Patents

Literature

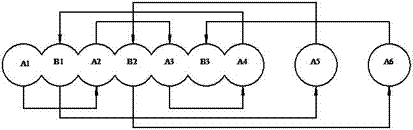

33results about How to "Control Horizontal Shift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

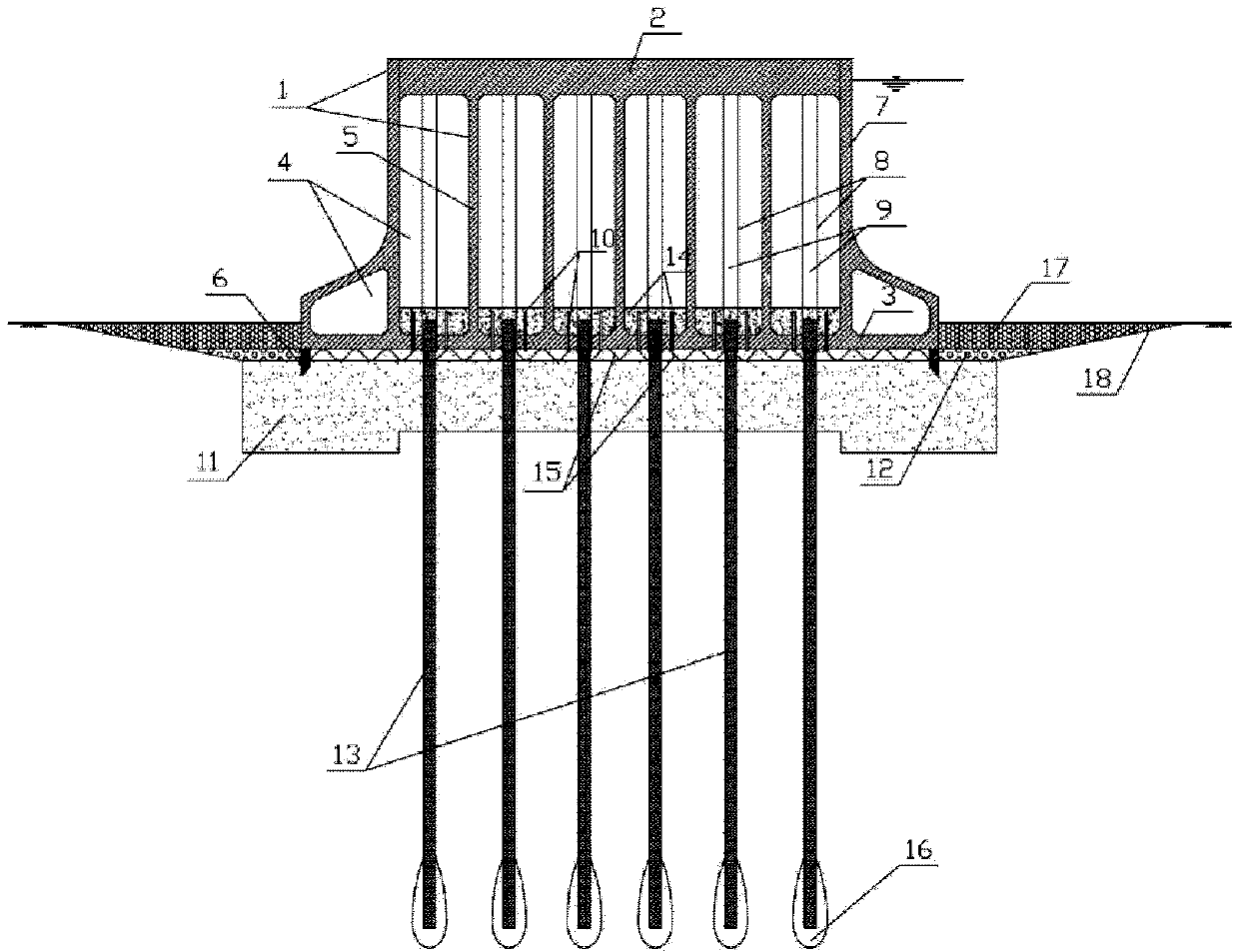

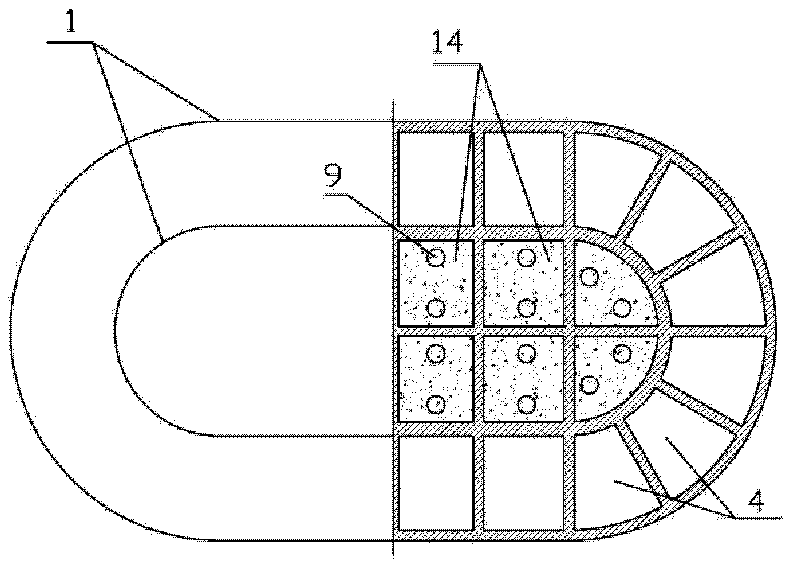

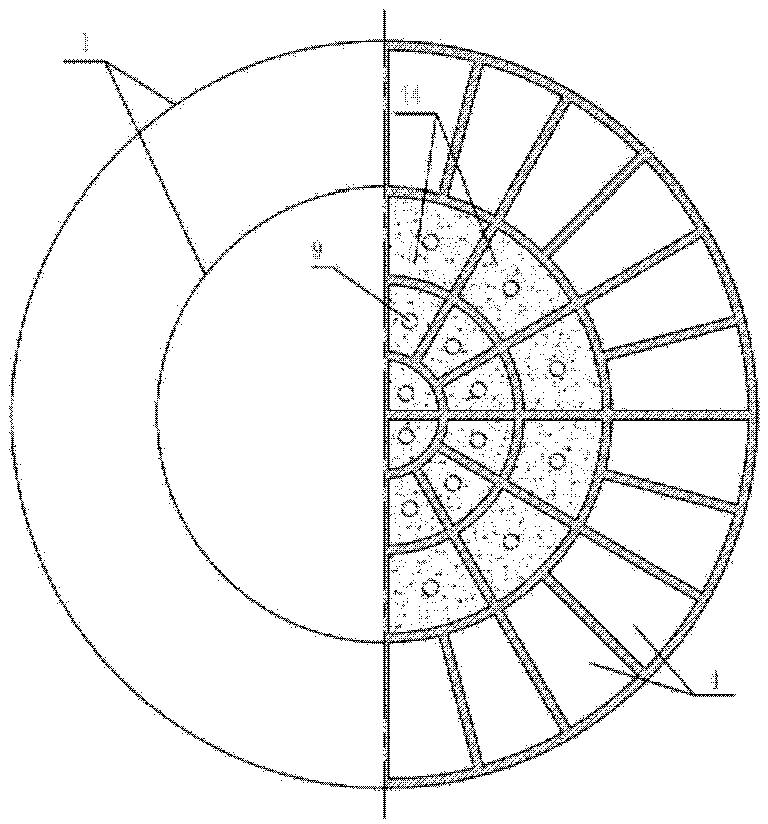

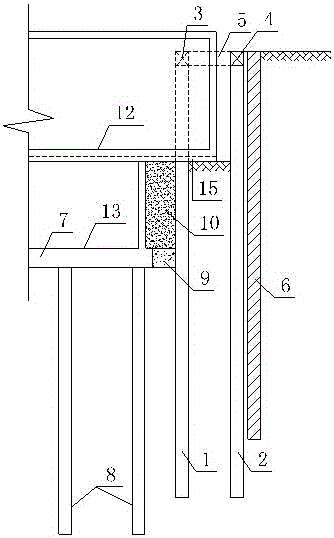

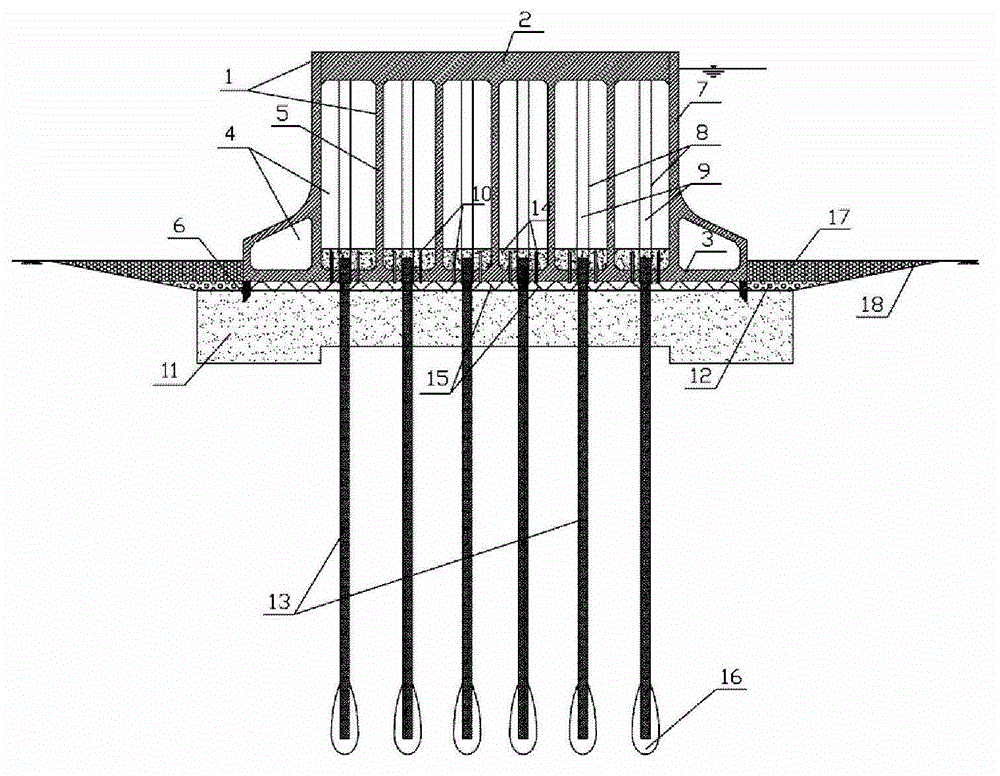

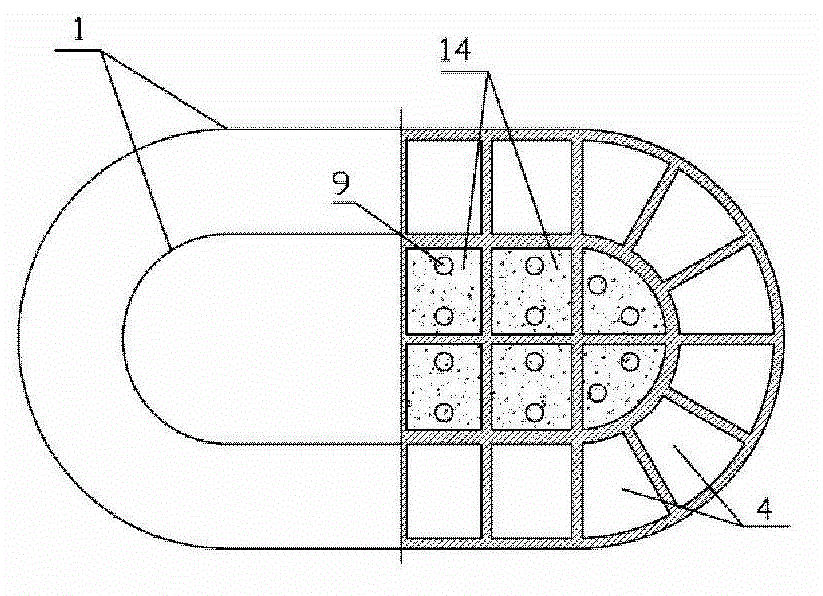

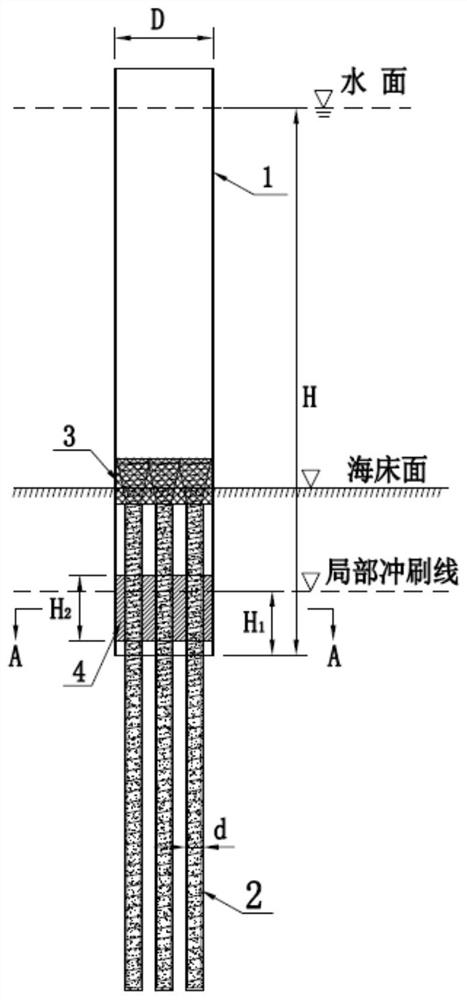

Caisson and pile combined foundation of consolidated subsoil and construction method of caisson and pile combined foundation

