MEMS pressure sensor oil-filled core body and packaging method thereof

A technology of pressure sensors and oil cores, applied in piezoelectric/electrostrictive/magnetostrictive devices, measurement of the property and force of piezoelectric resistance materials, fluid pressure measurement by changing ohmic resistance, etc., can solve the problem of sensor accuracy Reduce, microcircuit fatigue damage and other problems, achieve the effect of less lead wire interconnection, improve high and low temperature precision, and high product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

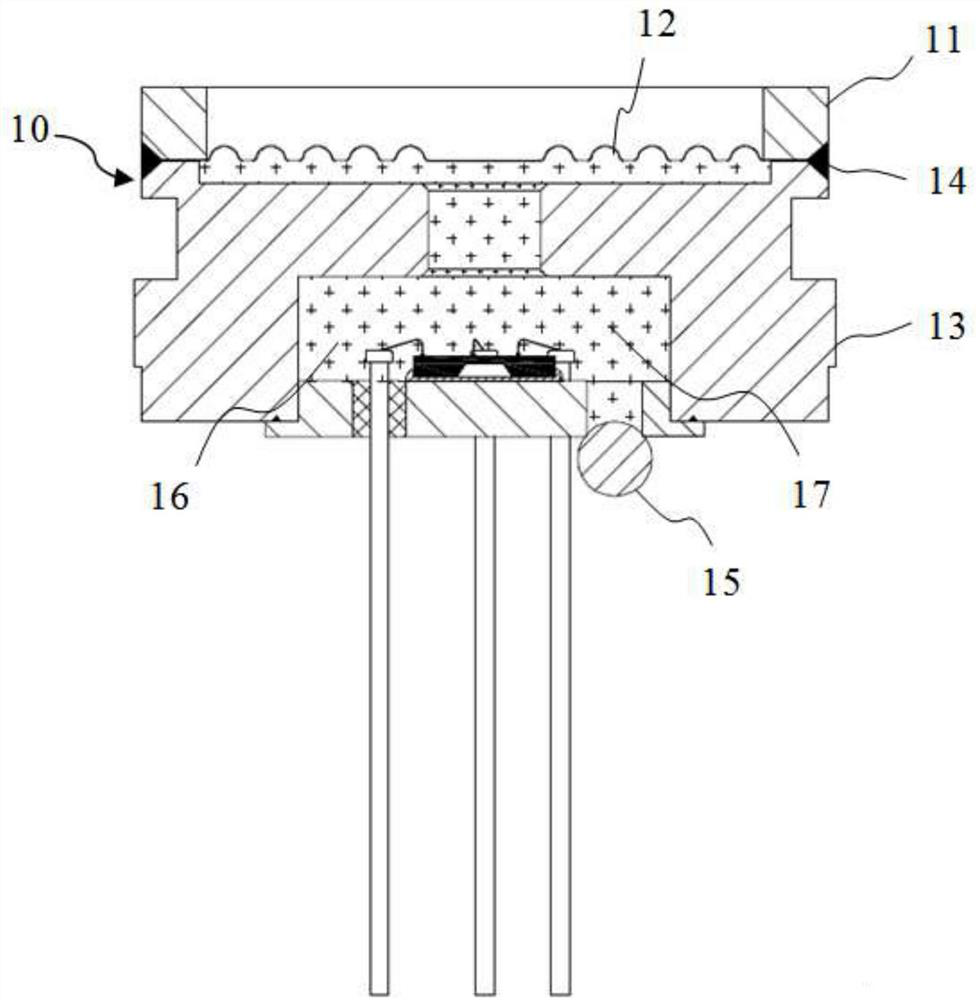

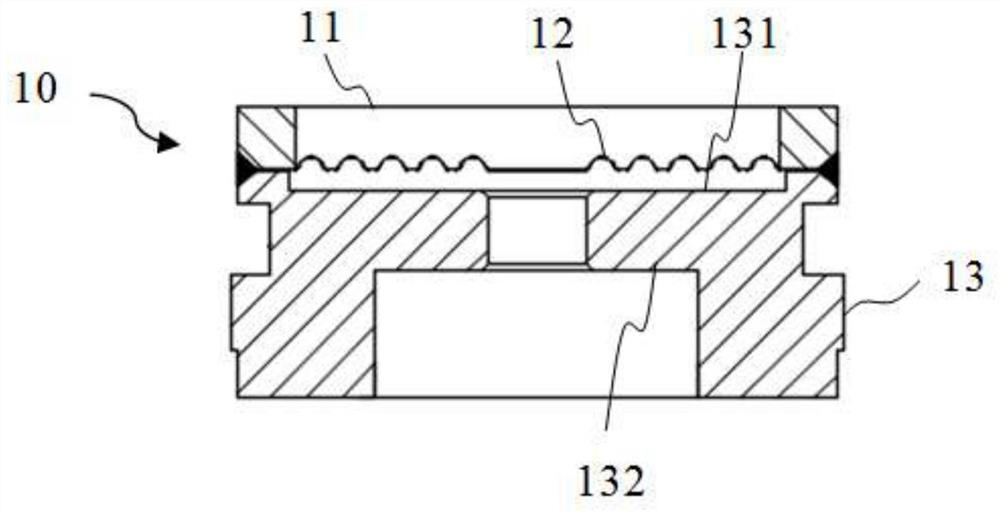

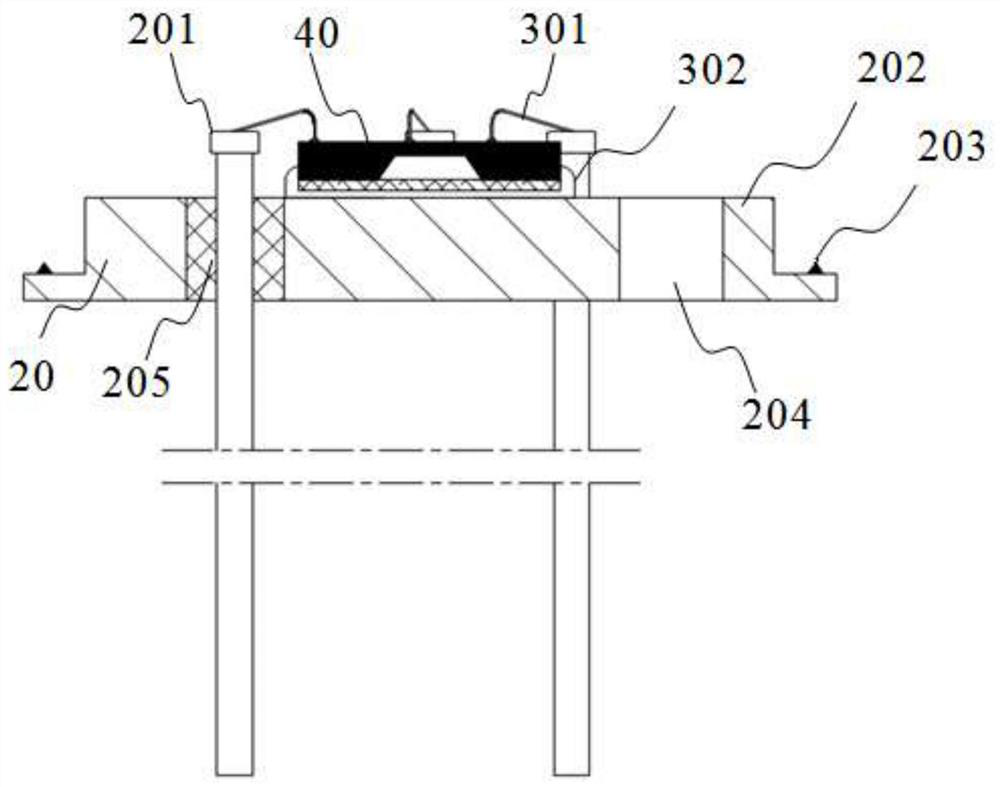

[0044] see Figure 1-5, a MEMS pressure sensor oil-filled core, including a cover 10, a base 20 and a sensitive component 40; the base 20 is provided with a sensitive component 40; the sensitive component 40 includes a silicon elastic diaphragm 41 and a signal calibration module 42, the silicon elastic membrane Chip 41 and signal calibration module 42 are all arranged on the bare chip, so that both are located on the same horizontal plane; The signal calibration module 42 is located on different planes, and the signal calibration module 42 is located around the silicon elastic diaphragm 41, so as to prevent the stress change of the silicon elastic diaphragm 41 from affecting the signal calibration module 42, causing the circuit in the signal calibration module 42 to be damaged It is beneficial to ensure the accuracy; the principle is that the silicon elastic diaphragm 41 will generate strain under pressure, resulting in different changes in the resistance value of the semicond...

Embodiment 2

[0058] see Figure 6-7 The difference from Embodiment 1 is that there is no back pressure sheet between the patch adhesive 302 and the sensitive component 40, and the center of the patch adhesive 302 is provided with a round hole, and the lower surface of the base 20 is provided with a through hole communicating with the round hole. The hole 510 makes the oil-filled core communicate with the atmospheric environment, so that the measured value relative to the atmospheric pressure can be detected.

[0059] When using:

[0060] (1) The external pressure acts on the pressure diaphragm 12, and the medium 17 filled in the sealed cavity 16 will be squeezed through the pressure diaphragm 12, and then the pressure will be transmitted to the sensitive component 40 by the medium 17, thereby causing silicon elasticity on the sensitive component 40 The change of the diaphragm 41, the pressure of the silicon elastic diaphragm 41 will produce strain, resulting in different changes in the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com