Patents

Literature

61results about How to "Improve anti-floating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

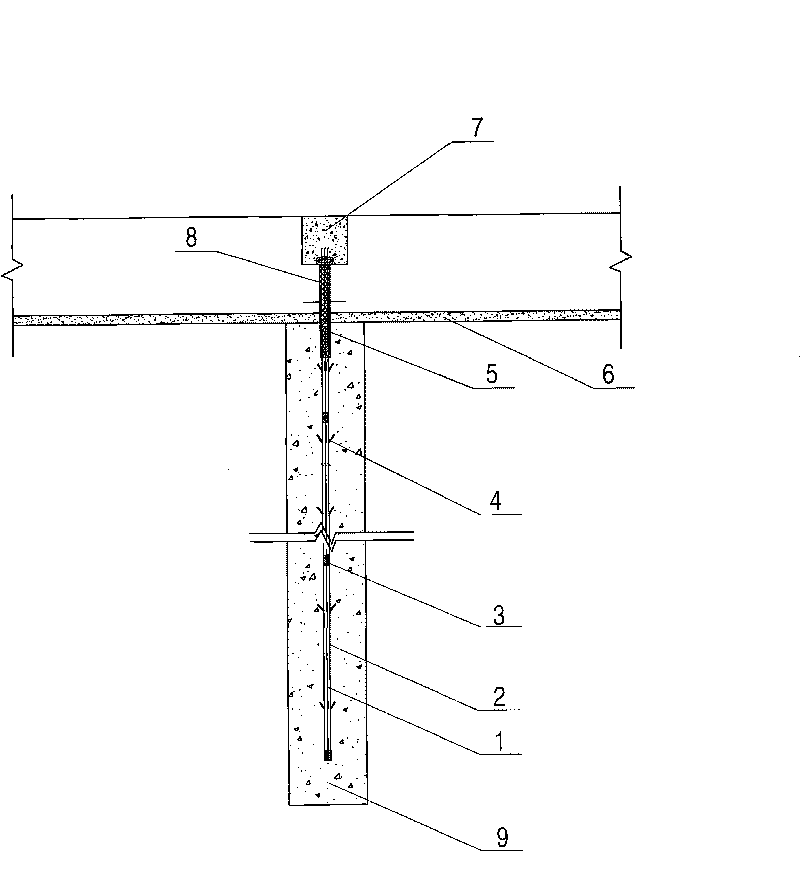

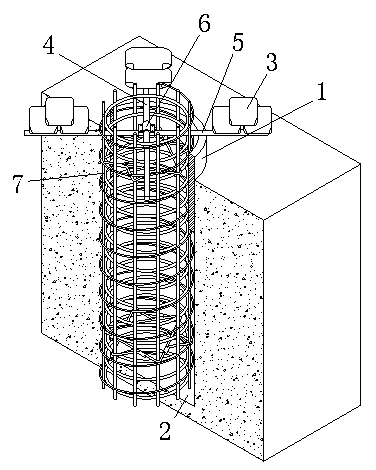

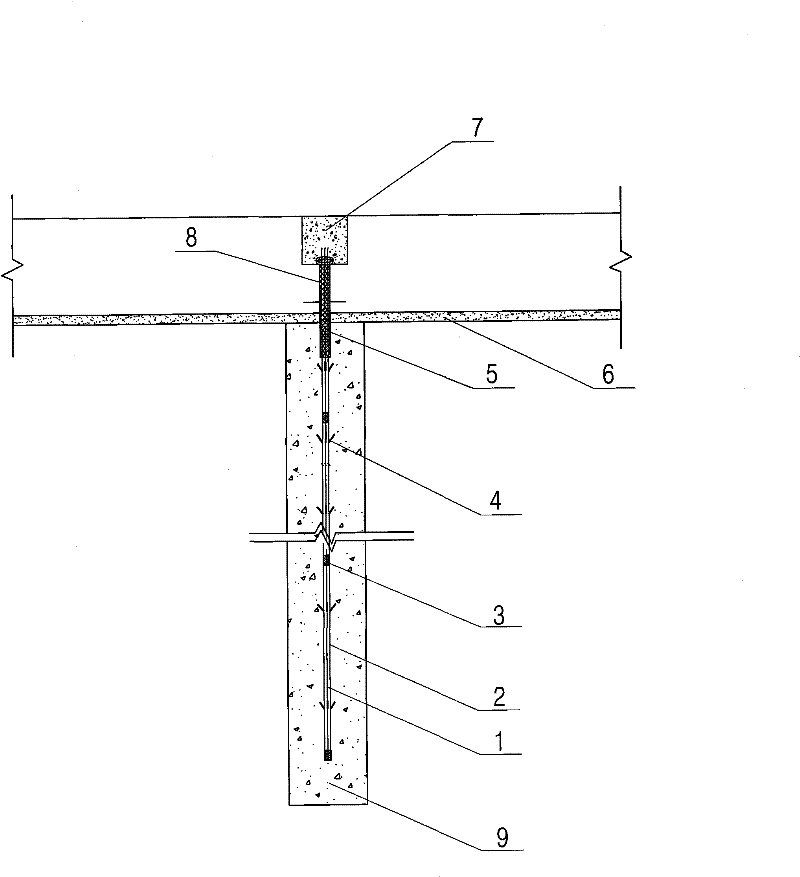

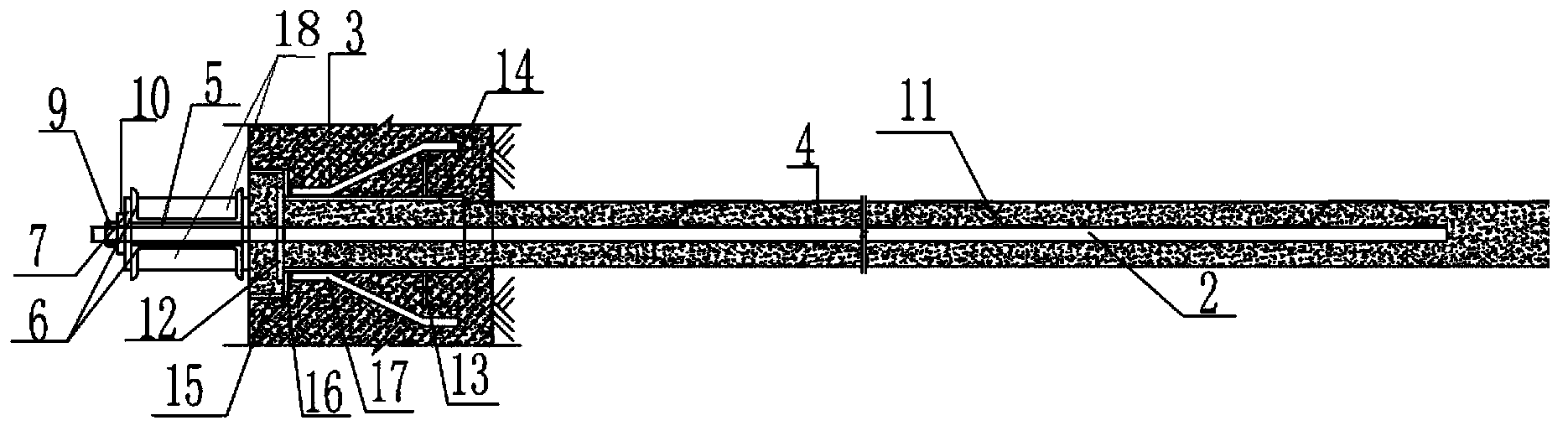

Prestressed anti-floating anchor rod and construction method thereof

ActiveCN101736760AIncrease frictionImprove anti-floating effectProtective foundationBuilding material handlingPre stressConfined water

The invention discloses a prestressed anti-floating anchor rod and a construction method thereof. The invention is characterized in that alignment steel tubes are arranged in an anchor rod body which is formed by a plurality of steel bars uniformly distributed along the circle, the steel bars are provided with a plurality of barbs, the alignment steel tubes are arranged at intervals along the axis of the anchor rod body and are fixedly connected with the steel bars, the barbs are welded with the steel bars. The construction method comprises the following steps: grouting into piles; arranging the anchor rod; locking the anchor rod; and sealing the anchor. Compared with the prior art, the invention has the advantages of simple structure, convenient construction, good anti-floating effect and low cost, especially being applicable to the reconstruction of old buildings with built underground structures and confined water.

