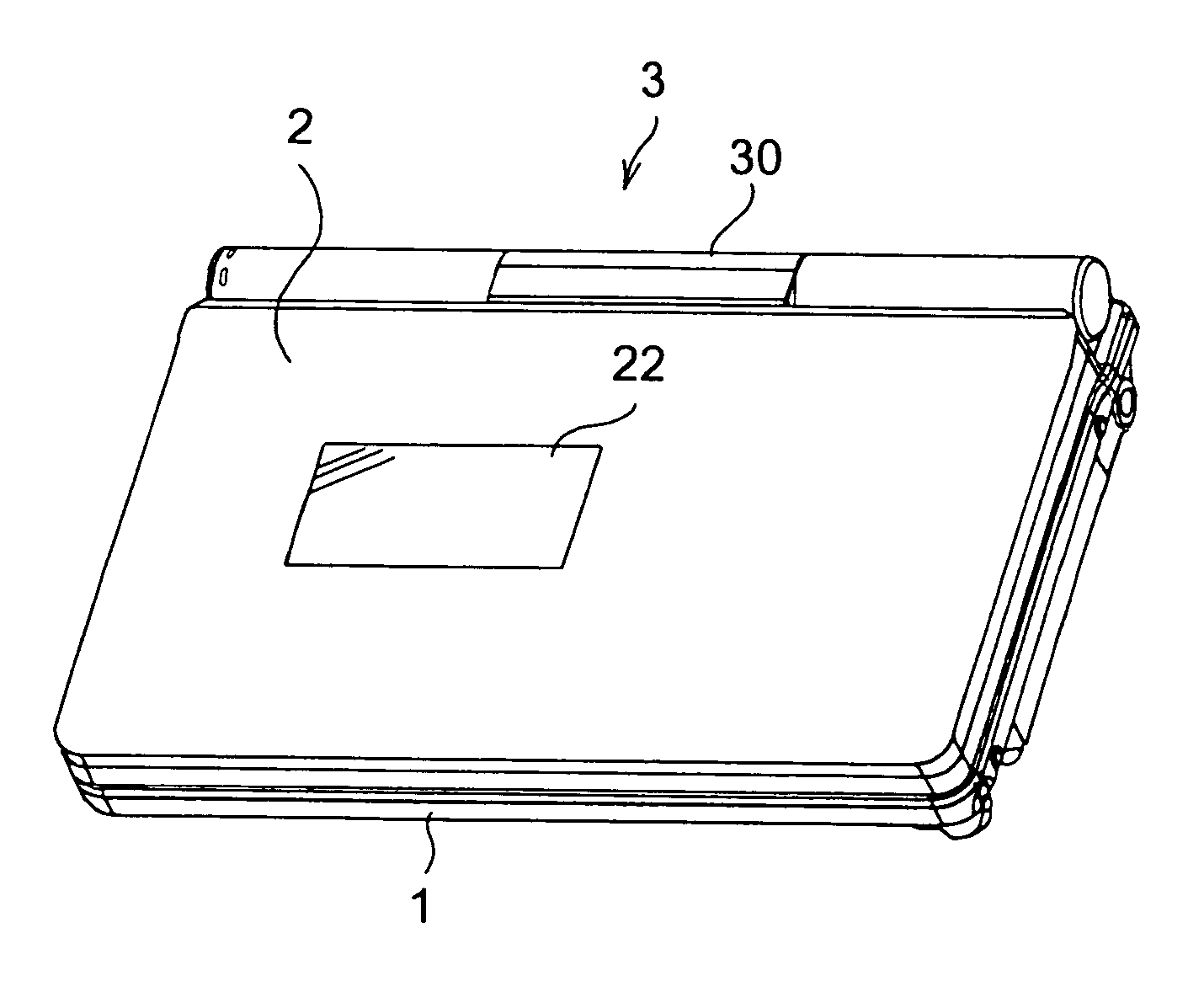

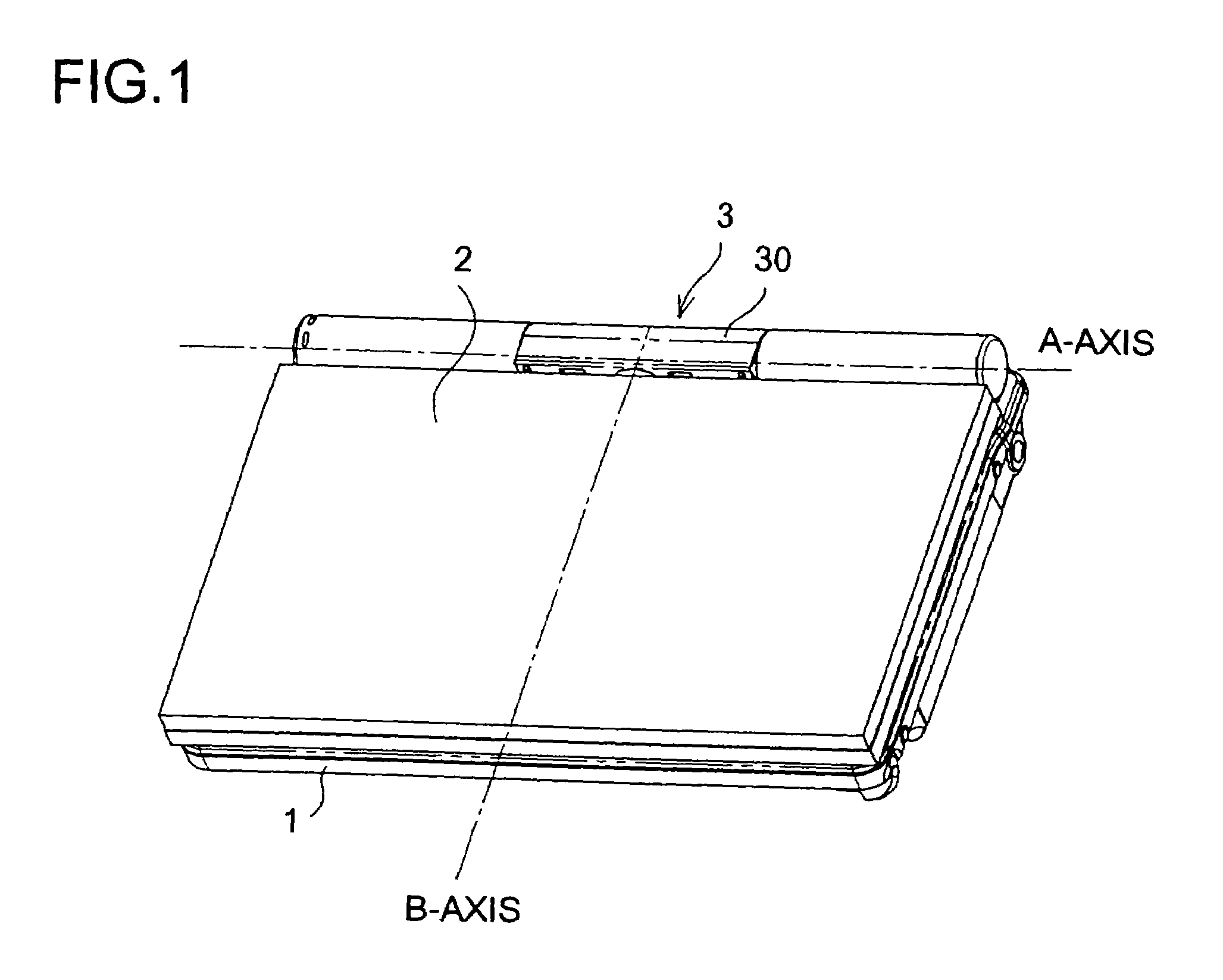

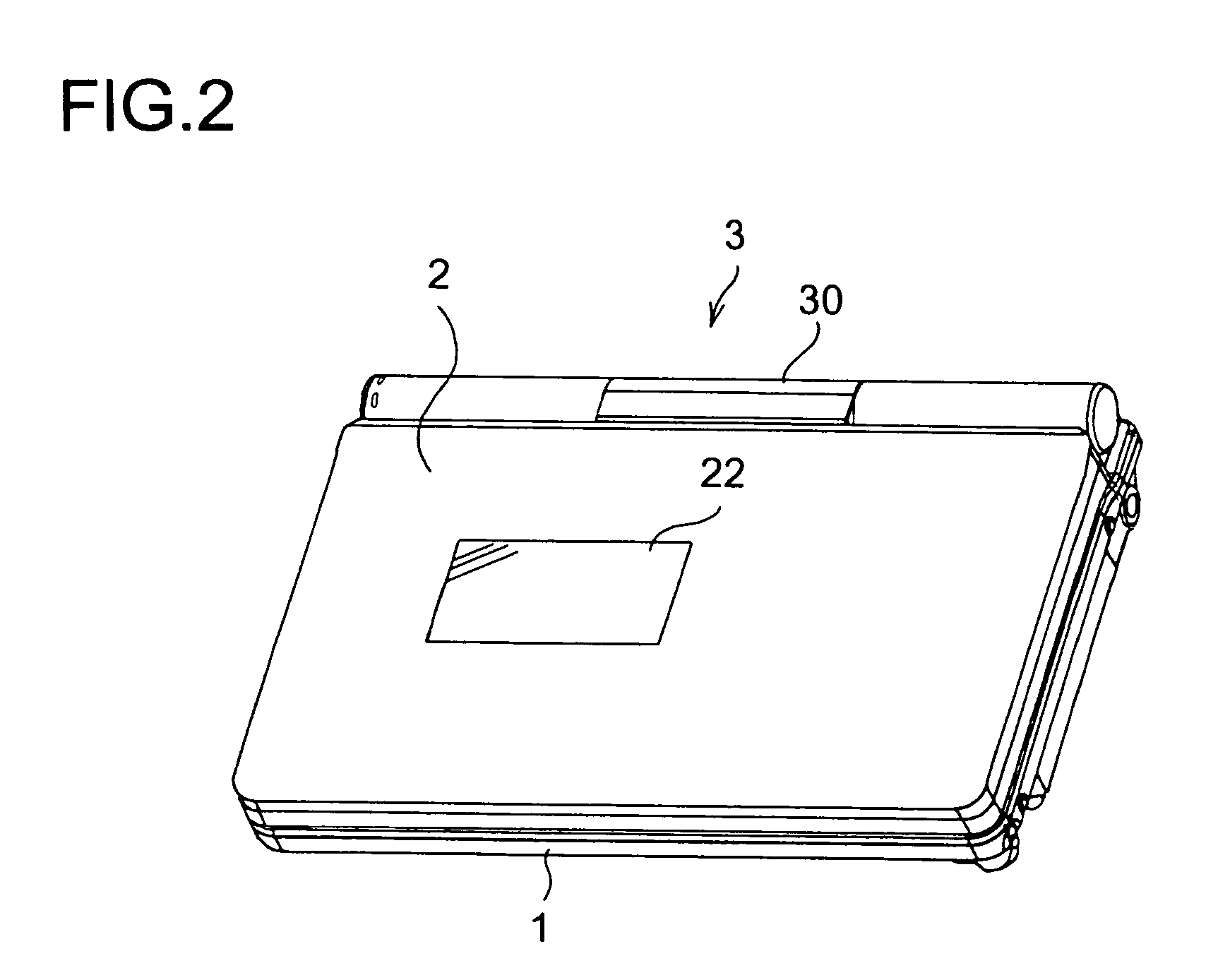

Electronic appliance

InactiveUS7016183B2Minimal displacementCompact mechanismElectronic switchingTypewritersCouplingEngineering

An electronic appliance includes a first casing having an input portion, a second casing having a screen display portion on one face thereof, a coupling, and a controller portion for controlling screen display on the screen display portion. The first and second casings are coupled together such that the electronic appliance can be moved between a first state, in which the second casing is unfolded relative to the first casing with the screen display portion pointing in the direction of the input portion, and a second state, in which the second casing is folded over the first casing with the face of the second casing opposite to the screen display portion facing the face of the first casing on which the input portion is provided. When the appliance changes between the first and second states, the controller portion rotates the screen display by 90° between the first and second states.

Owner:SHARP KK

Displacement control valve

ActiveUS8079827B2Reduce manufacturing costStart fastOperating means/releasing devices for valvesPipeline systemsDisplacement controlControl valves

Owner:MAHLE INT GMBH +1

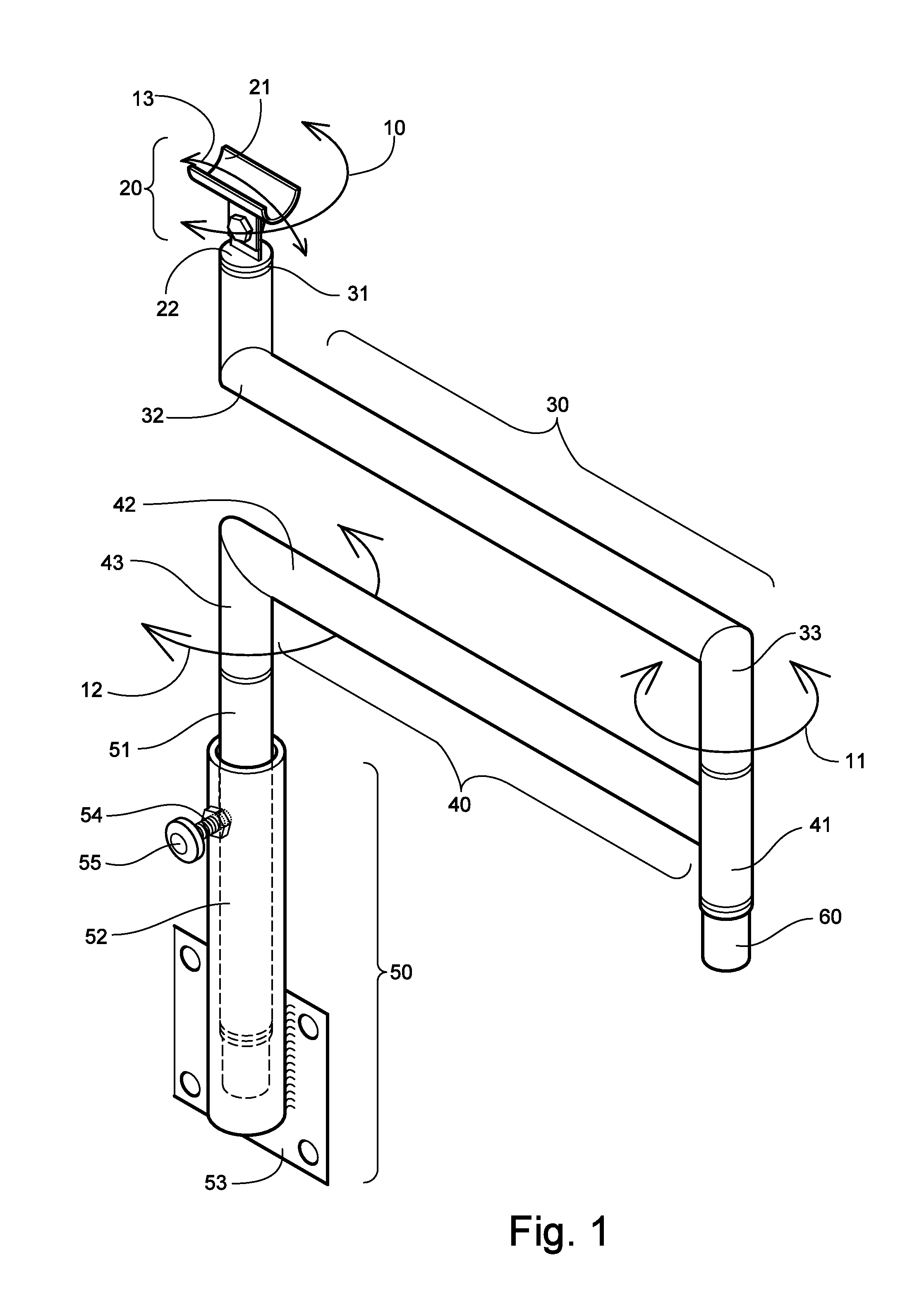

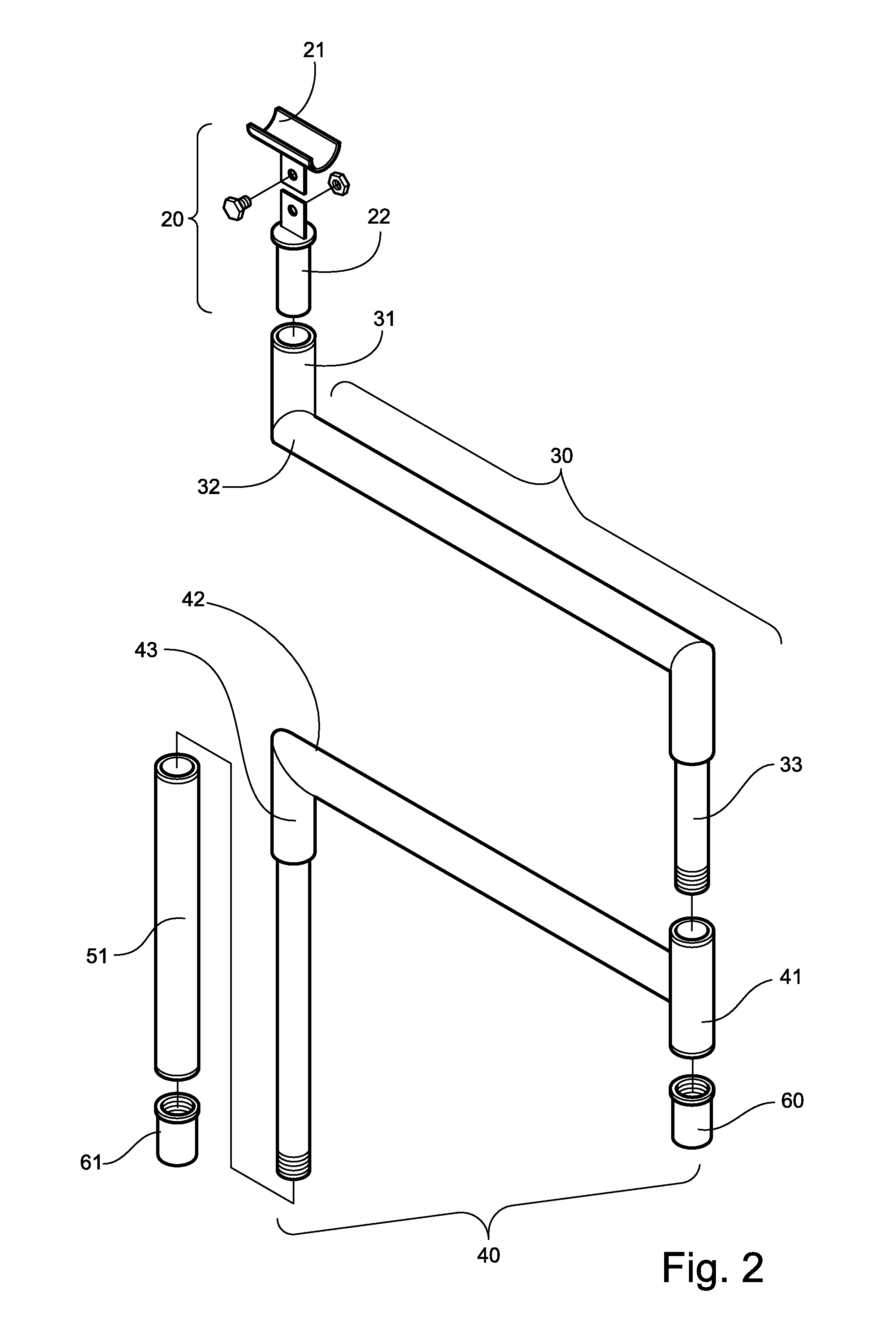

Rotatable gun rest

The invention is a device that allows a marksman to easily rotate and position a gun from the elevated position of a deerstand. The invention utilizes displaced parallel axes of rotation so that the marksman can maximize the mobility of the gun during shot selection while at the same time minimizing both noise and personal bodily displacement.