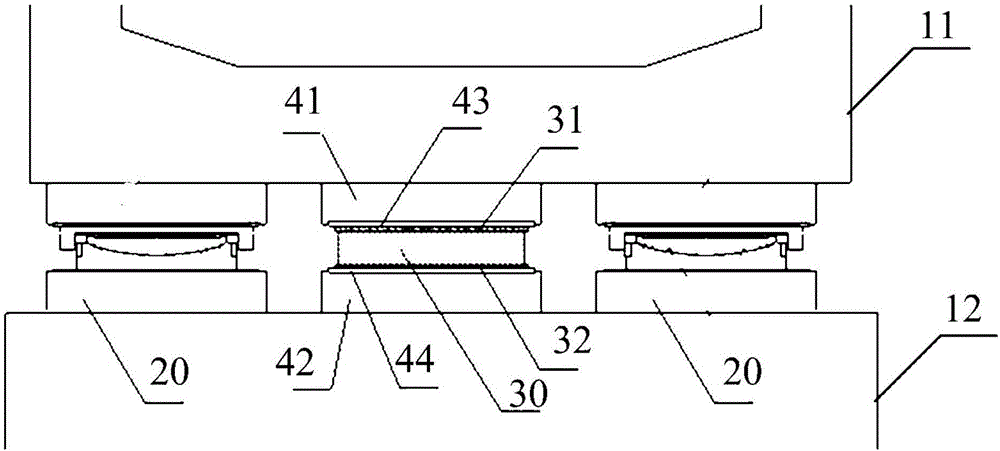

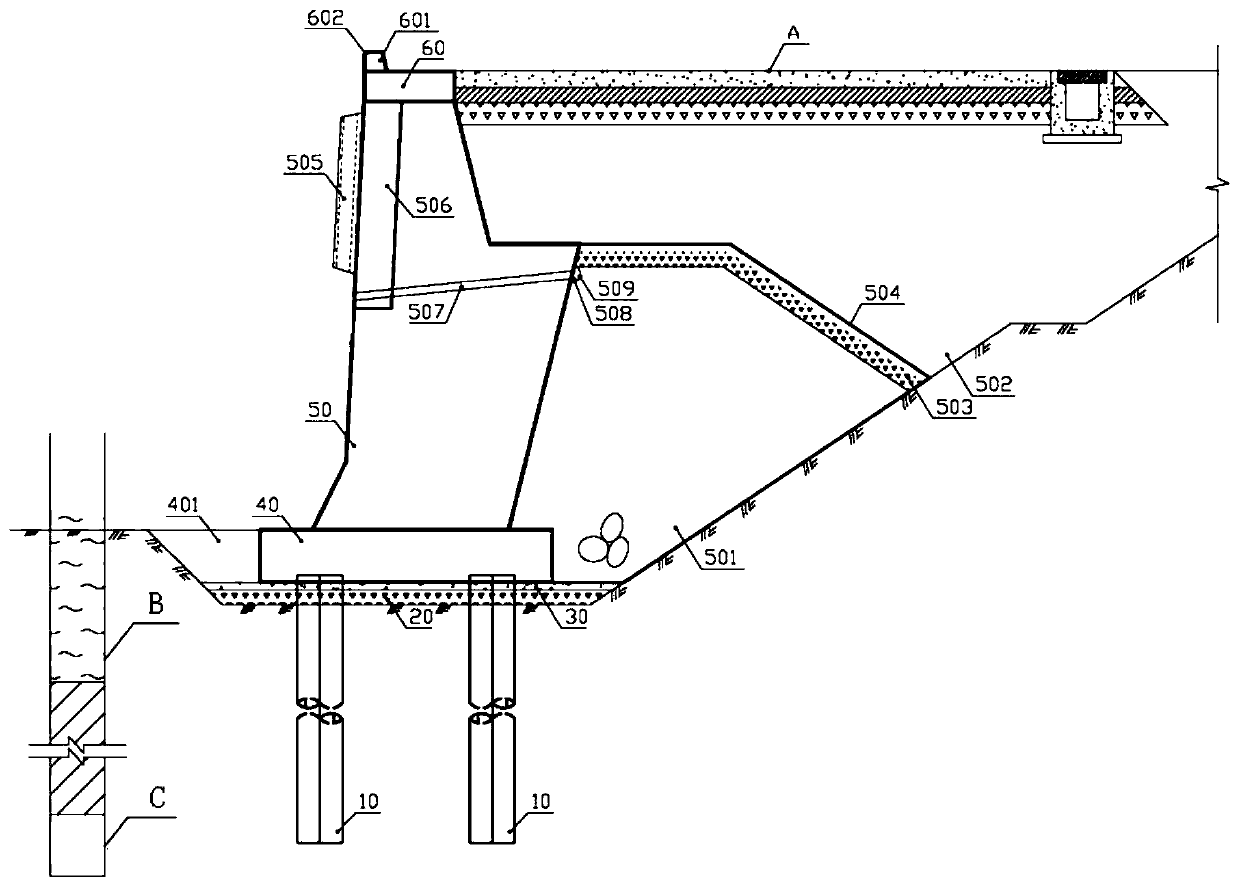

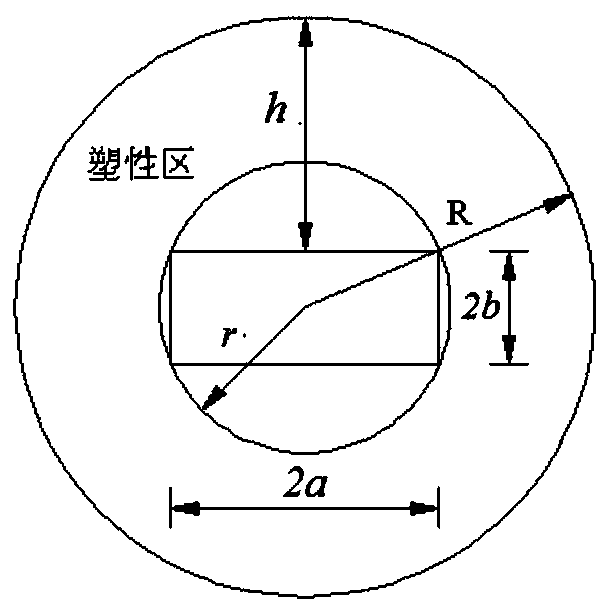

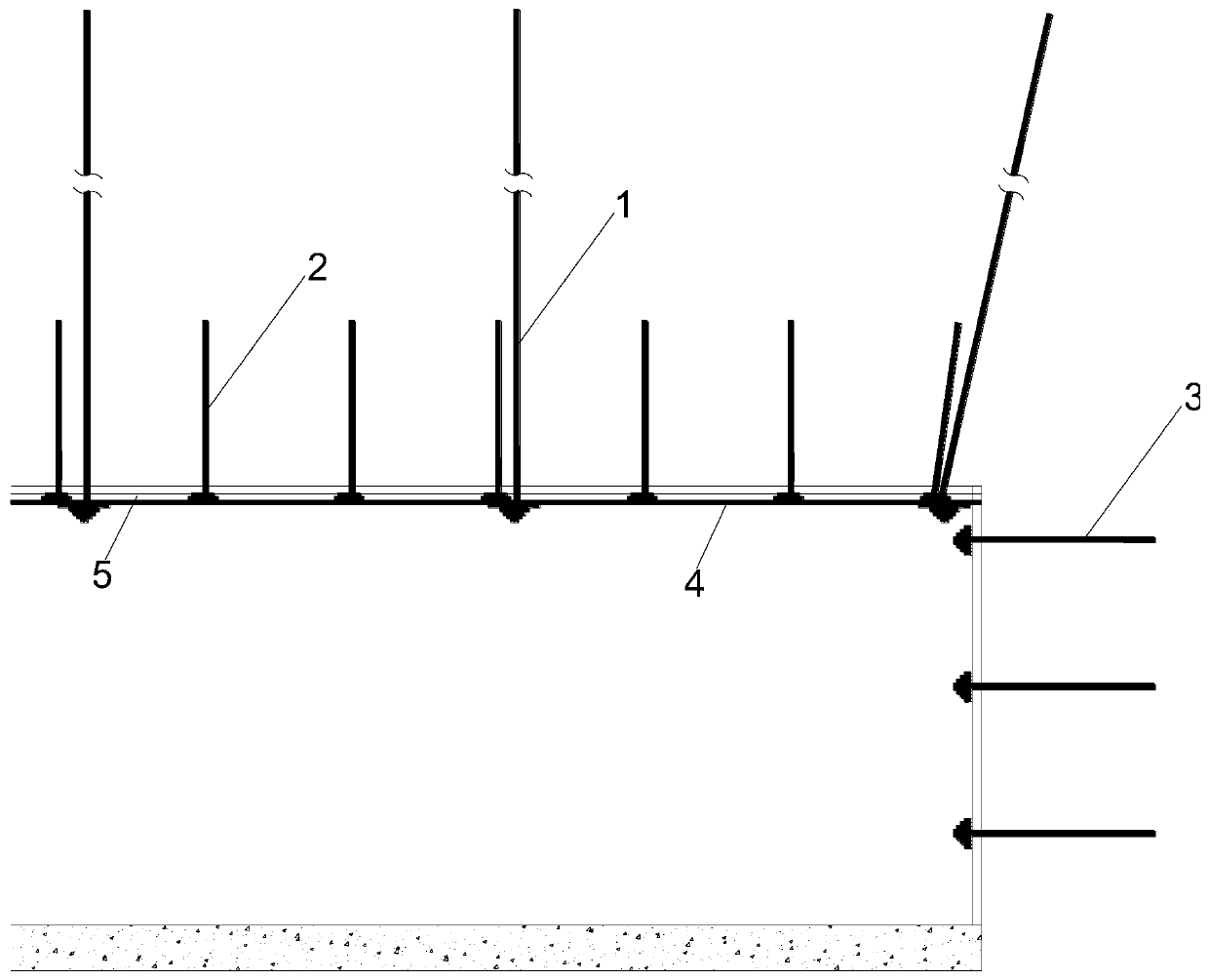

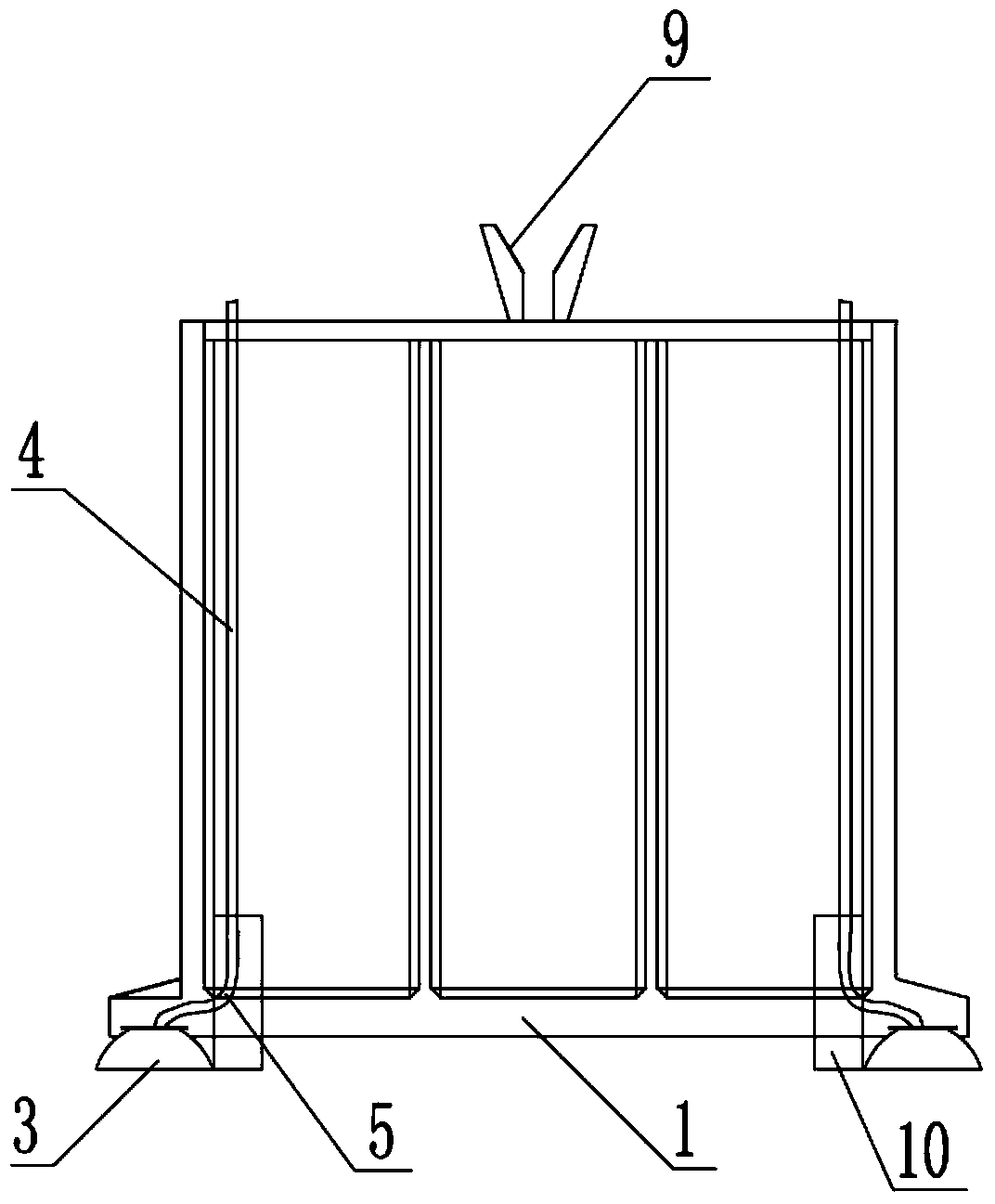

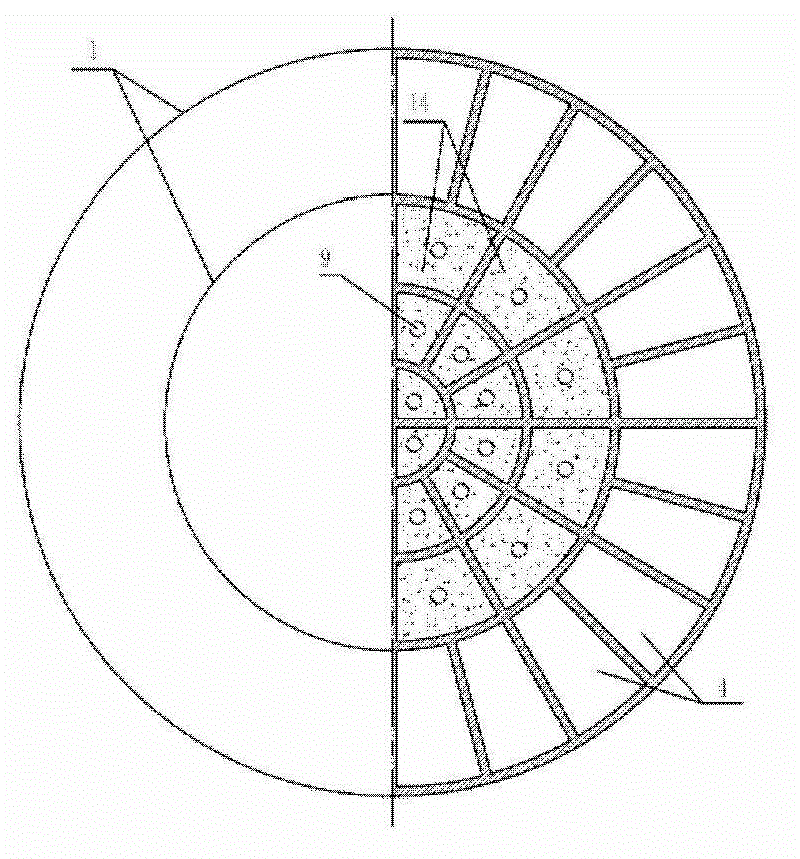

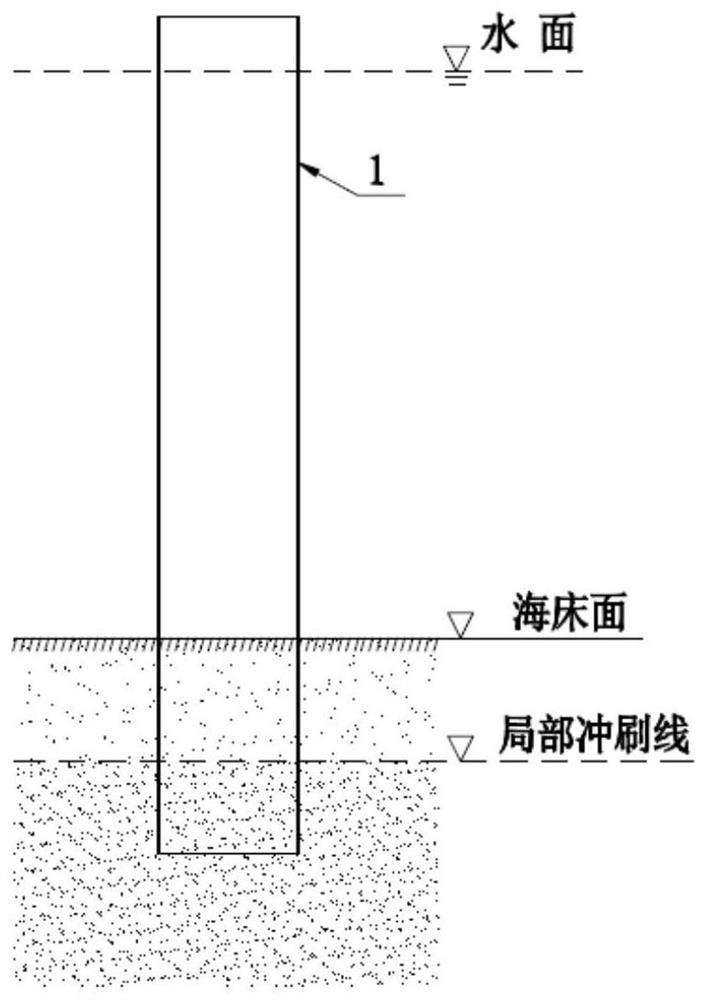

The invention discloses a caisson and pile combined foundation of consolidated subsoil and a construction method of the caisson and pile combined foundation. The caisson and pile combined foundation of the consolidated subsoil comprises the consolidated subsoil, a sand-gravel cushion, a caisson, bored piles, pile bottom grout, top seal concrete and scour protection. The main construction method comprises the following steps: consolidating the foundation with an underwater compaction sand pile or a deep-layer cement mixing pile; laying the sand-gravel cushion on the consolidated subsoil; sinking the caisson with a skirt, pile sinking guide holes and grouting reserved pipes on the sand-gravel cushion; after the caisson is located, constructing bored piles through the pile sinking guide holes; after construction of the bored piles, casting the top seal concrete at the bottom in the caisson; grouting the bottom of the caisson through the grouting reserved pipes at the bottom of the caisson, carrying out pile bottom grouting through grouting pipes in the pile, and at last casting the top plate of the caisson. In the construction process, the scour protection shall be performed around the caisson according to requirements. The caisson and pile combined foundation of the consolidated subsoil and the construction method of the caisson and pile combined foundation, disclosed by the invention, can effectively improve vertical and horizontal bearing capacity of the caisson, and control sedimentation and horizontal displacement of the caisson.

Owner:CCCC HIGHWAY CONSULTANTS +1

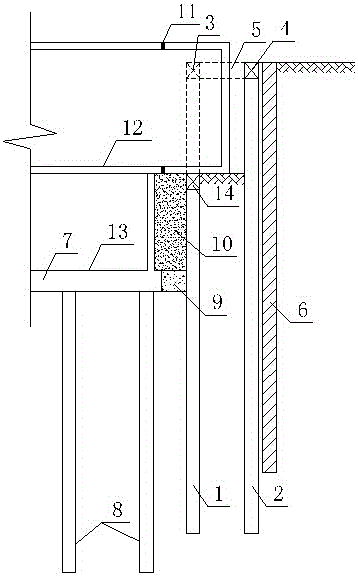

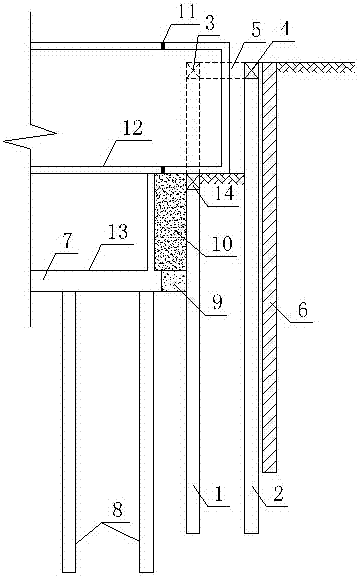

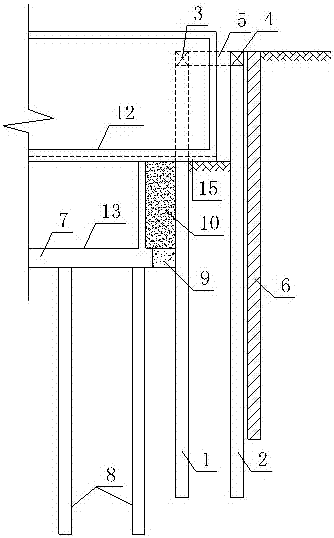

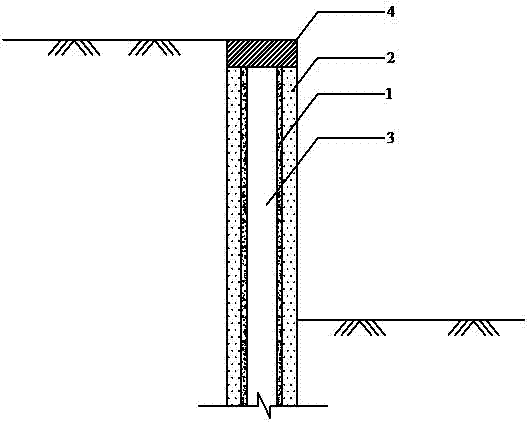

Double-row pile support structure capable of fully utilizing basement space and construction method of double-row pile support structure

The invention relates to a double-row pile support structure capable of fully utilizing basement space and a construction method of the double-row pile support structure, and belongs to the field of building construction and room buildings. A crown beam I is arranged on the top of a front row pile, and a crown beam II is arranged on the top of a rear row pile. The top of the front row pile and the top of the rear row pile are connected through a connecting beam I. A waterproof curtain pile is arranged in a pile rear soil body of the rear row pile. After a field is leveled, all project piles are constructed according to the design. A connecting beam II is poured on the top of the cut front row pile. The connecting beam II and a negative layer basement bottom plate are integrally poured. The part between the front row pile and a minus-two floor basement outer wall is filled with layering compaction filling soil. The part between the front row pile and a minus-two floor basement bottom plate is filled with plain concrete. According to the double-row pile support structure, double-row piles are changed into a single-row-pile structure with the same rigidity by means of the equal-rigidity replacement principle of the double row piles and the single row piles, the horizontal displacement of a support structure system can be controlled, and meanwhile the foundation pit support cost can be greatly reduced; and good economical efficiency is achieved in a foundation pit project with basements with multiple layers.

Owner:KUNMING UNIV OF SCI & TECH

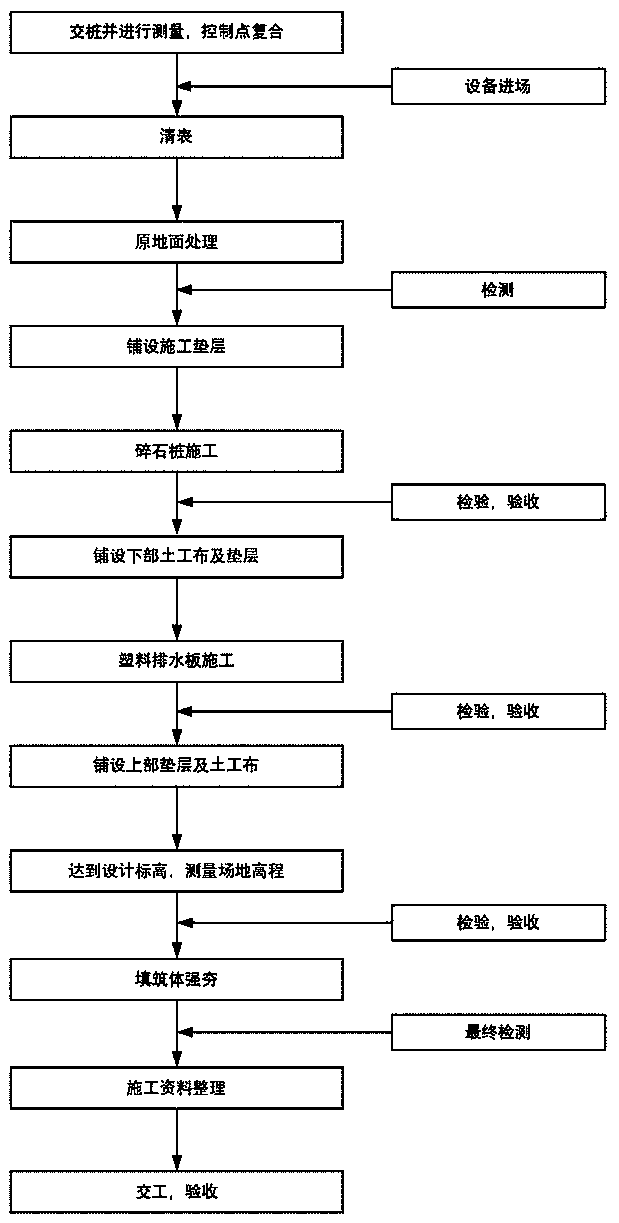

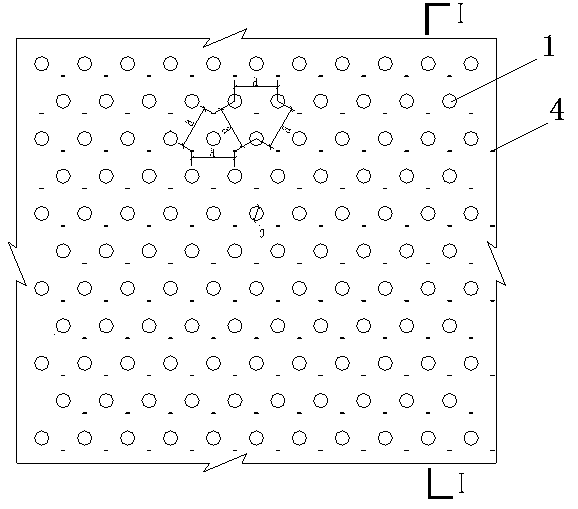

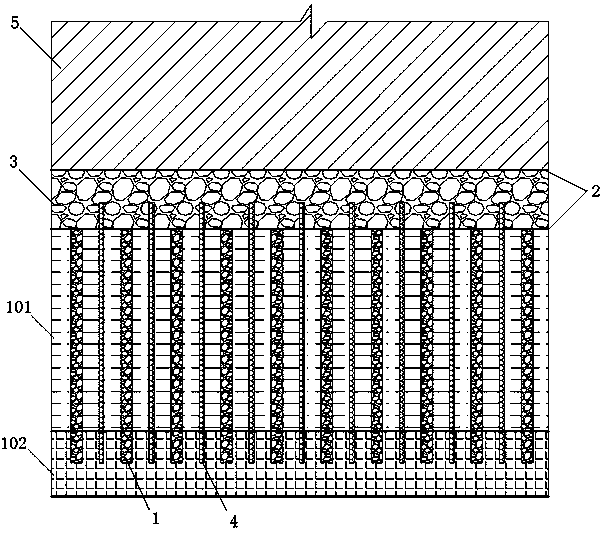

Method for carrying out dynamic compaction composite treatment on sludge soil foundation through gravel piles, drain board and upper filling body

InactiveCN110820716AEasy constructionImprove drainage capacitySoil preservationSoil scienceDynamic compaction

The invention provides a method for carrying out dynamic compaction composite treatment on a sludge soil foundation through gravel piles, a drain board and an upper filling body, and belongs to the technical field of building foundation treatment. The method comprises the steps that S1, a construction cushion layer is laid; S2, construction of the gravel piles is achieved, and a vibration sunken tube method is adopted; S3, geotechnical cloth and a cushion layer below the tops of the gravel piles are laid; S4, construction of the plastic drain board is achieved; S5, an upper cushion layer and geotechnical cloth are laid; and S6, layered and staged dynamic compaction of the filling body is achieved. By means of the method, the advantages of preloading and dynamic compaction dynamic consolidation of the gravel piles and the plastic drain board are achieved fully, the advantages are complemented, and the defects of a single foundation treatment method are avoided.