Owner:SHANGHAI ZHIPING FOUNDATION ENG CO LTD

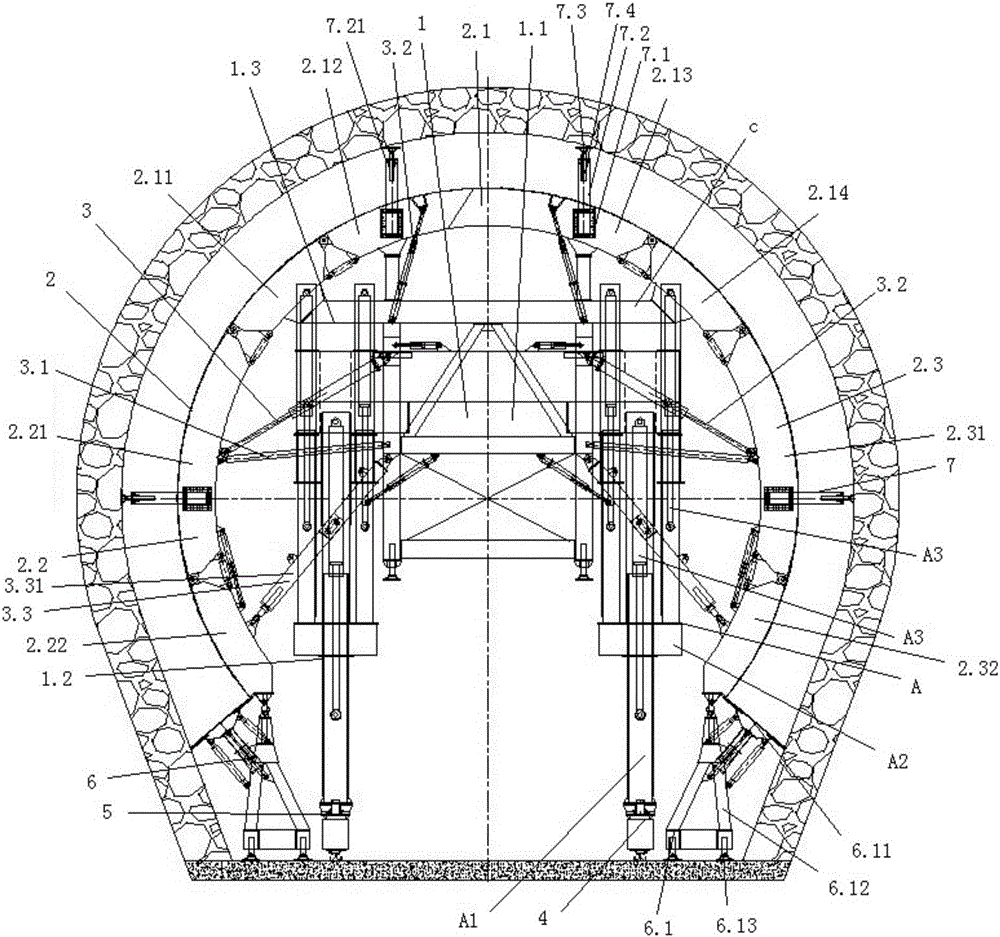

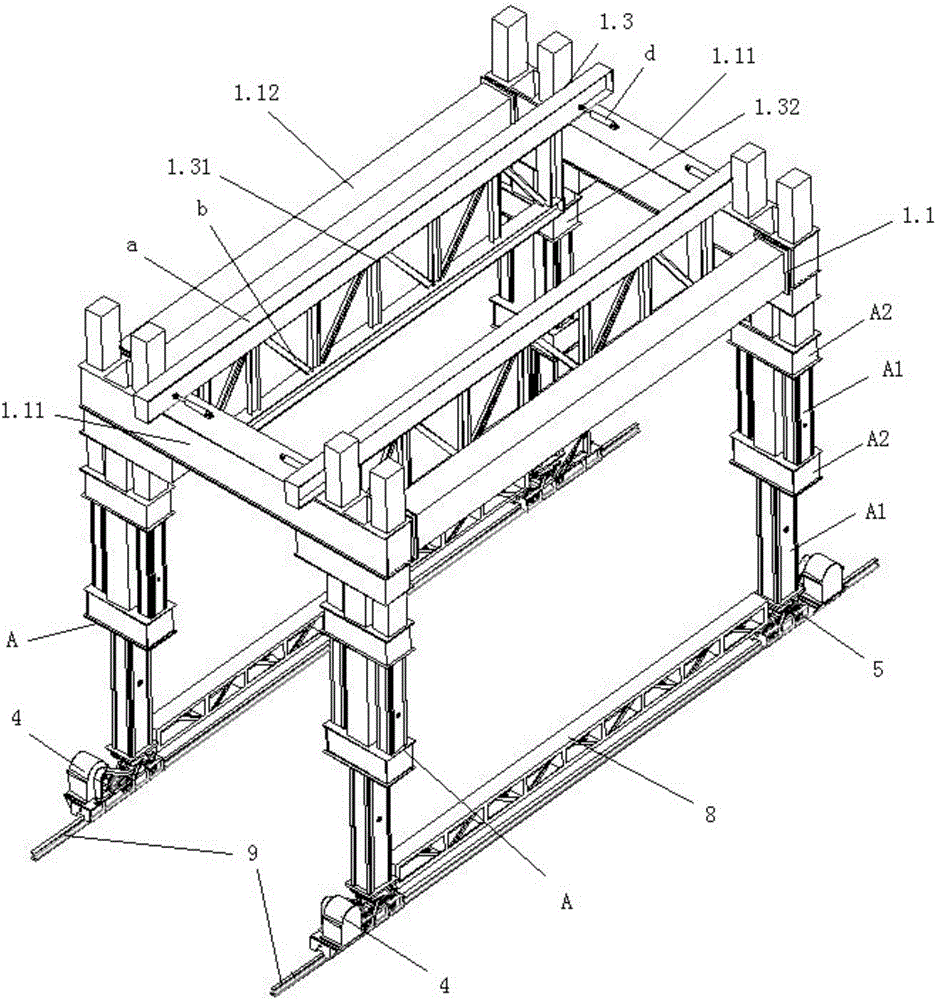

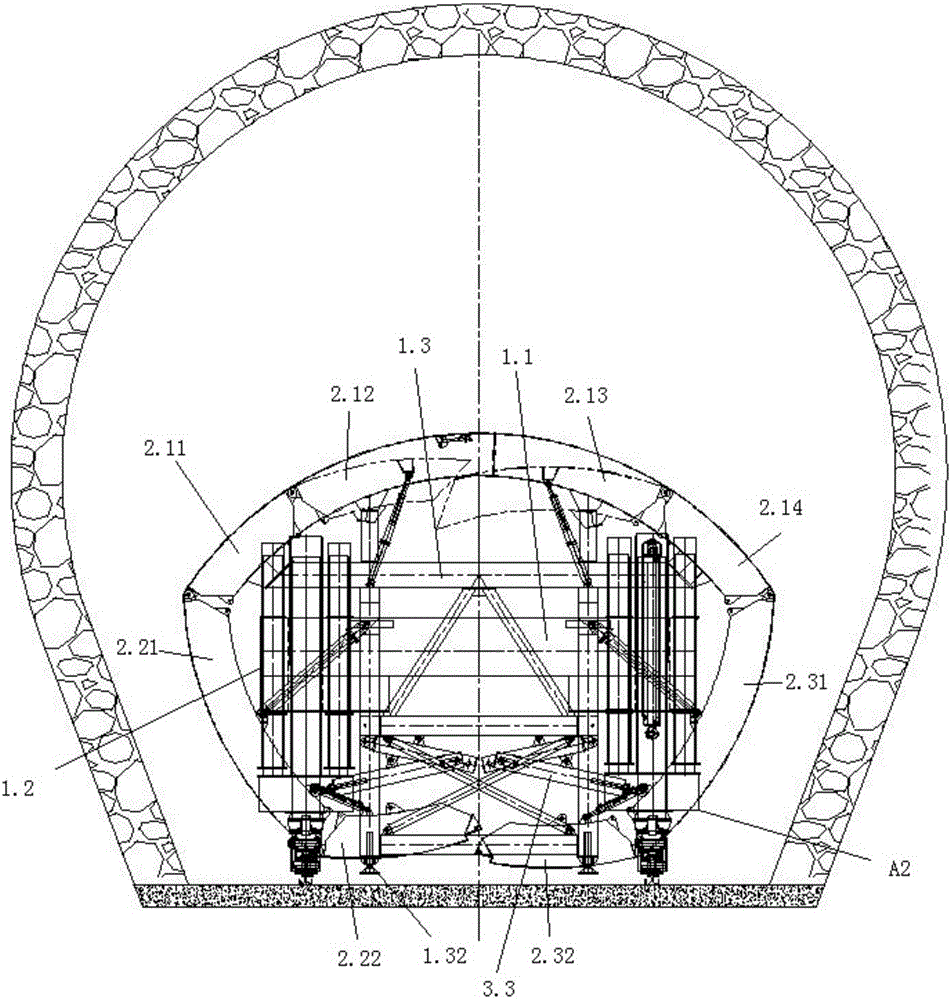

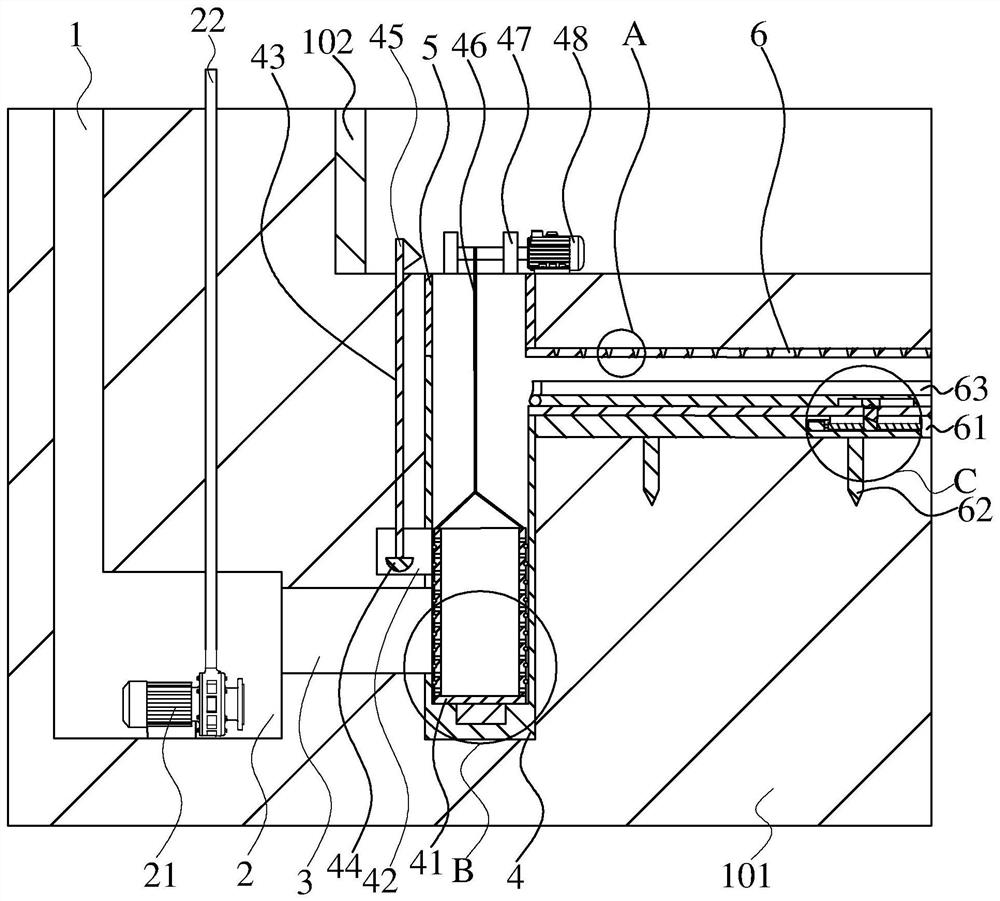

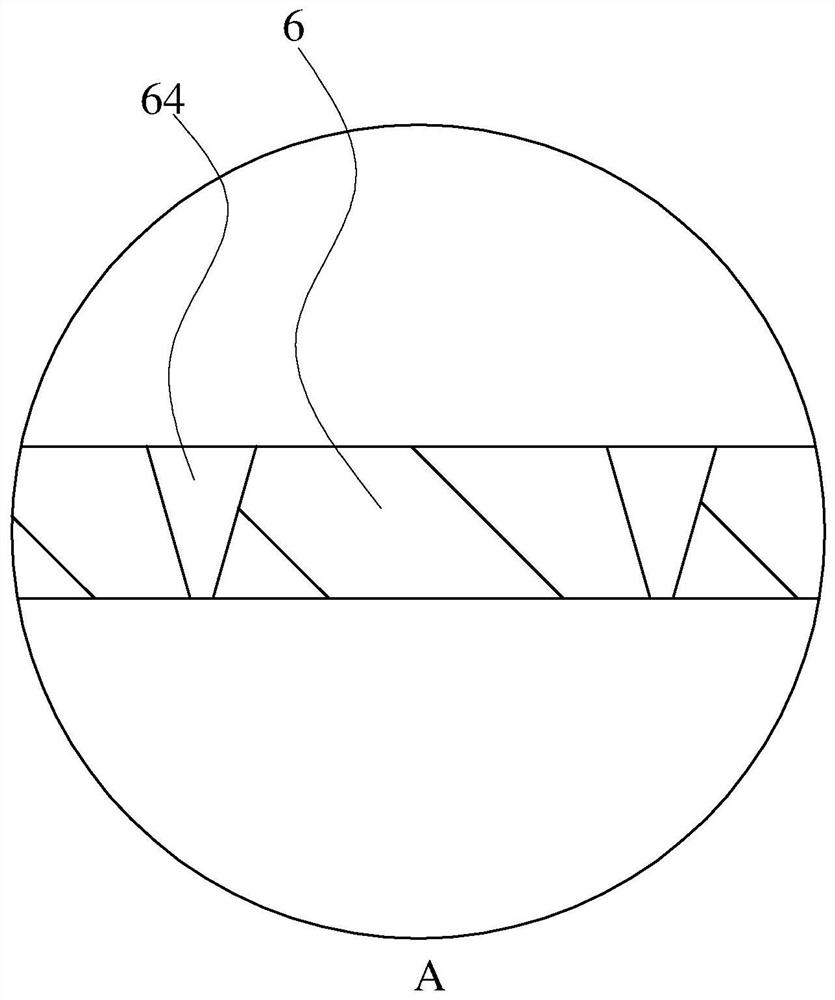

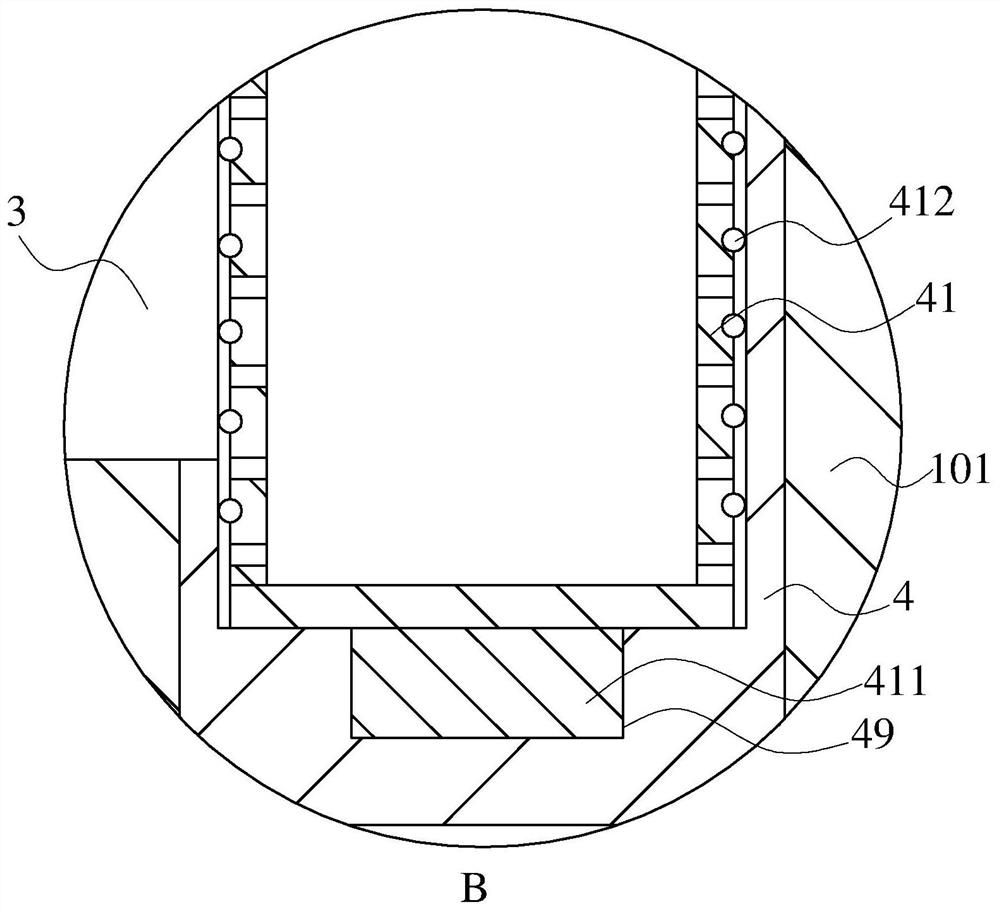

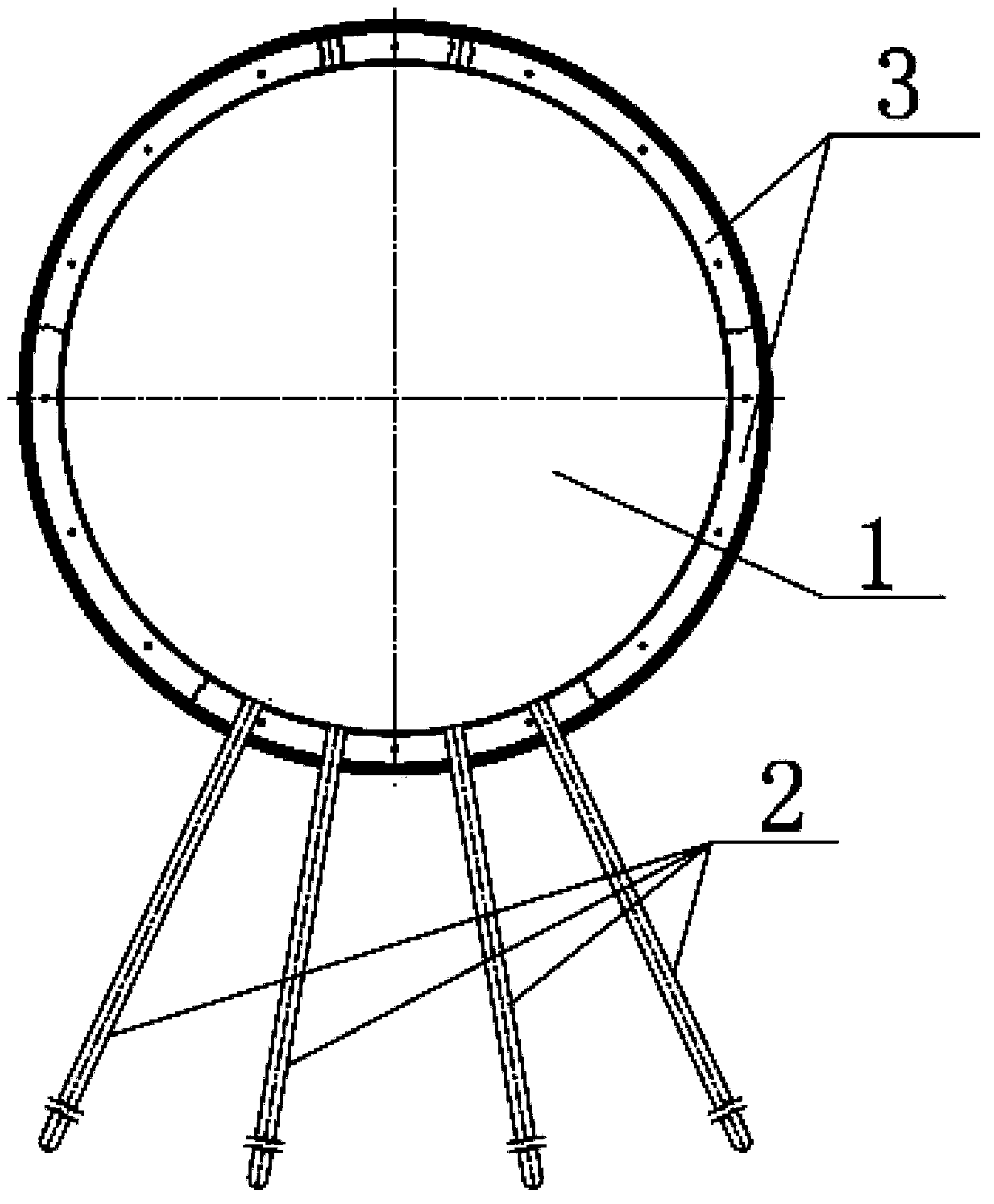

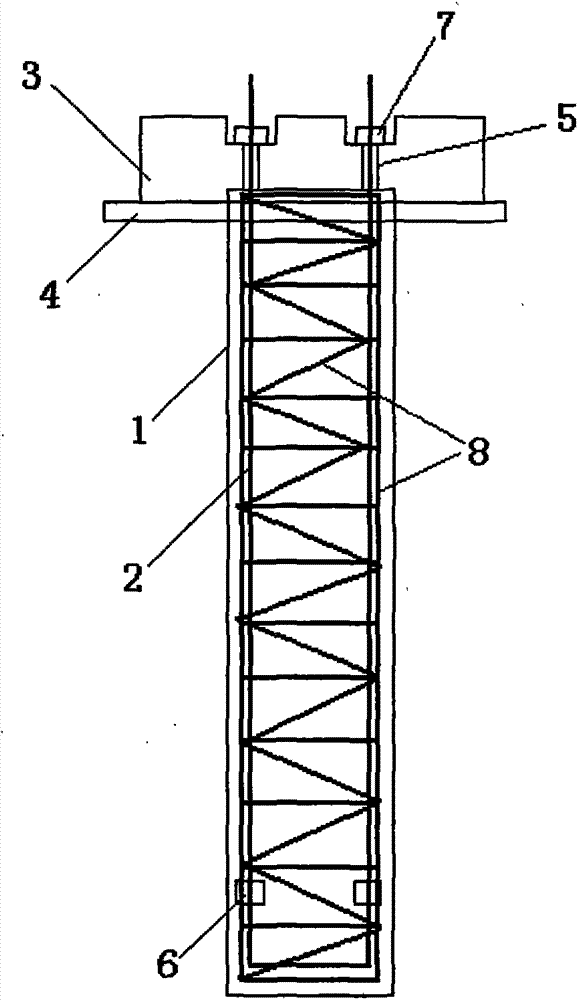

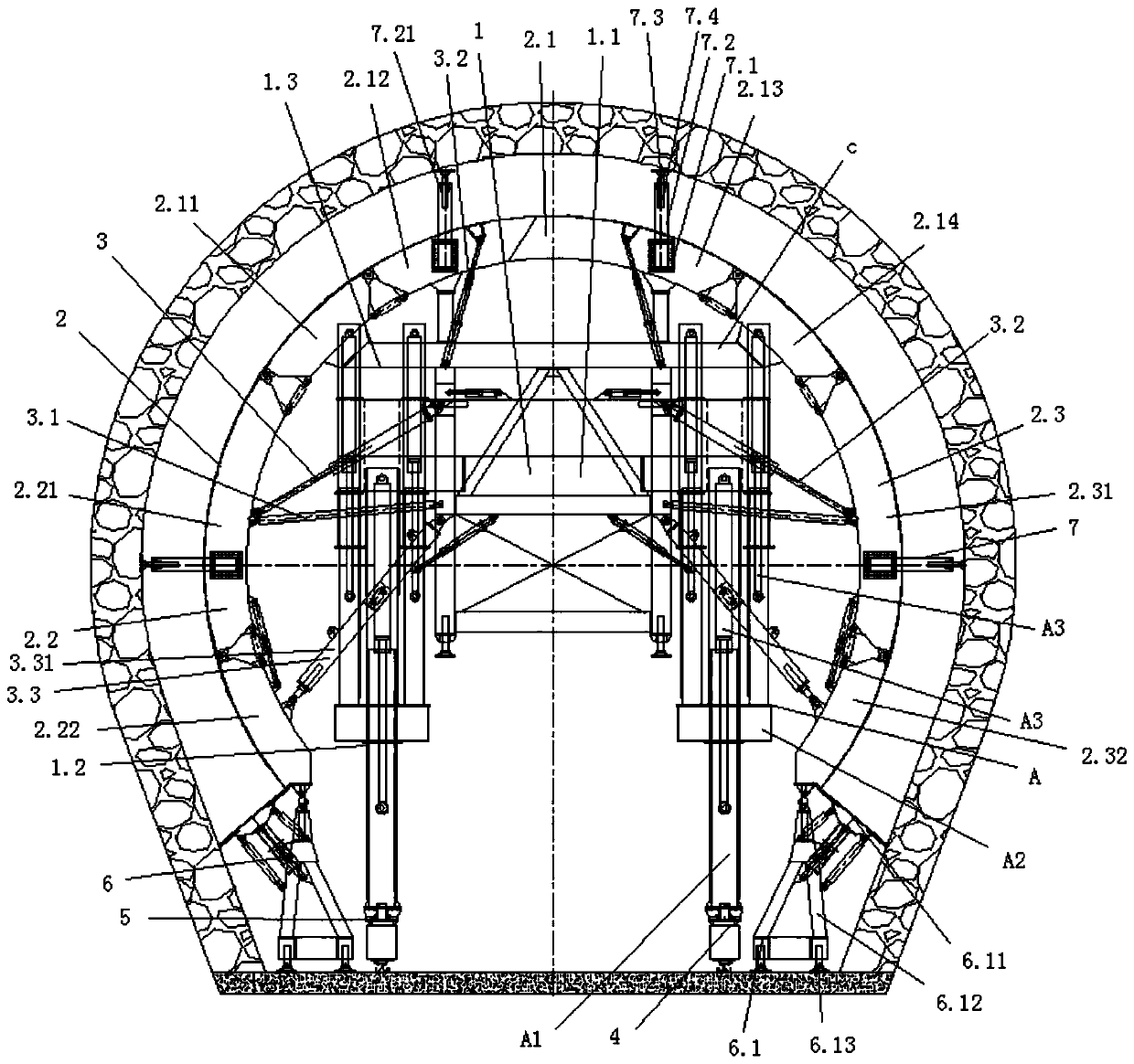

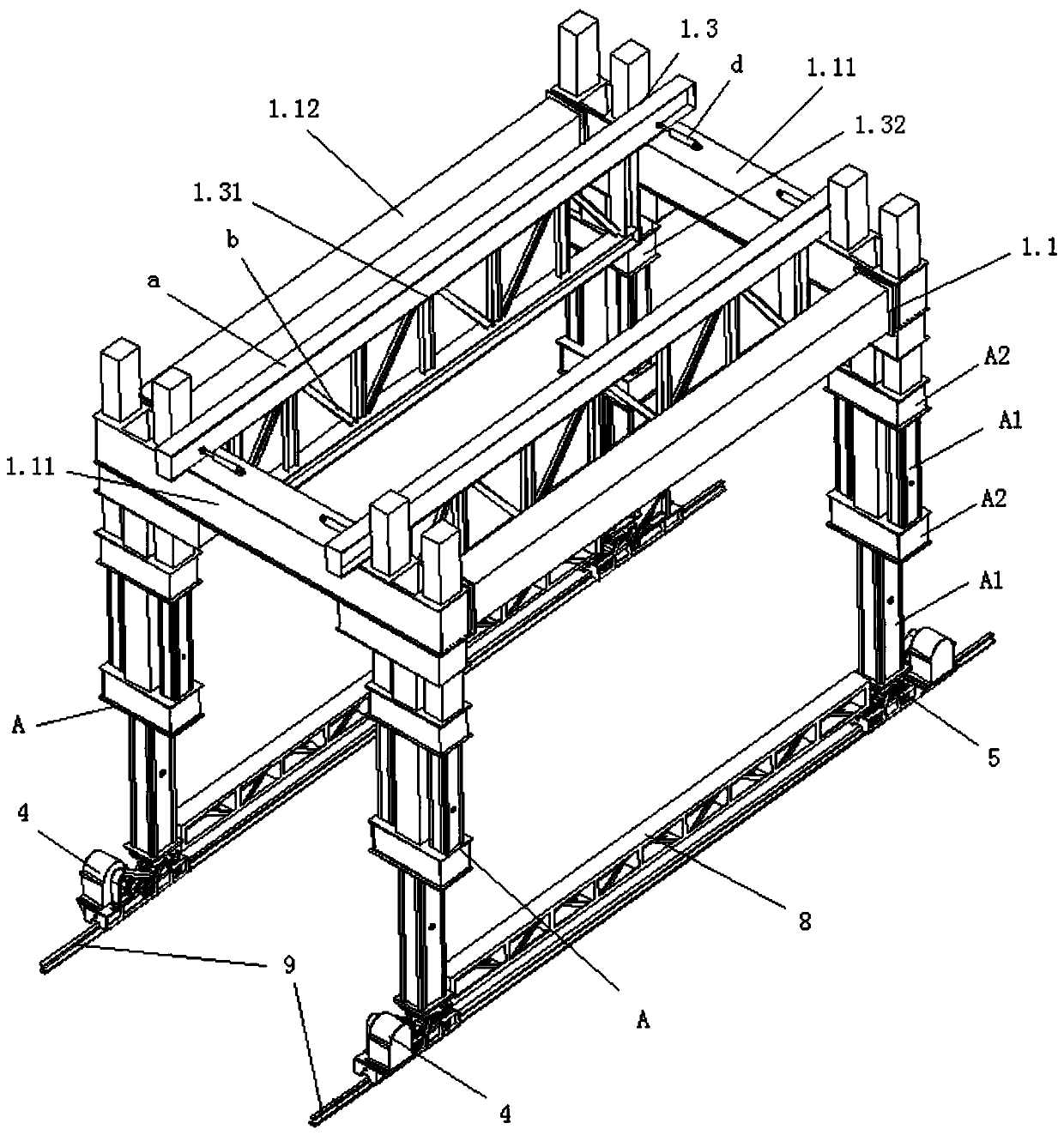

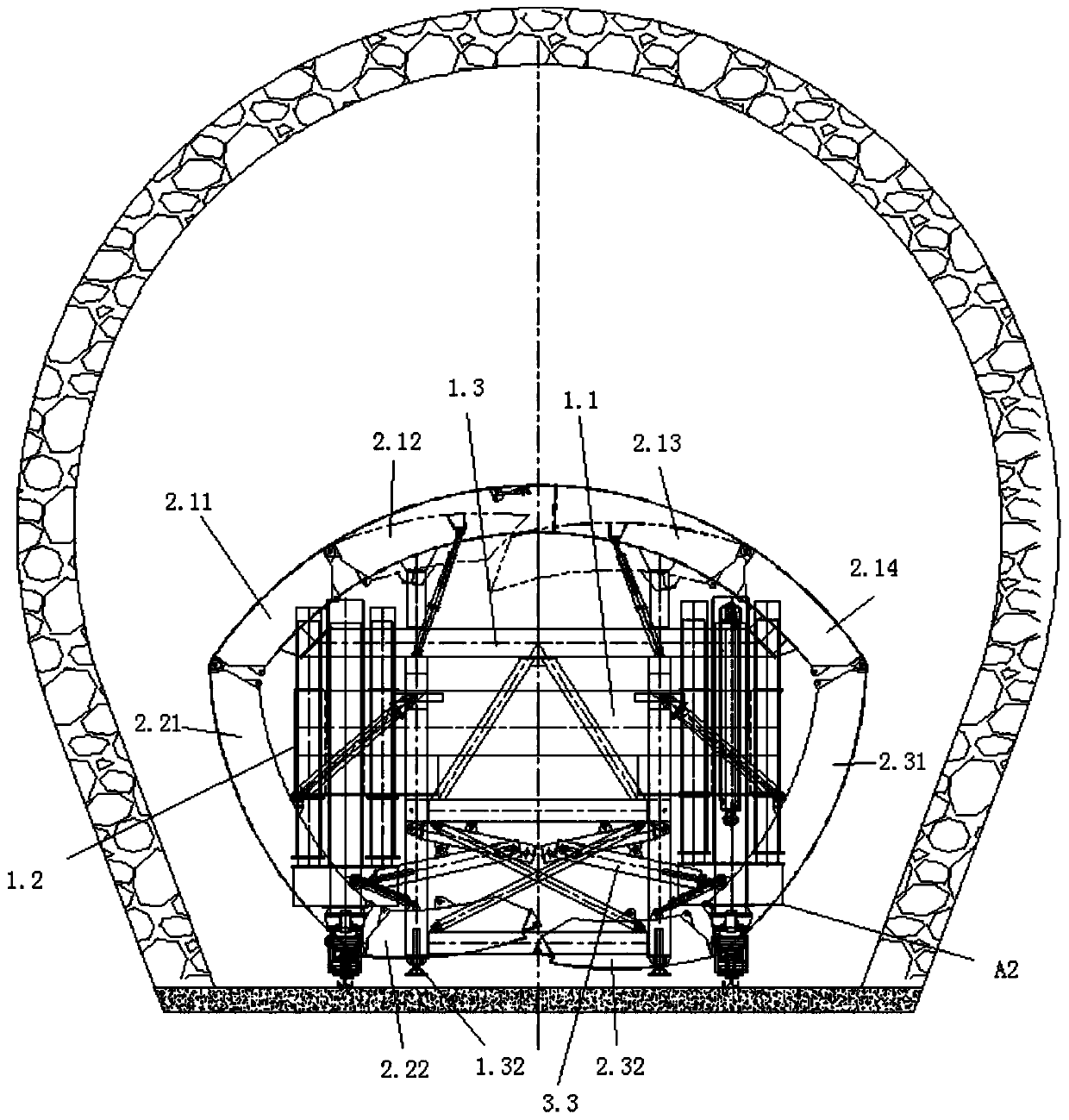

Section-variable tunnel-crossing lining trolley

ActiveCN106593472AEnsure normal walkingBig liftUnderground chambersTunnel liningHydraulic cylinderEngineering

The invention provides a section-variable tunnel-crossing lining trolley which comprises a portal system, a template system, a connecting part and a walking mechanism, wherein the portal system comprises a frame part, a jacking mechanism and a bracket part; the jacking mechanism comprises multiple sets of jacking single pieces; each of the jacking single pieces comprises a multi-level jacking part; the bracket part comprises a truss girder and an adjusting support frame for a walking mechanism; the template system comprises a top template, a left template and a right template; and the connecting part comprises a support jack and a hydraulic cylinder. The section-variable tunnel-crossing lining trolley provided by the invention has the effects that the whole structure is simple; the assembling is convenient; the jacking mechanism is in a multi-level jacking mode; the trolley not only can adapt to the construction for the tunnel sections in different heights but also can achieve higher lifting volume; the trolley can meet the requirement of constructing multiple parallel tunnels by one trolley in the manner of constructing the working tunnel; due to the design of the bracket part, the lining trolley can meet the stability requirement, and meanwhile, the structure is simplified and the whole trolley can be supported.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD +1

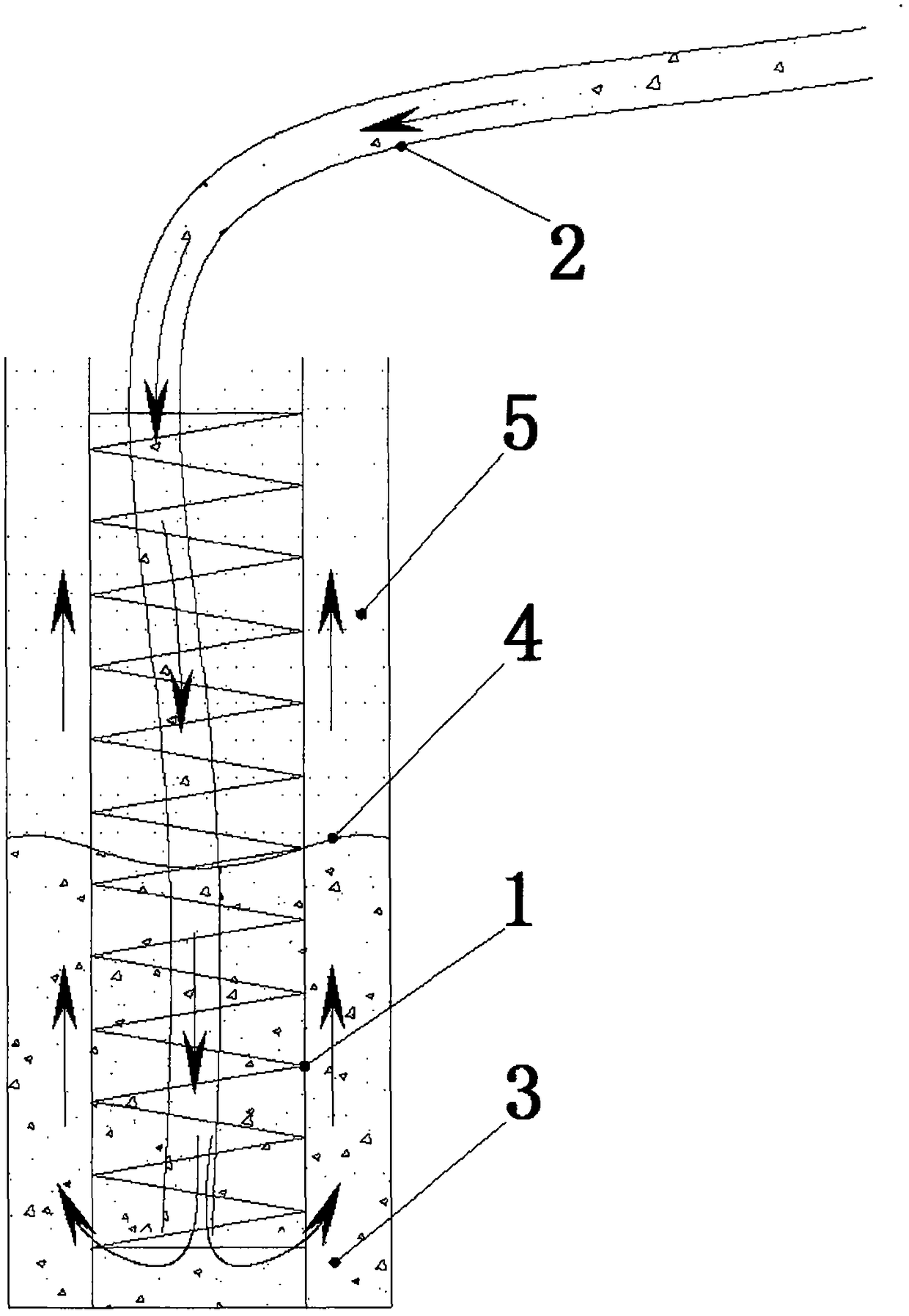

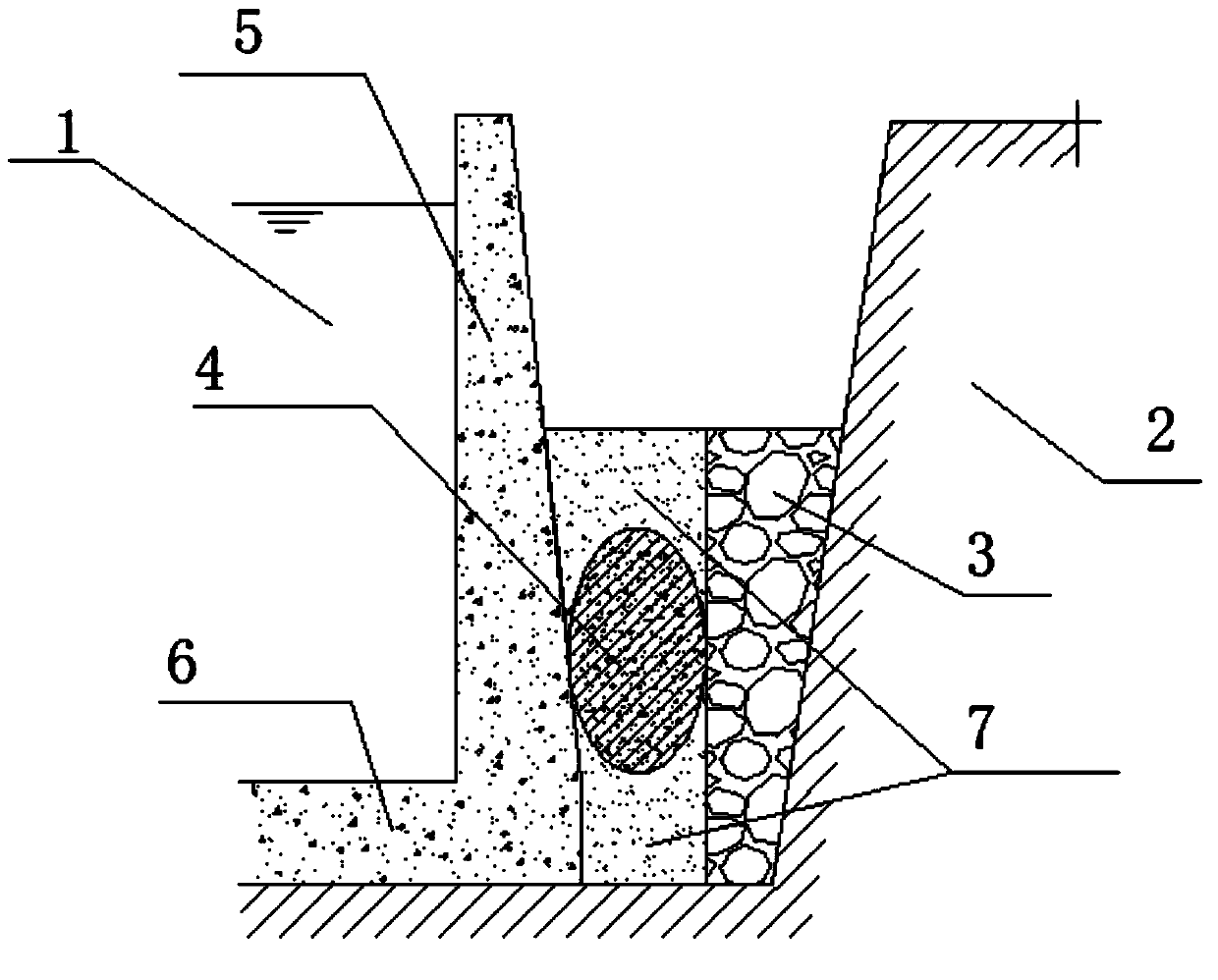

Drainage and anti-float method for underground building and its used device

InactiveCN1657712ALow costEasy to operateArtificial islandsProtective foundationEngineeringTube drain

Draining and anti-floating method of under ground building and its device relates to building technology. In accordance with the proposal of the invention, draining pipe is set in the foundation of underground building, with void on it for underground water penetrating into it, assembling the underground water then draining it, being blind drain with drainage outlet, then the water is sent out through draining pipe. The invention makes use of draining pipe underground to drain the underground water out, effectively solving the auti-floating of underground building.

Owner:无锡市建筑设计研究院有限责任公司

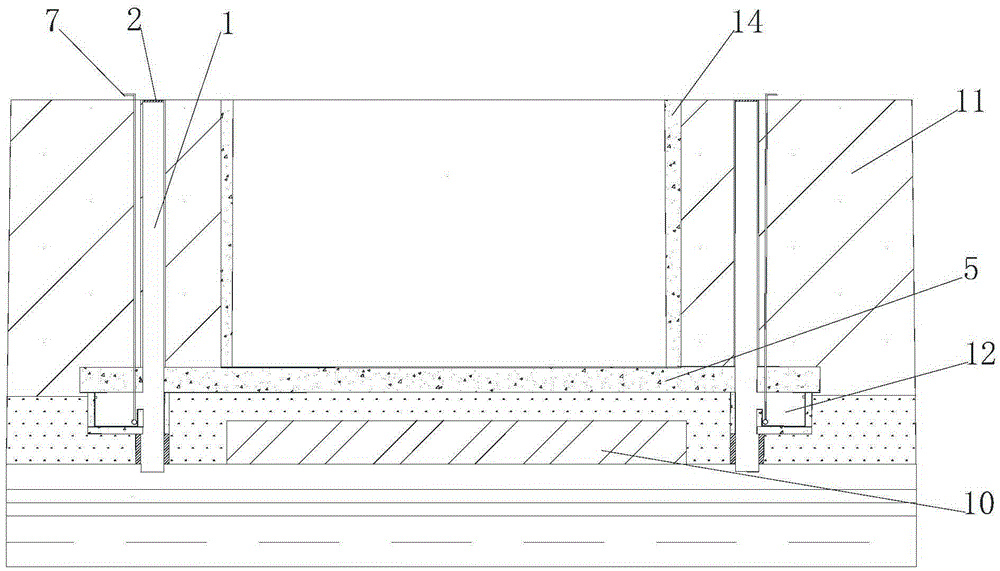

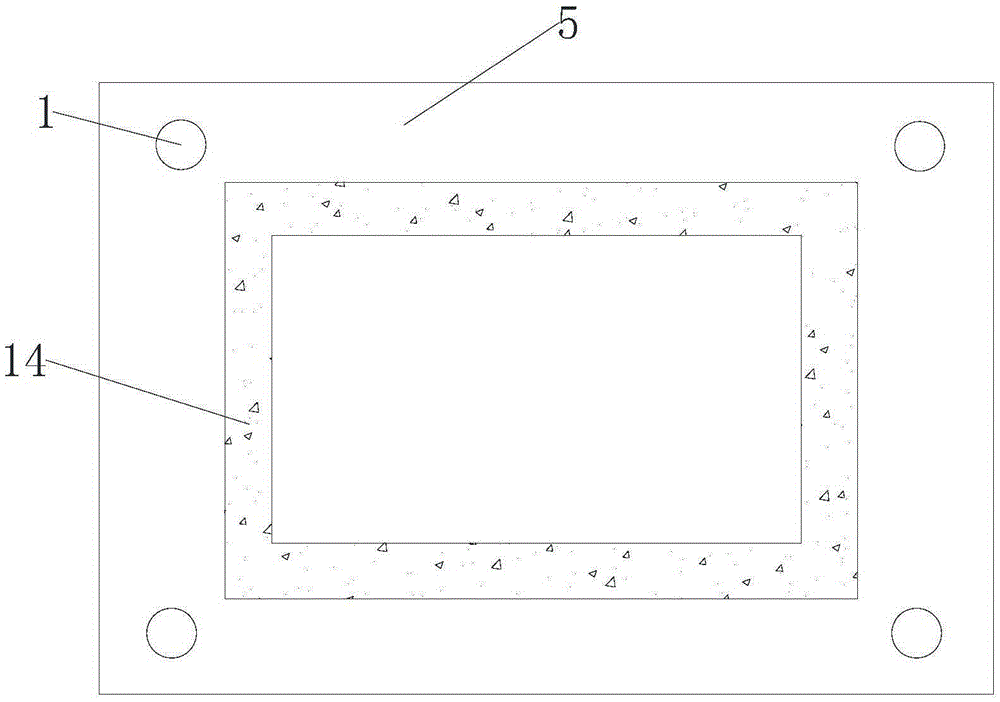

Basement anti-floating system based on low horizontal grout curtain and depressurization through water drawing

The invention relates to a basement anti-floating system based on a low horizontal grout curtain and depressurization through water drawing. The basement anti-floating system comprises a dewatering well structure and the horizontal grout curtain. The dewatering well structure comprises a dewatering well, a water storing pool, a water pump and a water level sensor. The dewatering well is arranged on a basement bottom plate on the periphery of a basement. The well opening of the dewatering well is directly connected to the ground. The bottom of the dewatering well penetrates into the position below the basement bottom plate. The water storing pool is arranged under the basement bottom plate and communicated with the dewatering well. The water pump and the water level sensor are arranged in the water storing pool. The water level sensor is connected with the water pump. The water level sensor is arranged under the basement bottom plate Compared with the prior art, the negativity and passivity of frequently-used methods for resisting the underground water buoyance at present are overcome, and the effect of basement anti-floating is achieved in two aspects that the buoyance of the underground water is reduced and the upper resistance for balancing the underground water buoyance is increased; the basement anti-floating system is suitable for regions where the requirement for the environment is high, the basement buried depth is large and the underground water level is high, and has good market value.