Owner:MCDONALD DANIEL E

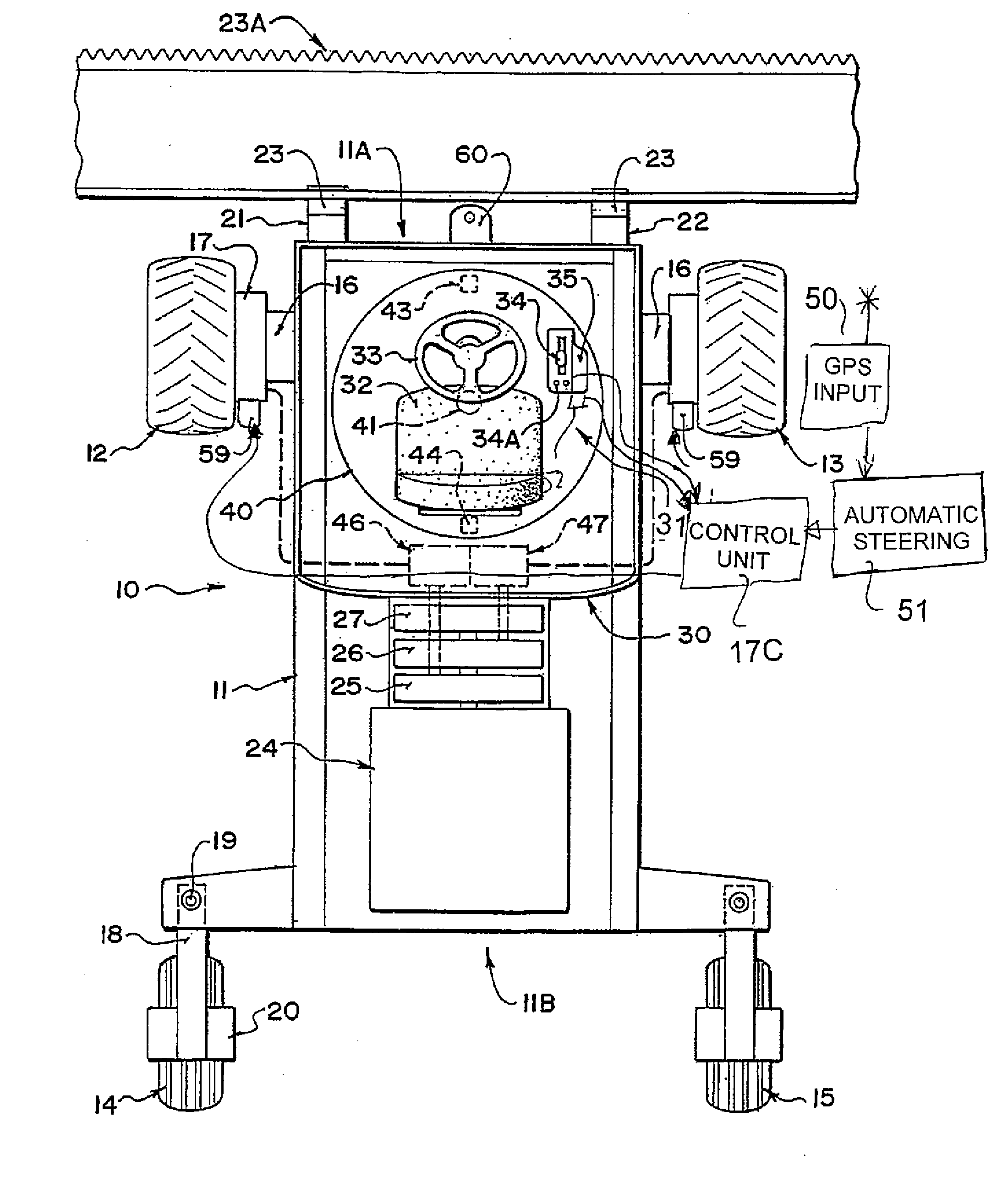

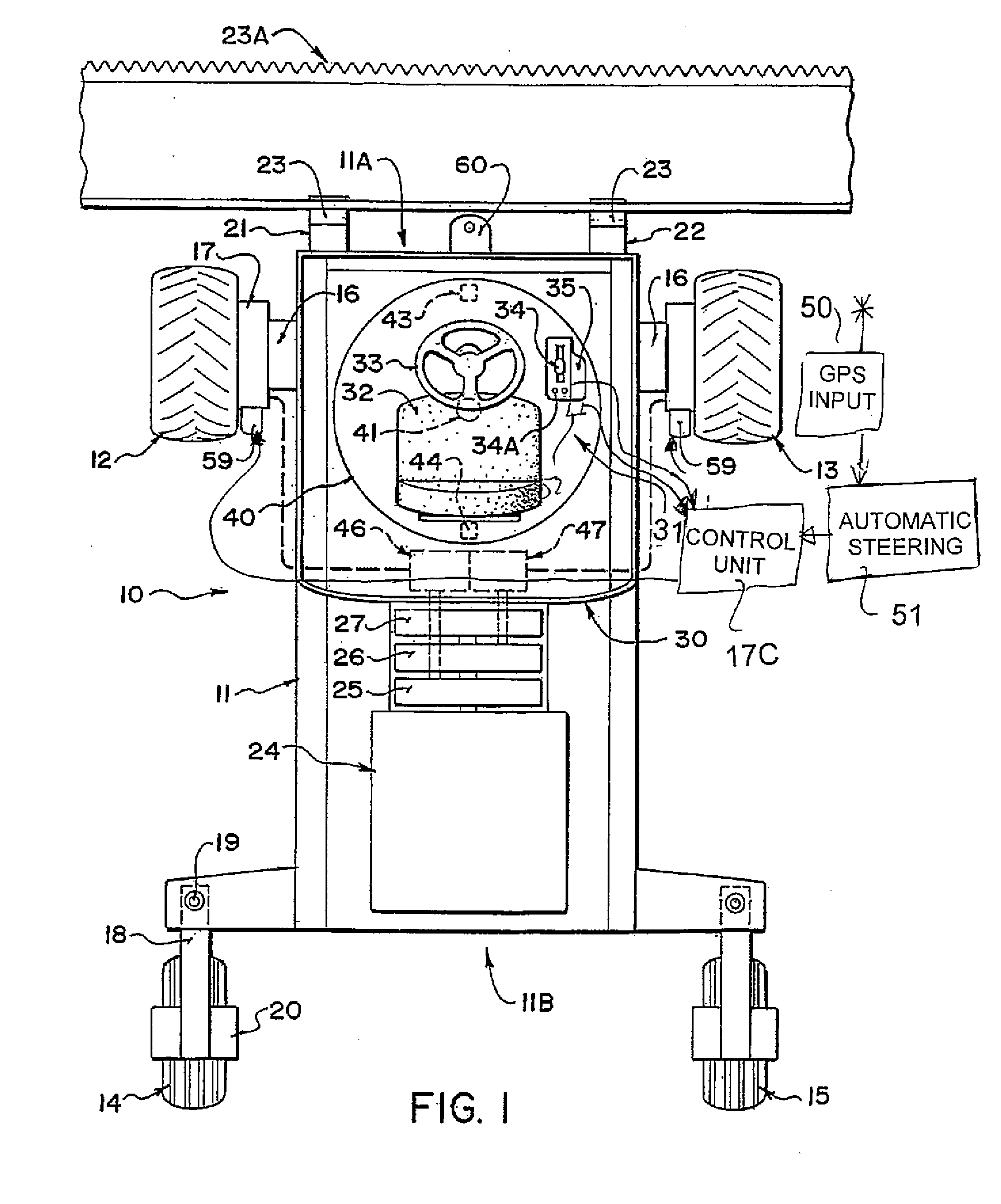

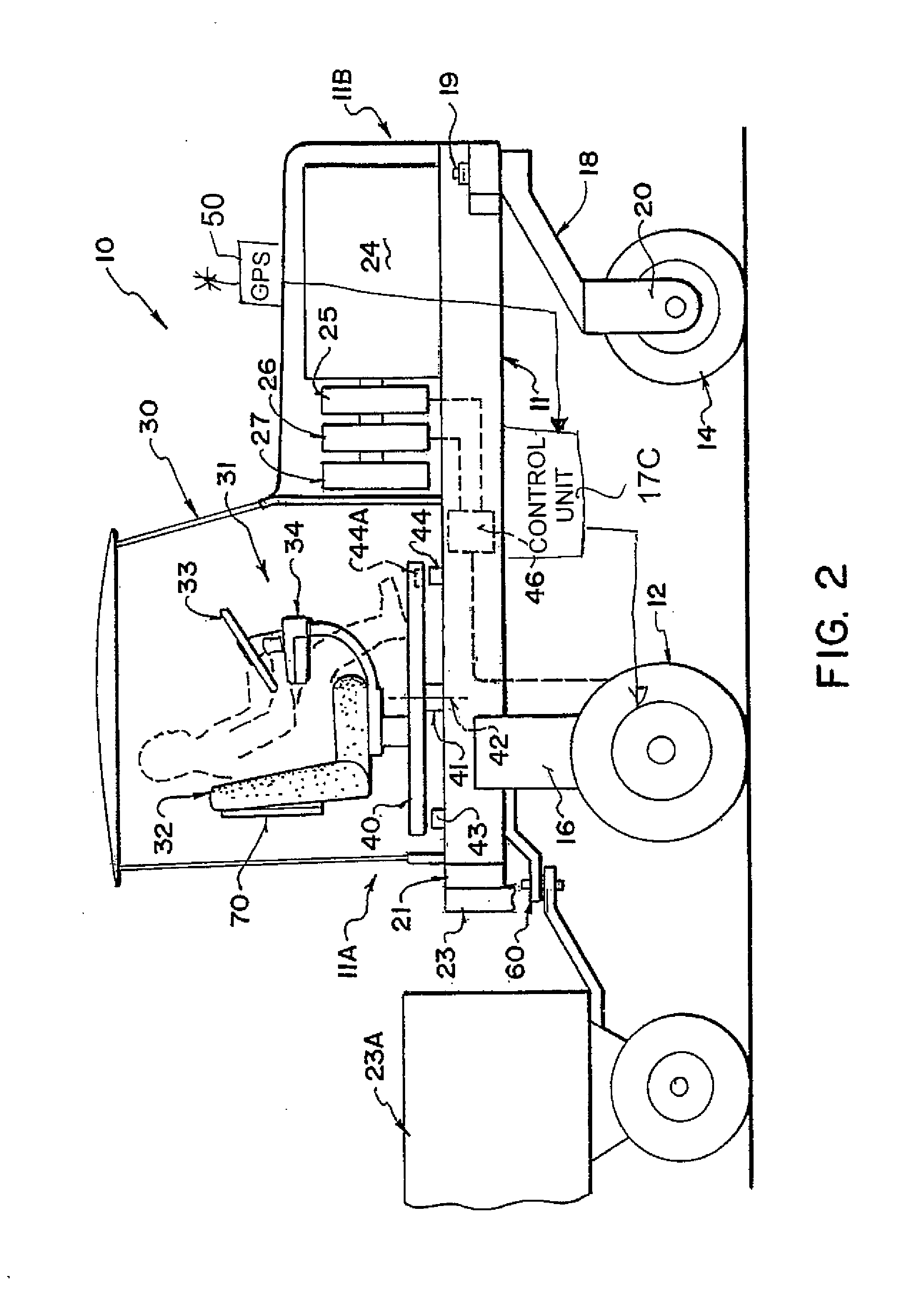

Speed and Steering Control of a Hydraulically Driven Tractor

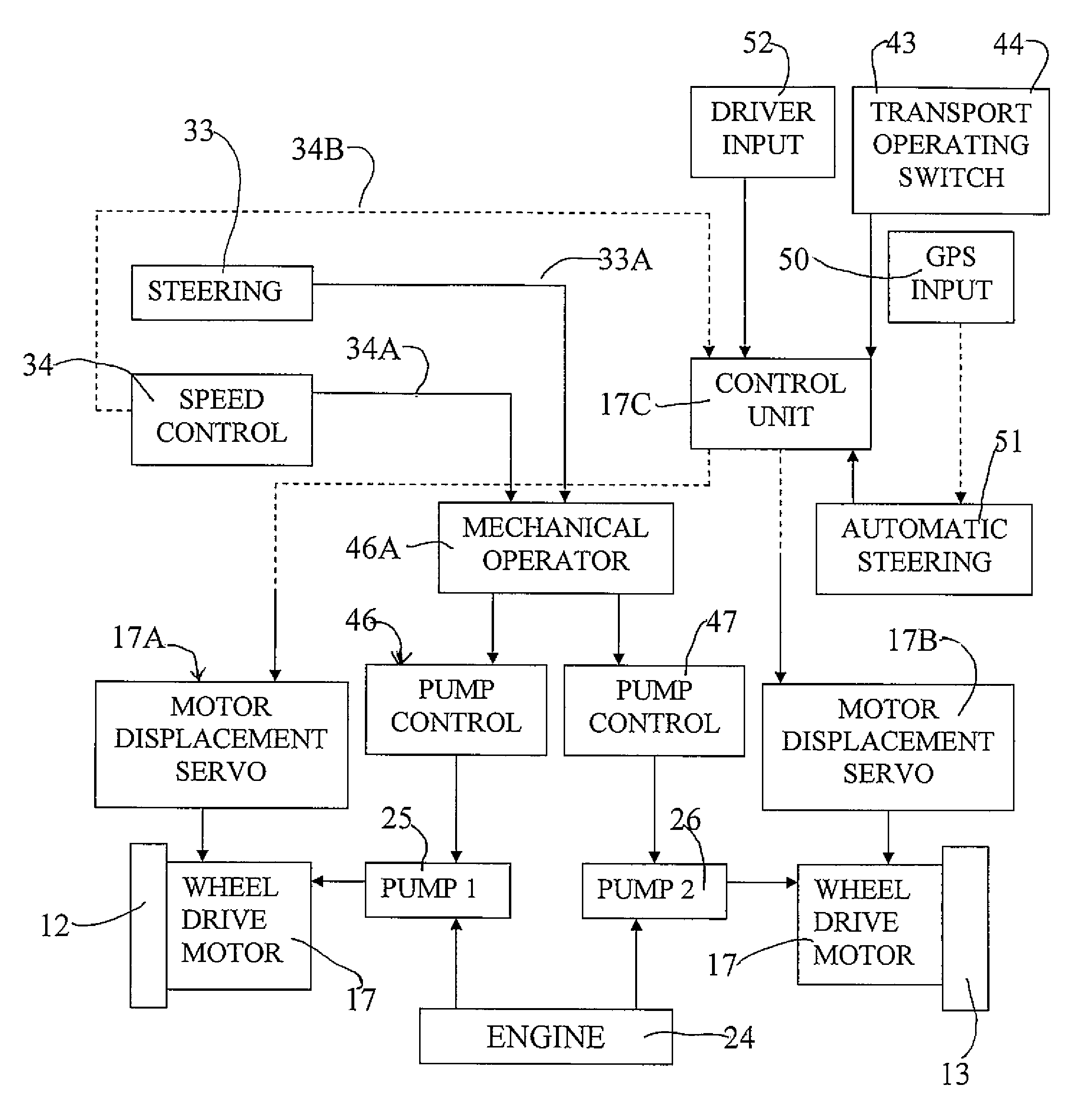

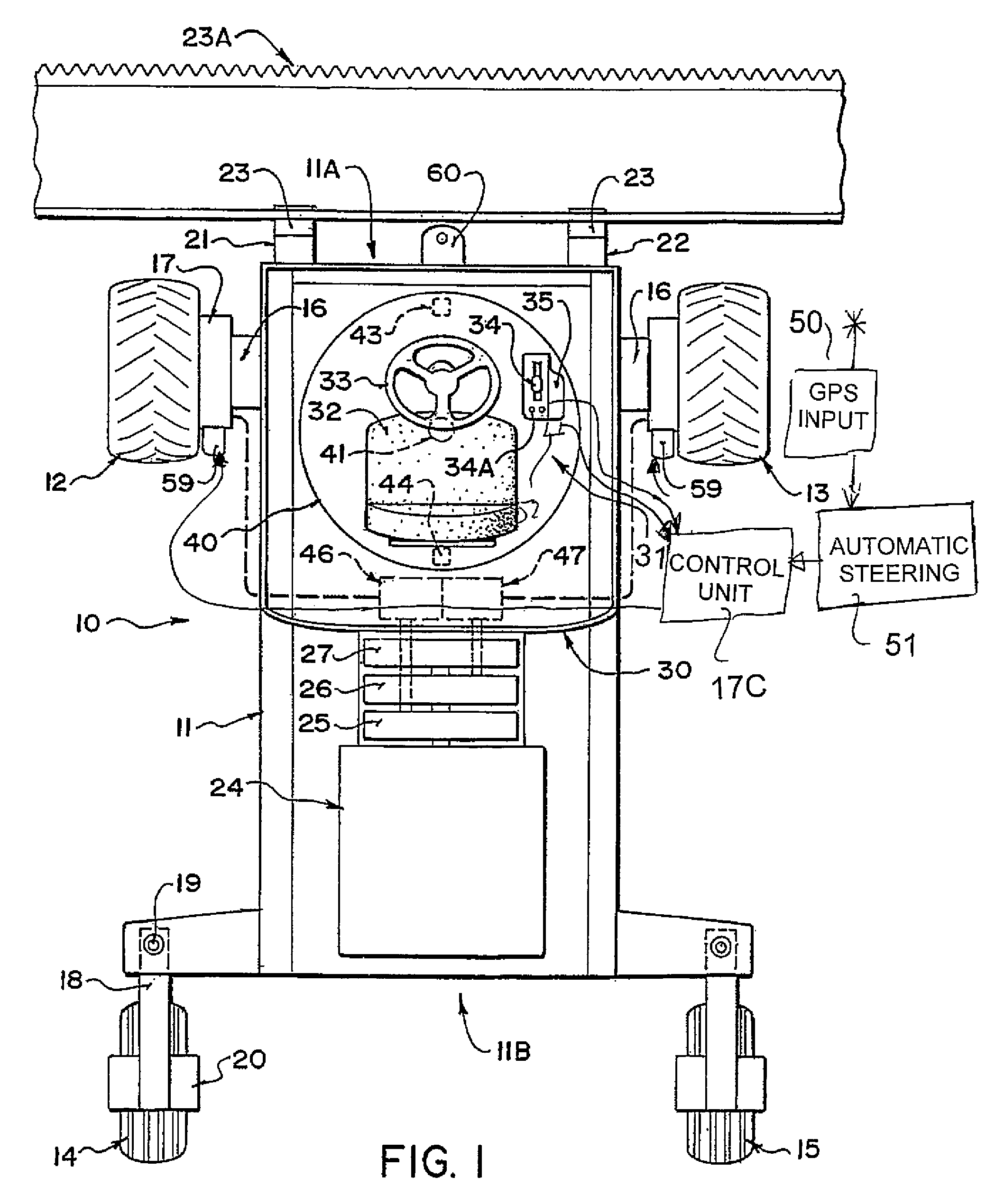

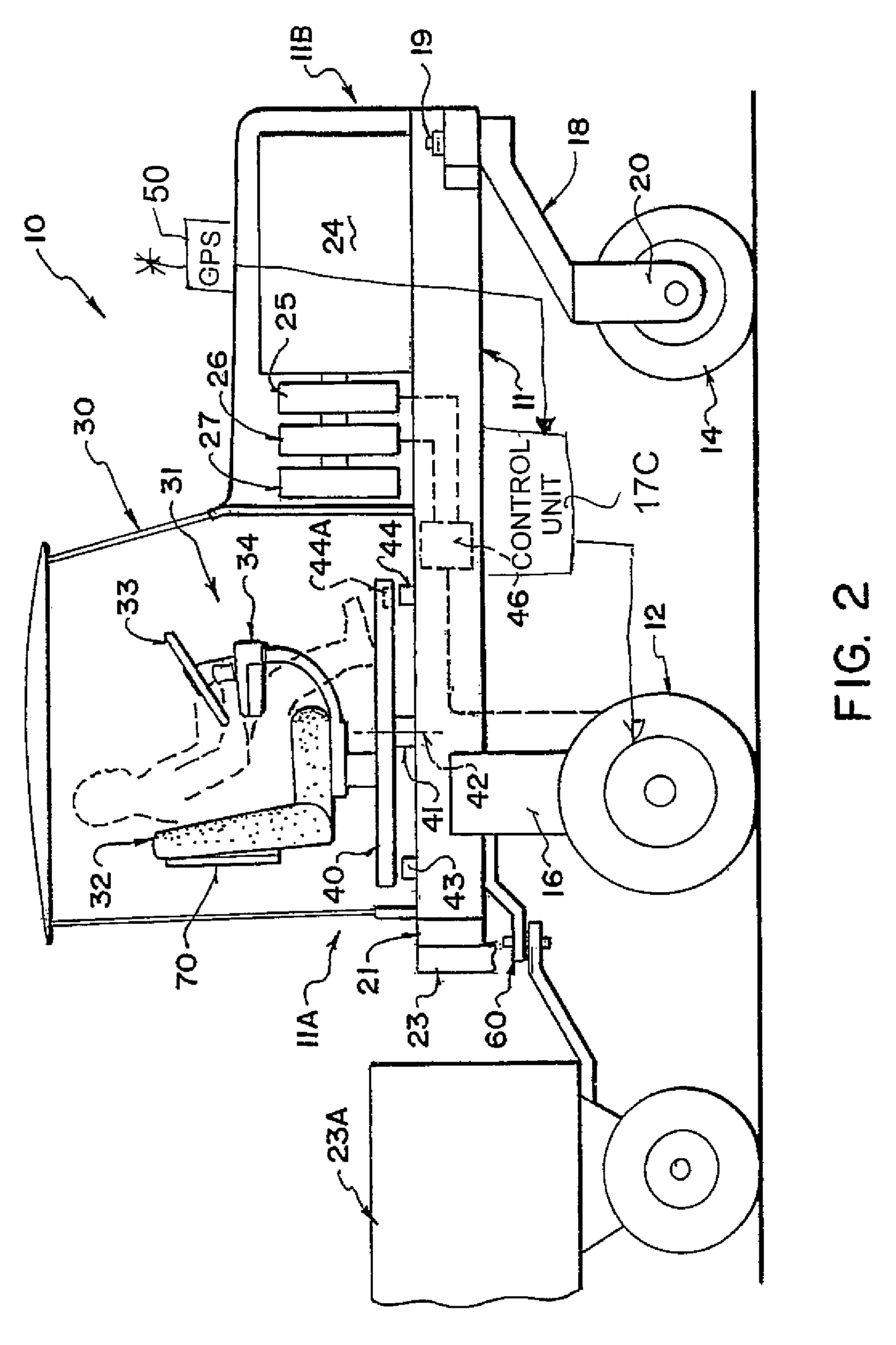

ActiveUS20140138166A1Reduce in quantityEliminate deflectionGuiding agricultural machinesAlternative steering controlHydraulic motorDrive wheel

A tractor has hydraulically driven wheels at a cab end and castor wheels at an engine end. Each driven wheels is driven by a hydraulic motor with a continuous adjustment of the motor displacement, with the motor being driven by a pump also having continuous displacement. The motor displacement is controlled by an electronic controller in response to stroking of the speed control lever to manage the displacement to provide required drive torques at different points in the stroke. There is provided an automatic steering system having a guidance controller arranged to receive GPS position information which controls the steering by differentially adjusting the displacement of the motors so that the automatic steering is independent of the manual steering which controls the pumps.

