Patents

Literature

156results about How to "Reduce precision error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

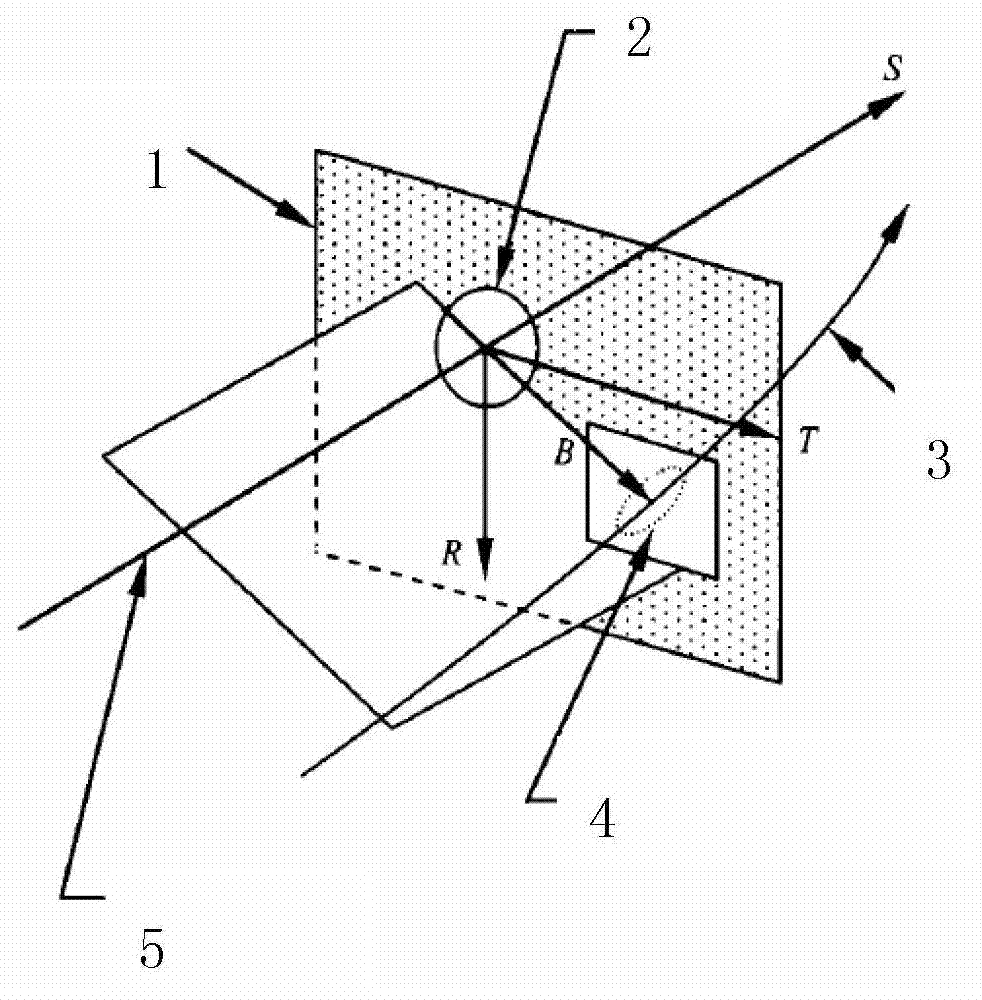

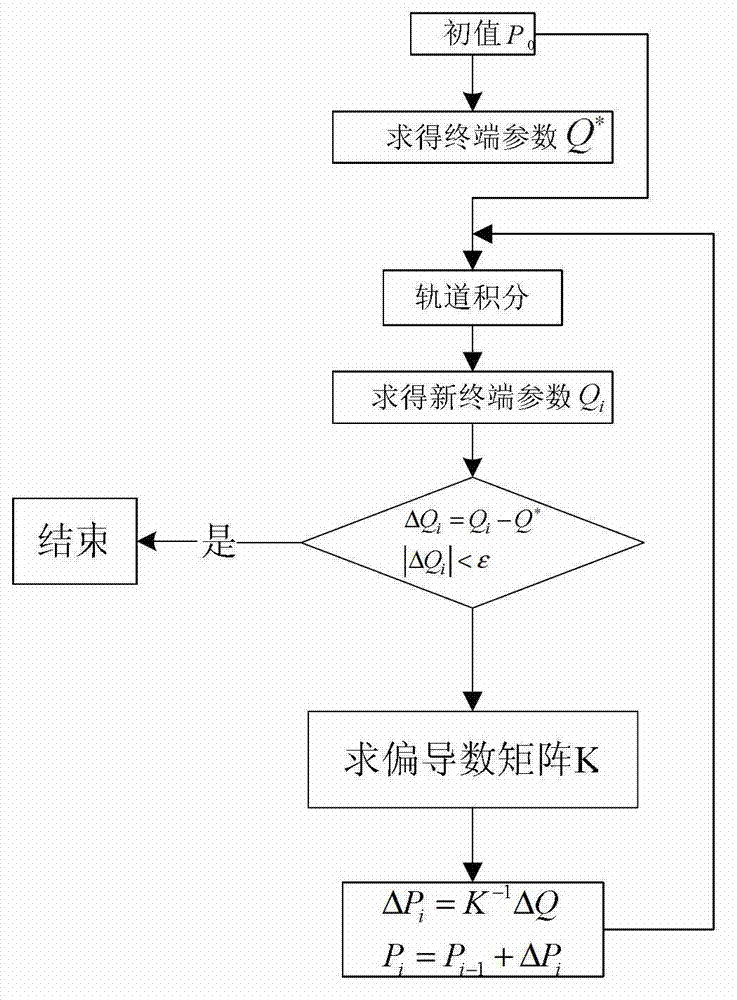

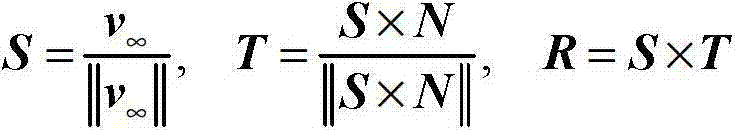

Track design method of deep space probe and based on differential modification

InactiveCN103198187AMeet the task requirementsMeet the requirements of the flight missionSpecial data processing applicationsAlgorithmGenetic algorithm

A track design method of a deep space probe and based on differential modification relates to the field of track design of the deep space probe. The track design method includes the following steps: calculating an initial value according to track parameter of the deep space probe and determined by a genetic algorithm or a Pork Chop Plots method, conducting track numerical integration operation under an accurate kinetic model according to the initial value of control parameter to obtain a terminal parameter value, comparing the parameter value obtained by calculation with a standard parameter to obtain a parameter deviation value to calculate a new control parameter according, utilizing the new control parameter to conduct track integral operation on the kinetic model again to obtain a new terminal parameter value deviation value and repeating the above process till the terminal parameter meets the requirement for accuracy. The track design method breaks up a partial derivative array into three portions, and provides a specific expression form. The new track parameter obtained by calculation meets any requirement for accuracy. The partial derivative array is suitable for different requirements for navigation calculation and error analysis and the like.

Owner:HARBIN INST OF TECH

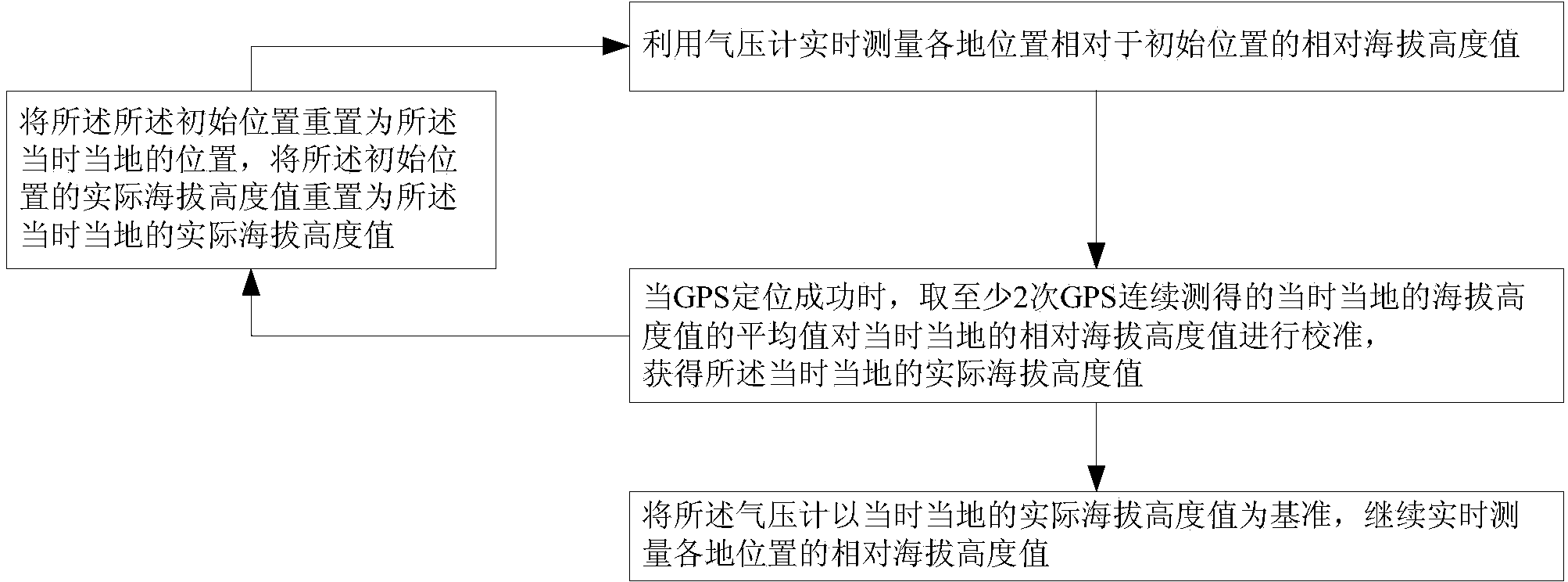

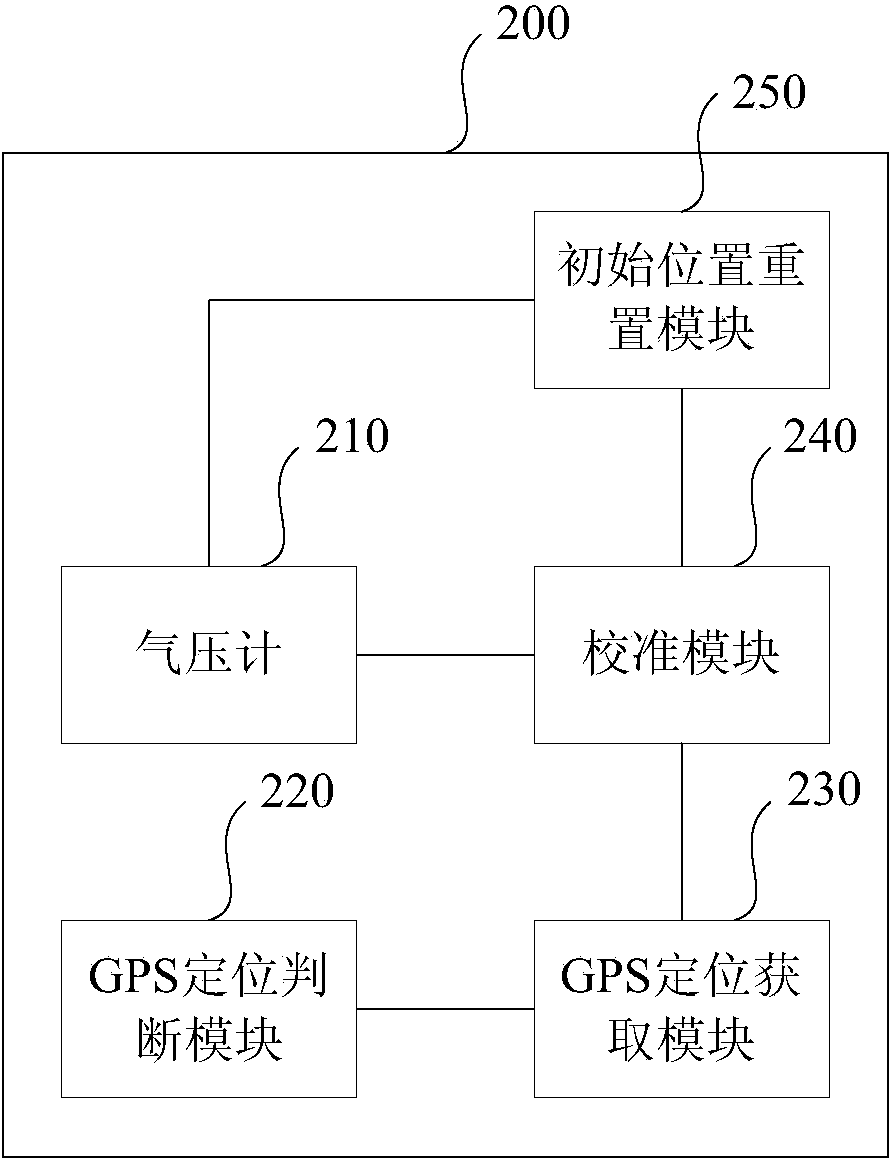

Altitude measuring method and system

ActiveCN103994754AAltitude is real-time stable and accurateReduce precision errorHeight/levelling measurementSignal-to-noise ratio (imaging)Satellite

The invention provides an altitude measuring method and system. The altitude measuring method comprises the steps: measuring a relative altitude value of each position relative to an initial position in real time by using a barometer; when a GPS (Global Positioning System) is successful in positioning, namely, the number of received satellites is more than 5 and the signal to noise ratio is more than 26, averaging current and local altitudes continuously measured by the GPS at least twice to calibrate a current and local relative altitude, namely assigning the current and local relative altitude as an average value to obtain a current and local actual altitude; and with the current and local actual altitude as a datum, continuously measuring the relative altitude of each position by the barometer in real time. According to the altitude measuring method and system, the GPS and the barometer are integrated, the basic altitude is calibrated through the GPS, and the relative height is calculated by using the barometer, thus a real-time stable and accurate altitude is obtained, and an error is less than 5 m, with accuracy corrected to the meter level.

Owner:SHANGHAI PATEO ELECTRONIC EQUIPMENT MANUFACTURING CO LTD +1

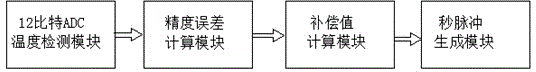

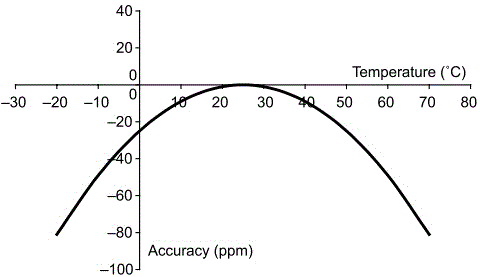

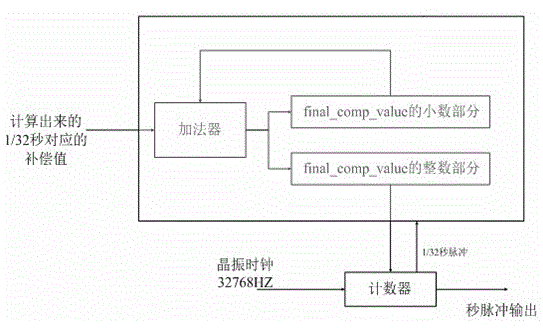

Smart meter RTC timing precision correction circuit and method thereof

ActiveCN105573106AReduce power consumptionLow costChanging number of pulses per unit timeClock ratePulse number

The invention relates to the field of smart meters, and specifically relates to a smart meter RTC timing precision correction circuit and a method thereof. The circuit comprises a 12-bit ADC temperature detection module, a precision error calculation module, a compensation value calculation module and a second pulse generation module. The method comprises the following steps: screening out a crystal oscillator; fitting a curve; calculating the error of the crystal oscillator; calculating the compensation value; working out the pulse compensation cycle according to the compensation value; defining the accumulative error; and adjusting a counter according to the accumulative error and the pulse number corresponding to the compensation cycle, wherein the counter stops counting for one beat if the error of the crystal oscillator is positive and the clock frequency is quicker, and the counter adds 2 to the number if the error of the crystal oscillator is negative and the clock frequency is slower. Through the correction method of the invention, a precise second pulse can be obtained, there is no need for a large amount of stored data, the memory is saved, power consumption is reduced, the timing precision is improved, and the influence of temperature on the timing precision is reduced.

