Earthquake isolation and reduction structure and earthquake reduction method thereof

A technology of shock isolation and rubber bearing, applied in bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of unsatisfactory shock absorption effect and high construction cost, and achieve the improvement of the level of building industrialization, the force is clear, and the production is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

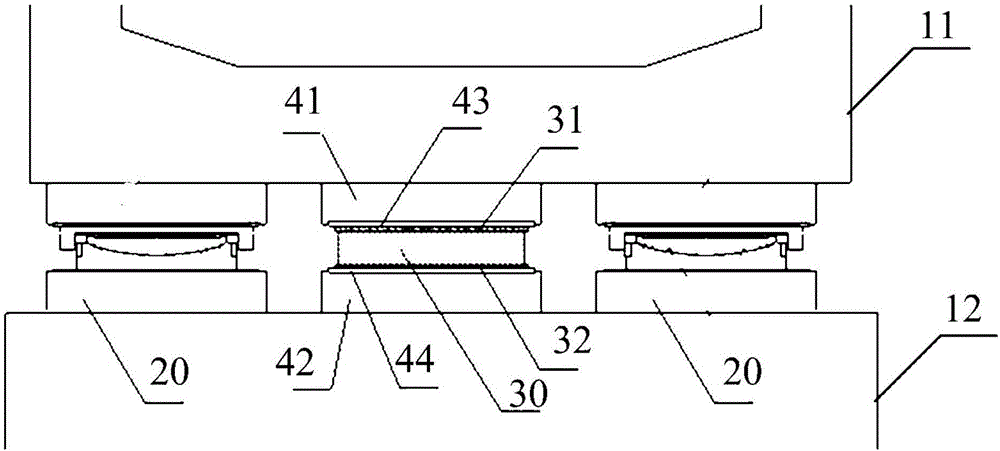

[0024] see figure 1 , a shock-absorbing and isolating structure, including several spherical bearings 20 arranged at intervals between the upper and lower structures (11, 12) of the bridge, at least one rubber bearing (not shown) arranged side by side at adjacent intervals Between the spherical bearings 20, the rubber bearings from top to bottom are an upper cushion block 41, a rubber bearing body 30 and a lower cushion block 42, and the top and bottom ends of the rubber bearing body 30 are respectively provided with upper and lower supports. Seat steel plate (31,32), upper and lower support steel plate (31,32) and corresponding upper and lower spacer (41,42) are respectively provided with upper and lower spacer steel plate (43,44), upper , Lower pad steel plates (43,44) are embedded in the upper and lower pads (41,42). Specifically, by arranging a plurality of spherical bearings 20 between the upper and lower structures (11, 12) of the long-span low-pier continuous girder br...

Embodiment 2

[0030] read on figure 1 , the present embodiment discloses a shock absorbing method utilizing the shock absorbing and isolating structure of the present invention, comprising the following steps:

[0031] Step 1: fixedly connect the spherical bearing 20 and the rubber bearing between the upper and lower structures (11, 12) of the bridge, and make the spherical bearing 20 and the rubber bearing arranged side by side at intervals;

[0032] Step 2: When an earthquake occurs and the lateral force exceeds the horizontal seismic force threshold, the spherical bearing 20 is sheared, and the rubber bearing and the upper and lower bearing steel plates (31, 32) at the upper and lower ends of the rubber bearing do not slide relative to each other. Therefore, the rubber bearing and the spherical bearing 20 jointly bear the horizontal force, reduce the seismic force, realize the control of the horizontal displacement of the girder bridge body, and prevent the damage of the long-span low-pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com