Owner:MACDON INDS

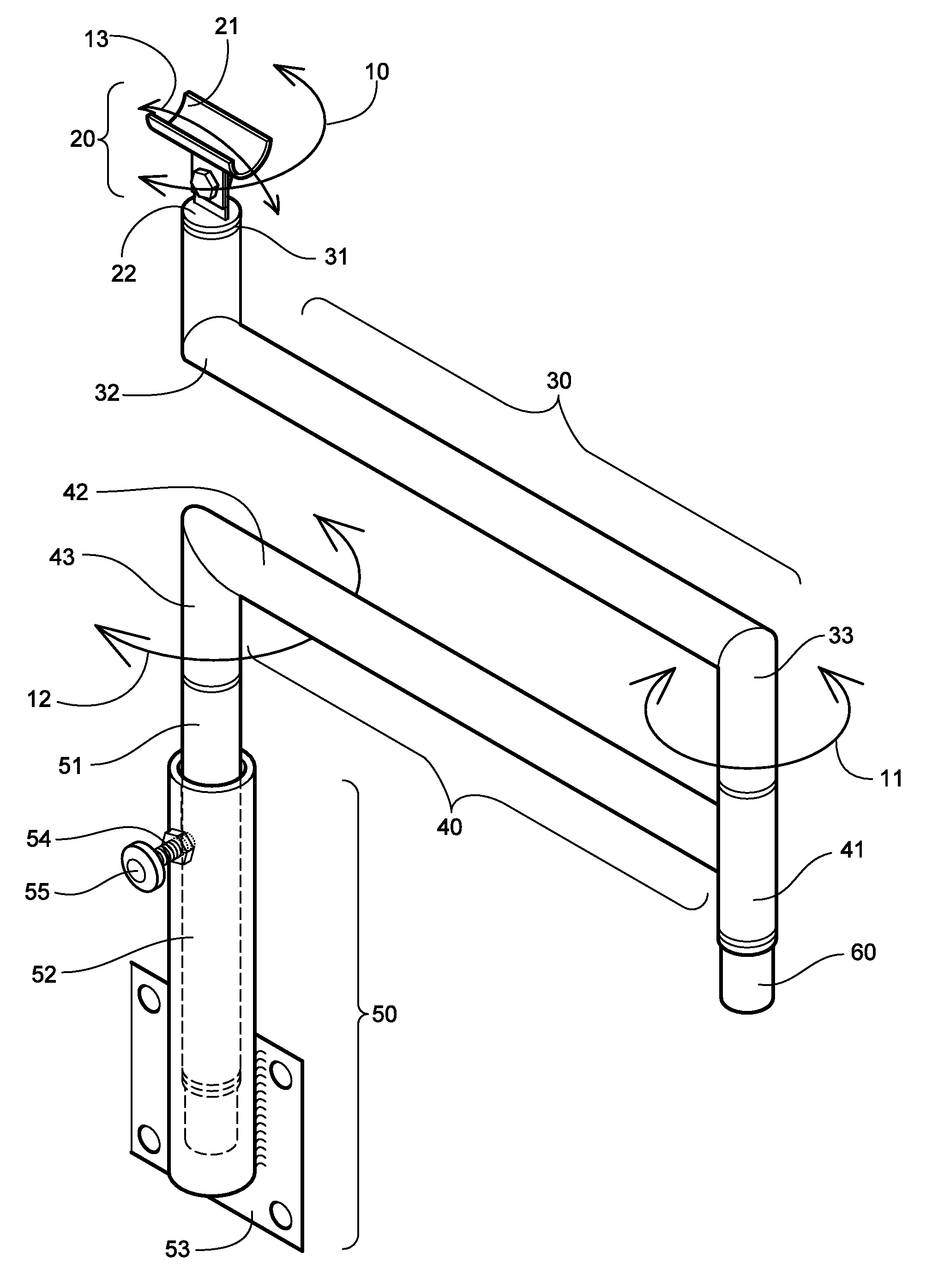

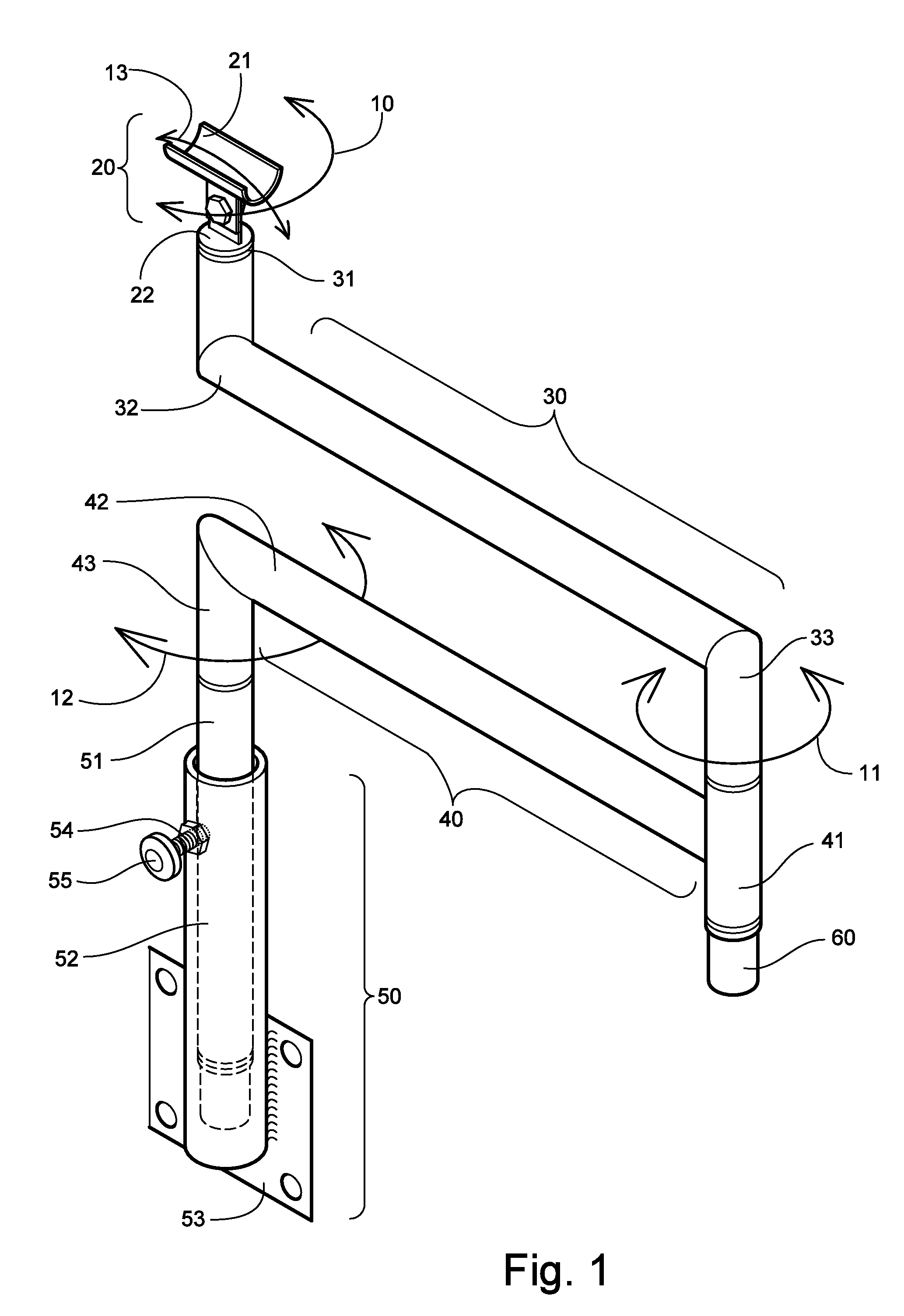

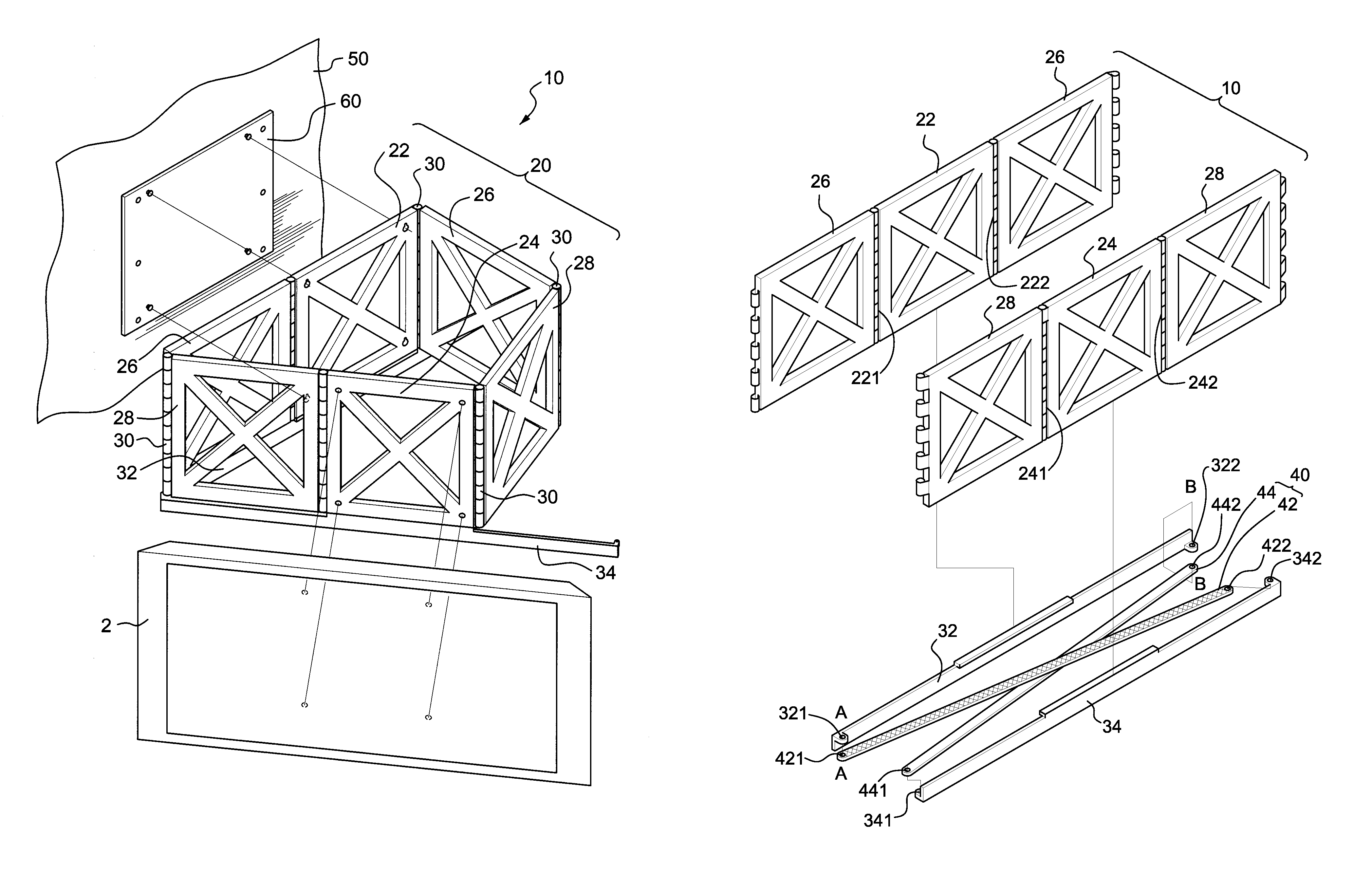

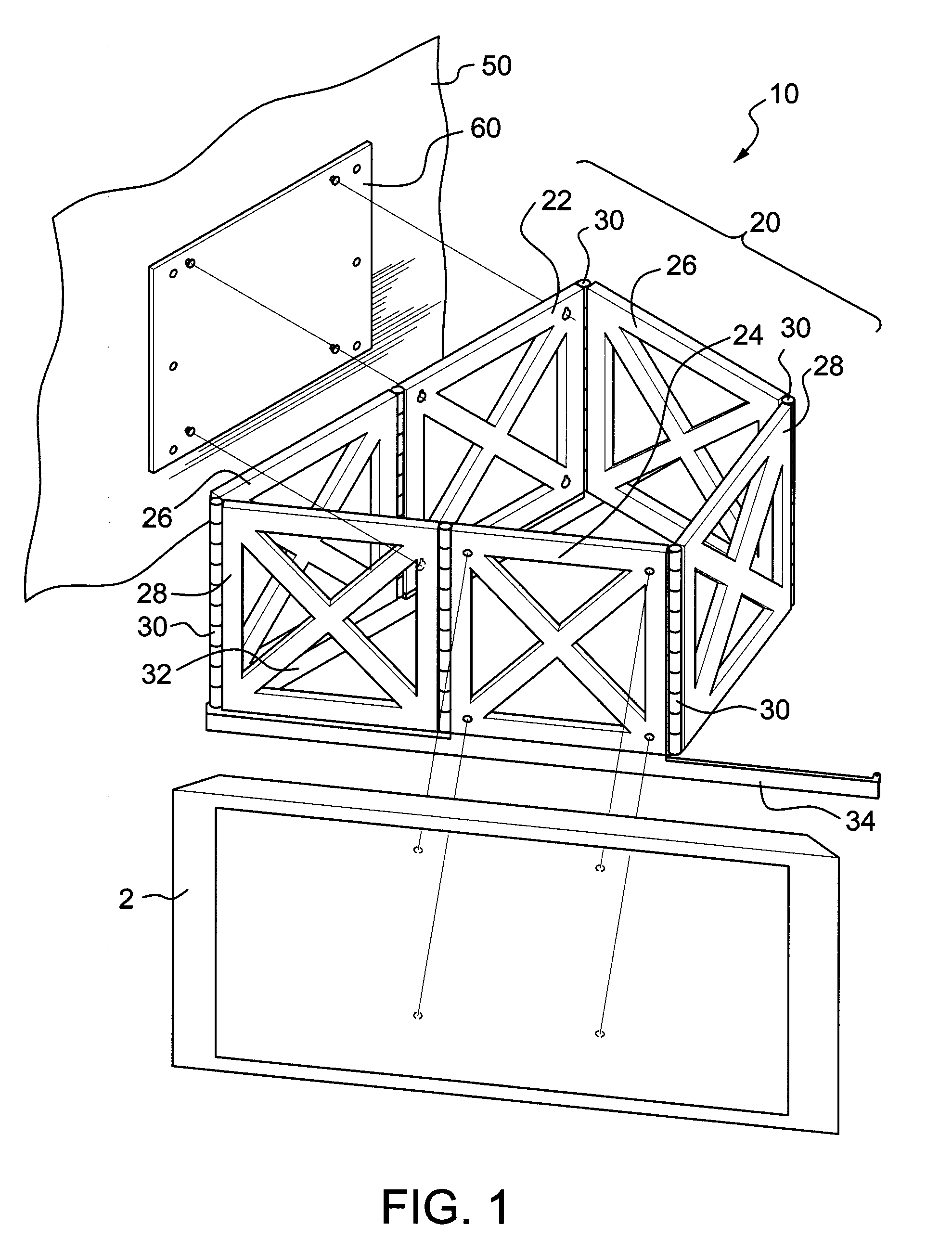

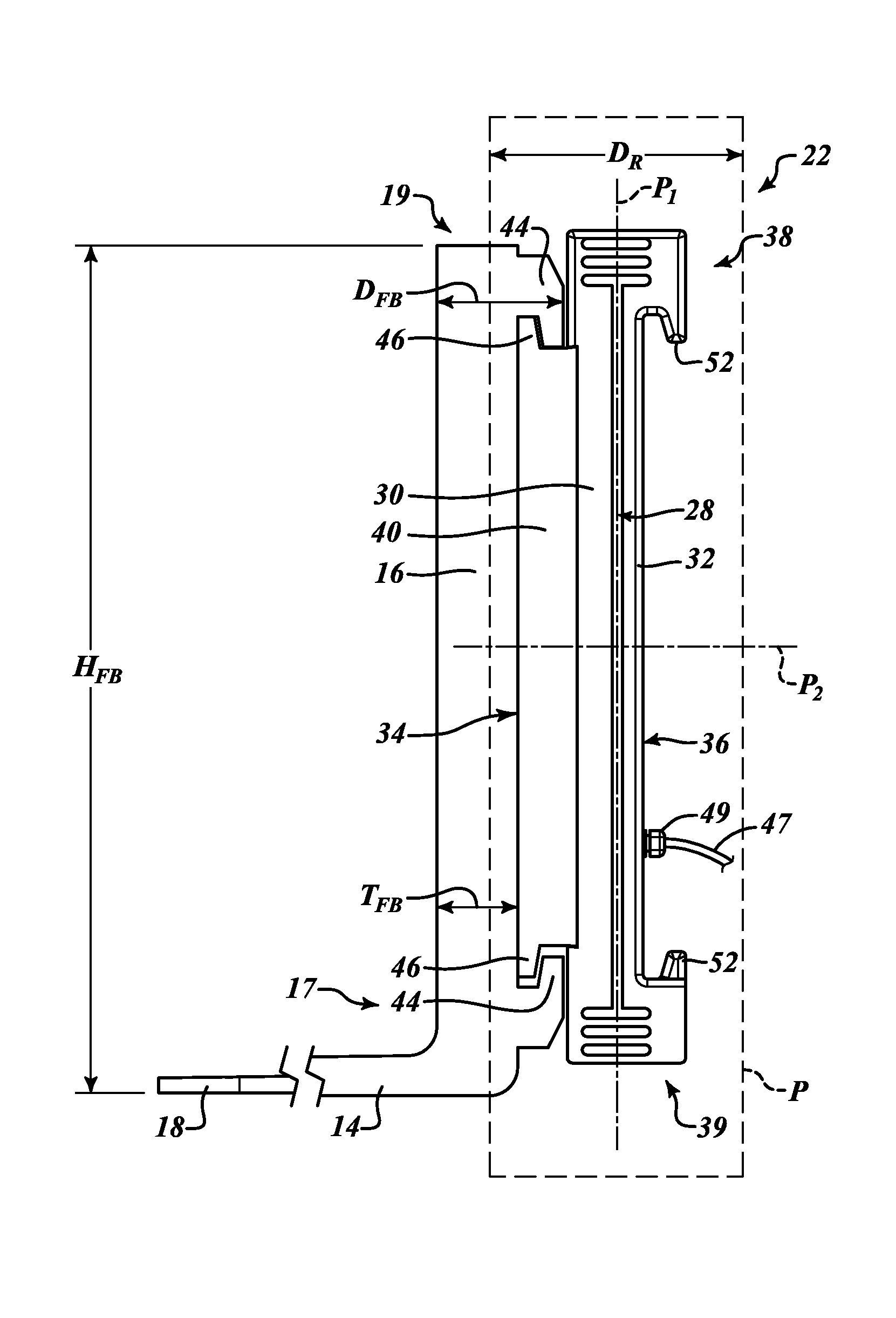

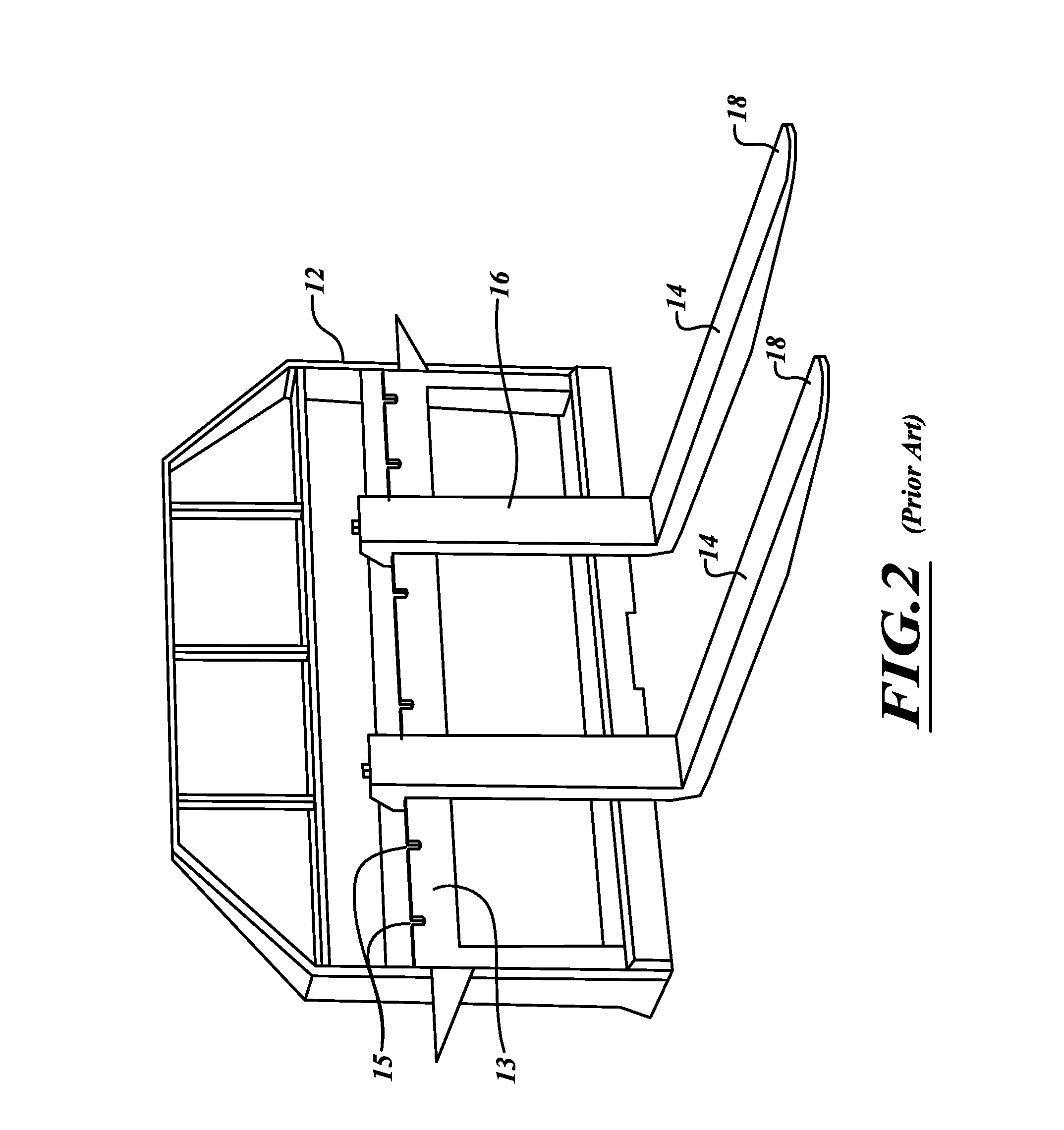

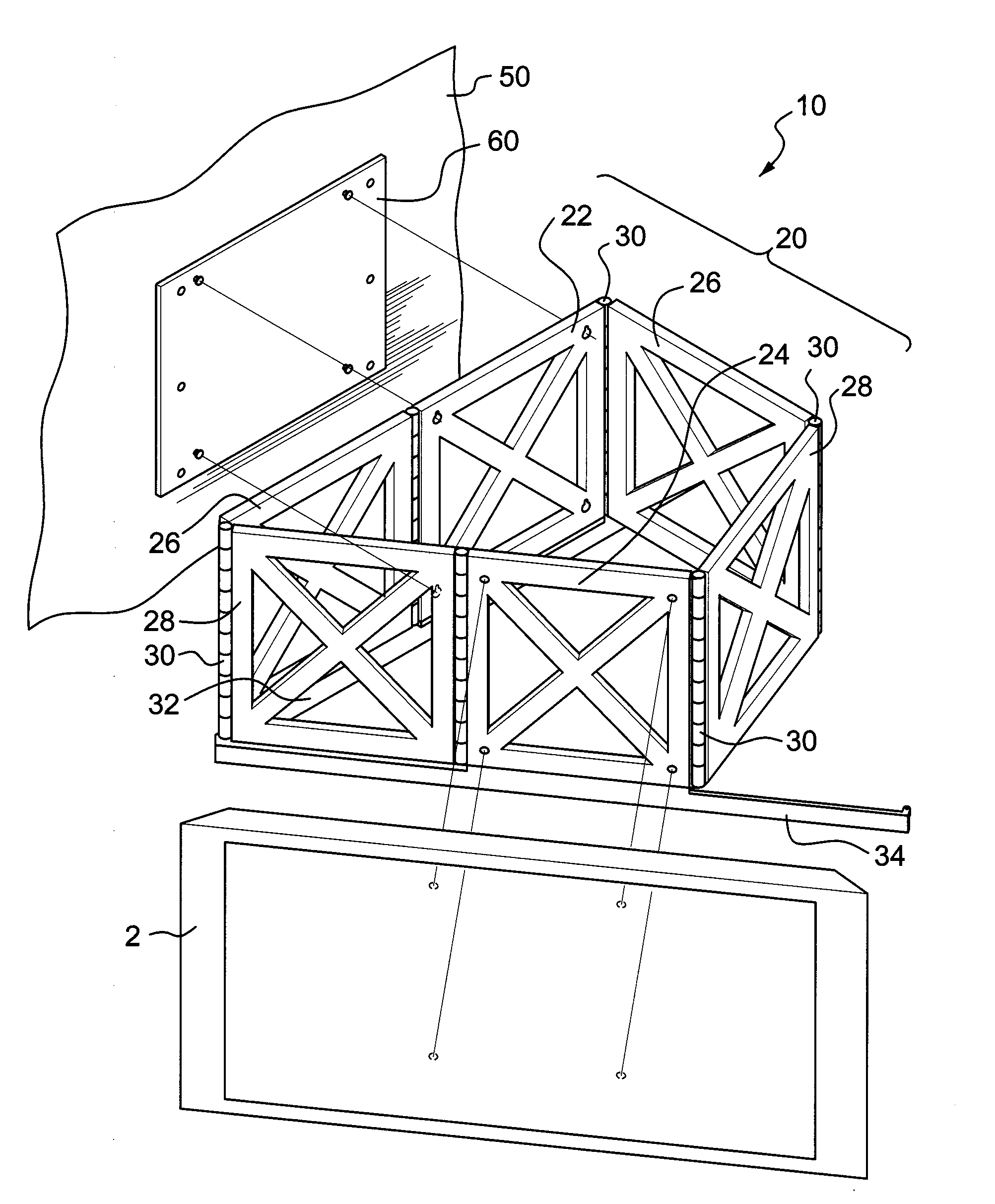

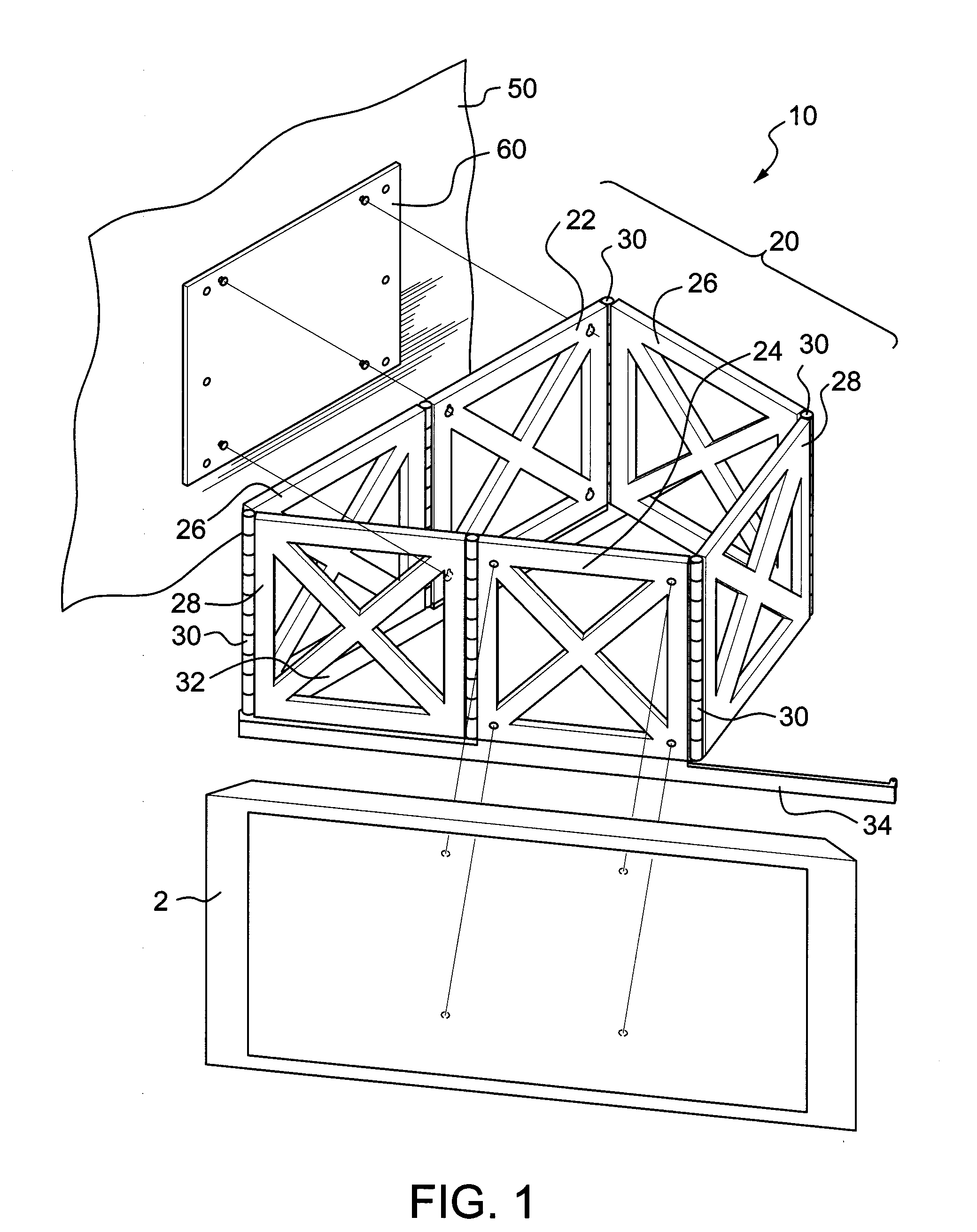

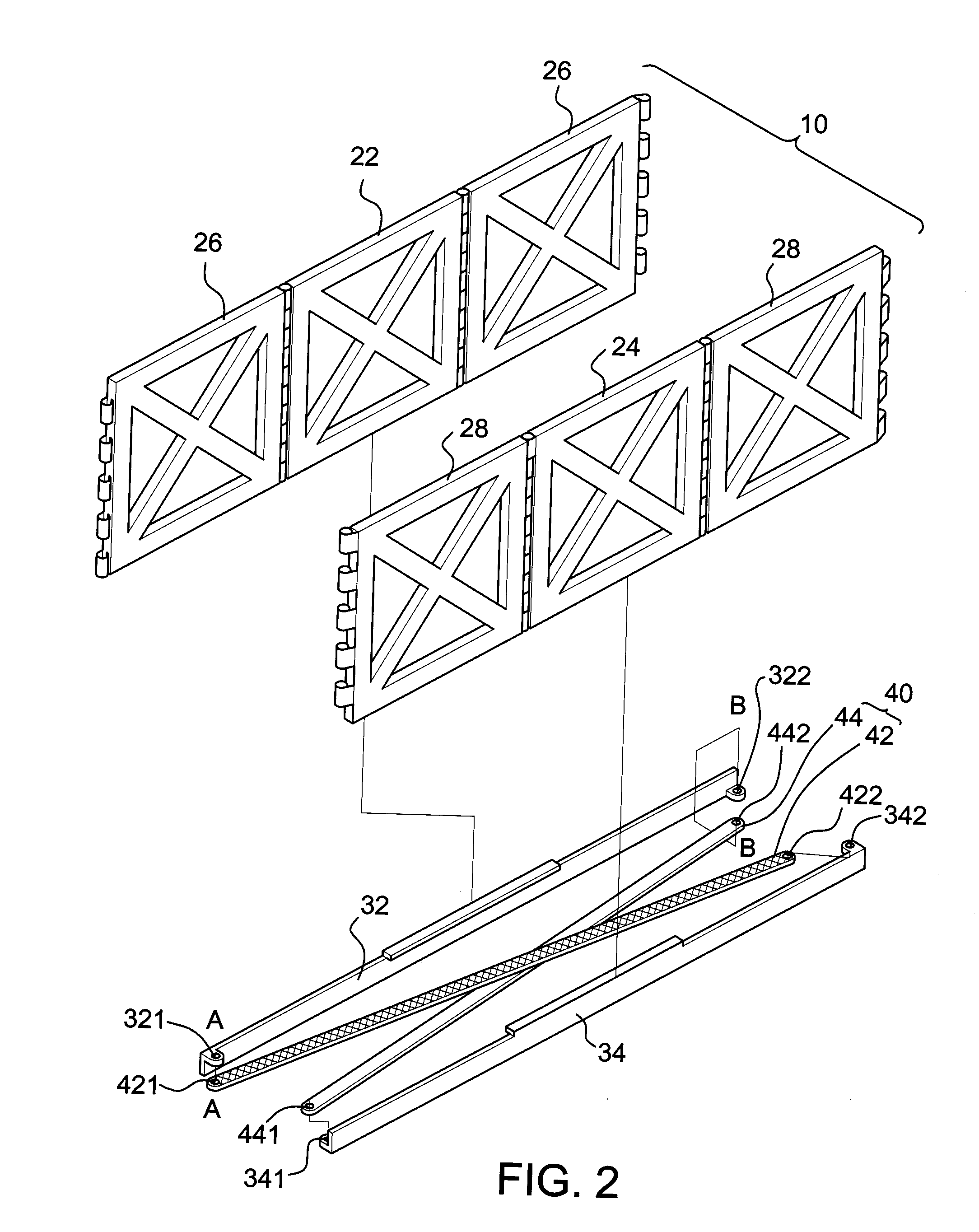

Flat panel display mounting device

InactiveUS7648112B2Overcome weakness in structurePrevent movementDigital data processing detailsStands/trestlesDisplay deviceEngineering

A flat panel display mounting device for securing a flat panel display, such as an LCD or plasma television, to a support surface, such as a wall, is disclosed. The flat panel display mounting device comprises a plurality of members in the form of support panels pivotally connected together and a rotation control mechanism connected thereto so that the flat panel display mounted on the device can be rotated to a desired angle and the center of gravity of the flat panel display during rotation can be maintained as close to the support surface as possible, so as not to generate additional burden to the flat panel display mounting device.

Owner:LEW ANDREW H +4

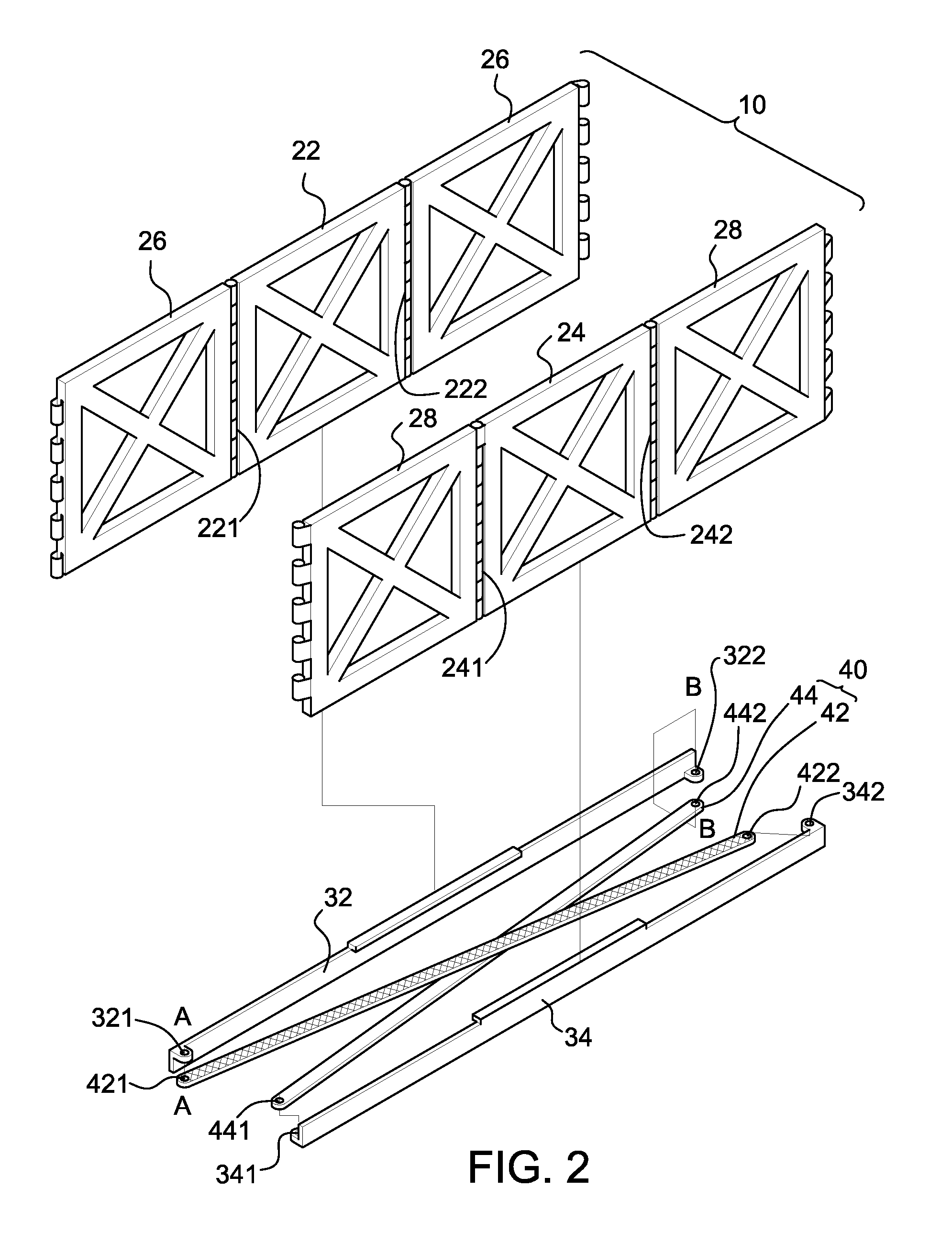

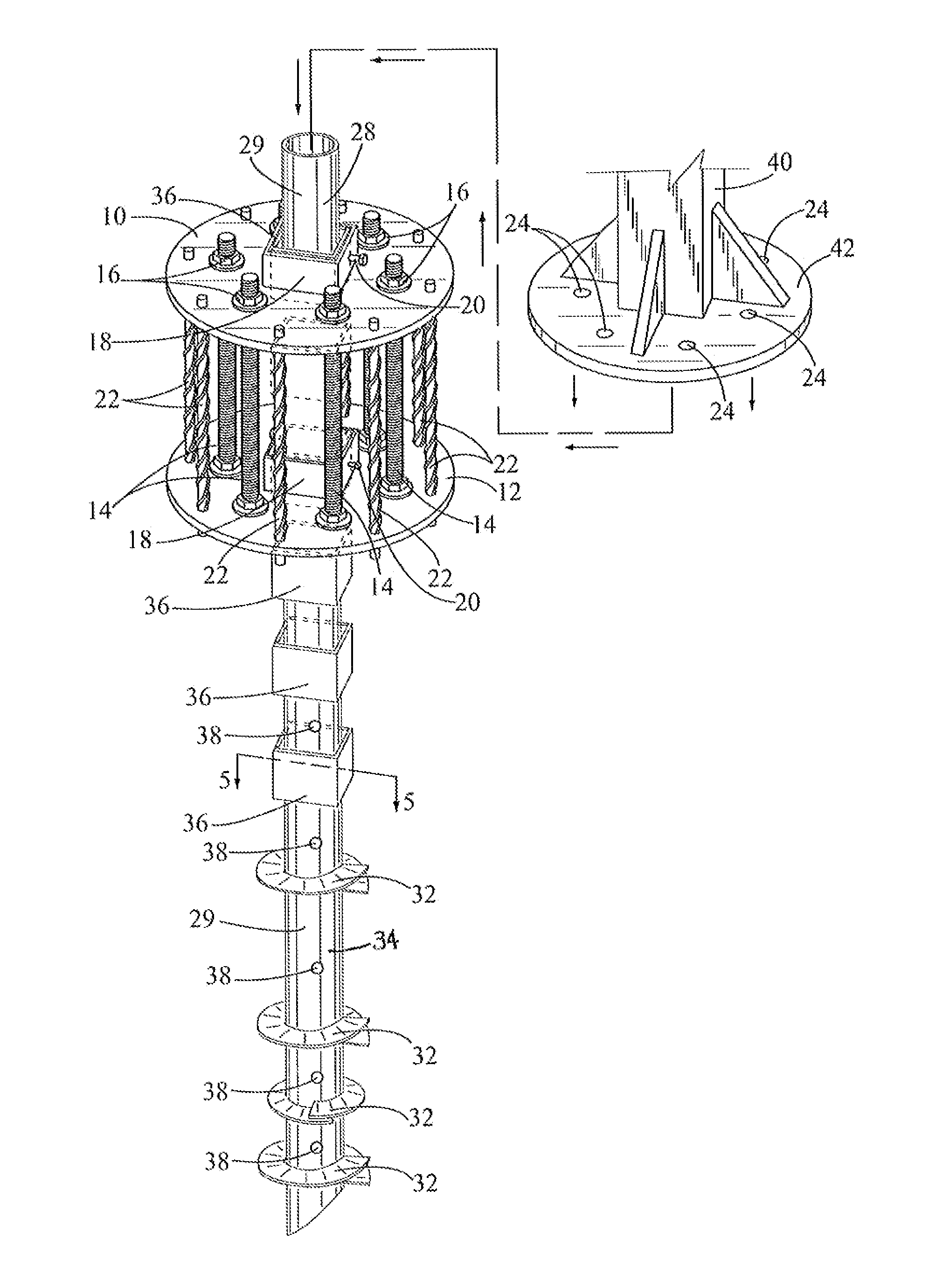

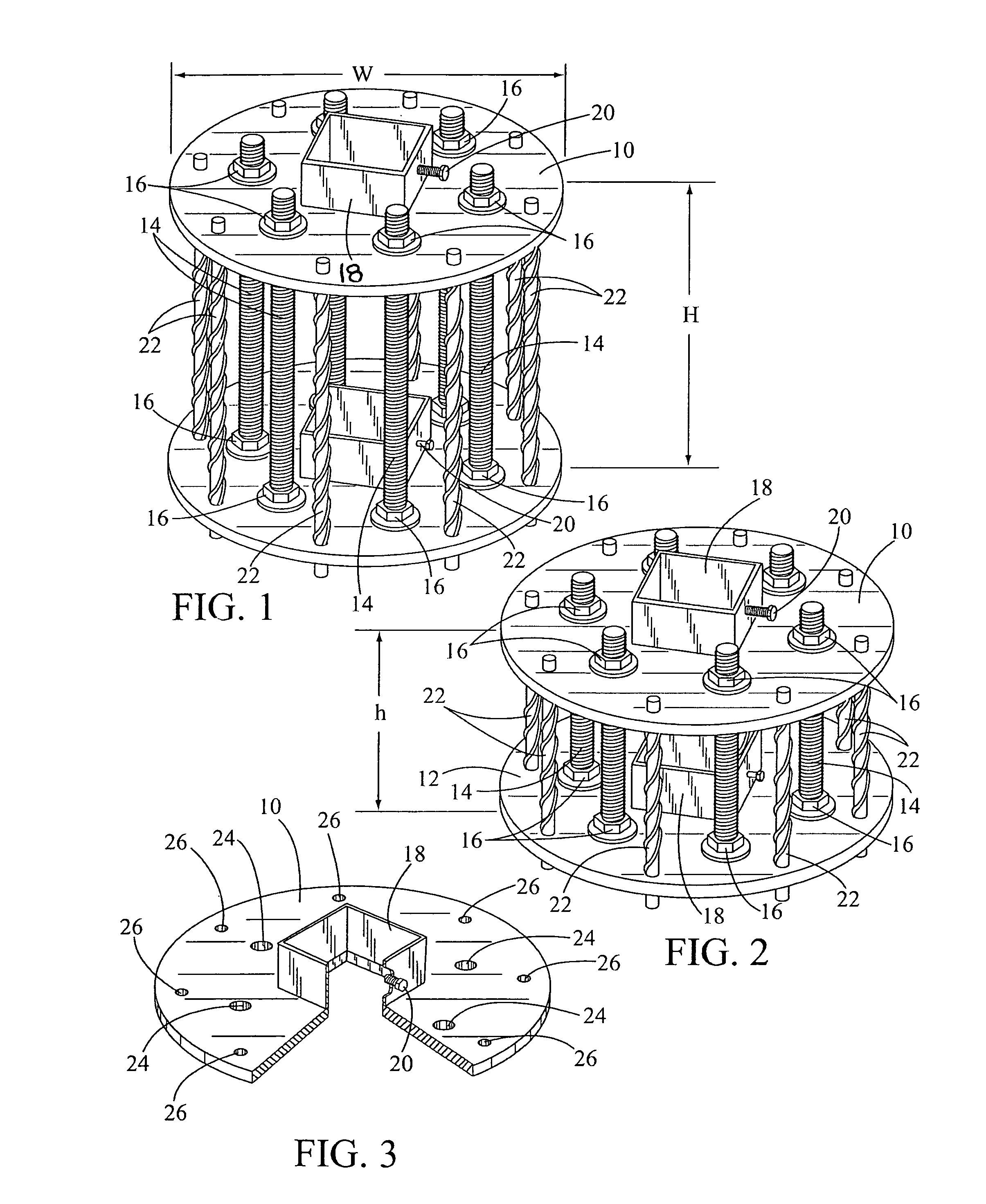

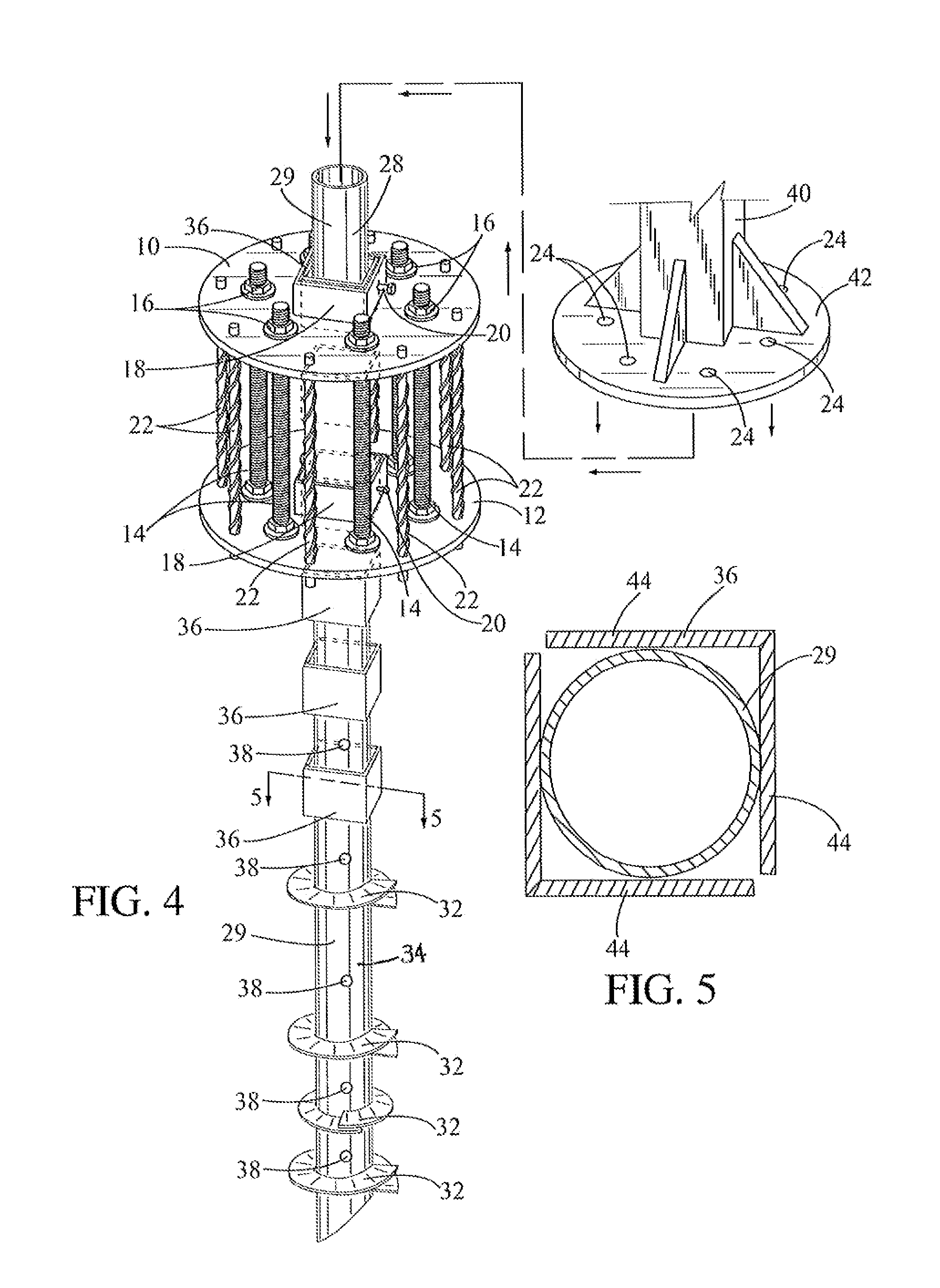

Helical pier with adjustable pierhead plates for supporting a structure above a ground surface

A helical pier for receipt in a ground surface and including an annular, adjustable, upper pierhead plate and an annular, adjustable, lower pierhead plate. The two plates include threaded bolts and nuts for securing the plates together in a spaced relationship. The upper and lower plates include a drive lug frame centered thereon. The pierhead plates are adapted for slidable receipt around a top portion of the helical pier. The helical pier includes spaced apart helice and spaced apart angular shaped drive lugs. The drive lugs are used for driving the helical pier into the ground surface. Also, the drive lug frames on the pierhead plates are received around selected drive lugs and secured thereto using set screws.

