Thin-wall square box hollow floor mandrel and anti-floating method thereof

A hollow floor and mandrel technology, applied in the direction of floors, formwork/formwork/work frames, building components, etc., can solve the problems of increasing labor intensity of workers, reducing construction efficiency, slow construction progress, etc., to improve the reuse rate , Reduce construction cost and improve construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

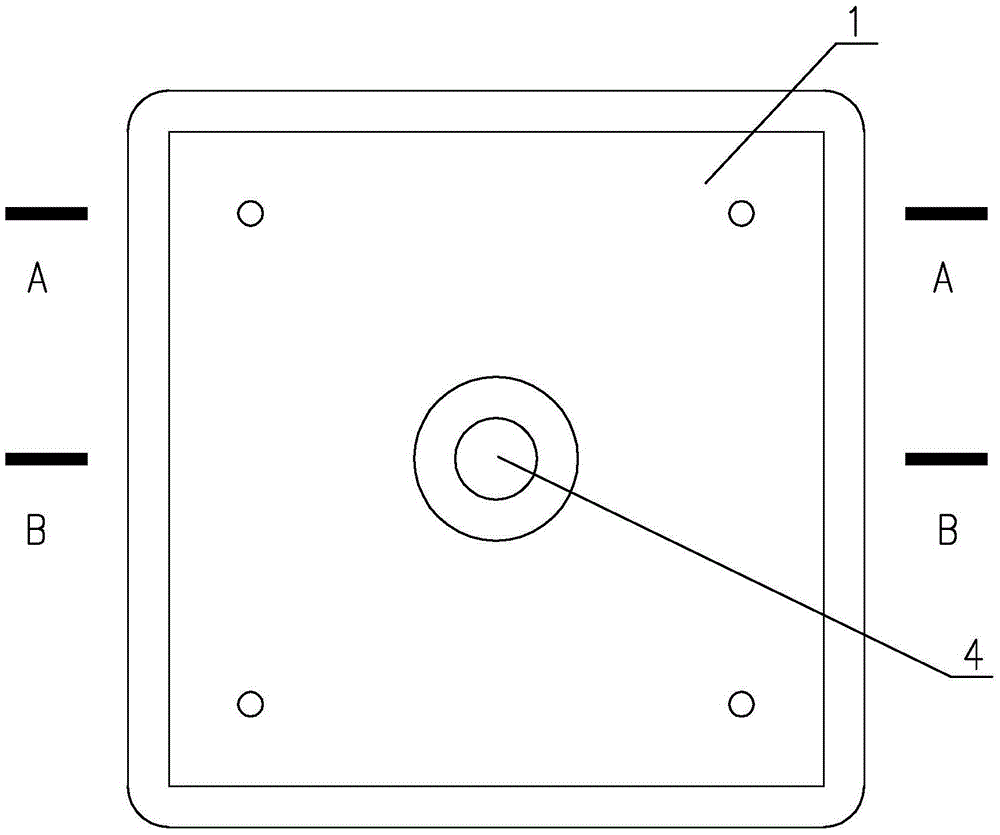

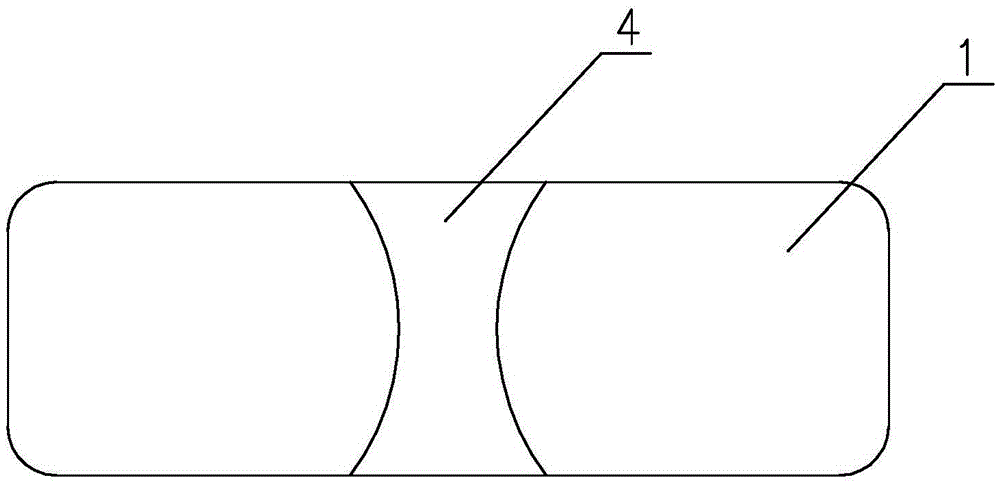

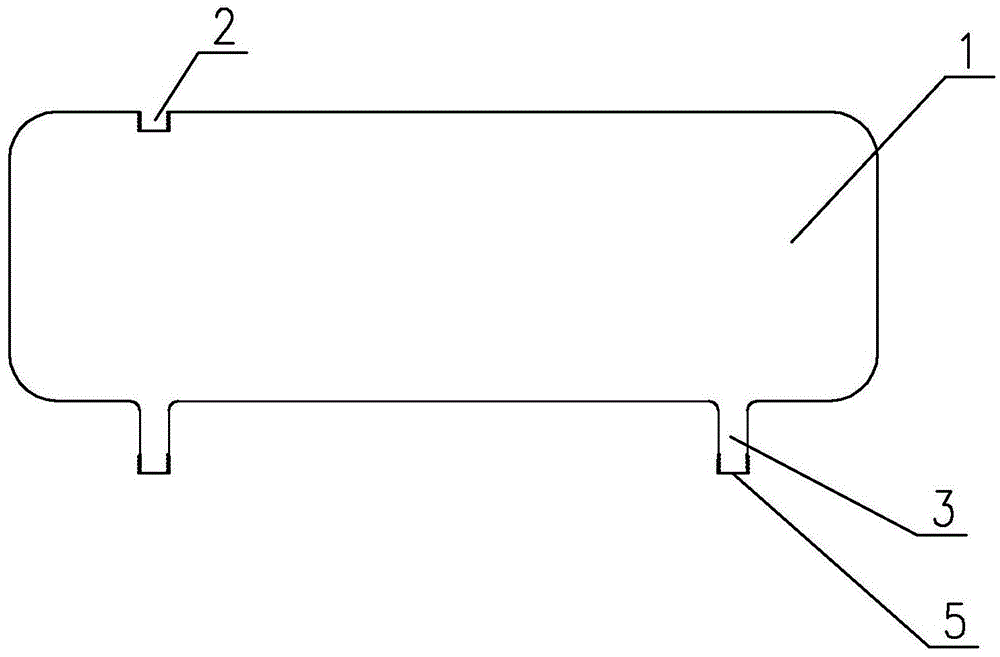

[0037] Such as Figure 1~4 As shown, it is a thin-walled square box hollow floor mandrel 1 of the present invention, which is a block body with a hollow cavity, generally square or rectangular, and is provided on the mandrel 1 for injecting liquid into the mandrel. 1, the liquid injection hole 2 that can be opened and closed, the liquid injection hole 2 is located on the top surface of the mandrel 1, specifically, a plug is provided on the orifice of the liquid injection hole to realize the opening and closing of the liquid injection hole. On the bottom surface of the mandrel 1, at least three supports 3 for supporting on the formwork are evenly distributed. In this embodiment, there are four supports 3, which are respectively located at the four corner positions of the mandrel. The bottom surface of the mandrel 1 is also provided with an openable and closable tubular drain hole for draining the liquid in the mandrel 1, and the drain hole extends to the formwork. The core mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com