Owner:山西机械化建设集团有限公司

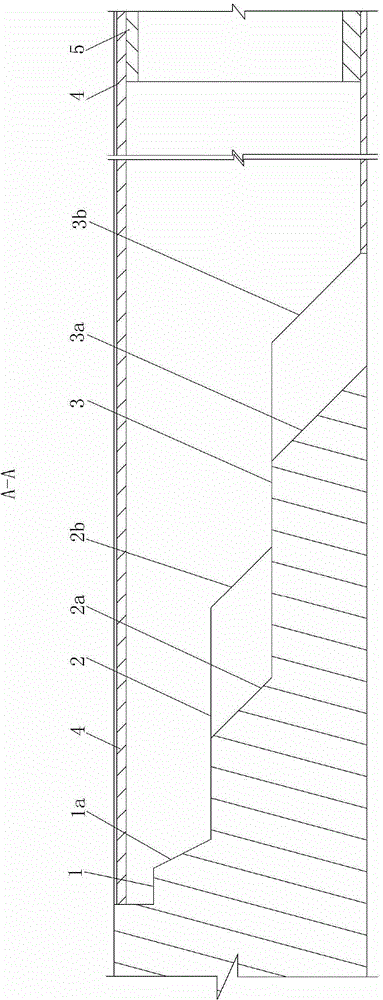

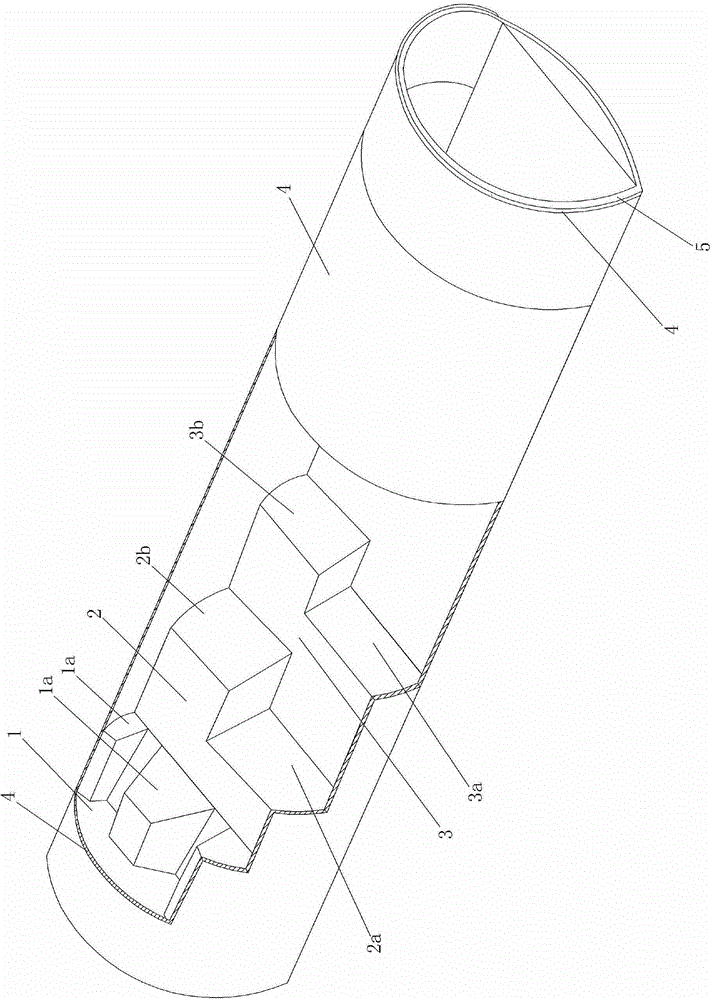

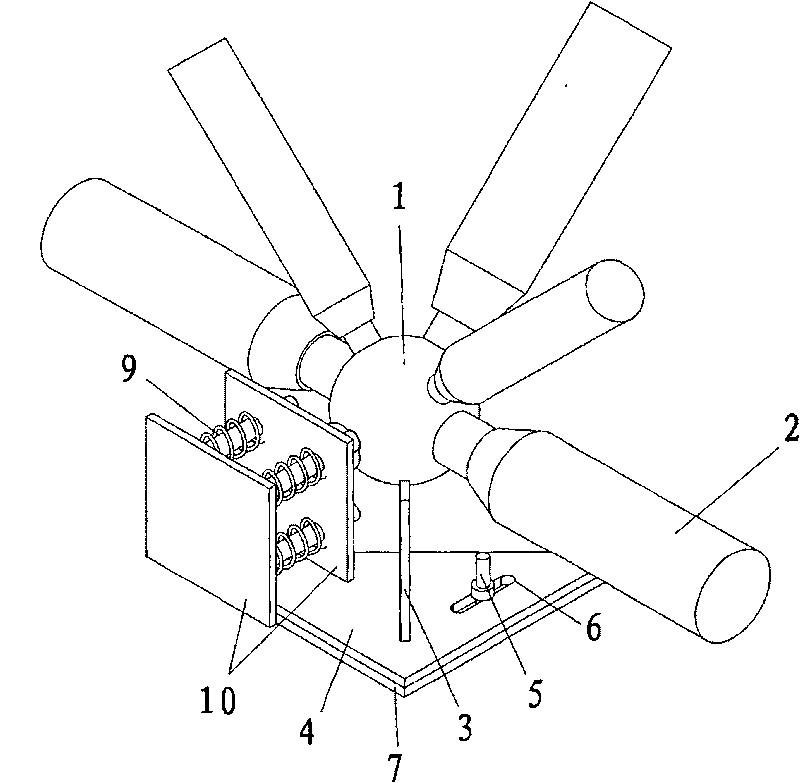

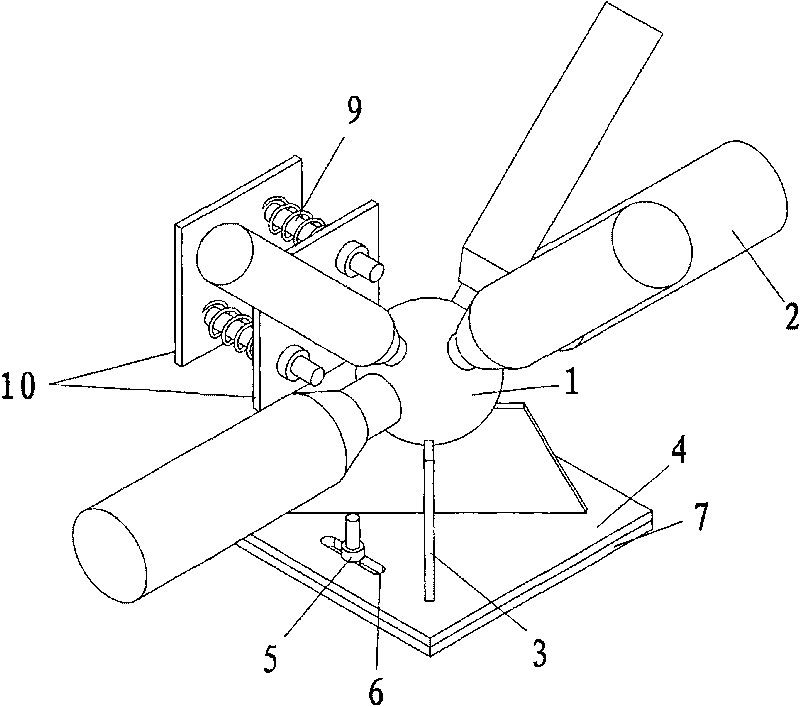

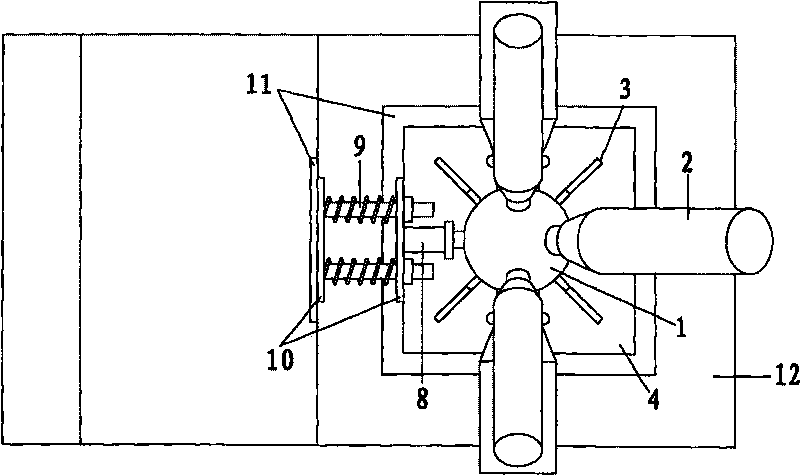

Offshore steel pipe distributed post-grouting device, air-type grouting assembly and construction method

InactiveCN111501761ARealization of groutingAdjustable grouting reinforcement rangeBulkheads/pilesSlurryPipe

The invention discloses an offshore steep pipe distributed post-grouting device, an air-type grouting assembly and a construction method. The air-type grouting assembly comprises a grouting pipe for being placed into a vertical square grouting channel, square rubber air bags which are wrapped on the outer side of the grouting pipe at upper and lower intervals, an upper air pipe connected with thesquare rubber air bag at the upper end to inflate the square rubber air bag, and a lower air pipe connected with the square rubber air bag at the lower end to inflate the square rubber air bag, and aplurality of slurry outlets are uniformly formed in the outside surface, avoiding the square rubber air bags at the upper and lower ends, of the grouting pipe; and the square rubber air bags are filled under the action of external air pressure, and the square rubber air bags at the upper and lower ends under the sufficient air state form a local closed space with the vertical square grouting channel. According to the air-type grouting assembly, a closed space is formed by using the square rubber air bags arranged up and down and the inner wall of the vertical square grouting channel under sufficient air state, and the local grouting in the vertical square grouting channel is achieved.

Owner:都城伟业集团有限公司 +1

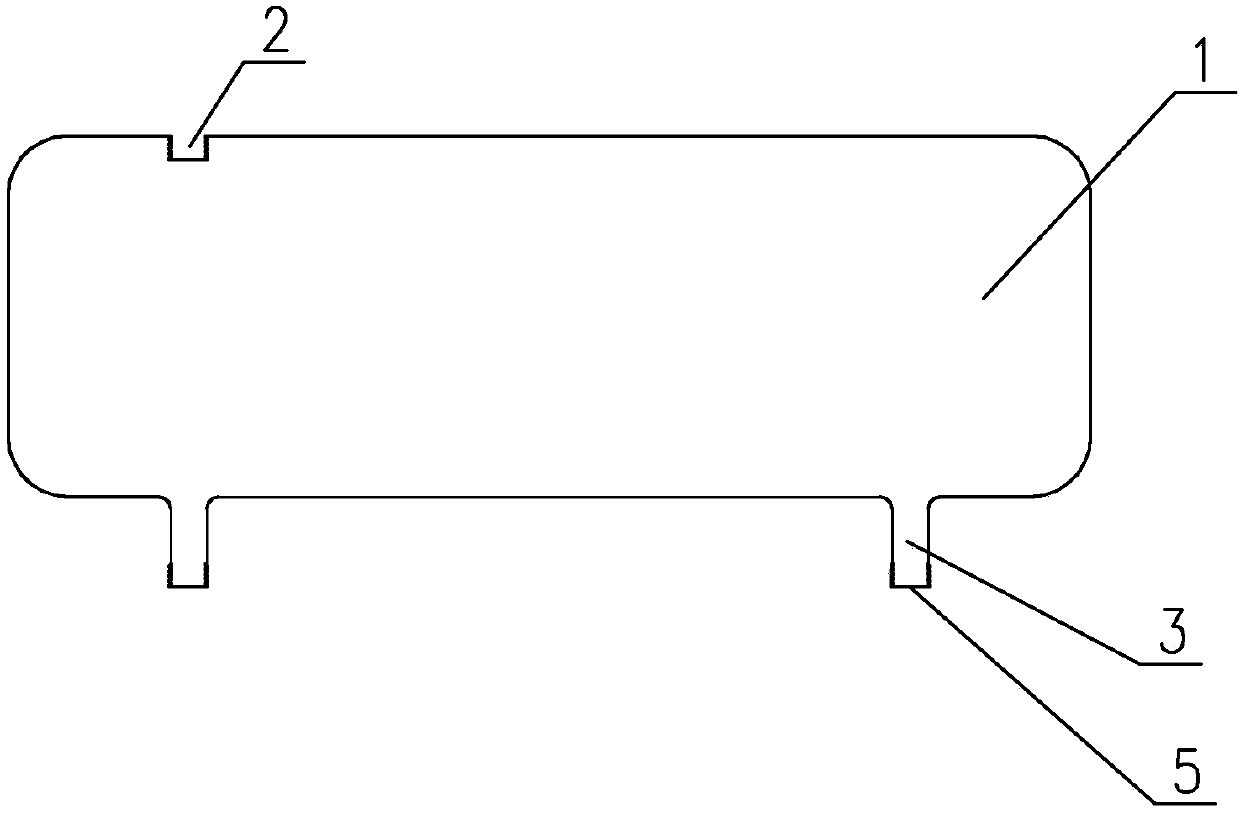

Deep basement supporting construction method

InactiveCN105887891AMeet the requirements of construction safety and stabilityControl Horizontal ShiftArtificial islandsExcavationsSteel columnsBasement floor

The invention discloses a deep basement supporting construction method. The deep basement supporting construction method is characterized by comprising the following construction steps of: (1) constructing a layer of steel column foundation piles, two layers of steel column foundation piles, a layer of steel columns and two layers of steel columns; (2) constructing basement supporting row piles; (3) constructing basement waterproof curtains, and using cement mixing piles as the basement waterproof curtains; (4) constructing a layer of basement inner ring ring-beams and a layer of basement outer ring ring-beams; (5) constructing a layer of diagonal braces and angle braces; (6) carrying out pit earth excavation till reaching the construction elevation of the bottoms of two layers of basement inner ring ring-beams; (7) constructing two layers of basement inner ring ring-beams and two layers of basement outer ring ring-beams; (8) constructing two layers of diagonal braces; (9) carrying out pit earth excavation till reaching the construction elevation of the bottoms of three layers of basement bottom plates; (10) constructing the basement bottom plates; (11) constructing the outer concrete wall of the basement; (12) dismantling the two layers of basement inner ring ring-beams, the two layers of basement outer ring ring-beams and two layers of diagonal braces; (13) constructing two layers of basement floors; (14) dismantling a layer of basement inner ring ring-beams and a layer of basement outer ring ring-beams; and (15) constructing a layer of basement floors.