Owner:LUDWIG MICHAEL R

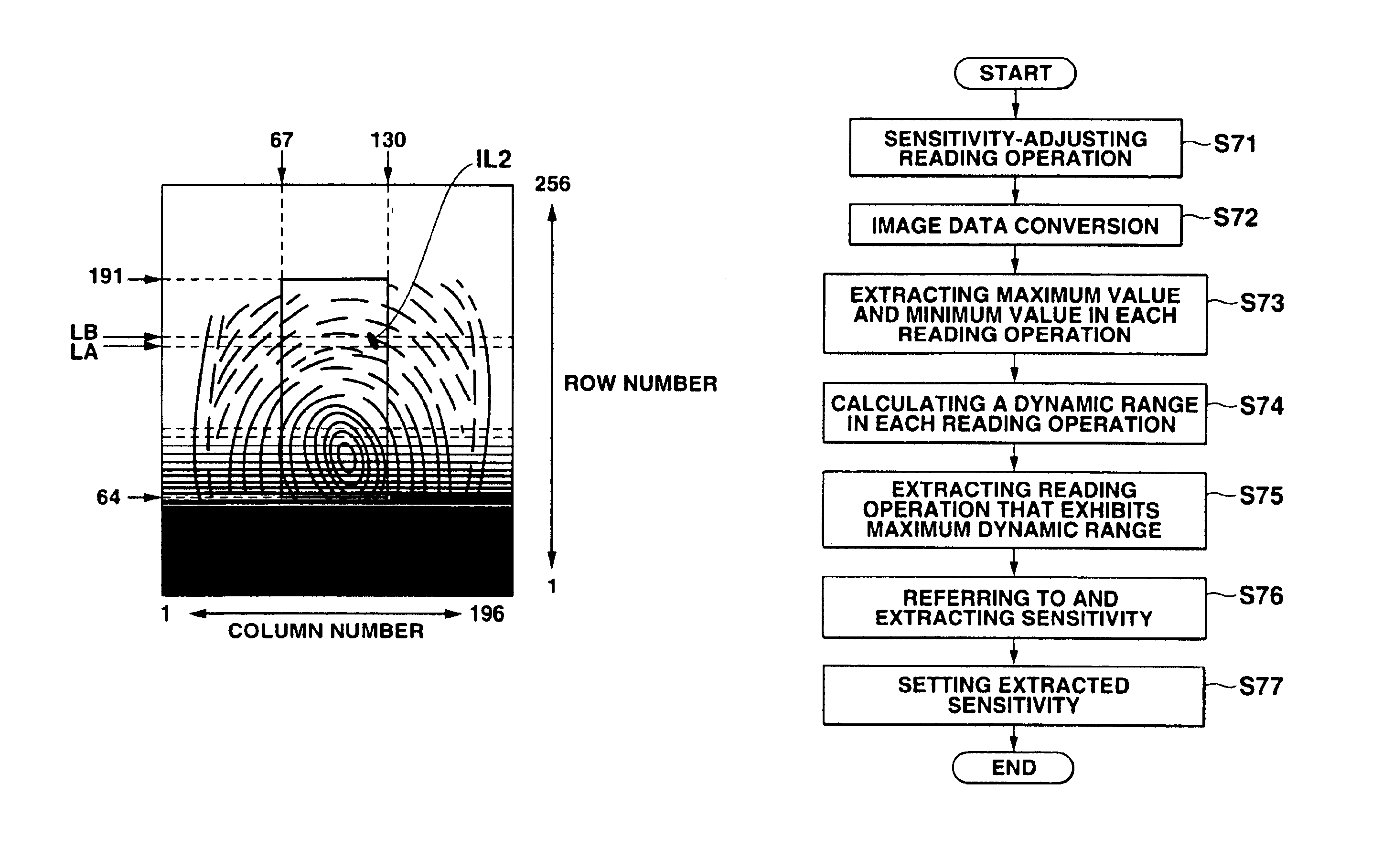

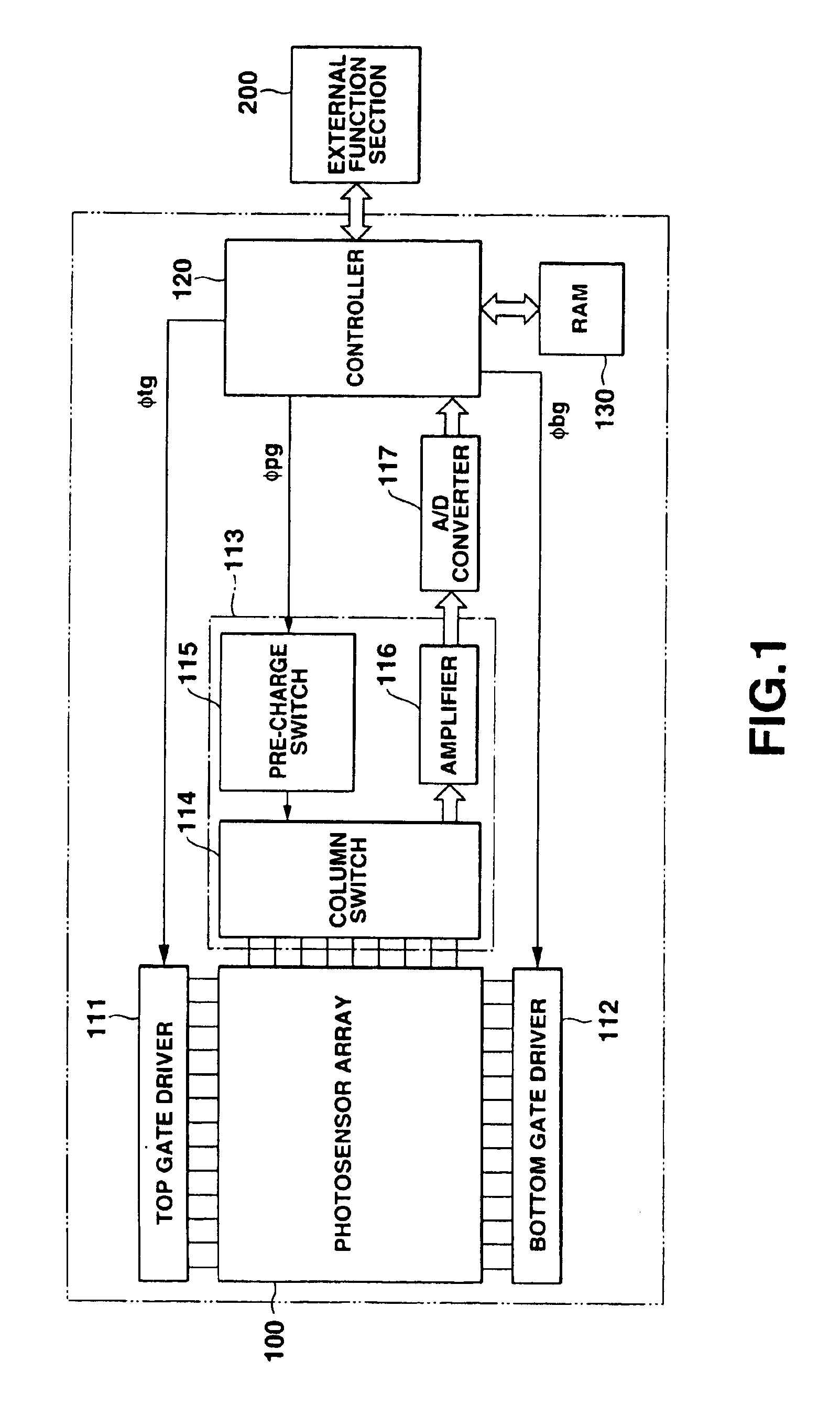

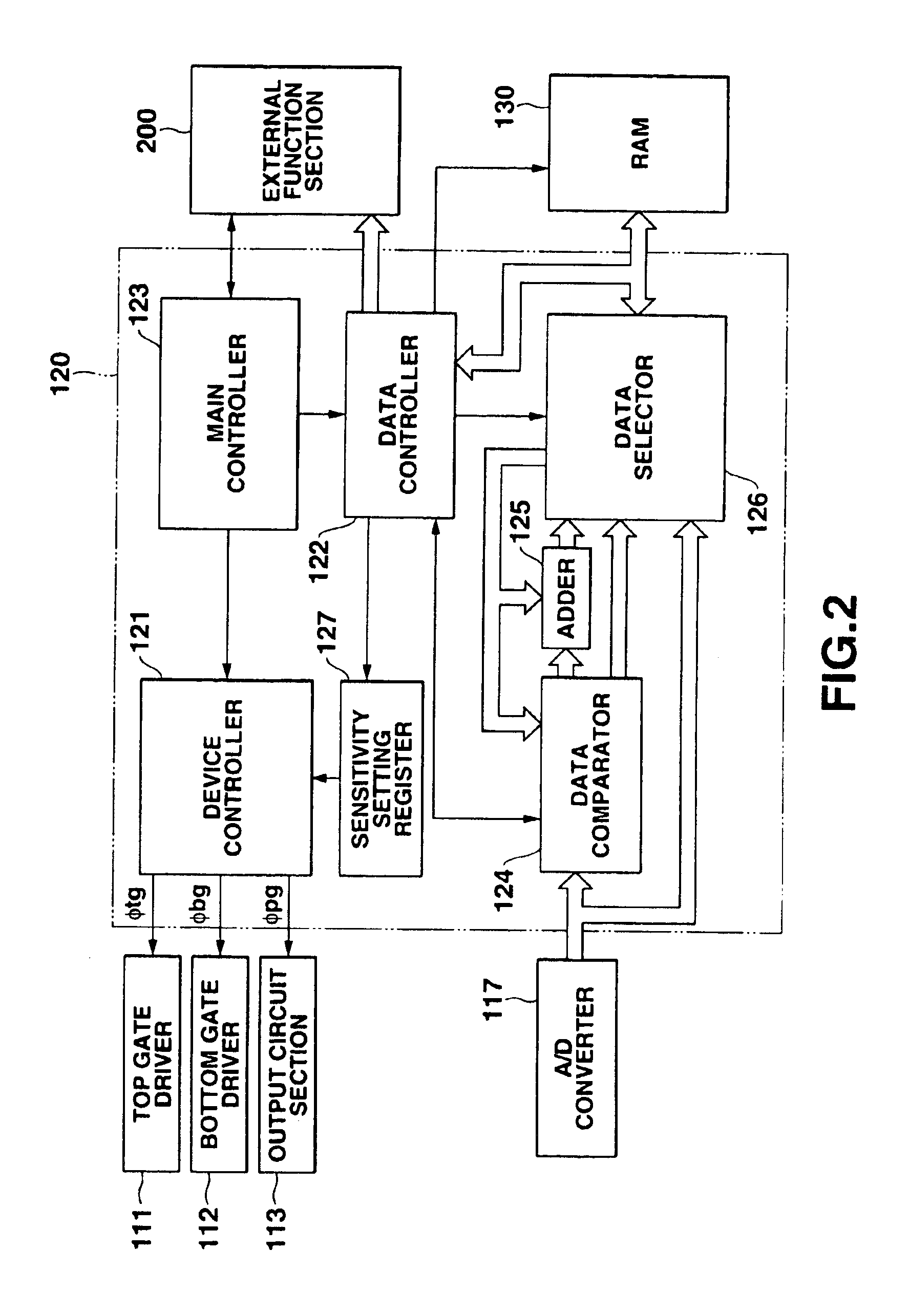

Photosensor system and drive control method thereof

InactiveUS6867811B2Accurate imagingReduce the amount requiredTelevision system detailsTelevision system scanning detailsSensitivity distributionComputer science

A photosensor system performs a sensitivity-adjusting reading operation with respect to a subject image, while simultaneously changing the image reading sensitivity stepwise for each of rows of a photosensor array or for specific rows thereof. The dynamic ranges of the lightness data on the read subject image are checked to see how they are distributed in relation to the image reading sensitivities. On the basis of this distribution, an image reading sensitivity that contributes to an optimal image reading state is extracted as an optimal image reading sensitivity.

Owner:CASIO COMPUTER CO LTD

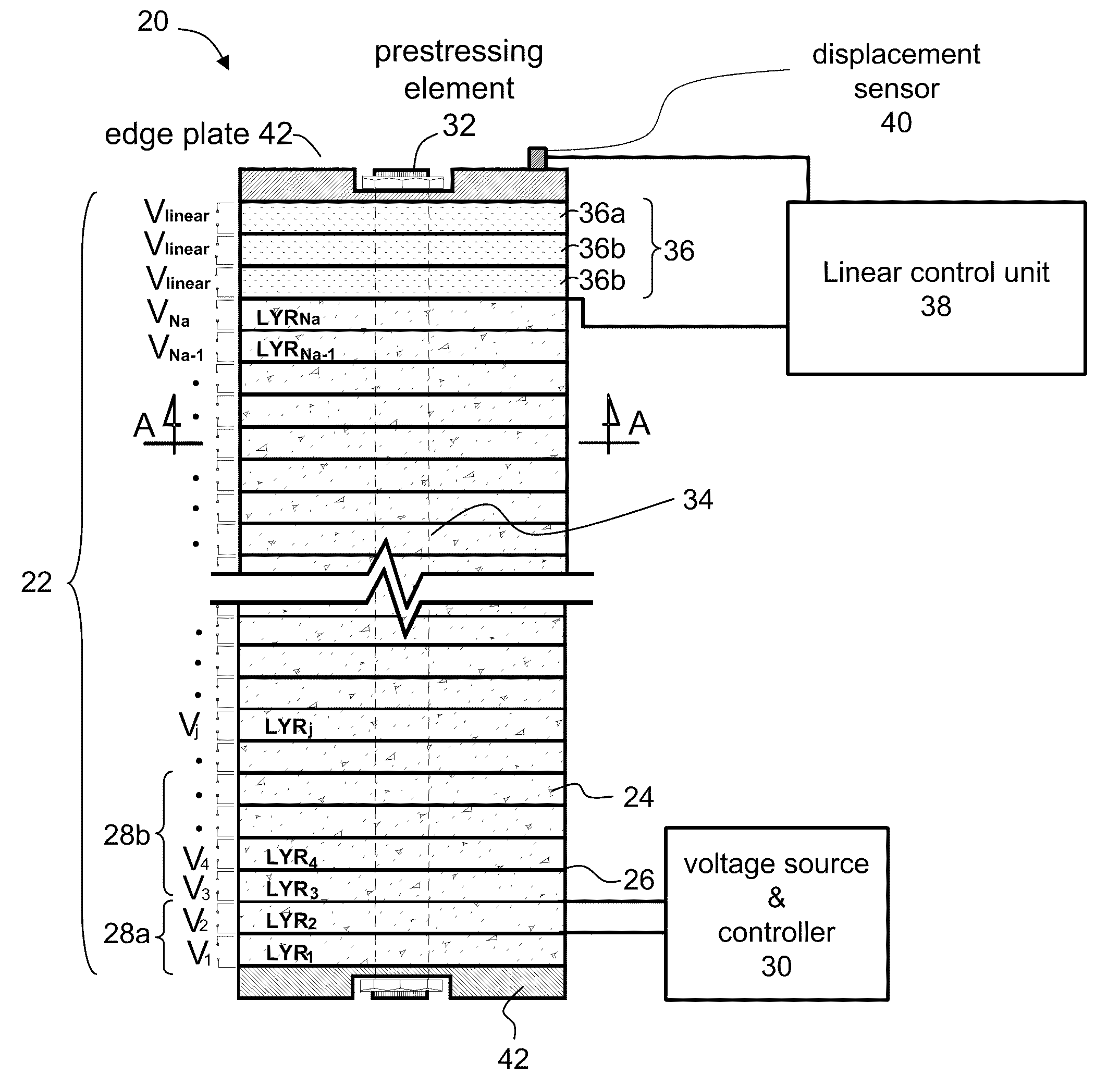

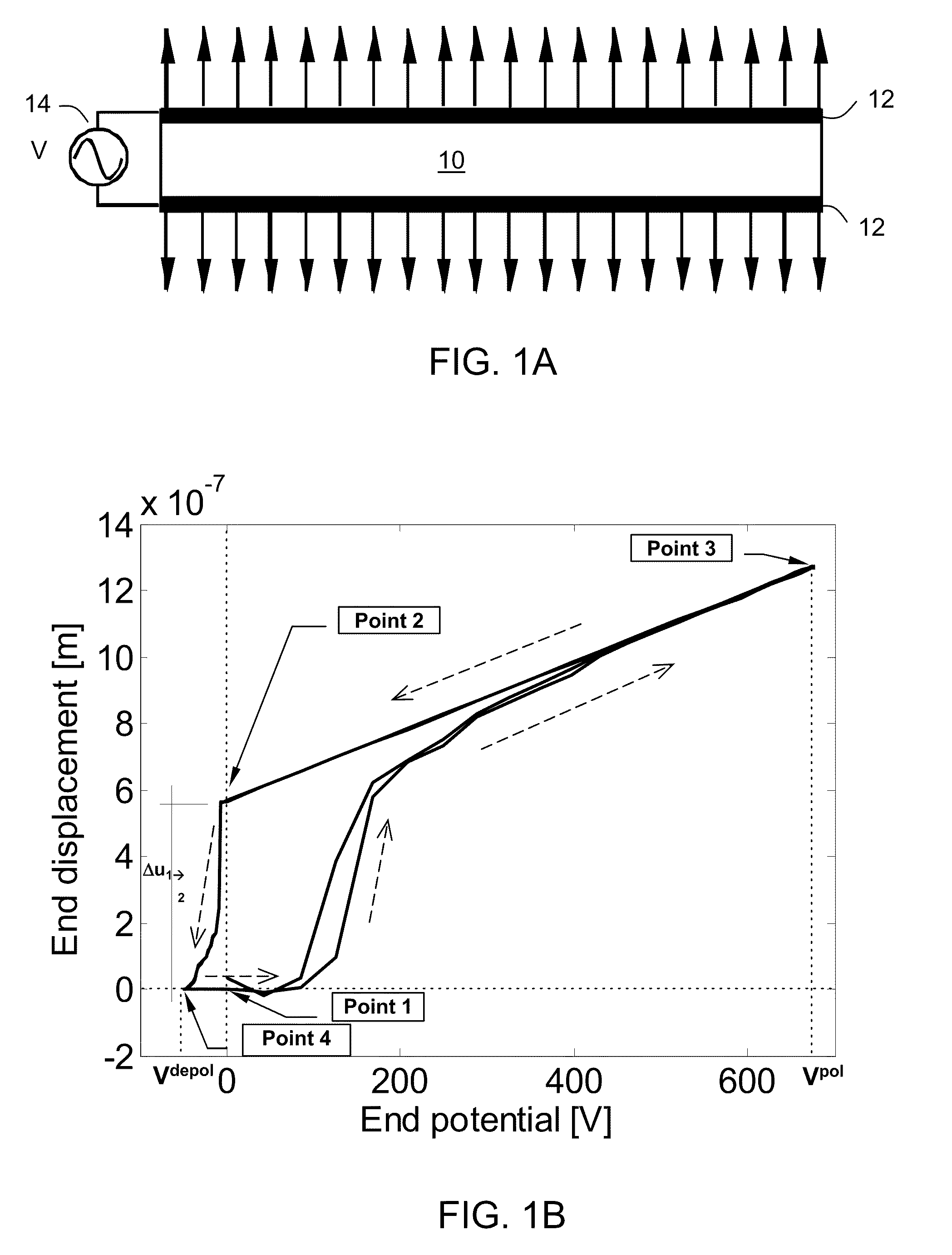

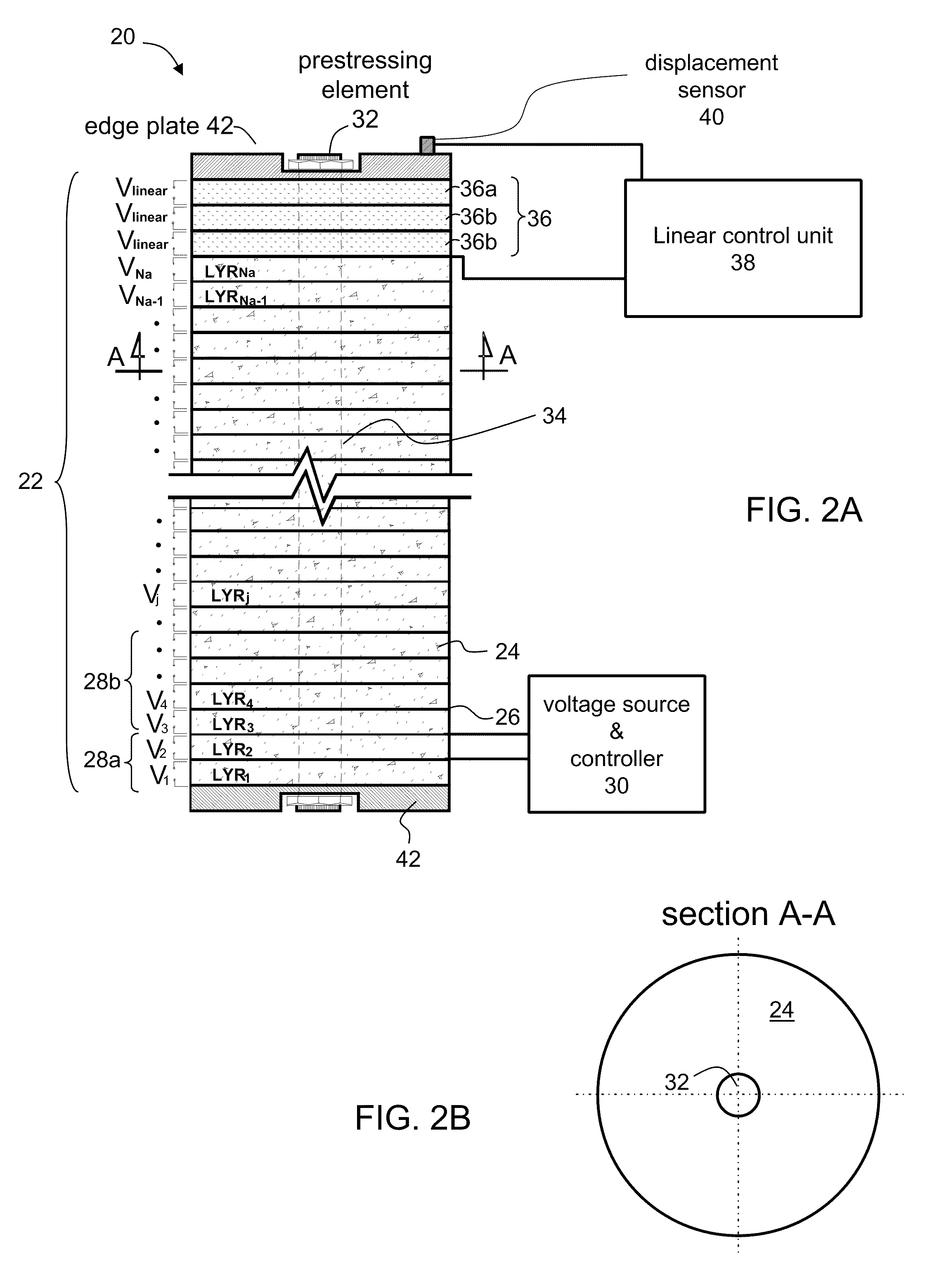

Piezoelectric-ferroelectric actuator device

ActiveUS20100320868A1Minimal displacementPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesEngineeringActuator

An actuator device is disclosed. The actuator device comprises a stack of piezoelectric-ferroelectric active layers separated by surface electrodes. At least a few of the surface electrodes are independently addressable such that at least two active layers are biasable by different voltages. In an embodiment of the invention, at least a few of the voltages induce a nonlinear ferroelectric effect.

Owner:TECHNION RES & DEV FOUND LTD

Speed and steering control of a hydraulically driven tractor

ActiveUS8985252B2Minimal displacementReduce in quantityAlternative steering controlGuiding agricultural machinesHydraulic motorAutomatic steering

A tractor has hydraulically driven wheels at a cab end and castor wheels at an engine end. Each driven wheels is driven by a hydraulic motor with a continuous adjustment of the motor displacement, with the motor being driven by a pump also having continuous displacement. The motor displacement is controlled by an electronic controller in response to stroking of the speed control lever to manage the displacement to provide required drive torques at different points in the stroke. There is provided an automatic steering system having a guidance controller arranged to receive GPS position information which controls the steering by differentially adjusting the displacement of the motors so that the automatic steering is independent of the manual steering which controls the pumps.

Owner:MACDON INDS

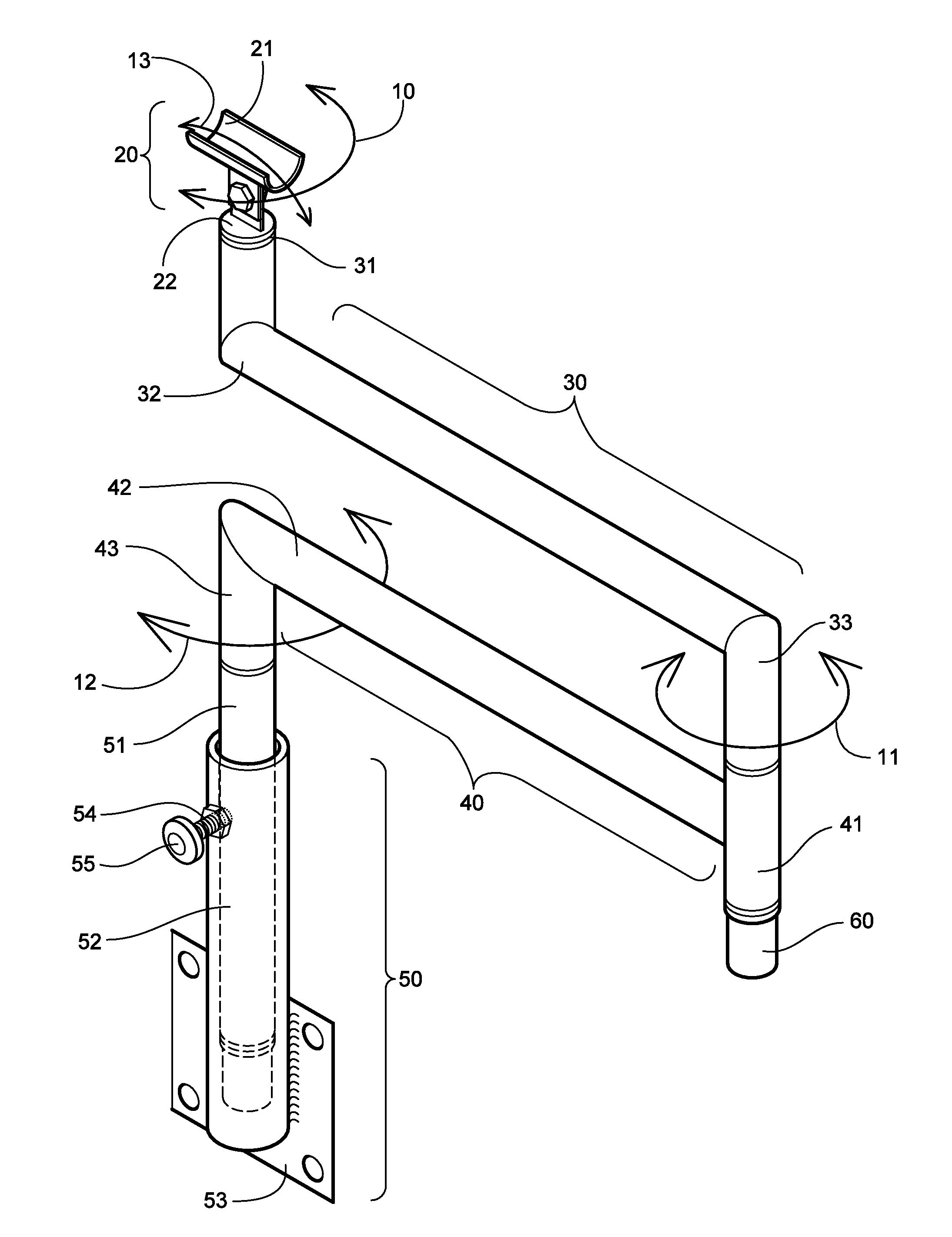

Rotatable gun rest

The invention is a device that allows a marksman to easily rotate and position a gun from the elevated position of a deerstand. The invention utilizes displaced parallel axes of rotation so that the marksman can maximize the mobility of the gun during shot selection while at the same time minimizing both noise and personal bodily displacement.

