Tensile bonded rebar structure

A technology of planting bars and steel bars, which is applied in the direction of building construction, construction, building maintenance, etc., can solve the problems of large column damage, insufficient bearing capacity, and insufficient tensile capacity of the interface of planting bars, so as to improve the bearing capacity, increase the bearing capacity, The effect of reducing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

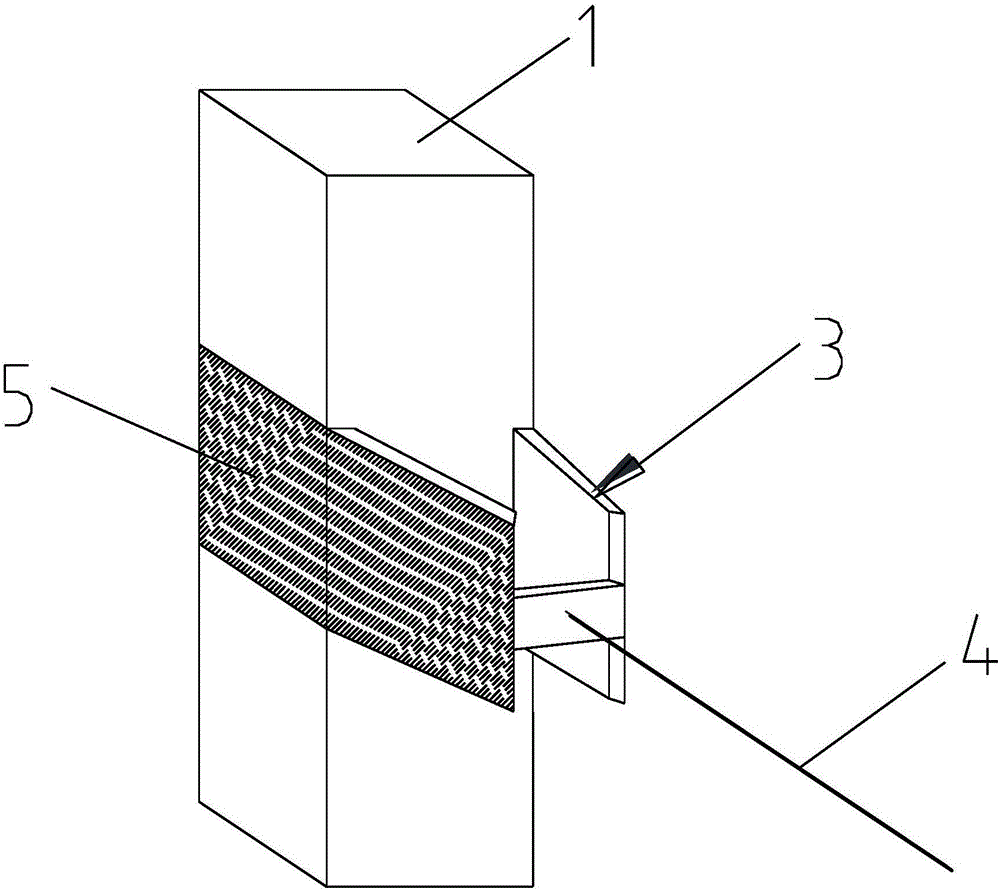

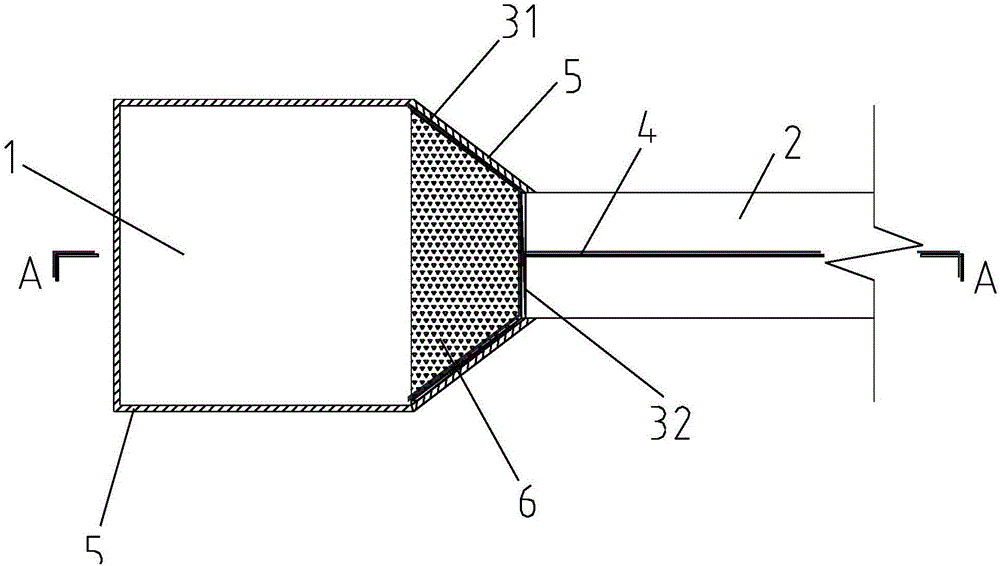

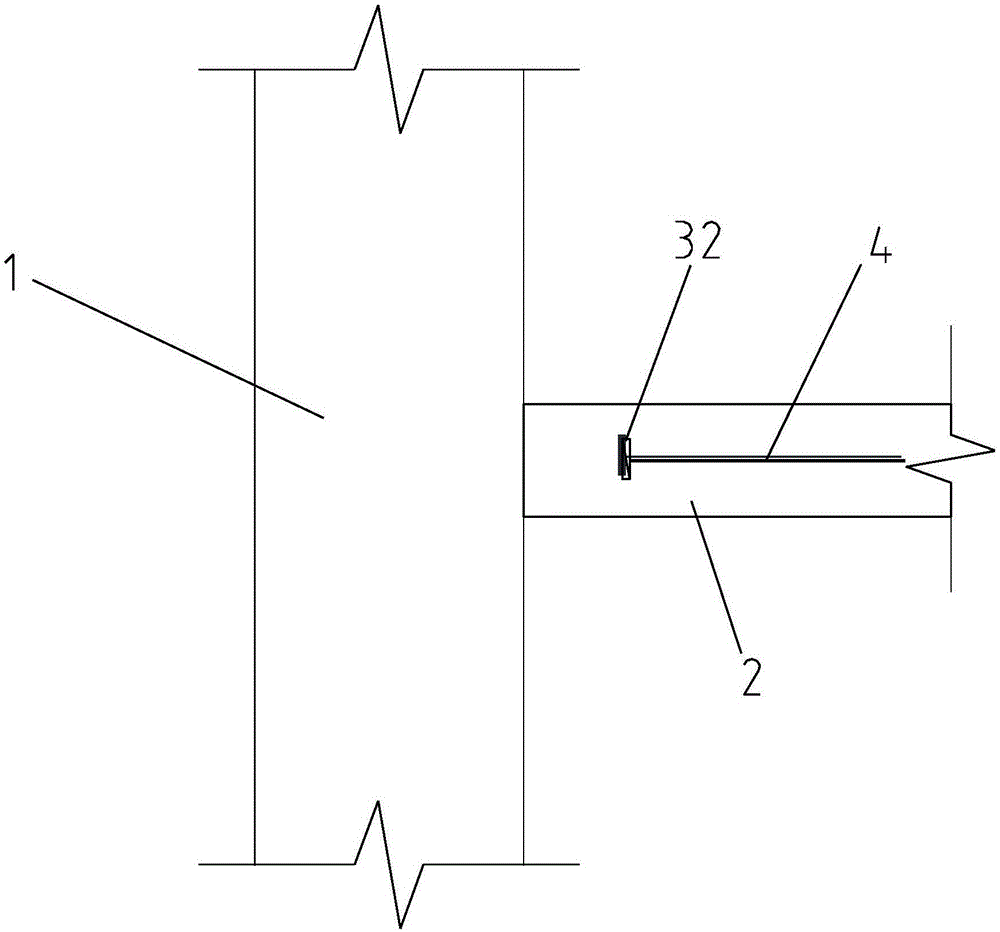

[0022] according to Figure 1-3 As shown, this embodiment provides a tensile reinforcement structure for connecting the original concrete column 1 and the newly added beam 2. The tensile reinforcement structure includes a connection that is arranged on the surface of the original concrete column 1 that needs reinforcement The steel plate 3 is bolted or welded on the connecting steel plate 3 and has a steel bar 4 that extends into the interior of the new beam 2 along the extension direction of the new beam 2, and is used to paste and fix the connecting steel plate 3 on the original concrete column 1 Carbon fiber cloth on 5.

[0023] The present invention uses the eight-shaped connecting steel plate 3 and the steel bar 4 bolted or welded on the web 32 of the connecting steel plate 3, and the carbon fiber cloth 5 wrapped around the outer periphery of the original concrete column 1 and connected to the eight-shaped connecting steel plate 3. The tension-rebar planting structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com