Owner:朱奎

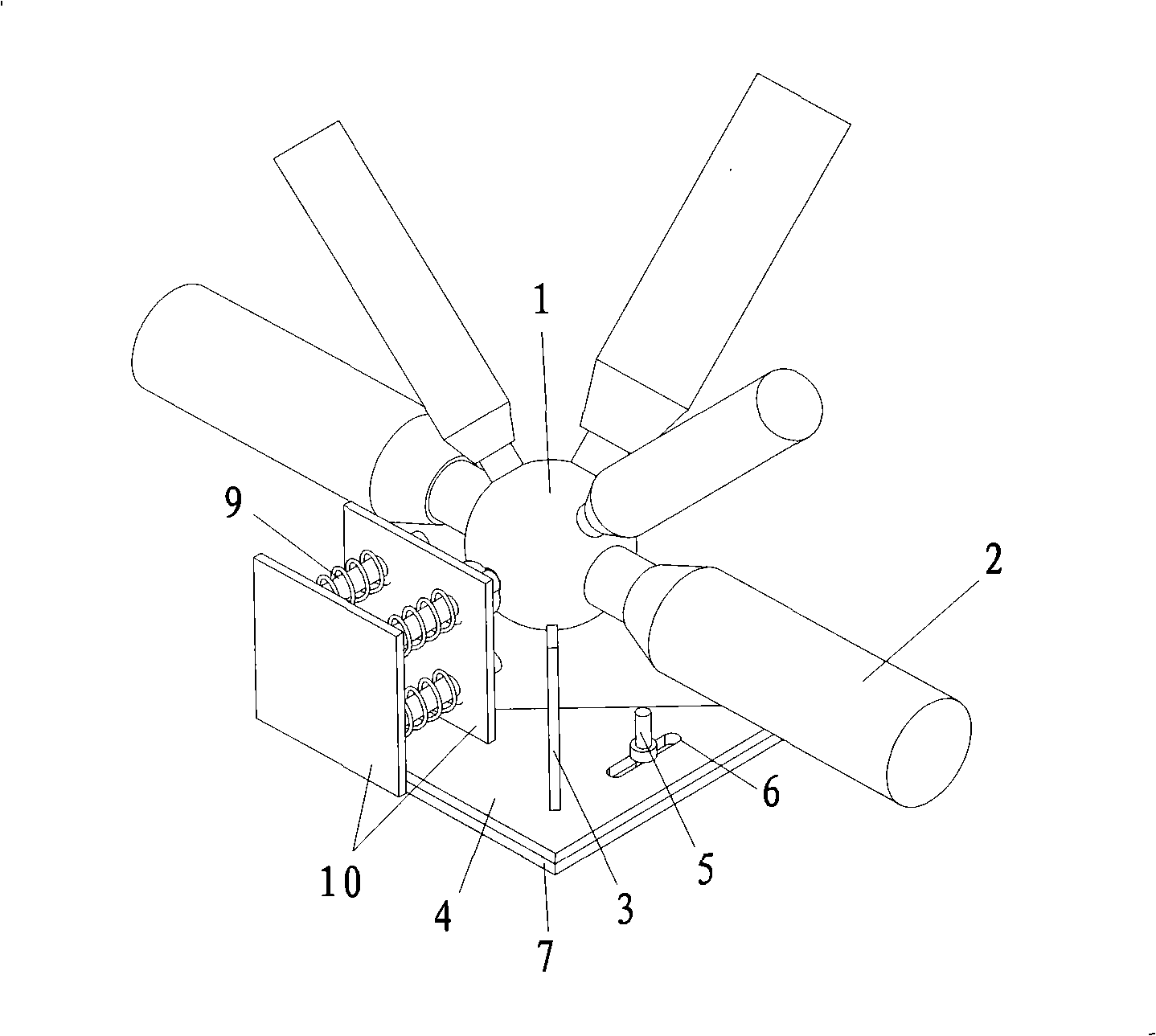

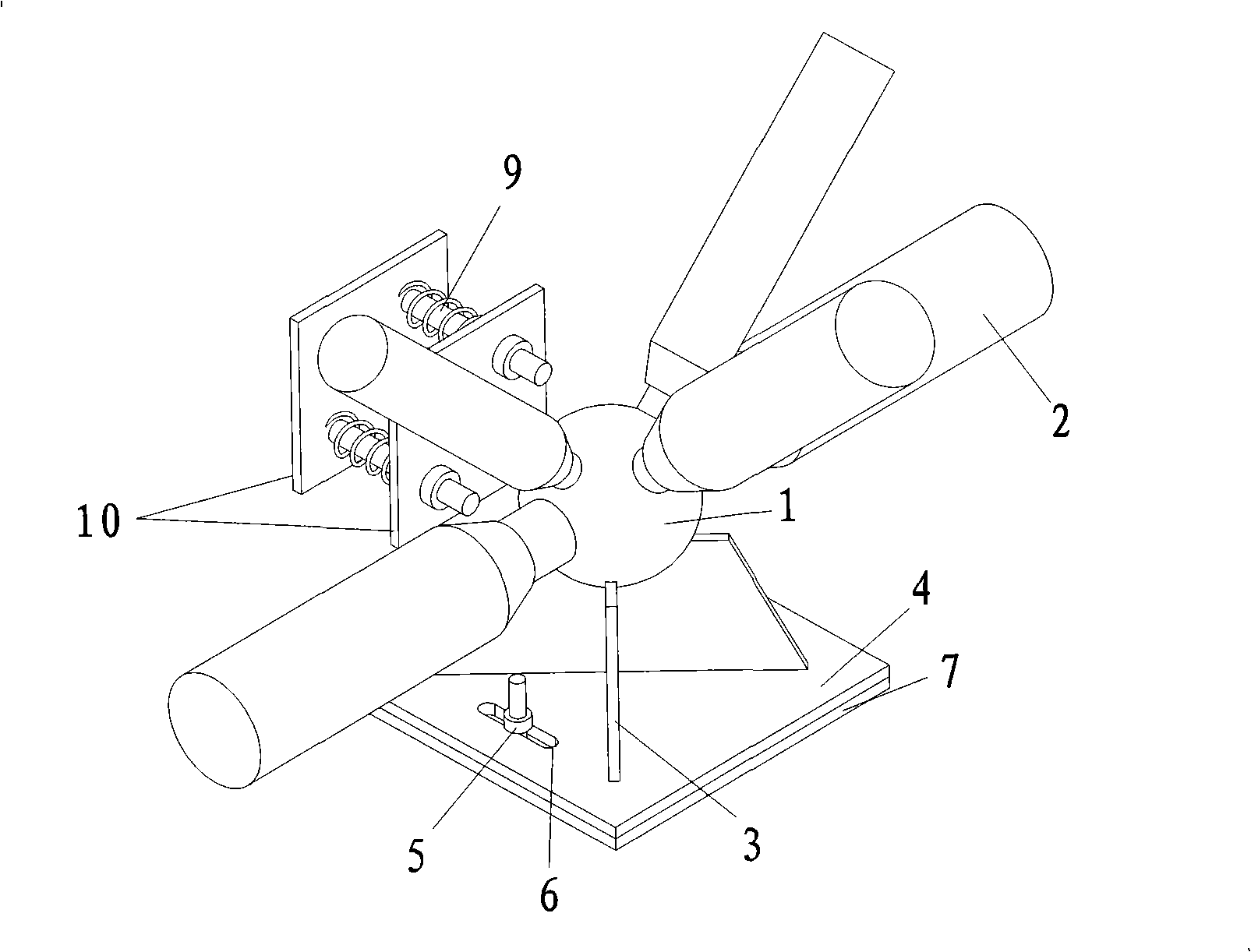

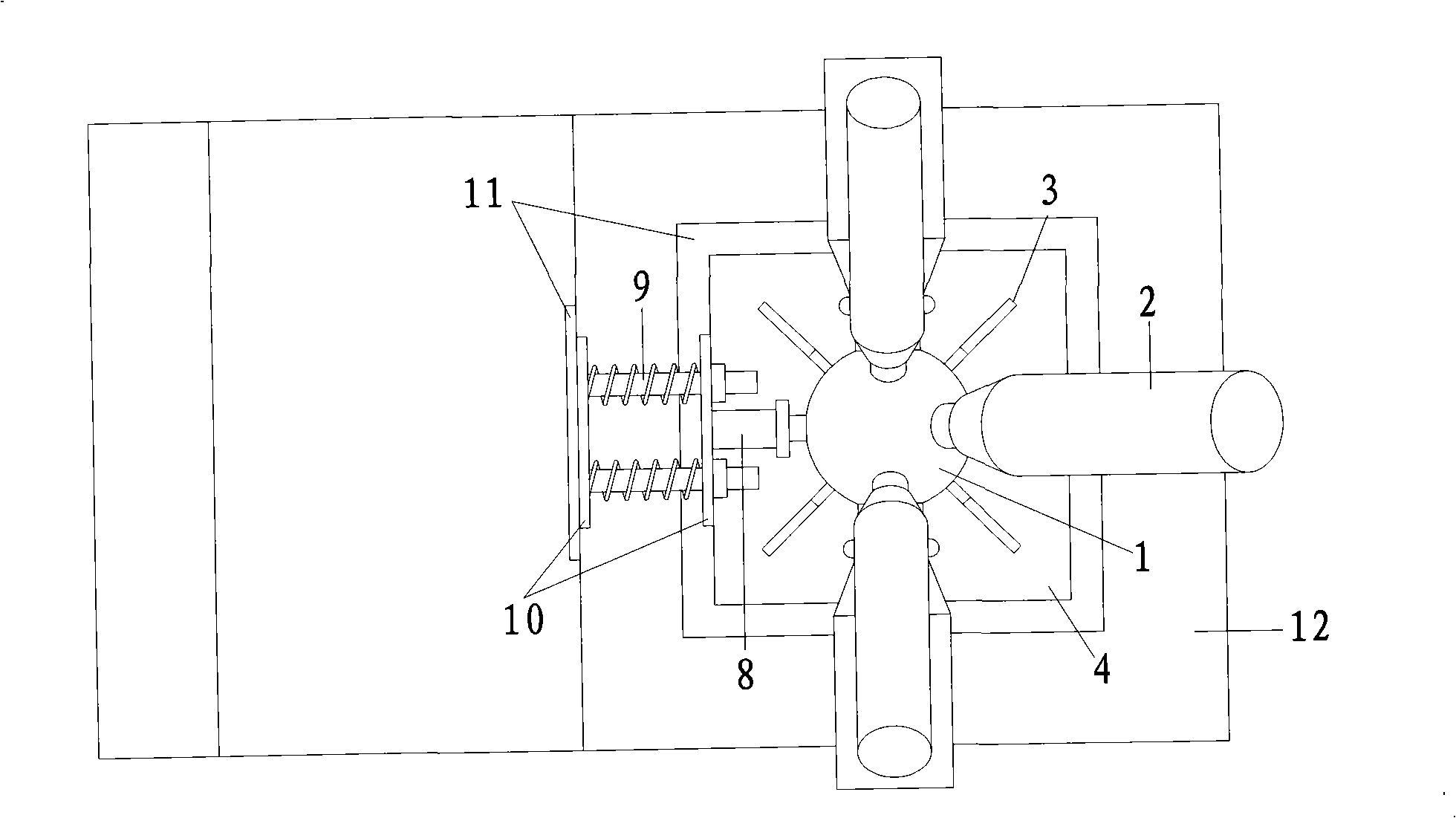

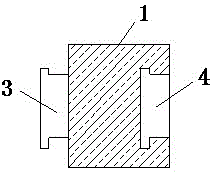

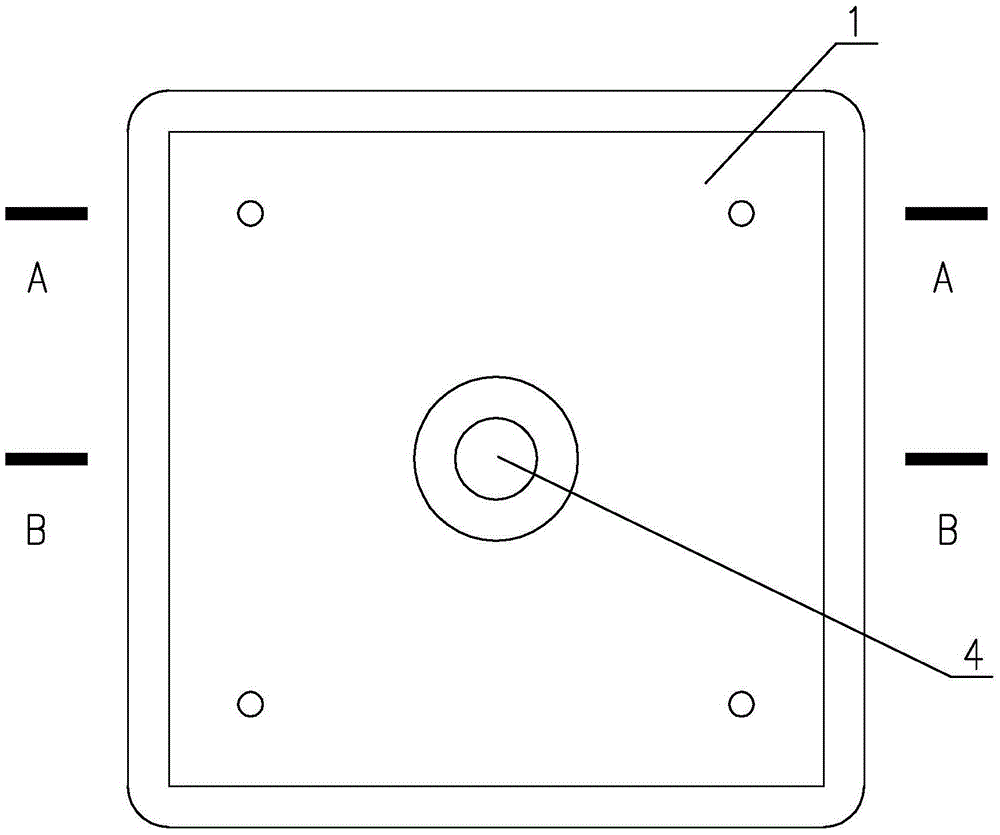

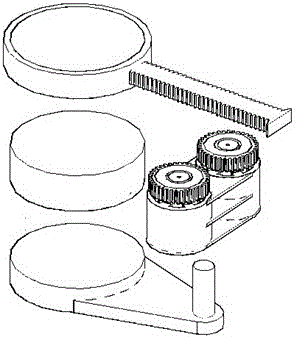

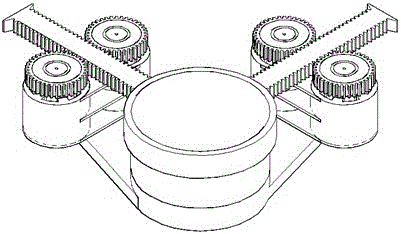

Horizontally adjustable stiff support of lattice framed structure

ActiveCN101314963AImprove mechanical performanceControl steel consumptionArched structuresVaulted structuresSlide platePre embedding

The invention discloses a horizontal rigidity adjustable support with a grid structure. The support comprises a support ball joint, grid components, a cross-shaped rib plate, a support base plate, an anchor bolt, a sliding chute, a sliding plate, a support steel tube, a pre-embedded steel plate and a lower structure. A steel plate, the sliding plate and the support base plate are respectively arranged on the pre-embedded steel plate in sequence; the cross-shaped lib plate is arranged on the support base plate; the support ball joint is arranged on the cross-shaped lib plate; the plurality of grid components are arranged on the support ball joint; the support steel tube is arranged in the horizontal direction of the circle center passing through the support ball joint; the other end of the support steel tube is connected with a rigidity adjusting device; the sliding chute is arranged on the support base plate; the anchor bolt matched with the sliding chute is arranged on the pre-embedded steel plate; and the anchor bolt respectively penetrates through the steel plate, the sliding plate and the support base plate. The support has the advantages that the adjustment and the optimization of the horizontal rigidity of the support can be realized; the reaction force and the horizontal displacement of the horizontal rigidity adjustable support with the structure can be effectively controlled; and the mechanical performance of the structure under the actions of temperature, earthquake and dynamic loading can be improved to a certain extent.

Owner:GUANGSHA CONSTR GROUP +1

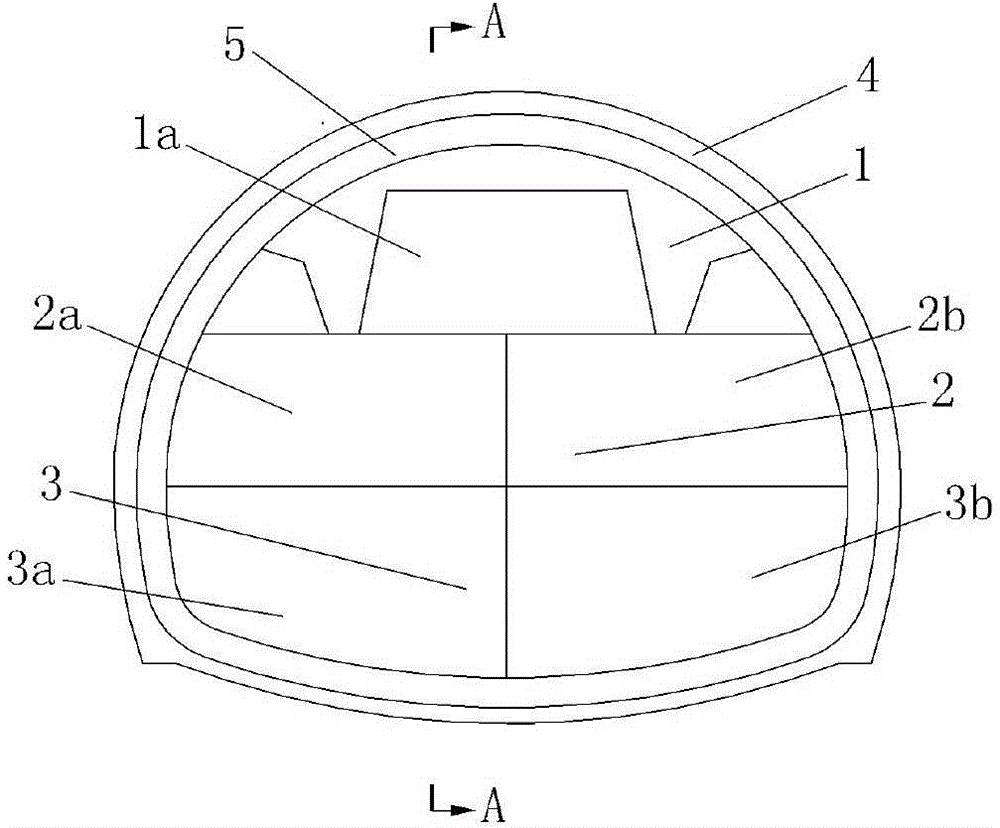

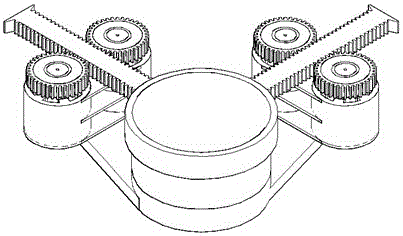

Earthquake isolation and reduction structure and earthquake reduction method thereof

PendingCN106351118AControl Horizontal ShiftAvoid destructionBridge structural detailsBridge erection/assemblyHorizontal forceBridge engineering

The invention provides an earthquake isolation and reduction structure and an earthquake reduction method thereof, belongs to the technical field of bridge engineering and aims to solve the problem that the conventional earthquake isolation and reduction method is unsatisfactory in earthquake reduction effect or high in manufacturing cost. The structure comprises a plurality of spherical support seats and rubber support seats which are arranged between an upper structure and a lower structure of a bridge at intervals, wherein each rubber support seat comprises an upper cushion block, a rubber support seat body and a lower cushion block which are successively arranged from top to bottom; an upper support seat steel plate and a lower support seat steel plate are arranged at the top end and the bottom end of each rubber support seat body respectively; upper cushion block steel plates and lower cushion block steel plates are arranged between the upper and lower support seat steel plates and the corresponding upper and lower cushion blocks respectively; the upper and lower cushion block steel plates are embedded in the upper and lower cushion blocks. The earthquake reduction method comprises the following steps: firstly fixedly connecting the spherical support seats and the rubber support seats between the upper structure and the lower structure of the bridge, arranging the spherical support seats and the rubber support seats at intervals in parallel; then shearing off the spherical support seats when the earthquake occurs, enabling the rubber support seats to bear the horizontal force so as to control the horizontal displacement of a bridge body.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Consolidated floor

InactiveCN106049816AControl vertical displacementControl Horizontal ShiftFlooringEngineeringVertical displacement

Owner:无锡市天龙装饰材料有限公司

Excavating method suitable for large section loess tunnels

InactiveCN103089270BReduce security risksControl Horizontal ShiftTunnelsSoil scienceUltimate tensile strength

Owner:SOUTHWEST JIAOTONG UNIV

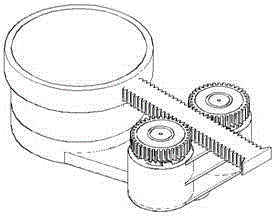

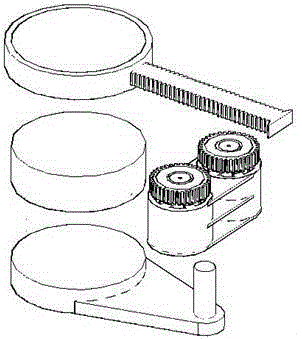

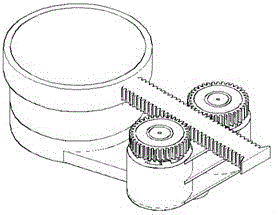

Intelligent electromagnetic control vibration isolating support

ActiveCN105113654AControl Horizontal ShiftSmall electromotive forceShock proofingMechanical energyEngineering

The invention provides an intelligent electromagnetic control vibration isolating support. The intelligent electromagnetic control vibration isolating support comprises a traditional vibration isolating support, a pressure induction device, an electromagnet upper plate, an electromagnet lower plate, an upper transmission connecting rod, a lower connecting plate, a one-way bearing, a transmission gear, a direct-current generator, a control circuit, a working circuit and a storage battery. Mechanical energy generated when a structure slides horizontally is transmitted to an energy system through a mechanical transmission system under regulation and control of a control system, and is converted into electric energy by the direct-current generator, multistage earthquake control is implemented through the control circuit comprising a pressure sensor, namely, only a storage battery charging circuit is started when a small or middle earthquake occurs, and an electromagnet system working circuit is started when a major earthquake occurs. Moreover, counterforce for driving the direct-current generator also controls horizontal movement of the vibration isolating support. The intelligent electromagnetic control vibration isolating support is suitable for a vibration isolating structure of which a support possibly has over-large tensile stress, and can be used with various vibration isolating supports. Besides, the intelligent electromagnetic control vibration isolating support is novel in design concept, and has good three-dimensional mechanical property; and integration degrees of a mechanical system, an electromagnetic system and the control system are high.

Owner:TONGJI UNIV

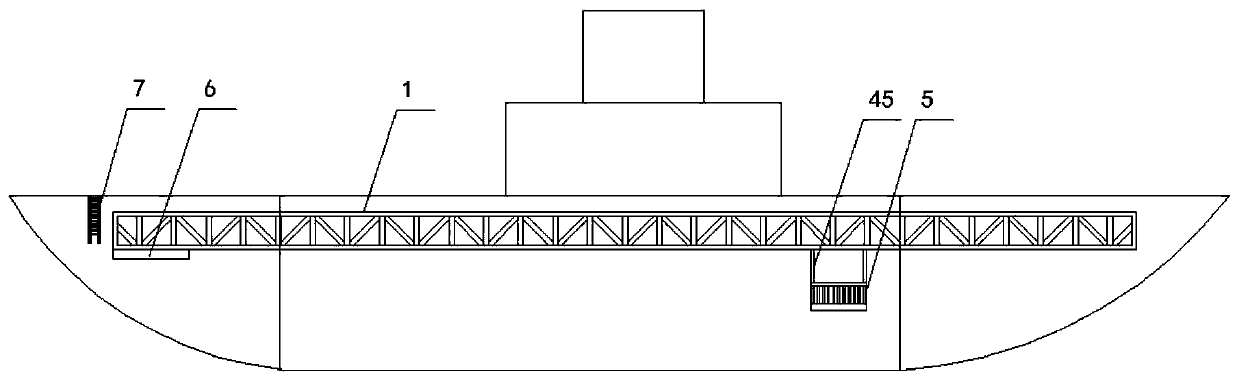

Maintenance platform for ship body

InactiveCN110422275AImprove bearing capacityStable structureDry-dockingSlipwaysWind drivenMotor drive

The invention provides a maintenance platform for a ship body. The platform comprises an n-shaped fixing frame with one side fixedly arranged on the top of the side surface of the ship body, wherein apair of oppositely arranged sliding rails are fixedly arranged on two sides of the inner part of the fixing frame, a sliding trolley is connected in the sliding rails in a sliding mode, the sliding trolley is provided with a winding device, the winding device comprises two winding motors, two winding driving rollers and two winding driven rollers, each of the two ends of each winding driven roller is provided with an annular groove, the inner part of each annular groove is fixedly connected with a steel rope, the bottoms of the steel ropes are connected with a maintenance table, the winding motors drive the winding driving rollers to rotate so as to drive the winding driven rollers to rotate, and the winding driven rollers rotate to achieve winding of the steel ropes. According to the platform, the hanging type maintenance table is arranged, the height displacement and the horizontal displacement of the maintenance table can be controlled through the sliding trolley and the winding device, so that the use efficiency of the side surface of the ship body is high.

Owner:ZHEJIANG OCEAN UNIV

Low pile gravity type wharf suitable for soft soil foundation and construction method of low pile gravity type wharf

PendingCN110004876AReinforcing effectReasonable structural designBreakwatersQuaysSoil propertiesReinforced concrete

The invention relates to a low pile gravity type wharf suitable for a soft soil foundation and a construction method of the low pile gravity type wharf, and belongs to the field of wharfs, which solves the problems that an existing gravity type wharf is influenced by foundation soil properties, large post-construction settlement exists commonly, and the construction period is long. The low pile gravity type wharf includes a plurality of rigid foundation piles, a reinforced concrete structure base plate, a plain concrete wall body and a reinforced concrete copping, wherein the structure foundation of the low pile gravity type wharf adopts the rigid foundation piles, the bottoms of the rigid foundation piles enter a hard soil layer, a broken stone cushion layer and a plain concrete cushion layer are sequentially paved on the upper parts of the rigid foundation piles, the reinforced concrete structure base plate is casted on the tops of the rigid foundation piles, the reinforced concretecopping is arranged on the top surface of the plain concrete wall body, and a riprap refilling structure layer, an inverted filtering layer, a geotechnical cloth and a dang residue layer are sequentially arranged on the rear of the plain concrete wall body from the top to the bottom. According to the low pile gravity wharf and the construction method, properties of the rigid foundation piles are used, settlement and horizontal displacement can be effectively controlled, the reinforcing effect of whole stability on the wharf is also achieved, and the construction period of the wharf is effectively shortened.