Owner:CRM ICBG (WUXI) CO LTD

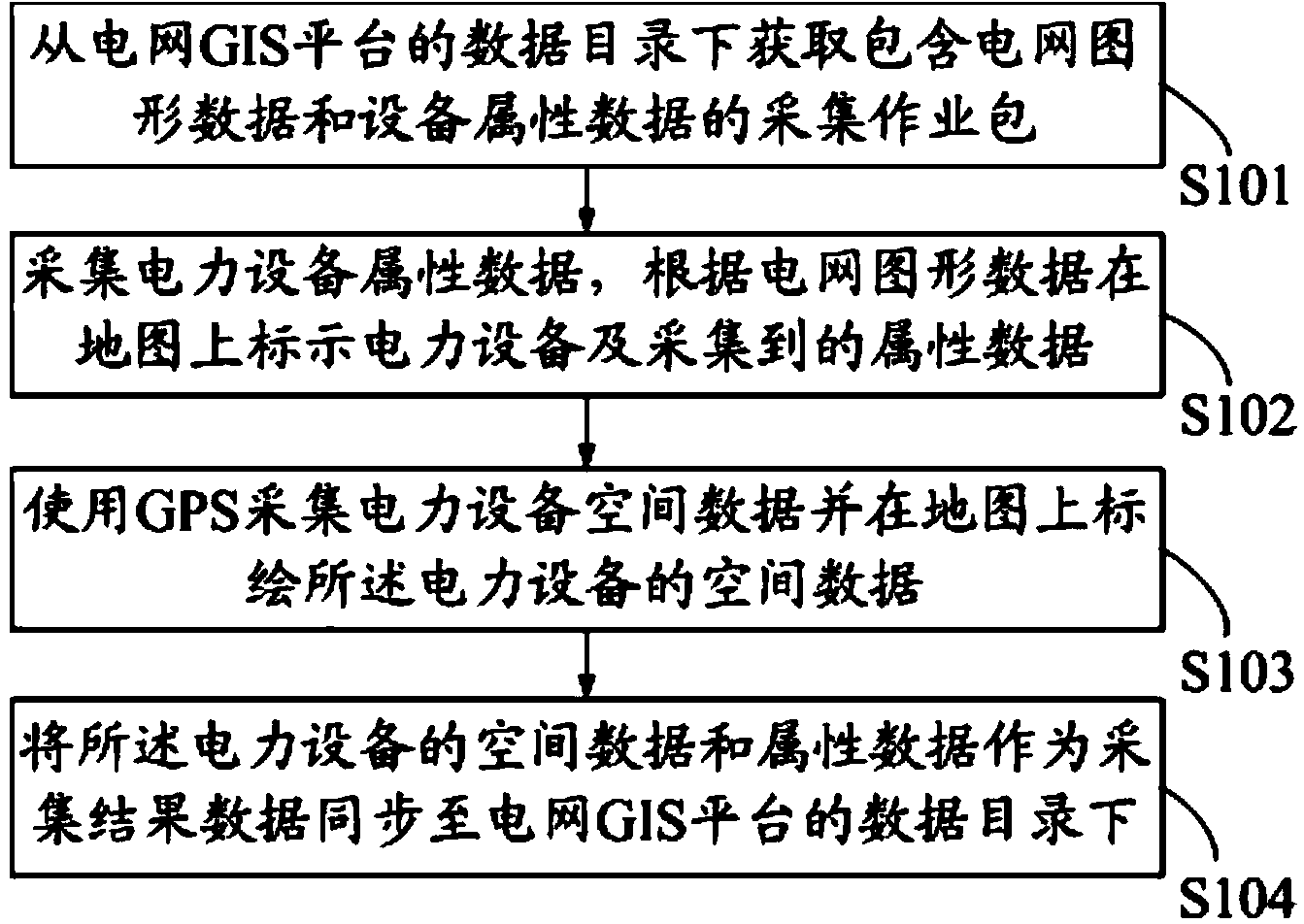

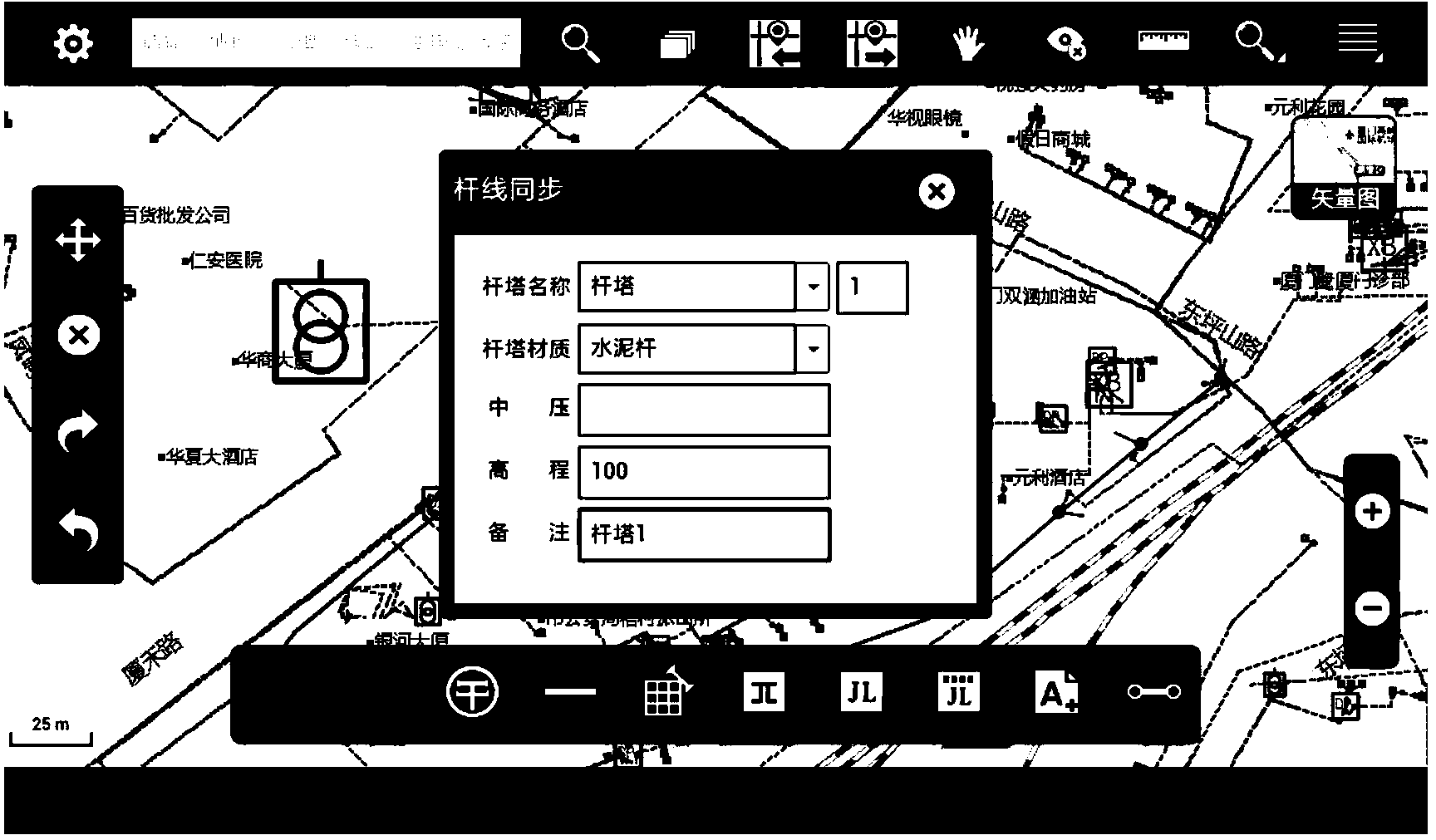

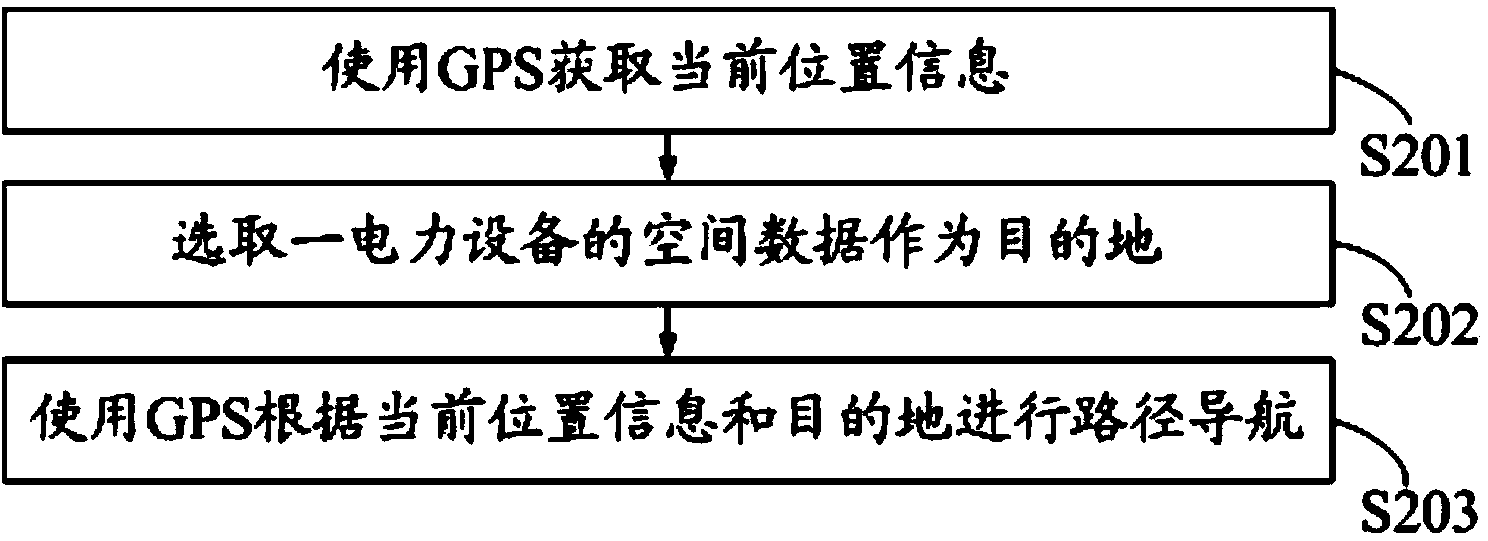

Electric power GIS (geographic information system) data collecting system and method based on mobile equipment

InactiveCN103455634ARapid positioningReduce precision errorSpecial data processing applicationsElectric power equipmentPower grid

The invention discloses an electric power GIS (geographic information system) data collecting method based on mobile equipment. The method includes: acquiring a collecting operation packet containing power grid pattern data and equipment attribute data from a data category of a power grid GIS platform; collecting electric power equipment attribute data, and marking electric power equipment and the attribute data thereof on a map according to the power grid pattern data; using a GPS (global positioning system) to collect electric power equipment spatial data and drawing the same on the map; synchronizing the electric power equipment spatial data and attribute data serving as the collecting results to the data category of the power grid GIS platform. The invention further discloses an electric power GIS data collecting system based on the mobile equipment.

Owner:STATE GRID CORP OF CHINA +1

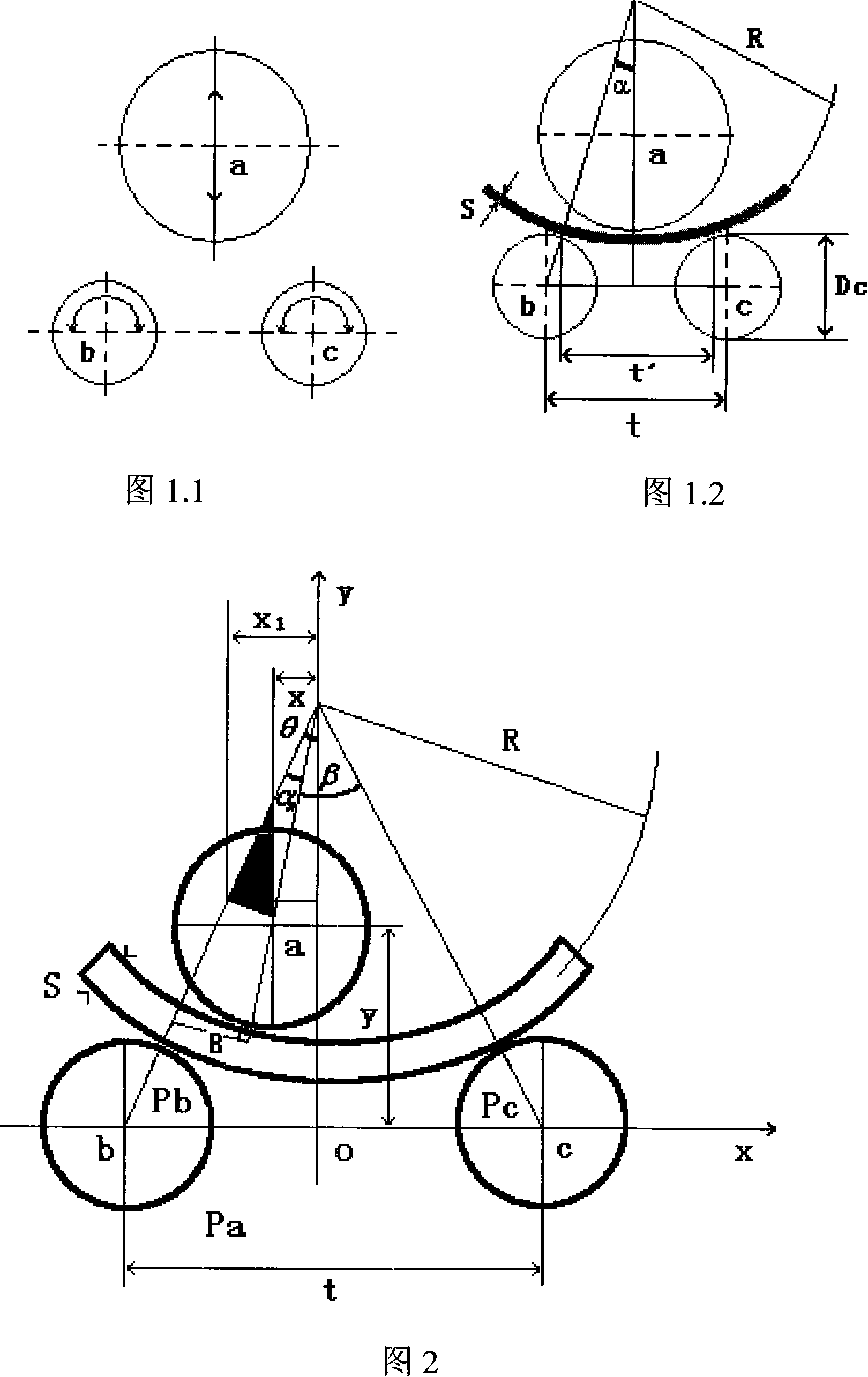

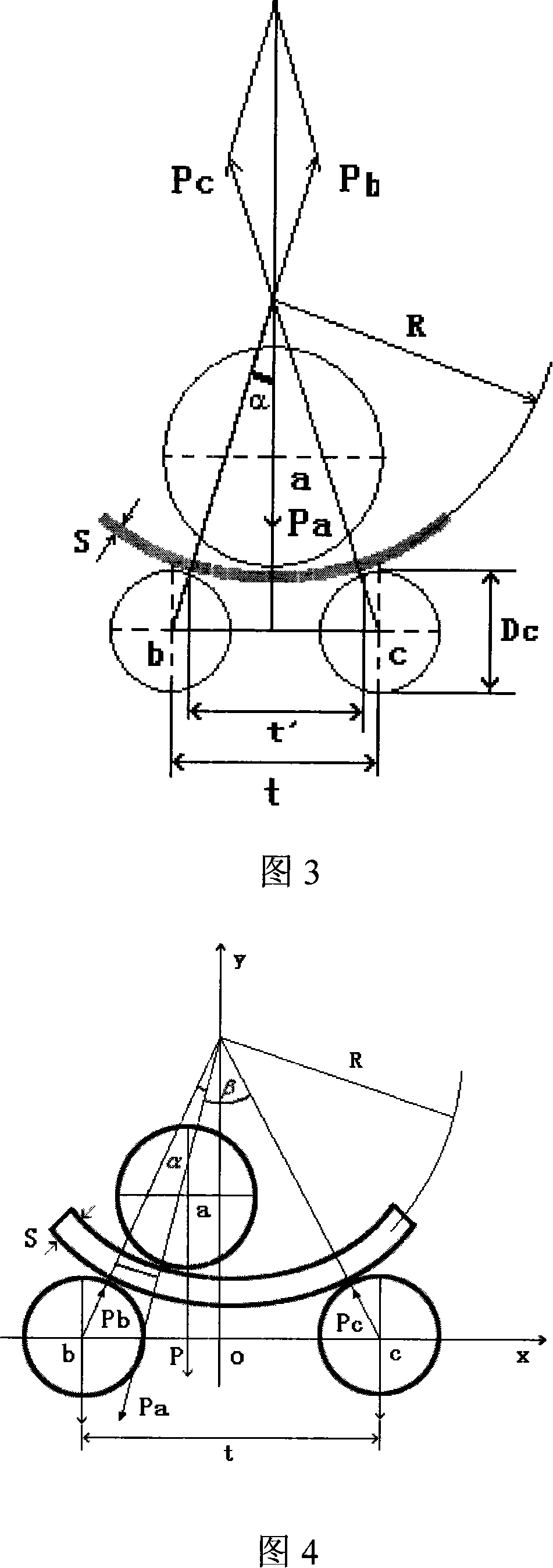

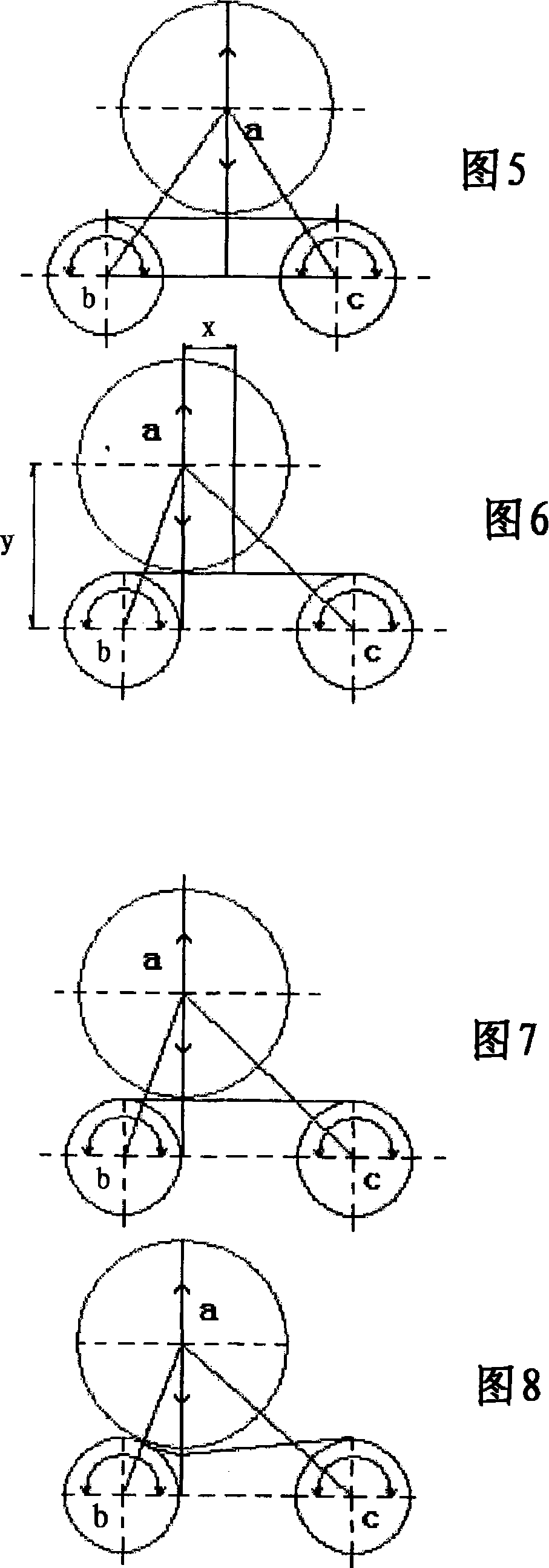

Control method for horizontal down-regulation type 3-roller lapping machine

InactiveCN101109945AReduce precision errorHigh control precisionNumerical controlEngineeringVertical shift

A horizontal down regulation method used for controlling the three rolls plate bending machine; firstly, ascertaining the radius, the sheet material width and the sheet material thickness of the work piece as well as the strength coefficient and the yield strength of work piece materials. Based on the optimizing of the remained straight edge, the horizontal shift, three vertical shifts and two depressing values are calculated out for coiling or pre-flex so as to spool out the cylinders with various diameters. The utility model has the advantages of high control precision and low trueness error for the roll bending.

