Double-row pile support structure capable of fully utilizing basement space and construction method of double-row pile support structure

A technology of supporting structure and construction method, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of high rigidity of cantilevered double-row pile supporting structure, insufficient utilization of basement space, and inability to meet the deformation of foundation pit, etc. Achieve the effect of increasing the available space, increasing the use, and controlling the displacement of the pile body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

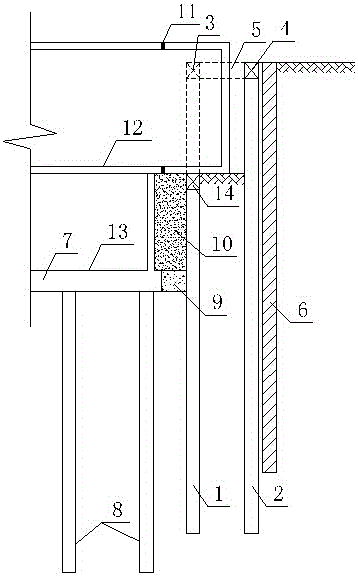

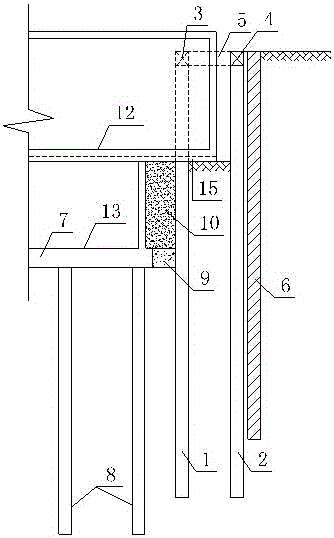

[0027] Embodiment 1: as figure 1 As shown, a double-row pile support structure that can make full use of the basement space consists of a front row of piles 1, a rear row of piles 2, crown beams I3, crown beams II4, connecting beams I5, water-stop curtain piles 6, basement 7, Engineering pile 8, plain concrete 9, layered tamped filling 10, basement floor 12, basement floor 13, connecting beam Ⅱ 14; among them, the top of pile 1 in the front row is equipped with crown beam Ⅰ 3, and the pile in the back row The top of pile 2 is provided with crown beam II4, the pile tops of front row pile 1 and rear row pile 2 are connected by coupling beam I5, and water-stop curtain pile 6 is installed in the soil behind the back row pile 2 piles. Construct all engineering piles 8, and pour a connecting beam II14 on top of pile 1 in the front row after removal. Layer tamped fill soil 10, fill plain concrete 9 between the front row of piles 1 and the basement floor 13 of the negative second flo...

Embodiment 2

[0042] Embodiment 2: as figure 1 Shown, basically the same as embodiment 1, its difference:

[0043] A construction method for a double-row pile support structure capable of making full use of basement space, wherein the length of the front row of piles 1 can be designed to be greater than the length of the rear row of piles 2 .

Embodiment 3

[0044] Embodiment 3: as figure 1 Shown, basically the same as embodiment 1, its difference:

[0045] A double-row pile support structure that can make full use of the basement space, the pile bodies of the front row of piles 1 and the rear row of piles 2 are arranged in a "T"-shaped array and arranged at intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com