Spring contact plate

a spring contact plate and end fitting technology, applied in the direction of vehicle maintenance, vehicle cleaning, cleaning equipment, etc., can solve the problems of lack of lv standardization driven by an agency or industry group, difficult to maneuver the movable vacuum cleaner to various locations in the house, and inability to always be practical, so as to achieve good electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

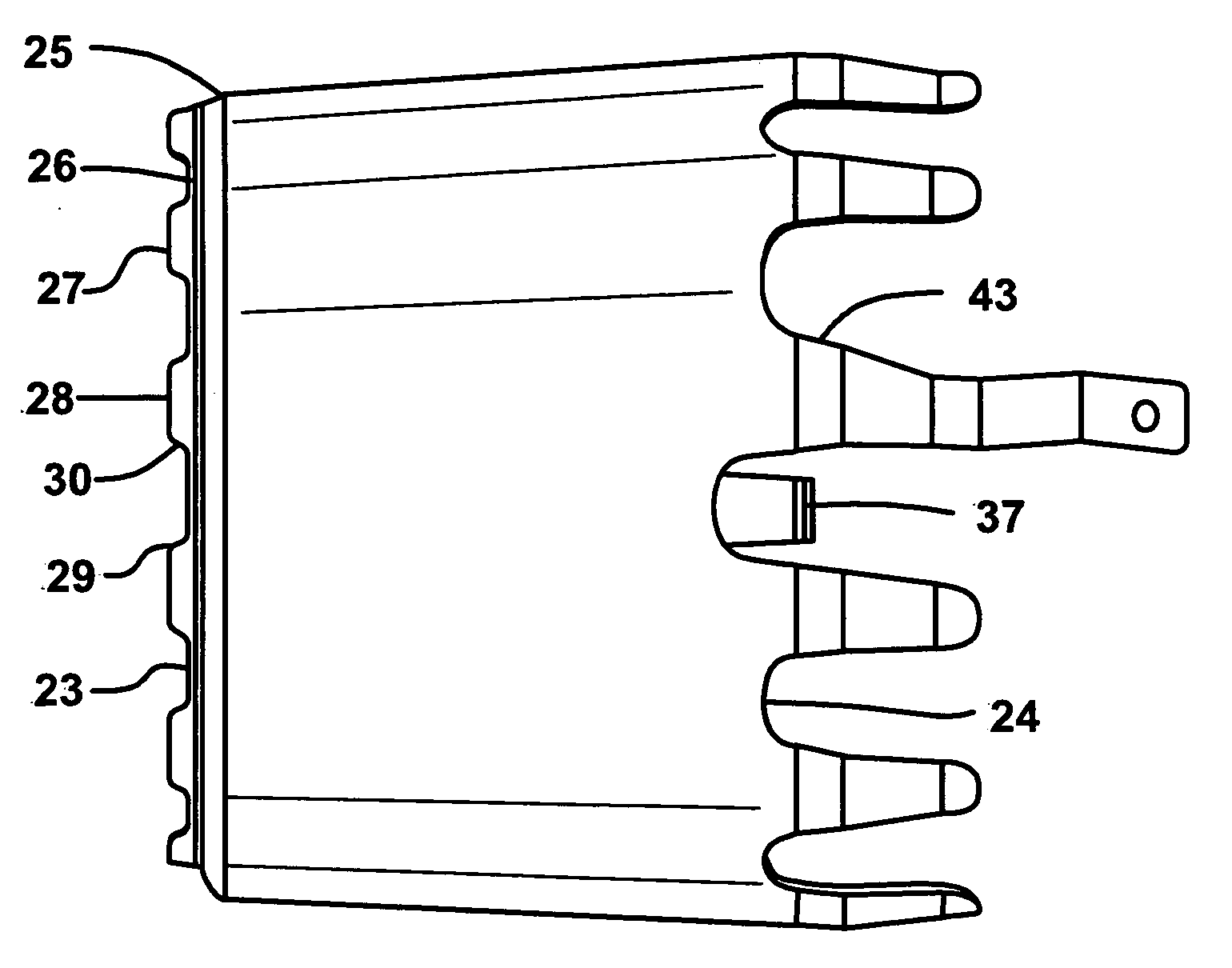

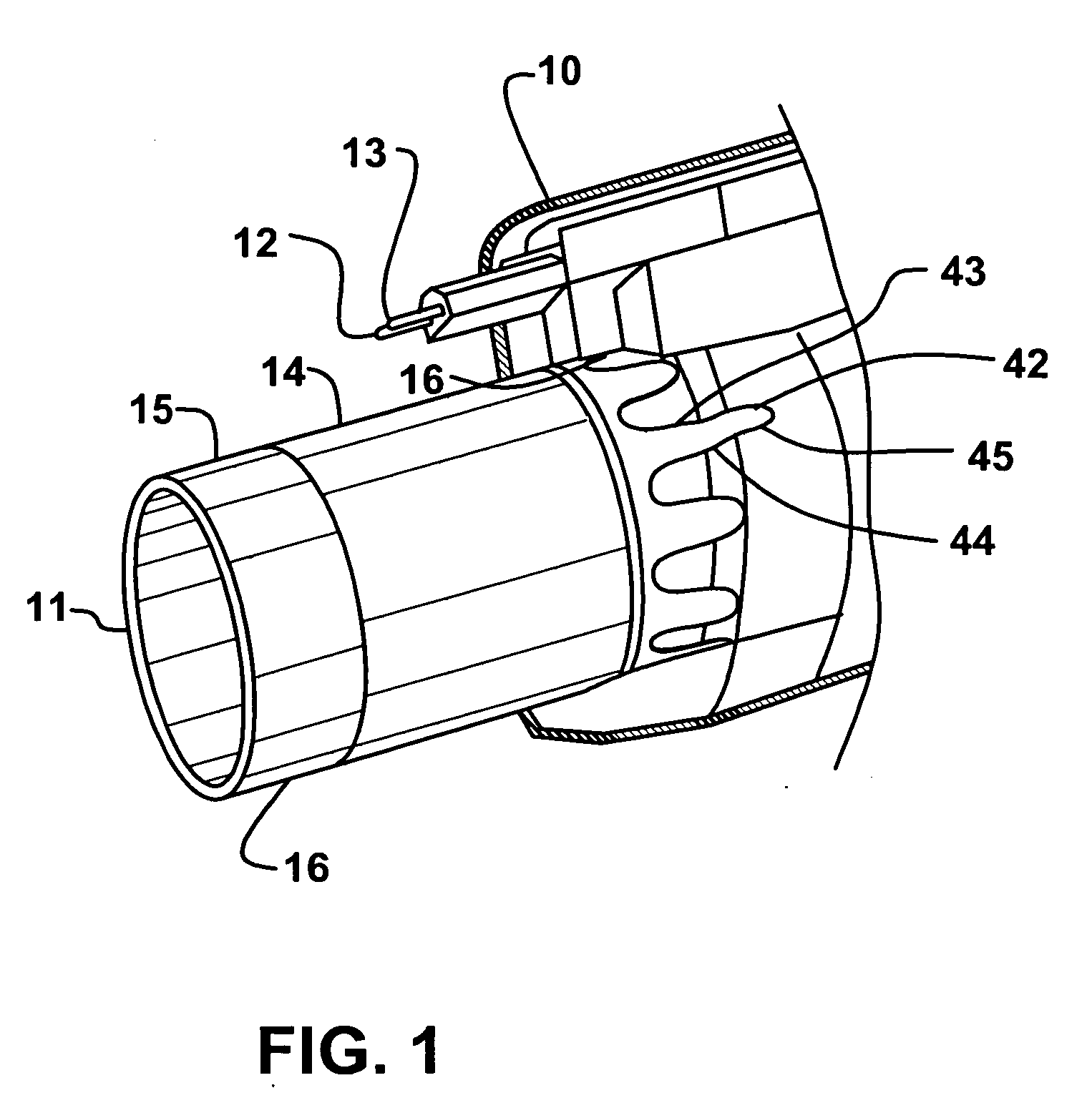