Owner:湖北鄂重重型机械有限公司

Intelligent substation protection device synchronization performance test system and method based on GPS (globe positioning system) accurate time synchronization technology

InactiveCN103293414AMeet the requirements of different test scalesReduce precision errorElectrical testingSmart substationLow voltage

The invention discloses an intelligent substation protection device synchronization performance test system and method based on a GPS (globe positioning system) accurate time synchronization technology. The system comprises a plurality of subunits, each subunit comprises a relay protection test unit and a corresponding clock extension unit, the clock extension unit in each subunit is connected with a GPS receiving device, and the relay protection test units are guaranteed to start sending data at the same moment. The method is mainly used for synchronization performance test of intelligent substation protection devices under the circumstance of conventional transformer sampling, includes two modes that a protection device samples directly from a secondary winding and samples via a merging unit, and is applicable to main substation protection for high-medium-low voltage side sampling, bus protection for cross-interval sampling, differential protection of a line with an intelligent substation on one side and a traditional substation on the other side, differential protection of a line with intelligent substation on both sides and the like.

Owner:STATE GRID CORP OF CHINA +2

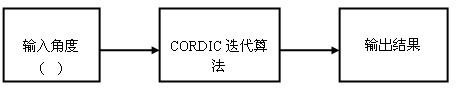

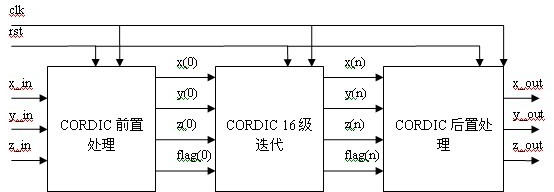

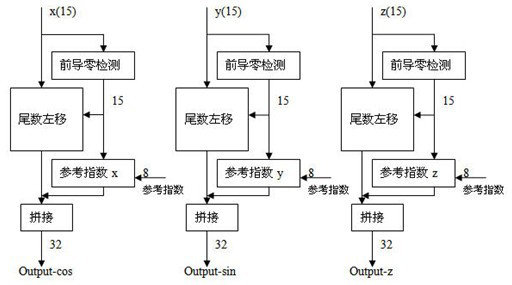

Triangle function implementation method based on field programmable gata array (FPGA)

InactiveCN102542336AEasy to use, convenient and flexibleReduce precision errorMathematical modelsComputer scienceField-programmable gate array

A triangle function implementation method based on a field programmable gata array (FPGA) comprises results of a triangle function are calculated out by means of three designed sub-modules, namely a coordinated rotation digital compute (COREDIC)_PRE preprocessing module, a COREDIC module and a COREDIC_POST postprocessing module, wherein the COREDIC_PRE preprocessing module expands an input angle [2n] (n=0, 1, 2...) into any angles and performs amplification processing; the input angle is converted into a first quadrant according to symmetry of the triangle function before iteration; the COREDIC module utilizes design of a streamline structure; and the COREDIC_POST postprocessing module converts results calculated out in the COREDIC before being output into an IEEE-754 standard format in a post processing mode. The triangle function implementation method based on the FPGA utilizes 16-level iterative operation with the accuracy error smaller than 10-3. The advantage of high speed of the COREDIC algorithm is especially shown when the triangle function is used in algorithm processing by means of the FPGA.

Owner:XIAN KEYWAY TECH

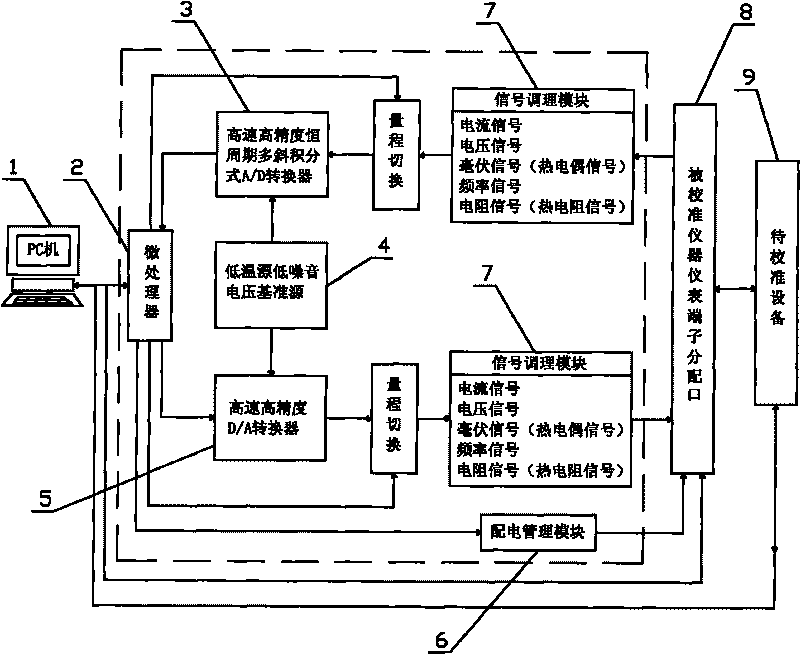

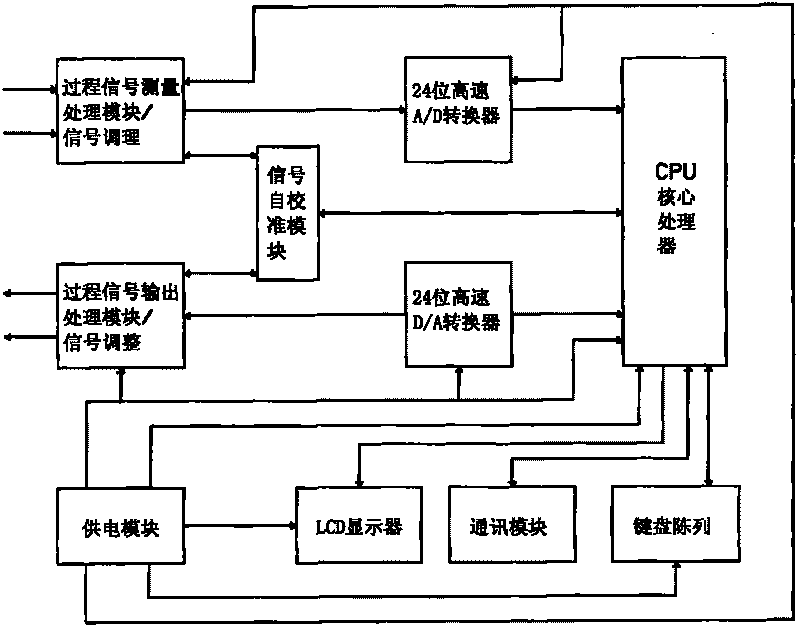

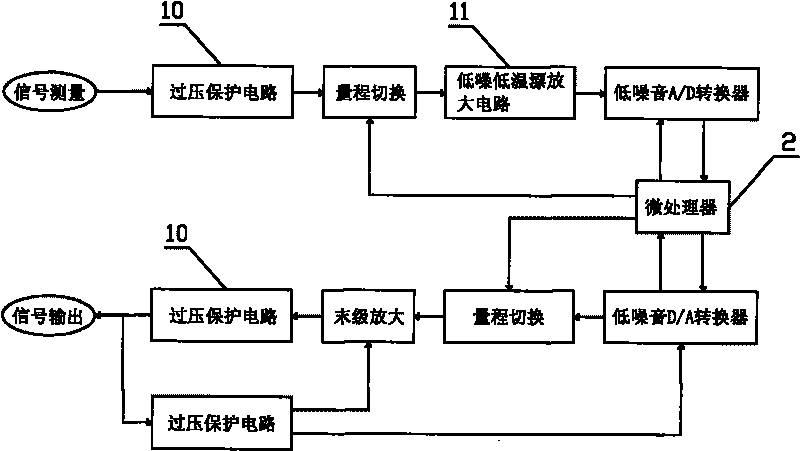

High-speed high-precision process parameter online calibration tester

InactiveCN101738947AFast conversionReduce precision lossProgramme control in sequence/logic controllersLow noiseMeasuring instrument

The invention relates to a measuring instrument for an automation meter and discloses a high-speed high-precision process parameter online calibration tester. The tester comprises a microprocessor which is connected with a PC computer and used for data communication, and a measuring module, an output module, a power distribution management module and a signal conditioning module which are connected with the microcomputer; the measuring module comprises a high-speed high-precision constant-cycle multiple oblique integral A / D convertor; and the output module comprises a high-speed high-precision A / D convertor, wherein a low-temperature drift low-noise voltage reference source is connected between the high-speed high-precision constant-cycle multiple oblique integral A / D convertor and the high-speed high-precision A / D convertor. The tester is mainly used for measuring an industrial autocontrol system (DCS and PLC) and other automation meters and performing automatic high-precision calibration testing on output signals, can be used for research and development of products and quality detection and control of the products on a production line, and is widely applied to the maintenance and calibration of apparatus and instruments in the production process in electric power, petrifaction, metallurgy and the like.

Owner:杭州精久科技有限公司

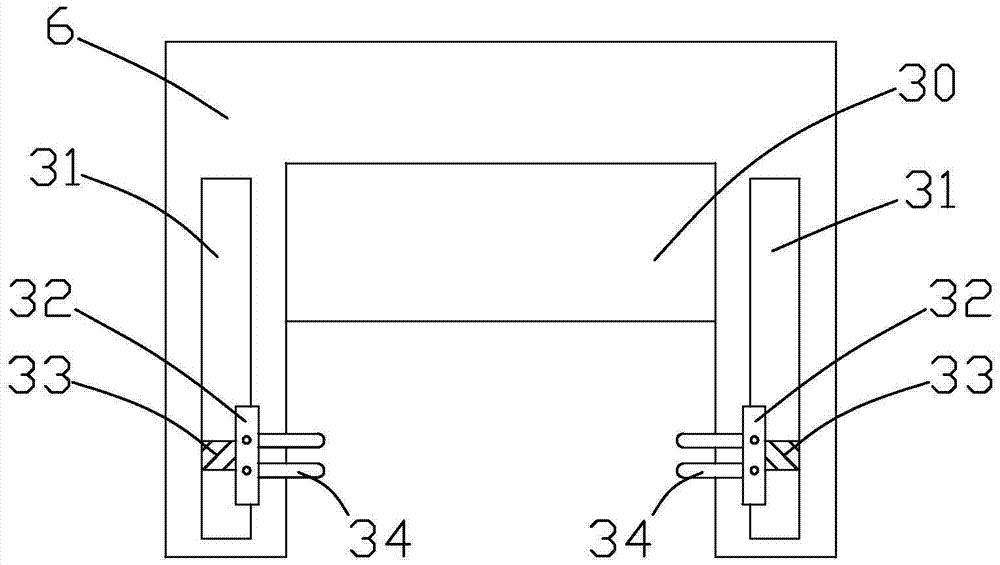

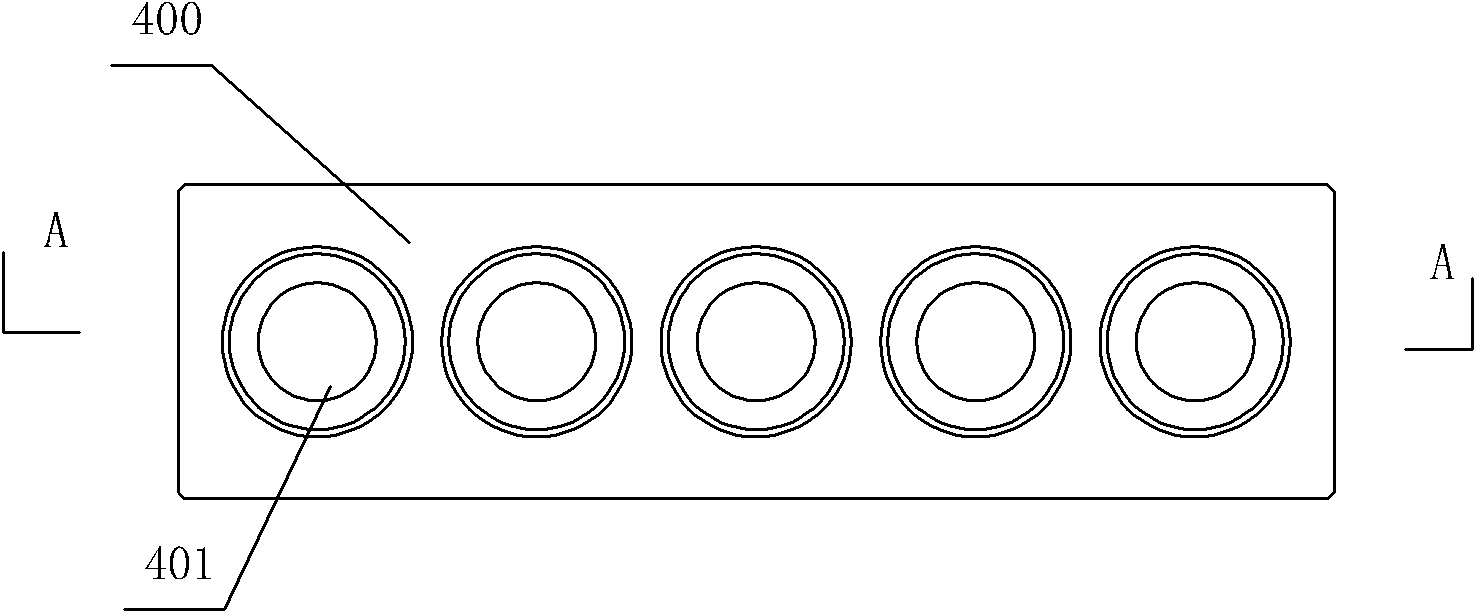

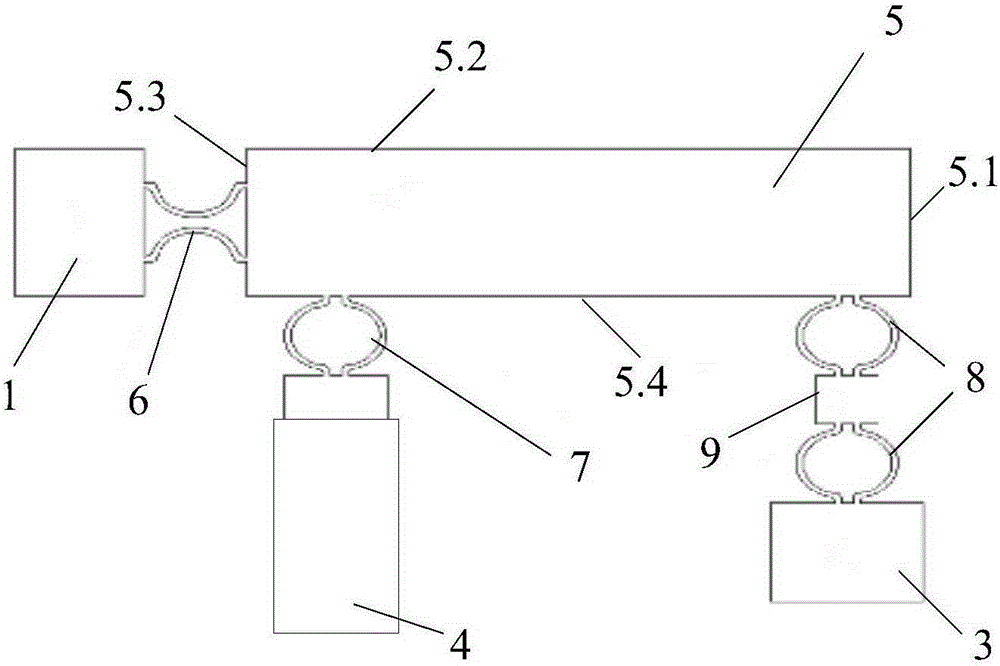

Longitudinal mechanical flexibility compensation device for worktable of bending machine and manufacturing method of longitudinal mechanical flexibility compensation device

PendingCN109332434AHigh mobile consistencyEliminate or offset accumulated errorsShaping toolsOther manufacturing equipments/toolsEngineering

The invention discloses a longitudinal mechanical flexibility compensation device for a worktable of a bending machine and a manufacturing method of the longitudinal mechanical flexibility compensation device, and belongs to the technical field of bending machines. The longitudinal mechanical flexibility compensation device comprises an upper sloping plate and a lower sloping plate; the upper sloping plate and the lower sloping plate are of an integral structure and consistent in size; first slope surfaces in the longitudinal direction are arranged on the lower surface of the upper sloping plate; the slopes of the first slope surfaces are reduced from a larger slope Kj to a smaller slope Ki from the middle to the two ends; the two adjacent first slope surfaces are connected through an arcsurface; the radians of the arc surfaces are increased from a smaller radian Ri to a larger radian Rj from the middle to the two ends; and second slope surfaces corresponding to the first slope surfaces are arranged on the upper surface of the lower sloping plate. The upper sloping plate and the lower sloping plate are of an integrated structure and consistent in size, so that the moving consistency of the lower sloping plate is high, accumulative errors can be eliminated or cancelled, and the bending molding accuracy is ensured.

Owner:ANHUI LIYUAN NUMERICAL CONTROL CUTTING TOOL & PATTERNS MFG

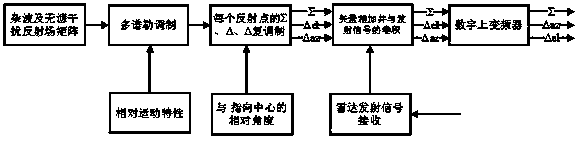

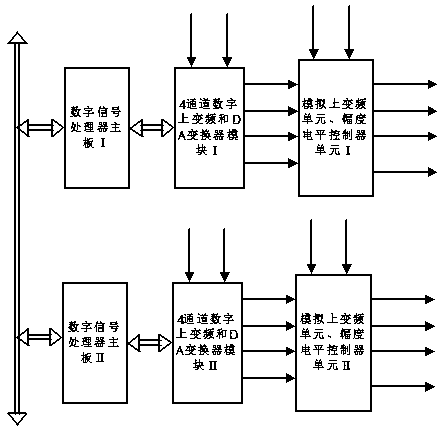

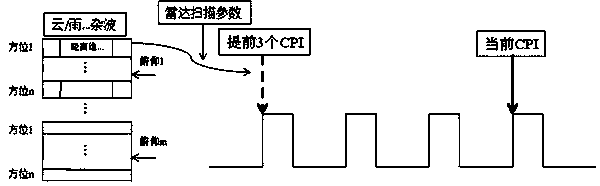

Dual-polarized passive jamming pulse signal precise generation method

ActiveCN104215945AAchieve precise productionReduce precision errorWave based measurement systemsEngineeringRadar signals

The invention discloses a dual-polarized passive jamming pulse signal precise generation method used for generating a dual-polarized passive jamming pulse signal precisely. The dual-polarized passive jamming pulse signal precise generation method comprises the steps of: uploading original artificial data of artificial cloud, rain, ground, sea and foils through a production line mode; convoluting the original artificial data and a radar signal parameter to generate a passive jamming scattered echo signal; aligning with a pulse with the precision error less than 5 ns; downloading the data at a high speed; delaying precisely when the error is less than 5 ns; controlling precisely when a pulse width error is less than 5 ns; performing dual-polarized modulation on the signal to realize precise generation of the passive jamming pulse signal.