Owner:TONGJI UNIV

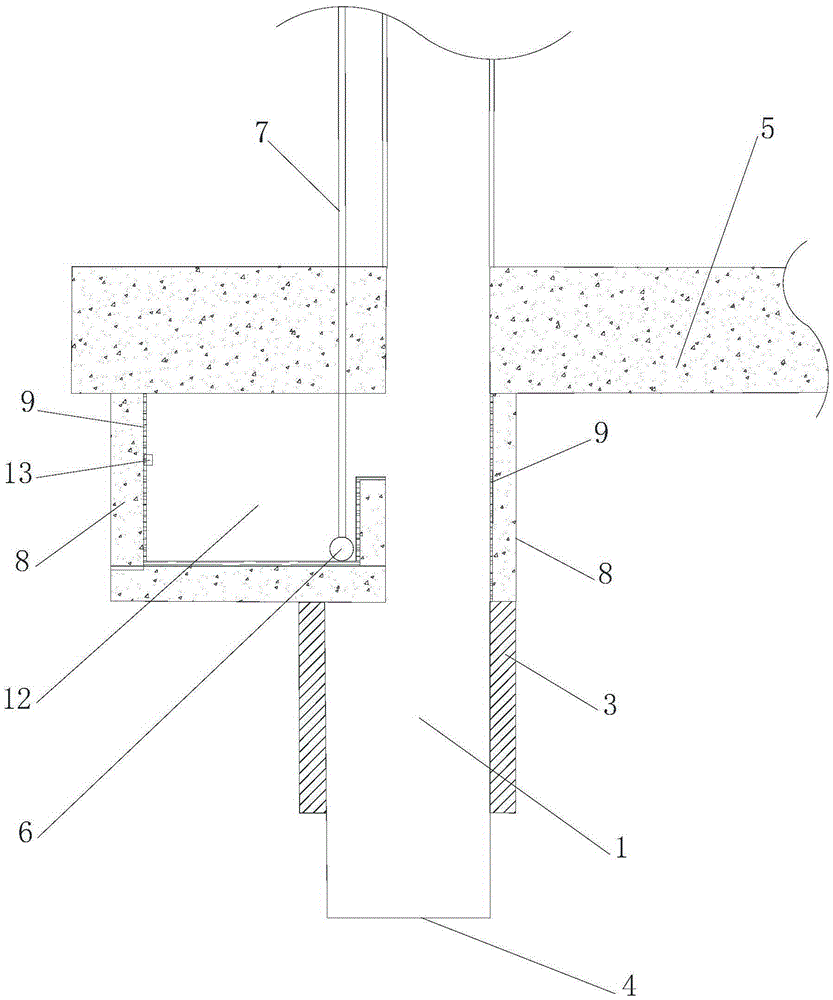

Interception and drainage pressure-reduction anti-floating system

The invention discloses an interception and drainage pressure-reduction anti-floating system which comprises a waterproof curtain arranged around an underground structure. A plurality of water collecting pits are formed below a bottom plate of the underground structure. Immersible pumps and water level induction switches are arranged in the water collecting pits. Well holes are formed in the bottoms of the water collecting pits. Pressure-reduction well pipes are arranged in the well holes. Anti-filtration layers are arranged around the pressure-reduction well pipes. The tops of the pressure-reduction well pipes are higher than openings of the well holes. The anti-filtration layers are located in the water collecting pits. The pressure-reduction well pipes are mainly formed by axially and vertically stacking a plurality of non-fine concrete well rings. The non-fine concrete well rings comprise upper annular ring beams, lower annular ring beams, stand columns and non-fine concrete wedge-shaped blocks. By means of cooperative work of the system, buoyant force on the bottom plate can be effectively reduced, the drainage amount can be controlled, the surrounding is protected against surface subsidence caused by the too large drainage amount, the number of uplift piles and the number of uplift anchor rods are greatly decreased, non-fine concrete blocks can be conveniently dismounted and replaced, and it is guaranteed that a pressure-reduction well has enough durability.

Owner:SOUTH CHINA UNIV OF TECH

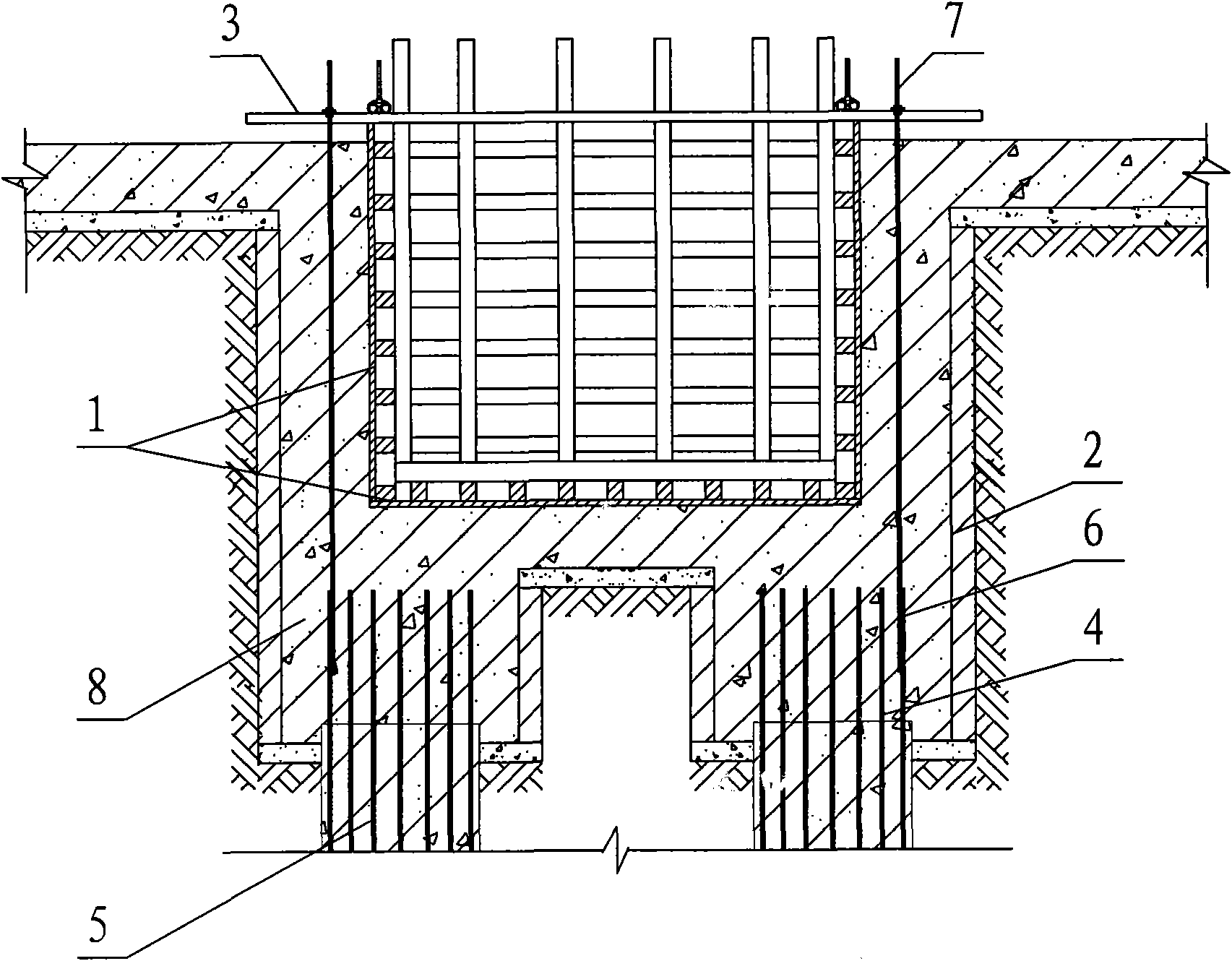

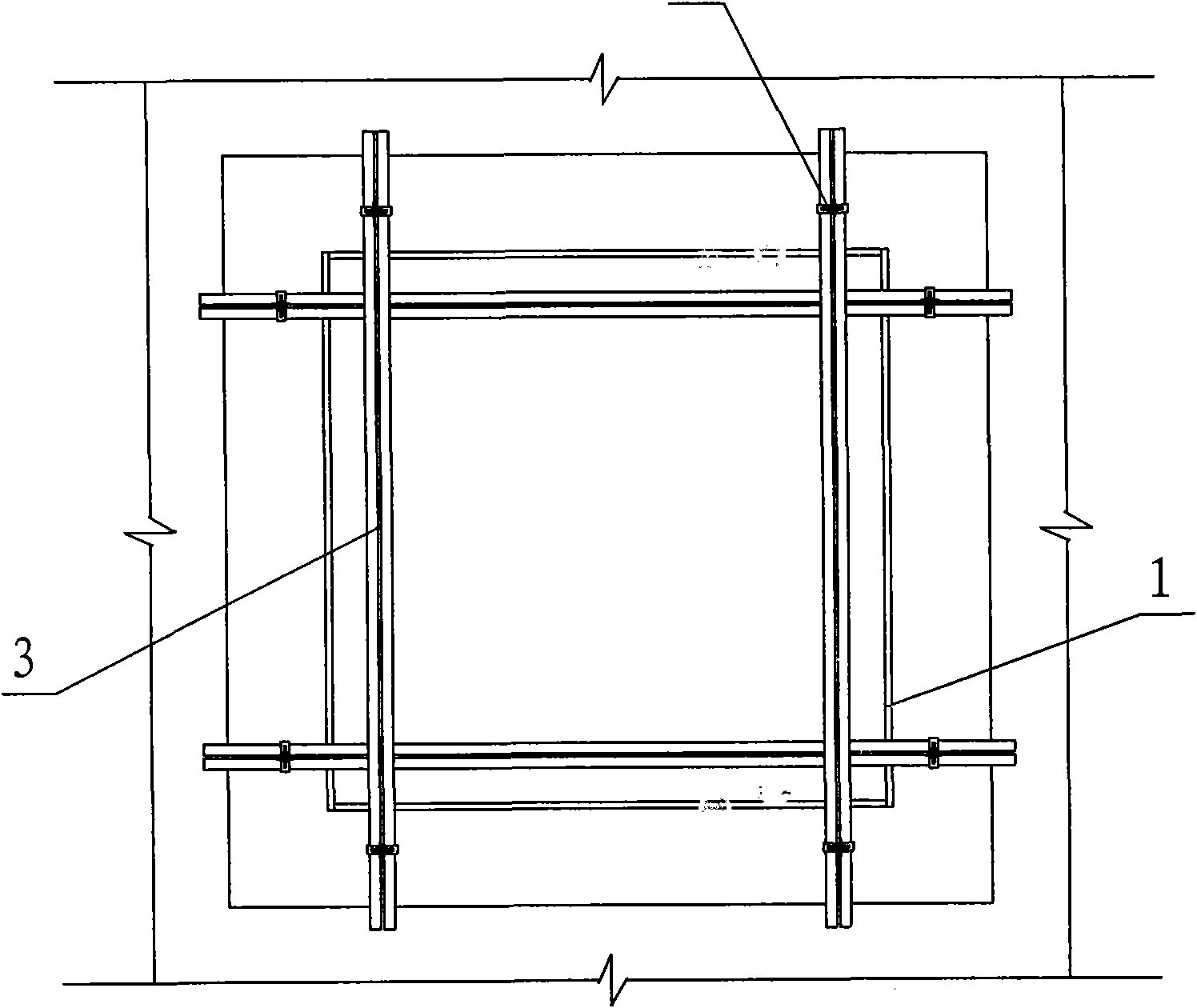

Construction method for resisting uplift in internal mold of concrete box

The invention provides a construction method for resisting the uplift in the internal mold of a concrete box. The method comprises the following steps: welding the longitudinal reinforcing steel bars on the box wall of the concrete box to be cast with the main reinforcing steel bars of a pile foundation at the bottom of a foundation pit; embedding an internal mold in the foundation pit and arranging a batten or a support tube at the top of the internal mold; tensioning the longitudinal reinforcing steel bars of the box wall, which are welded with the main reinforcing steel bars of the pile foundation, and then, fixedly connecting the upper ends of the longitudinal reinforcing steel bars of the box wall with the batten or the support tube; and casting the concrete and resisting the buoyant force of the concrete applying on the bottom plate of the box mold by the reaction force generated by the welded longitudinal reinforcing steel bars of the box wall and the batten or the support tube, so that the internal mold can be pressed by the support tube to prevent the internal mold from going up. The invention is suitable for resisting the buoyant force in the internal mold of a small-size concrete box and has the characteristics of reliable buoyancy resistance and easily guaranteed construction quality; and compared with the conventional method, the invention does not need secondary transport with high labor consumption, economizes on human resources and improves the production efficiency.

Owner:HUNAN SUNPEAK CONSTR

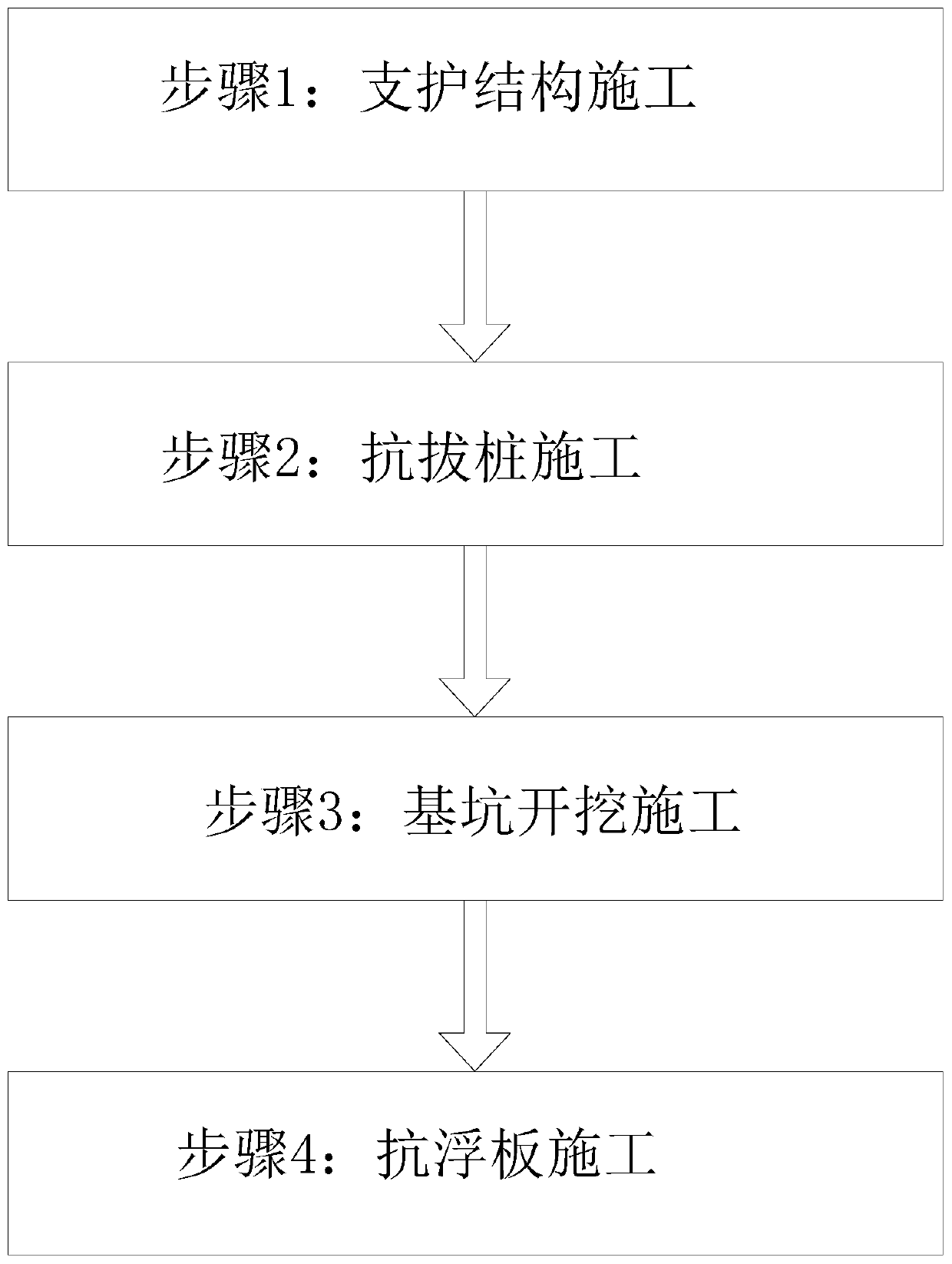

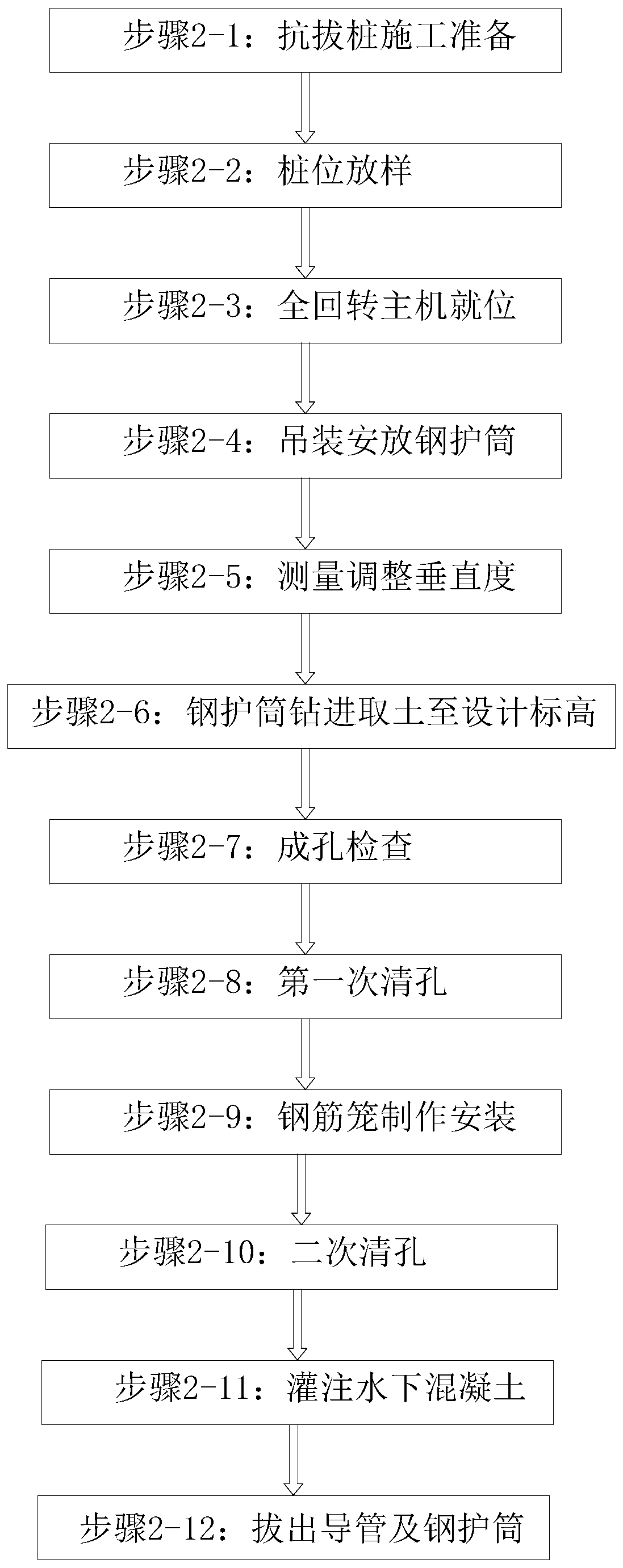

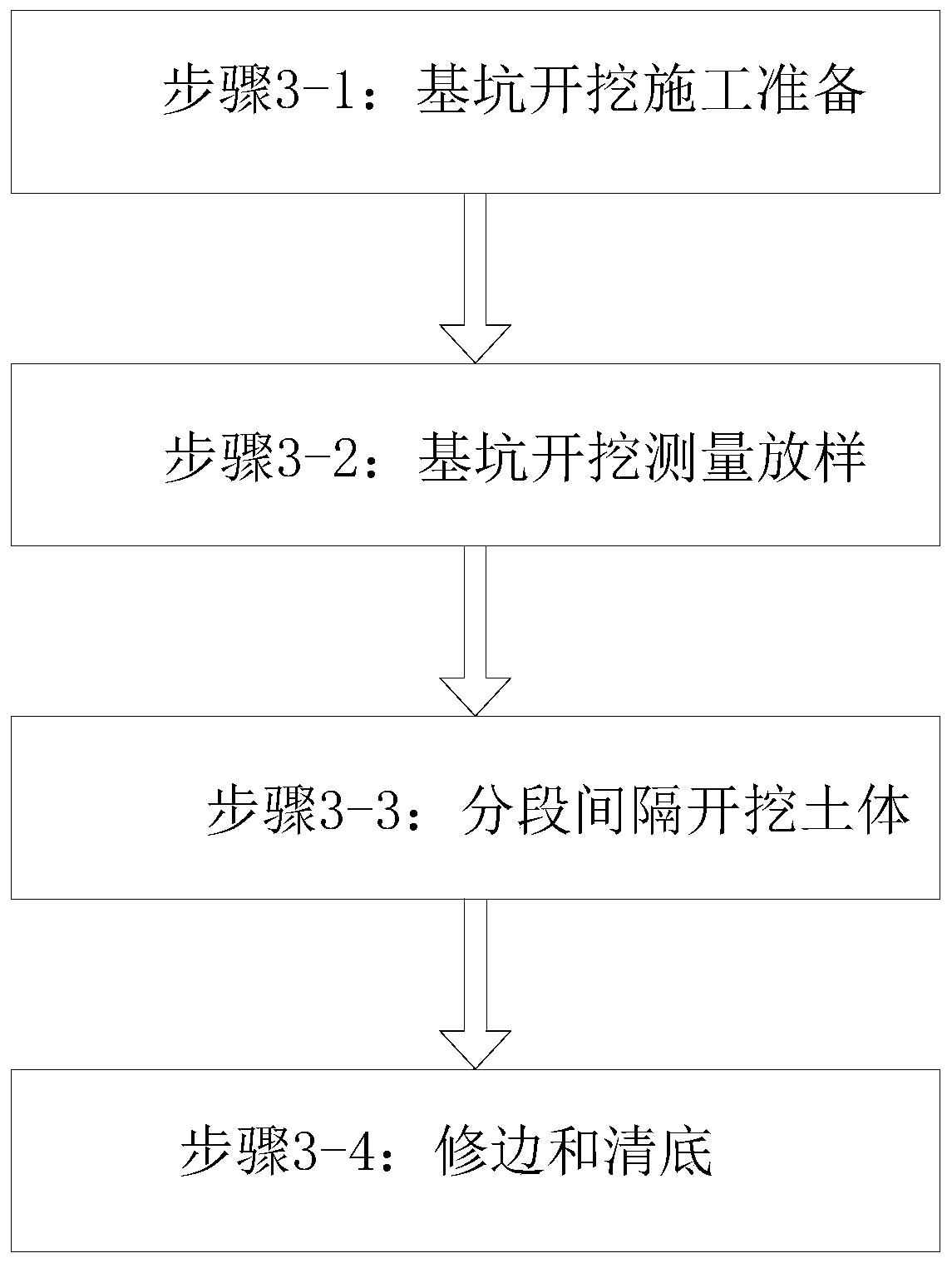

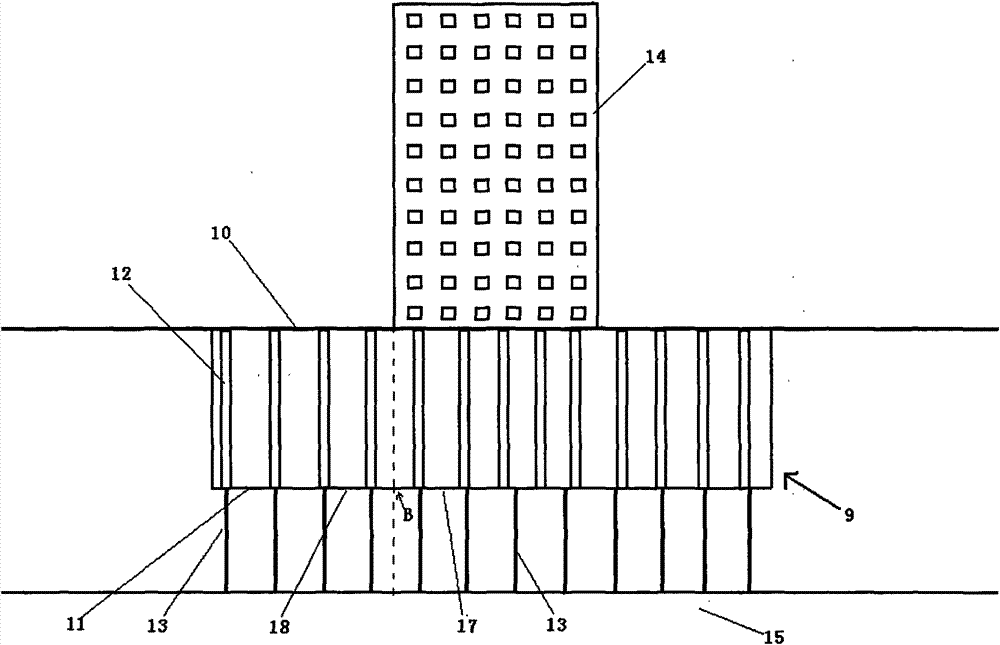

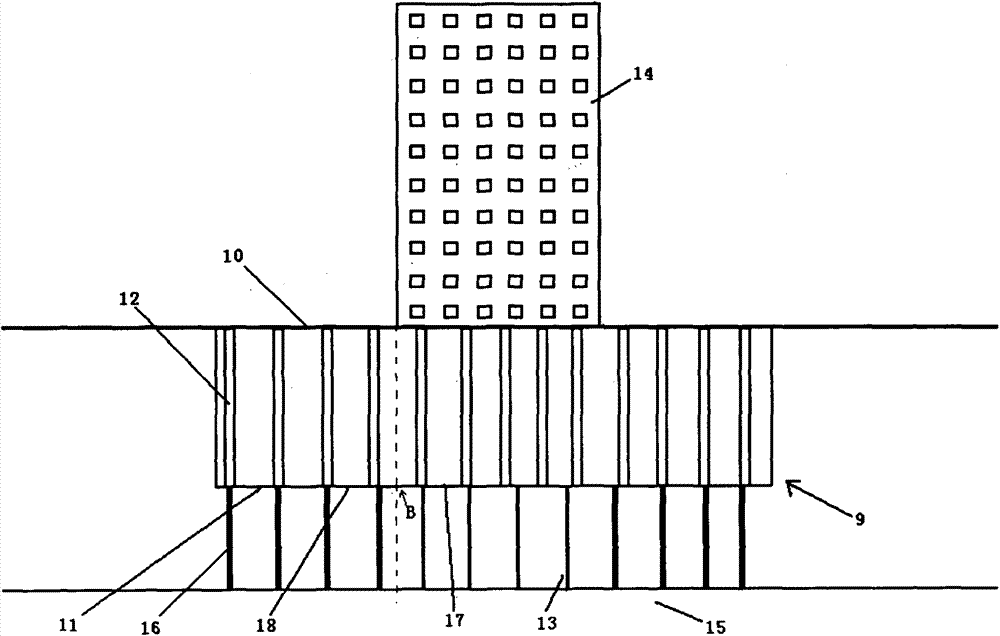

Anti-floating construction method and structure for earth excavation of subway tunnel foundation pit with shallow earth covering at pit bottom