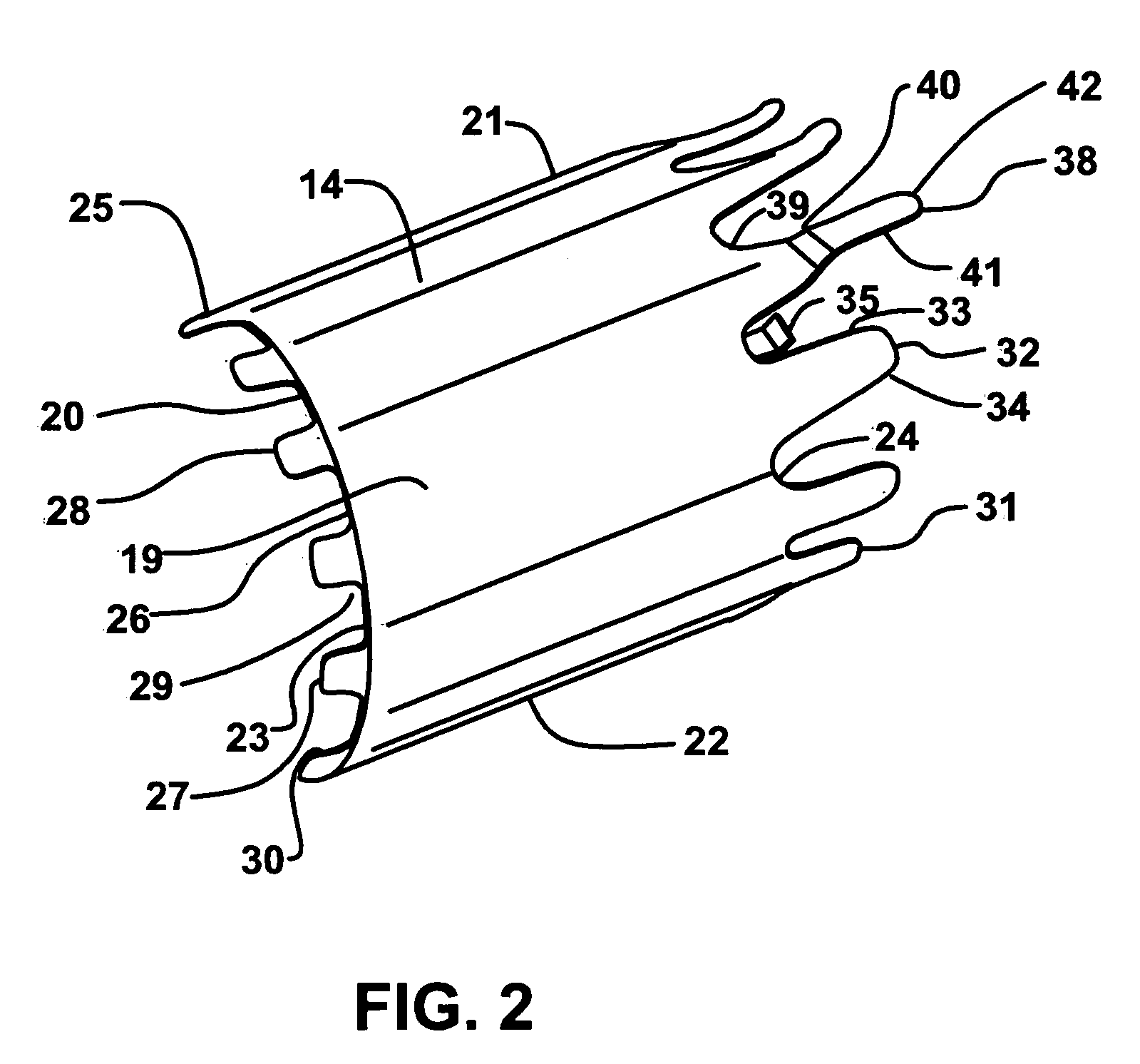

[0023]As seen in FIG. 1, there is a core 10 over which a housing 53 is secured. The core has an end fitting that is secured to an end of a hose (not shown). The core 10 has a first end that is secured to a hose and a second end 11 opposite the first end. The second end 11 of the core 10 is adapted to be inserted into an opening in the Type A wall valve or an opening in a motorized power head or other accessory. The housing 53 has a pair of high voltage connectors 12 and 13 to provide power to the power nozzle or other powered device on the opposite end of the hose from the housing 53 when the core 10 is inserted in a Type A wall outlet. In this embodiment there are a pair of pins or pigtails extending from the housing that are insertable into a pair of pin openings in the wall valve. In an alternate configuration of the wall valves there may be a direct connection instead of pigtails. They both use LV contact plates, but the supply of HV power is different. In direct connect, power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com