Owner:NANJING CHANGFENG AEROSPACE ELECTRONICS SCI & TECH

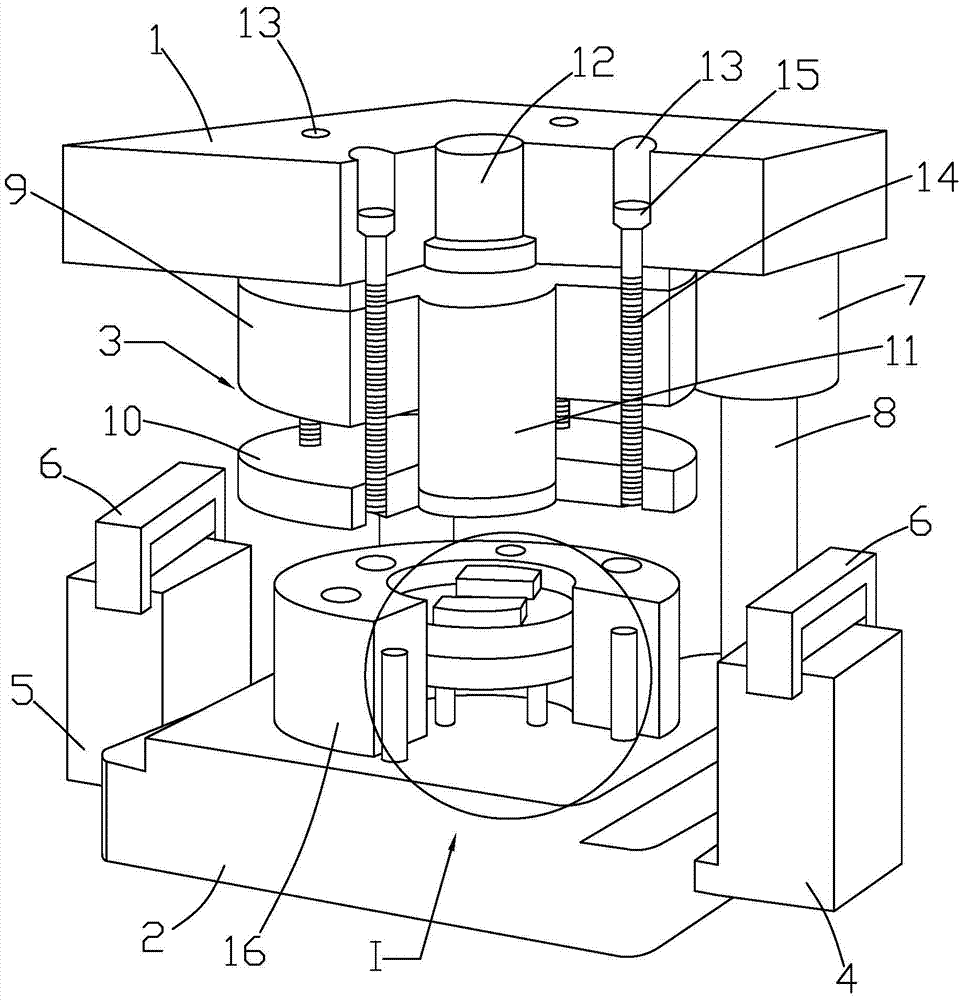

Silicon steel sheet punching machine for production of fan motor rotor

InactiveCN105449946AReduce impactAffect the service lifeMetal-working feeding devicesManufacturing stator/rotor bodiesHydraulic cylinderPunching

The invention discloses a silicon steel sheet punching machine for production of a fan motor rotor. The silicon steel sheet punching machine comprises an upper top plate, a base, a stamping mechanism, a feeding box body and a discharging box body, wherein a main hydraulic cylinder is arranged on the upper top plate, at least two lifting hydraulic cylinders are arranged on the bottom surface of the upper top plate and connected onto the top surface of the base via a piston rod, a punching processing table is arranged at the center of the top surface of the base and fixedly connected onto the base via a limitation rod, a stamping through hole is formed in the center of the punching processing table, a buffer mechanism is arranged in the stamping through hole, the feeding box body and the discharging box body are respectively arranged at the two sides of the base, and feeding positioning devices are arranged on the top surfaces of the feeding box body and the discharging box body. The silicon steel sheet punching machine is simple in structure and has high practicability, continuous transmission of silicon steel sheets can be fulfilled, and the transmission efficiency of the silicon steel sheets is improved; and moreover, the punching process of the silicon steel sheets with different sizes and types can be met, the silicon steel sheets after being punched are automatically stacked and formed, and the production process of the rotor is simplified.

Owner:SHENGZHOU BEIYULING MOTOR FACTORY

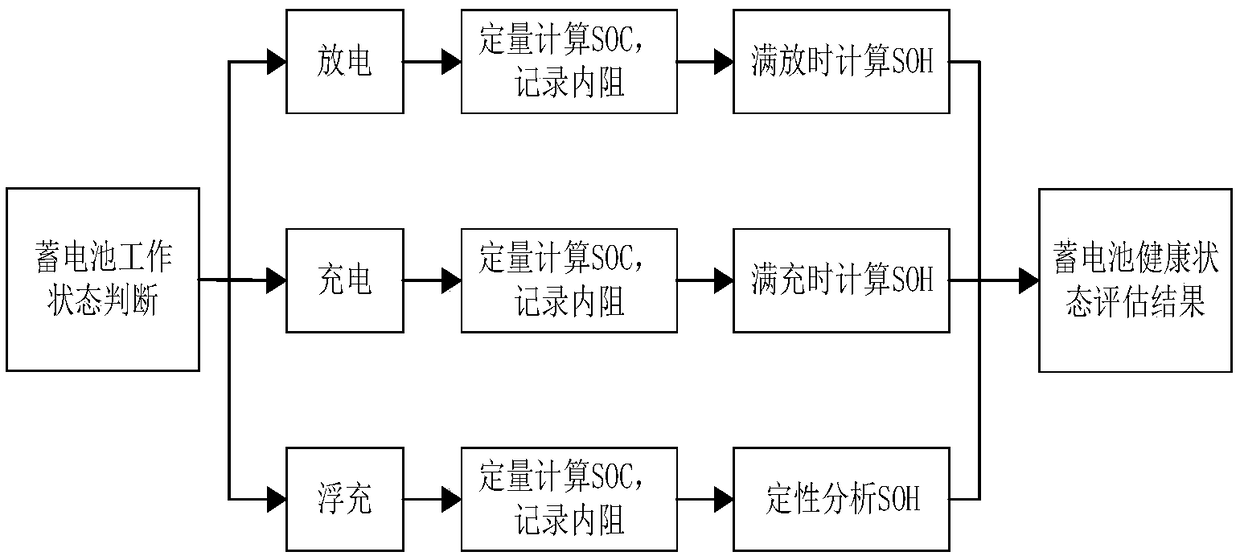

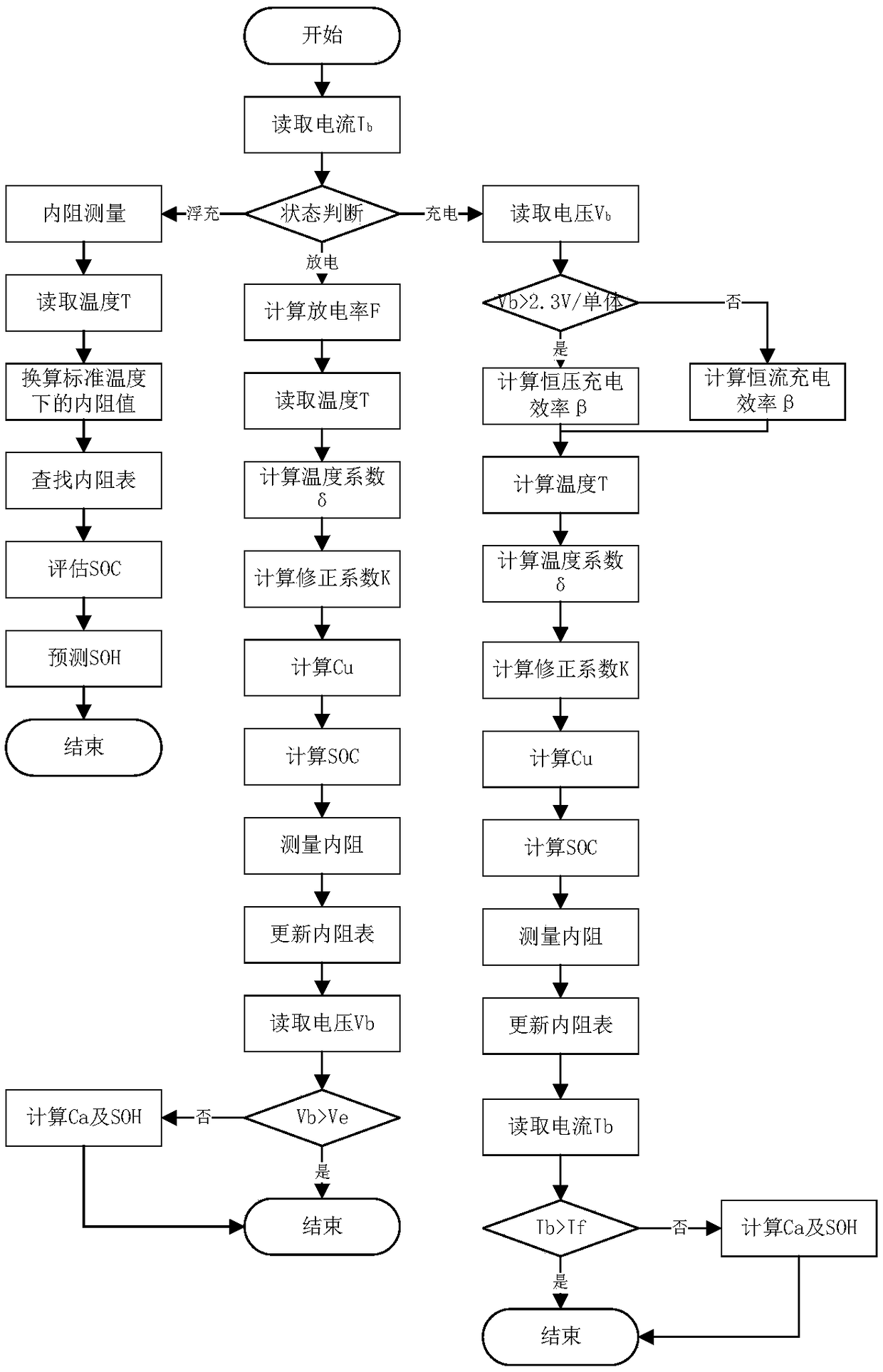

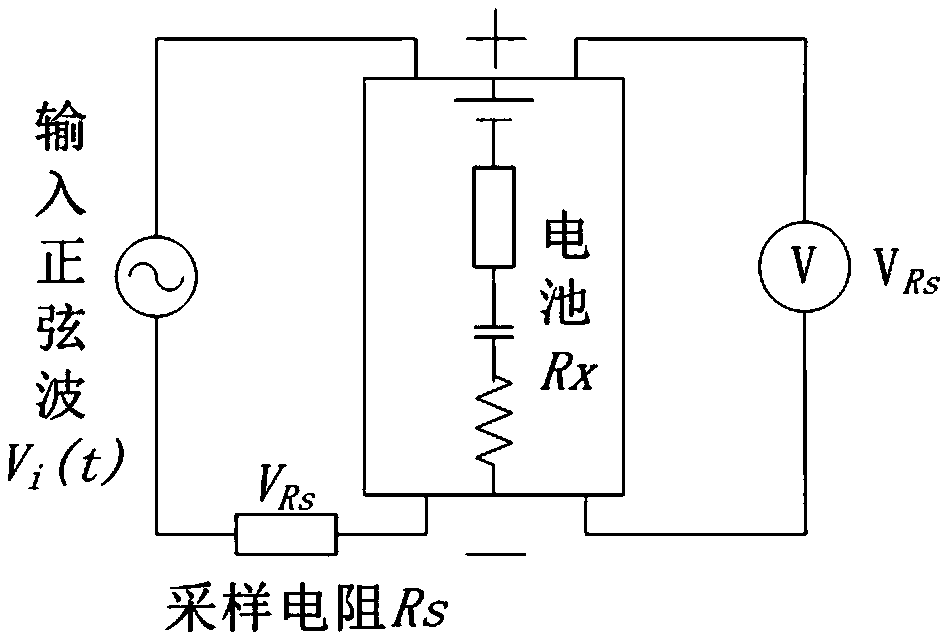

Online monitoring method for communication battery health degree

InactiveCN109061518AReduce precision errorStrong applicabilityElectrical testingWork statusFloating charge

The invention discloses an online monitoring method for a communication battery health degree. The current, the terminal voltage and the internal resistance of a storage battery under various different working states are monitored in real time, an improved ampere-hour method is used for calculating the capacity of the storage battery, and meanwhile, the influence of the discharge rate, the chargeefficiency and the temperature of the storage battery on the capacity is corrected, the state of health of the storage battery under a charge and discharge state can be quantified, and a basis is provided for the qualitative analysis of the state of health of the storage battery under a floating charge state so as to realize the all-around judgment of the state of health of the storage battery under the conditions of charge, discharge and floating charge. The method has the advantages of being high in applicability and accuracy, simple in implementation and the like, so that the method can beused for discovering storage battery individuals which may have hidden dangers in advance, the reliability and the guarantee level of the storage battery can be effectively improved, and the method ishigh in practicality.