Owner:日昌升集团有限公司

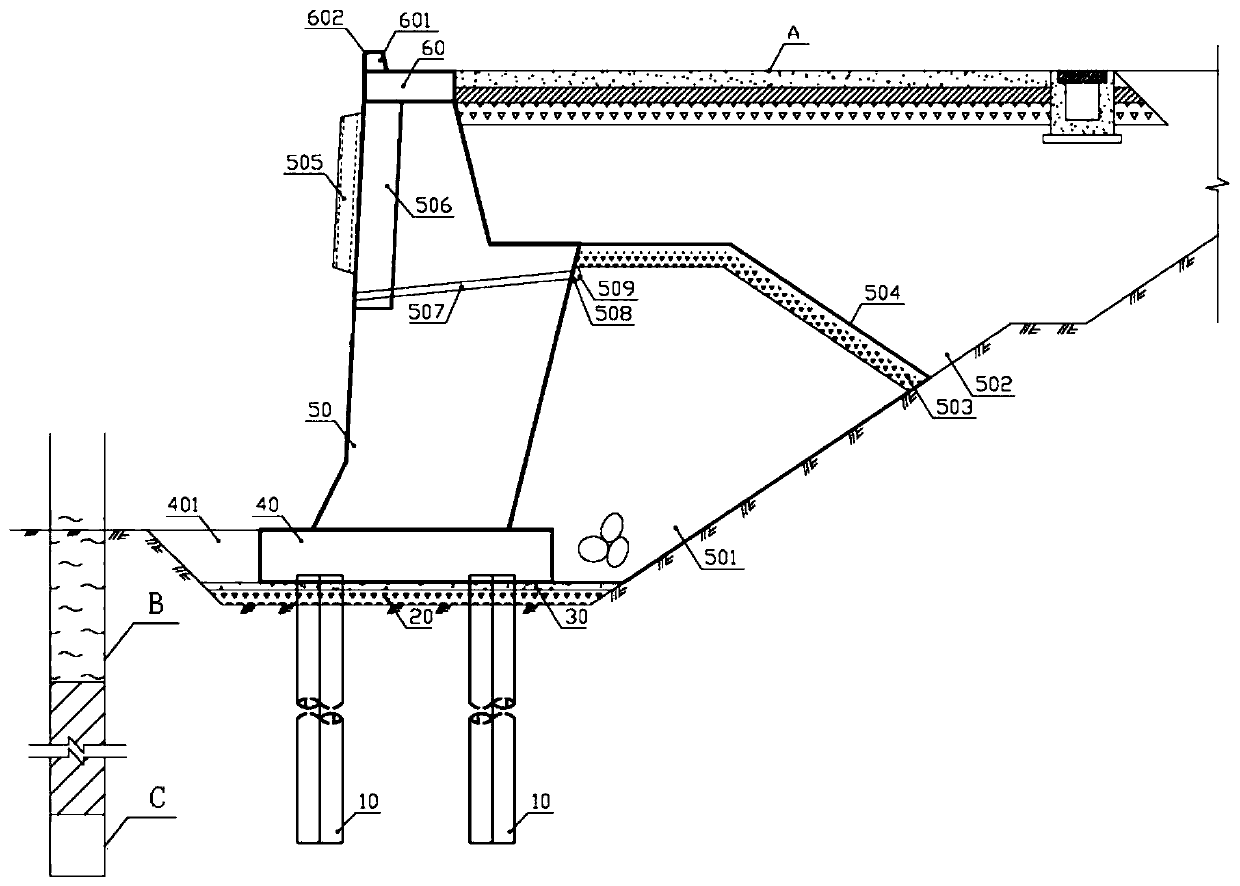

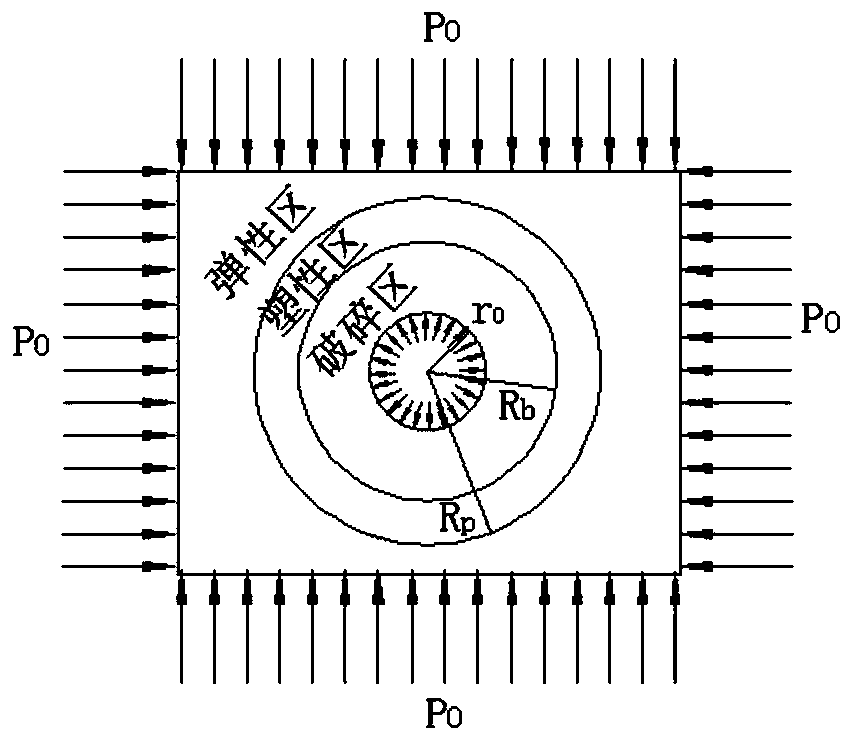

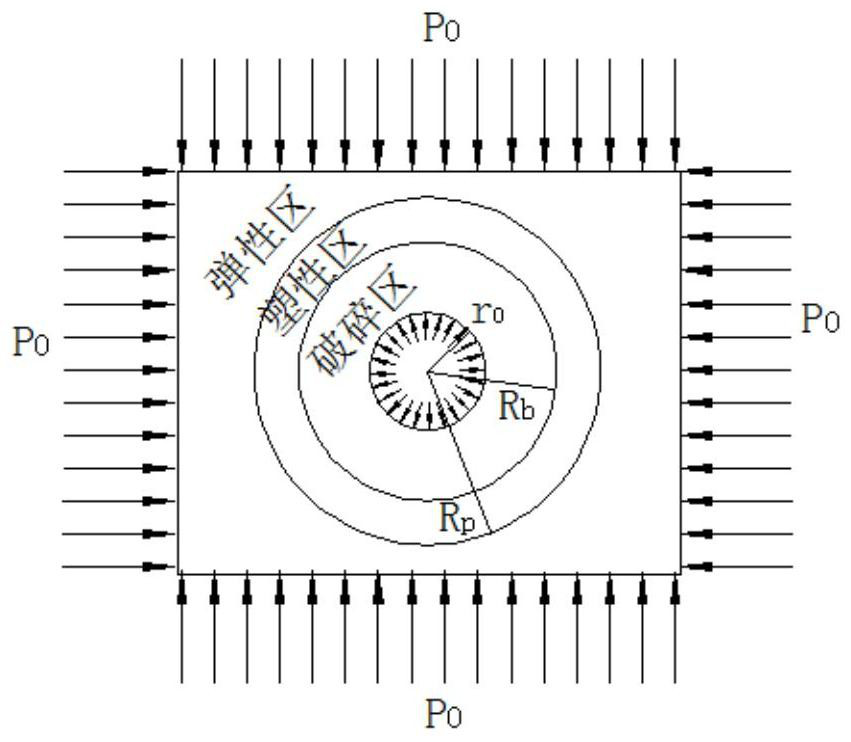

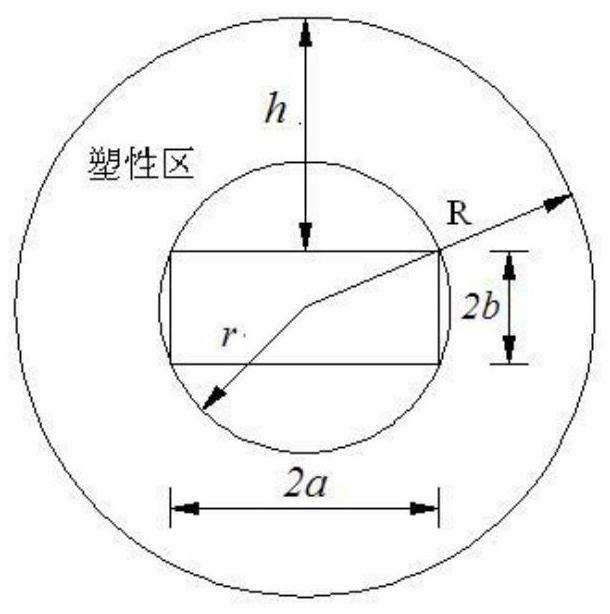

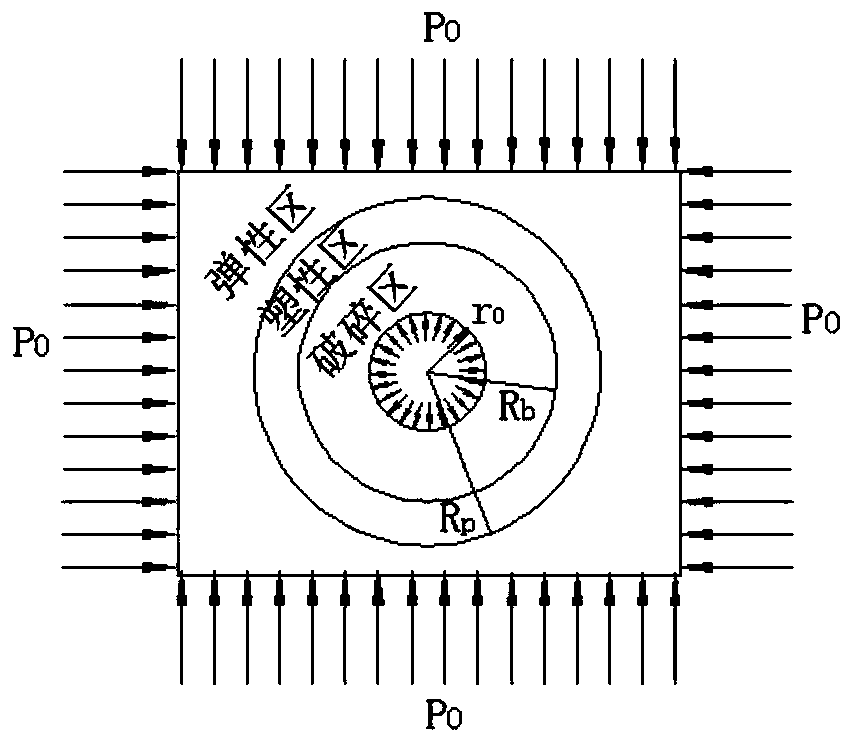

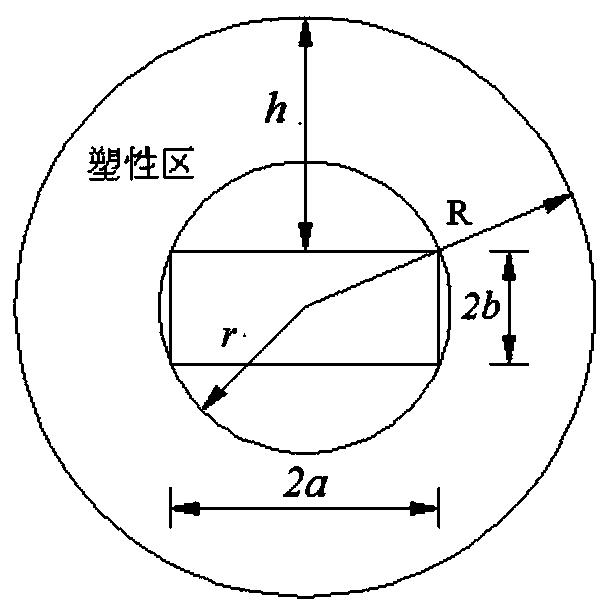

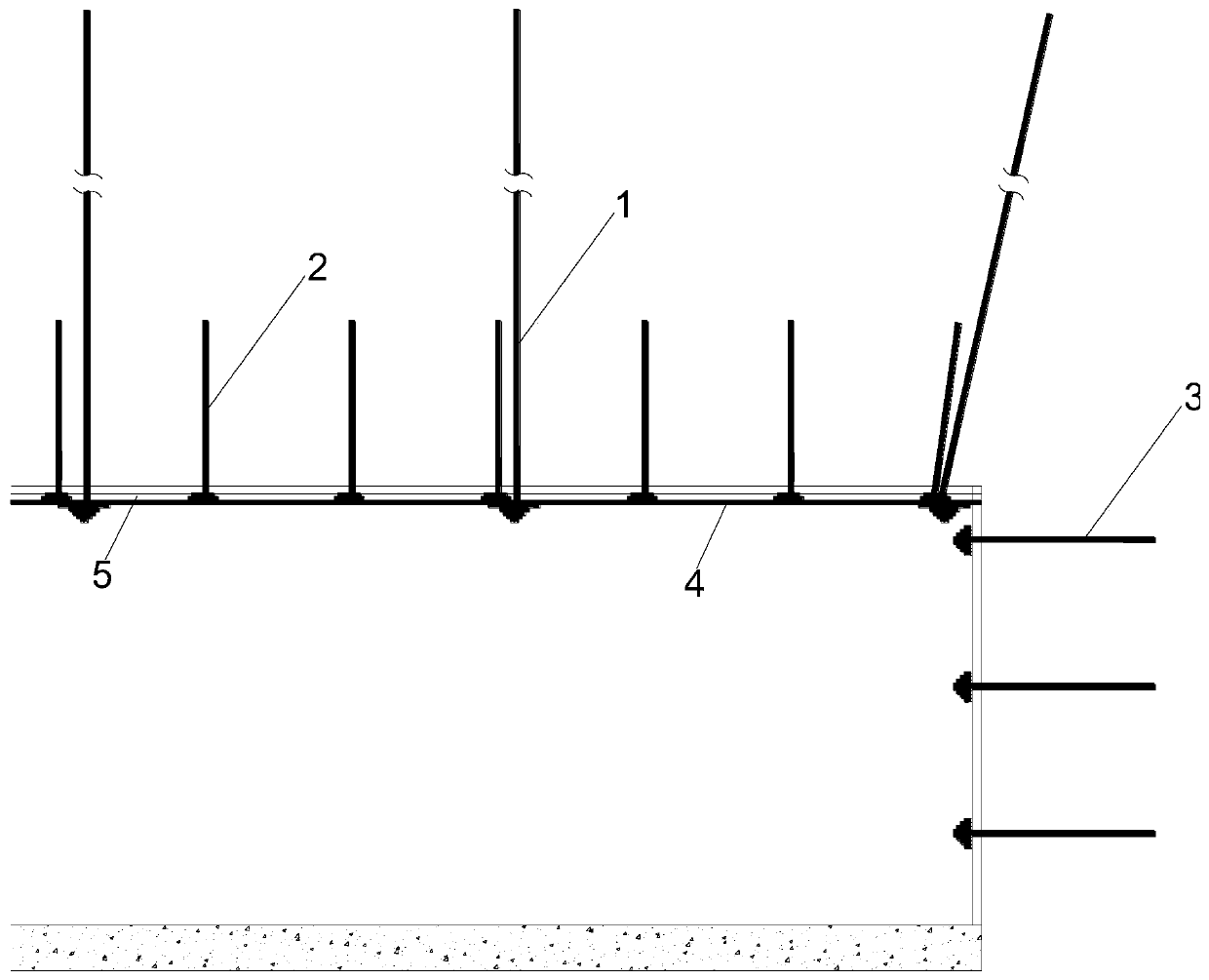

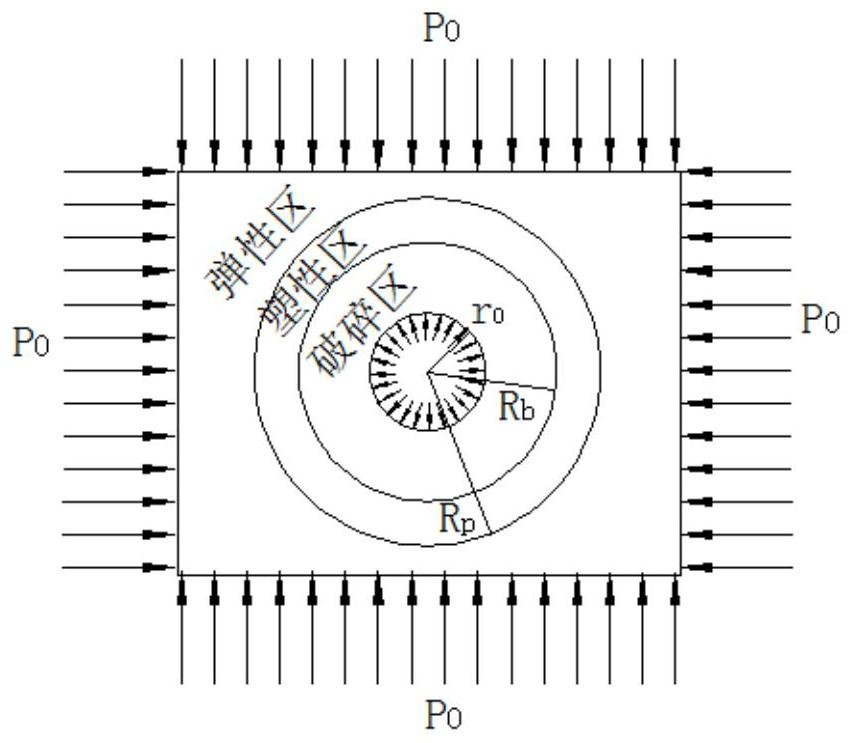

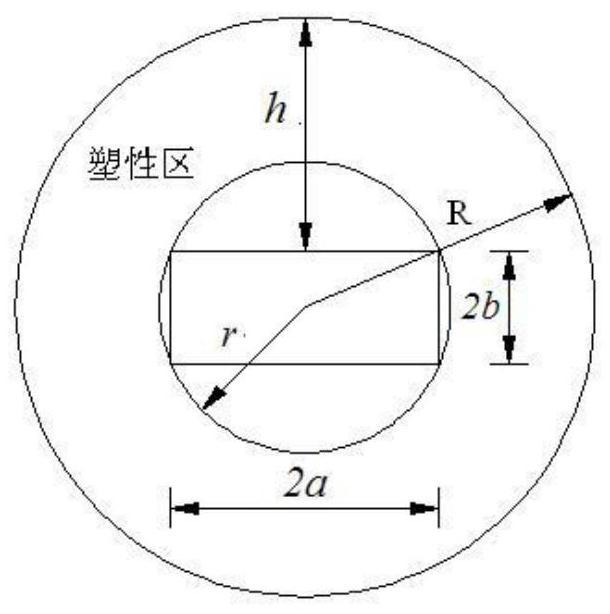

Comprehensive mechanized coal mining face withdraw channel anchor rod and anchor cable supporting determining method

ActiveCN110821535ANo need for secondary reinforcement support designReduce vertical deformationData processing applicationsMining devicesMining engineeringStructural engineering

The invention discloses a comprehensive mechanized coal mining face withdraw channel anchor rod and anchor cable supporting determining method. The method comprises the following steps that firstly, the radius of a top plate breaking zone and the radius of a plastic zone are calculated; secondly, parameters of top plate anchor rods are calculated, wherein the parameters of the top plate anchor rods include the length of the top plate anchor rods, the row distance between the top plate anchor rods and the prestress of top plate anchor ropes; and fourthly, parameters of side anchor rods are calculated, wherein the parameters of the side anchor rods include the length of the side anchor rods, the row distance between the side anchor rods and the prestress of the side anchor rods. By means ofthe determining method, it can be ensured that a working face support in coal mine production can be withdrawn in a safe state; and furthermore, the production cost of a coal mine can be reduced, theproduction efficiency can be improved, and theoretical reference is provided for the design and study of coal mine withdraw road supports in future.

Owner:XIAN UNIV OF SCI & TECH

Construction method for super large pile distance deep foundation pit supporting system

InactiveCN111424675AReduce usageAchieve protectionExcavationsSupporting systemArchitectural engineering

The invention provides a construction method for a super large pile distance deep foundation pit supporting system. Two rows of supporting piles are constructed at equal distances in the length direction of a foundation pit; when an existing structure exists at the construction part of the supporting piles, the supporting piles are constructed after crossing of the existing structure; after the supporting piles are constructed, crown beams are constructed at the tops of the supporting piles, and then board walls are constructed between the supporting piles located on the two sides of the existing structure, wherein the board walls are constructed with a reverse method; and after the board walls are constructed, the supporting system is constructed. The distance of the equal distance construction of the supporting piles is not larger than two times the diameter of the supporting piles, and the distance between the supporting piles on the two sides of the existing structure is larger than two times the diameter of the supporting piles. Compared with the prior art, row pile supporting and the reverse building method construction are combined, the advantages of the row pile supportingand the reverse building method construction are fully utilized, the structure is simple, safety and reliability are achieved, construction is convenient, and the manufacturing cost is low. Meanwhile,no anchor rope is used, an existing building and existing pipelines are protected while the foundation pit is protected, and good application prospects in foundation pit supporting in the fields suchas city municipal administration are achieved.

Owner:POWERCHINA XIBEI ENG

Island constructing caisson without leveling of foundation bed and construction method

InactiveCN103669379ARaise the verticalImprove carrying capacityCaissonsUltimate tensile strengthBallast

The invention relates to an island constructing caisson without leveling of a foundation bed. The island constructing caisson without leveling of the foundation bed comprises a prefabricated caisson body, a grouting bag is arranged on a bottom plate of the caisson, and the grouting bag is connected with a grouting pipe. The invention further relates to a construction method of the island constructing caissons. The method includes the following steps that one caisson is positioned according to pre-determined design; the caisson is made to sink through ballast; when the caisson sinks to the pre-determined height, the caisson body is supported with a supporting device; binding material is injected to the grouting bag from the grouting pipe; after the binding material solidifies and reaches certain strength, the supporting device is taken out; sand and the ballast are injected to the bottom of the caisson, and pouring is performed; after the caisson is installed, a next caisson is installed according to the same steps. Due to the fact that grout is injected into the grouting bag after the caisson is placed well, concrete sets fast, the caisson body can be supported by the set concrete, setting is easy to control in the early stage of a caisson foundation, and setting and inclination in the construction period are not be caused easily.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG

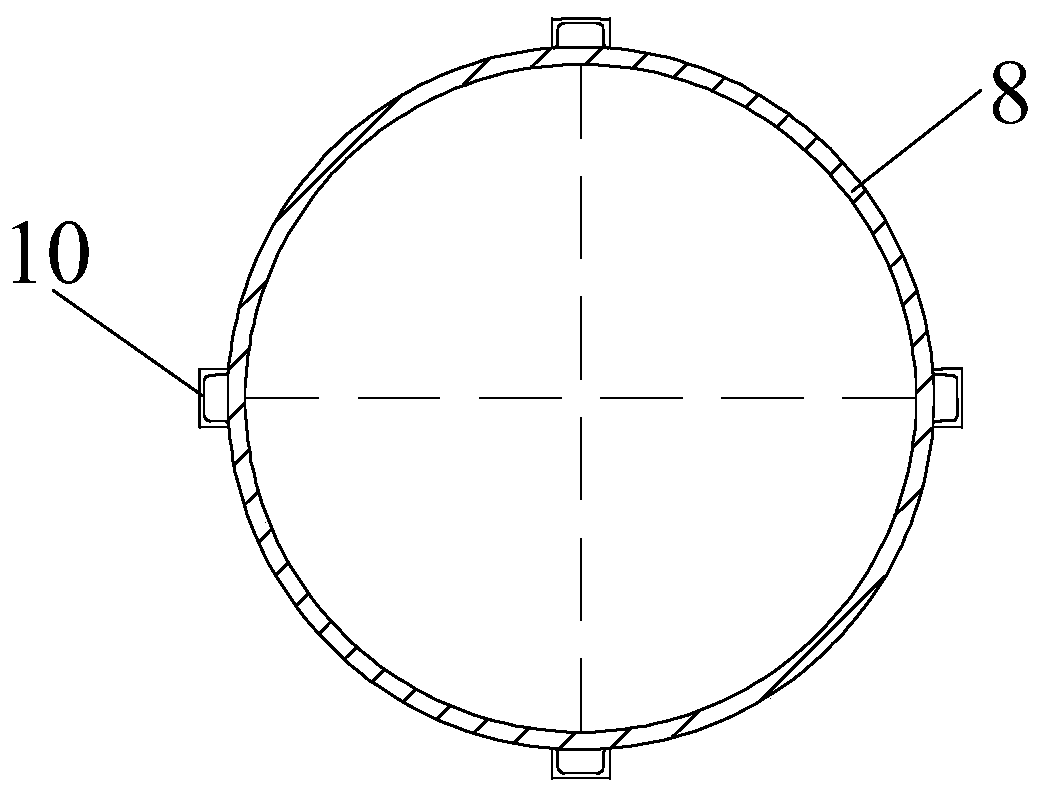

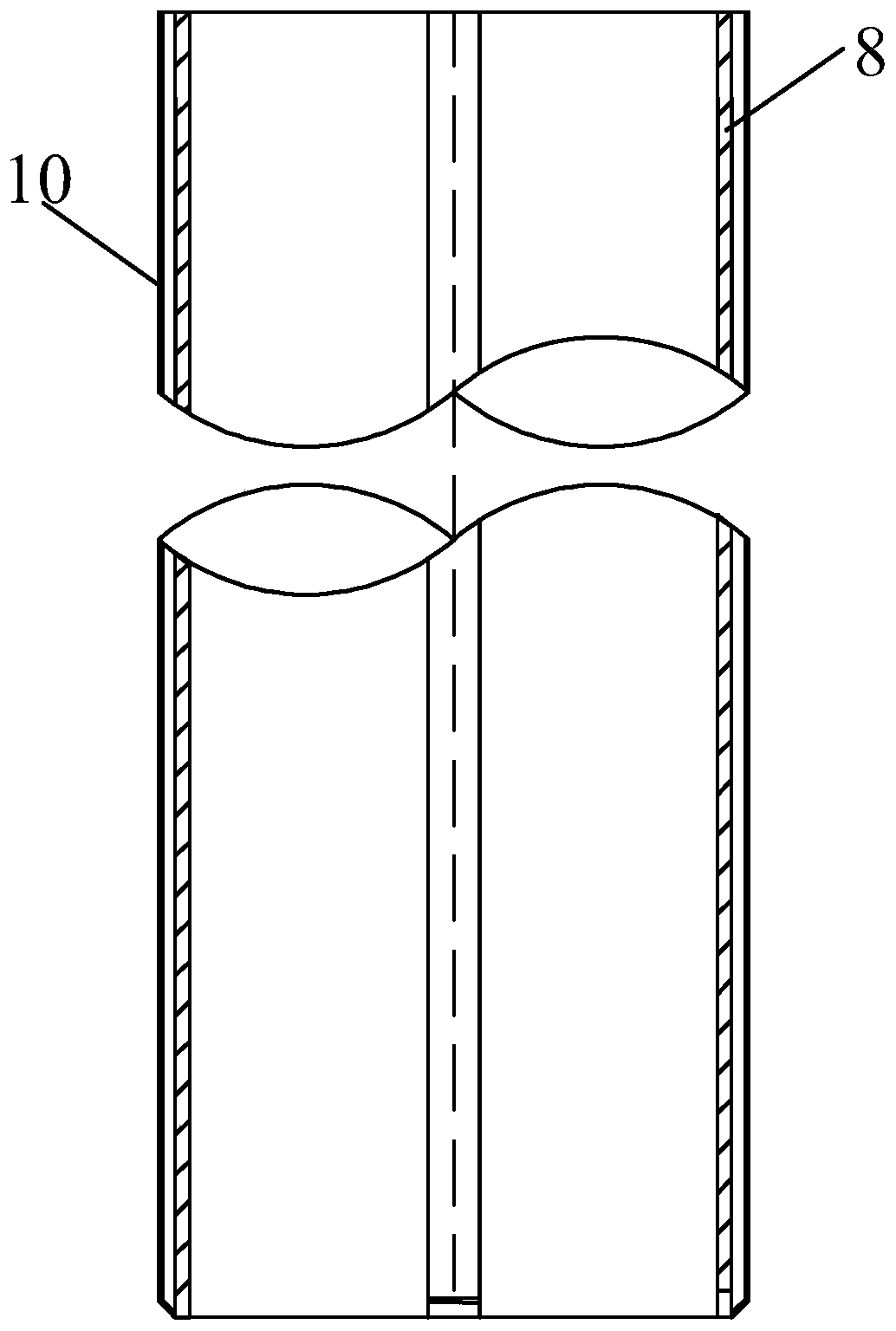

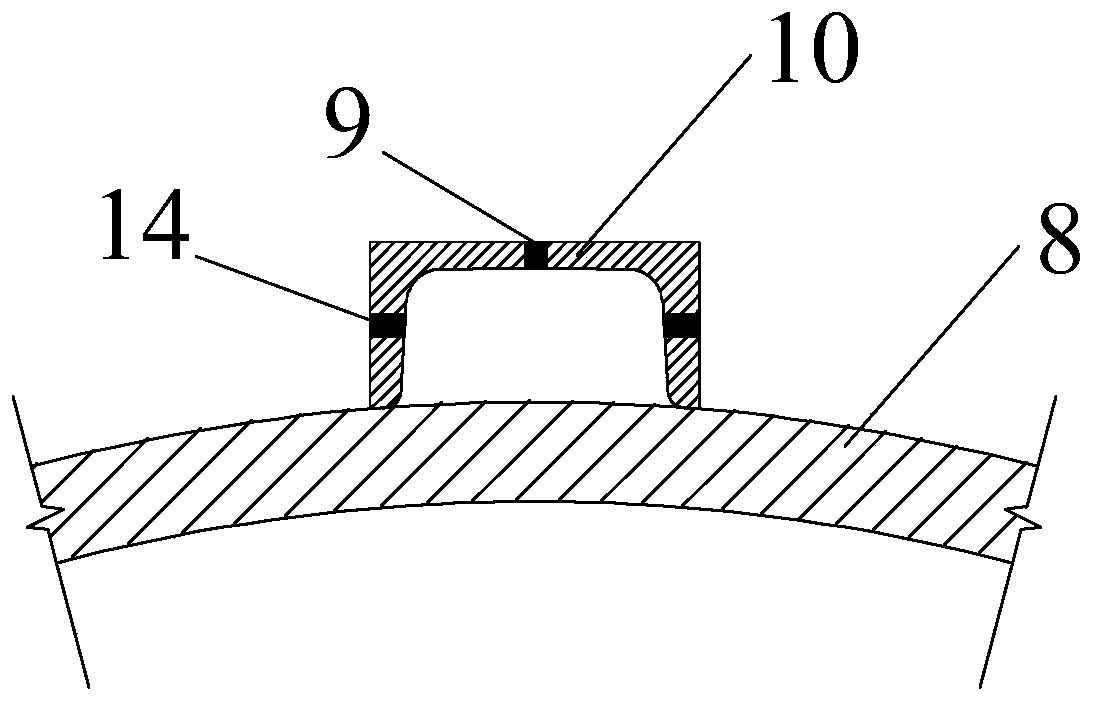

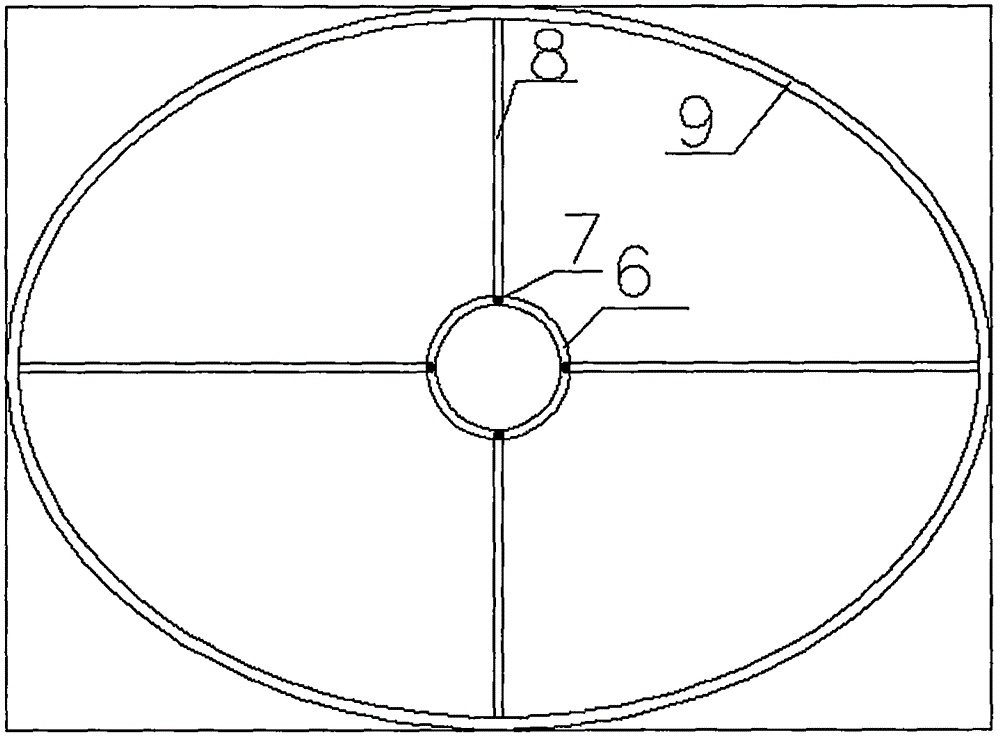

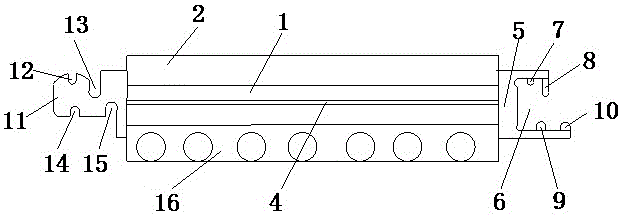

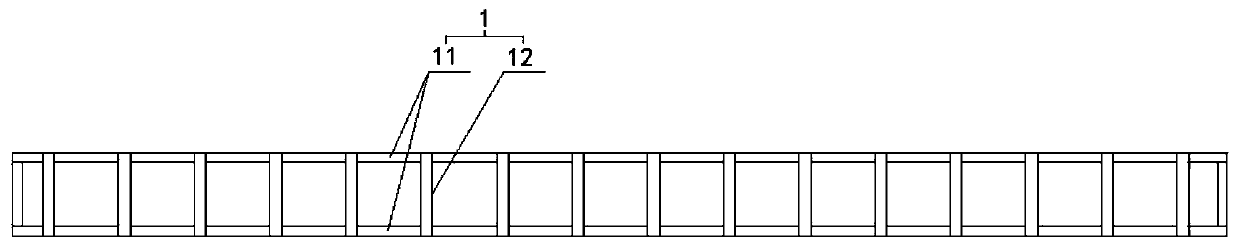

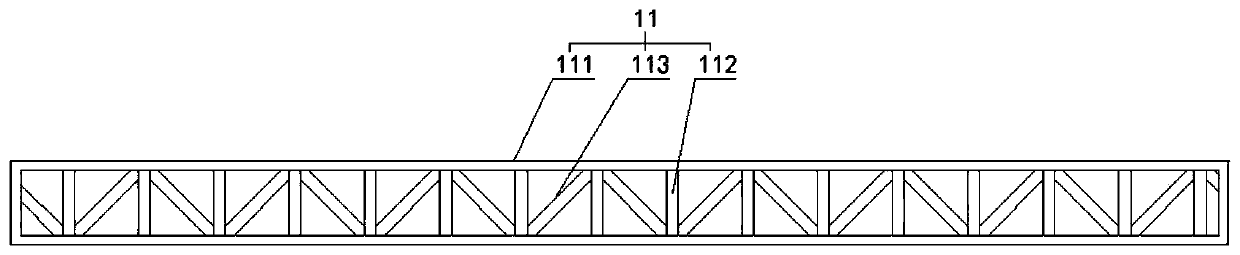

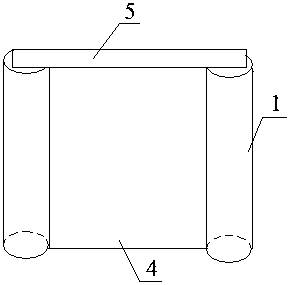

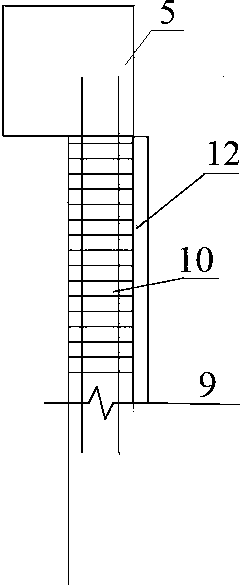

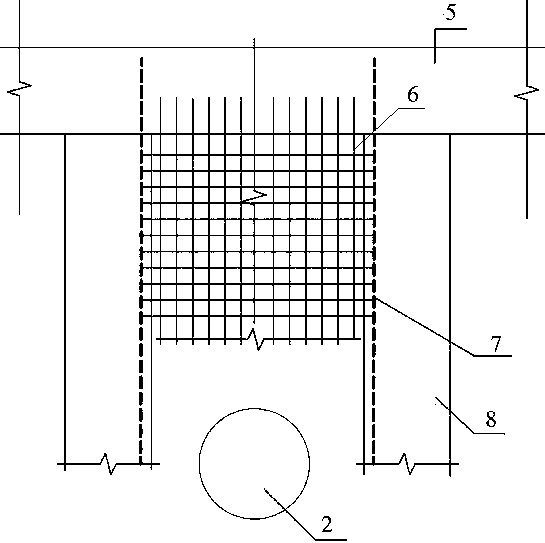

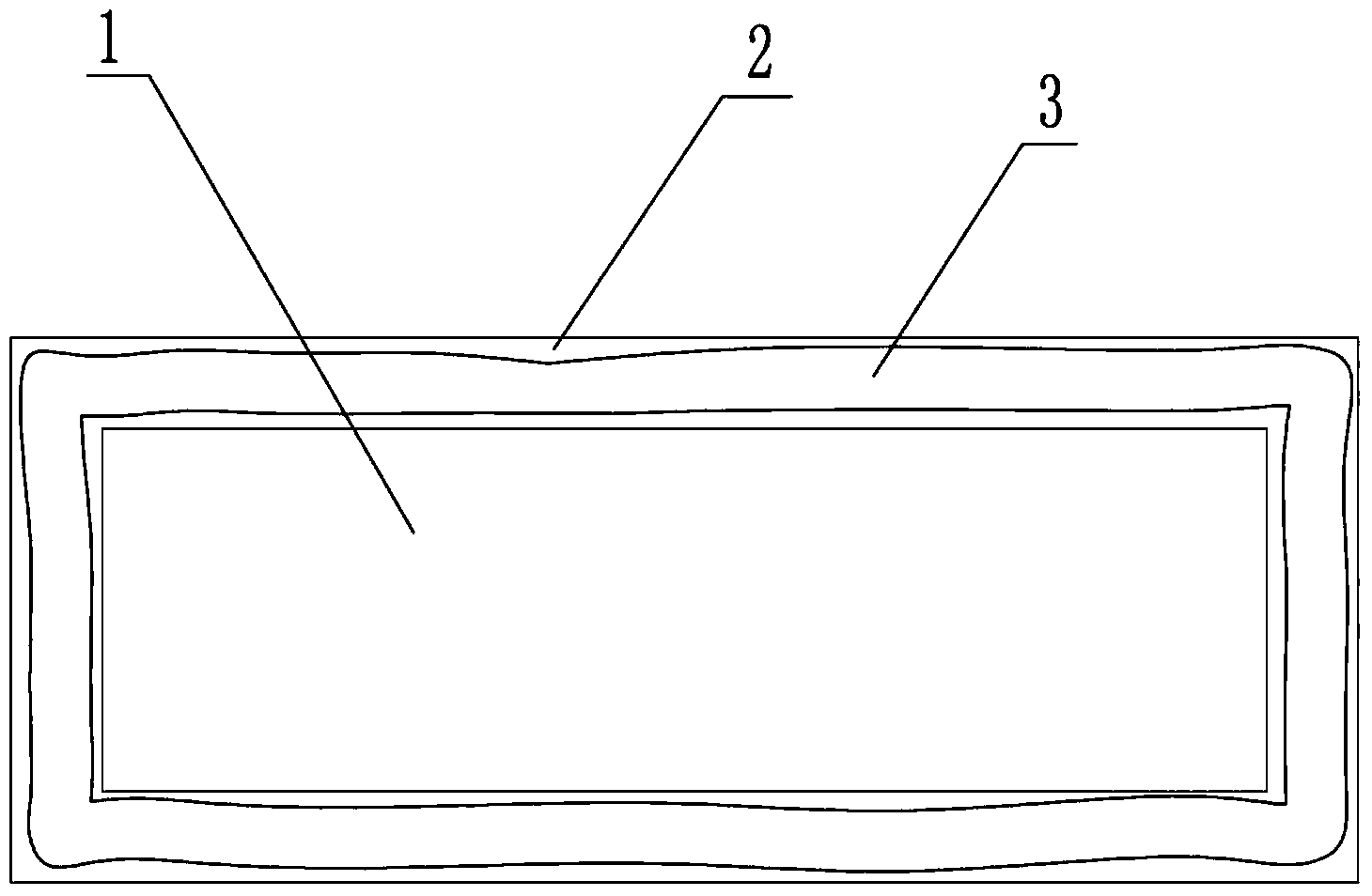

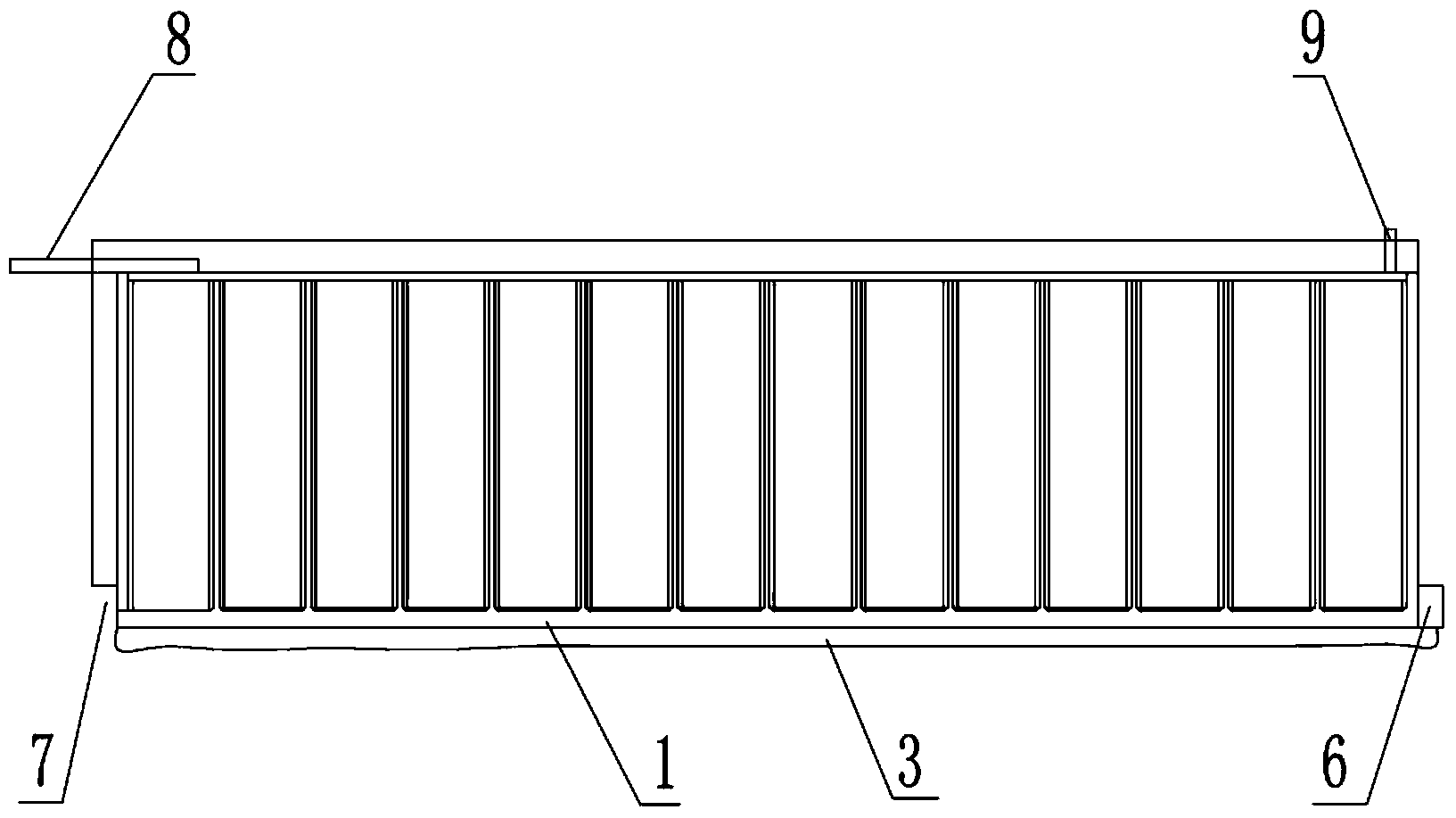

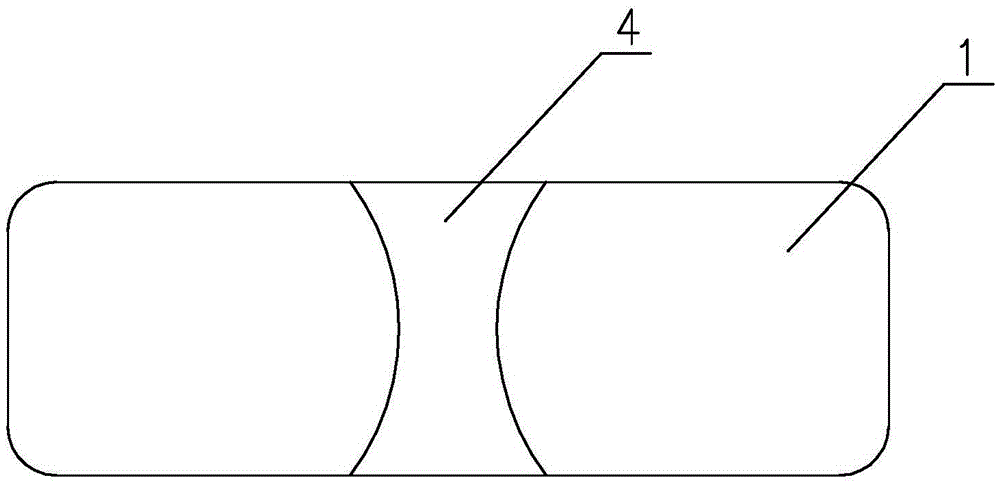

