Construction method for super large pile distance deep foundation pit supporting system

A technology of deep foundation pit support and construction method is applied in the construction field of deep foundation pit support system with super large pile spacing, which can solve the problems of large environmental risk of foundation pit support, high cost of pile support system, disturbance of base soil, etc. Achieve good social and economic benefits, convenient construction, and increase the effect of horizontal stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

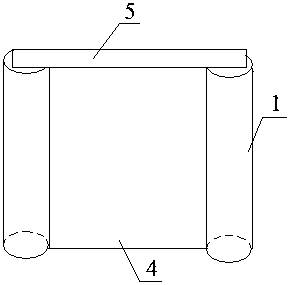

[0040] In order to realize pile row support with large pile spacing under unfavorable engineering geological conditions such as the presence of sand layers, this embodiment provides a construction method for a deep foundation pit support system with super large pile spacing, and the construction is carried out at equal intervals along the length direction of the foundation pit. Two rows of support piles 1, when there is an existing structure 2 at the construction site of the support pile 1, construct the support pile 1 after crossing the existing structure 2, and construct the crown on the top of the support pile 1 after the construction of the support pile 1 Beam 5, and then construct slab wall 4 between the support piles 1 on both sides of the existing structure 2, wherein the slab wall 4 is constructed by the reverse method, and the support system is constructed after the slab wall 4 is completed.

[0041] The present invention is applicable to the foundation pit engineering...

Embodiment 2

[0043] This embodiment provides a construction method for a deep foundation pit support system with super large pile spacing. Two rows of support piles 1 are constructed at equal intervals along the length direction of the foundation pit. When there are existing structures 2 at the construction site of the support piles 1 After crossing the existing structure 2, the support pile 1 is constructed. After the construction of the support pile 1, the crown beam 5 is constructed on the top of the support pile 1, and then the slab wall is constructed between the support pile 1 on both sides of the existing structure 2. 4. Among them, the board wall 4 is constructed by the reverse method, and the support system is constructed after the board wall 4 is completed.

[0044] The distance between the support piles 1 and the construction of equal intervals is not greater than twice the diameter of the support piles 1, and the distance between the support piles 1 on both sides of the existing...

Embodiment 3

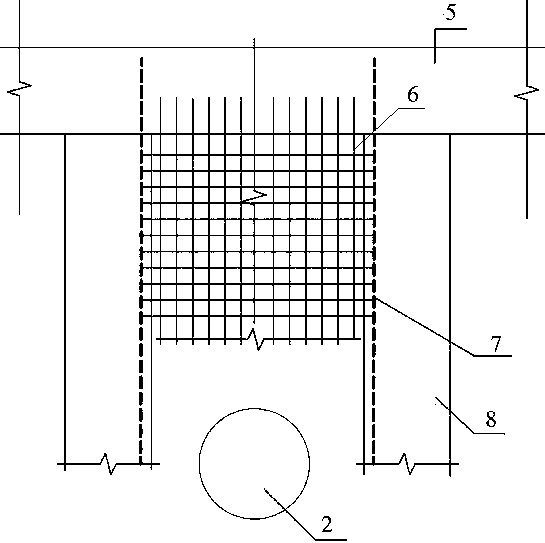

[0047] On the basis of Embodiment 1, this embodiment provides a construction method for a deep foundation pit support system with super large pile spacing, which specifically includes the following steps:

[0048] Step 1) construction of the support pile 1, when encountering the existing structure 2, the construction of the support pile 1 is carried out across the existing structure 2;

[0049] Step 2) After the construction of the support pile 1 is completed, the crown beam 5 is constructed;

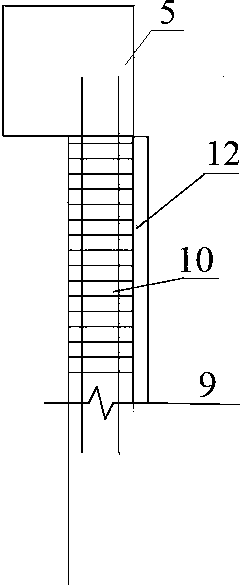

[0050] Step 3) Carry out earthwork excavation layer by layer at the setting position of the slab wall 4, expose the support pile 1, lower the reinforcement model of the slab wall 10 on the first layer, and connect the support pile 1 and the crown beam 5 to the first layer slab respectively Wall 10 reinforcement connection; such as figure 1 shown;

[0051] Step 4) Casting the first layer of slab wall 10 from top to bottom between the two retaining piles 1, using wooden formwork 12 as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com