Owner:MCDONALD DANIEL E

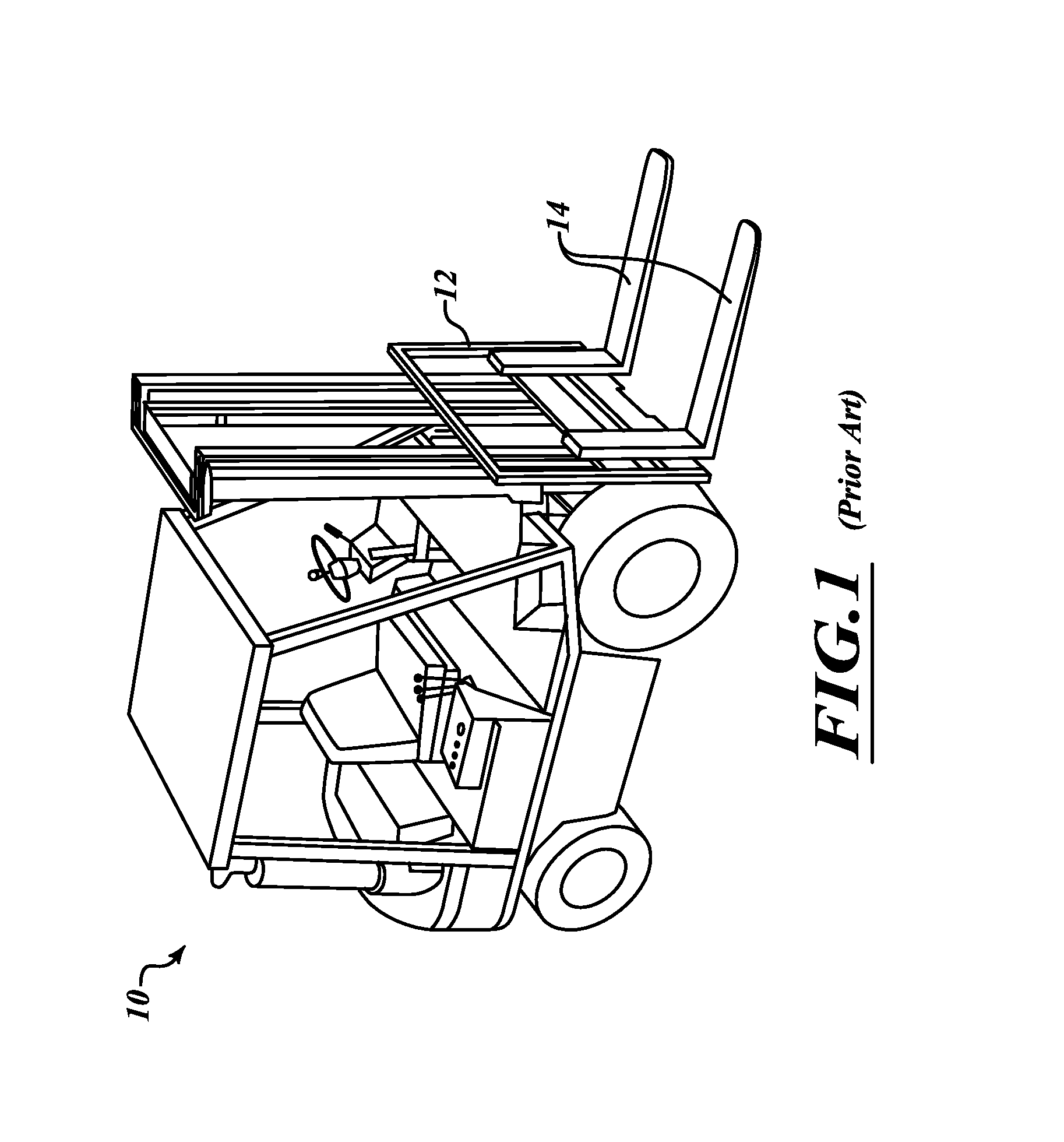

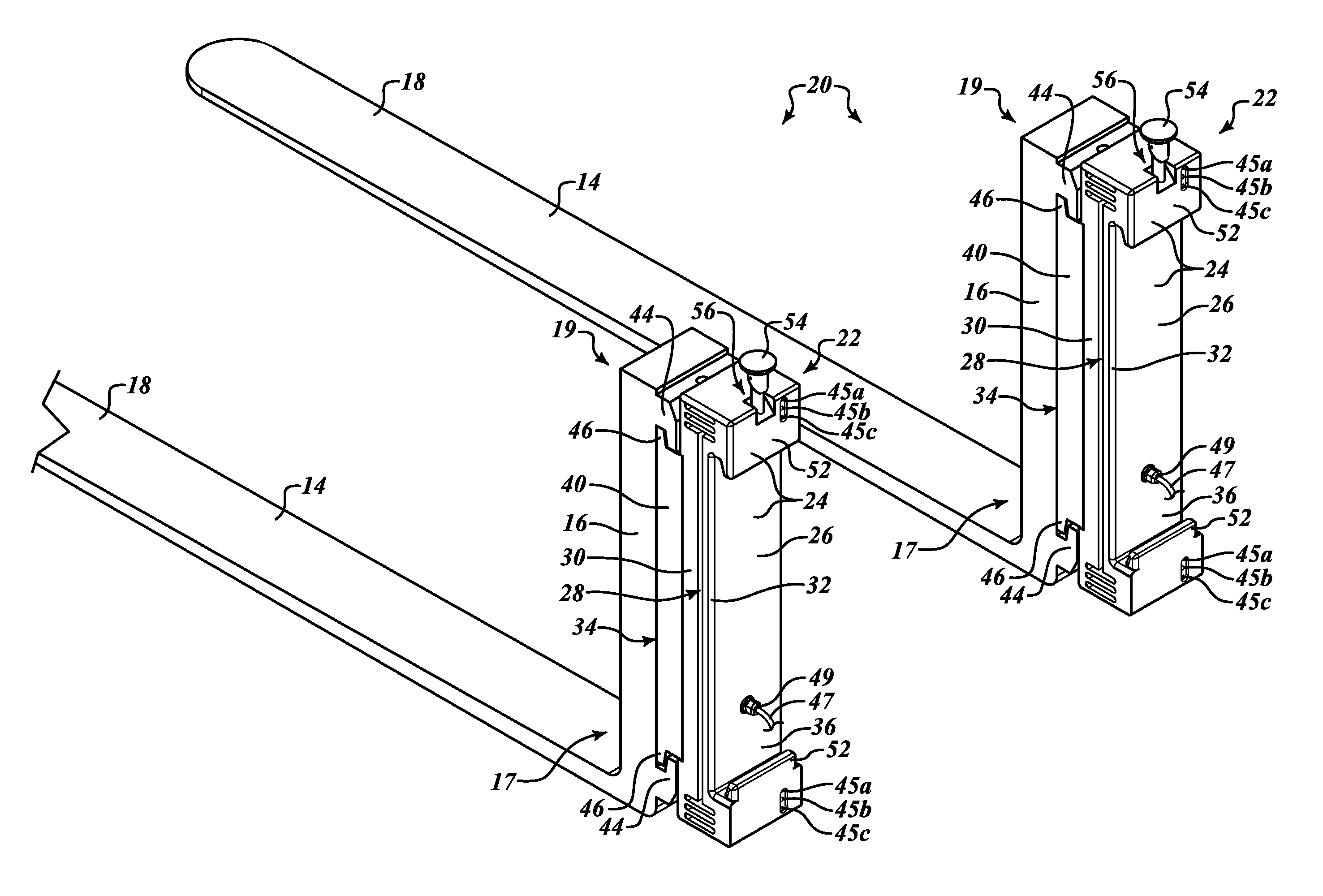

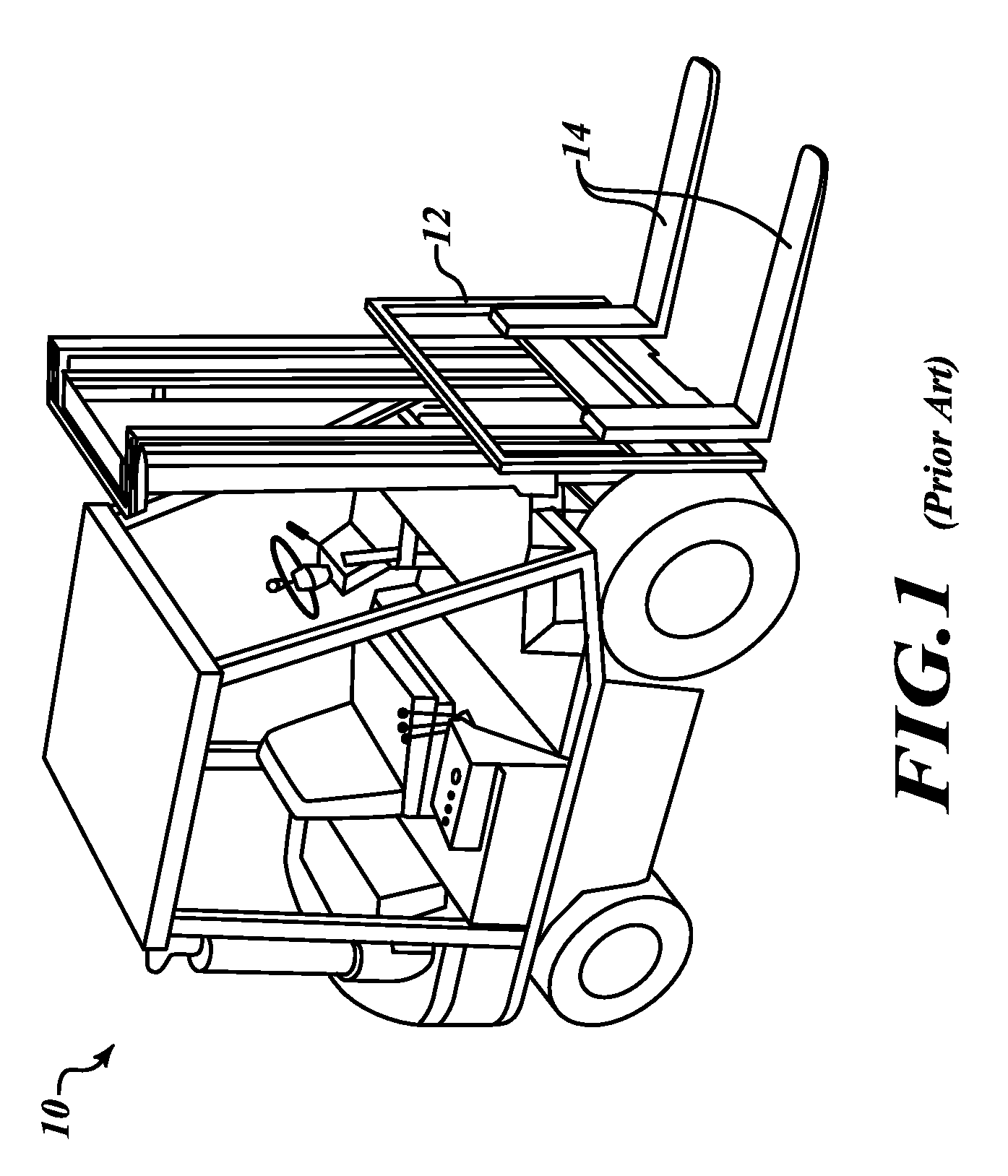

Forklift scale, load cell thereof and method of measuring a forklift load

ActiveUS20140262550A1Easy to installEasy to removeSafety devices for lifting equipmentsWeighing apparatus for materials with special property/formEngineeringLoad cell

A forklift scale to measure a load carried by a pair of forks of a forklift that includes a fork carriage to movably position the forks. The forklift scale includes a pair of load cells that are configured to mount to the fork carriage independent of each other and to removably receive a respective fork of the forklift. Each load cell includes a structural arrangement that couples the respective fork to the fork carriage during operation such that an entirety of the load carried by the forks during operation is transmitted to the carriage via the pair of load cells. Other related forklift scales, load cells thereof and methods of measuring a forklift load are also provided.

Owner:SANTI LARRY D

Flat panel display mounting device

InactiveUS20090065670A1Overcome weakness in structurePrevent movementDigital data processing detailsStands/trestlesDisplay deviceRotation control

A flat panel display mounting device for securing a flat panel display, such as an LCD or plasma television, to a support surface, such as a wall, is disclosed. The flat panel display mounting device comprises a plurality of members in the form of support panels pivotally connected together and a rotation control mechanism connected thereto so that the flat panel display mounted on the device can be rotated to a desired angle and the center of gravity of the flat panel display during rotation can be maintained as close to the support surface as possible, so as not to generate additional burden to the flat panel display mounting device.

