Pile filling machine for building secondary structure

A technology of secondary structure and filling piles, which is applied in the direction of building structure, construction, building maintenance, etc., can solve the problems of slow project progress, high construction cost, and high labor intensity, and achieve fast project progress, low construction cost, and low labor costs. low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

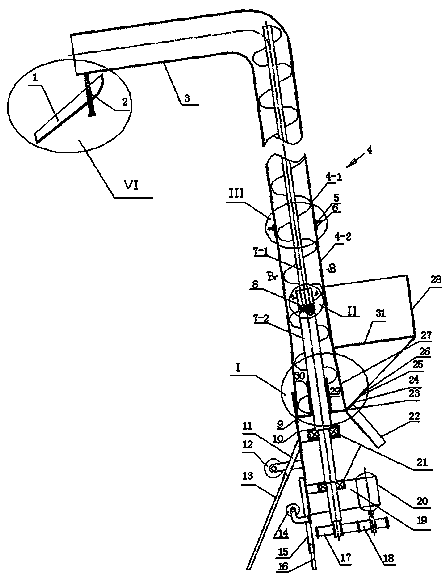

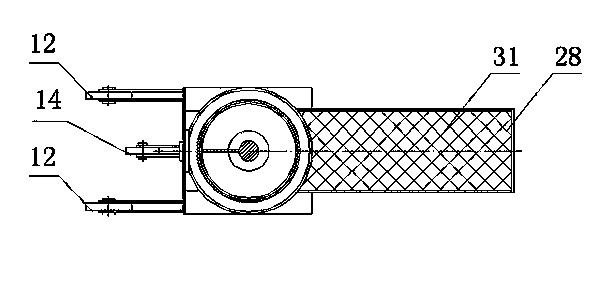

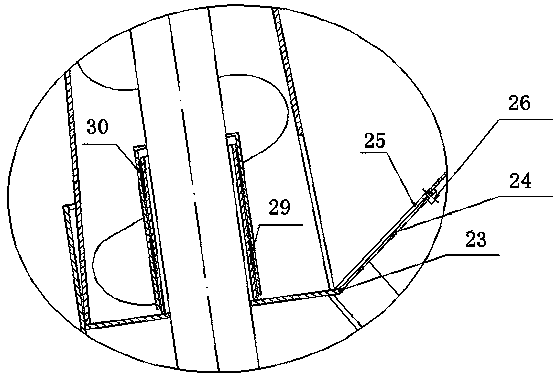

[0023] As shown in the figure, the special pile filling machine for the secondary structure of the building includes a screw hoist. The upper end of the helical drum 4 of the helical hoist is provided with a discharge pipe 3 for changing the flow direction of the concrete in the helical drum 4. In the discharge pipe 3 The lower part of the front end is provided with a pouring chute 1, and the pouring chute 1 can swing around the shaft 2 fixed on the discharge pipe 3.

[0024] The discharge pipe 3 and the spiral drum 4 have the same diameter, and the discharge pipe 3 and the spiral drum 4 form a 90° bend. In the working state, the spiral drum 4 is slightly inclined to the direction of the secondary structure pile, and the discharge pipe 3 naturally forms a downward The inclination angle, the angle of the inclination angle is subject to the natural flow of concrete.

[0025] The spiral drum 4 is formed by butt joints of upper and lower segments, and the lower segment drum 4-2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com