Low pile gravity type wharf suitable for soft soil foundation and construction method of low pile gravity type wharf

A technology of gravity wharf and soft soil foundation, applied in wharf field, can solve the problems of gravity wharf impact, long construction period, settlement after major construction, etc., and achieve the effects of controlling settlement and horizontal displacement, convenient construction and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

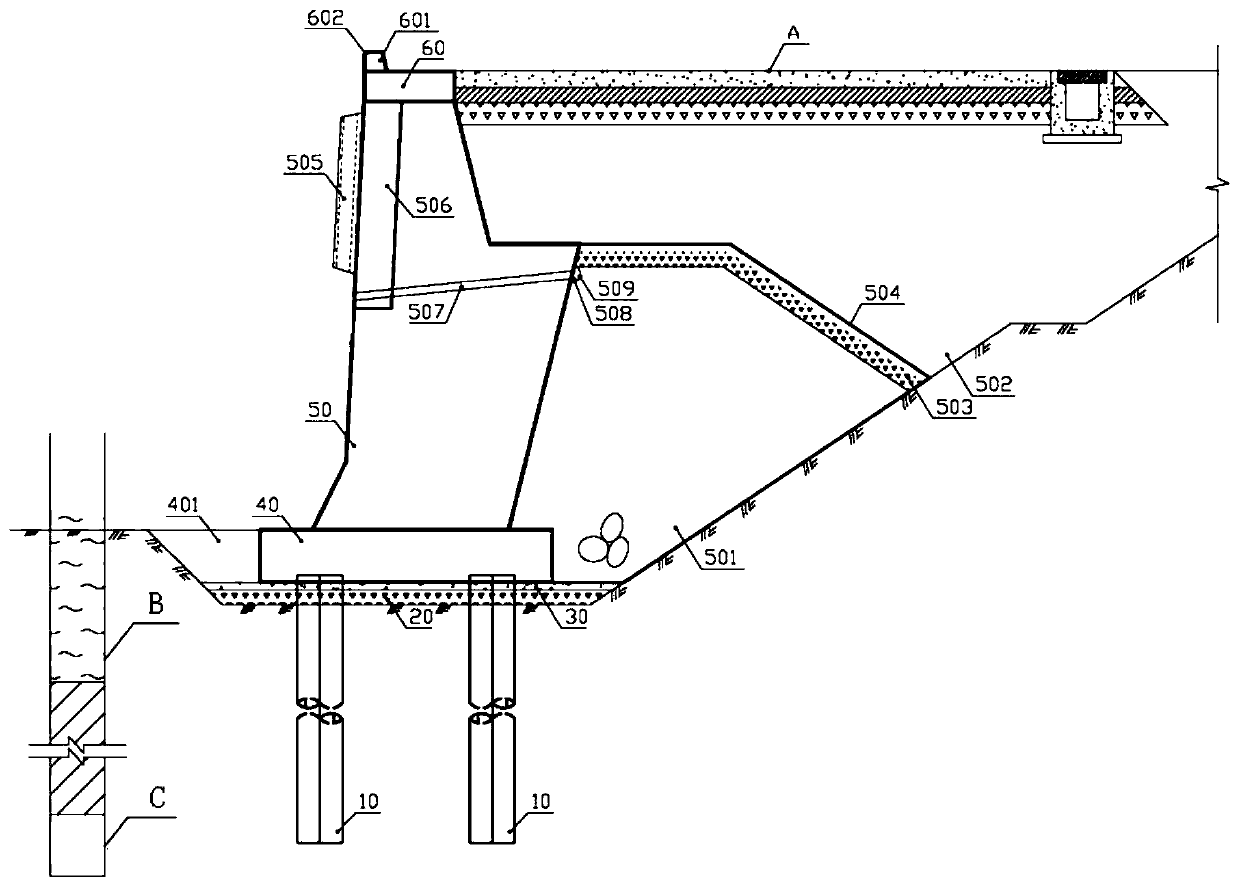

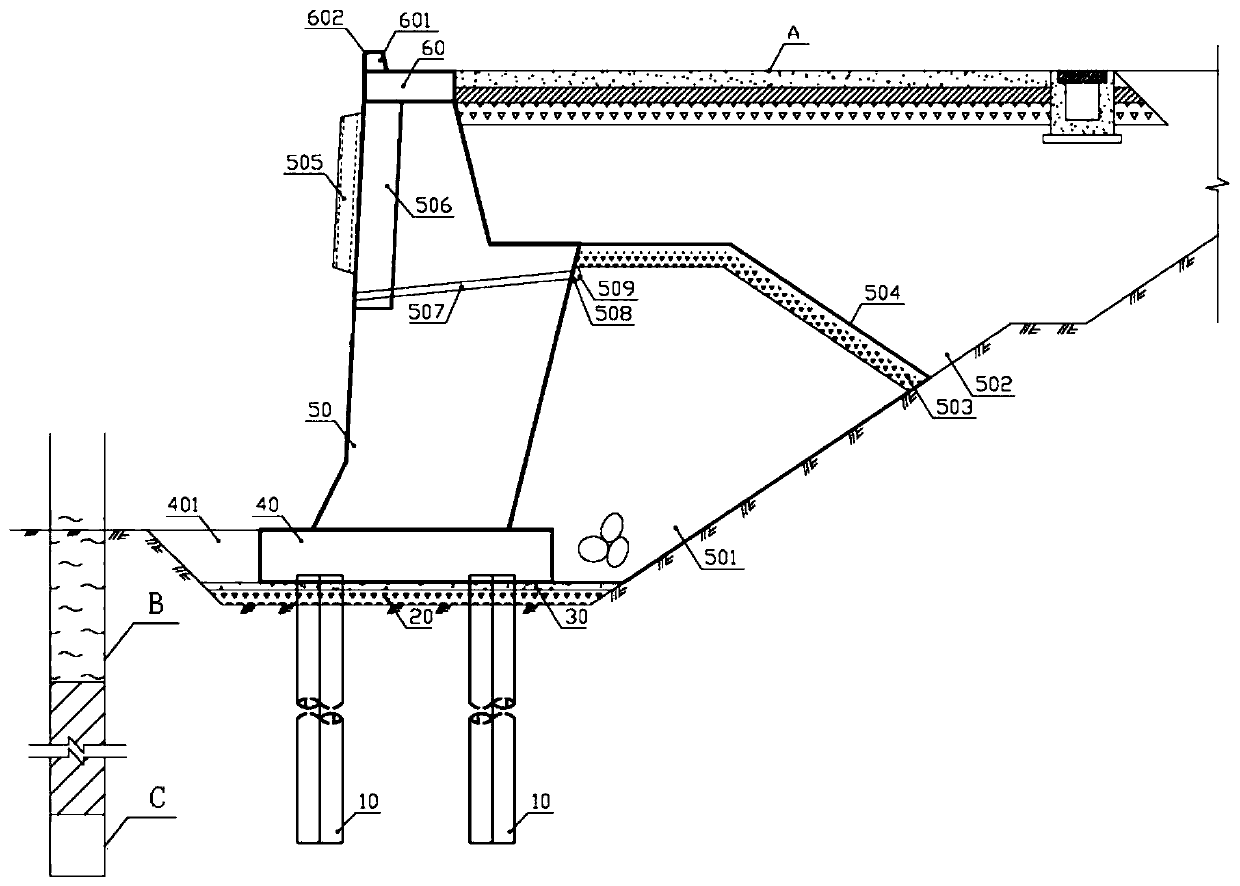

[0022] Specific embodiment one: the low-pile gravity wharf suitable for soft ground in this embodiment includes a plurality of rigid foundation piles 10, a reinforced concrete structure floor 40, plain concrete walls 50 and reinforced concrete topping 60, the low-pile gravity wharf The structural foundation adopts rigid foundation pile 10, the bottom of rigid foundation pile 10 is inserted into the hard soil layer, the upper part of rigid foundation pile 10 is laid gravel cushion 20 and plain concrete cushion 30 in sequence, and the top of rigid foundation pile 10 is poured with steel bars The concrete structure bottom plate 40, the upper surface of the reinforced concrete structure bottom plate 40 is provided with a plain concrete wall body 50, and the top surface of the plain concrete wall body 50 is provided with a reinforced concrete topping 60, and the wall behind the plain concrete wall body 50 is arranged sequentially from bottom to top There are riprap backfill structur...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment is different from Embodiment 1 in that the rigid foundation pile 10 is a PHC pile or a cast-in-situ pile.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the top part of the rigid foundation pile 10 enters the reinforced concrete structure bottom plate 40, and the depth of the top entering the reinforced concrete structure bottom plate 40 is 10-50 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com