Owner:LEW ANDREW H +4

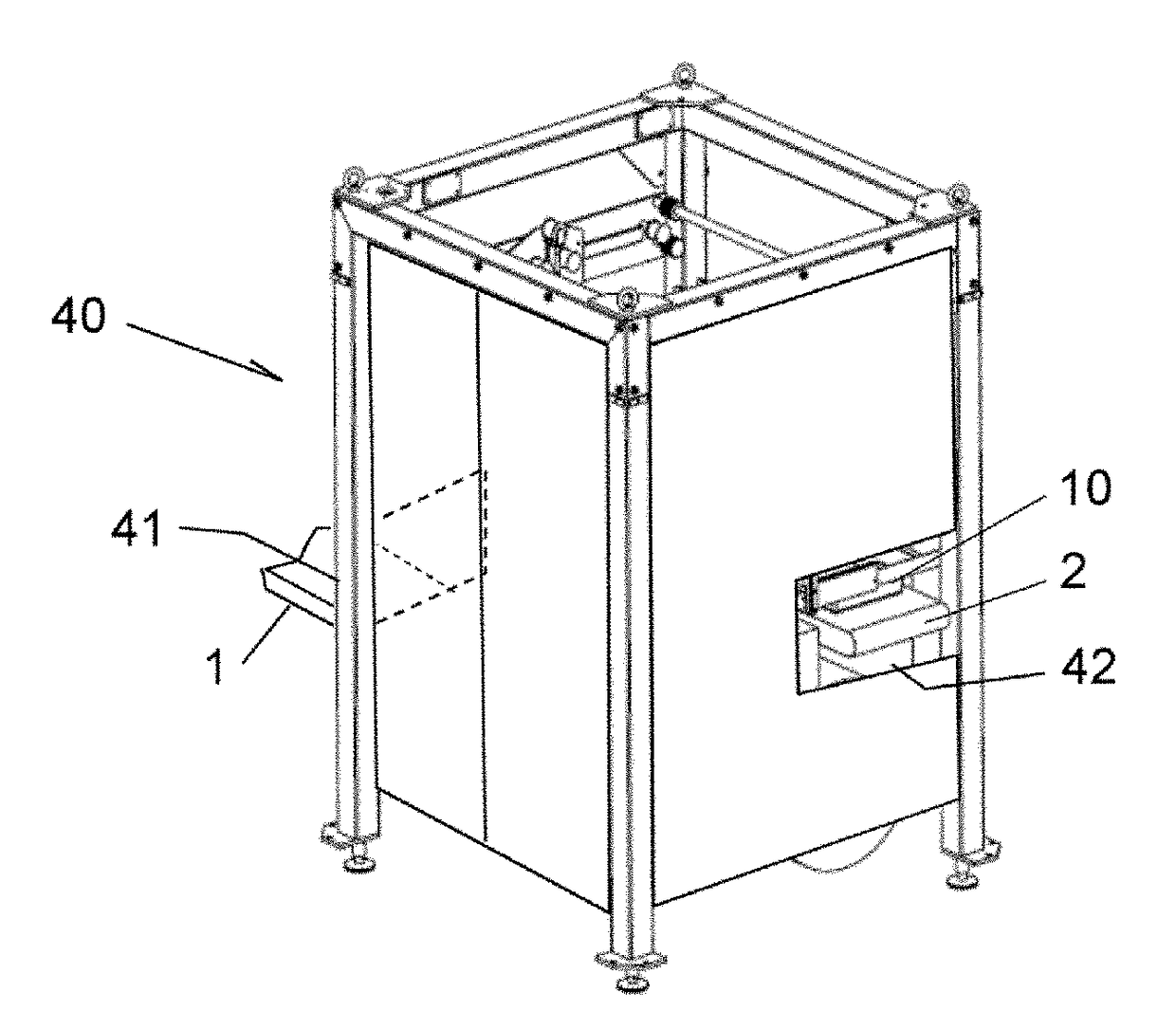

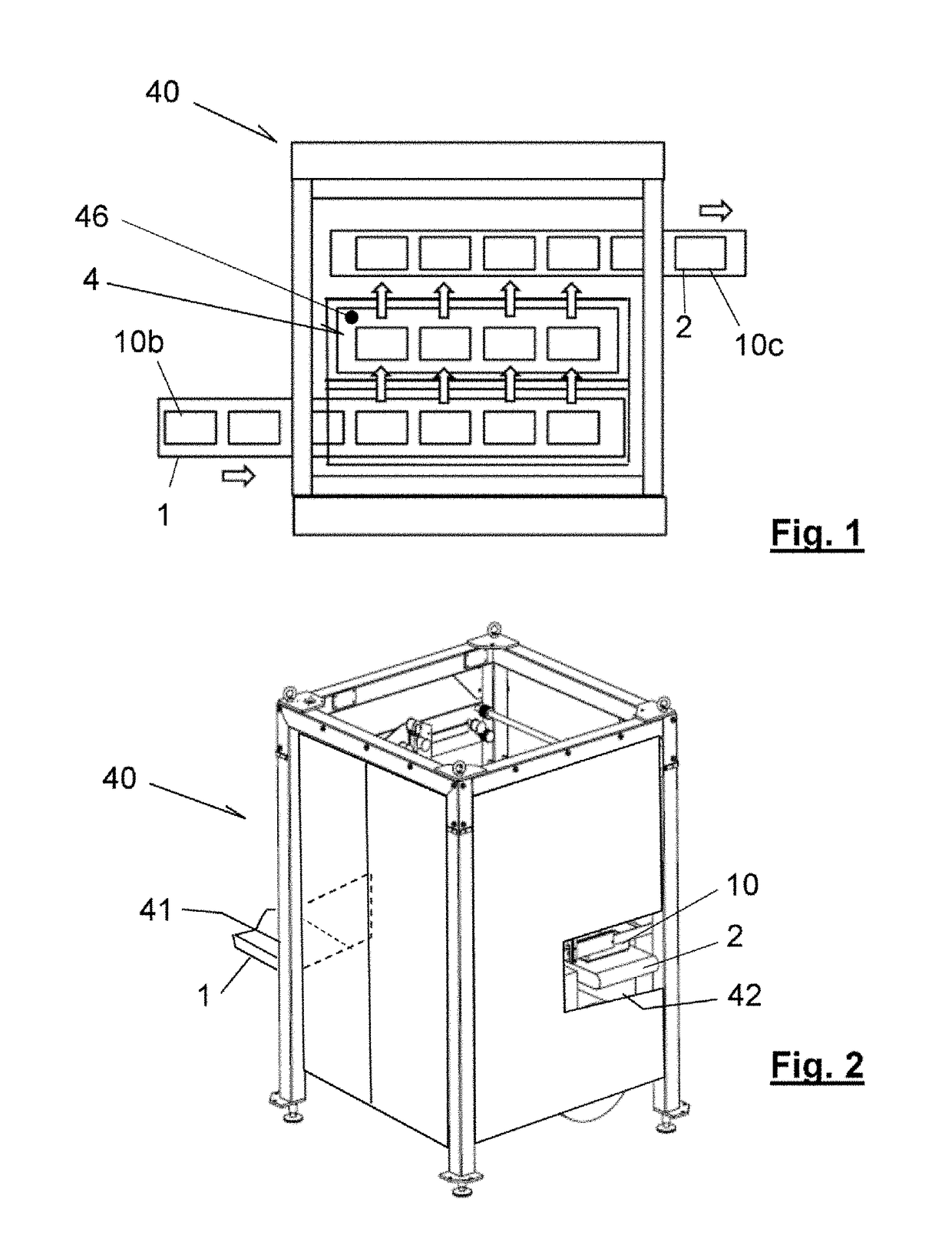

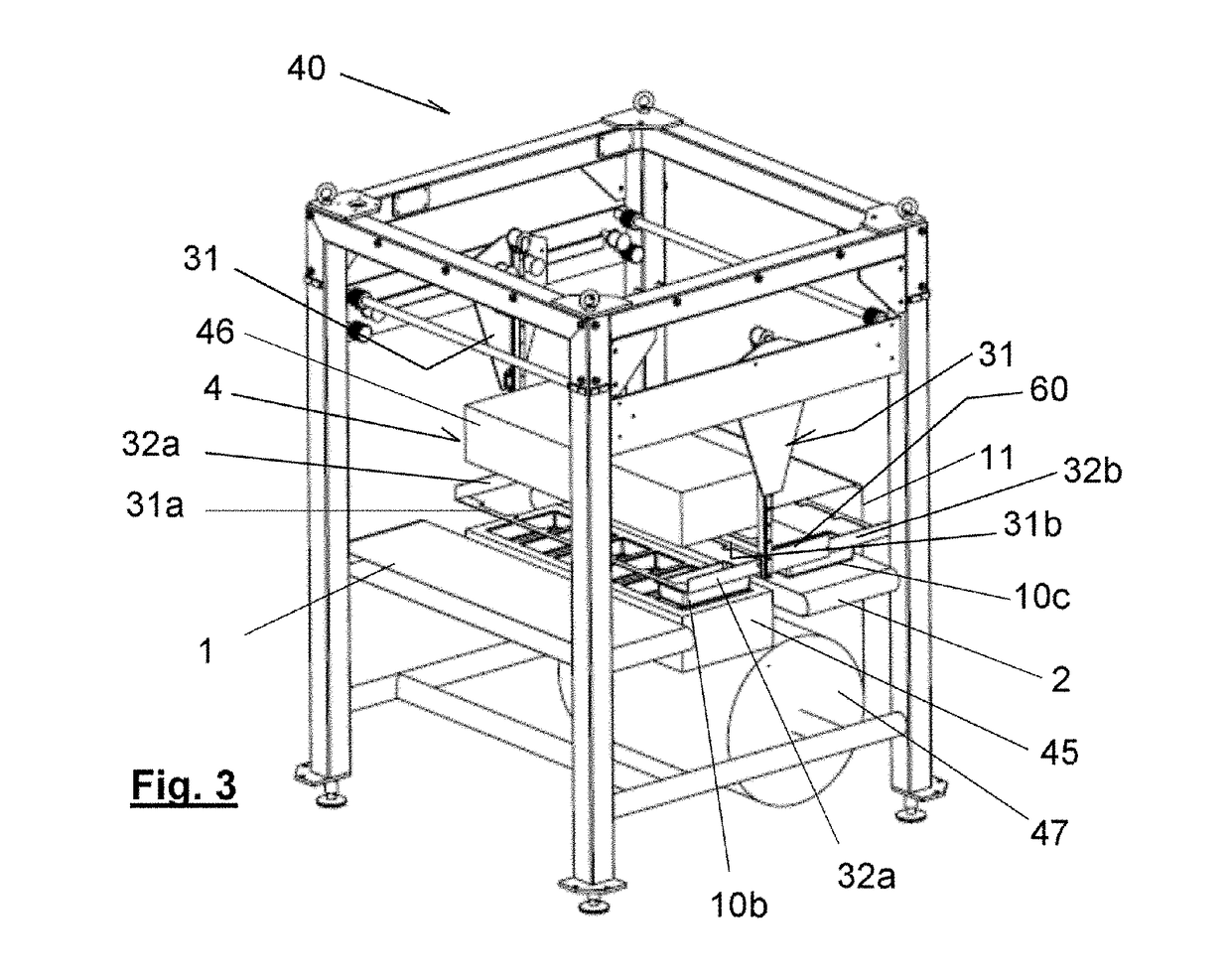

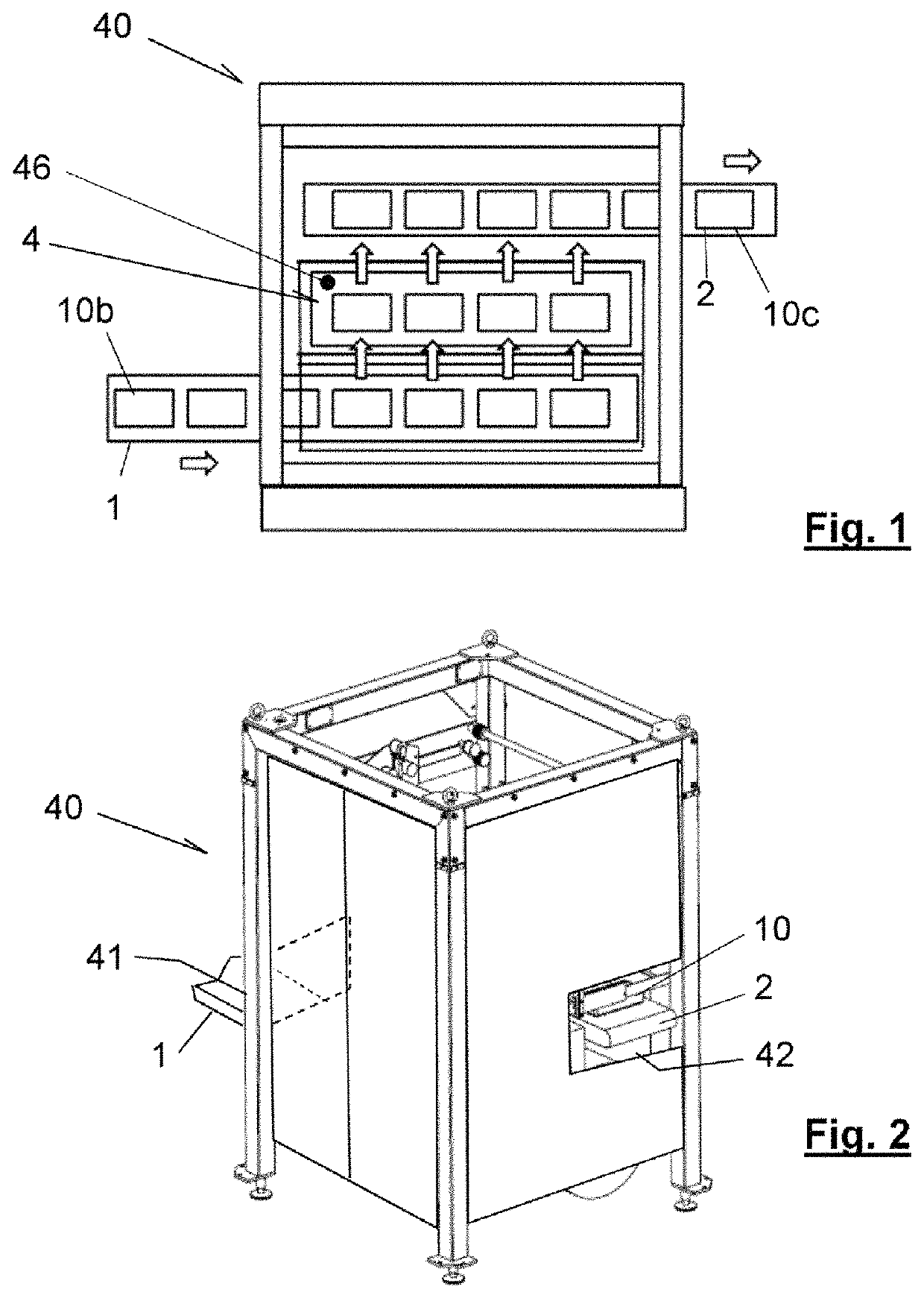

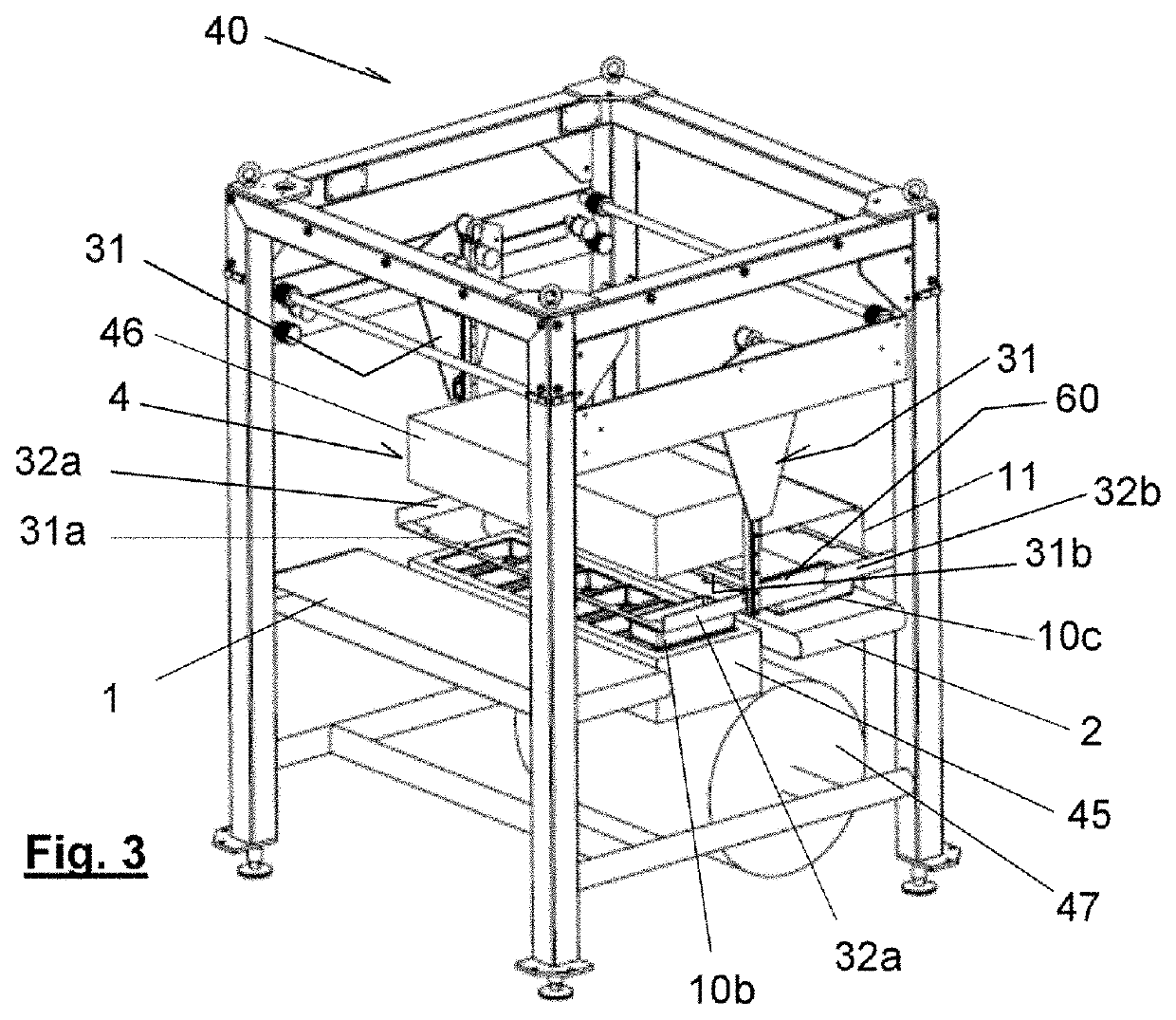

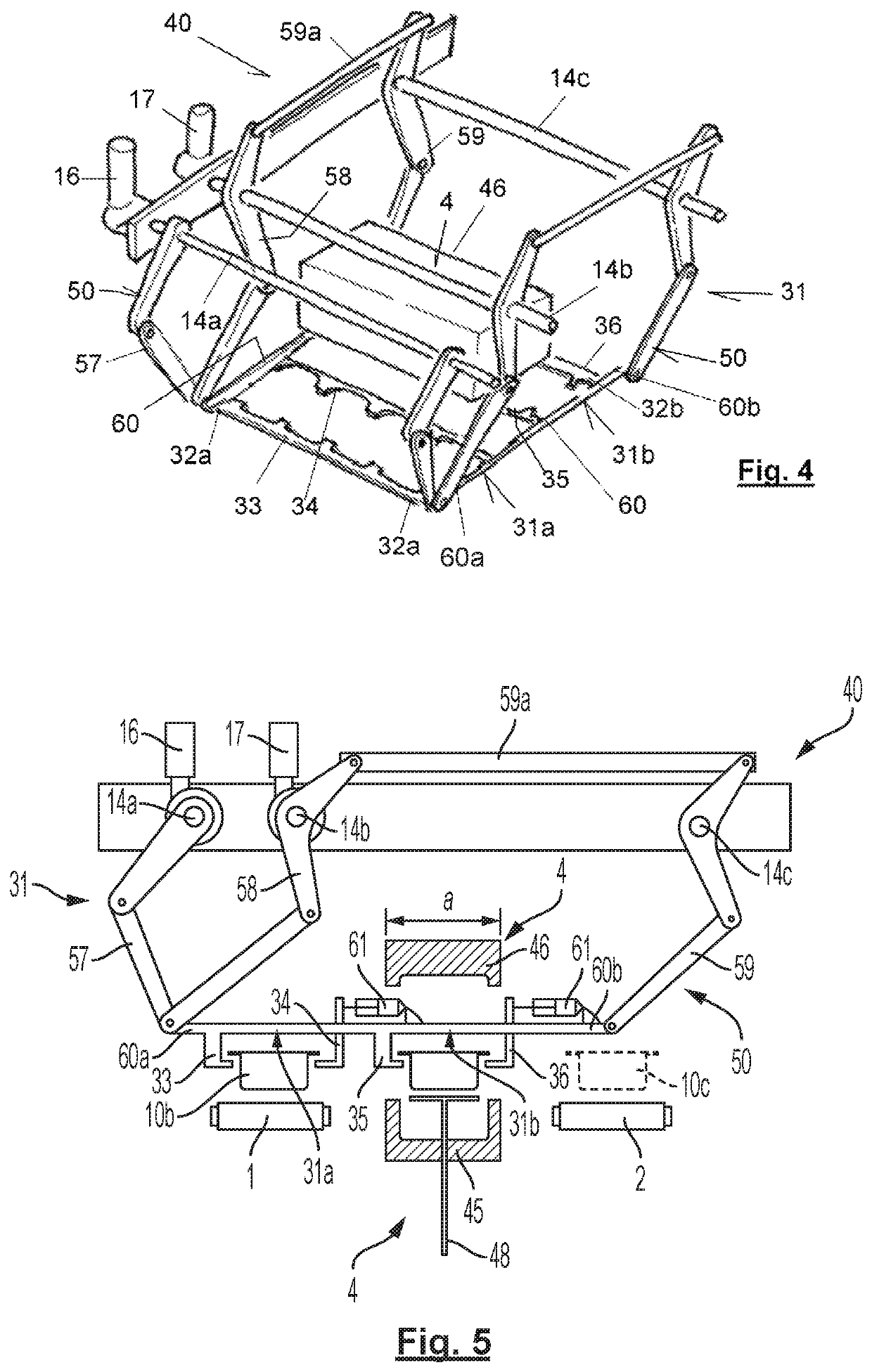

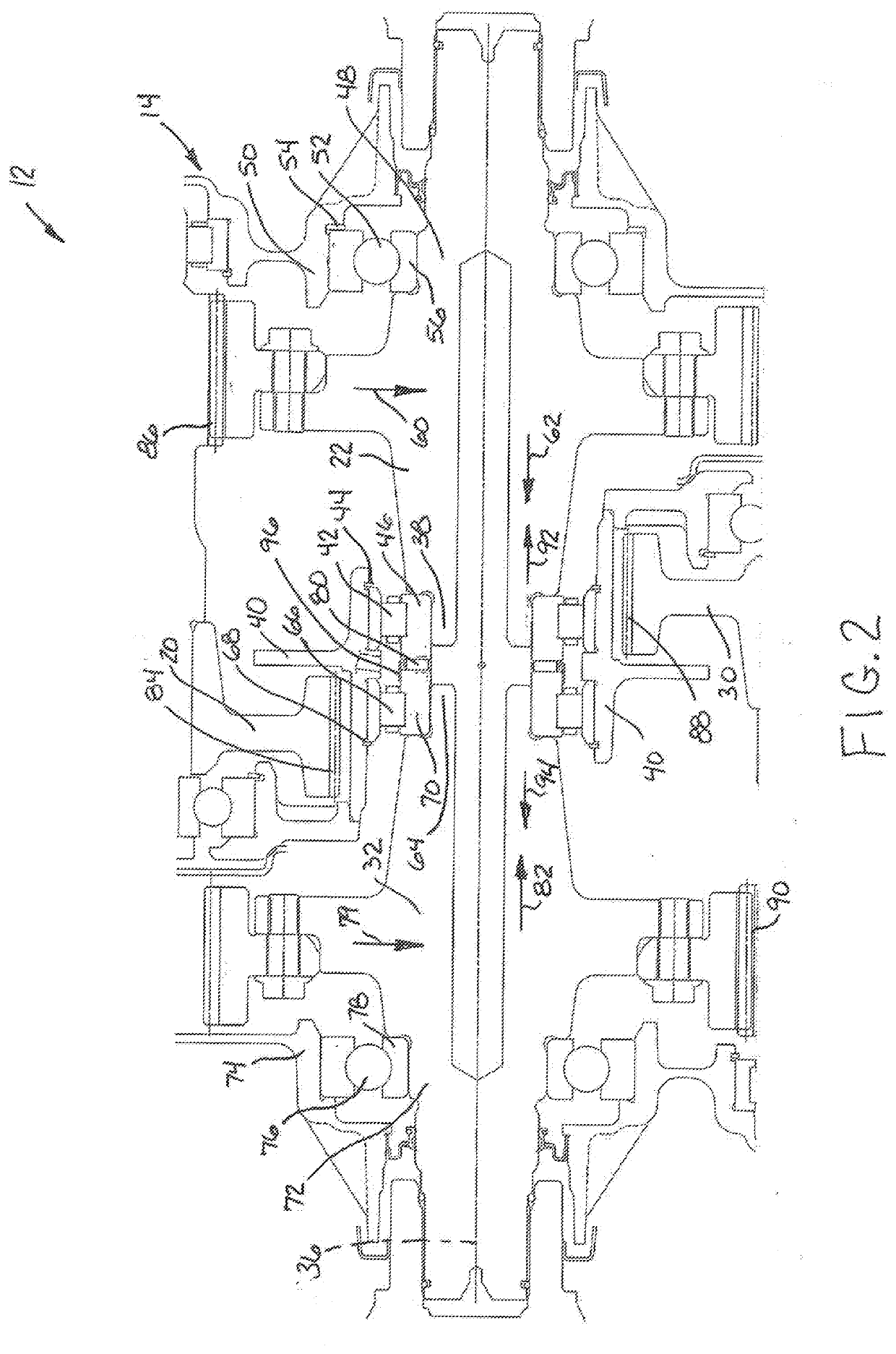

Work station for a packaging line and a packaging line comprising at least two of said work stations

ActiveUS20180029733A1Increase ratingsReduce displacementPackaging automatic controlPackaging under special atmospheric conditionsModular constructionTransfer mechanism

A work station (40) for a packaging line having an apparatus (4) for executing a simultaneous action on packages (10) of an alignment of packages with a tool (46); and a transfer mechanism (31) for the simultaneous transport of an alignment of packages to be processed (10b) to the apparatus (4) and of an alignment of processed packages (10c) from the apparatus (4). The alignments are arranged parallel to each other and the transport direction of the packages are perpendicular to the alignments, the transfer mechanism (31) thus having a first and a second transport group (31a, 31b), one of which hangs from two movable parts (60) of the transfer mechanism (31) which are movable on respective parallel planes of movement and which do not interfere with the vertical projection of the tool (46). A packaging line (101, 102, 103) with modular construction having such work stations.

Owner:NEXES CONTROL DESIGN ENG S L U

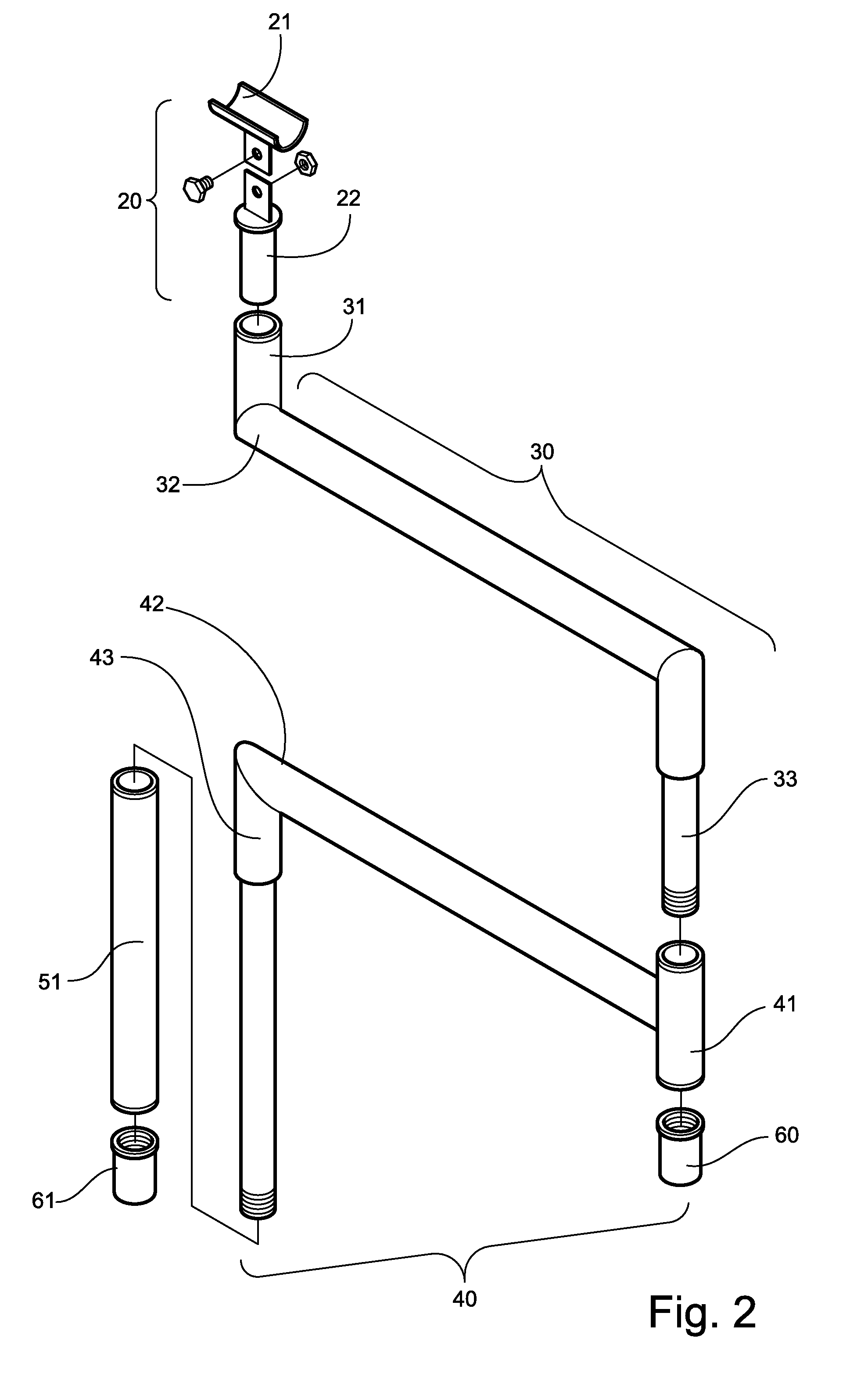

Vehicle sun visors with support rods

InactiveUS7458628B2Easy constructionMinimal displacementAntiglare equipmentMonocoque constructionsVisorMechanical engineering

A vehicle sun visor including a visor body and a support rod disposed on the visor body. The support rod is adapted to engage a support hook mounted to a vehicle cabin ceiling. The support rod includes a core rod member mounted on the visor body and an outer sleeve disposed on the outer peripheral side of the core rod member. The outer sleeve includes first and second semi-circular cylindrical sleeve halves each having at least one resilient engaging portion formed integrally therewith. The resilient engaging portions resiliently engage an outer peripheral surface of the core rod member. The semi-circular cylindrical sleeve halves may have similar configurations with each other.

Owner:KYOWA SANGYO +1

Forklift scale, load cell thereof and method of measuring a forklift load

ActiveUS9562804B2Easy to installEasy to removeSafety devices for lifting equipmentsSpecial purpose weighing apparatusEngineeringLoad cell

A forklift scale to measure a load carried by a pair of forks of a forklift that includes a fork carriage to movably position the forks. The forklift scale includes a pair of load cells that are configured to mount to the fork carriage independent of each other and to removably receive a respective fork of the forklift. Each load cell includes a structural arrangement that couples the respective fork to the fork carriage during operation such that an entirety of the load carried by the forks during operation is transmitted to the carriage via the pair of load cells. Other related forklift scales, load cells thereof and methods of measuring a forklift load are also provided.

Owner:SANTI LARRY D

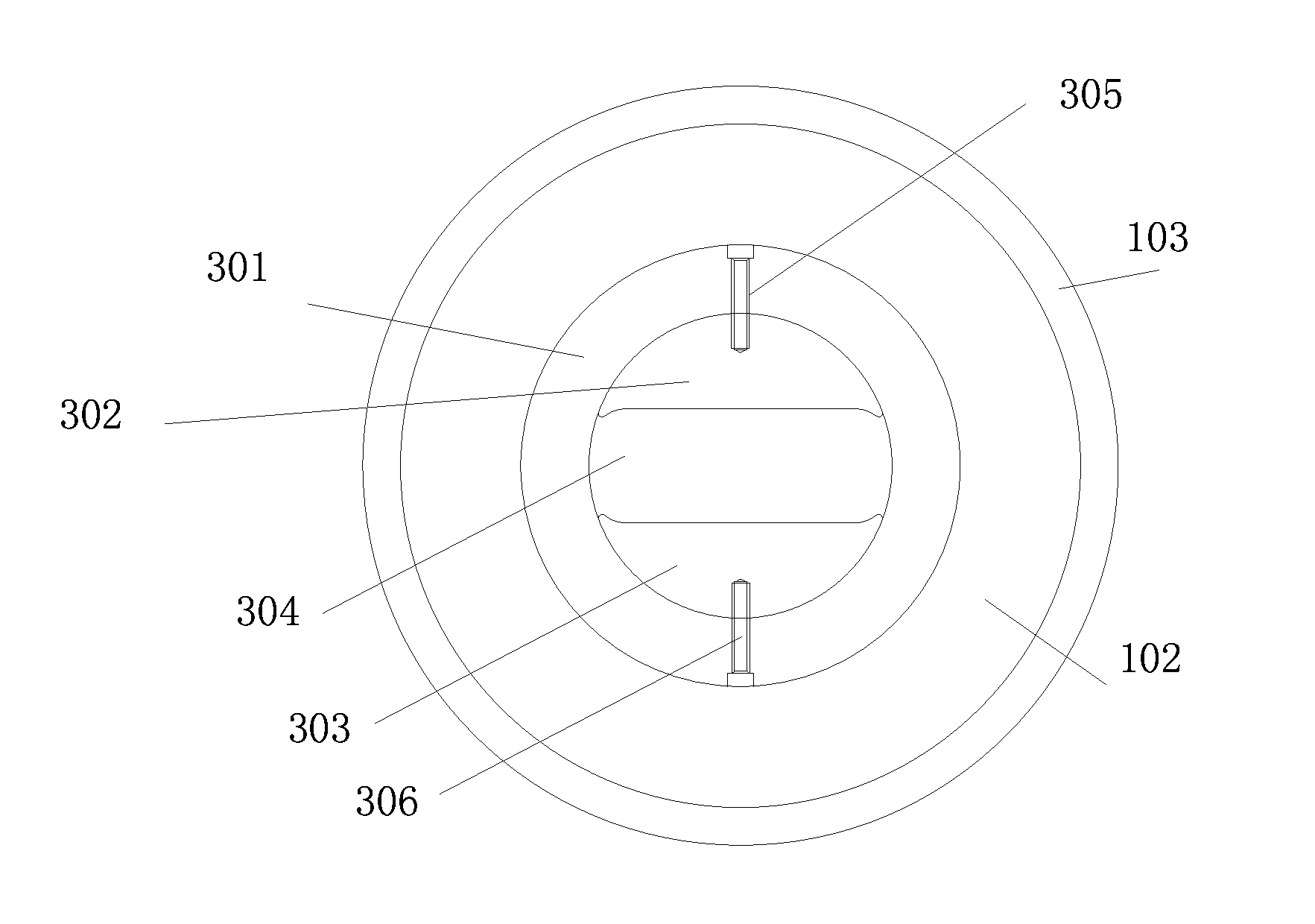

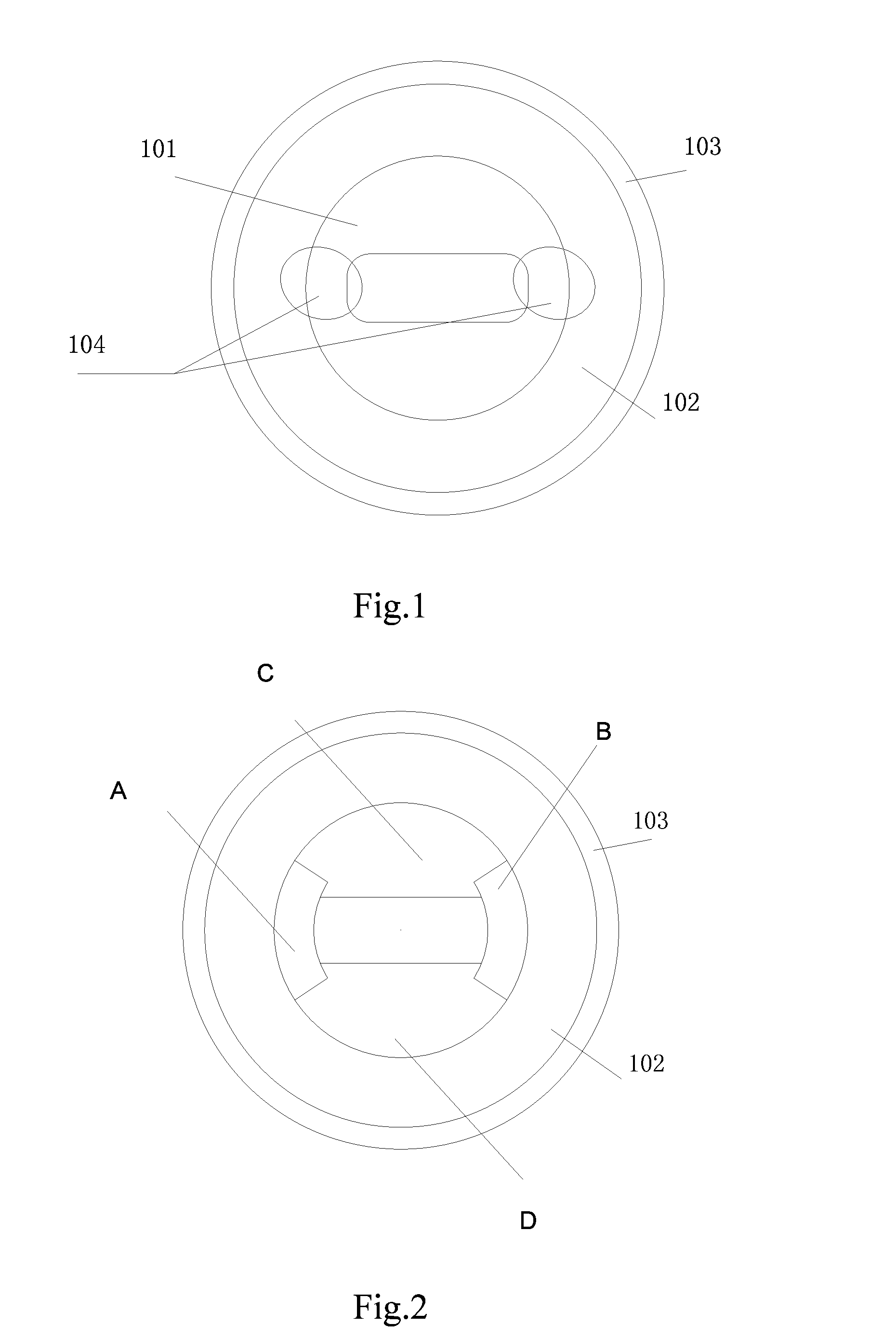

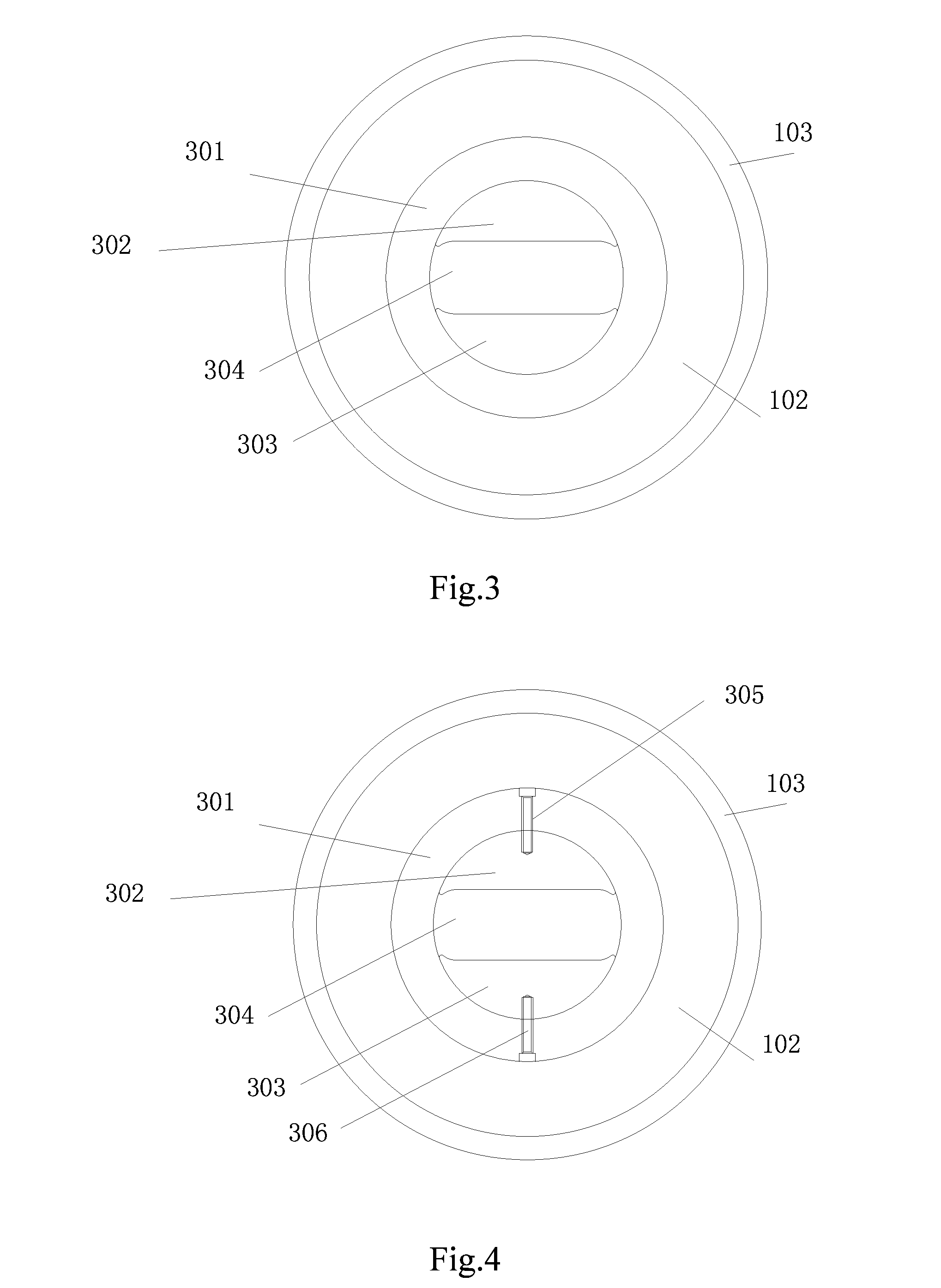

Inner sleeve for a flat extrusion cylinder and a flat extrusion cylinder

InactiveUS20120125069A1Extend your lifeImprove stress distributionExtrusion diesExtrusion containersStress distributionEngineering

An inner sleeve for a flat extrusion cylinder includes an inner sleeve ring piece, an upper insert piece and a lower insert piece. The inner sleeve ring piece is positioned in an intermediate sleeve of the flat extrusion cylinder. The upper insert piece and the lower insert piece are symmetrically disposed on an inner wall of the inner sleeve ring piece to form an inner sleeve working die cavity of the flat extrusion cylinder. Arc surfaces of two insert pieces match with the arc inner wall of the inner sleeve ring piece, so as to improve the stress distribution at interface portions between the flat surface and the arc surface of the inner sleeve working die cavity. When the flat extrusion cylinder is operated, the insert pieces will make a minor displacement in upward and downward direction due to the pressure from the inner sleeve working die cavity, such that the inner sleeve ring piece is elastically deformed in a circumferential direction, thereby generating a resisting force against the peak stress in the cylinder. In the flat extrusion cylinder according to the present invention, concentrated internal stress is uniformly transmitted to the inner sleeve ring piece, which decreases the peak stress in dangerous sections and achieves cylinder-type stress distribution in the flat extrusion cylinder. Thus, the stress received by the inner sleeve ring piece is distributed uniformly, thereby increasing the lifespan of the entire flat extrusion cylinder.