PendingCN110080237AImprove anti-floating effectSufficient pullout resistanceProtective foundationExcavationsStructure of the EarthEnvironmentally friendly

The invention discloses an anti-floating construction method and structure for earth excavation of a subway tunnel foundation pit with shallow earth covering at the pit bottom. The construction methodcomprises the steps that a supporting structure is constructed, and supporting construction is conducted according to foundation pit supporting design requirements; uplift piles are constructed, namely a row of uplift cast-in-place piles are respectively arranged on the outer side of the safety protection line; foundation pit excavation construction is conducted, specifically, foundation pit excavation construction is conducted in a segmented excavation mode; anti-floating plate construction is conducted, specifically, anti-floating plate construction is conducted in a segmented constructionmode; the construction structure comprises uplift piles and an anti-floating plate, the uplift piles are arranged on the two sides of a tunnel in rows, the two rows of uplift piles are arranged outside safety lines on the two sides of the tunnel, and the anti-floating plate is poured at the upper ends of the uplift piles and stretches across the two rows of uplift piles; the anti-floating construction method and structure for earth excavation of a subway tunnel foundation pit with shallow earth covering at the pit bottom have the advantages of being good in anti-floating effect, simple in construction technology, high in construction efficiency, low in construction cost, environmentally friendly and the like, and the advantages which are not achieved in the prior art are achieved.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

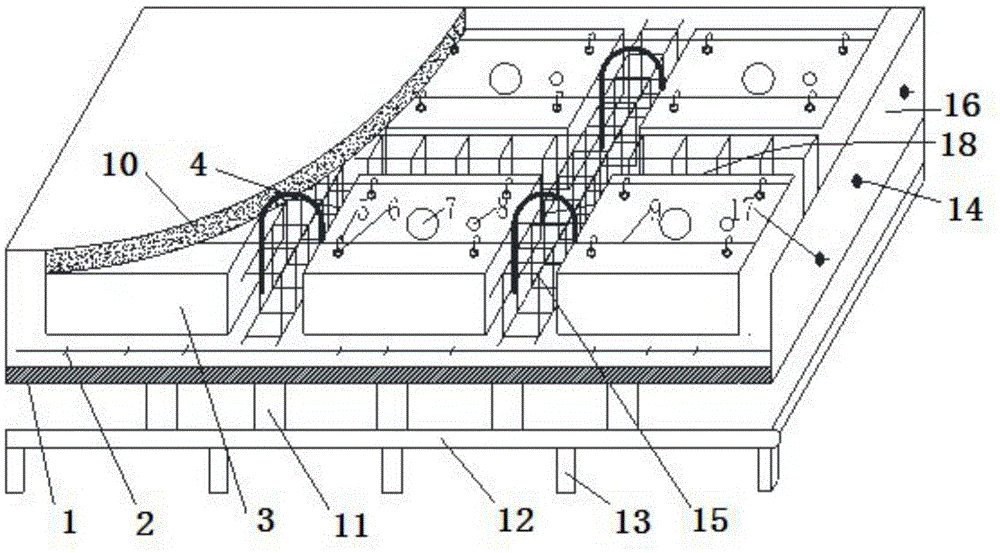

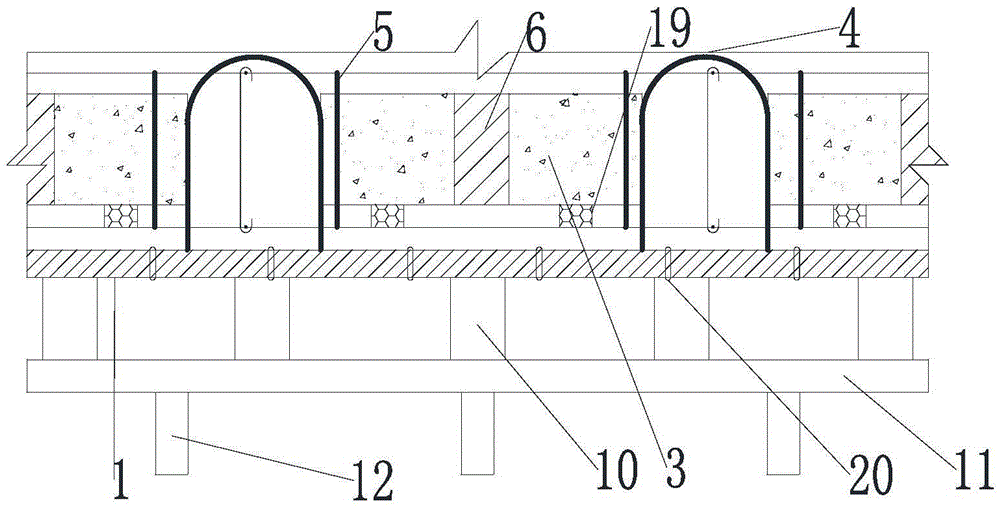

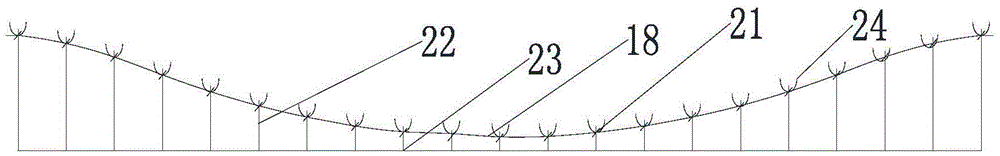

Construction method for slowly-bonded hollow prestressing floor slab through large-span ultra-thick cast-in-place post-tensioning method

The invention discloses a construction method for a slowly-bonded hollow prestressing floor slab through a large-span ultra-thick cast-in-place post-tensioning method. The method includes the main construction steps of (1) bottom formwork laying, (2) reinforcing steel bar construction, (3) side formwork installation, (4) prefabricated hollow block installation and reinforcement, (5) concrete pouring, and (6) prestressing tension. Main floor slab reinforcing steel bars are connected with a side formwork, so that the position of a main reinforcing steel bar framework is fixed. Prefabricated hollow blocks are connected with the main floor slab reinforcing steel bars through anti-floating reinforcing steel bars. The good effect is achieved in dealing with floating of the hollow blocks. U-shaped clips are used for locating the hollow blocks in the horizontal direction. Slowly-bonded prestressing reinforcing steel bars are located through locating supports accurately. By the adoption of the construction method, the use amount of concrete is reduced, the construction efficiency is improved, the manufacturing cost is reduced, damage to the environment is reduced, and the economic and social benefits are good.

Owner:JIANGSU HUAJIANG CONSTR GROUP

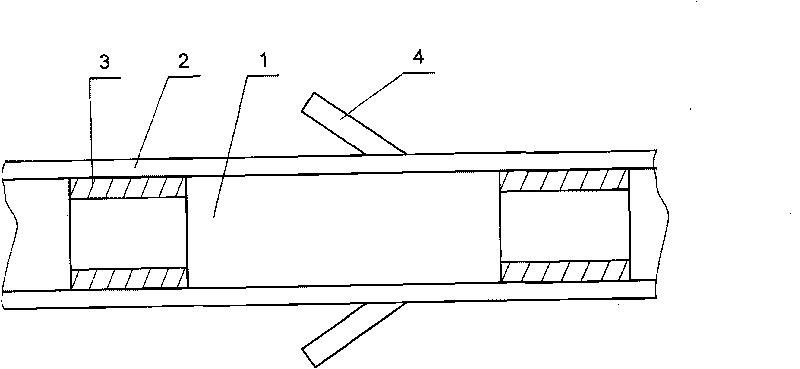

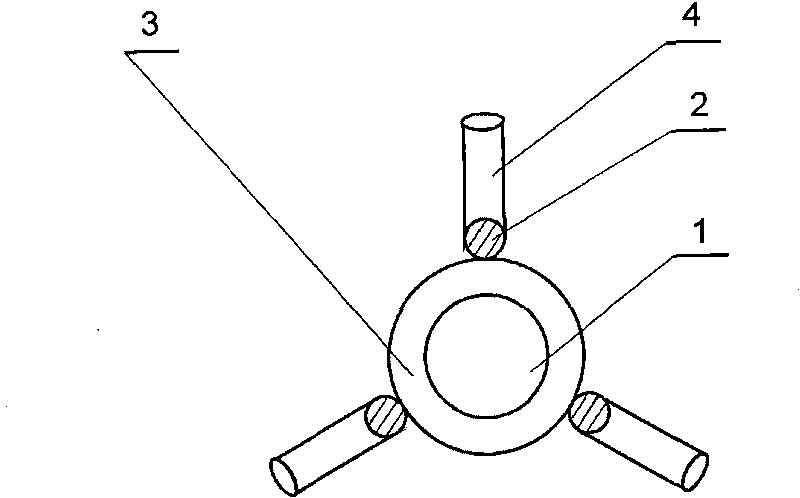

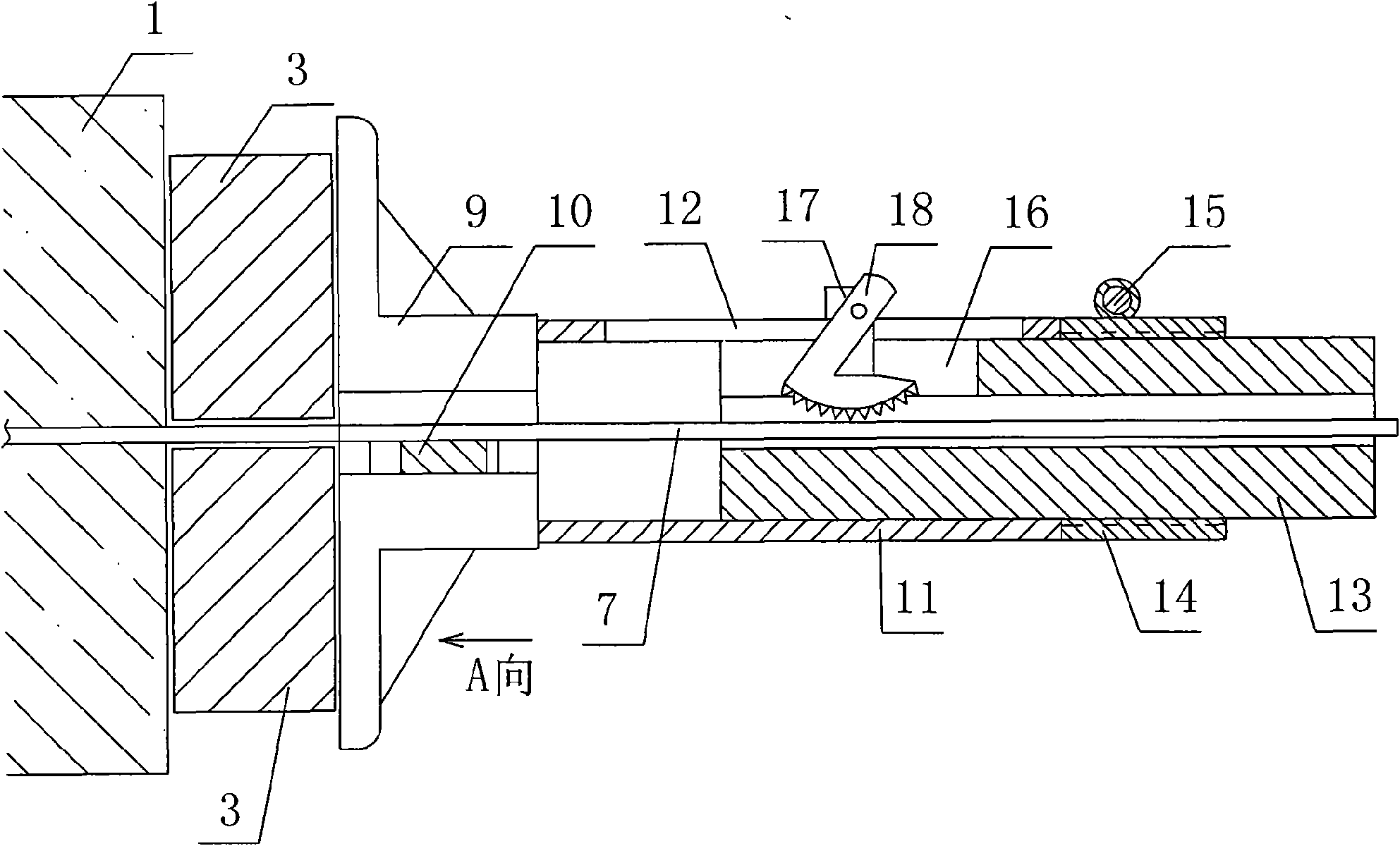

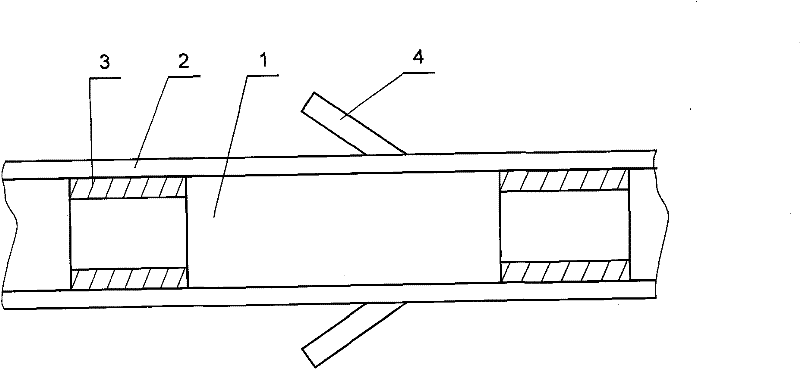

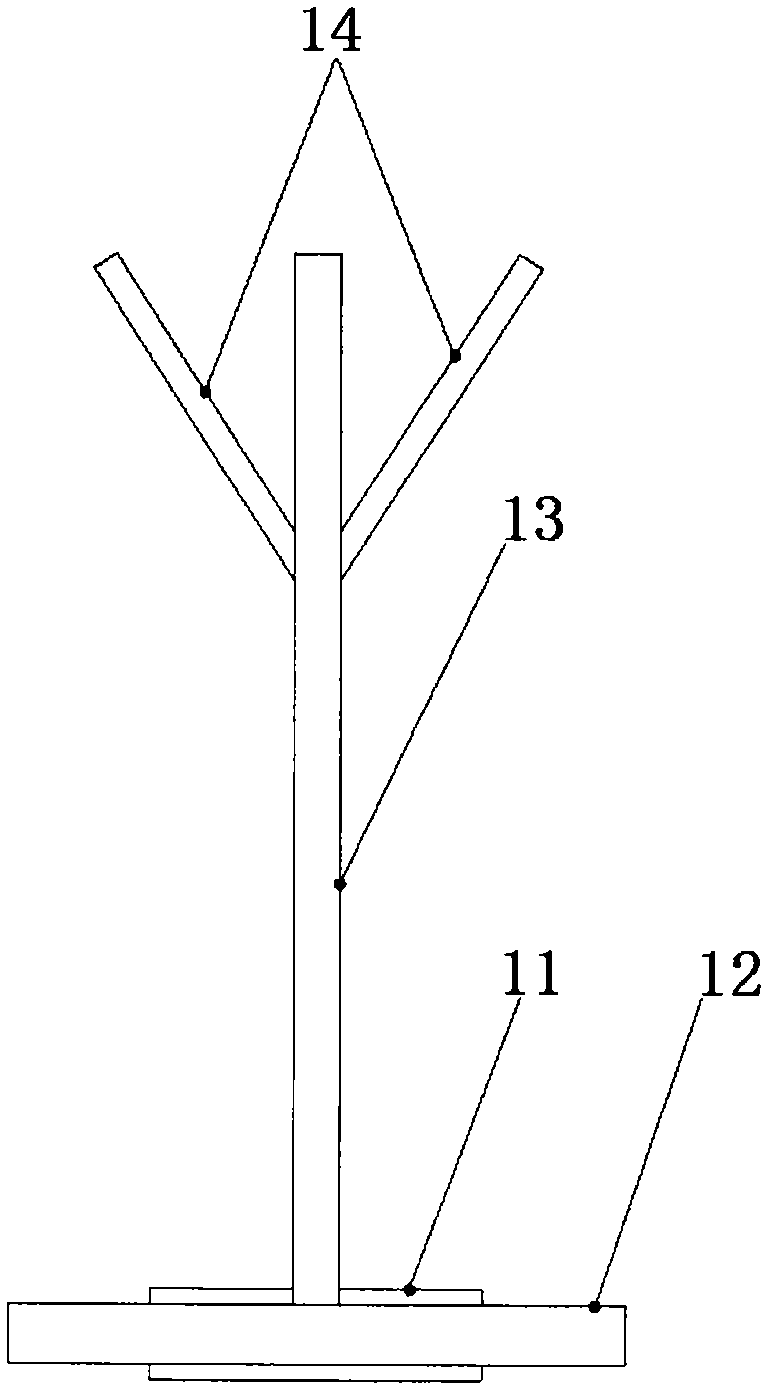

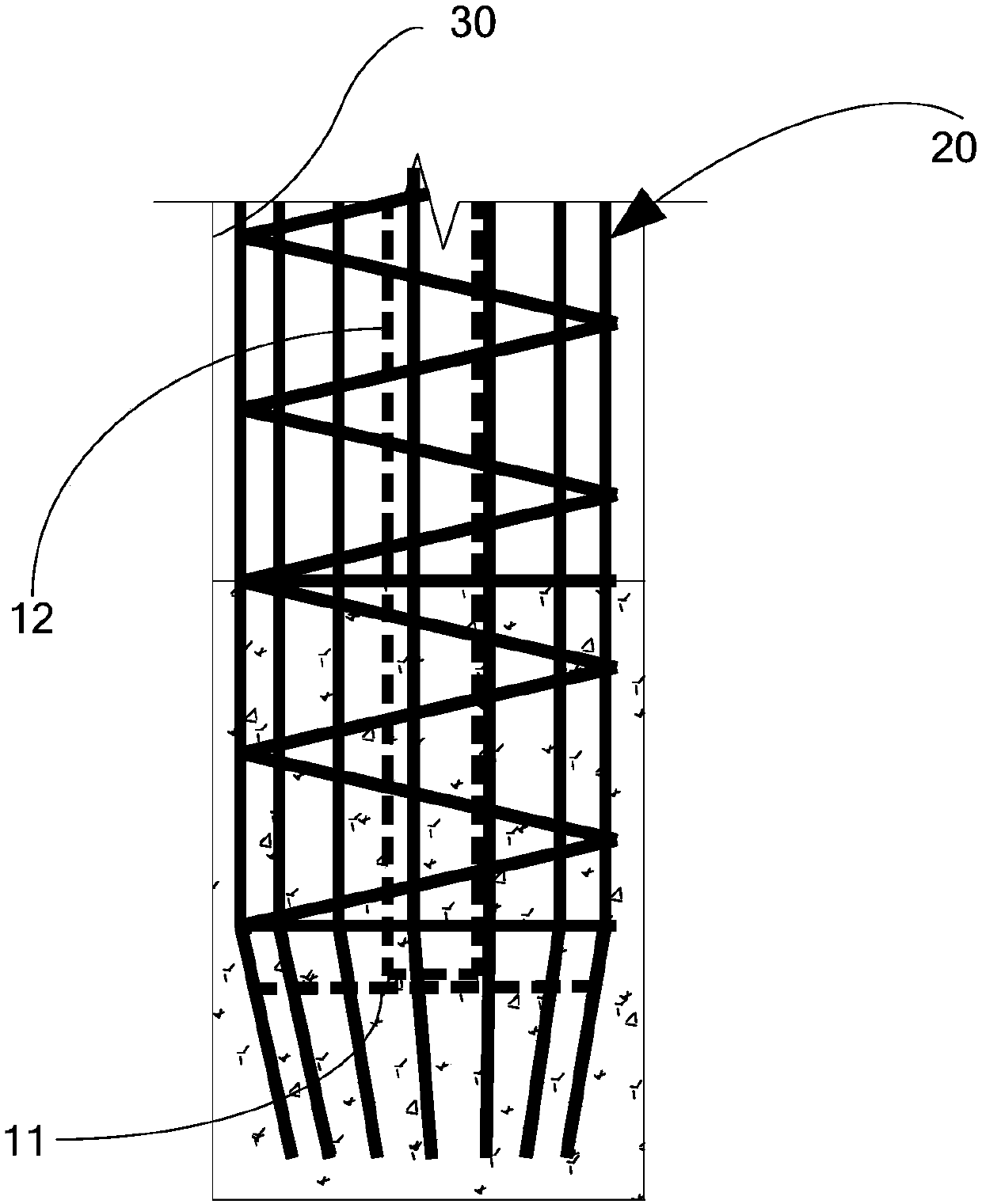

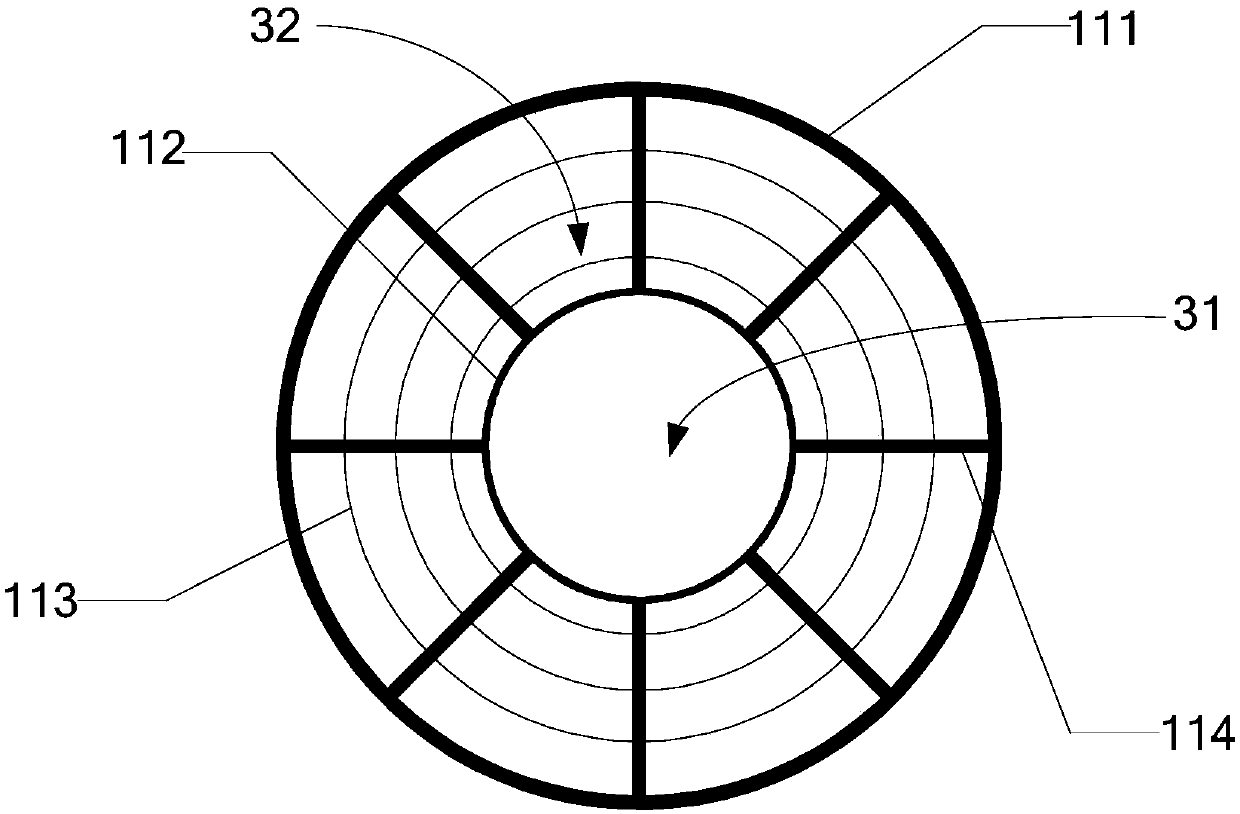

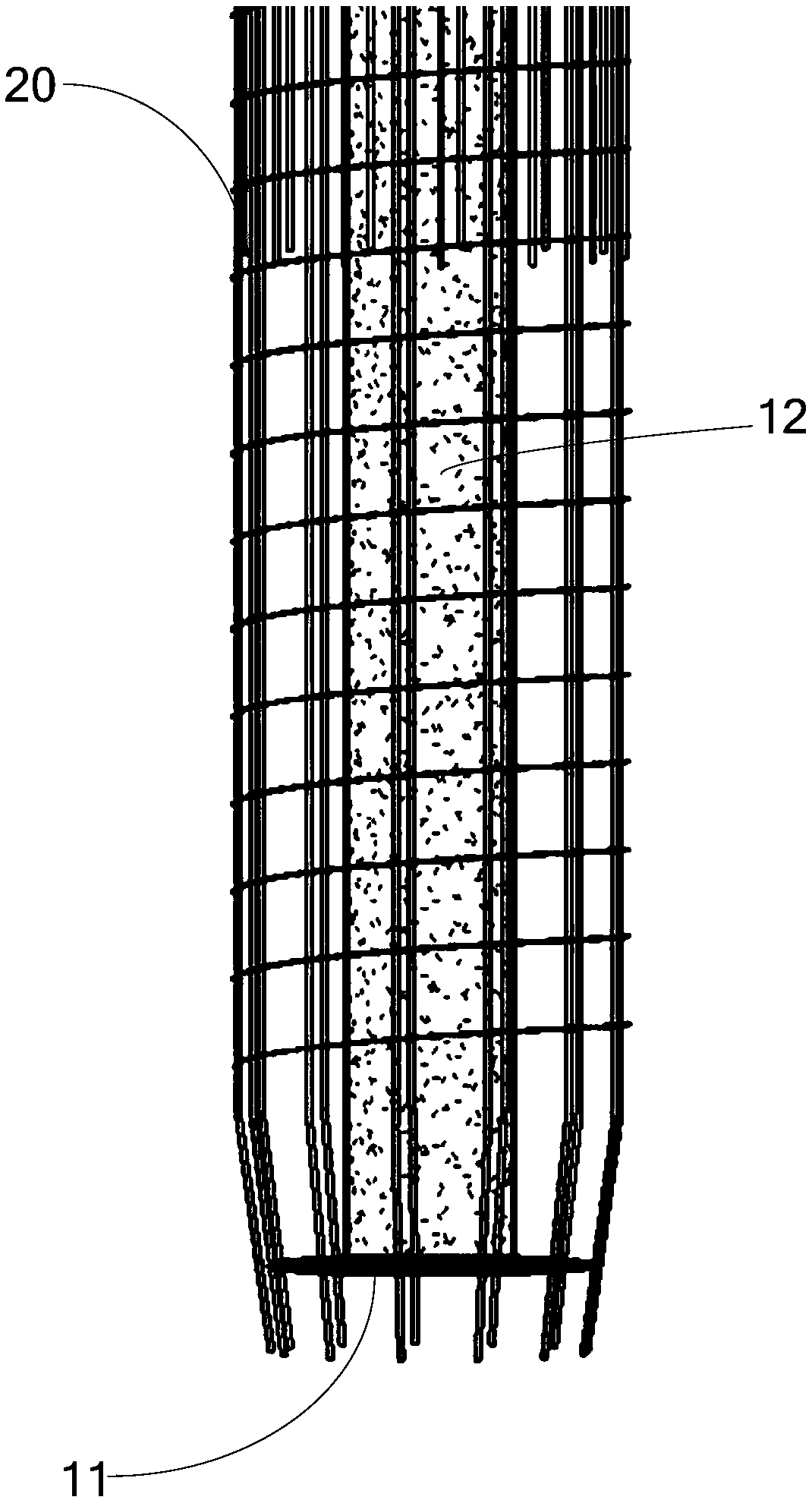

Anti-floating construction method and device for large-diameter cast-in-situ bored pile steel reinforcement cage

ActiveCN104294816AGood anti-floating effectEasy to makeProtective foundationBulkheads/pilesEngineeringRebar

The invention discloses an anti-floating construction method and device for a large-diameter cast-in-situ bored pile steel reinforcement cage. The method comprises the steps that the welded steel reinforcement cage is perpendicularly placed in a large-diameter cast-in-situ bored pile; the top of the steel reinforcement cage is higher than the height of an opening of a large-diameter bored hole; a steel tube frame is arranged on the top of the steel reinforcement cage, and counter weights are arranged on the steel pipe frame; perfusion construction is carried out; the steel reinforcement cage is prevented from floating through the counter weights in the perfusion process, and therefore the perfusion quality of the large-diameter cast-in-situ bored pile steel reinforcement cage is ensured. The method and device are suitable for constructing hole pile steel reinforcement cages with the diameter of 3m and more than 3 m in a cast-in-situ bored (stamped) pile and have the advantages of being obvious in anti-floating effect, easy to manufacture and mount, low in investment cost and the like.