Owner:STATE GRID CORP OF CHINA +1

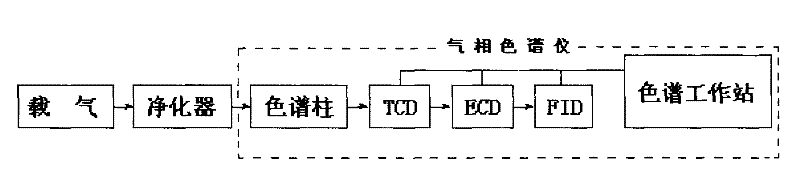

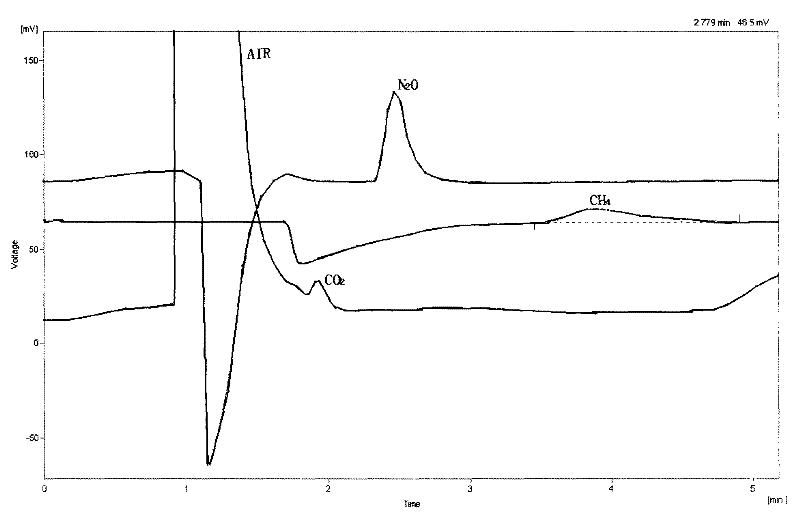

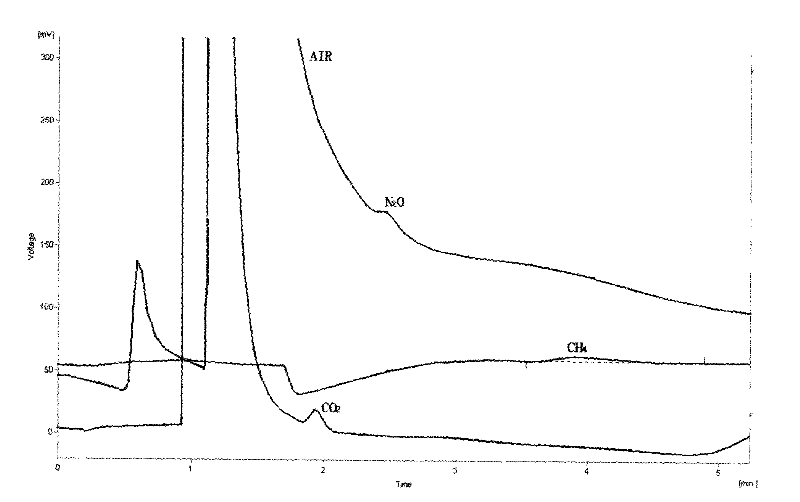

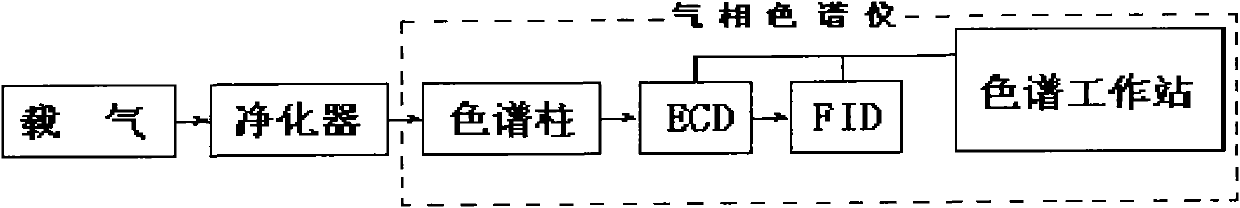

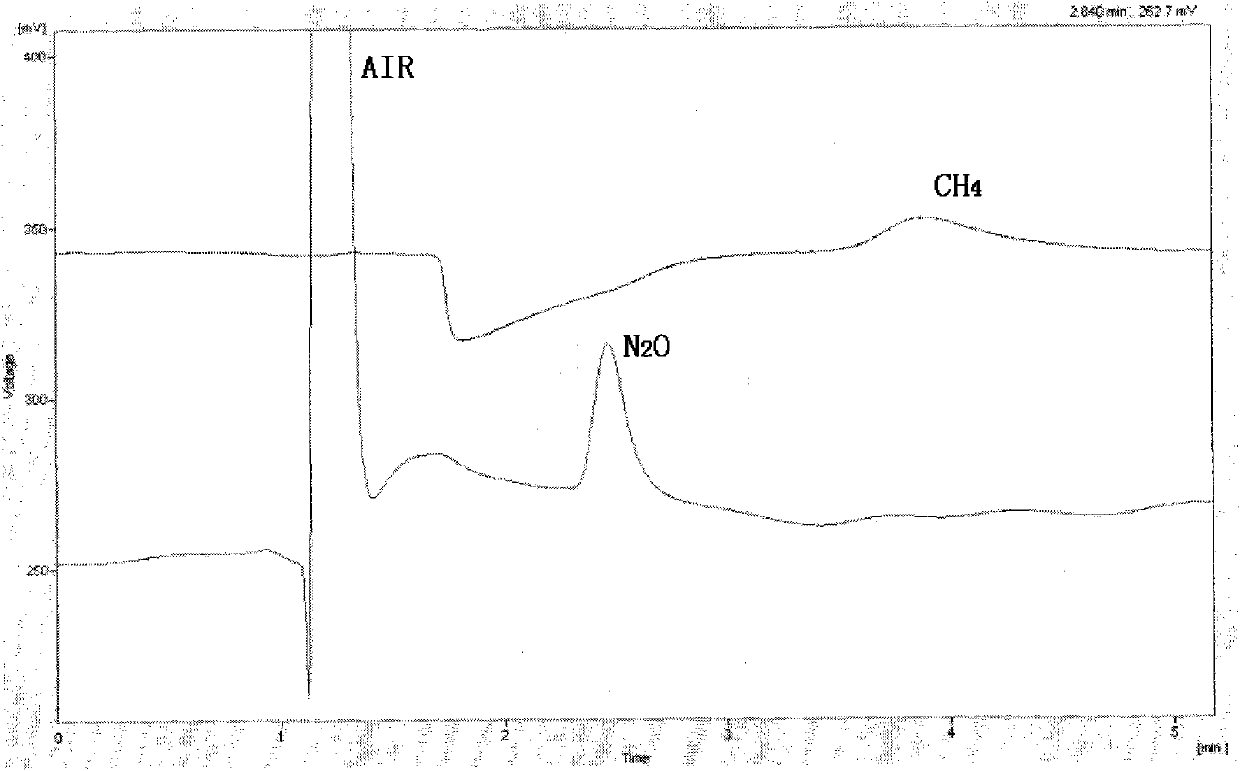

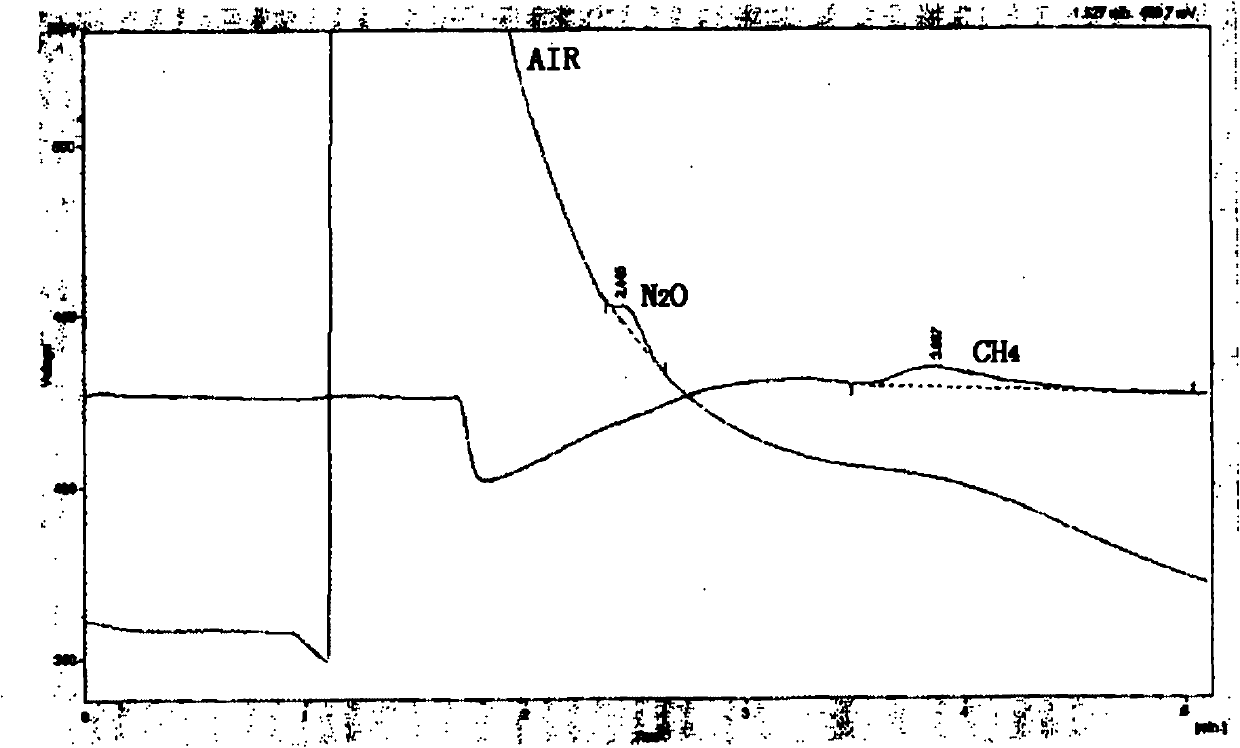

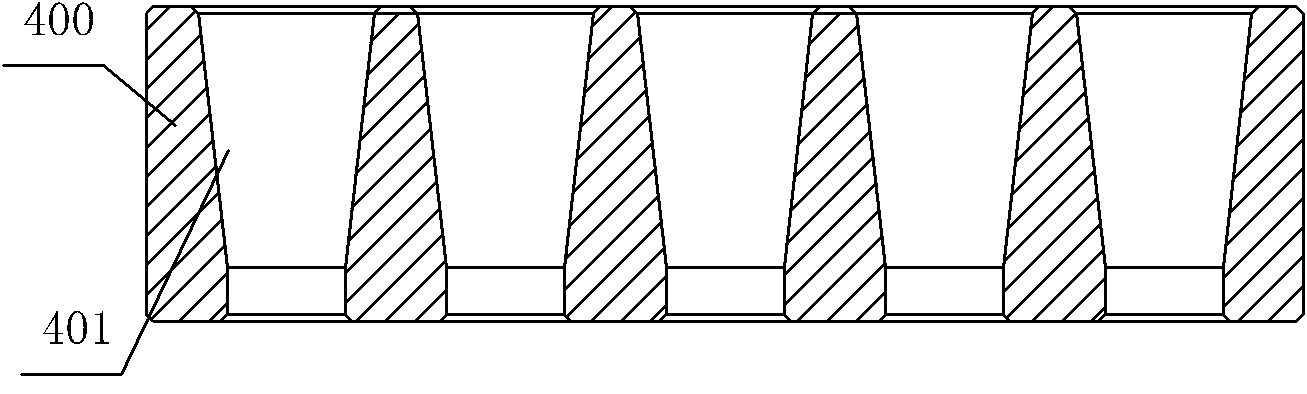

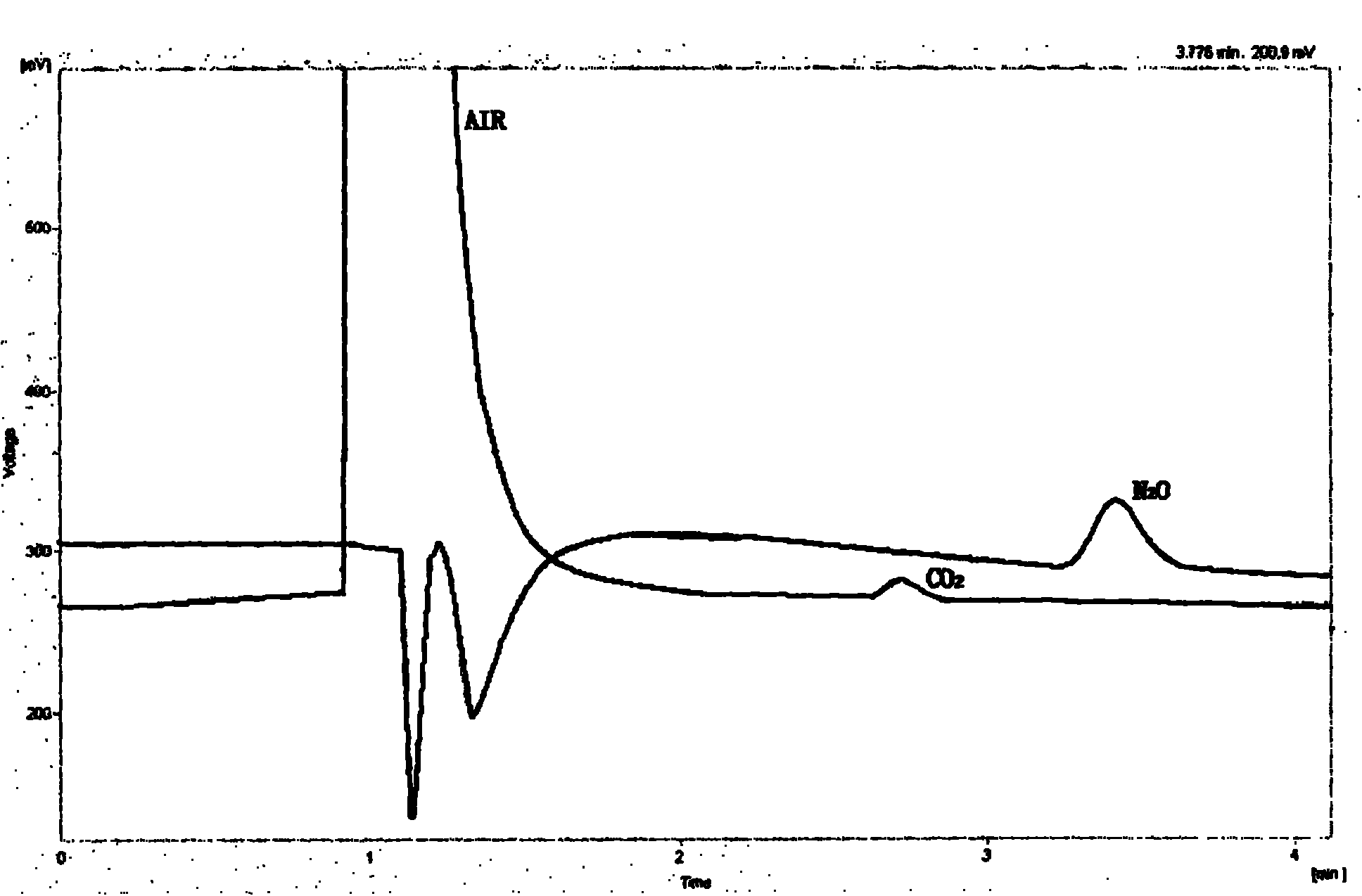

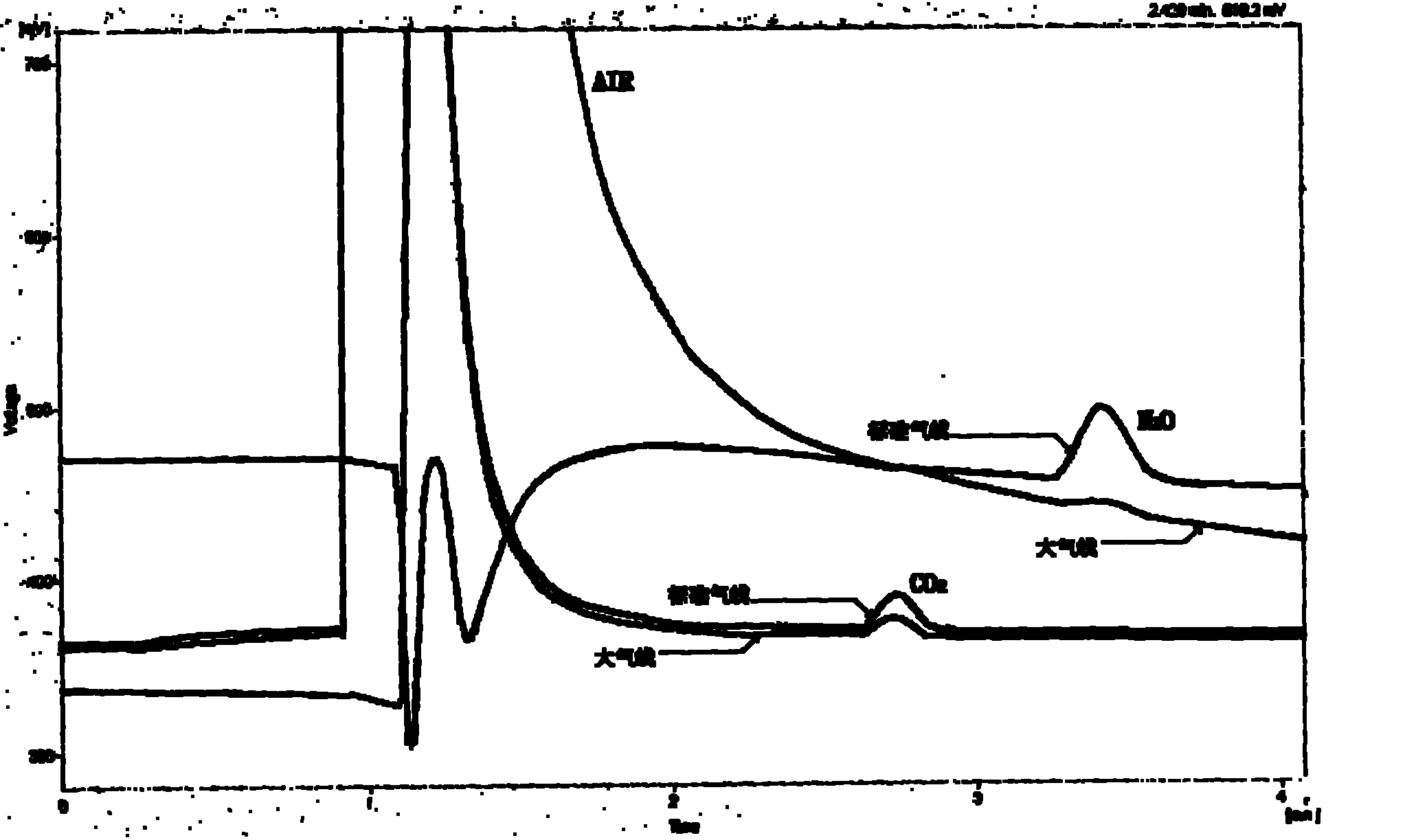

Method for analyzing nitrous oxide, methane and carbon dioxide in atmosphere by injecting sample once

InactiveCN102243219AReduce precision errorShort measuring cycleComponent separationChromatography columnMethane

The invention relates to a method for analyzing nitrous oxide, methane and carbon dioxide in atmosphere by injecting a sample once, comprising the following steps of: firstly, passing a carrier gas at a purity of 10-5% below through a purifier with 0.20-0.60 MPa of output pressure so that the purity of the purified carrier gas is 10-6% or 10-7% below; secondly, charging the purified carrier gas in a chromatographic column with a to-be-tested sample in a gas chromatograph, after an adsorption-desorption function, orderly conveying the nitrous oxide, methane and carbon dioxide in the to-be-tested sample into a thermal conductivity cell detector, an electron capture detector and a hydrogen flame ionization, then detecting at 90-350 DEG C; and finally, simultaneously inputting the data obtained by the thermal conductivity cell detector, the electron capture detector and the hydrogen flame ionization into the chromatographic working station of the gas chromatograph to obtain an analysis result chromatogram. The method in the invention is simple, easy to operate, and capable of efficiently decreasing data precision error and shorting sample measurement period.