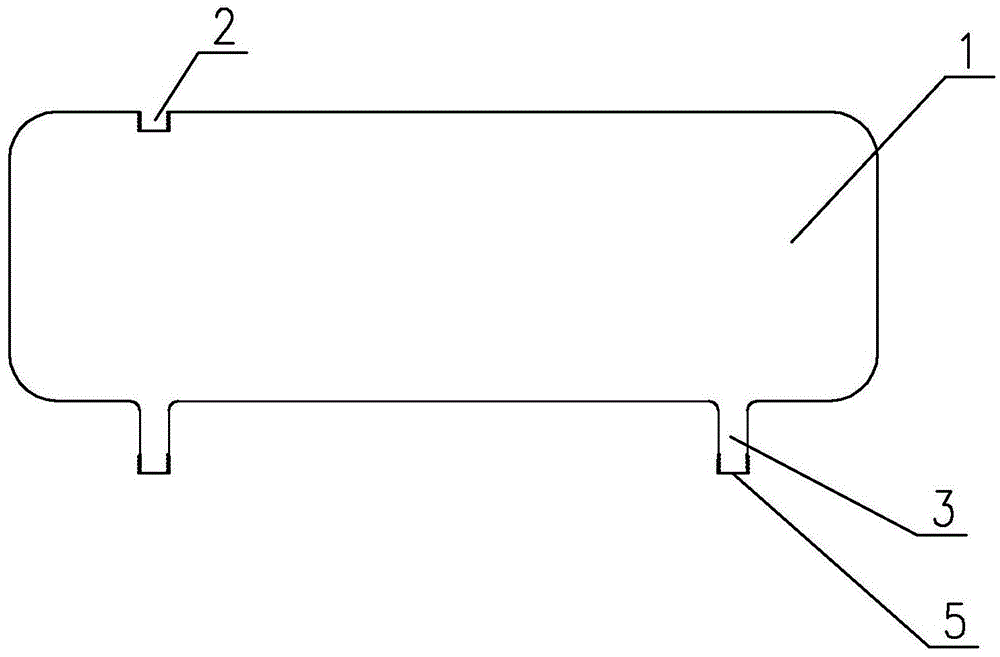

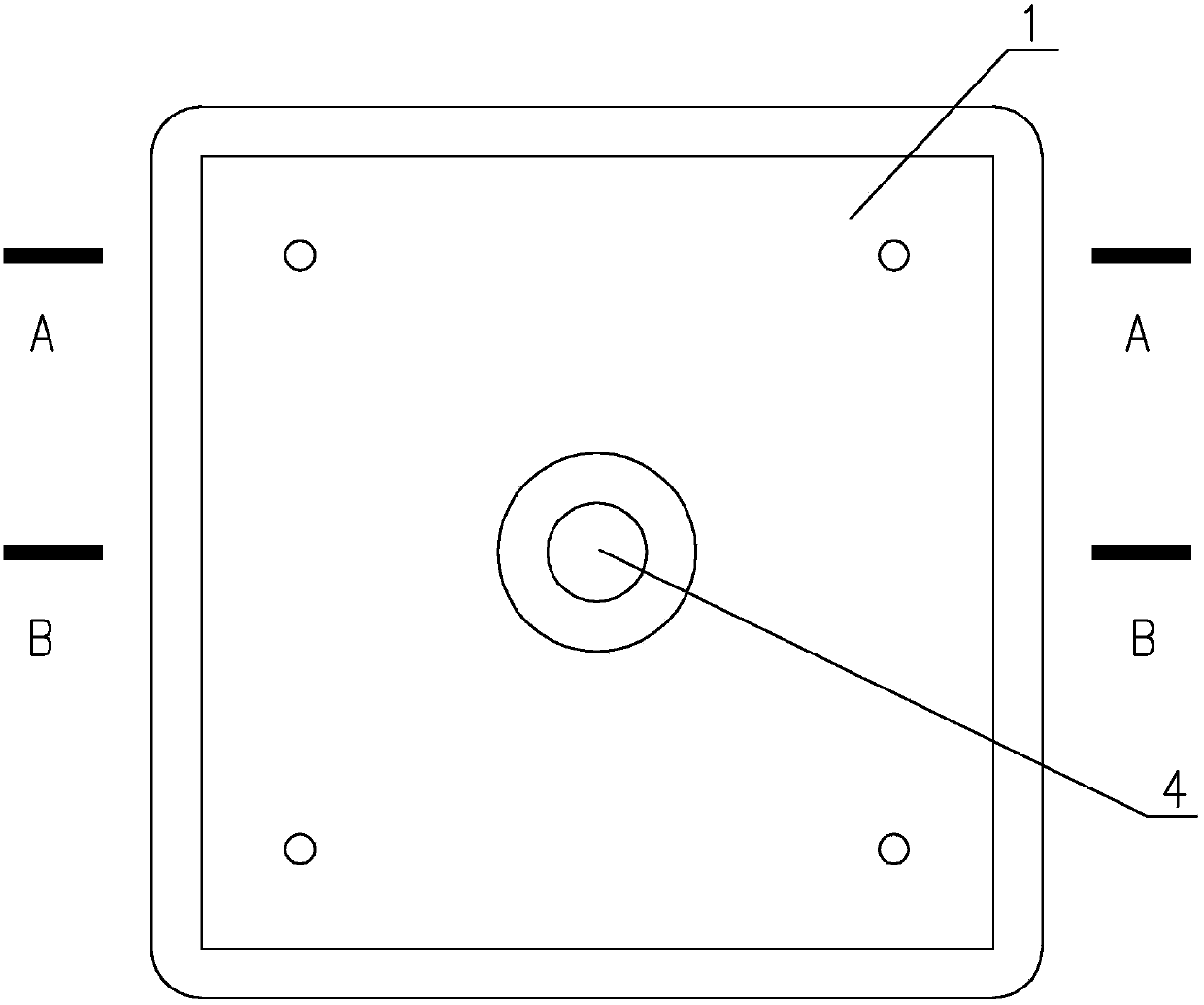

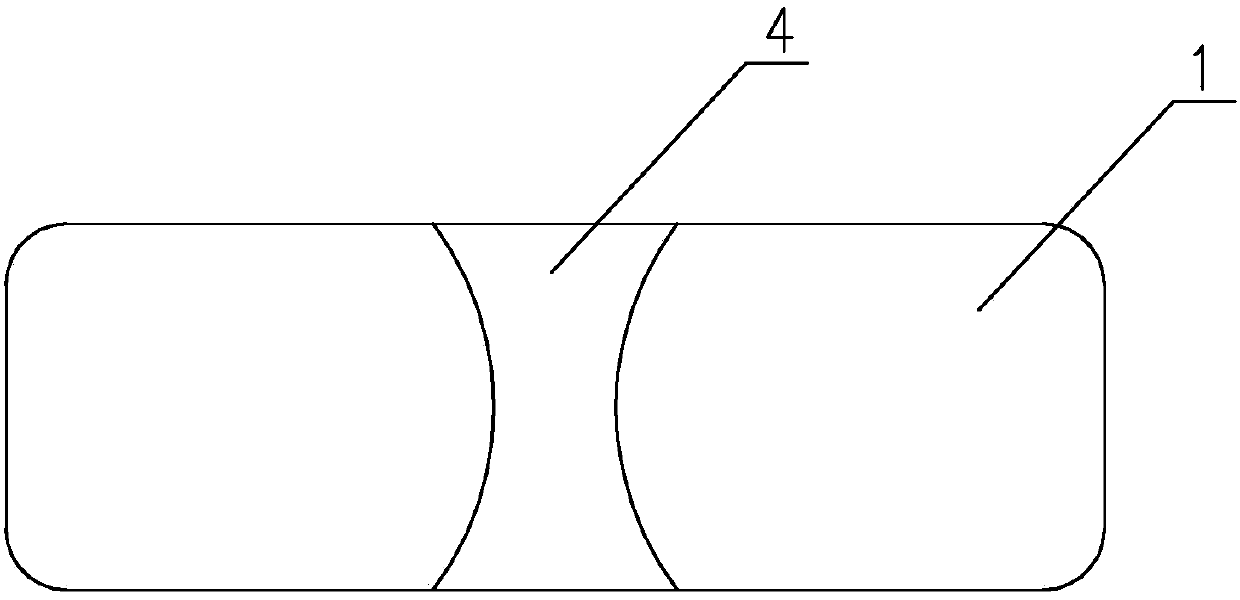

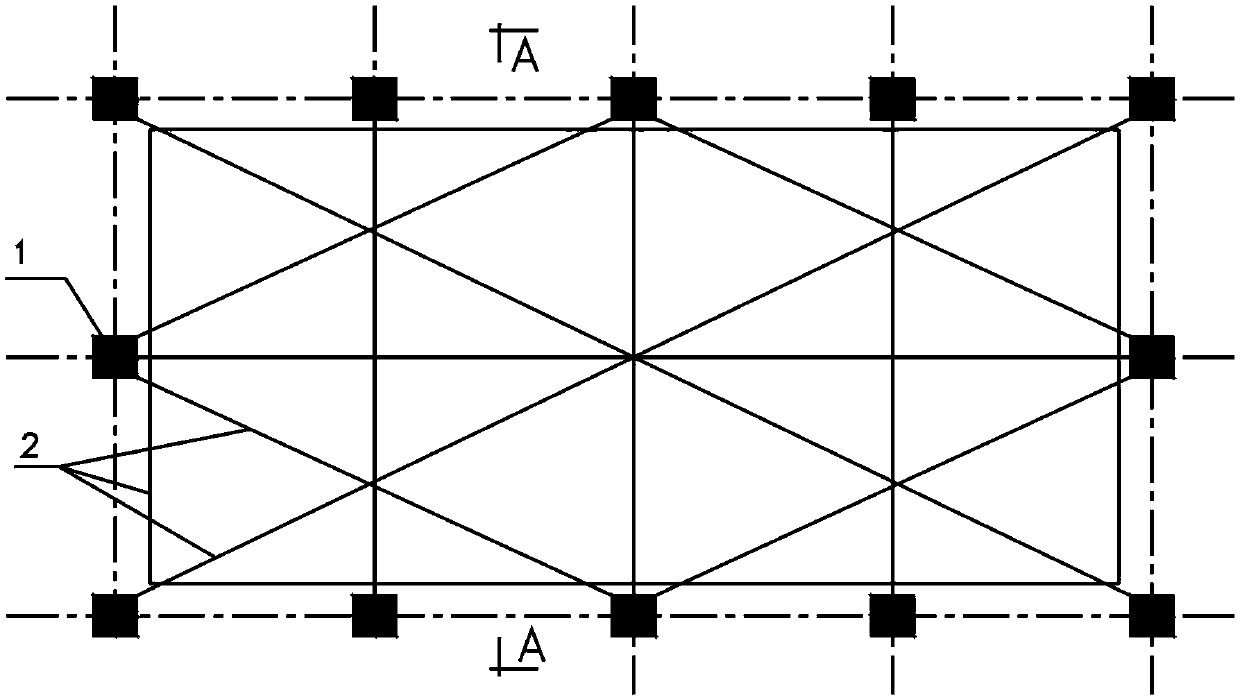

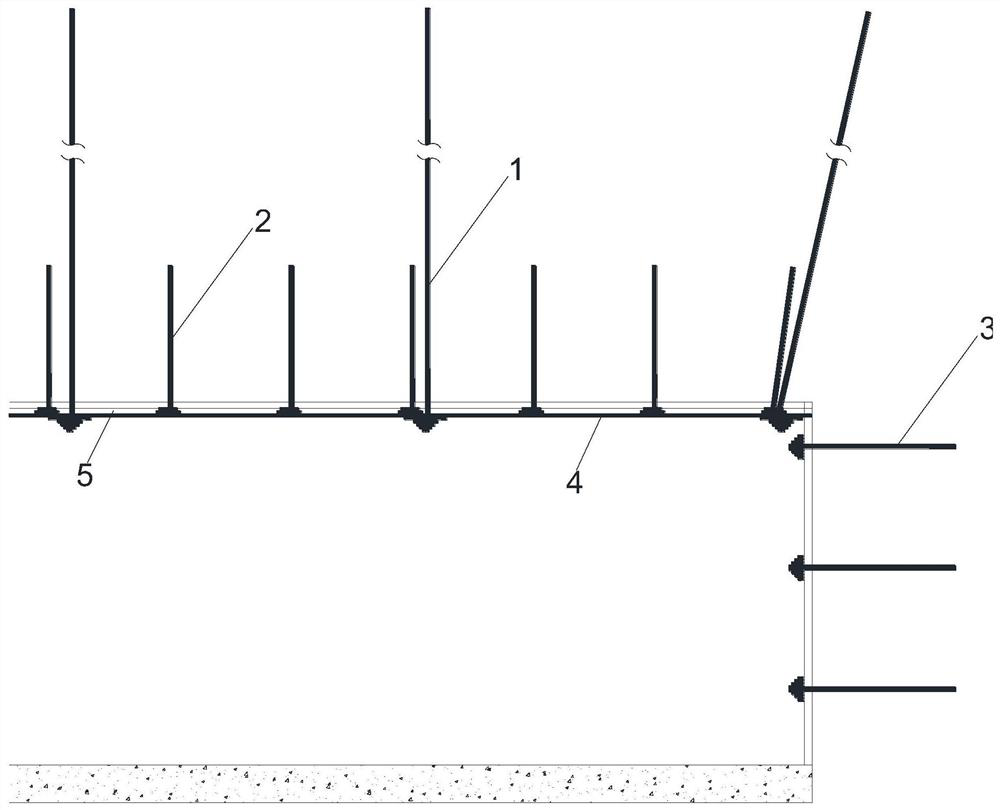

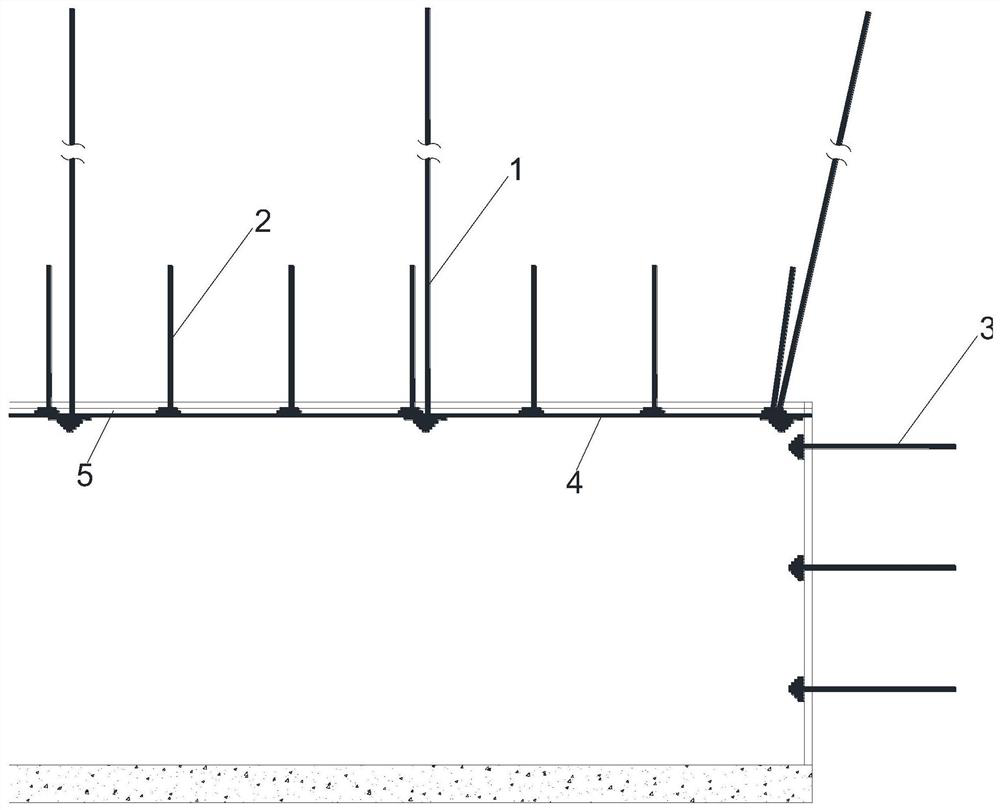

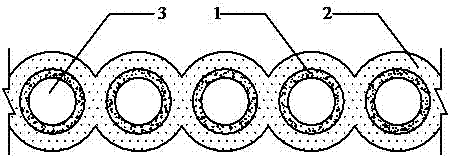

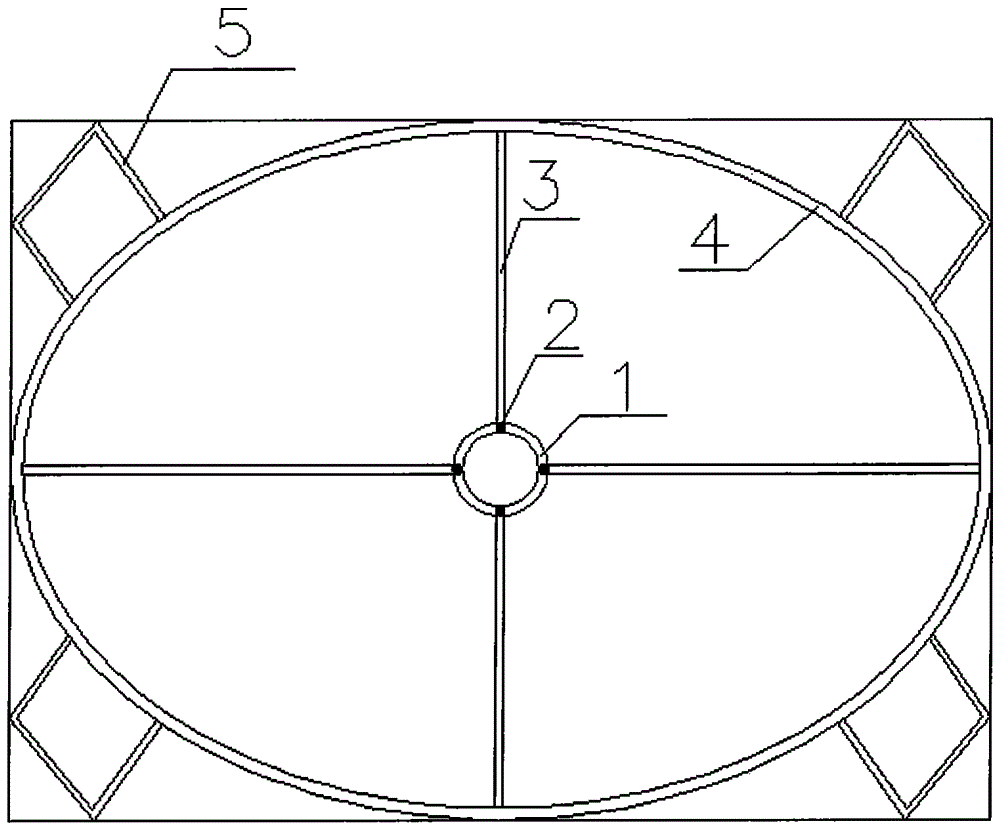

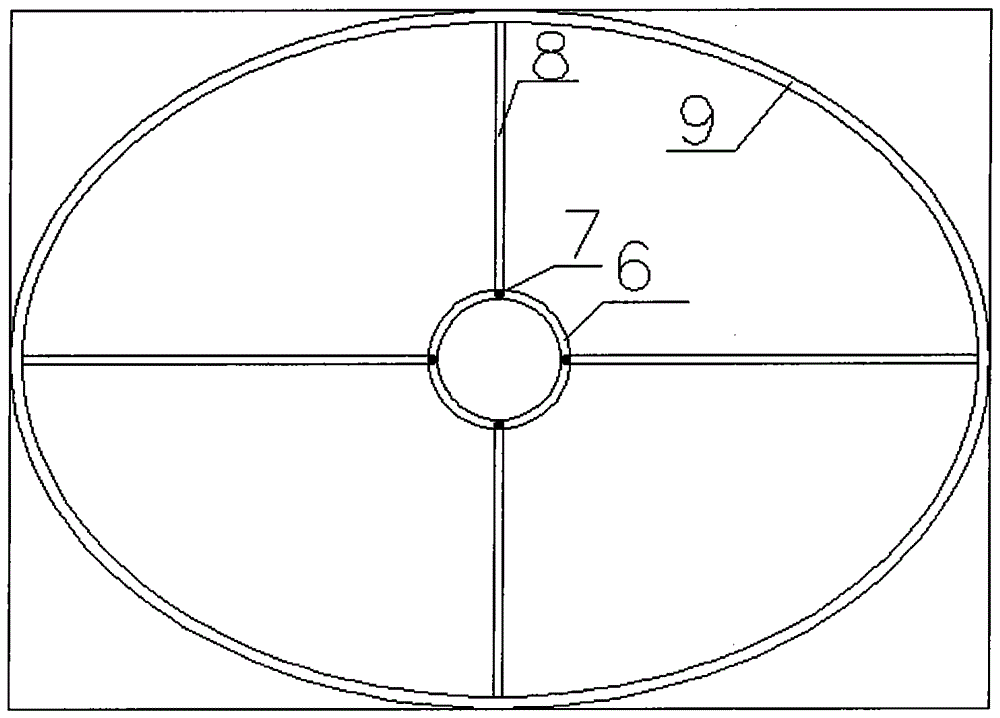

Thin-wall square box hollow floor mandrel and anti-floating method thereof

ActiveCN105604317AControl Horizontal ShiftAnti-floatingFloorsForms/shuttering/falseworksEngineeringUltimate tensile strength

