A high-precision measuring device for large-stroke displacement based on the working principle of dynamic balance

A working principle and high-precision technology, applied in the direction of measuring device, using stable shear force to test material strength, using stable tension/pressure to test material strength, etc., to achieve high measurement accuracy and solve the problem of high-precision two-way measurement , good economy and the effect of promoting value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

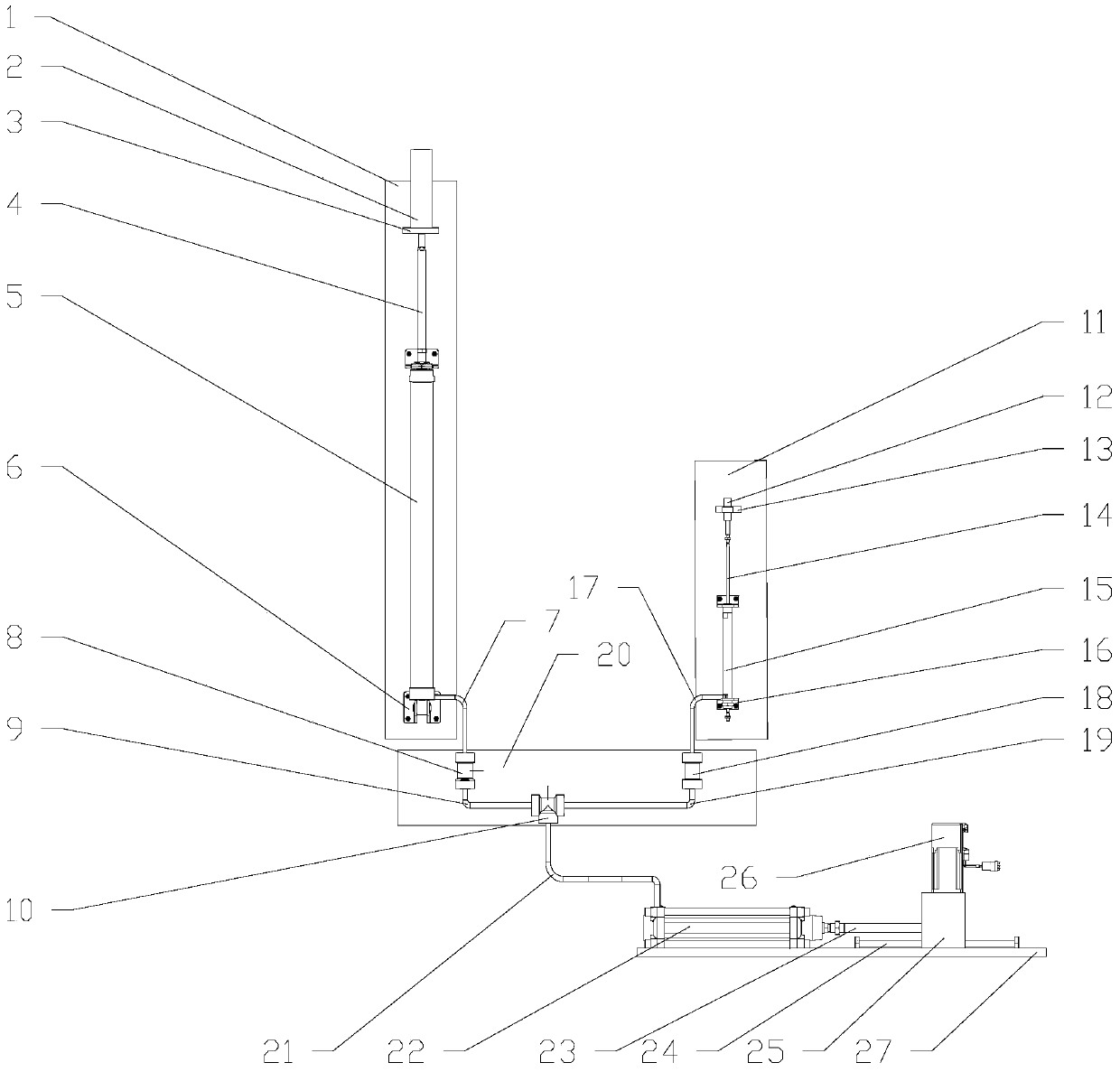

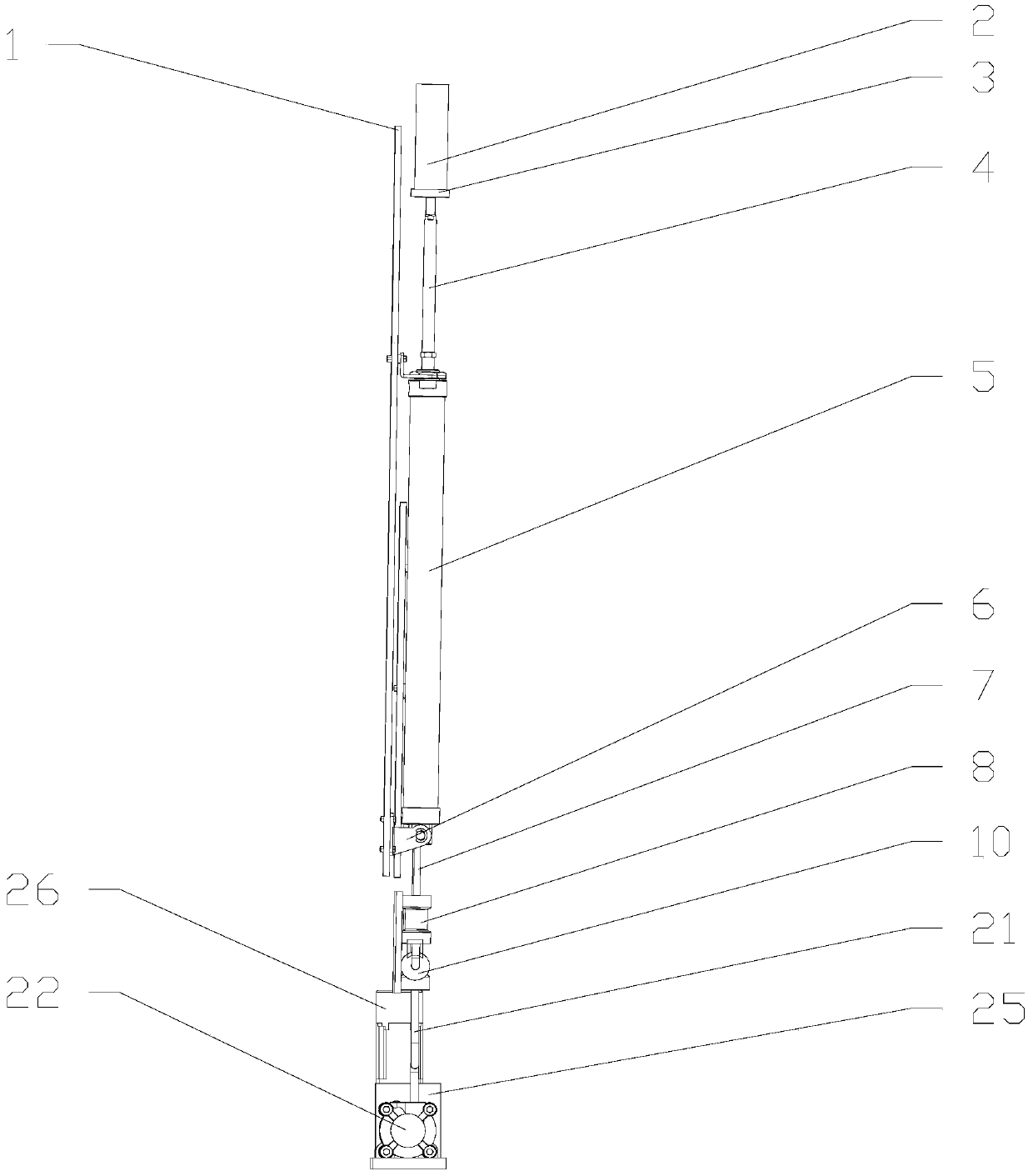

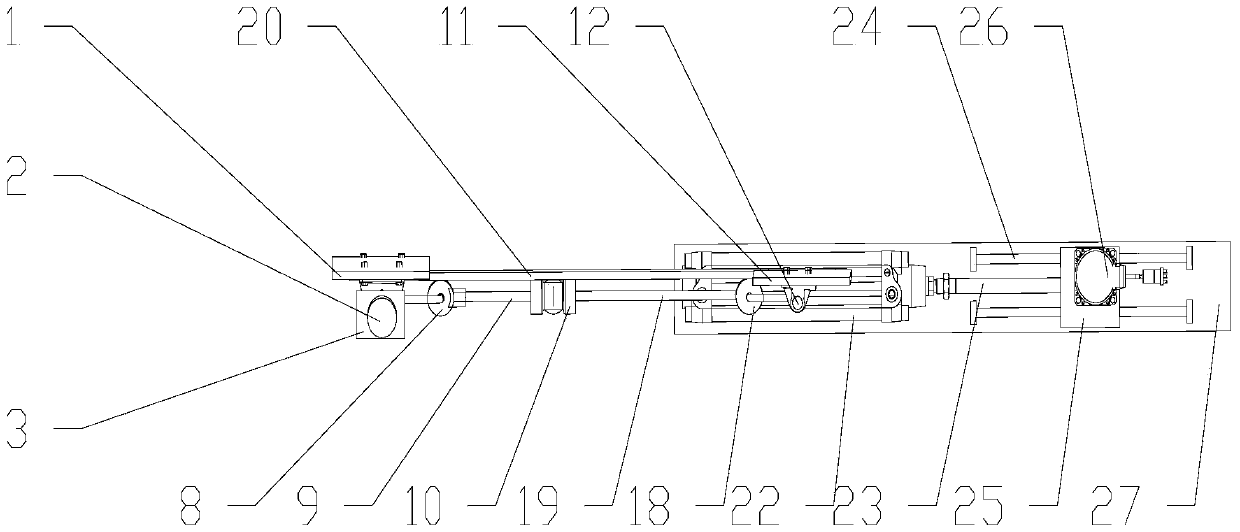

[0021] Such as Figure 1-5 As shown, the parts are cleaned with kerosene during assembly, and the mating surface is oiled after drying. The unprocessed surface of each part should be cleaned, the burrs should be removed, the anti-rust paint should be dipped, and multi-layer raw tape should be wound on the sealing port to strictly ensure the hydraulic cylinder And the tightness of the connection between the hydraulic cylinder and the hose; figure 1 You can clearly see three sets of hydraulic cylinder subsystems A, B, and C. The A subsystem includes the plunger hydraulic cylinder A fixed plate, the oil cylinder / air cylinder output shaft, the axial movement measuring baffle, and the plunger hydraulic cylinder A. Output shaft, plunger-type hydraulic cylinder A, plunger-type hydraulic cylinder A fixing fixture, upper co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com