Owner:LANZHOU CENT FOR OIL & GAS RESOURCES INST OF GEOLOGY & GEOPHYSICS CAS

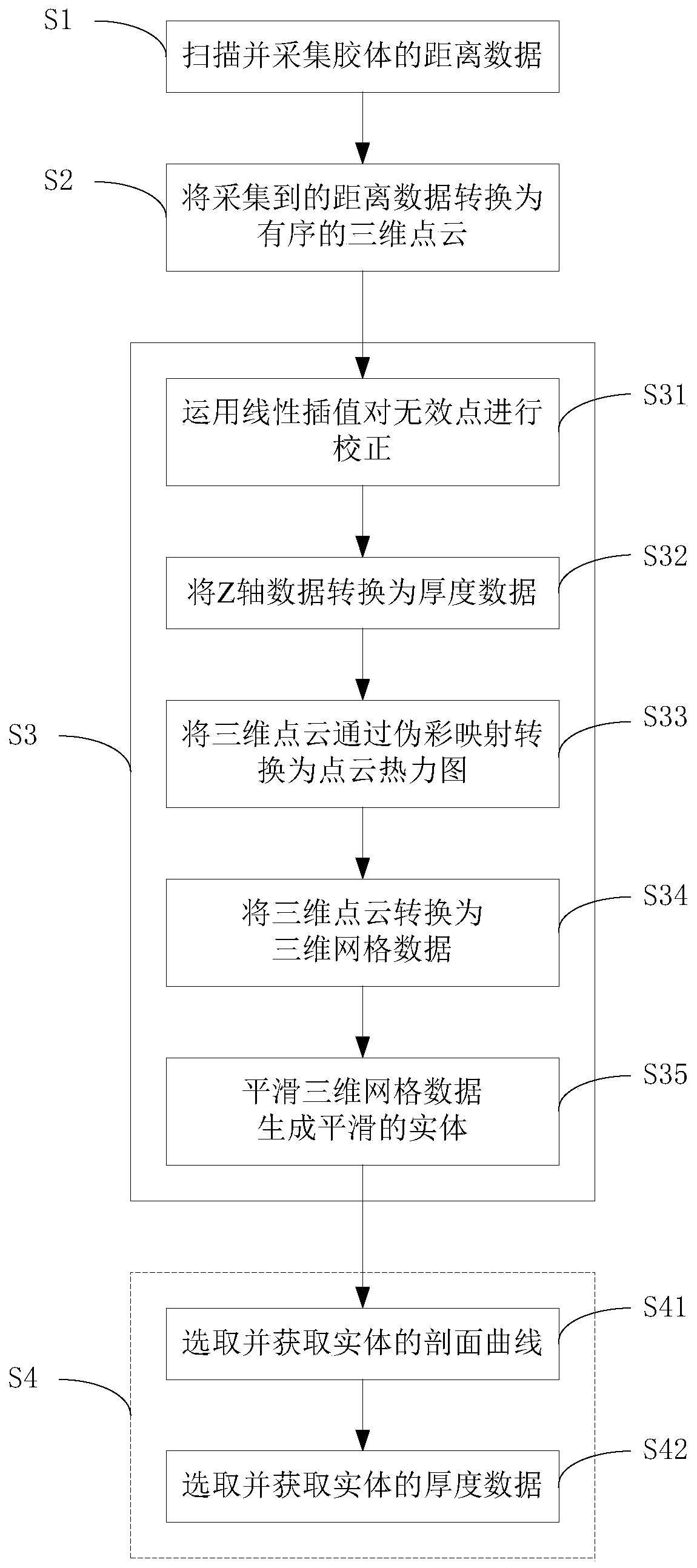

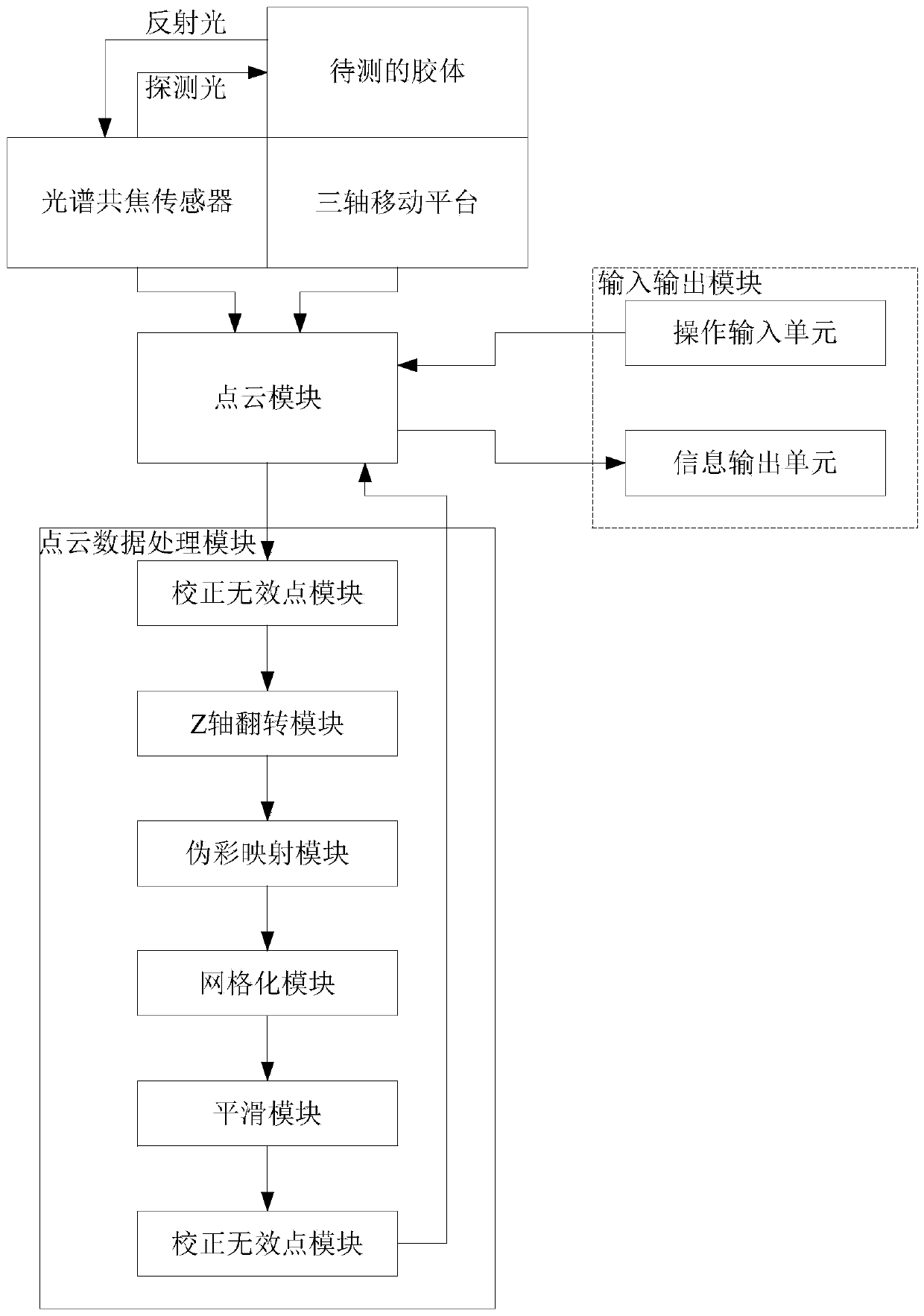

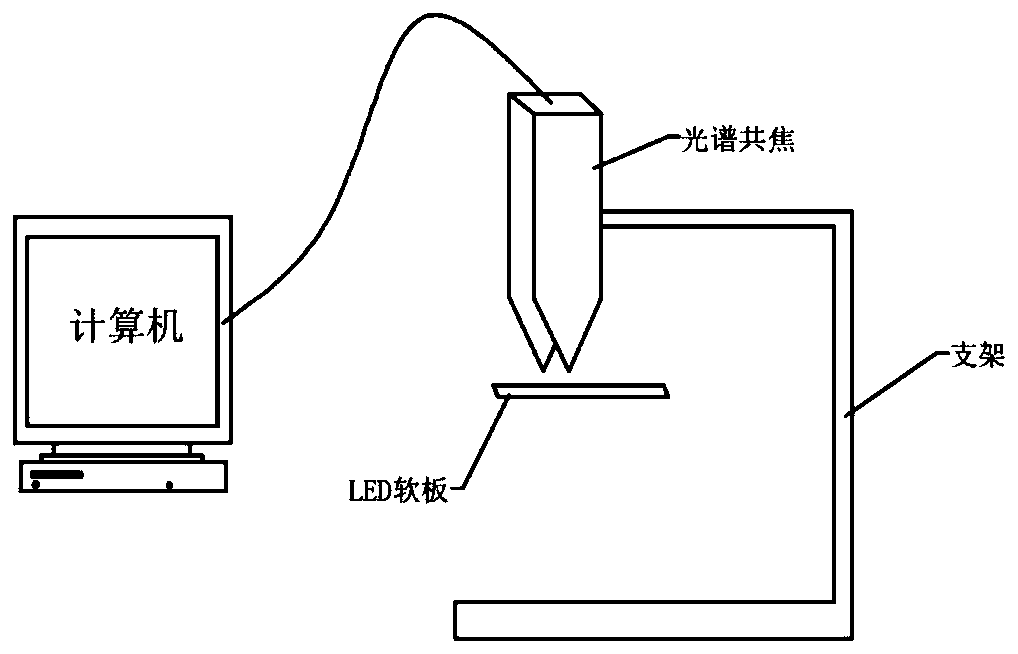

Colloid three-dimensional reconstruction and thickness measurement method and system based on spectral confocal

The invention provides a colloid three-dimensional reconstruction and thickness measurement method and system based on spectral confocal. The system comprises a spectral confocal sensor, a three-axismobile platform, a point cloud module, a point cloud data processing module and an input and output module. Nano-scale distance data of the glue coating colloid of awidget is acquired through spectralconfocal sensorin combination withthethree-axis mobile platform, and ordered three-dimensional point cloud data is formed through combination; invalid point correction, Z-axis overturning, pseudo-color mapping, gridding and smoothing are carried out on point cloud data, three-dimensional point cloud is updated, the distance between the focus of detected light and the focus of purple light is calculated, the function of visually measuring the thickness of needed widget colloid in real time is achieved, and through test verification, the measurement precision reaches the nanoscale.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

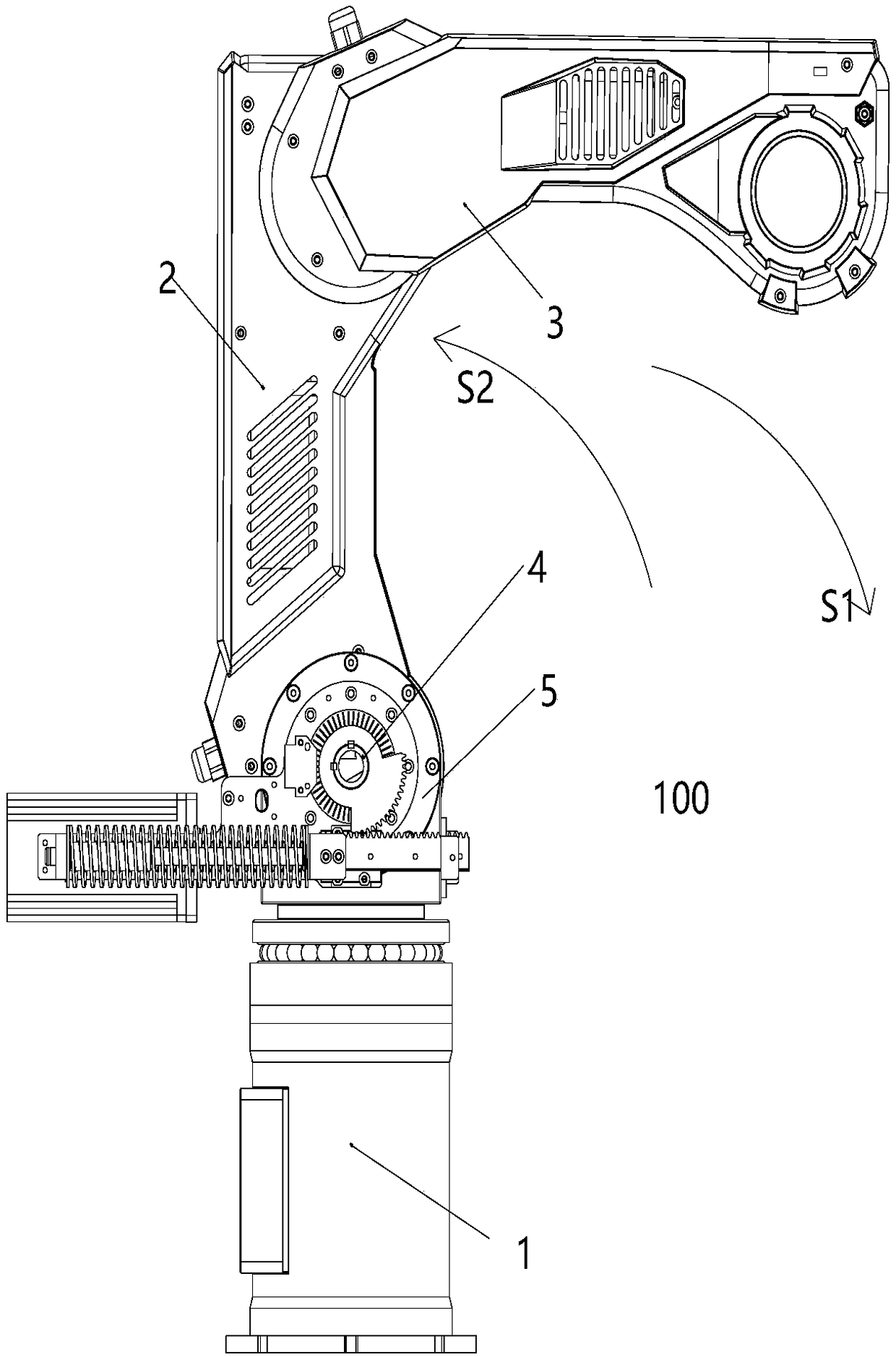

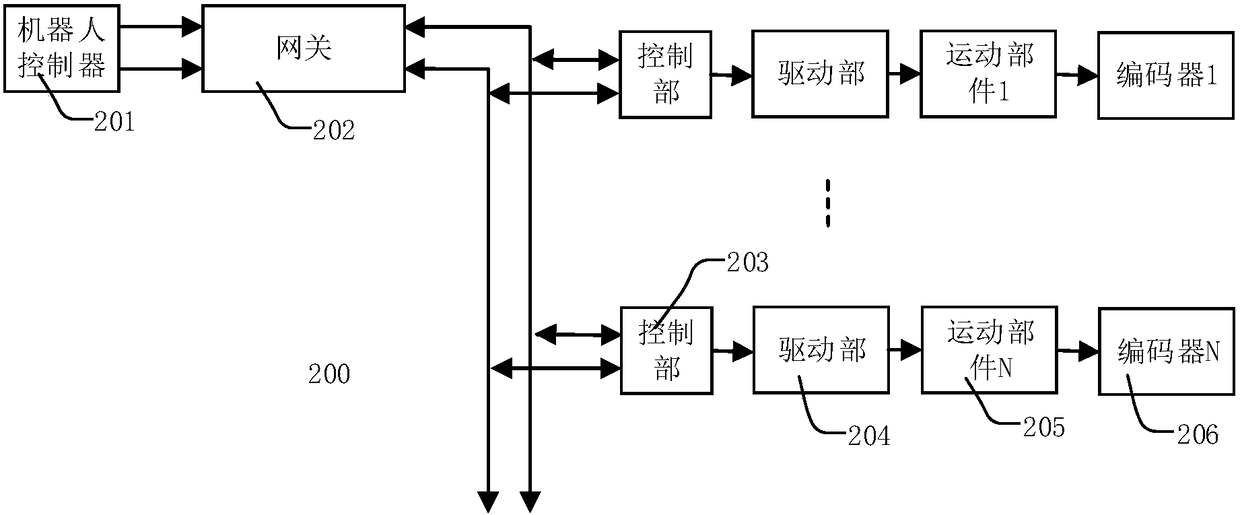

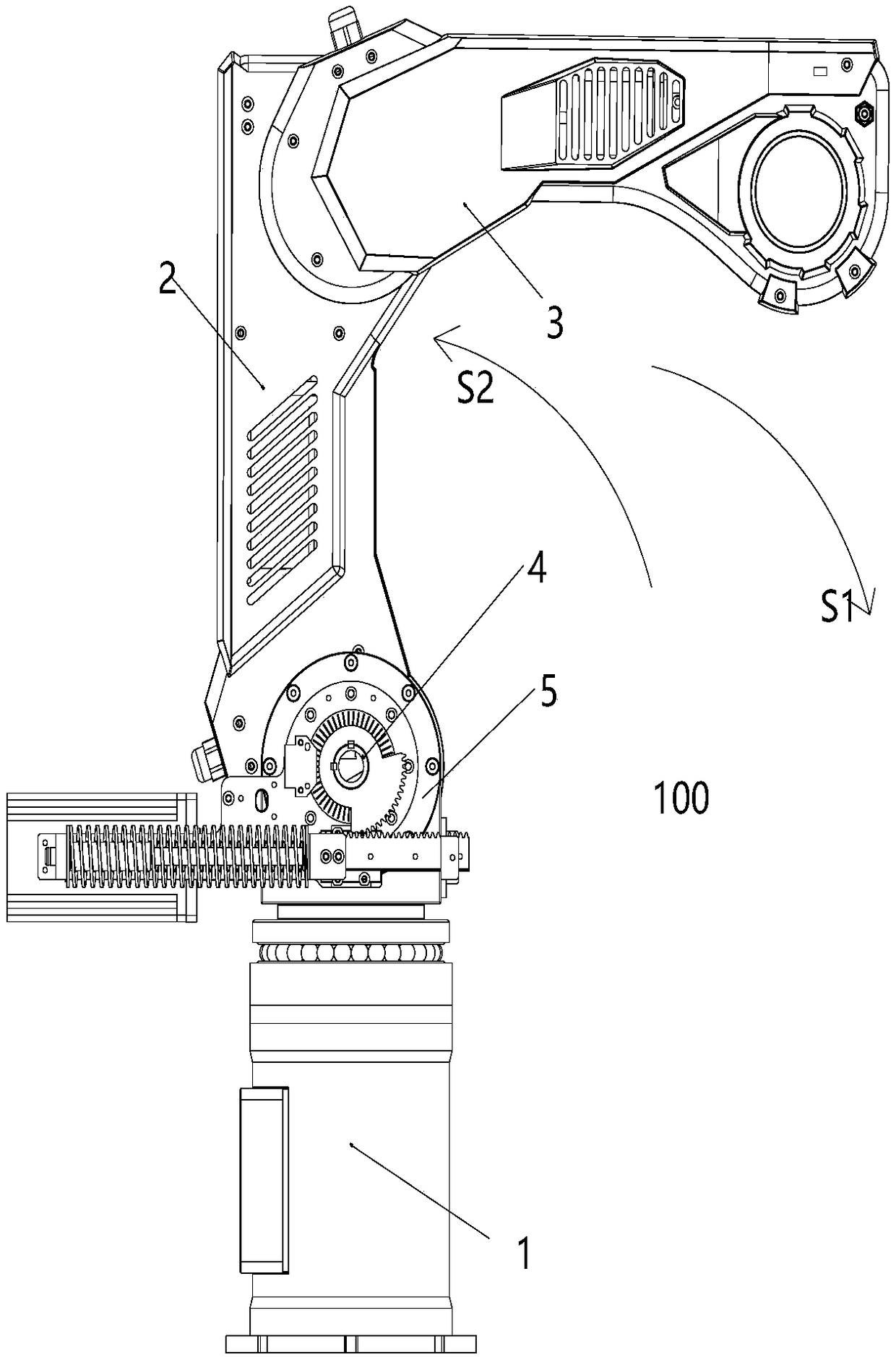

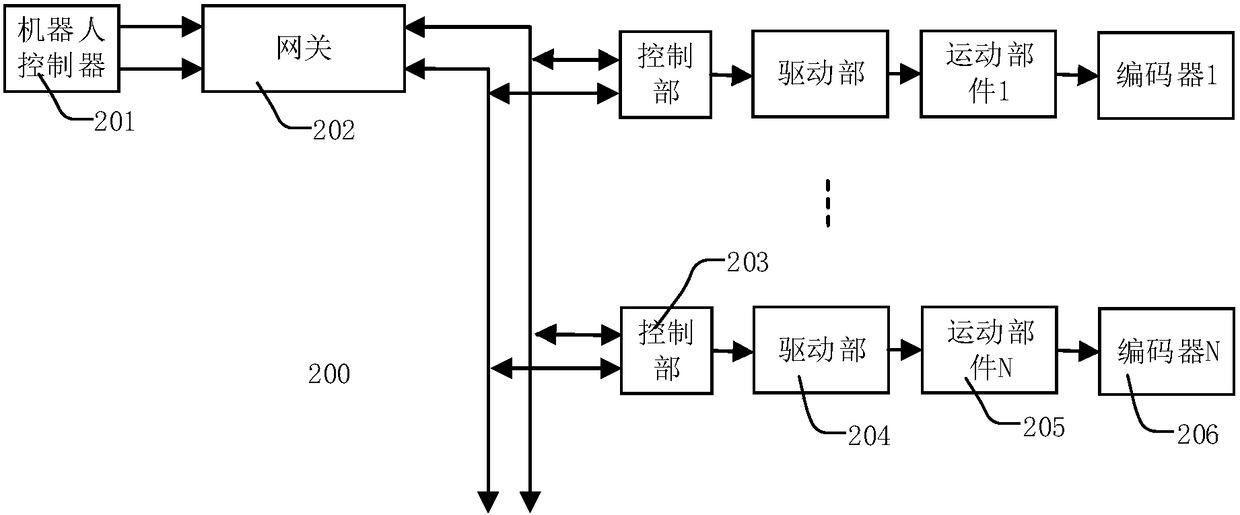

Robot with feedback control function, motion control system, method and medium

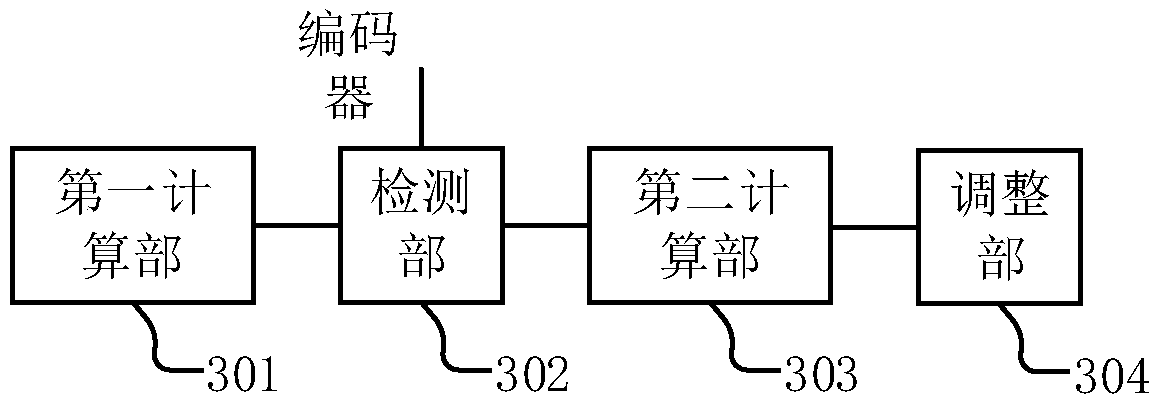

ActiveCN108453733ARealize real-time compensationHigh movement precisionProgramme-controlled manipulatorImage resolutionControl system

The invention relates to a robot with a feedback control function. The robot with the feedback control function comprises a control part, a drive part, a motion part and an encoder. The control part comprises a first calculation part used for calculating according to motion parameters and a resolution ratio of the encoder to obtain a theoretical microstep numerical value between two lines of the encoder, and a theoretical period value corresponding to each theoretical microstep numerical value; a detection part used for receiving pulse data of the encoder in real time; a second calculating part used for calculating according to the theoretical microstep numerical value between the two lines of the encoder, the theoretical period value corresponding to each theoretical microstep numerical value, and an actual microstep numerical value between the current two lines of the encoder to obtain a time difference value between a theoretical time value and an actual time value between the current two lines of the encoder; and an adjustment part used for calculating according to the time difference value to obtain an actual period value corresponding to a theoretical microstep numerical value between last two lines of the encoder, wherein the actual period value is used as a period value after the drive part is updated. The robot provided by the invention is high in positioning accuracyand small in error.

