Humid environment earthen site slump damage flexible drainage bamboo fiber rod reinforcement method

A wet environment and soil ruins technology, which is applied in the field of reinforcement and management of slump damage in underground soil ruins, can solve the problems of aggravation, slump damage intensity, stiffness inconsistency, shrinkage and hole collapse, etc., achieve good tensile strength, improve Effect of Drained Shear Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

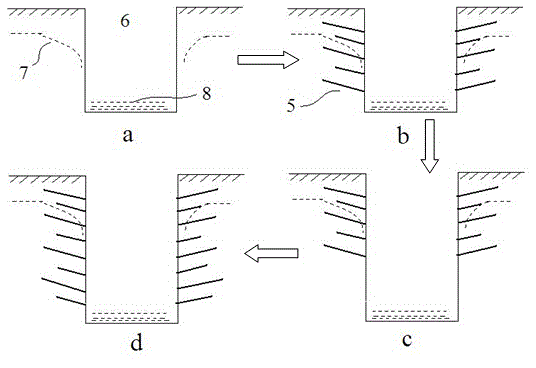

[0032] A method for reinforcing flexible drainage bamboo fiber rods for slumping disease in underground soil ruins under humid environment, comprising the following steps:

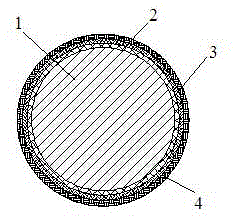

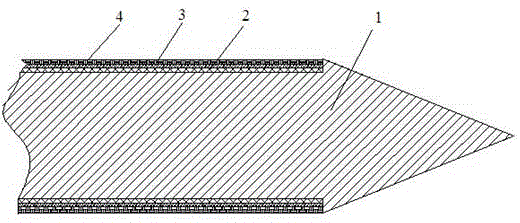

[0033] (1) Process the bamboo pole material into a diameter The bamboo fiber rod is used as the core material 1 of the flexible drainage bamboo fiber rod 5, and the length is 0.5m; and the chemical solution method is used to carry out anti-corrosion and anti-corrosion treatment;

[0034] (2) Geotextile / cloth drainage structure layer: take bamboo fiber pole as the core material 1 and wrap three layers of geotextile / cloth from the inside to the outside as the drainage structure layer; the structure settings and functions of the three layers of civil fabric / cloth are: the innermost The layer is a geotextile 2 with a thickness of 0.1mm, which is firmly bonded to the bamboo fiber rods with adhesives such as epoxy resin, in order to increase the grip force of the interface; -1 ~10 -2 cm / s) non-woven geotextil...

Embodiment 2

[0037] (1) Process the bamboo pole material into a diameter The bamboo fiber rod is used as the core material 1 of the flexible drainage bamboo fiber rod 5, and the length is 2.0m; and use asphalt to boil for a period of time to carry out anti-corrosion treatment;

[0038] (2) Geotextile / cloth drainage structure layer: take bamboo fiber pole as the core material 1 and wrap three layers of geotextile / cloth from the inside to the outside as the drainage structure layer; the structure settings and functions of the three layers of civil fabric / cloth are: the innermost The layer is a geotextile 2 with a thickness of 0.5mm, which is firmly bonded to the bamboo fiber rods with adhesives such as epoxy resin, in order to increase the grip force of the interface; -1 ~10 -2 cm / s) non-woven geotextile 3 (thickness about 2mm), the purpose is to play a role in proper drainage and decompression in the soft plastic-flow plastic site soil, and improve the undrained shear strength of the site...

Embodiment 3

[0041] (1) Process the bamboo pole material into a diameter The bamboo fiber rod is used as the core material 1 of the flexible drainage bamboo fiber rod 5, and the length is 1.0m; and use asphalt to boil for a period of time to carry out anti-corrosion treatment;

[0042] (2) Geotextile / cloth drainage structure layer: Bamboo fiber poles are used as the core material 1 and three layers of geotextile / cloth are wrapped from the inside to the outside as the drainage structure layer; the structure settings and functions of the three layers of civil fabric / cloth are: the innermost The layer is a geotextile 2 with a thickness of 0.3 mm, which is firmly bonded to the bamboo fiber rods with adhesives such as epoxy resin, in order to increase the grip force of the interface; -1 ~10 -2 cm / s) non-woven geotextile 3 (thickness about 2mm), the purpose is to play a role in proper drainage and decompression in the soft plastic-flow plastic site soil, and improve the undrained shear strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com