Owner:CCFED THE FIRST CONSTR & ENG

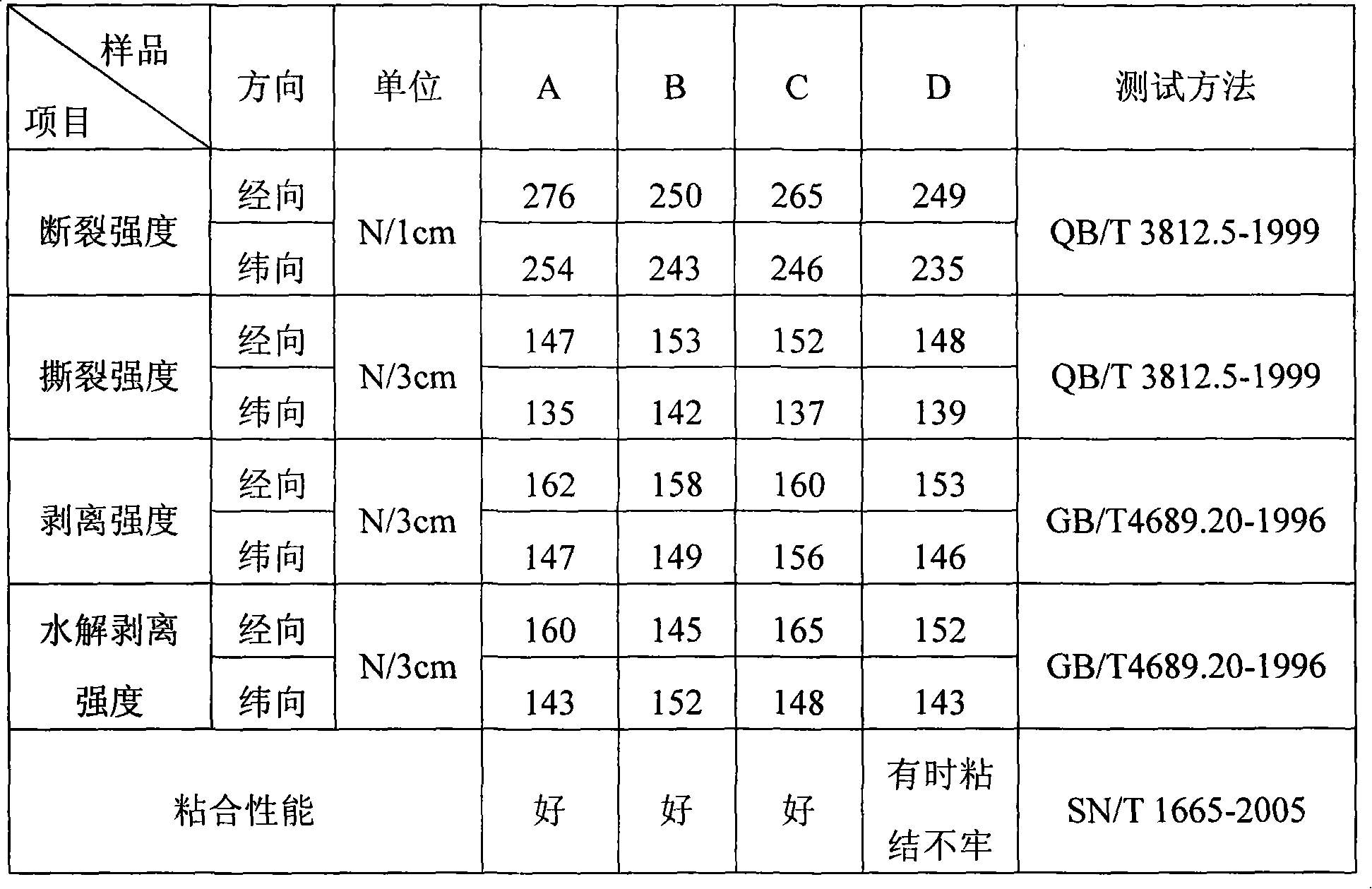

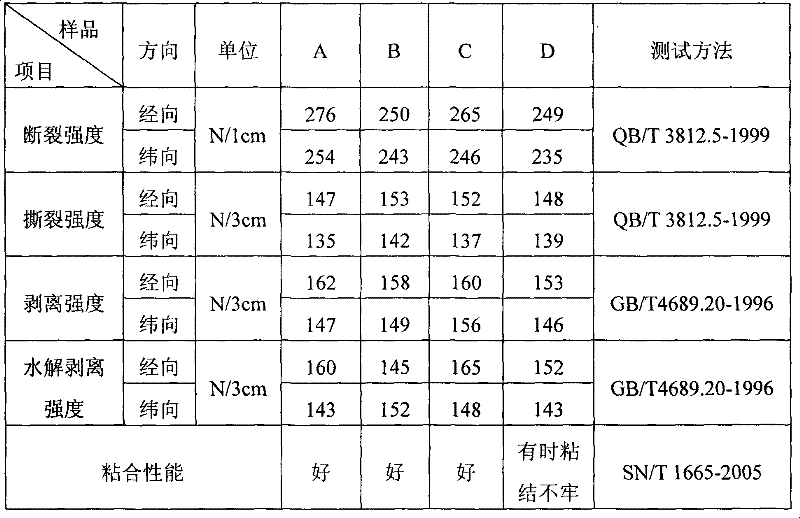

Anti-flooding assistant, preparation method thereof and use thereof

The invention discloses an anti-flooding assistant, which contains polyurethane resin, polyurea, high-thixotropy solid powder and an organic solvent. The invention also provides a method for preparing the anti-flooding assistant, which comprises the following steps: adding amine into solvent polyurethane resin paste, stirring and uniformly mixing the mixture, dripping isocyanate, and stirring the resulting mixture for reaction for synthesizing polyurea; and adding the high-thixotropy solid powder into a product and allowing the high-thixotropy solid powder to disperse uniformly. The invention also discloses the use of the anti-flooding assistant in coating and coloring of the surface of leather synthesized by using ultrafine fibers. The anti-flooding assistant has dynamic and static anti-flooding performance that is better than that of conventional wetting agent, dispersant and anti-flooding assistant, is complete compatible with a resin system which is the same as the anti-flooding assistant, avoids generating finished product drawbacks when the additive amount increases, simplifies the production of synthetic leathers and facilitates operation.

Owner:HUAFON MICROFIBER SHANGHAI

Construction method of prestressed anti-floating anchor rod

ActiveCN101736760BIncrease frictionImprove anti-floating effectProtective foundationBuilding material handlingConfined waterPre stress

The invention discloses a prestressed anti-floating anchor rod and a construction method thereof. The invention is characterized in that alignment steel tubes are arranged in an anchor rod body which is formed by a plurality of steel bars uniformly distributed along the circle, the steel bars are provided with a plurality of barbs, the alignment steel tubes are arranged at intervals along the axis of the anchor rod body and are fixedly connected with the steel bars, the barbs are welded with the steel bars. The construction method comprises the following steps: grouting into piles; arranging the anchor rod; locking the anchor rod; and sealing the anchor. Compared with the prior art, the invention has the advantages of simple structure, convenient construction, good anti-floating effect and low cost, especially being applicable to the reconstruction of old buildings with built underground structures and confined water.

Owner:SHANGHAI ZHIPING FOUNDATION ENG CO LTD

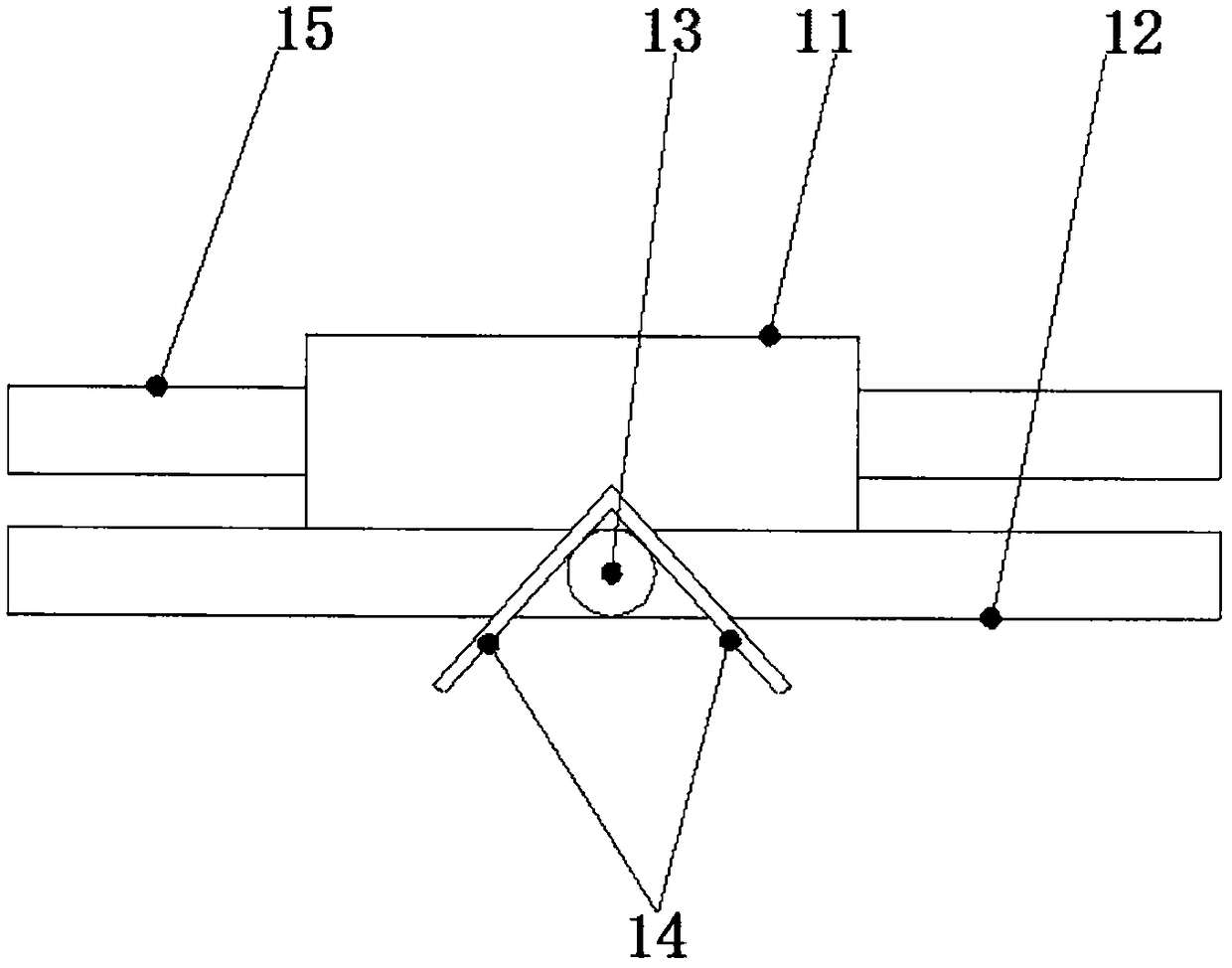

Cast-in-place concrete pile reinforcement cage barbed floating prevention device and application method thereof

The invention provides a cast-in-place concrete pile reinforcement cage barbed floating prevention device. The floating prevention device comprises a base, barbs, springs and limiting stop dogs, wherein the base is fixed to the outer sidewall of a reinforcement cage; one end of each barb is rotatably connected to one end of the base; the springs are used for forming pretightening force between thebarbs and the base; the limiting stop dogs are fixed to the upper surface of the base; one end of each limiting stop dog abuts against the upper surface of the corresponding barb and is used for limiting the extreme position of the barb in the rotating process. According to the floating prevention device, the barbs and the base are connected through hinges and the springs to enable the barbs andthe base to be closed and opened; when the barbs and the base are in an opened state, the reinforcement cage can be dropped and lifted up conveniently; when the barbs and the base are in a closed state, the tip ends of the barbs can firmly grasp the hole wall, and the floating prevention effect is good; during pouring of concrete, the cast-in-place concrete pile reinforcement cage barbed floatingprevention device can prevent the reinforcement cage from floating without additional staff and devices.

Owner:SHANXI CONSTR ENG CO LTD

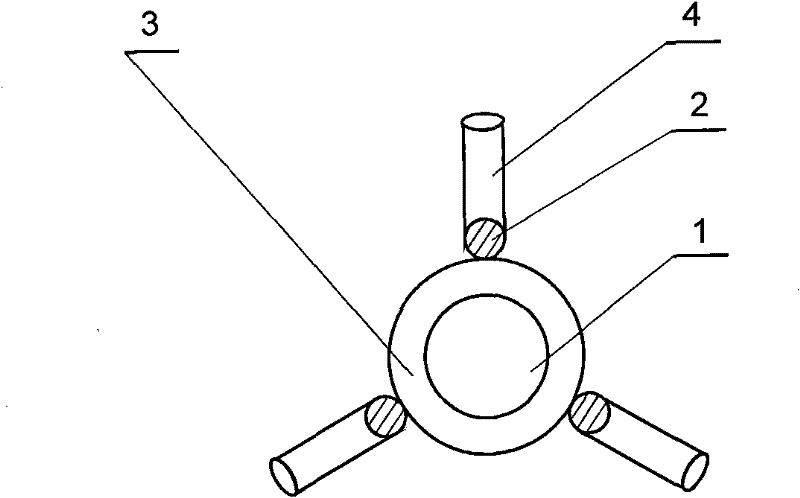

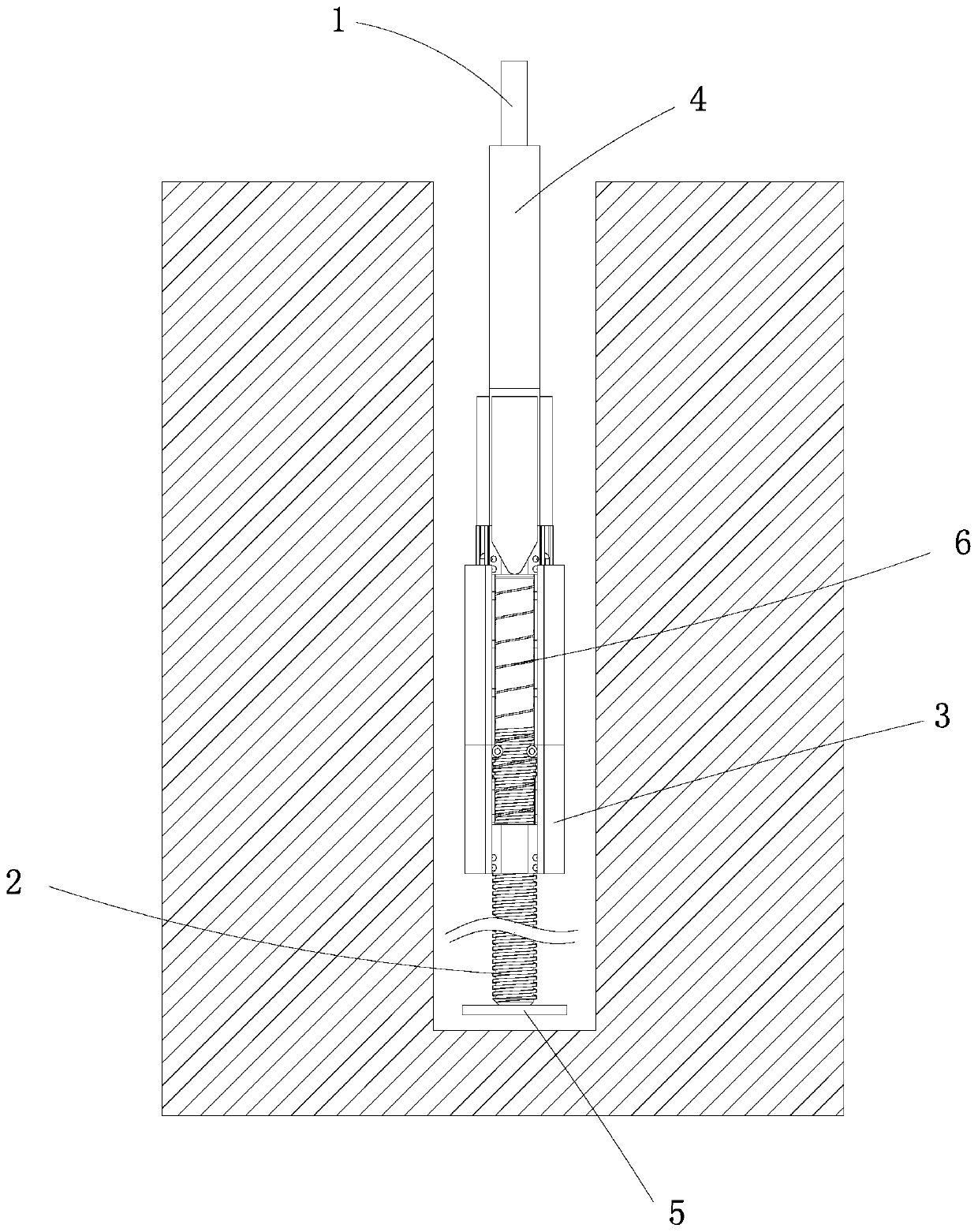

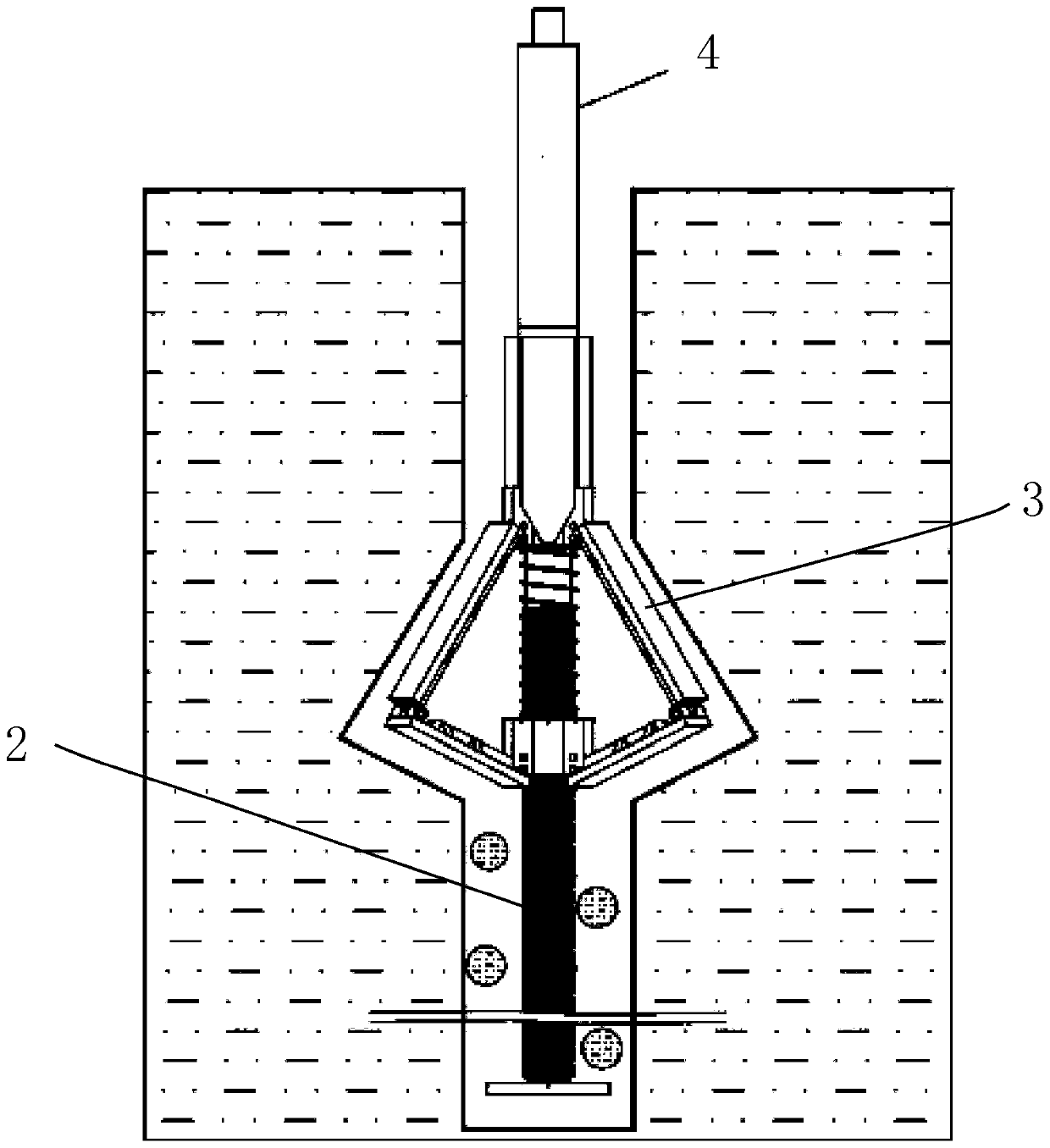

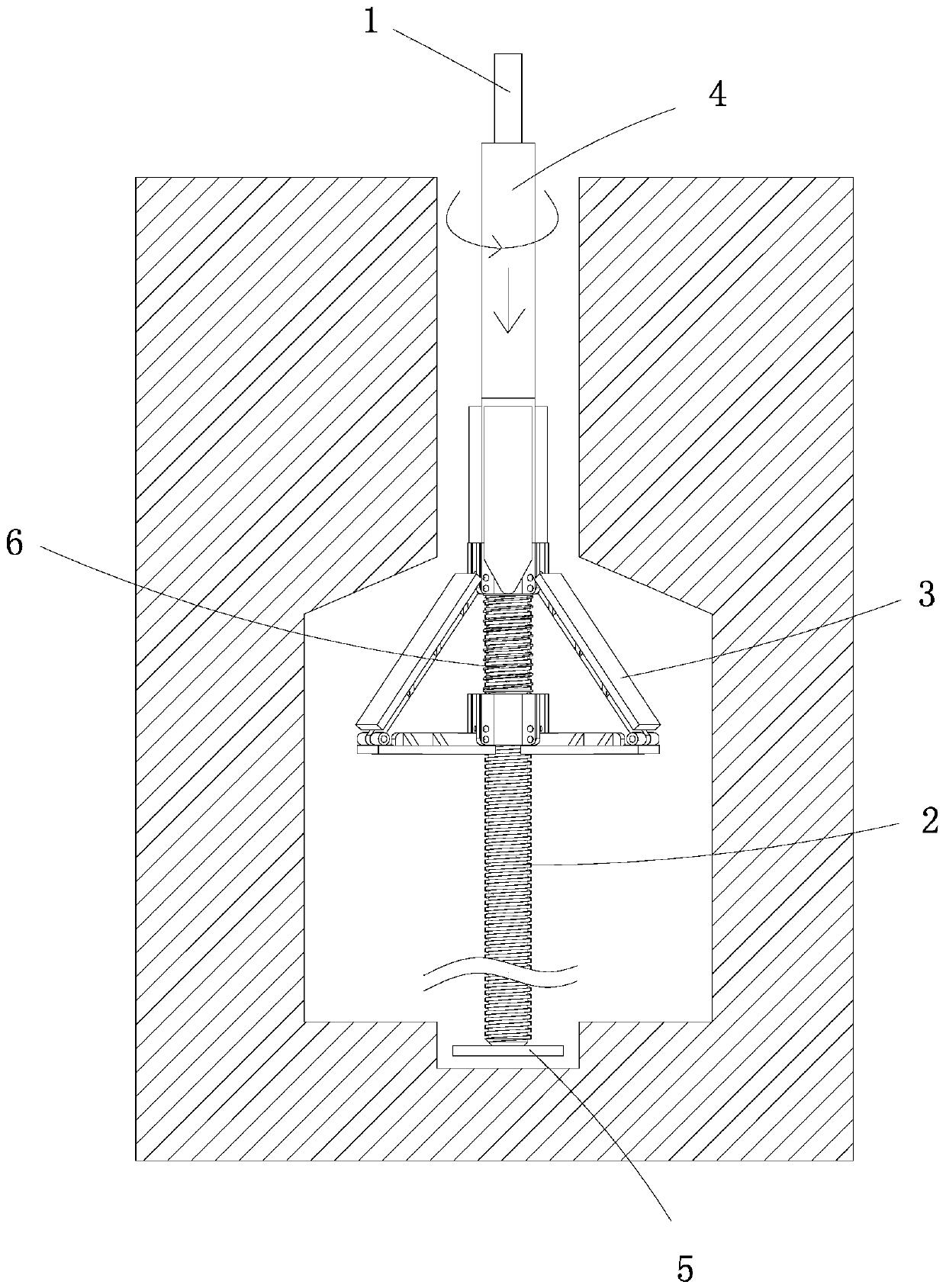

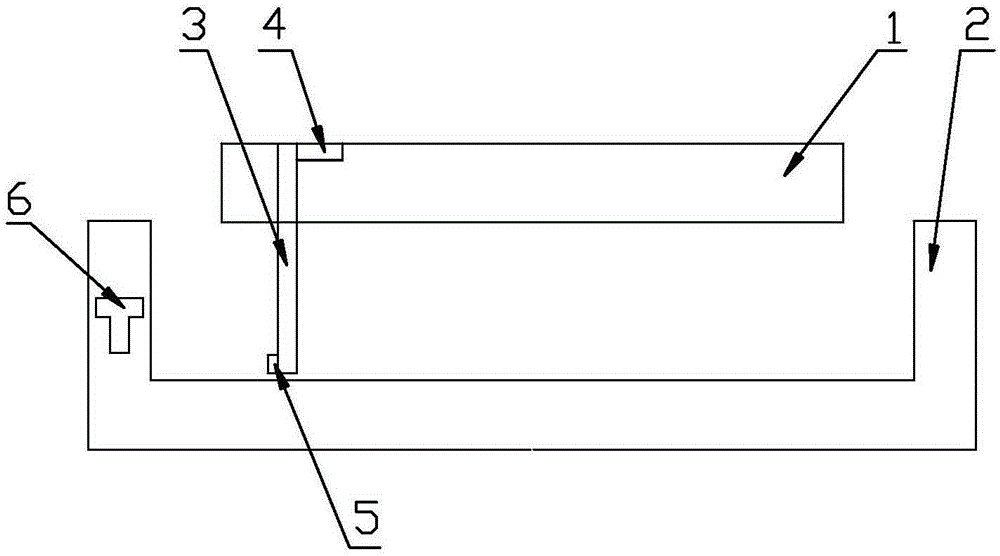

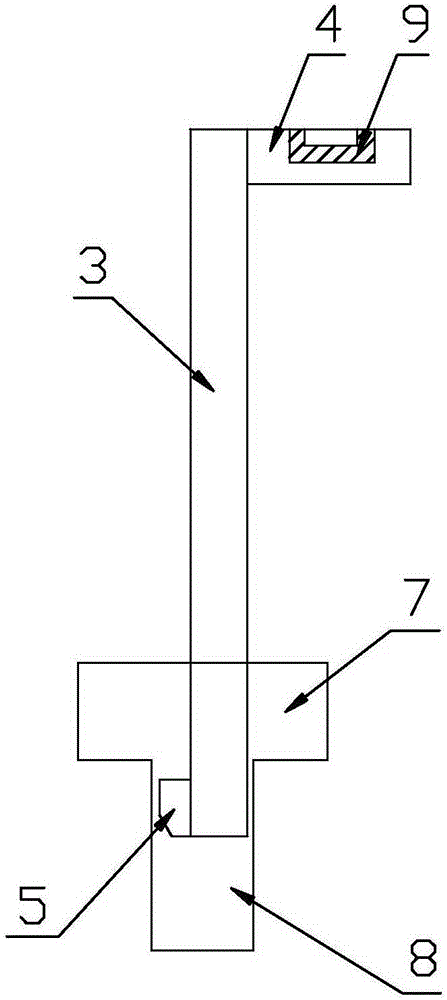

Self-expanded body anti-floating anchor rod

PendingCN110004928ALarge apertureEasy to operateProtective foundationBulkheads/pilesEngineeringDeep hole

The invention discloses a self-expanded body anti-floating anchor rod, and relates to the technical field of construction engineering. The self-expanded body anti-floating anchor rod is a pressure-bearing type self-expanded body anchor rod and includes a main rod, an expanded body anchoring mechanism and a driving piece, wherein the expanded body anchoring mechanism is arranged on the main rod, the driving piece sleeves the expanded body anchoring mechanism, and the driving piece drives the expanded body anchoring mechanism to expand in the radial direction and to move along the main rod in the axial direction so as to perform hole expanding movements. According to the self-expanded body anti-floating anchor rod, the driving piece drives the expanded body anchoring mechanism to expand in the radial direction and to move along the main rod in the axial direction to perform the hole expanding movements, thus a hole diameter of a deep hole is widened, hole expanding positioning is accurate, and the shape is fixed; and the self-expanded body anti-floating anchor rod is simple in structure, convenient to operate and good in anti-floating effect.