Owner:MEGAROBO TECH CO LTD

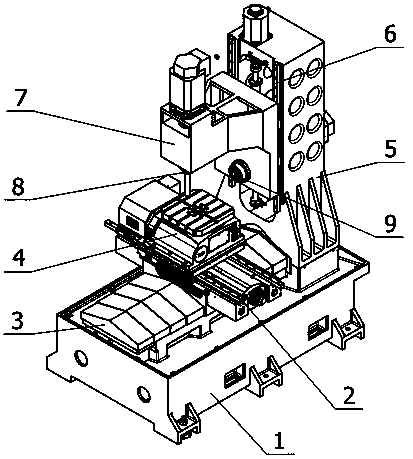

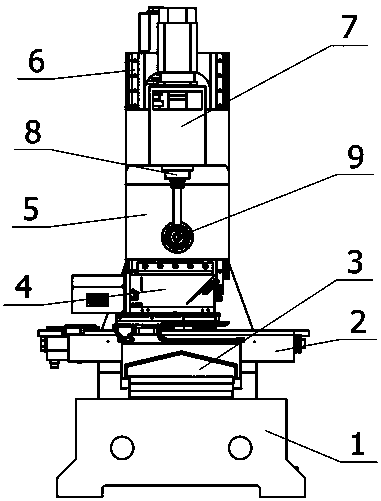

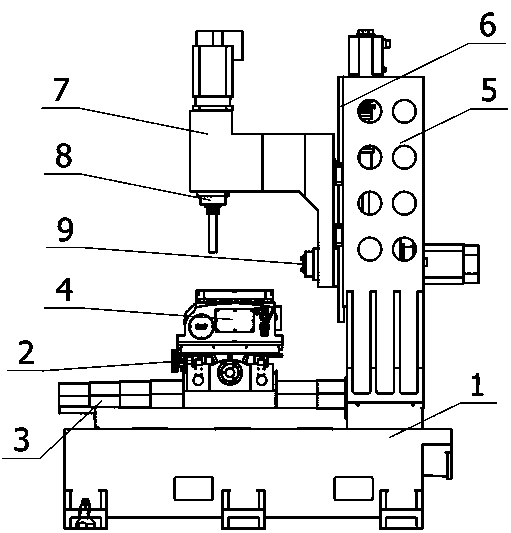

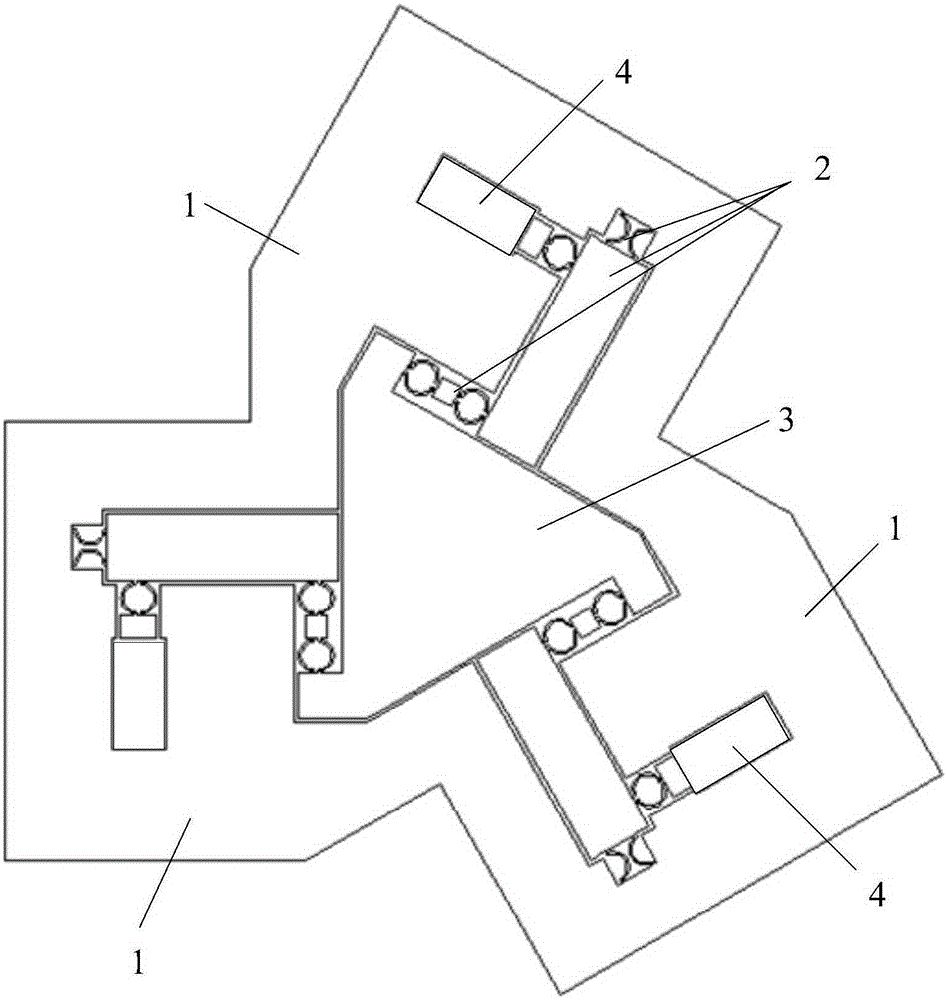

Multi-surface integrated processing center

PendingCN108274248AReduce processing timeReduce precision errorFeeding apparatusLarge fixed membersEngineeringWorkload

The invention discloses a multi-surface integrated processing center. The multi-surface integrated processing center is characterized by only comprising a stand column, wherein a set of Z-axis motionmechanisms is utilized to drive a main shaft mounting frame; a vertical type main shaft and a horizontal type main shaft are simultaneously integrated on a main shaft mounting table; the vertical typemain shaft is mounted on a horizontal extending part of the main shaft mounting frame; the horizontal type main shaft is mounted on a vertical extending part; or the horizontal type main shaft and the vertical type main shaft are integrated on the horizontal extending part. A workpiece is mounted on a workbench which rotates by 360 degrees, and the rotary workbench is additionally arranged on a rail of an axis X and a rail of an axis Y. The multi-surface integrated processing center can complete processing processes for the top surface and four side surfaces of the workpiece once, does not need to re-clamp the workpiece halfway, reduces replacement time, and solves the problem that precision is reduced as the workpiece is clamped by many times. According to the multi-surface integrated processing center disclosed by the invention, one stand column and one set of Z-axis lifting mechanisms are adopted, so that equipment cost is reduced, programming simplification is facilitated, and programming workload of an operator is reduced.

