Anti-floating construction technology and pouring mould structure of gypsum cavity mould boxes

A construction technology and cavity mold technology, which is applied in the field of building floor pouring, can solve problems such as pouring quality problems, and achieve the effects of simple structure, convenient construction, and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

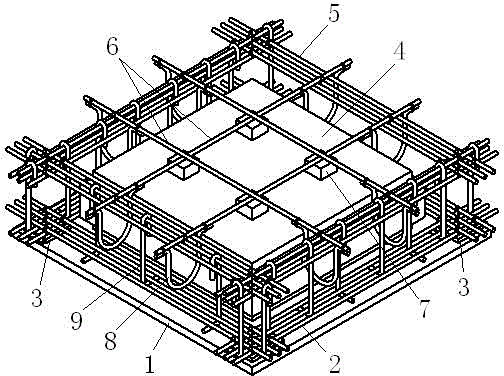

Image

Examples

Embodiment Construction

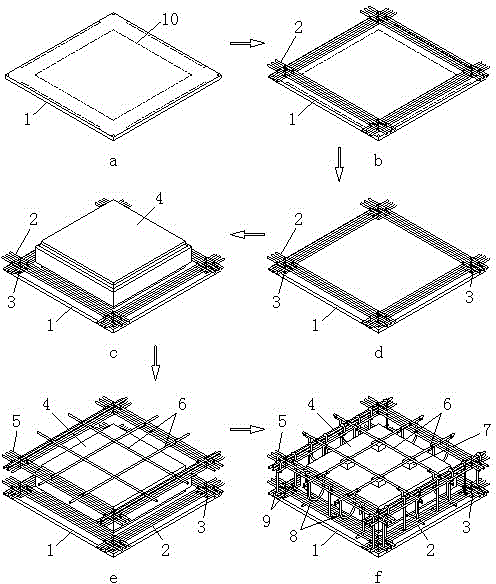

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

[0026] Embodiments of the present invention: a kind of gypsum cavity mold box anti-floating construction technology of the present invention is to carry out construction according to the following steps:

[0027] Step 1, pop up the outline of the rib beam on formwork 1 (see figure 2 In a) of the rib beam, the longitudinal and transverse bottom reinforcements are placed within the outline of the rib beam, and the intersection points of the vertical and horizontal bottom reinforcements are fixed with wire binding or spot welding to form the bottom reinforcement mesh 2 (see figure 2 in b);

[0028] Step 2, place the support block 3 under the intersection point of the bottom reinforcement mesh 2, and fix the bottom reinforcement mesh 2 and the formwork 1 with tie wires (see figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com