The invention discloses a thin-wall square box hollow floor mandrel and an anti-floating method thereof. The thin-wall square box hollow floor mandrel is a block with a hollow cavity and is provided with an openable liquid injection hole used for injecting liquid into the mandrel, at least three supports used for being supported by a template are evenly distributed on the bottom surface of the mandrel, an openable tubular liquid discharge outlet used for discharging liquid in the mandrel is also formed in the bottom surface of the mandrel, and the liquid discharge outlet extends to the template. By the adoption of the mandrel, construction is easy, the anti-floating effect is good, horizontal movement of the mandrel can be well controlled, and construction quality is improved; the recycle rate of the template is increased, construction cost is reduced, the labor intensity of workers is relieved greatly, and construction efficiency is improved greatly. The mandrel is provided with the supports, and compared with existing mandrels adopting cushion blocks for supporting, the mandrel has the advantage that due to the omission of cushion blocks, extract building materials for floating resistance are not needed; furthermore, liquid used for being injected into the mandrel can be recycled, so that construction cost is further reduced.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

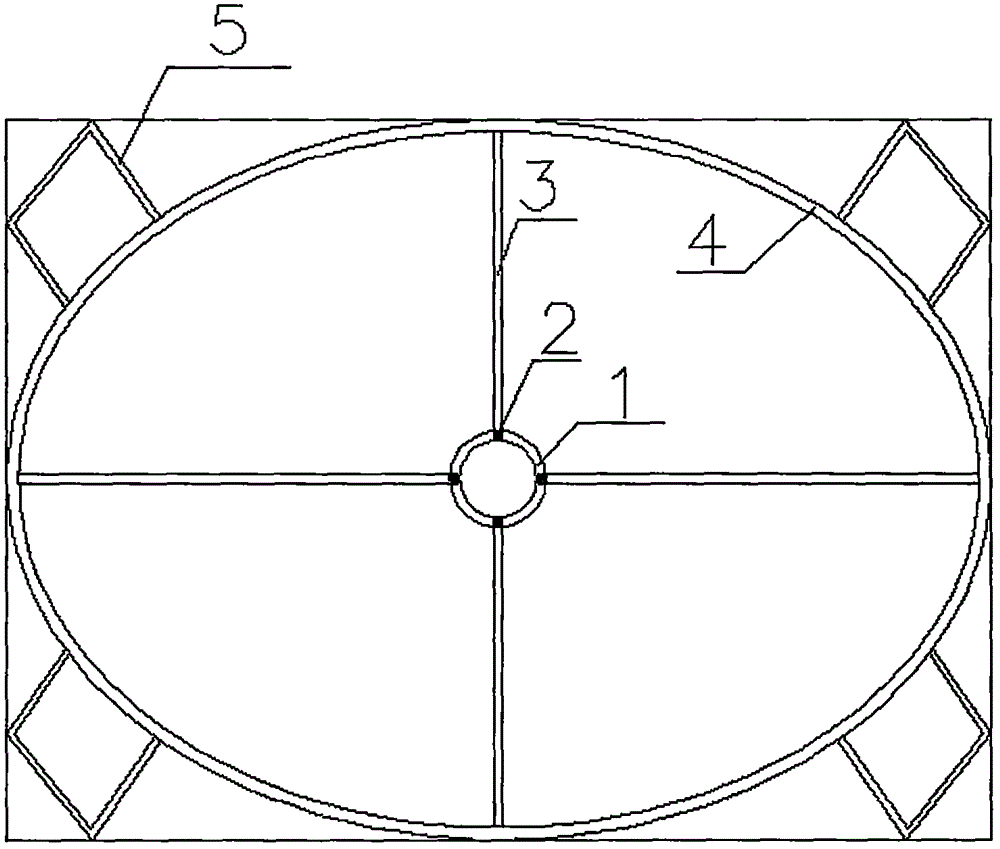

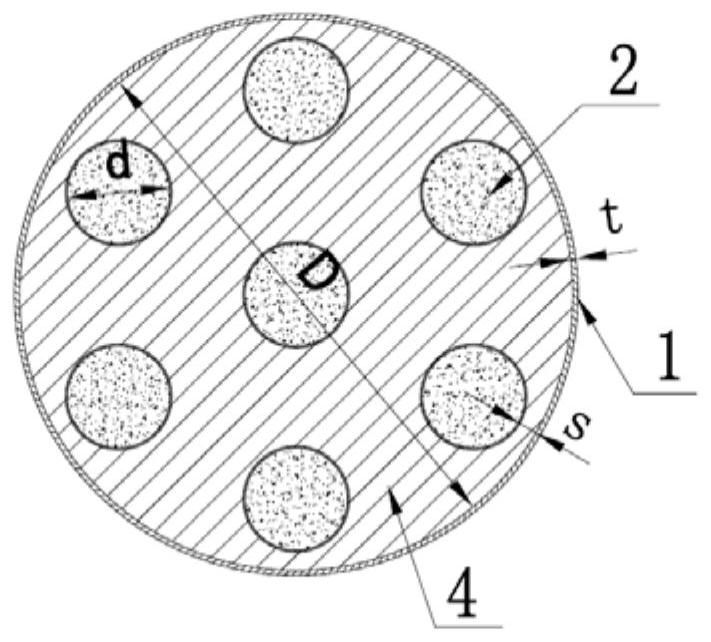

Combined caisson and pile foundation for strengthening foundation and construction method thereof

The invention discloses a caisson and pile combined foundation of consolidated subsoil and a construction method of the caisson and pile combined foundation. The caisson and pile combined foundation of the consolidated subsoil comprises the consolidated subsoil, a sand-gravel cushion, a caisson, bored piles, pile bottom grout, top seal concrete and scour protection. The main construction method comprises the following steps: consolidating the foundation with an underwater compaction sand pile or a deep-layer cement mixing pile; laying the sand-gravel cushion on the consolidated subsoil; sinking the caisson with a skirt, pile sinking guide holes and grouting reserved pipes on the sand-gravel cushion; after the caisson is located, constructing bored piles through the pile sinking guide holes; after construction of the bored piles, casting the top seal concrete at the bottom in the caisson; grouting the bottom of the caisson through the grouting reserved pipes at the bottom of the caisson, carrying out pile bottom grouting through grouting pipes in the pile, and at last casting the top plate of the caisson. In the construction process, the scour protection shall be performed around the caisson according to requirements. The caisson and pile combined foundation of the consolidated subsoil and the construction method of the caisson and pile combined foundation, disclosed by the invention, can effectively improve vertical and horizontal bearing capacity of the caisson, and control sedimentation and horizontal displacement of the caisson.

Owner:CCCC HIGHWAY CONSULTANTS +1

A thin-walled square box hollow floor mandrel and its anti-floating method

ActiveCN105604317BControl Horizontal ShiftAnti-floatingFloorsForms/shuttering/falseworksEngineeringUltimate tensile strength

The invention discloses a thin-wall square box hollow floor mandrel and an anti-floating method thereof. The thin-wall square box hollow floor mandrel is a block with a hollow cavity and is provided with an openable liquid injection hole used for injecting liquid into the mandrel, at least three supports used for being supported by a template are evenly distributed on the bottom surface of the mandrel, an openable tubular liquid discharge outlet used for discharging liquid in the mandrel is also formed in the bottom surface of the mandrel, and the liquid discharge outlet extends to the template. By the adoption of the mandrel, construction is easy, the anti-floating effect is good, horizontal movement of the mandrel can be well controlled, and construction quality is improved; the recycle rate of the template is increased, construction cost is reduced, the labor intensity of workers is relieved greatly, and construction efficiency is improved greatly. The mandrel is provided with the supports, and compared with existing mandrels adopting cushion blocks for supporting, the mandrel has the advantage that due to the omission of cushion blocks, extract building materials for floating resistance are not needed; furthermore, liquid used for being injected into the mandrel can be recycled, so that construction cost is further reduced.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

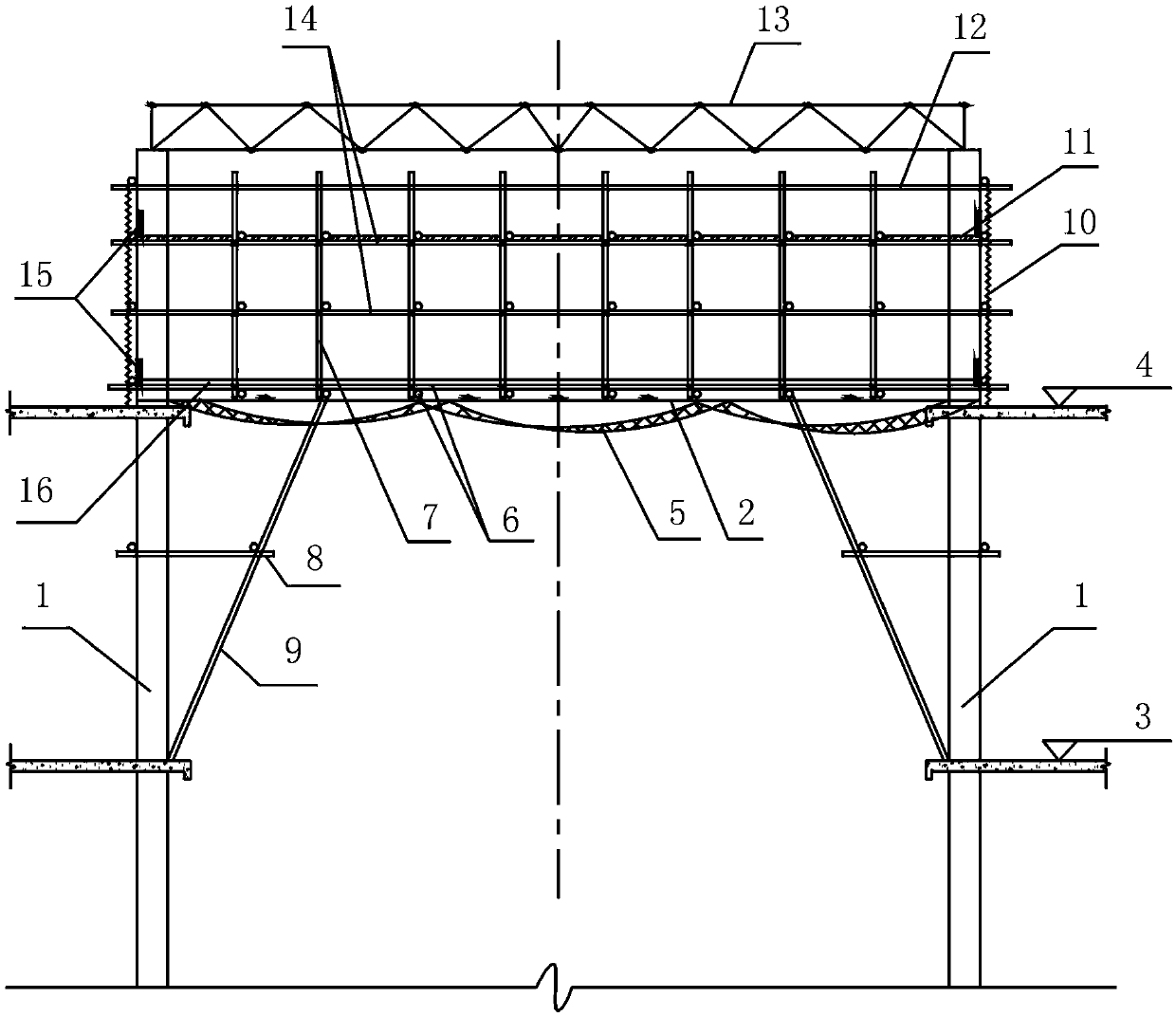

Suspended cable-pipe composite scaffolding construction platform and construction method of protection system

ActiveCN103669815BEliminate the cumbersome process of setting upEnsure safetyBuilding material handlingBuilding scaffoldsFalseworkComposite construction

The invention relates to a method for constructing a hanging rope and pipe combined all-round scaffold construction platform and a protective system. The method is characterized by comprising steps of 1), erecting the hanging rope and pipe combined all-round scaffold construction platform, in other words, (1) arranging steel ropes within a range encircled by structure columns or reinforcement pull rings so as to form a net, (2) laying 'bottom' horizontal tubes on steel rope planes in a longitudinally and transversely staggered manner, (3) arranging diagonal bracings, (4) connecting and erecting upright tubes onto the 'bottom' horizontal tubes by the aid of steel pipe fasteners, (5) erecting horizontal cross rods on the upright tubes according to safety technical specifications for building fastener type steel pipe scaffolds to form an all-round scaffold body, (6) fully laying scaffold floors on the uppermost-layer horizontal cross rods to form an operation platform, and (7) arranging safety protective fences on the upright tubes around the operation platform; 2), constructing the construction all-closed safety protective system. The method has the advantages that the hanging rope and pipe combined all-round scaffold construction platform and the protective system can be safely and quickly constructed by the method, and cross operation or normal use of relevant functional zones below construction regions can be guaranteed.

Owner:CHINA FIRST METALLURGICAL GROUP

A steel column concrete root deep water foundation structure and its construction method

ActiveCN109024578BGive full play to mechanical propertiesReduce dosageBulkheads/pilesSteel columnsSeabed

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Horizontally adjustable stiff support of lattice framed structure

ActiveCN101314963BImprove mechanical performanceControl steel consumptionArched structuresVaulted structuresSlide plateEngineering

The invention discloses a horizontal rigidity adjustable support with a grid structure. The support comprises a support ball joint, grid components, a cross-shaped rib plate, a support base plate, ananchor bolt, a sliding chute, a sliding plate, a support steel tube, a pre-embedded steel plate and a lower structure. A steel plate, the sliding plate and the support base plate are respectively arranged on the pre-embedded steel plate in sequence; the cross-shaped lib plate is arranged on the support base plate; the support ball joint is arranged on the cross-shaped lib plate; the plurality of grid components are arranged on the support ball joint; the support steel tube is arranged in the horizontal direction of the circle center passing through the support ball joint; the other end of thesupport steel tube is connected with a rigidity adjusting device; the sliding chute is arranged on the support base plate; the anchor bolt matched with the sliding chute is arranged on the pre-embedded steel plate; and the anchor bolt respectively penetrates through the steel plate, the sliding plate and the support base plate. The support has the advantages that the adjustment and the optimization of the horizontal rigidity of the support can be realized; the reaction force and the horizontal displacement of the horizontal rigidity adjustable support with the structure can be effectively controlled; and the mechanical performance of the structure under the actions of temperature, earthquake and dynamic loading can be improved to a certain extent.

Owner:GUANGSHA CONSTR GROUP +1

A Determination Method for Bolt and Cable Support of Retraction Passage in Fully Mechanized Mining Face

ActiveCN110821535BNo need for secondary reinforcement support designReduce vertical deformationData processing applicationsMining devicesPre stressArchitectural engineering

The invention discloses a method for determining the anchor bolt and cable support of a retraction channel of a fully mechanized mining face, comprising the following steps: step 1, calculating the radius of the roof rupture zone and the radius of the plastic zone; step 2, calculating the parameters of the roof bolt, The parameters of the roof anchor rod include the length of the roof anchor rod, the row spacing between the roof anchor rods and the prestress of the roof anchor rod; step 3, calculate the parameters of the roof anchor cable, and the parameters of the roof anchor cable include the length of the roof anchor cable, the roof anchor rod and the roof anchor rod. The row spacing between the anchor cables and the prestressing of the roof anchor cables; step 4, calculating the parameters of the anchor bolts, the parameters of the anchor bolts include the length of the anchor bolts, the row spacing between the anchor bolts and the anchor bolts prestressed. The determination method of the invention can not only ensure that the working face support is withdrawn in a safe state during the production of the coal mine, but also can reduce the production cost of the coal mine, improve the production efficiency, and provide a theoretical reference for the support design and support research of the coal mine retraction roadway in the future. .

Owner:XIAN UNIV OF SCI & TECH

A destructive test method for a hollow floor gypsum filling box

ActiveCN111044715BControl Horizontal ShiftControl densityMaterial testing goodsClassical mechanicsTest analysis

The invention discloses a destructive test method for a gypsum filling box of a hollow floor, which comprises the following steps: Step 1, test preparation; Step 2, preparation of the gypsum filling box; Step 3, damage detection, and the concrete layer whose strength reaches more than 50% Cut the formed hollow floor, cut out two gypsum mold boxes as test objects, observe the cut surface and weigh the weight of the gypsum mold boxes; step 4, compare and observe the test phenomena and record; step 5, test analysis; step 6 , to draw the experimental conclusion. This method can well control the horizontal displacement and floating phenomenon of the gypsum filling box when pouring concrete, and ensure that the cross-sectional size of each component and the thickness of the steel protection layer of the upper and lower plates meet the specifications, design requirements and the compactness of the concrete under the gypsum filling box. It is convenient to control the damage of the gypsum filling box during the vibrating process of concrete pouring, resulting in the increase of concrete volume, and has the advantage of simple and fast construction technology.

Owner:重庆河邦建材有限公司

Intelligent electromagnetic control vibration isolation support

ActiveCN105113654BControl Horizontal ShiftSmall electromotive forceShock proofingMechanical energyEngineering

Owner:TONGJI UNIV

Destructive test method for hollow floor gypsum filling box

ActiveCN111044715AControl Horizontal ShiftControl floating phenomenonMaterial testing goodsArchitectural engineeringTest analysis

The invention discloses a destructive test method for a gypsum filling box of a hollow floor. The method comprises the steps: step 1, making test preparation; step 2, preparing a gypsum filling box; step 3, carrying out damage detection; to be specific, cutting the hollow floor formed by the concrete layer with the strength reaching over 50% to obtain two gypsum mold boxes serving as test objects,observing the tangent planes, and weighing the weights of the gypsum mold boxes; step 4, comparing, observing and recording a test phenomenon; step 5, carrying out test analysis; and step 6, obtaining a test conclusion. With the method, the phenomena of horizontal displacement and upward floating of the gypsum filling box during concrete pouring can be well controlled; the sectional dimension ofeach component and the thickness of the reinforcing steel bar protective layers of the upper and lower plates are ensured to meet the specification and design requirements and the compactness of concrete at the lower part of the gypsum filling box is ensured; the problem of concrete quantity increase caused by damage of the gypsum filling box in the concrete pouring and vibrating process is conveniently solved. The construction process is simple and quick.

Owner:重庆河邦建材有限公司

A double-row pile supporting structure capable of making full use of basement space and its construction method

The invention relates to a double-row pile support structure capable of making full use of basement space and a construction method thereof, belonging to the fields of building construction and house construction. In the present invention, the top of the front row of piles is provided with a crown beam I, and the pile top of the rear row of piles is provided with a crown beam II. For water-stop curtain piles, after the site is leveled, all engineering piles shall be constructed according to the design, and a connecting beam II shall be poured on the top of the piles in the front row after removal, and the connecting beam II and the basement floor of the negative first floor shall be integrally poured. Fill the layered rammed soil between the outer walls of the basement, and fill plain concrete between the front row of piles and the basement floor of the negative second floor. The present invention replaces double-row piles and single-row piles with equal stiffness by replacing the double-row piles with single-row piles, which can not only control the horizontal displacement of the supporting structure system, but also greatly reduce the Pit support costs; it is more economical in foundation pit projects with multi-storey basements.

Owner:KUNMING UNIV OF SCI & TECH

Fully mechanized coal mining face retracement end mining method

The invention discloses a fully mechanized coal mining face retracement end mining method. The method comprises the following steps that a support is installed in a retracement channel; the working face bottom plate is adjusted to be 180 mm-220 mm higher than the retracement channel bottom plate; the support of anchor rods and anchor cables of the retracement channel is determined and then the retracement channel is supported by using the anchor rods and the anchor cables; and end-mining net-hanging coal mining is performed; and mining is stopped and the fully mechanized mining equipment is retraced. According to the method, end mining is conducted based on the supporting determination method of the top plate anchor rods, the top plate anchor cables and the side anchor rods, supporting reworking can be avoided on the basis that supporting design is completed in one step and end mining is ensured to be conducted smoothly.

Owner:XIAN UNIV OF SCI & TECH

A method of withdrawal and final mining in fully mechanized mining face

ActiveCN111022048BAvoid reworkGood luckUnderground miningSurface miningRock boltMechanical engineering

Owner:XIAN UNIV OF SCI & TECH

Large-diameter conjoined CS pipe pile foundation pit support structure and construction method thereof

InactiveCN106894425AControl Horizontal ShiftNo pollutionExcavationsBulkheads/pilesReinforced concreteStructure of the Earth

The invention discloses a large-diameter conjoined CS pipe pile foundation pit support structure. The structure comprises a conjoined CS pipe pile; and a reinforced integral reinforced concrete crown beam is arranged at the top of the conjoined CS pipe pile. The structure is characterized in that the CS pipe pile consists of rotary jetting cement soil pipe piles and drilled cast-in-place thin-wall reinforced concrete pipe piles coaxially arranged; and the CS pipe piles are arranged side by side, and are engaged and joined at the rotary jetting cement soil pipe piles. The invention further discloses a construction method of the large-diameter conjoined CS pipe pile foundation pit support structure; and the construction method mainly comprises three steps. The large-diameter conjoined CS pipe pile technology realizes an integral support target of soil retaining and water stop, is high in foundation pit horizontal displacement control capacity, is stable and reliable in construction quality, cannot generate such environmental pollution problems as mud generation, and effectively reduces the construction cost while shortening the construction period.

Owner:窦春晓

deep basement support

ActiveCN104695447BMeet the requirements of construction safety and stabilityControl Horizontal ShiftArtificial islandsExcavationsBasementConcrete beams

Owner:海南万泰建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com