Owner:CHINA JINGYE ENG TECH CO LTD

Anti-floating well lid

ActiveCN105178361AEasy to openWill not affect levelingArtificial islandsUnderwater structuresEngineeringMechanical engineering

The invention discloses an anti-floating well lid. The well lid comprises a lid body and a base, wherein the base is arranged in a bottom well mouth; the lid body is a circular structure fitted with the base; the lid body is connected on the base by virtue of an anti-floating structure; the anti-floating structure comprises a pin, a pin head and a pin bottom; the upper part of the pin is vertically and movably connected on the side edge of the lid body; a groove is formed in the lid body; the pin head is clamped in the groove; an opening which is a T-shaped structure is formed in the base; the opening comprises an upper part and a lower part; the pin is vertically arranged in the opening; and the pin bottom is clamped in the lower part of the opening. The anti-floating well lid is simple in structure, convenient in operation, good in anti-floating effect, capable of effectively preventing a well lid floating phenomenon caused by upward impact force to the well lid when lower pressure is extremely great because of rainwater and the like, and capable of realizing opening of the well lid by rotating.

Owner:泗县宁宇市政设施科技有限公司

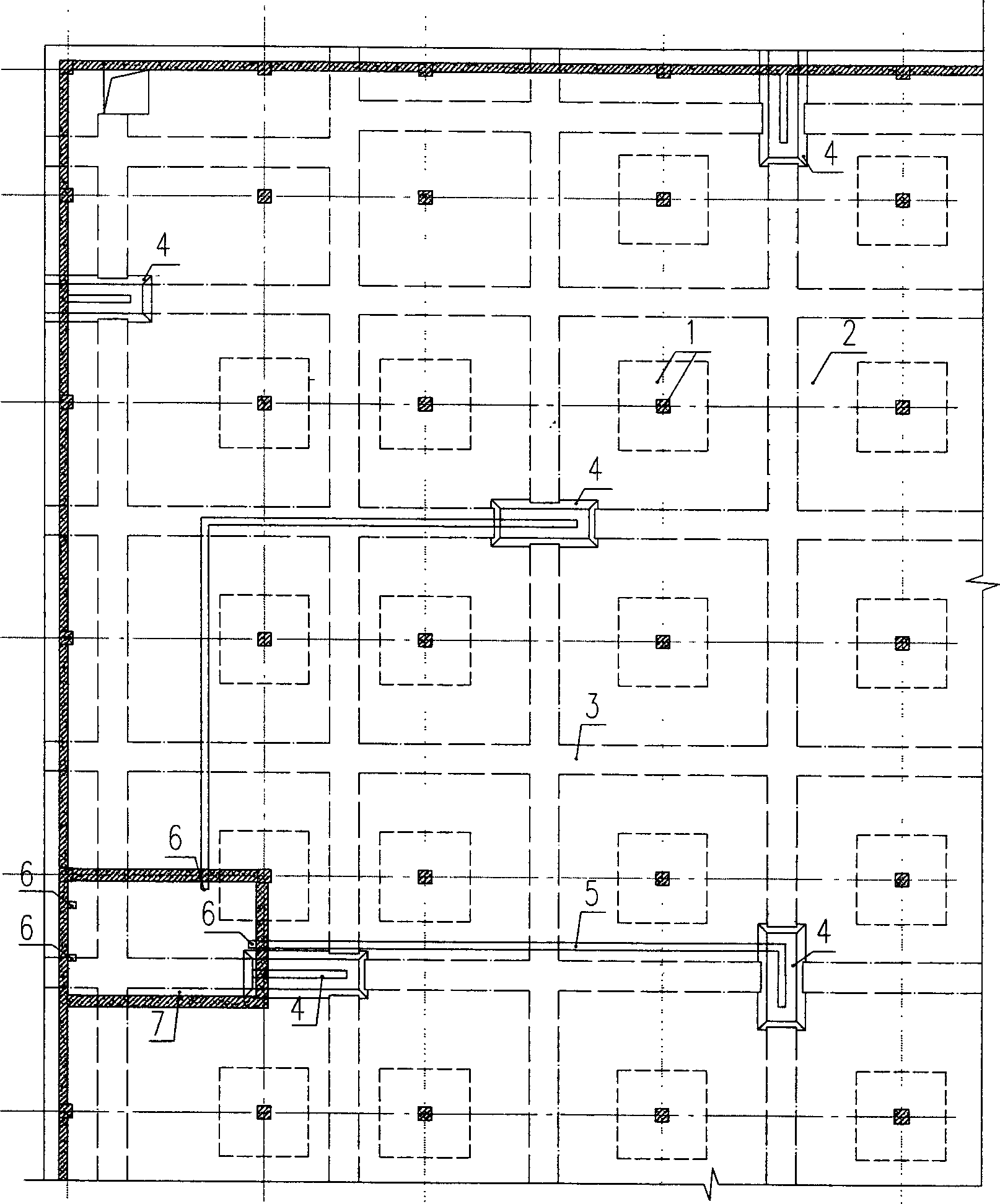

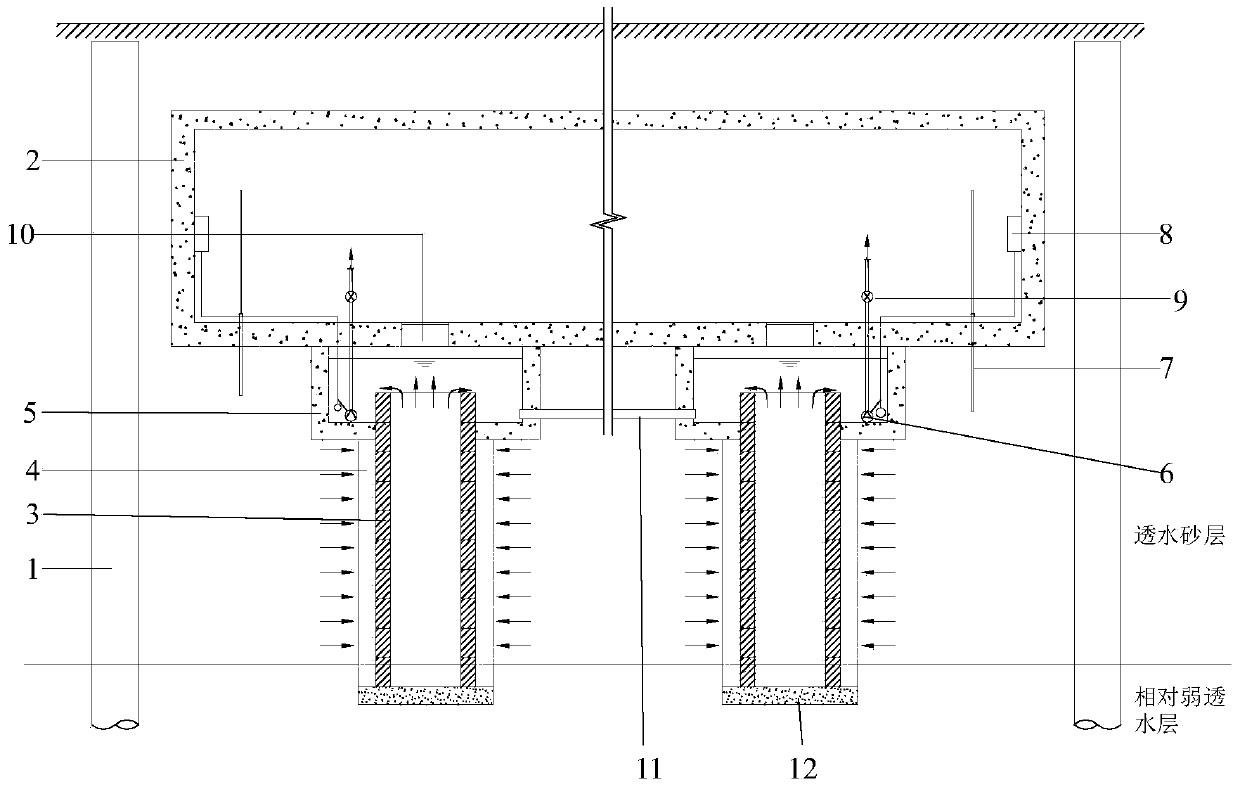

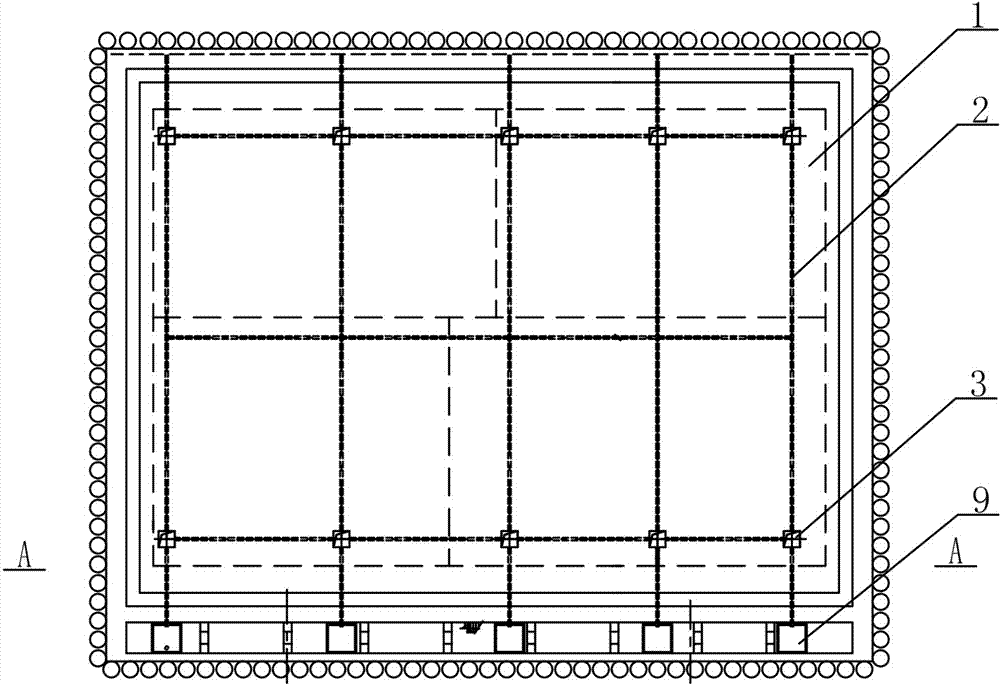

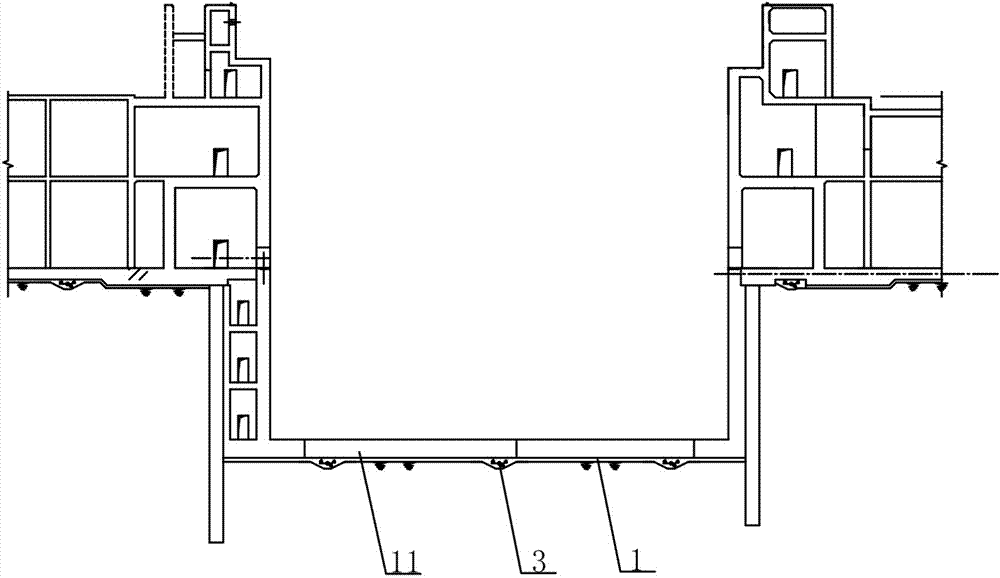

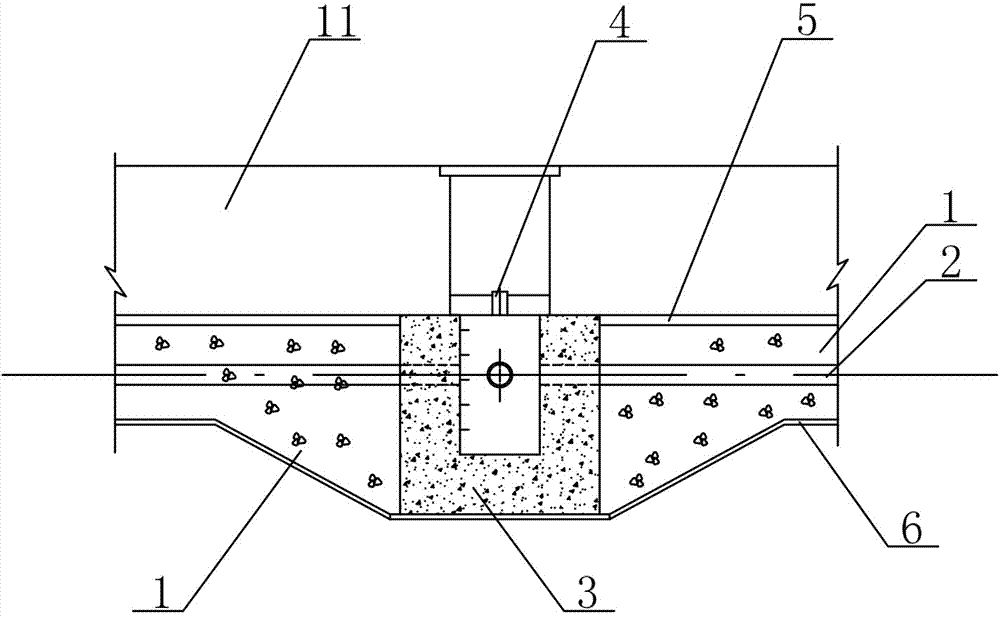

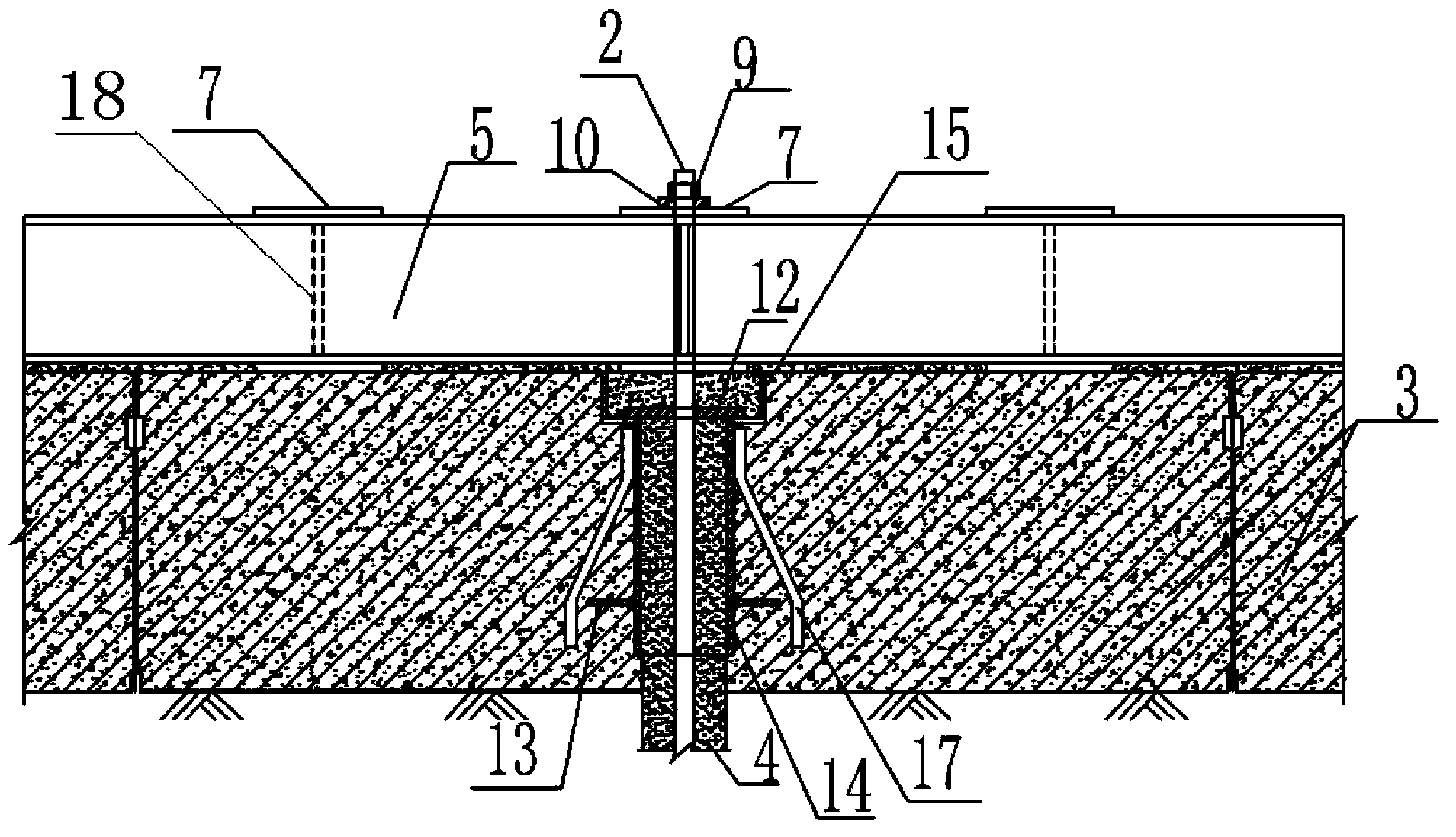

Pressure reduction and water drainage system under ultra-deep underground space structure bottom plate

InactiveCN104712000ALow crack resistance requirementsReduce settingsProtective foundationEngineeringWater well

The invention discloses a pressure reduction and water drainage system under an ultra-deep underground space structure bottom plate. The pressure reduction and water drainage system is characterized by being composed of an inverted filter, water drainage pipes, water collection wells and pumping wells, the inverted filter, the water drainage pipes, the water collection wells and the pumping wells are arranged below the bottom plate, and the water drainage pipes form a mesh-shaped water drainage pipe network through a plurality of steel pipes provided with small holes; the water collection wells are arranged at the joints of the water drainage pipes which are longitudinally and transversely intersected; the pumping wells are arranged outside the water drainage pipes and communicated with the water collection wells; underground water is converged to the water collection wells from the drainage pipes in the inverted filter and is pumped out through the pumping wells. Compared with the prior art, the requirement for the anti-crack performance of the bottom plate is low, the pressure reduction effect and the anti-floating effect are good, the surrounding ground surface settlement can be effectively controlled while the bottom plate meets the anti-floating requirement, the number of anti-floating piles which are arranged is greatly decreased, the structure is simple, construction is convenient, the engineering cost is low, and the pressure reduction and water drainage system is particularly suitable for the anti-floating design of an underground space structure which is 30 m deep.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Pile-foundation steel reinforcement cage anti-floating device and anti-floating method

The invention provides a pile-foundation steel reinforcement cage anti-floating device and anti-floating method. The pile-foundation steel reinforcement cage anti-floating device comprises a leakage plate used for being connected with a steel reinforcement cage and a grouting hard tube, a slurry outlet of the grouting hard tube is pressed against the leakage plate, and a first leakage hole locatedbelow the slurry outlet is formed in the leakage plate. The steel reinforcement cage is subjected to buoyancy, the leakage plate is fixedly connected to the bottom of the steel reinforcement cage, the steel reinforcement cage and the leakage plate are placed into the pile foundation hole together, the grouting hard tube is pressed against the leakage plate, the leakage plate is subjected to downward pressure from the grouting hard tube, the leakage plate is fixedly connected to the bottom of the steel reinforcement cage so as to applying the downward pulling force to the steel reinforcement cage, the pulling force is used for counteracting the buoyancy, and therefore the steel reinforcement cage can be prevented from floating. The grouting hard tube can also be used for pouring concrete in subsequent engineering, the first leakage hole is formed below the slurry outlet, and therefore the leakage plate cannot influence the flow of the concrete, and normal construction of the construction can be guaranteed. According to the pile-foundation steel reinforcement cage anti-floating device and anti-floating method, the structure is simple, necessary facilities for pile-foundation construction are fully utilized, the cost is low, and the anti-floating effect is good.

Owner:中建八局广西建设有限公司

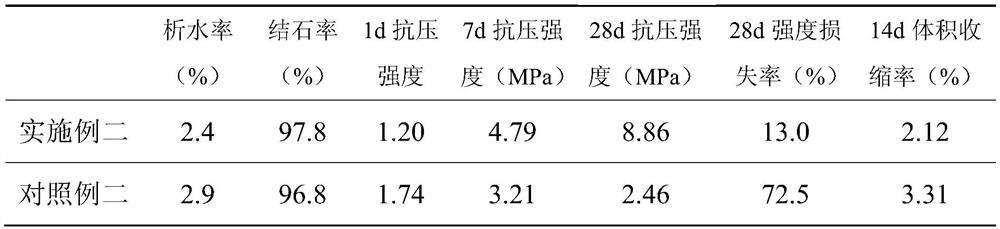

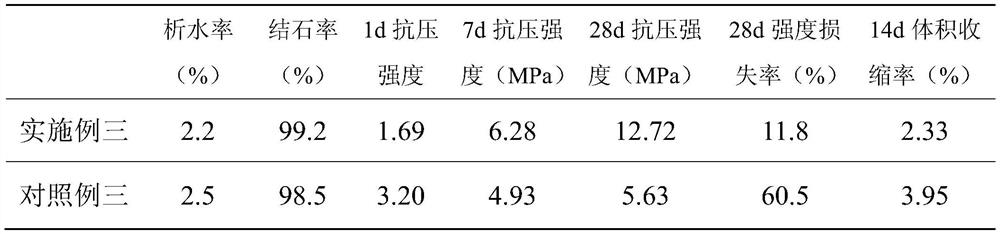

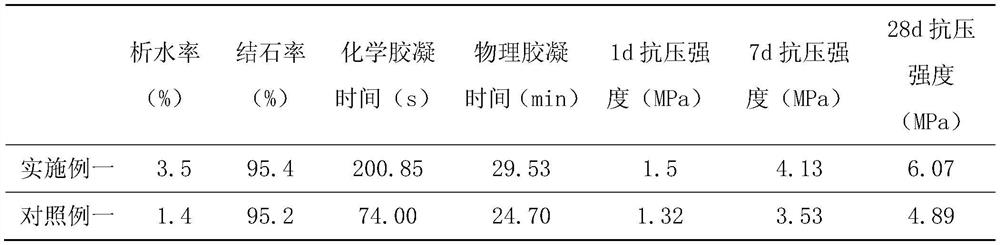

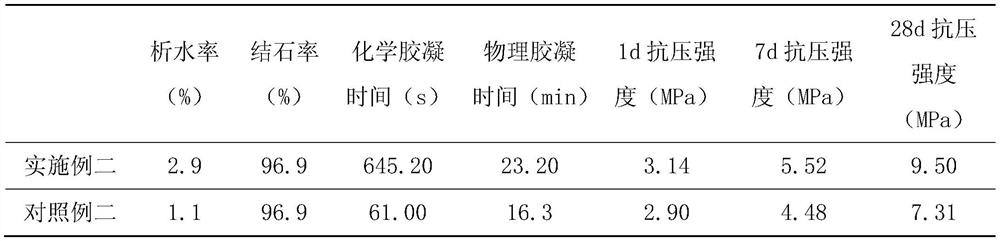

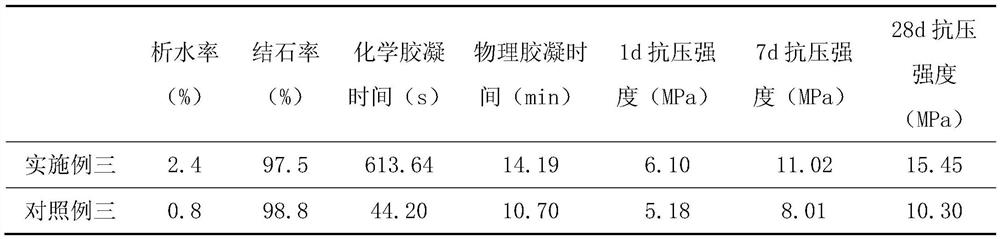

Product-stable cement-water glass double-liquid grouting material for shield synchronous grouting

PendingCN112028594AParticle dispersion increasedImprove stabilitySolid waste managementUnderground chambersPortland cementShrinkage rate

The invention discloses a product-stable cement-water glass double-liquid grouting material for shield synchronous grouting, which is composed of a liquid A and a liquid B. The product-stable cement-water glass double-liquid grouting material is characterized in that the liquid A comprises the following components: cement, fly ash, a retarder and water, wherein the cement is 42.5-grade ordinary Portland cement, the fly ash is II-grade fly ash, and the retarder is ammonium dihydrogen phosphate with the purity of more than or equal to 99.0%, the pH value of 4.0-4.5 and the clarity of less than or equal to 3; and the liquid B is water glass with the baume degree of 30-40 degrees and the modulus of 3.1-3.3. The grouting material is used for shield synchronous grouting, the gelling time is short, and the anti-floating performance of pipe pieces is good; and a reaction product is good in stability, not prone to disintegration and cracking under the natural condition of actual engineering, small in volume shrinkage rate and free of degradation of compressive strength, and a formed segmental lining structure is high in strength and good in waterproof performance.