Owner:SOUTHWEST ALUMINUM GRP

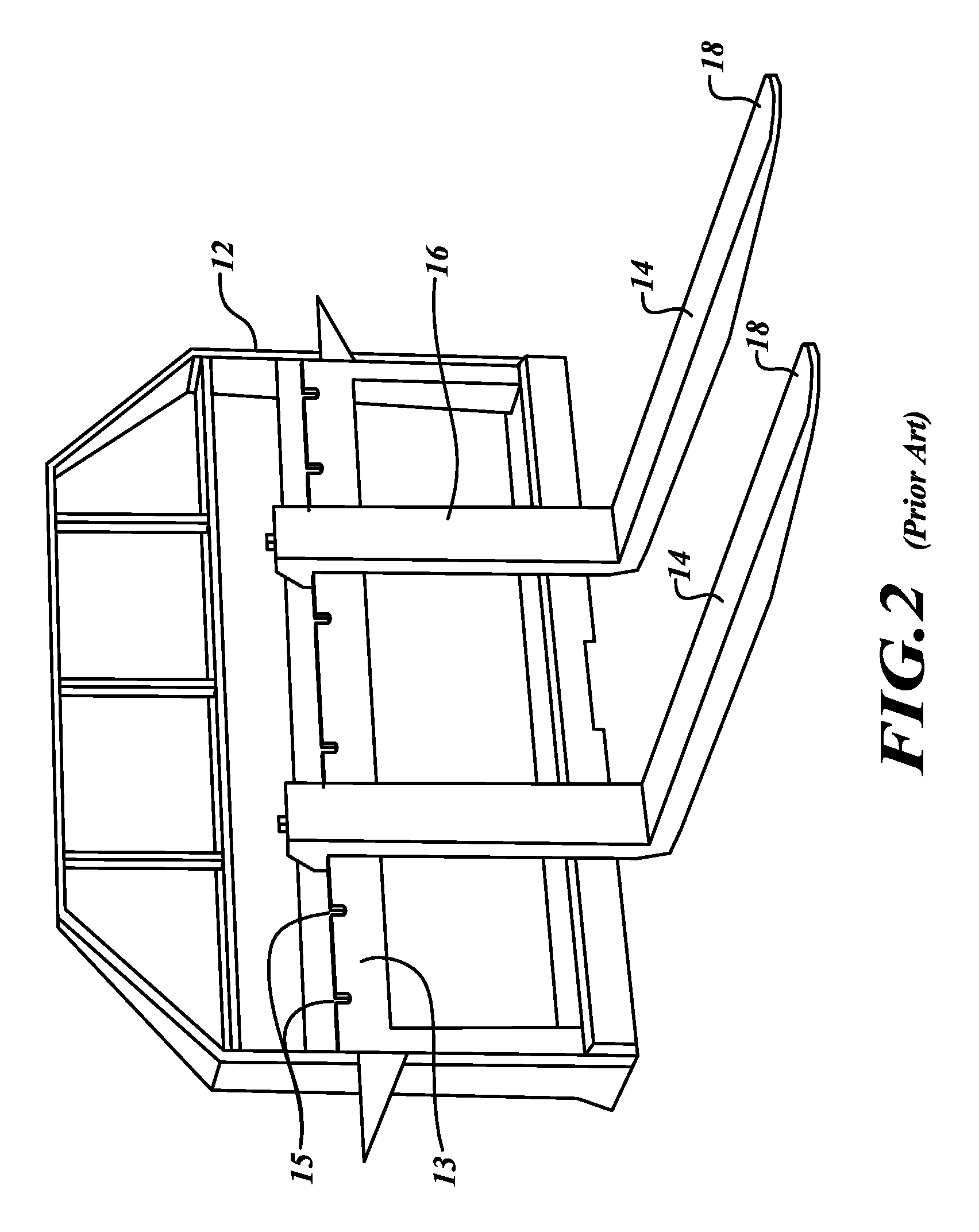

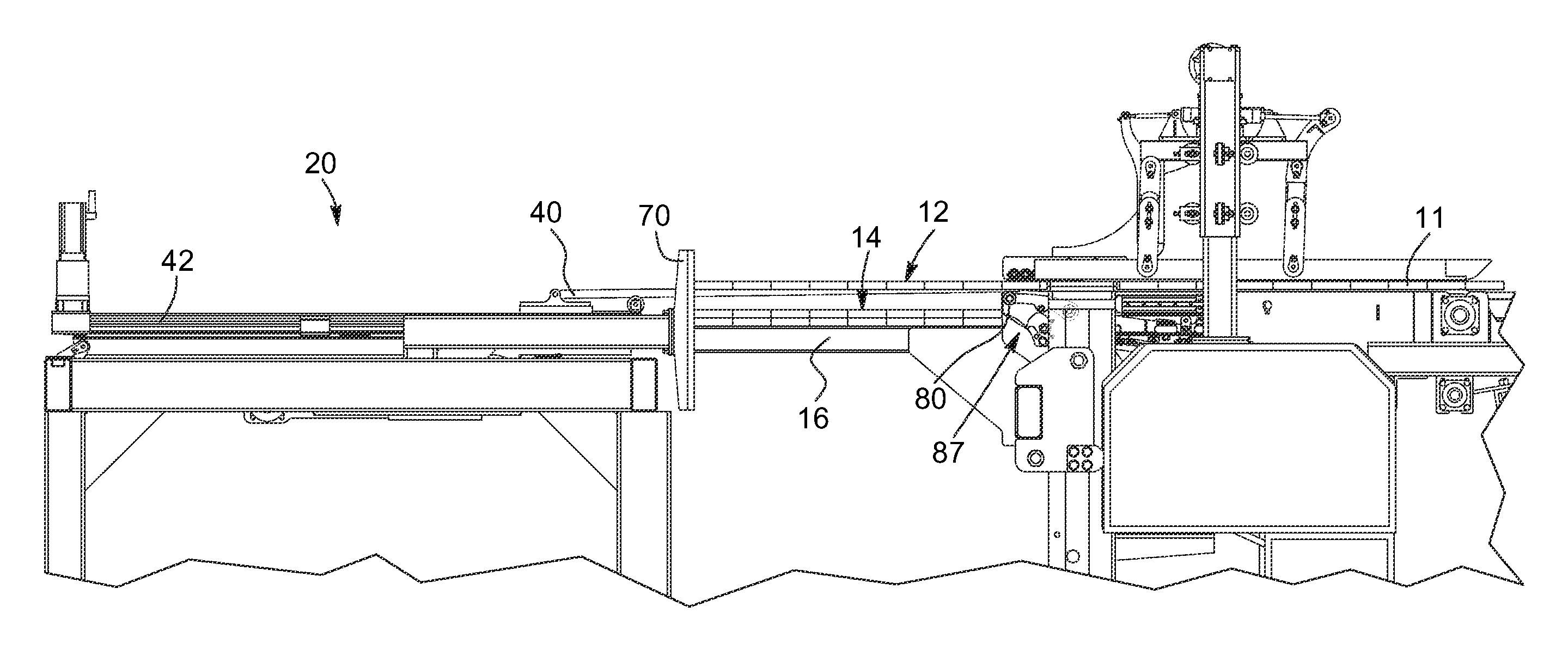

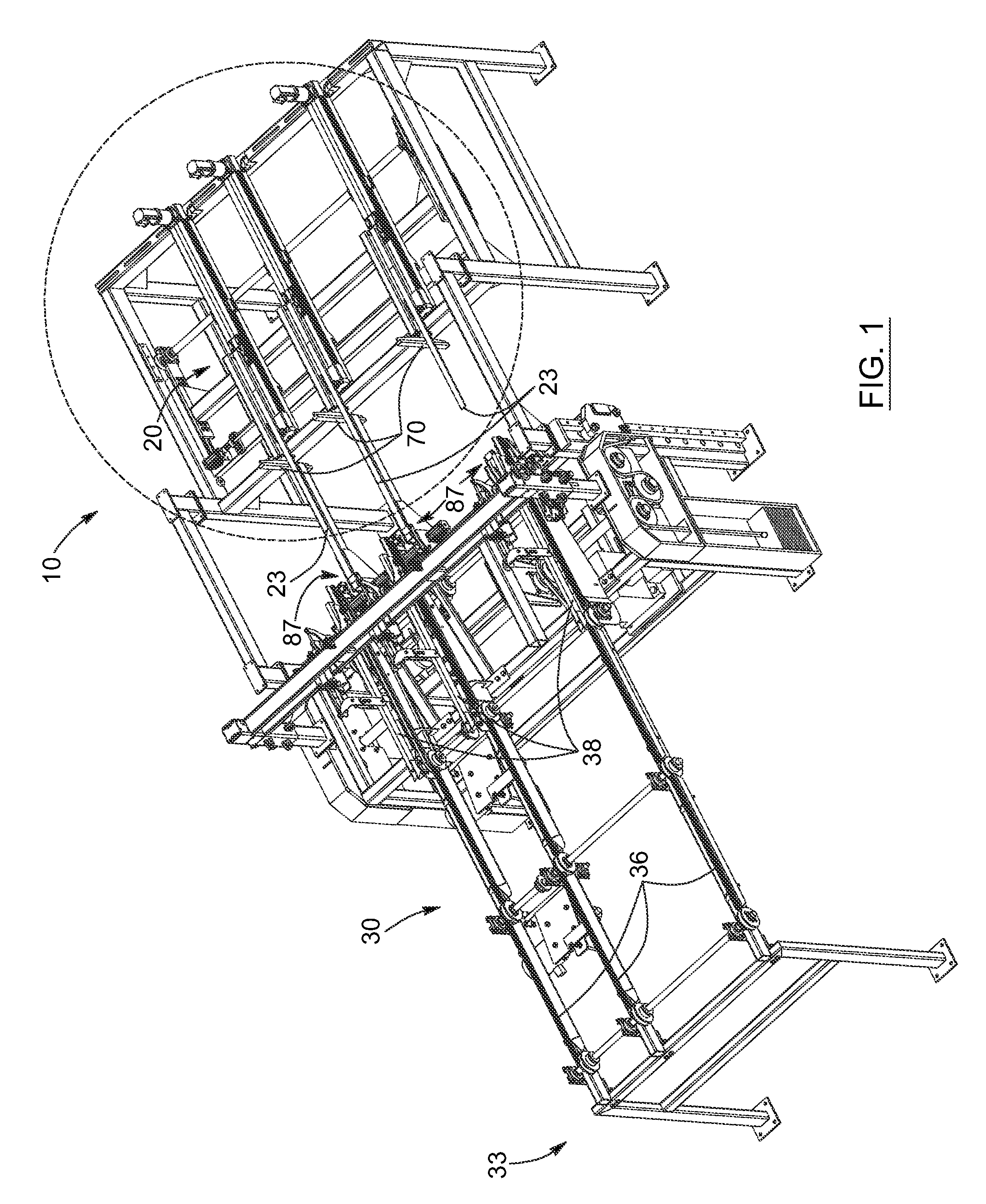

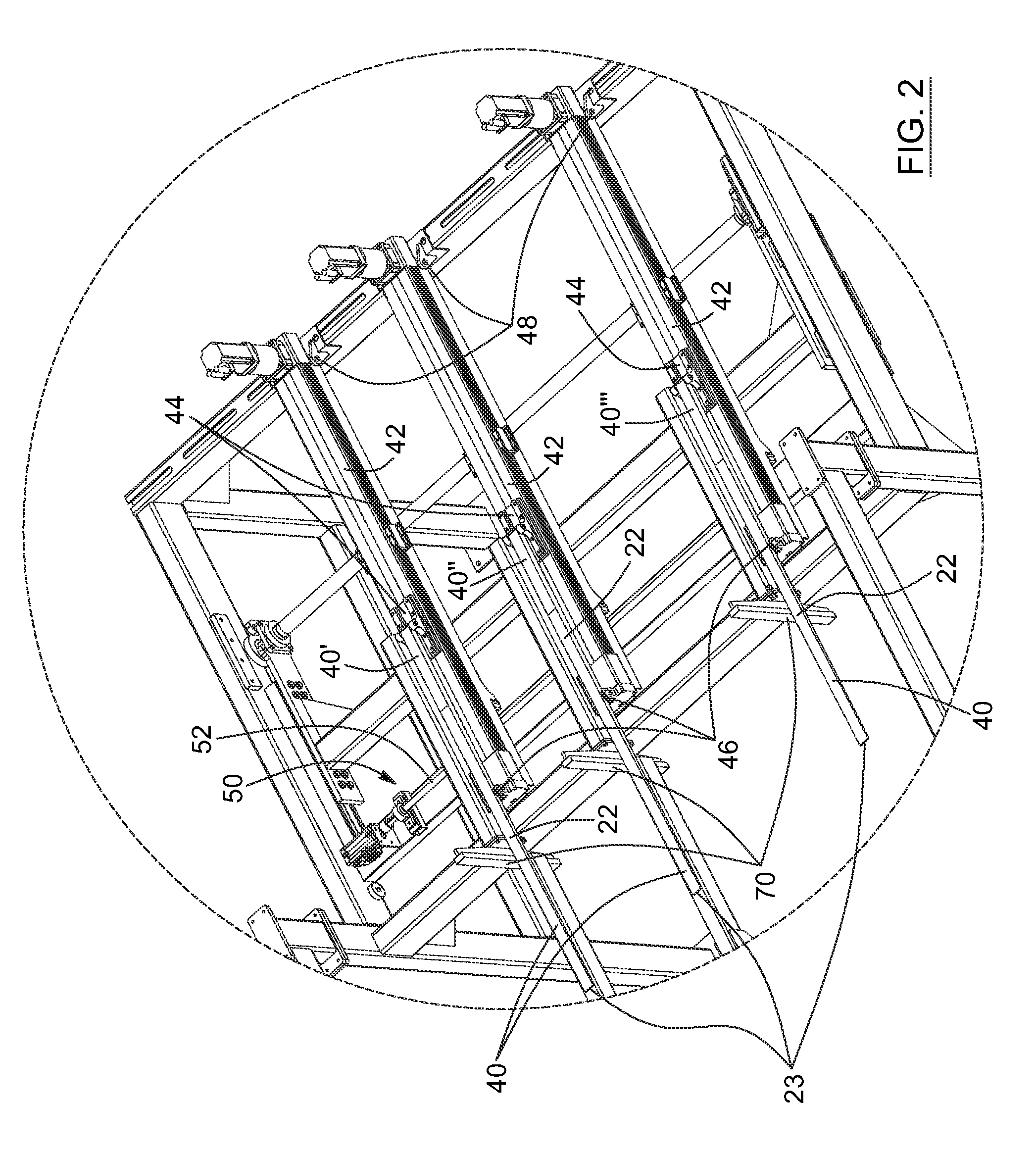

Board stacking apparatus

ActiveUS9272852B2Increase stacking speedReduced Power RequirementsConveyorsStacking articlesEngineeringMechanical engineering

A board stacking apparatus having one or more movable supports having at least two arms each, a rear stopper and a power assembly operatively connected to the movable support to move the same according to a layer stacking routine. The layer stacking routine includes positioning the movable support at a receiving position, maintaining the movable support in the receiving position while the boards are dispensed thereon, and moving the movable support in a rearward direction. The board stacking apparatus further comprises abutment components located proximate to and slightly below a board dispensing mechanism of the apparatus to support the receiving end of corresponding arms when in the receiving position.

Owner:9374-4399 QUEBEC INC

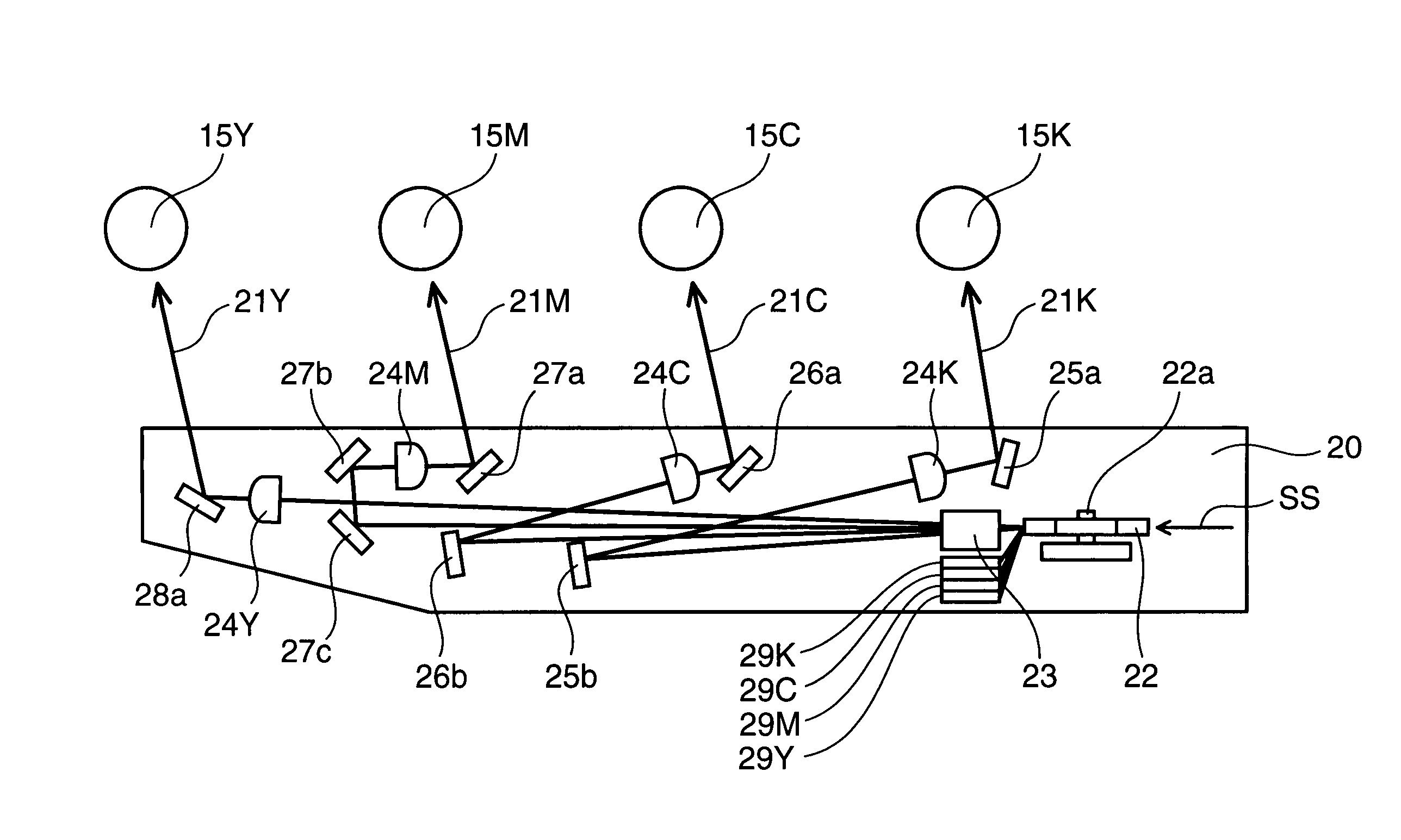

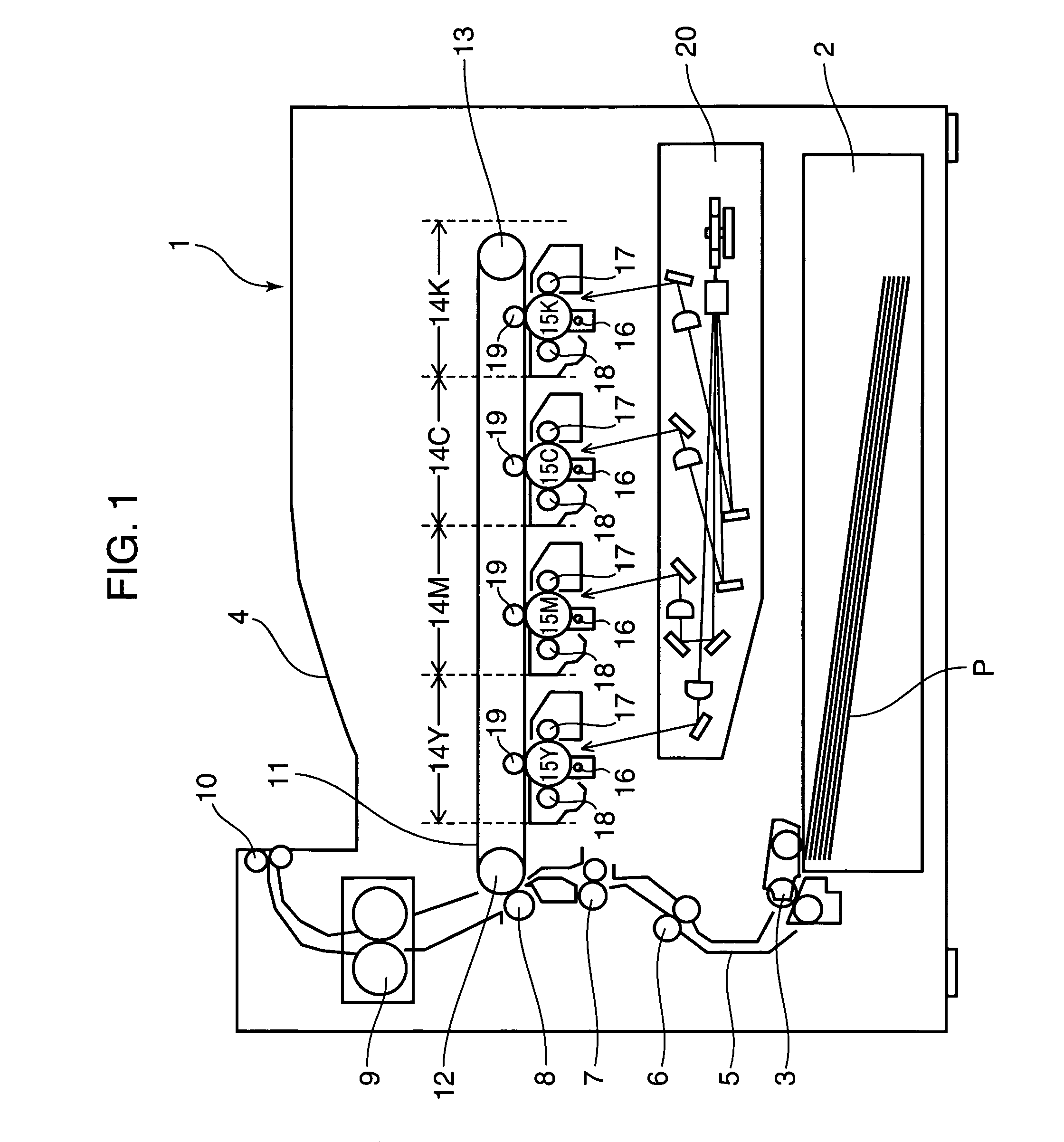

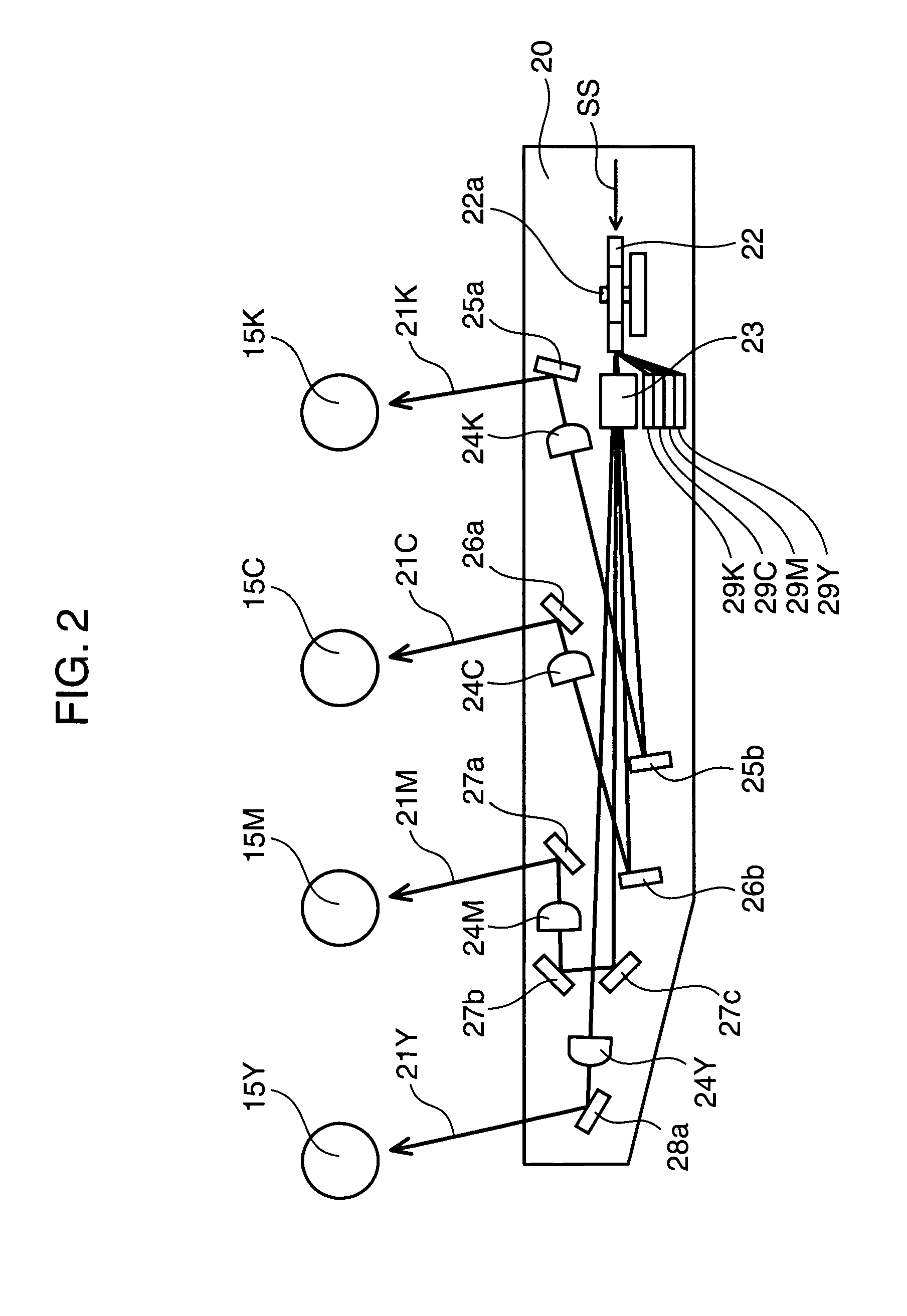

Optical scanning device and image forming apparatus equipped with the same

ActiveUS7518771B2Reduce colorReduce brightnessInking apparatusElectrographic process apparatusColor imageVisibility

An optical scanning device is configured in such a manner that, of four light beams for colors corresponding to black, cyan, magenta, and yellow, the angle of the reflection surface of the last folding mirror disposed in the optical path of a light beam corresponding to an image in black having the lowest brightness and the highest visibility is closest to vertical, and further, the angle of the reflection surface of the last folding mirror disposed in the optical path of a light beam corresponding to an image in yellow having the highest brightness and the lowest visibility is closest to horizontal. It is thus possible to reduce a color shift in the color image caused by reflecting a light beam having passed through the correction lens on the last folding mirror.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

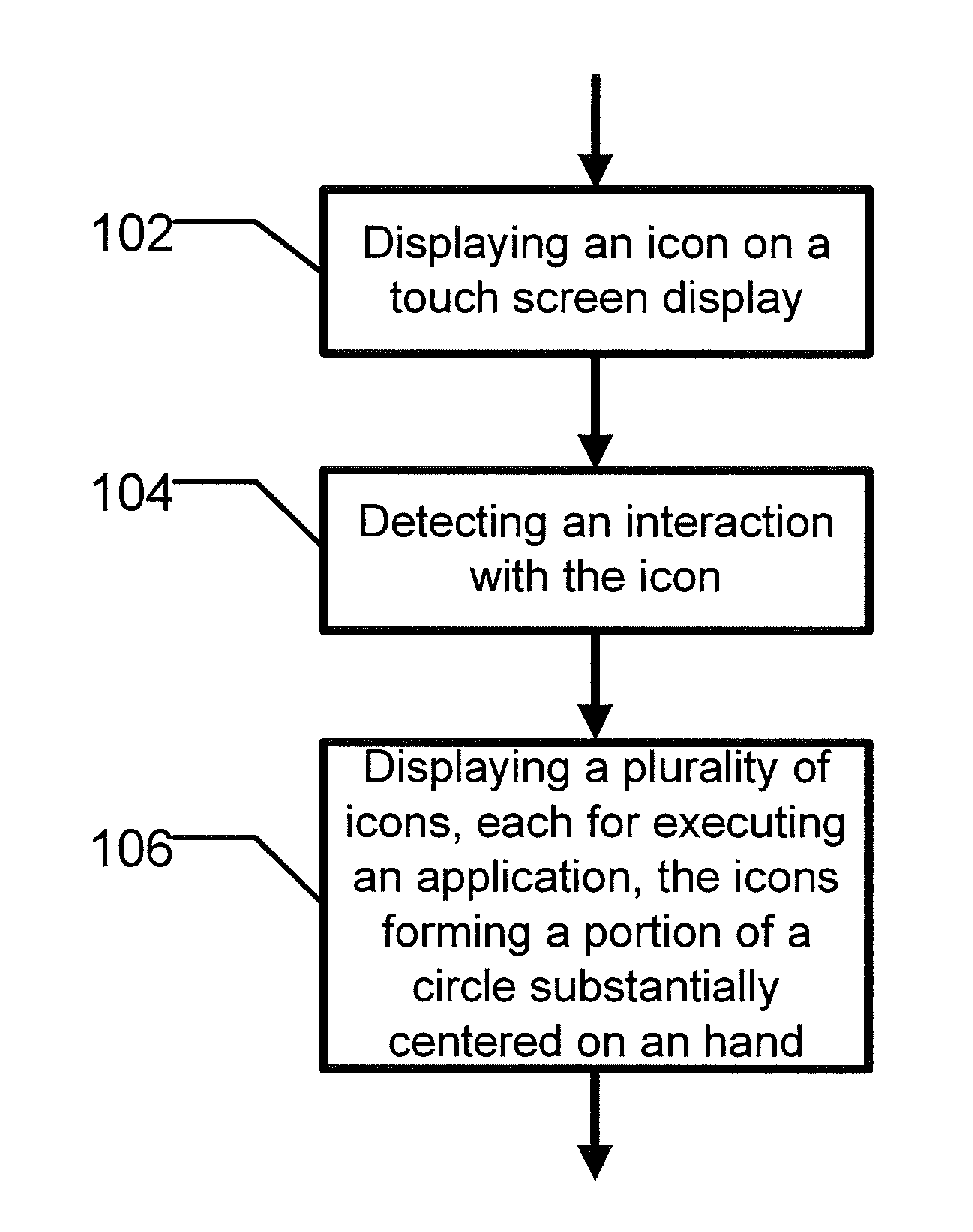

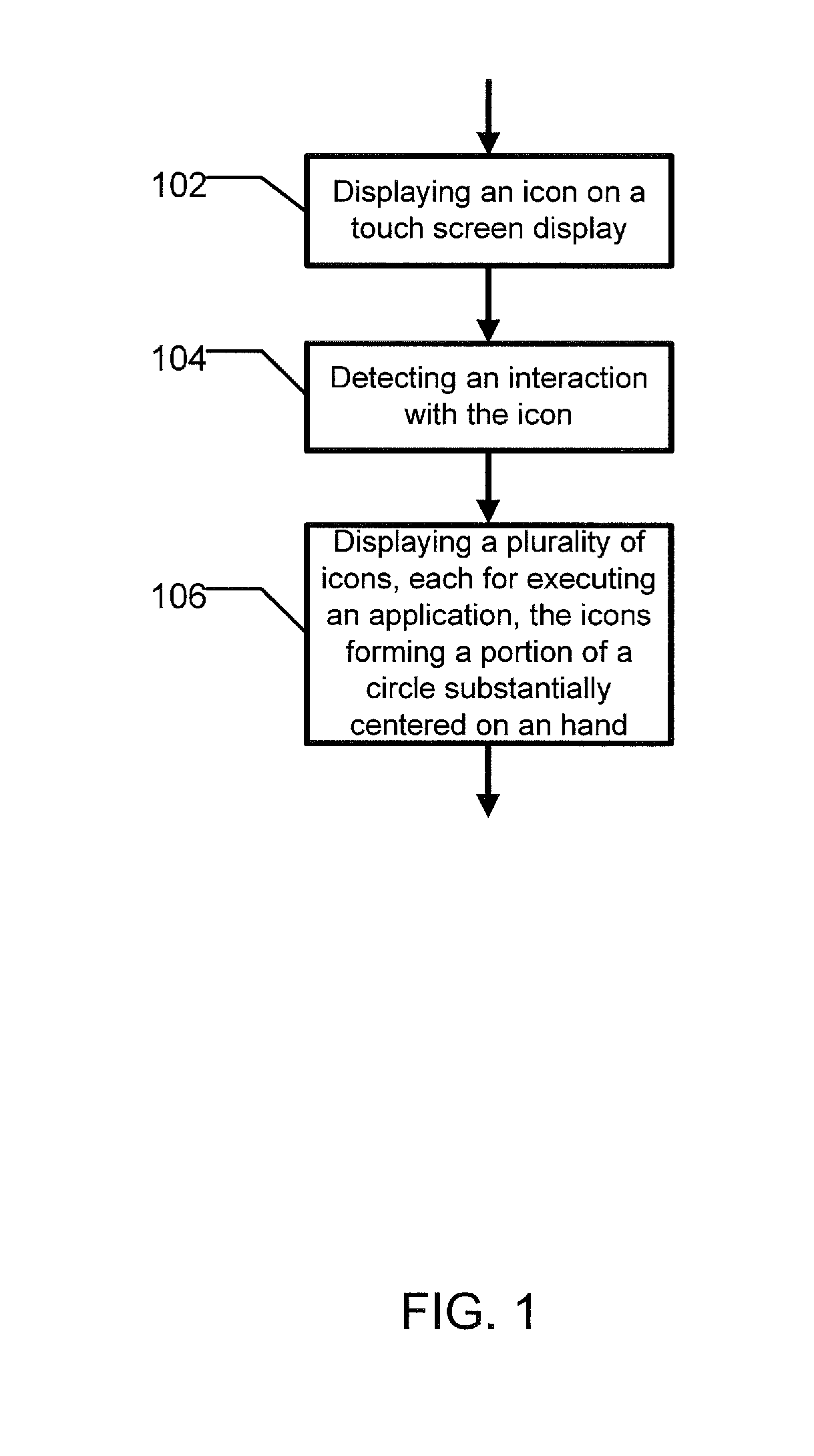

User interface and method for providing same

InactiveUS20130152016A1Minimal displacementInput/output processes for data processingDisplay deviceApplication software

A method for providing a user interface on a touch screen display, the user interface for performing one of executing an application, accessing a file and accessing a weblink, the method comprising displaying an icon on the touch screen display; detecting an interaction with the icon displayed, said interaction being performed by a hand of a user; displaying a plurality of icons on the touch screen display, each icon of the plurality of icons for performing one of executing an application, accessing a file and accessing a weblink, the plurality of icons forming a portion of a circle substantially centered on the hand such that each icon is accessible with a minimum displacement of a finger of an open hand of the user.

Owner:MARTINOLI JEAN BAPTISTE

Vehicle sun visors with support rods

InactiveUS20050264023A1Easy constructionMinimal displacementAntiglare equipmentMonocoque constructionsEngineeringMechanical engineering

A vehicle sun visor including a visor body and a support rod disposed on the visor body. The support rod is adapted to engage a support hook mounted to a vehicle cabin ceiling. The support rod includes a core rod member mounted on the visor body and an outer sleeve disposed on the outer peripheral side of the core rod member. The outer sleeve includes first and second semi-circular cylindrical sleeve halves each having at least one resilient engaging portion formed integrally therewith. The resilient engaging portions resiliently engage an outer peripheral surface of the core rod member. The semi-circular cylindrical sleeve halves may have similar configurations with each other.