Owner:SOUTHWEST JIAOTONG UNIV +1

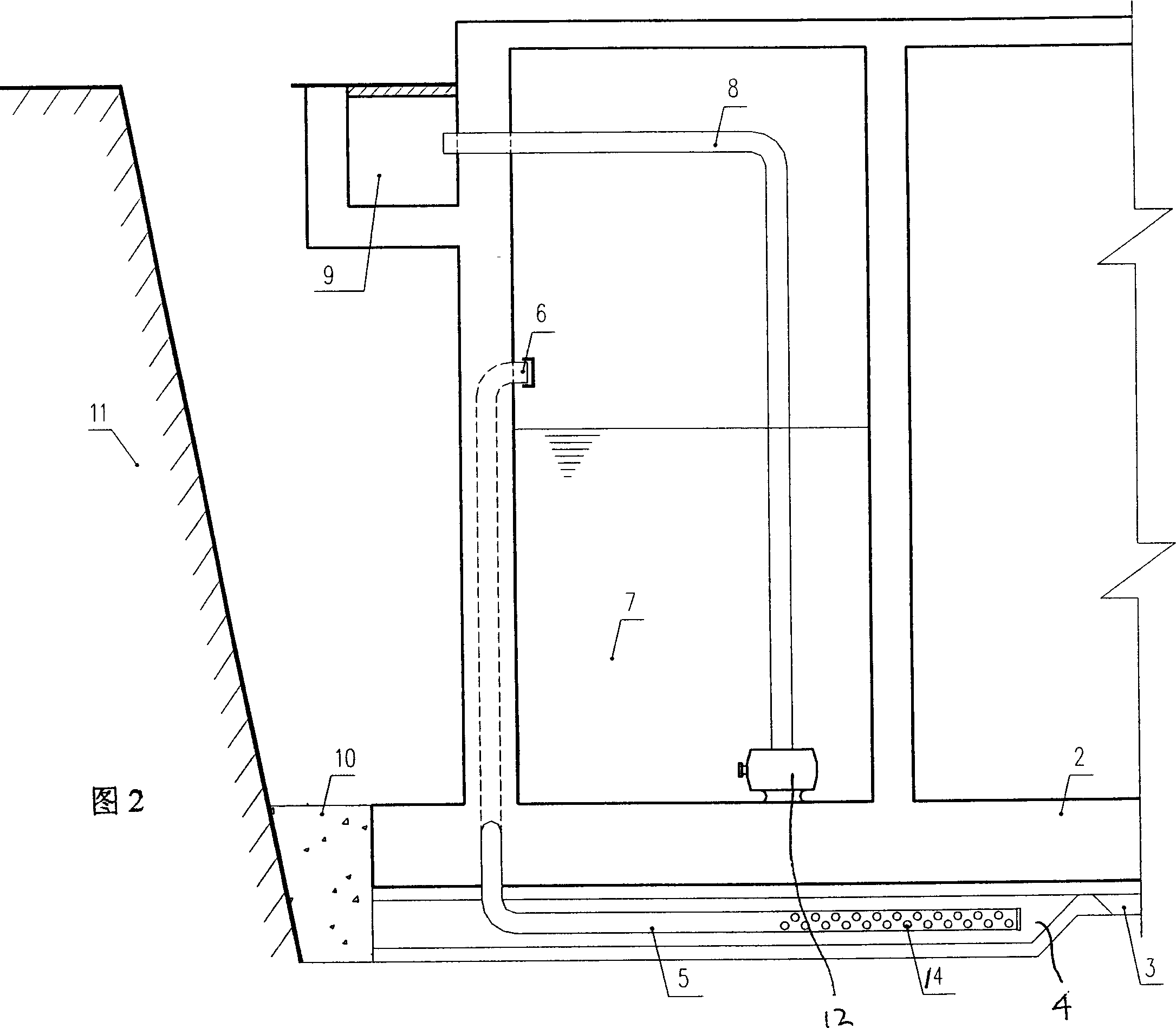

Basement emergency anti-floating structure and construction method thereof

ActiveCN112031044AImprove pumping effectImprove anti-floating effectFatty/oily/floating substances removal devicesSewerage structuresPipeMechanical engineering

The invention relates to a basement emergency anti-floating structure and a construction method thereof. The anti-floating structure comprises a dewatering well, a water storage pool, and a water inlet pipe. The water inlet pipe is used for being arranged under a basement, a water inlet hole is formed in the water inlet pipe, the end of the water inlet pipe is communicated with a settlement pipe,one end of the settlement pipe is communicated with the water inlet pipe, and the other end of the settlement pipe extends downwards vertically; a filter box is arranged at the end, away from the water inlet pipe, of the settlement pipe; the outer side wall of the end, away from the water inlet pipe, of the settlement pipe is communicated with a connecting pipe; and a water suction pump is arranged inside the water storage pool and connected with a water draining pipe. The construction method includes the steps that the water storage pool and the dewatering well are dug; the water suction pumpis installed and the water draining pipe is buried; the connecting pipe, the settlement pipe, and a cleaning pipe are embedded in sequence; the filter box is installed at the bottom of the settlementpipe; one end of a pull rope is connected with the filter box, and the other end of the pull rope extends to the basement from the cleaning pipe and is connected with a winding drum; and the water inlet pipe is buried, and supporting rods are inserted into a base layer. According to the basement emergency anti-floating structure and the construction method thereof, underground water can not be smoothly discharged, so that the anti-floating effect of the basement is improved.

Owner:ZHEJIANG SHUNJIE CONSTR GROUP

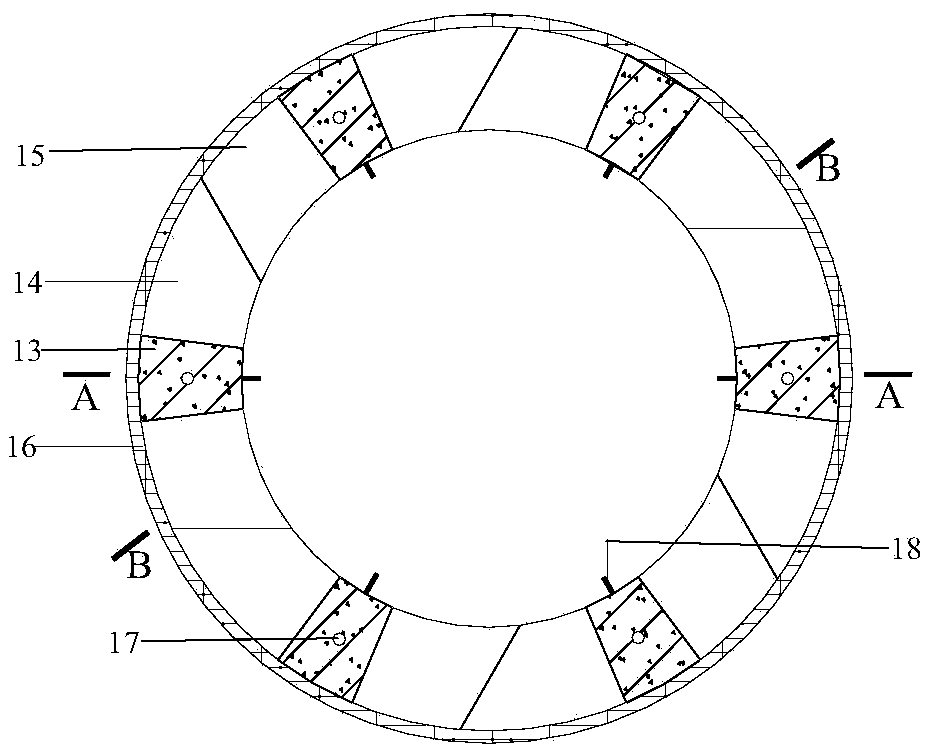

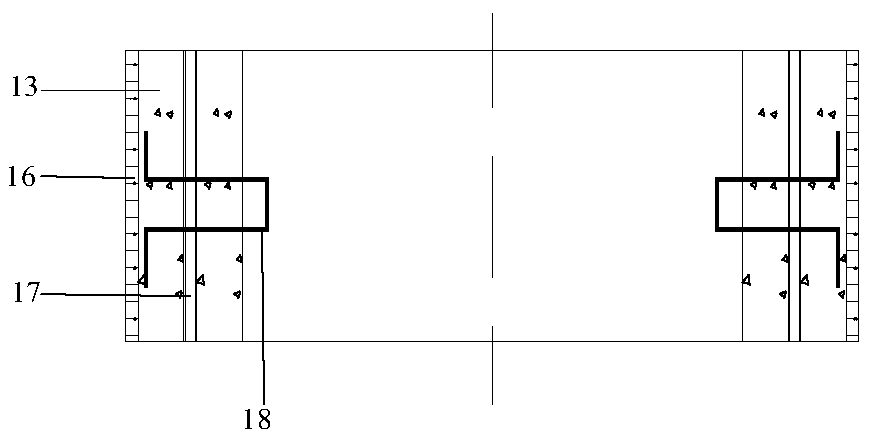

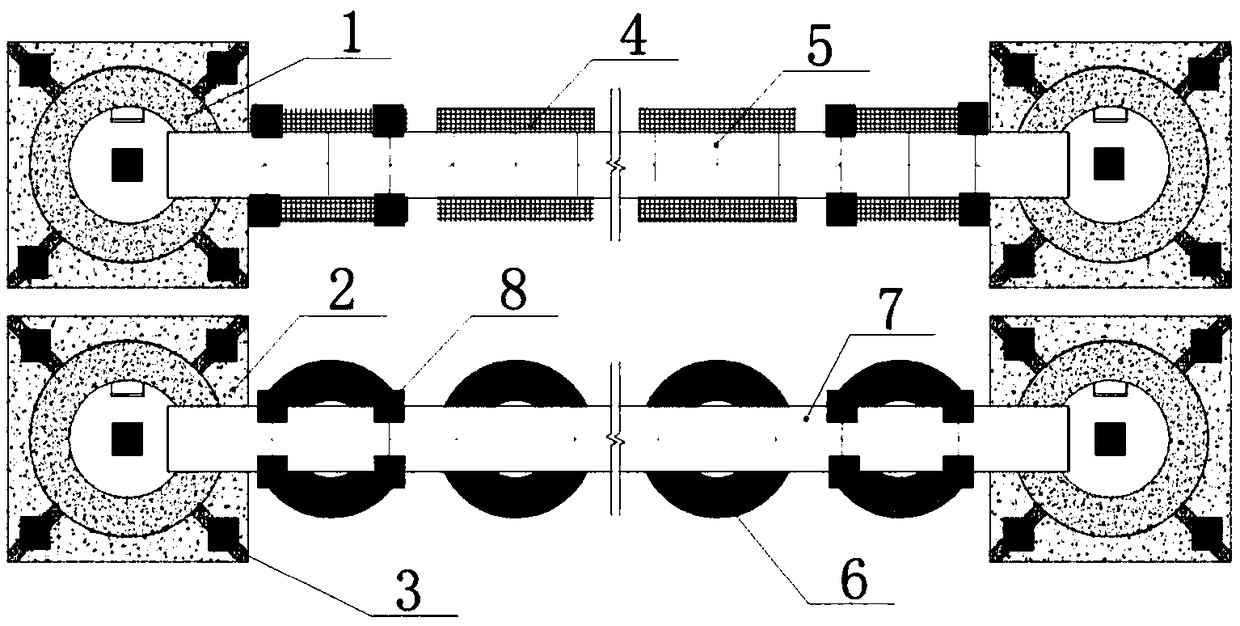

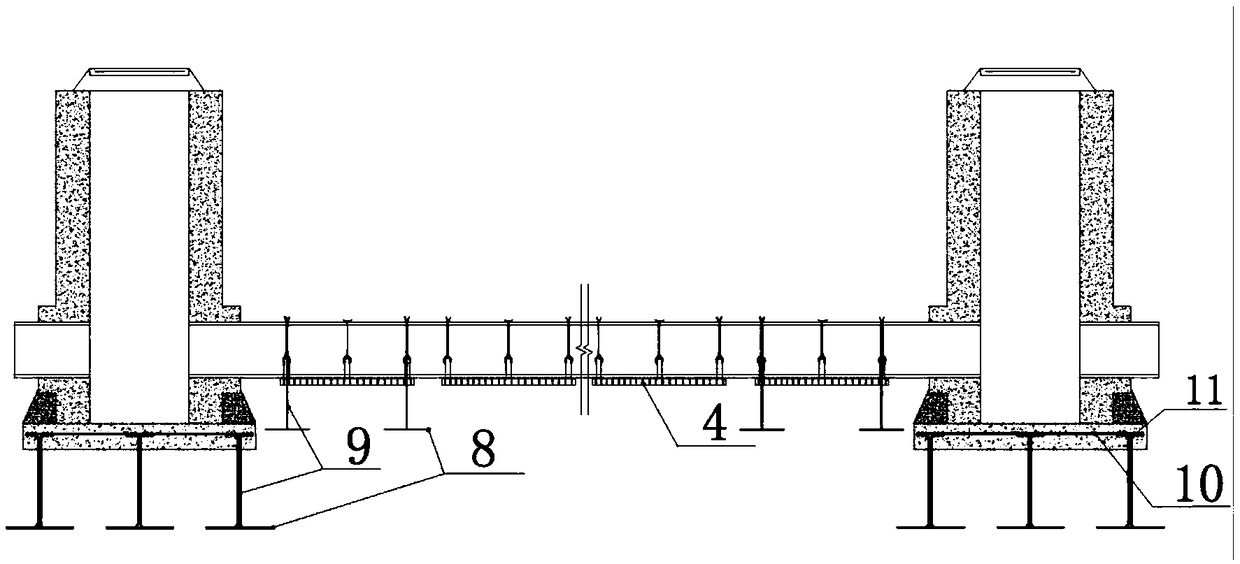

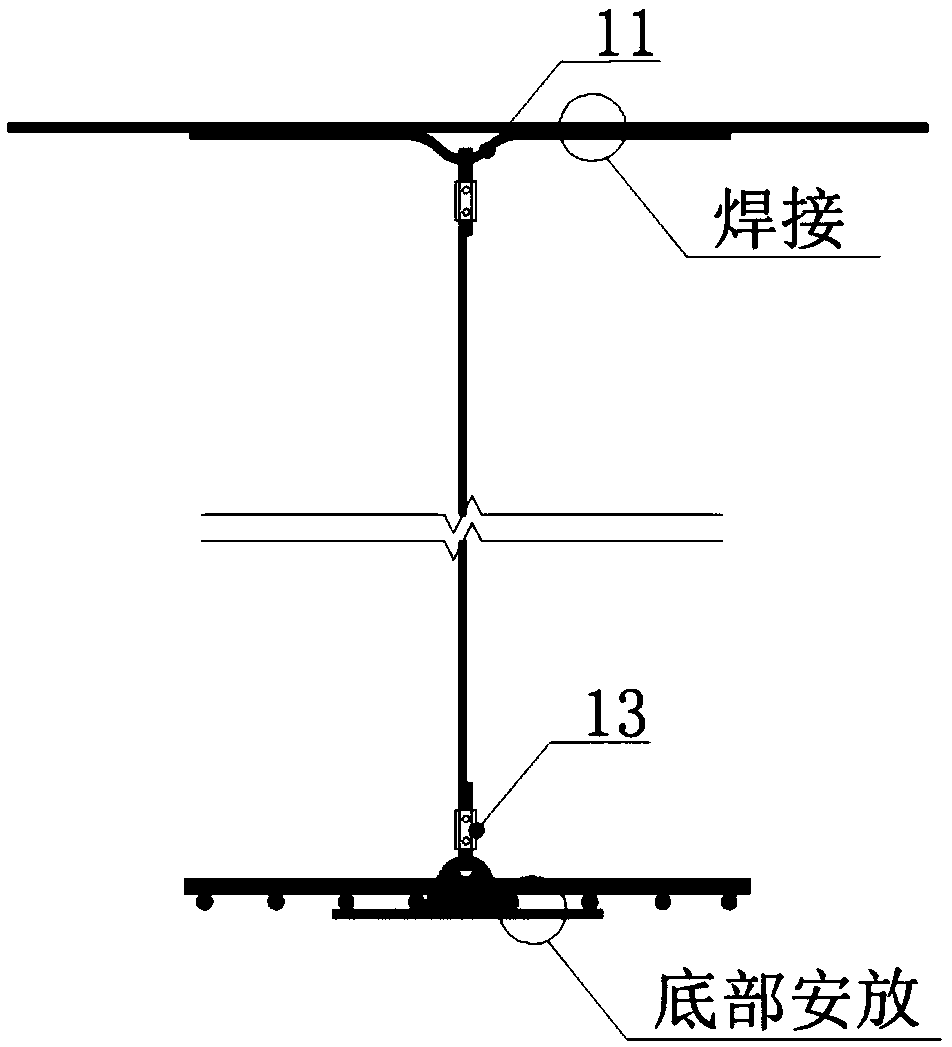

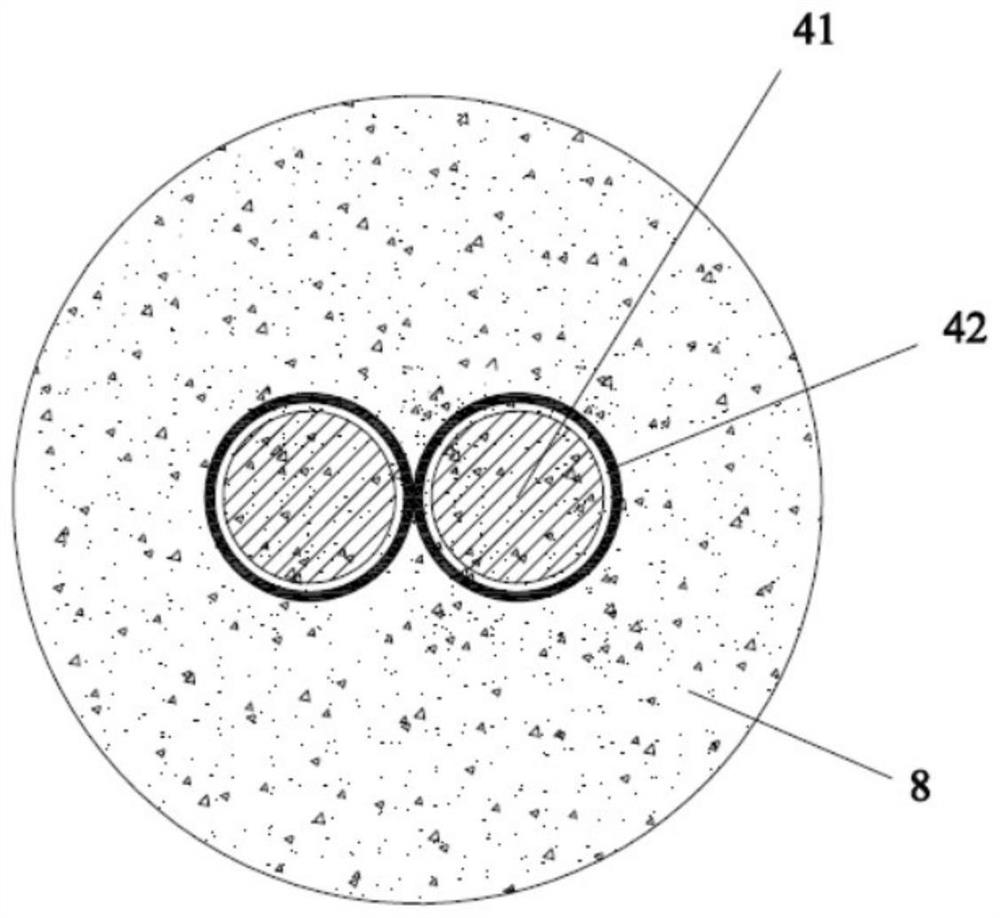

Anti-floating structure of shallow-buried shield tunnel

ActiveCN102776899BMeet the anti-floating requirements of tunnelsImprove waterproof performanceProtective foundationTunnelsBuilding constructionSteel structures

The invention discloses an anti-floating structure of a shallow-buried shield tunnel. The structure comprises anti-floating pile fixing holes, anti-floating piles, a plurality of steel structural beams and waterproof structures, wherein anti-floating pile fixing holes are arranged downwards along inner surfaces of tunnel segments, at least part of anti-floating piles are arranged in anti-floating pile fixing holes, waterproof structures are embedded inside tunnel segments, a plurality of anti-floating piles which are arranged coaxially along inner surfaces of tunnel segments are fixedly arranged on the same steel structural beam, waterproof structures comprise steel pipe bodies and steel water sealing rings, sealing end plates are arranged inside steel pipe bodies, steel water sealing rings are arranged on outer sides of steel pipe bodies, anti-floating pile holes are arranged on sealing end plates, waterproof structures are arranged above anti-floating pile fixing holes, anti-floating piles penetrates through anti-floating pile holes and anti-floating pile fixing holes, steel pipe bodies comprise first steel pipes and second steel pipes, and first steel pipes and second steel pipes are arranged coaxially. The structure meets the anti-floating requirements of the shallow-buried shield tunnel and can be used on the condition that uplift pile construction conditions or foundation pit bottom plates do not exist around the constructed shallow-buried tunnel.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD +1

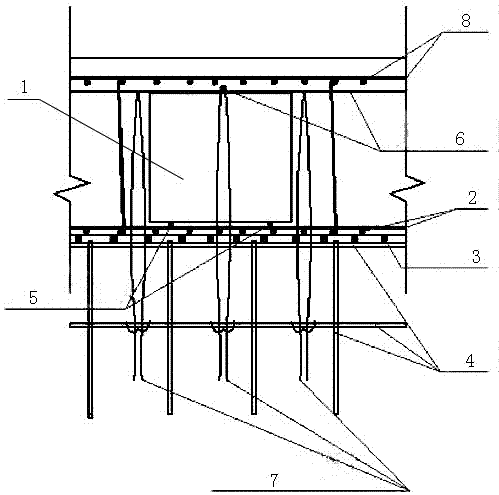

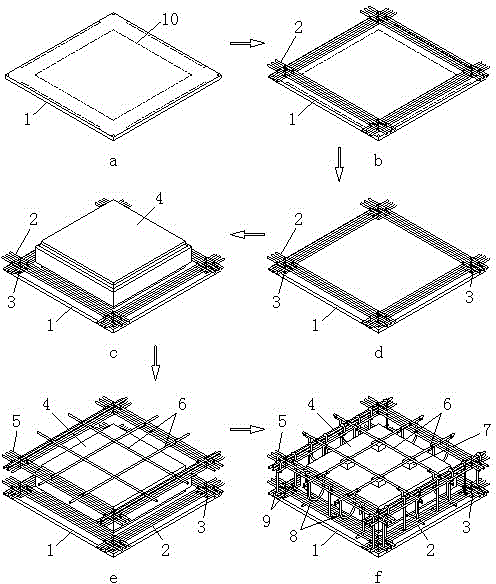

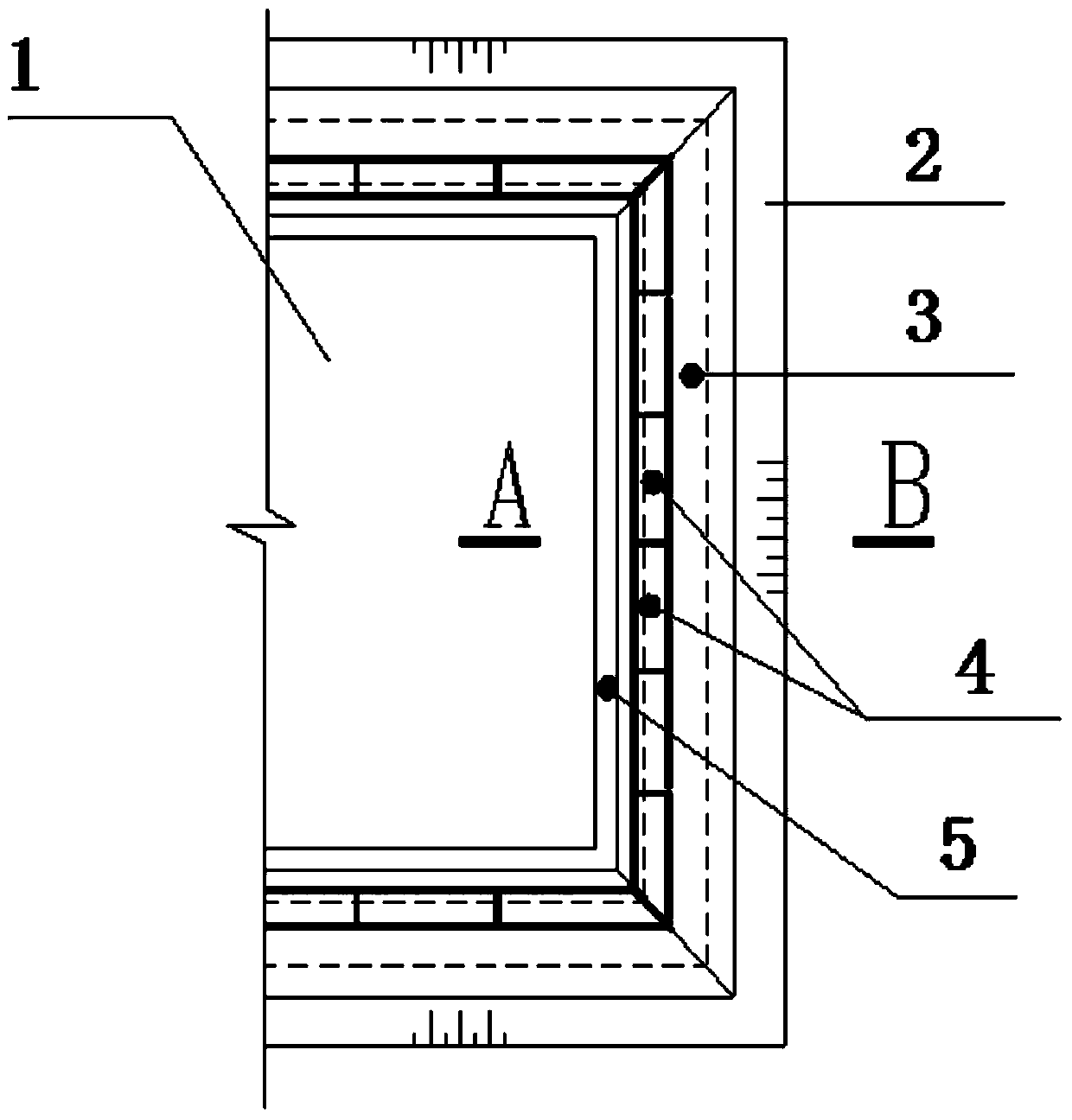

Anti-floating method for thin-walled square box in flat slab floor

InactiveCN107327064ASpeed up the construction progressGuarantee the quality of the projectFloorsRebarThin walled

The invention relates to an anti-floating method for a thin-walled square box in a flat slab floor. The anti-floating method comprises the following steps that firstly, construction is prepared; secondly, the square box is mounted, specifically, a bottom plate rib is mounted on a bottom plate formwork, supporting steel pipe frames are arranged below the bottom plate formwork, then the square box is hoisted onto the bottom plate rib through a hoisting basket, cushion blocks are placed on the bottom plate rib, and the square box is lifted and put onto the cushion blocks; and thirdly, the thin-walled square box is subjected to anti-floating fixing, specifically, two steel bars are arranged on the square box, the two steel bars are arranged in a crossed mode to be in a cross shape, then the steel bars and the supporting steel pipe frames below the bottom plate formwork are fixed in a bound mode through steel wires, reinforcing bars longitudinally and transversely arranged are arranged on the upper portions of the two steel bars, and at the four edges of the square box, the two cross-shaped steel bars which press the box tops are fixed to the supporting steel pipe frames in a bound mode through the steel wires. The problem of upward-floating of the thin-walled square box in the concrete pouring and vibrating processes is effectively solved, the construction efficiency is improved, the construction progress is accelerated, and a quite good anti-floating effect is achieved, so that the construction progress is accelerated. Certain reference and popularization significance is achieved for a similar construction technology.

Owner:SHANGHAI BAOYE GRP CORP

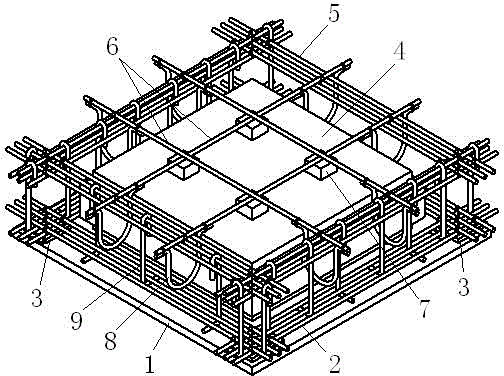

Anti-floating construction technology and pouring mould structure of gypsum cavity mould boxes

InactiveCN104060828APrevent floatingSimple structureFloorsBuilding reinforcementsEngineeringMechanical engineering

The invention discloses an anti-floating construction technology and a casting mould structure of gypsum cavity mould boxes. The anti-floating construction technology lies in that positioning ribs are arranged on the periphery of a gypsum cavity mould box to limit the gypsum cavity mould box to not to slip horizontally; positioning cushion blocks arranged at the top of the gypsum cavity mould box can transfer the buoyant force of the gypsum cavity mould box to anti-floating ribs and then to a bottom reinforcement net fixed on a mould plate to prevent the gypsum cavity mould box from floating through tie pieces. According to the anti-floating construction technology and the pouring mould structure of gypsum cavity mould boxes, the structure is simple, the construction is convenient; besides, the construction technology and the pouring mould structure are suitable for gypsum cavity mould box cast-in-place floors, and the advantages of obvious anti-floating effect, high easiness for implementation and low input cost are achieved.

Owner:CCFED THE FIRST CONSTR & ENG

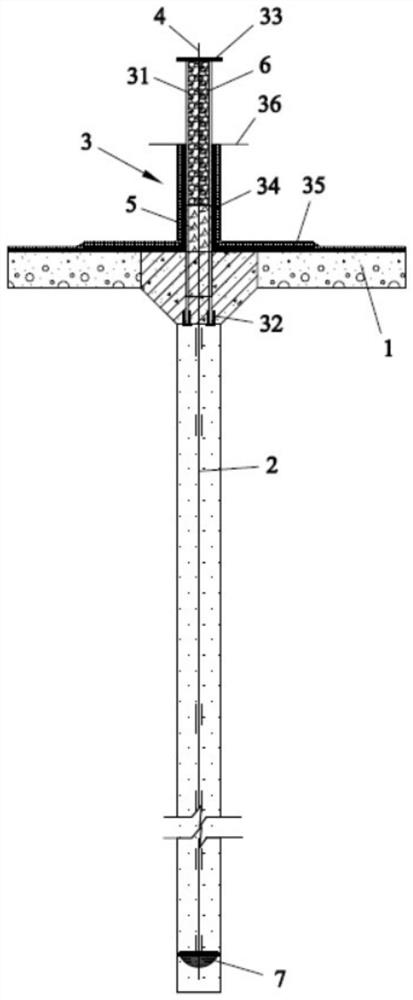

Underground space building pile body construction method of and underground space building structure

ActiveCN103790180AEnhanced tensile and crack resistanceAvoid stretchingArtificial islandsUnderwater structuresStructural engineeringHigh pressure

The invention discloses an underground space building pile body construction method. An underground space comprises a space bottom serving as the foundation of a building and a space top connected with the ground, wherein the space bottom is at least provided with a first part used for bearing high pressure and a second part used for bearing low pressure, the difference value between first force difference between the buoyancy force and pressure borne by the second part and second force difference between the buoyancy force and pressure borne by the first part is larger than the largest breaking-resistant strength of the joint part of the first part and the second part, a first pile body set used for supporting and fixing the first part is arranged below the first part, a second pile body set used for supporting and fixing the second part is arranged below the second part, and then the difference between the buoyancy force and pressure borne by the second part is smaller than the largest breaking-resistant strength and the largest tensile resistance of the second pile body set.

Owner:JIANGXI JIYE SCI & TECH

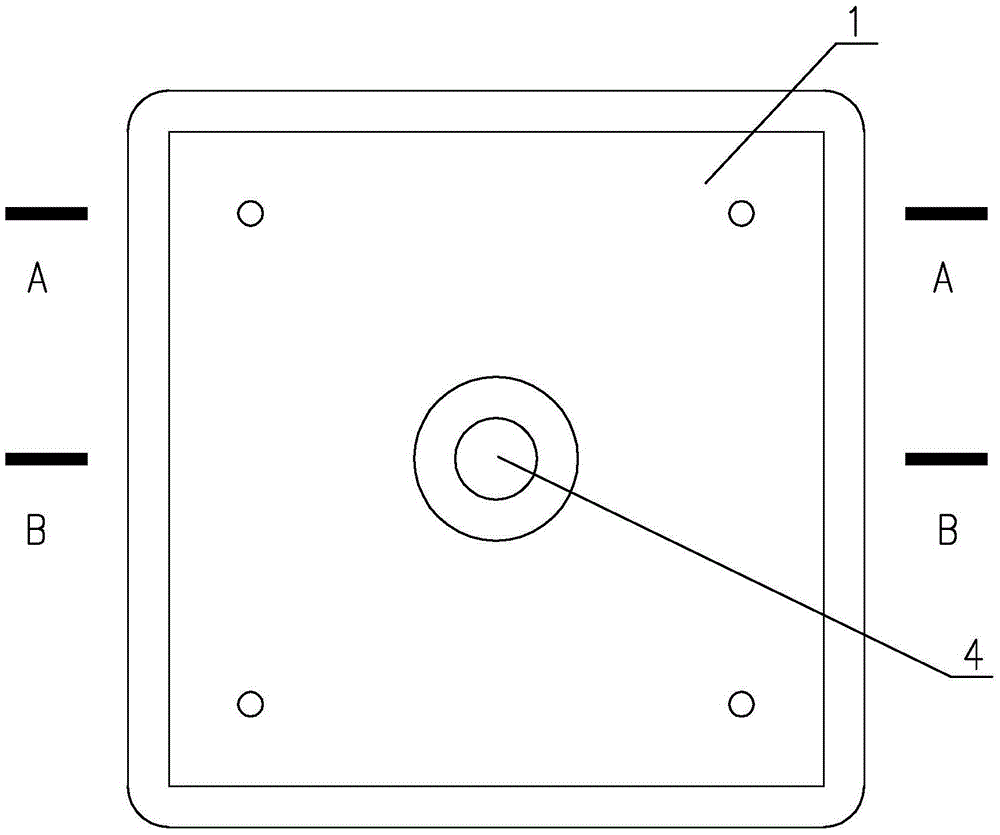

External baffle-block anti-floating method for reinforced concrete pool

ActiveCN104005430ASave the cost of anti-floatingImprove anti-floating effectProtective foundationBulk storage containerRebarReinforced concrete

The invention relates to an external baffle-block anti-floating method for a reinforced concrete pool, mainly solving the problem of high construction cost caused by an anti-floating technique taking single vertical direct "resistance" as primary in the prior art. By adopting the external baffle-block anti-floating method for the reinforced concrete pool, a baffle block having an elliptic cross section is arranged between a pool wall and an earth-retaining wall, the thickness of the cross section of the pool wall is variable, the side, contacted with the baffle block, of the earth-retaining wall is perpendicular to a pool bottom plate, and the baffle block is higher than the pool bottom plate and lower than an upper plane of the earth-retaining wall, so that the above-mentioned problem can be solved and the anti-floating method provided can be applied to the anti-floating design of a reinforced concrete pool.

Owner:SINOPEC SHANGHAI ENG +1

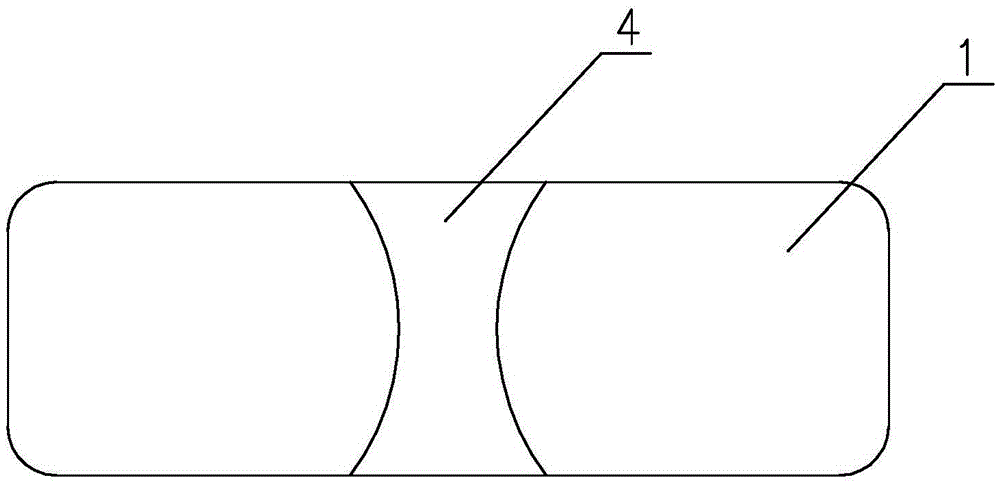

Thin-wall square box hollow floor mandrel and anti-floating method thereof

ActiveCN105604317AControl Horizontal ShiftAnti-floatingFloorsForms/shuttering/falseworksEngineeringUltimate tensile strength

The invention discloses a thin-wall square box hollow floor mandrel and an anti-floating method thereof. The thin-wall square box hollow floor mandrel is a block with a hollow cavity and is provided with an openable liquid injection hole used for injecting liquid into the mandrel, at least three supports used for being supported by a template are evenly distributed on the bottom surface of the mandrel, an openable tubular liquid discharge outlet used for discharging liquid in the mandrel is also formed in the bottom surface of the mandrel, and the liquid discharge outlet extends to the template. By the adoption of the mandrel, construction is easy, the anti-floating effect is good, horizontal movement of the mandrel can be well controlled, and construction quality is improved; the recycle rate of the template is increased, construction cost is reduced, the labor intensity of workers is relieved greatly, and construction efficiency is improved greatly. The mandrel is provided with the supports, and compared with existing mandrels adopting cushion blocks for supporting, the mandrel has the advantage that due to the omission of cushion blocks, extract building materials for floating resistance are not needed; furthermore, liquid used for being injected into the mandrel can be recycled, so that construction cost is further reduced.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

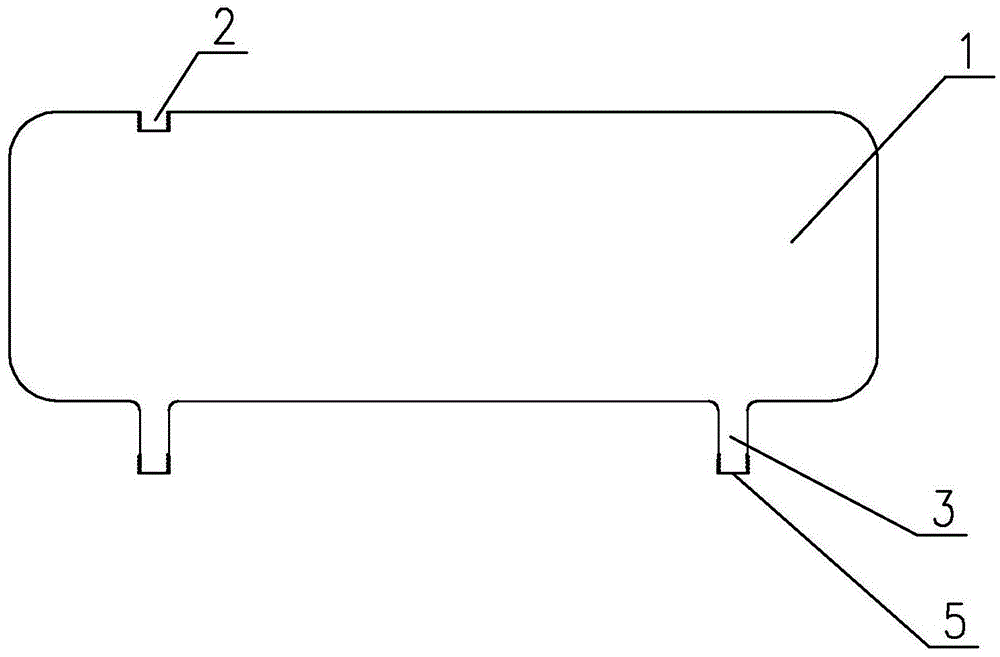

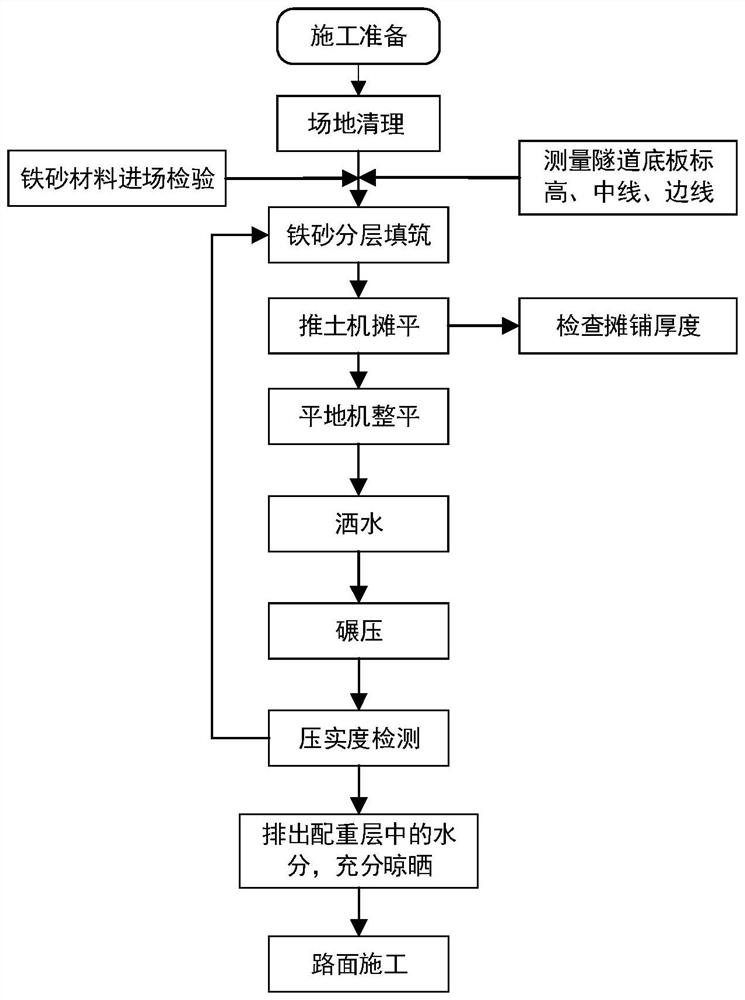

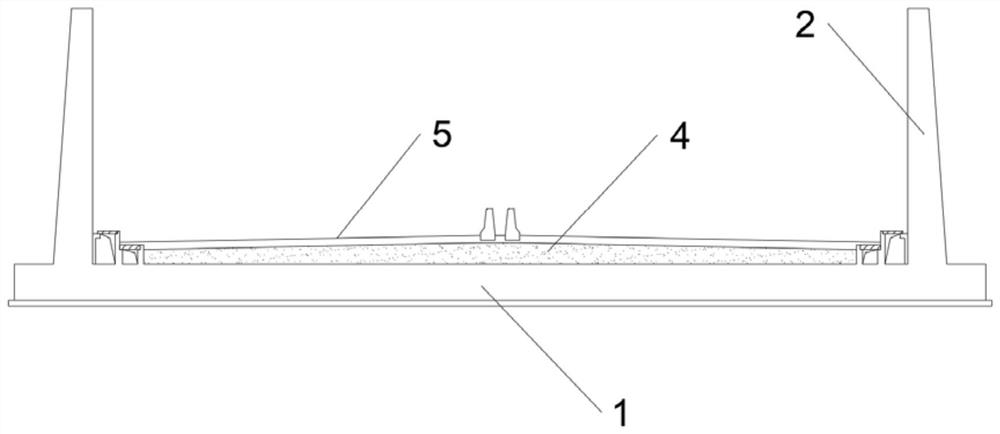

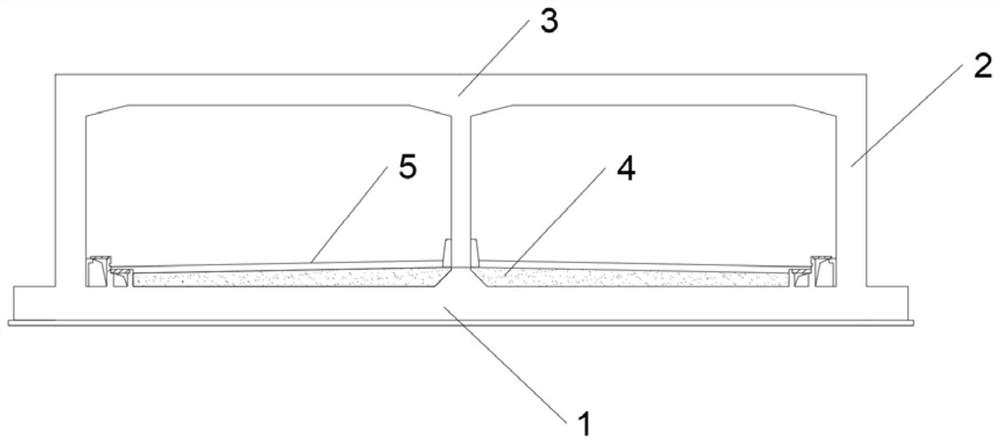

Open cut tunnel containing iron sand counterweight layer and construction method of open cut tunnel

InactiveCN114182755AEnsure stabilityEnsure safetyArtificial islandsProtective foundationRoad surfaceBase course

The invention relates to an open-cut tunnel containing an iron sand counterweight layer. The open-cut tunnel comprises a tunnel bottom plate, tunnel side walls, the iron sand counterweight layer and a tunnel internal road surface. The tunnel side walls are located on the left and right sides of the tunnel bottom plate, the iron sand counterweight layer is laid on the upper end face of the tunnel bottom plate, and the tunnel internal road surface is constructed on the upper end face of the iron sand counterweight layer. The invention further relates to a construction method of the open-cut tunnel containing the iron sand counterweight layer. The construction method comprises the following steps that a, the tunnel bottom plate and the tunnel side walls are constructed; b, constructing an iron sand counterweight layer, paving layer by layer, and compacting layer by layer; and c, constructing a tunnel internal pavement including a road pavement base layer and a pavement surface layer. The method is easy and convenient to construct, capable of remarkably improving the dead weight of a tunnel main body structure, obvious in anti-floating effect and used for the portion where the tunnel uplift pile cannot be constructed and belongs to the field of building construction.

Owner:广州市市政工程机械施工有限公司

Anti-floating system and construction method of sandbar sewage pipe, well

ActiveCN108894206AEliminate buoyancyAvoid deformationProtective foundationSoil preservationArchitectural engineeringSewage

The invention discloses a sandbar sewage pipe, well anti-floating system, include anti-float plates, Bundle wire, clip rib, steel mesh, U-groove ribs, steel plate fasteners, Staples, bracing ropes, Anti-float plate are arranged at that bottom of the pipeline and bind to the pipeline through bundle wires, A loc wire rib is inserted into that inn side of the bundle wire, and a binding surface with the pipe is added. The steel bar mesh sheet is arranged below the pipe and below the sewage well. The steel bar mesh sheet is welded with U-groove reinforcement or steel plate buckle, and the U-groovereinforcement is not only welded with the mesh surface of the steel bar mesh sheet, but also bound or welded with the reinforcement of the bottom plate foundation; The steel plate buckle is welded onthe reinforcing bar mesh sheet or pierced from the bottom of the reinforcing bar mesh sheet; The clasp binds the wire drawing rope to the pipe, the U-groove rib and the steel plate fastener. The claspbinds the wire drawing rope to the pipe, the U-groove rib and the steel plate fastener. The invention also discloses a construction method of the sandbar sewage pipe and the well anti-floating system. The invention changes the traditional method of deep burying, increasing dead weight and increasing fixed foundation, and provides a stable and safe anti-floating system and construction method forsandbar high-water-level pipe and well construction.

Owner:CHINA FIRST METALLURGICAL GROUP

Anti-floating anchor rod construction structure

PendingCN112681306AImprove structural strengthImprove anti-floating effectProtective foundationBulkheads/pilesScreedArchitectural engineering

The invention discloses an anti-floating anchor rod construction structure. The anti-floating anchor rod construction structure comprises a cushion layer, an anchor rod part, an anchor rod end part arranged at the top end of the anchor rod part, and a sleeve type anchorage device embedded in the anchor rod part and the anchor rod end part, wherein the anchor rod end part comprises a steel pipe, a rubber pad, an anchor cushion plate, a sealant, a waterproof coiled material and a water stop steel ring plate; the bottom of the steel pipe is embedded in the cushion layer; the rubber pad is mounted at the bottom end of the steel pipe, and butts against the top end of the anchor rod part; the anchor cushion plate is mounted at the top end of the steel pipe; the top end of the sleeve type anchorage device is fixedly arranged on the anchor cushion plate; the sealant wraps the steel pipe, and at least partially extends onto the cushion layer; the waterproof coiled material wraps the sealant, and at least partially extends onto the cushion layer; the water stop steel ring plate sleeves the steel pipe; and a non-cured layer and a micro-expansion waterproof mortar layer are filled in the steel pipe. The anti-floating anchor rod construction structure has the beneficial effects of high structural strength, capability of being applied to various complex construction environments and excellent anti-floating performance.

Owner:BEIJING URBAN CONSTR GROUP

Anti-blocking and anti-floating grouting material for shield tunnel synchronous grouting

PendingCN111995355AIncrease electromotive forcePrevent coalescenceUnderground chambersTunnel liningStructural engineeringSlurry

The invention discloses an anti-blocking and anti-floating grouting material for shield tunnel synchronous grouting, which comprises the following components: water, cement, water glass and a retarder, and is characterized in that the cement is 42.5-grade Portland cement; wherein the water glass is a sodium silicate aqueous solution with a baume degree of 30-40 degrees and a modulus of 3.1-3.3, and the retarder is an ammonium dihydrogen phosphate crystal with a purity of 99.0% or more, a pH value of 4.0-4.5 and a clarity of 3 or less. The grouting material not only has good anti-floating performance, but also can be used for quickly gelatinizing and eliminating buoyancy borne by the duct piece, so that the anti-floating requirement of the shield tunnel is met; the anti-blocking performanceis good, the situation that the grouting pipe is blocked due to the fact that slurry is gelled in the grouting pipe is avoided, and the construction efficiency is high; and meanwhile, the strength ofstones formed by grouting is high, so that the shield tunnel structure is more stable and reliable.

Owner:SOUTHWEST JIAOTONG UNIV +1

A lining trolley suitable for the construction of main tunnels and branch tunnels in parallel tunnels

ActiveCN106593472BEnsure normal walkingBig liftUnderground chambersTunnel liningHydraulic cylinderArchitectural engineering

The invention provides a section-variable tunnel-crossing lining trolley which comprises a portal system, a template system, a connecting part and a walking mechanism, wherein the portal system comprises a frame part, a jacking mechanism and a bracket part; the jacking mechanism comprises multiple sets of jacking single pieces; each of the jacking single pieces comprises a multi-level jacking part; the bracket part comprises a truss girder and an adjusting support frame for a walking mechanism; the template system comprises a top template, a left template and a right template; and the connecting part comprises a support jack and a hydraulic cylinder. The section-variable tunnel-crossing lining trolley provided by the invention has the effects that the whole structure is simple; the assembling is convenient; the jacking mechanism is in a multi-level jacking mode; the trolley not only can adapt to the construction for the tunnel sections in different heights but also can achieve higher lifting volume; the trolley can meet the requirement of constructing multiple parallel tunnels by one trolley in the manner of constructing the working tunnel; due to the design of the bracket part, the lining trolley can meet the stability requirement, and meanwhile, the structure is simplified and the whole trolley can be supported.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD +1

Anti-flooding assistant, preparation method thereof and use thereof

The invention discloses an anti-flooding assistant, which contains polyurethane resin, polyurea, high-thixotropy solid powder and an organic solvent. The invention also provides a method for preparing the anti-flooding assistant, which comprises the following steps: adding amine into solvent polyurethane resin paste, stirring and uniformly mixing the mixture, dripping isocyanate, and stirring theresulting mixture for reaction for synthesizing polyurea; and adding the high-thixotropy solid powder into a product and allowing the high-thixotropy solid powder to disperse uniformly. The inventionalso discloses the use of the anti-flooding assistant in coating and coloring of the surface of leather synthesized by using ultrafine fibers. The anti-flooding assistant has dynamic and static anti-flooding performance that is better than that of conventional wetting agent, dispersant and anti-flooding assistant, is complete compatible with a resin system which is the same as the anti-flooding assistant, avoids generating finished product drawbacks when the additive amount increases, simplifies the production of synthetic leathers and facilitates operation.

Owner:HUAFON MICROFIBER SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com