Owner:KYOWA SANGYO +1

Bearing and shaft arrangement for electric drive unit

ActiveUS11413947B2Improve noiseIncrease vibrationShaftsElectric propulsion mountingThrust bearingElectric drive

A bearing and shaft arrangement of an automobile vehicle electric drive unit includes a gearbox. A first electric motor within the gearbox is engaged with and axially rotates a first shaft within the gearbox. A second electric motor within the gearbox is engaged with and axially rotates a second shaft within the gearbox. A first roller bearing assembly supports the first shaft to a first structural member of the gearbox. A second roller bearing assembly supports the second shaft to the first structural member of the gearbox. A thrust bearing is positioned between the first roller bearing assembly and the second roller bearing assembly and directly contacts the first shaft and the second shaft in a drive mode and reacts a first axial load of the first shaft and a second axial load of the second shaft directed toward the first axial load.

Owner:GM GLOBAL TECH OPERATIONS LLC

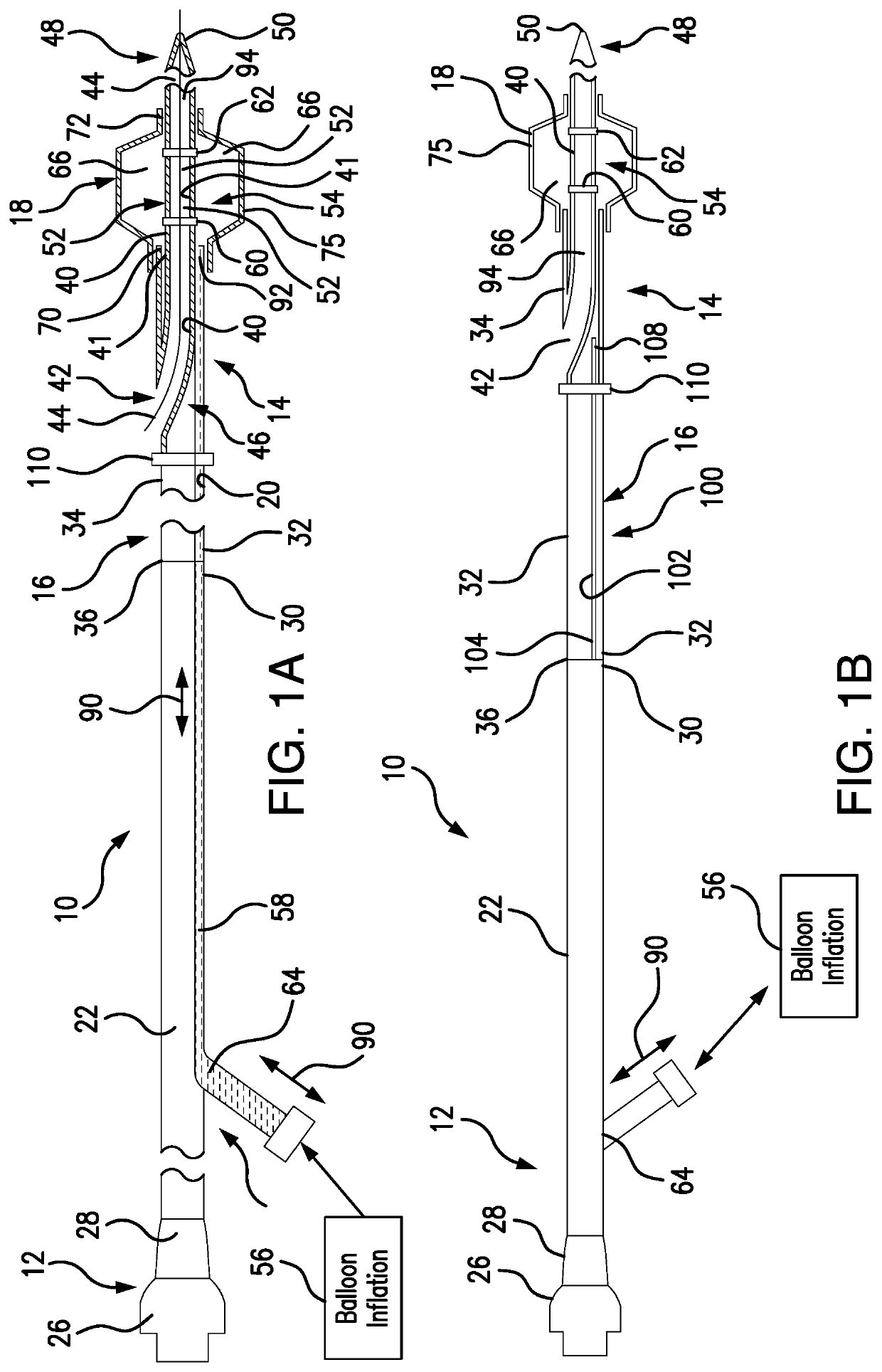

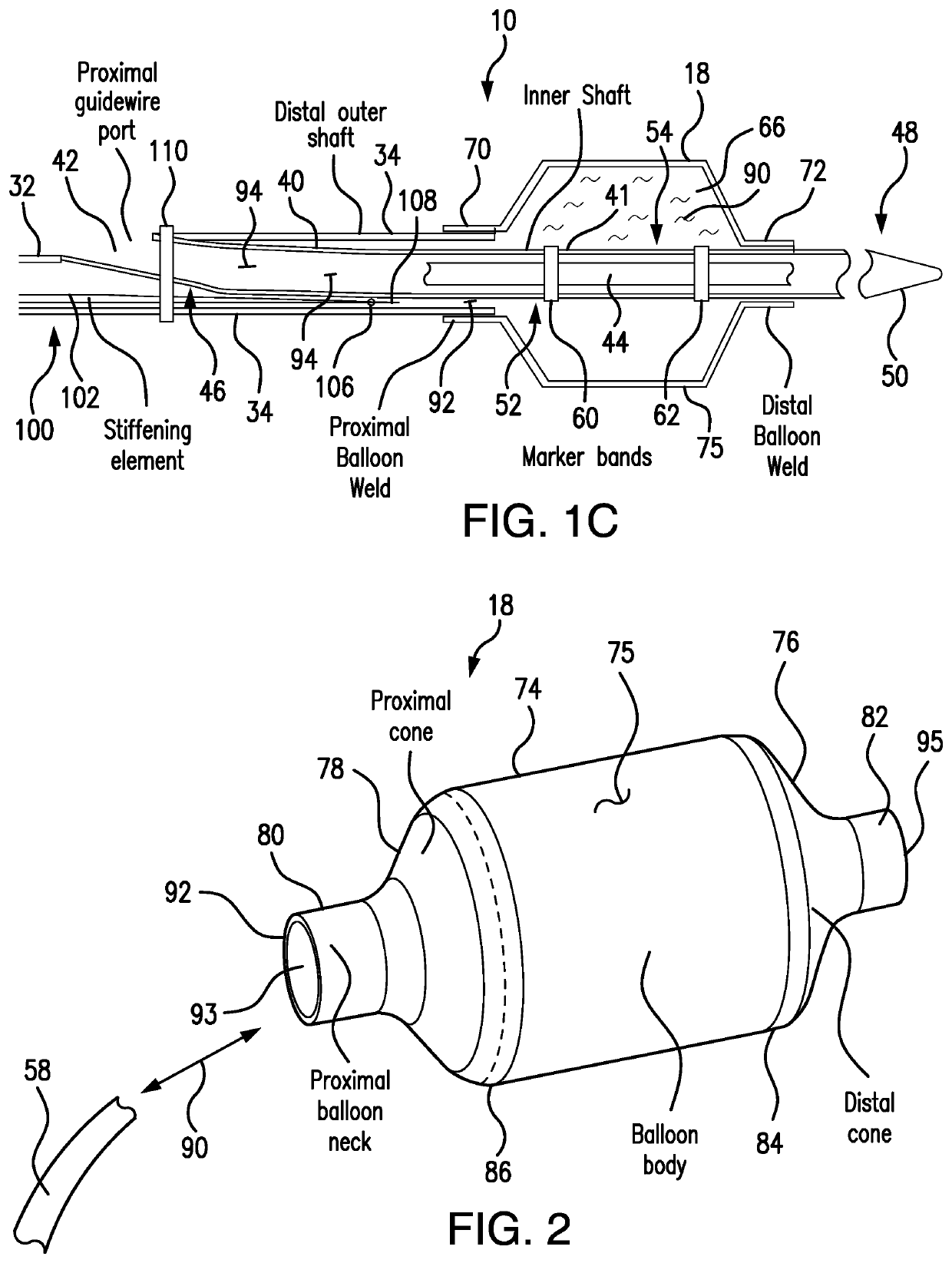

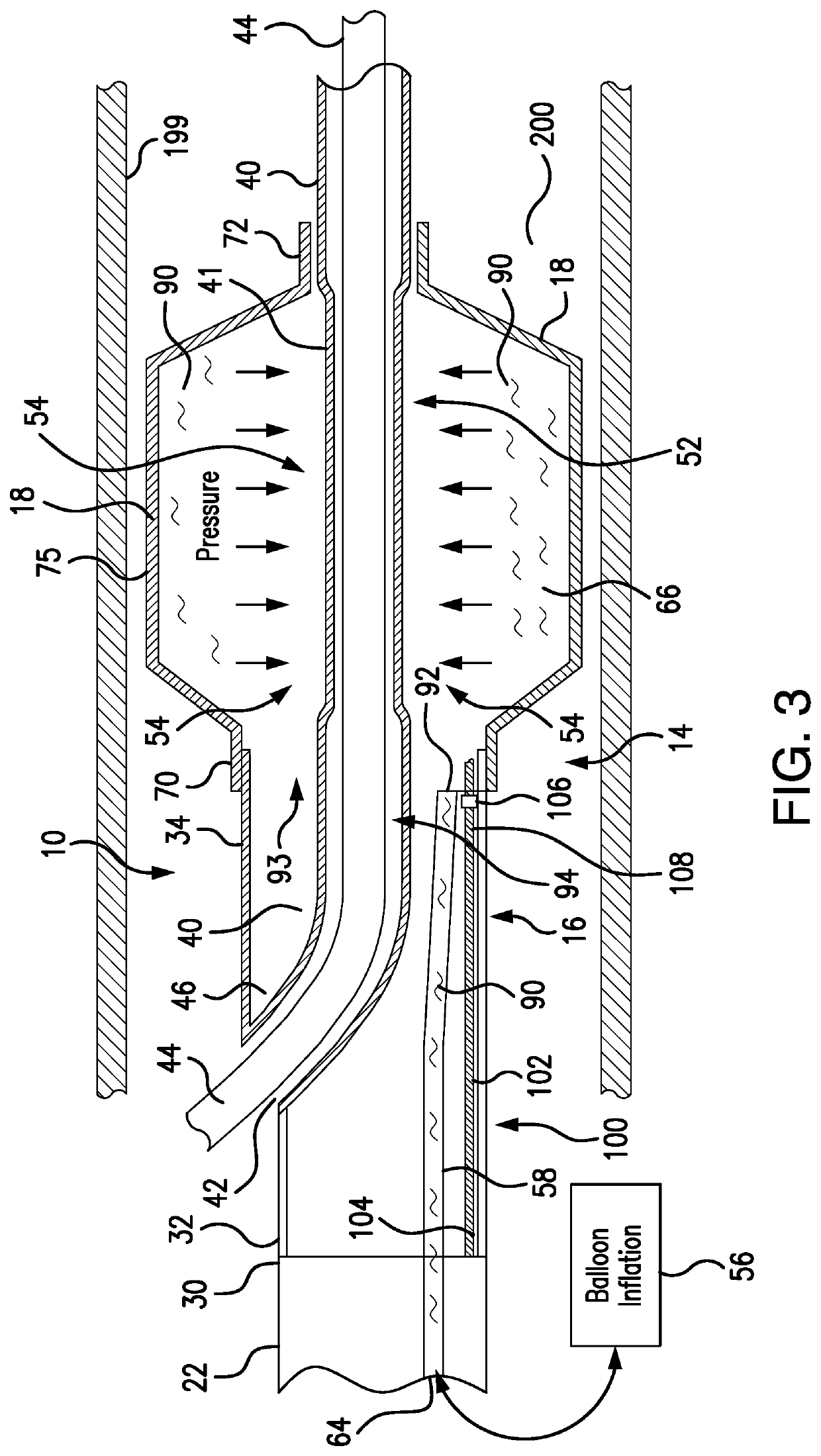

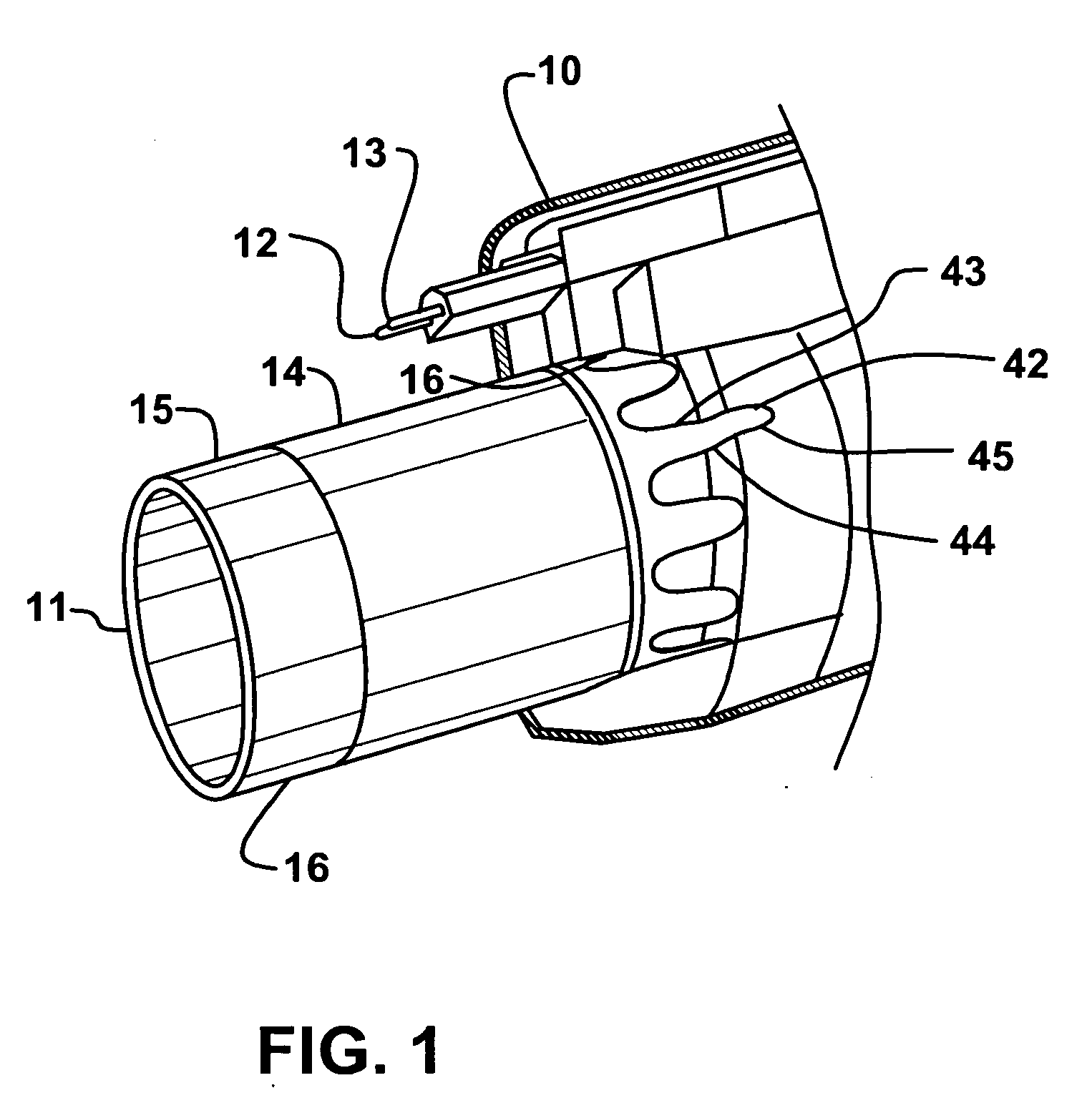

System and method for controlled delivery of medical devices into patient bodies

PendingUS20210228838A1Reduce in quantityReduce deliveryBalloon catheterGuide wiresSurgical operationTherapeutic Devices

Intravascular delivery system for deployment of a therapeutic device (such as a stent, and / or other therapeutic devices including balloon catheter(s), laser catheter(s), intravascular ultrasound (IVUS), Optical coherence tomography (OCT), drug delivery catheter(s), coil delivery catheter(s), etc.) as required by a particular surgical procedure, in a controlled and robust manner is supported by a lockable balloon catheter equipped with a locking mechanism configured to lock in vivo to a delivery component, such as a guidewire. The lockable balloon catheter can be controllably transitioned between locked and unlocked modes of operation by inflation / deflation of the balloon of the lockable balloon catheter. The system provides an enhanced interlocking interface between the delivery component and an inner shaft by a unique configuration of the inner shaft. Connection of the inner shaft / guidewire and / or outer shaft / inflation lumen to the balloon is by an extended “neck” at the end(s) of the balloon which snuggly envelopes the portions of the inner and / or outer shaft(s) entering / exiting the balloon, thus avoiding the bonding and simplifying fabrication process. Being in the locked mode of operation, the lockable balloon catheter facilitates delivery of the therapeutic device along the delivery component to a target site while enhancing the stability of the delivery component, especially near the target site.

Owner:ANCHOR BALLOON LLC

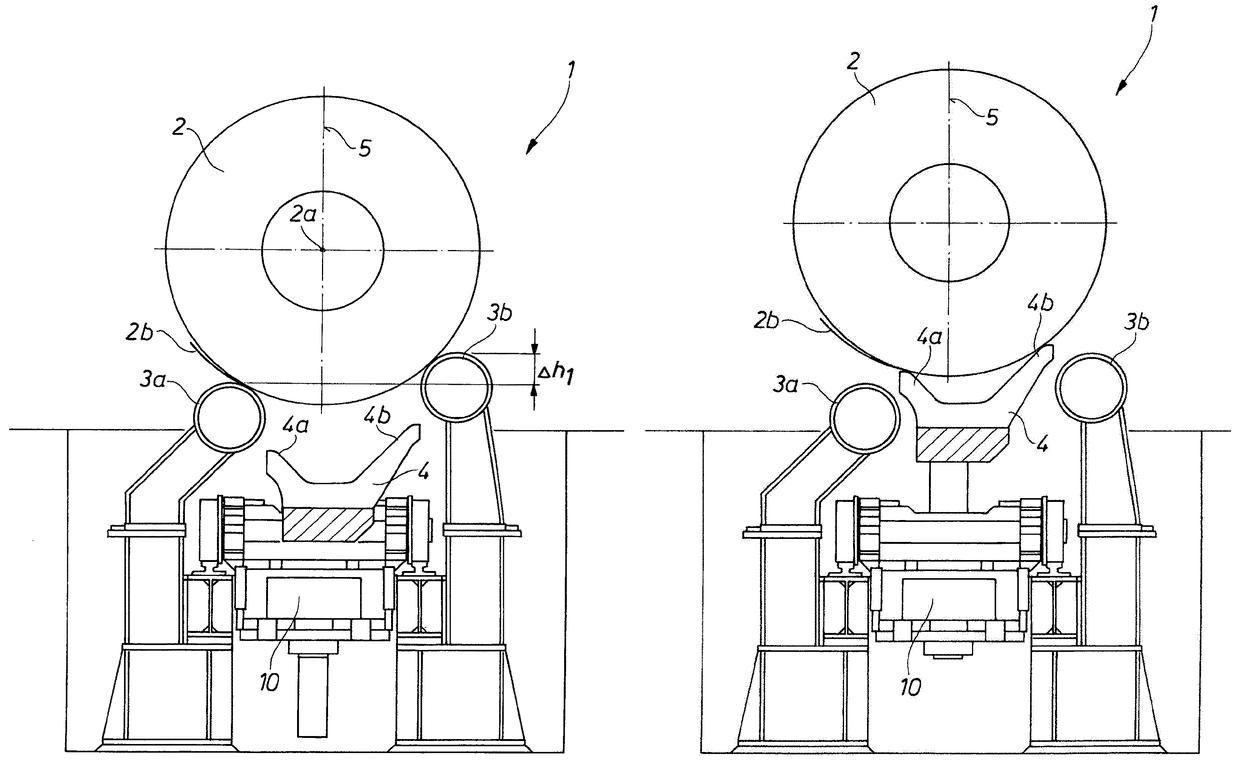

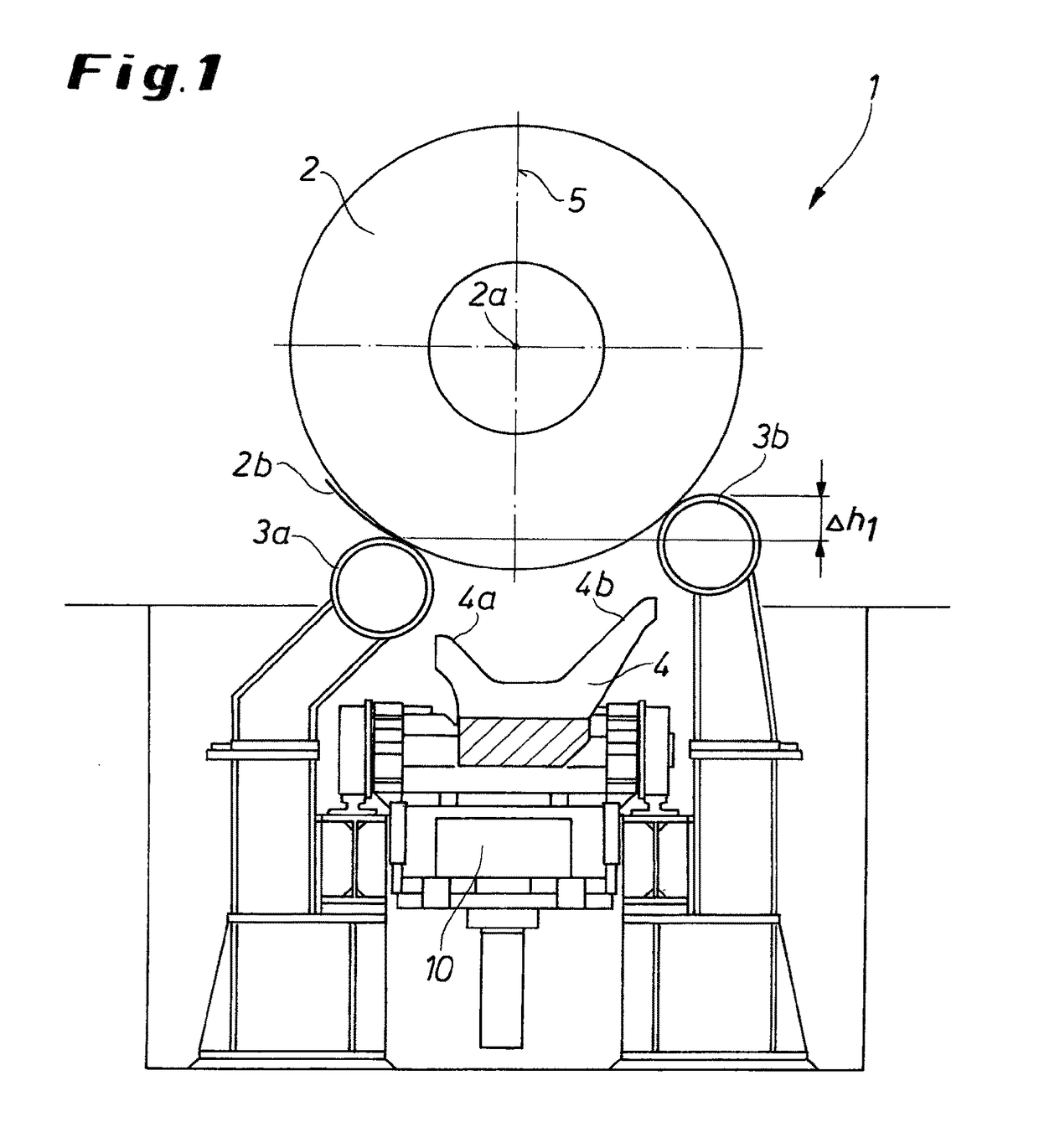

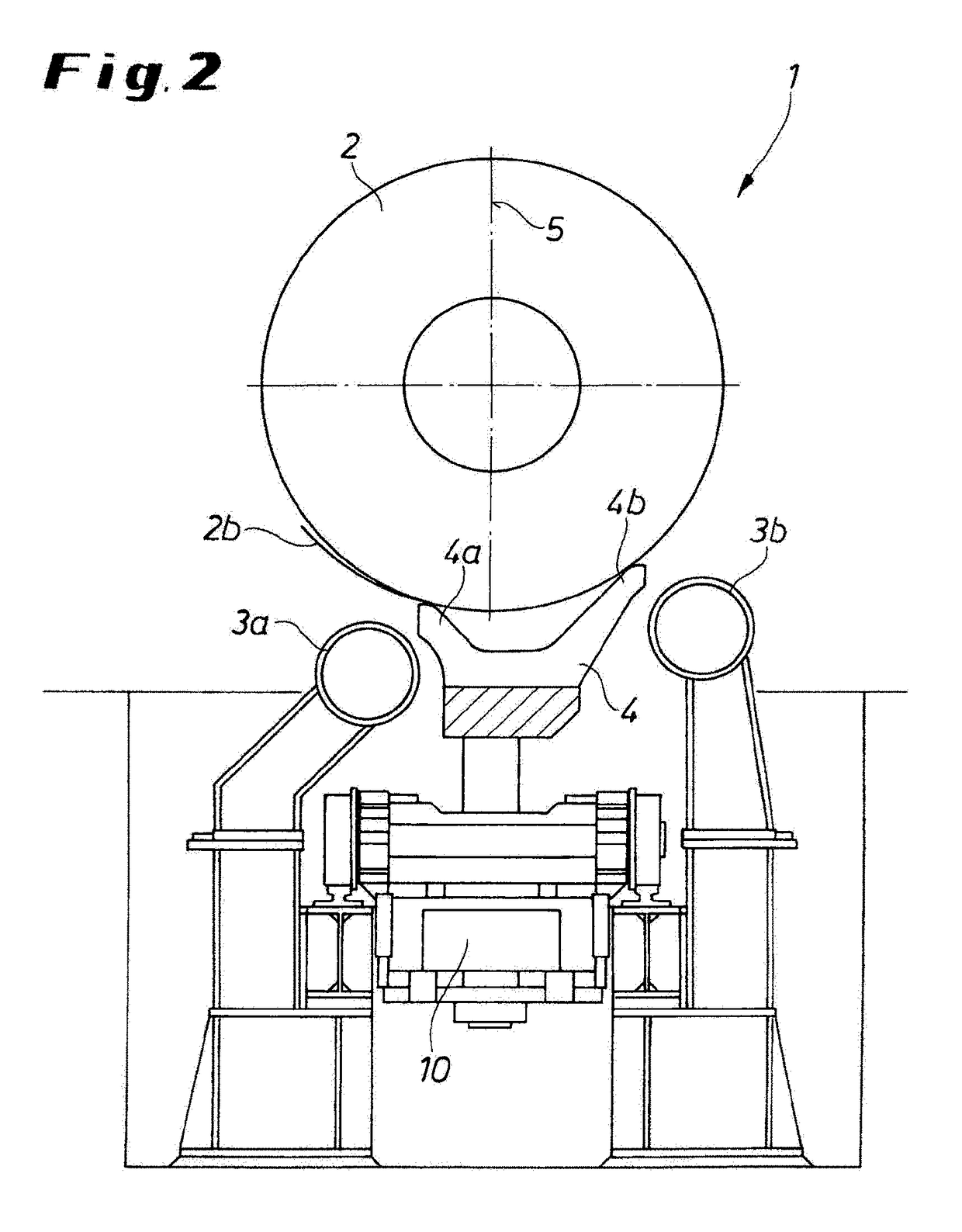

Asymmetric coil support

The invention relates to a device (1) in conveying equipment for moving metal strips wound to form coils (2), in particular produced from high-strength or ultra-high-strength steel grades, wherein for transport the coils (2) can be lifted and lowered from a resting position on a coil support (3) by means of a vertically adjustable coil lifting device (4), wherein the coil support (3) has two coil support elements (3a, 3b) which are laterally spaced apart from one another and the coil lifting device (4) has two support prongs (4a, 4b), characterized in that at least the coil support elements (3a, 3b) are disposed asymmetrically with respect to the vertical (5) through the center of rotation (2a) of the coil (2).

Owner:SMS LOGISTIKSYST

Work station for a packaging line and a packaging line comprising at least two of said work stations

ActiveUS10967998B2Increase ratingsReduce displacementPackaging by pressurising/gasifyingPackaging under vacuum/special atmosphereTransfer mechanismModular construction

A work station (40) for a packaging line having an apparatus (4) for executing a simultaneous action on packages (10) of an alignment of packages with a tool (46); and a transfer mechanism (31) for the simultaneous transport of an alignment of packages to be processed (10b) to the apparatus (4) and of an alignment of processed packages (10c) from the apparatus (4). The alignments are arranged parallel to each other and the transport direction of the packages are perpendicular to the alignments, the transfer mechanism (31) thus having a first and a second transport group (31a, 31b), one of which hangs from two movable parts (60) of the transfer mechanism (31) which are movable on respective parallel planes of movement and which do not interfere with the vertical projection of the tool (46). A packaging line (101, 102, 103) with modular construction having such work stations.

Owner:NEXES CONTROL DESIGN ENG S L U

Bearing and shaft arrangement for electric drive unit

ActiveUS20210188067A1Improve noiseIncrease vibrationShaftsElectric propulsion mountingElectric driveRoller bearing

A bearing and shaft arrangement of an automobile vehicle electric drive unit includes a gearbox. A first electric motor within the gearbox is engaged with and axially rotates a first shaft within the gearbox. A second electric motor within the gearbox is engaged with and axially rotates a second shaft within the gearbox. A first roller bearing assembly supports the first shaft to a first structural member of the gearbox. A second roller bearing assembly supports the second shaft to the first structural member of the gearbox. A thrust bearing is positioned between the first roller bearing assembly and the second roller bearing assembly and directly contacts the first shaft and the second shaft in a drive mode and reacts a first axial load of the first shaft and a second axial load of the second shaft directed toward the first axial load.

Owner:GM GLOBAL TECH OPERATIONS LLC

Spring contact plate

InactiveUS20100242207A1Easy to optimizePrevent movementSuction cleanersVehicle cleaningElectrical connectionEngineering

An improved end fitting for a hose adapted for use with a central vacuum system is provided. The end fitting has a housing and a cylindrical member extending from the housing. The cylindrical member is adapted to be received by a wall inlet. The cylindrical member has an end portion of a first diameter and a neck of a second smaller diameter and at least one spring contact plate positioned over the neck to provide an electrical connection to the wall inlet.

Owner:FLEXIBLE TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com