Owner:宁波江北百吉机械有限公司

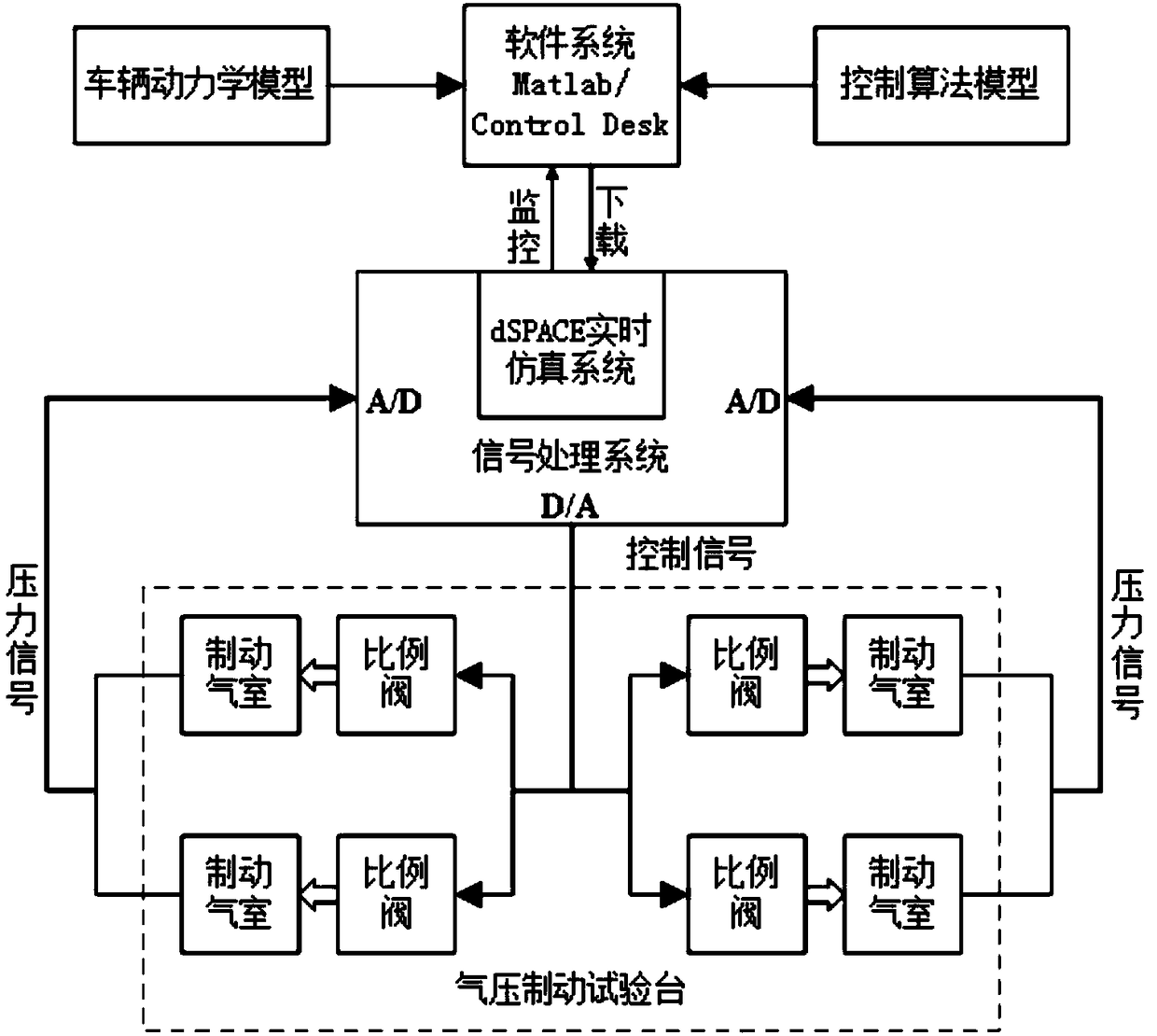

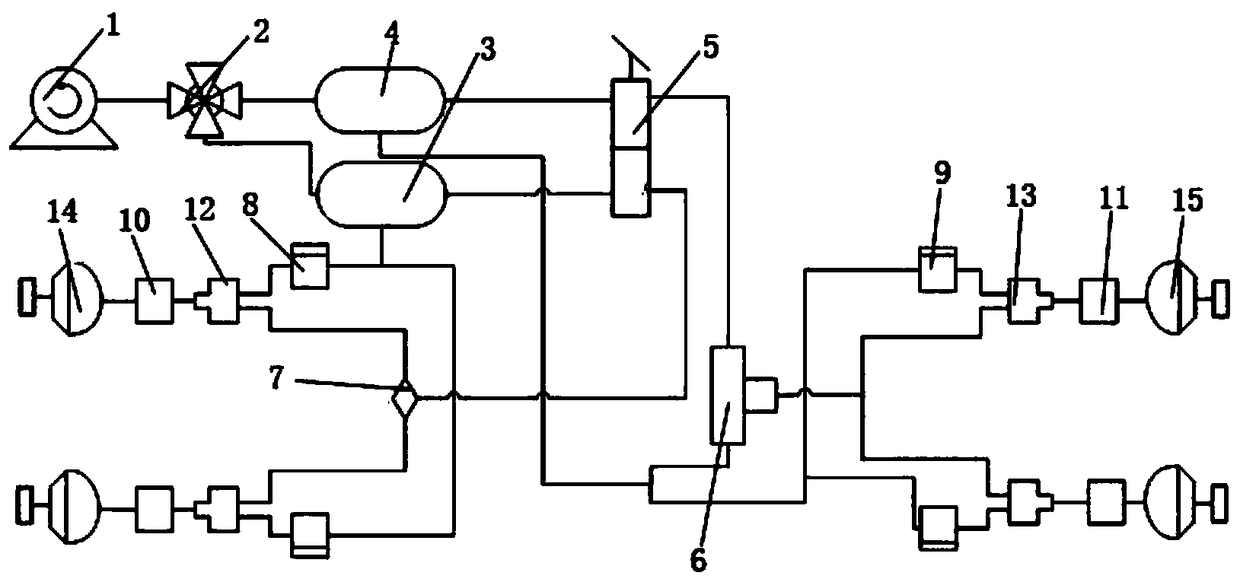

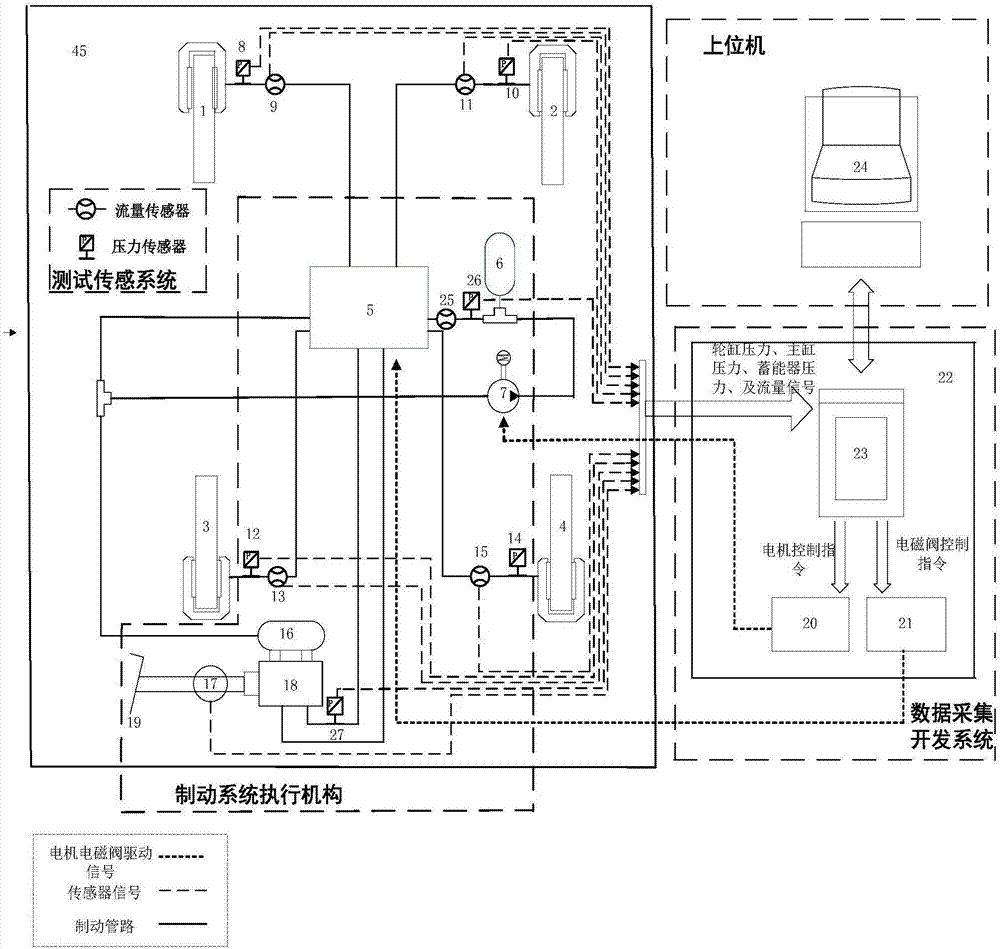

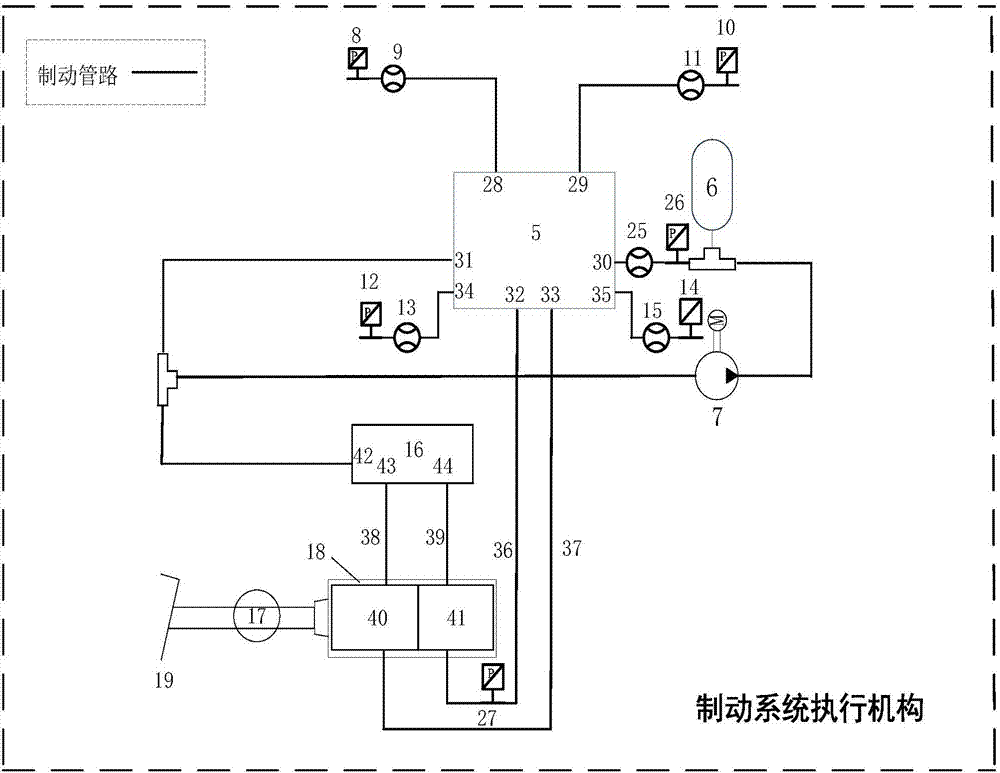

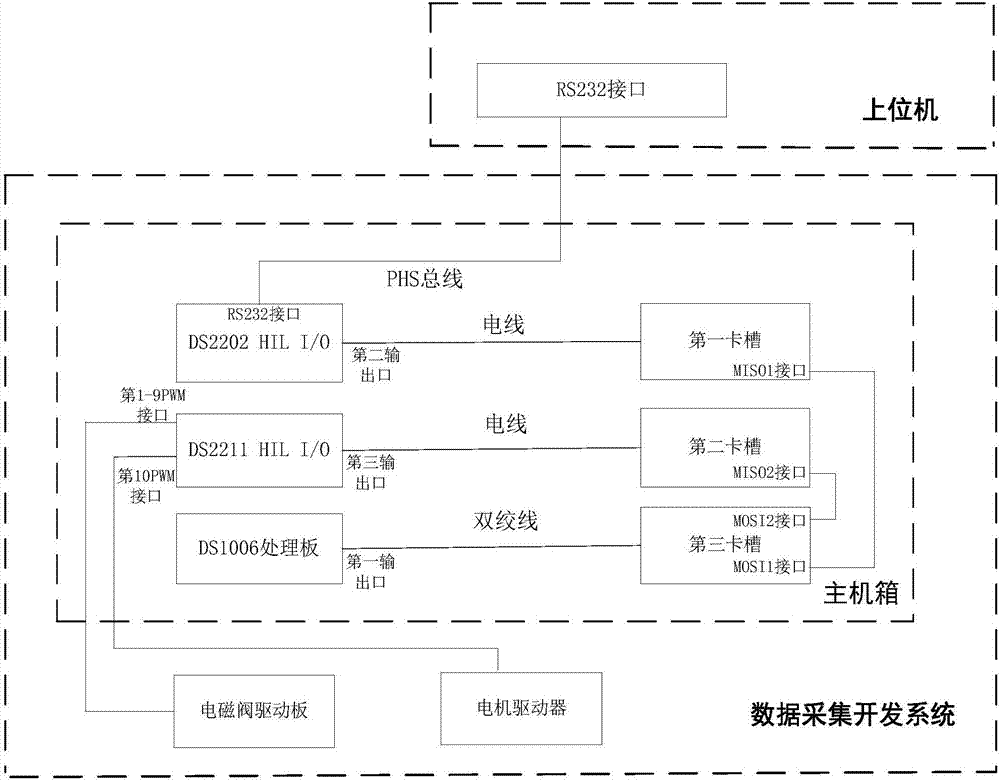

Commercial vehicle air pressure braking performance hardware in-loop testing system and testing method

ActiveCN109084991AAir brake performance truly reflectsImprove real-time performanceVehicle testingReal-time simulationSoftware system

The invention provides a commercial vehicle air pressure braking performance hardware in-loop testing system and a testing method. The commercial vehicle air pressure braking performance hardware in-loop testing system comprises an air pressure braking system testing platform, a real-time simulation platform, a software system and a signal processing system. The real-time simulation platform conducts digital communication with the air pressure braking system testing platform by a sensor and the signal processing system. The software system conducts digital communication with the real-time simulation platform with a data cable as a medium and based on an upper computer, and therefore air pressure braking performance hardware in-loop testing is achieved. The problem of an existing testing system of insufficient universality in commercial vehicle air pressure braking performance testing is solved.

Owner:WUHAN UNIV OF TECH

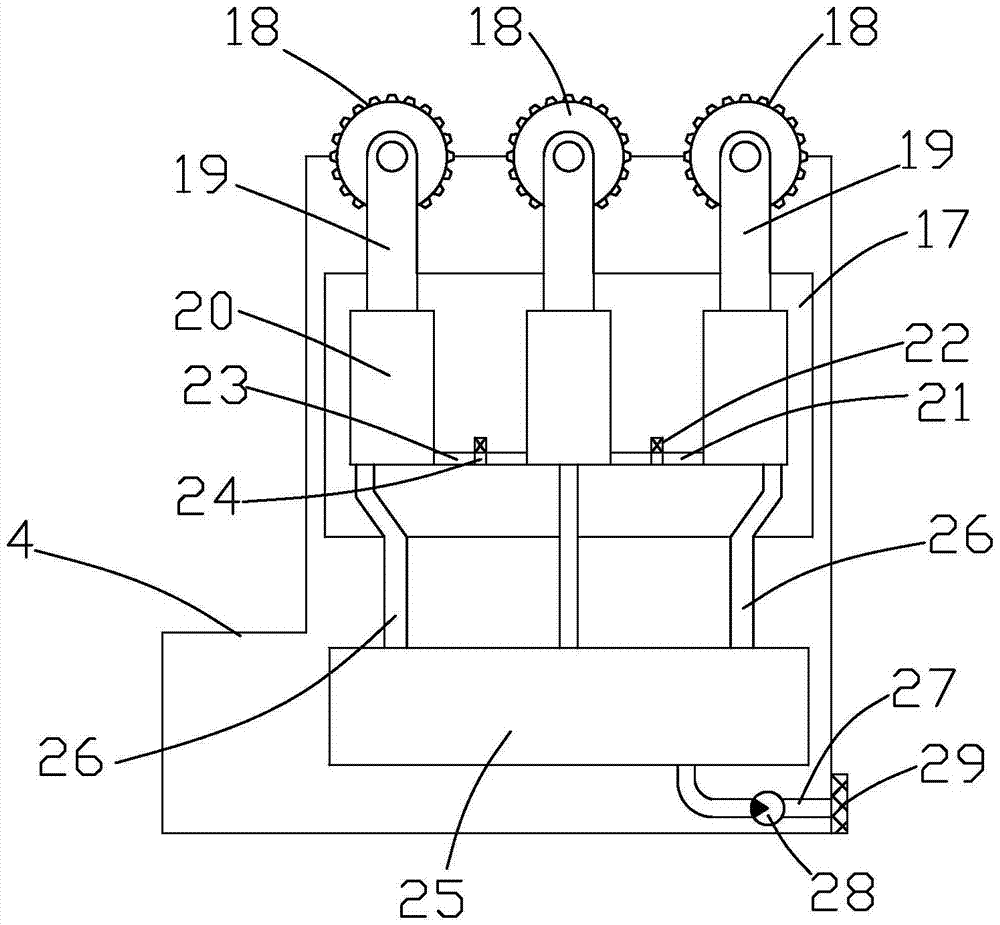

Multi-piece automatic blanking machine

ActiveCN102310227AHigh degree of automationEasy to operateMetal sawing devicesAgricultural engineeringMechanical equipment

The invention relates to the field of mechanical equipment for carrying out multi-piece sawing blanking on magnesium alloy sectional materials, in particular to a multi-piece automatic blanking machine. The multi-piece automatic blanking machine comprises a rack, a high-speed motor, a multi-station saw bit mechanism, a speed reducing motor, a main shaft, a first cam mechanism, a second cam mechanism, a multi-station metal sectional material fixture and an intermission mechanism, wherein the high-speed motor and the speed reducing motor are fixed on the rack, the multi-station saw bit mechanism is connected with the high-speed motor through a transmission belt, the multi-station saw bit mechanism comprises a multi-station saw bit shaft and at least two multi-station saw bits, the multi-station saw bits are arranged on the multi-station saw bit shaft, the main shaft is connected with the speed reducing motor through the transmission belt, the first cam mechanism is connected with the main shaft through a gear, the second cam mechanism is arranged on the main shaft and is connected with the multi-station sectional material fixture, and the intermission mechanism is arranged on the main shaft. The invention provides the multi-piece automatic blanking machine which has a simple structure, high efficiency and high precision and is convenient to operate.

Owner:嘉兴中科亚美合金技术有限责任公司

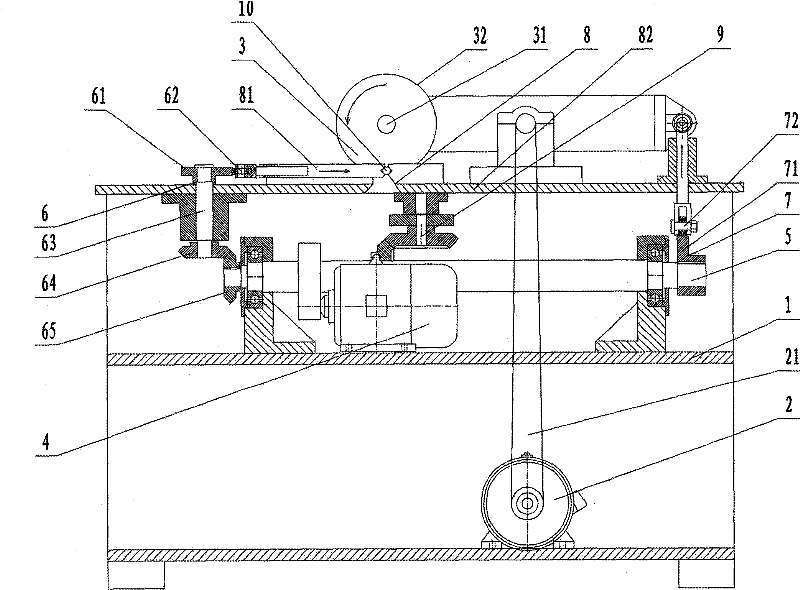

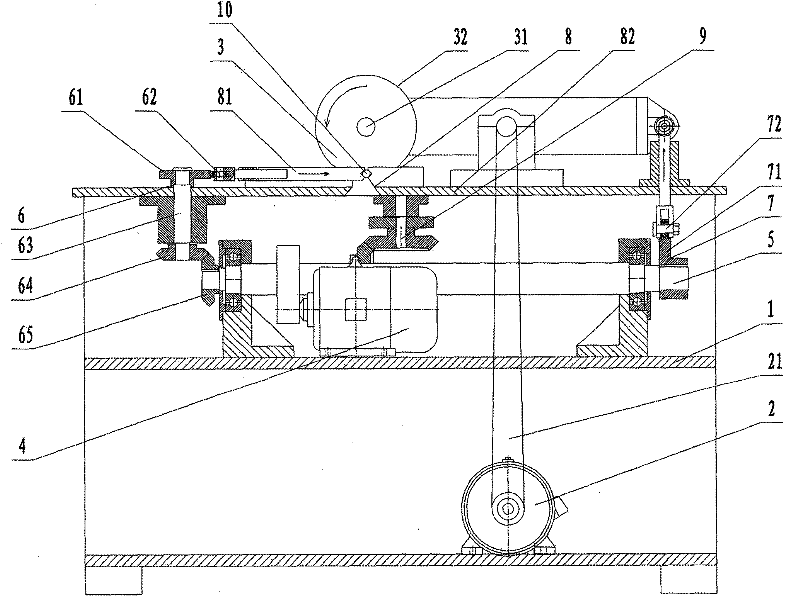

Vehicle line control hydraulic brake system hardware-in-the-loop test bed

ActiveCN106969920AReduce R&D costsReduce labor costsVehicle testingAutomotive engineeringPressure buildup

The invention discloses a vehicle line control hydraulic brake system hardware-in-the-loop test bed in order to solve the problem that with respect to an existing test bed, the detection precision is poor, the rapid pressure-buildup speed is too low and the steady-state error is too large. The vehicle line control hydraulic brake system hardware-in-the-loop test bed comprises a real-time platform and a line control hydraulic brake system, the real-time platform comprises a host computer and a data acquisition and exploitation system, and the host computer is in bus connection with the data acquisition and exploitation system; and the line control hydraulic brake system comprises a test sensing system, an experiment table basal body and a brake system execution mechanism. The experiment table basal body is installed on the foundation through a support platform, a left front-wheel brake, a right front-wheel brake, a left rear-wheel brake and a right rear-wheel brake of the experiment table basal body are installed on the support platform, and the test sensing system is connected with the four wheel brakes through brake hard tubes; the test sensing system is connected with the data acquisition and exploitation system through a wire; and the brake system execution mechanism is connected with the test sensing system through a brake hard tube, and the brake system execution mechanism is connected with the data acquisition and exploitation system through a wire.

Owner:JILIN UNIV

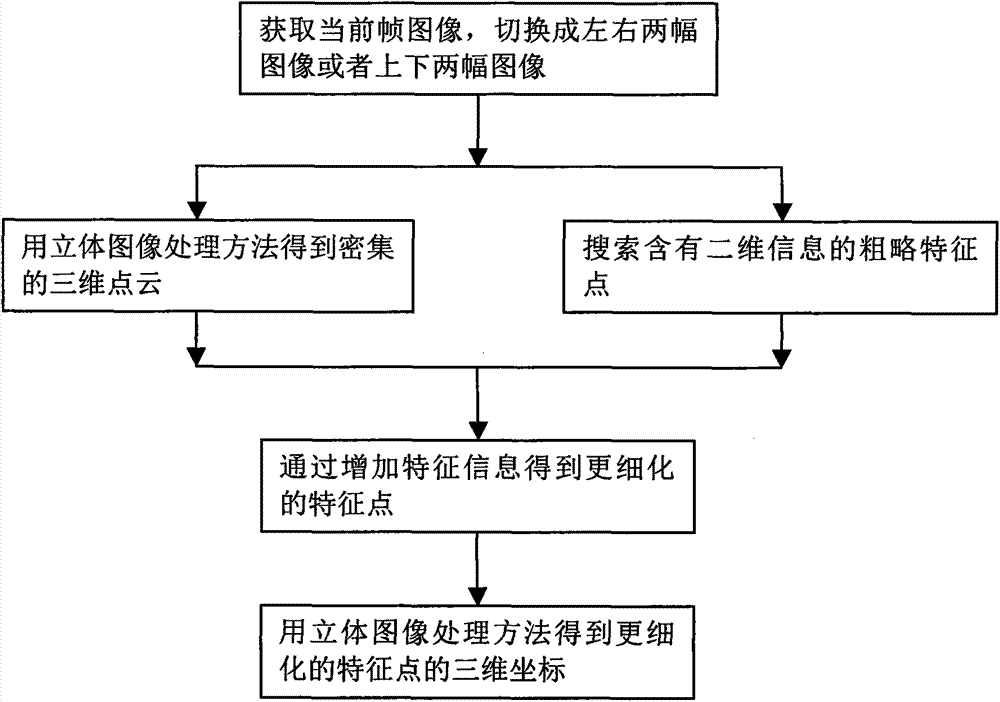

Three-dimensional imaging method

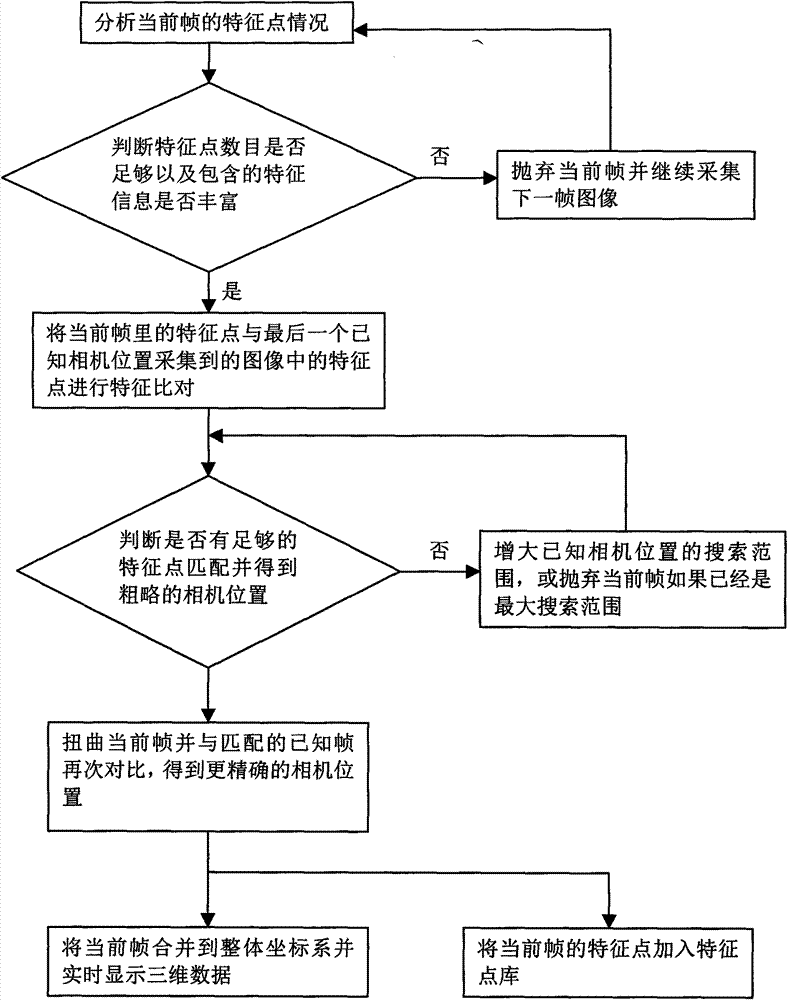

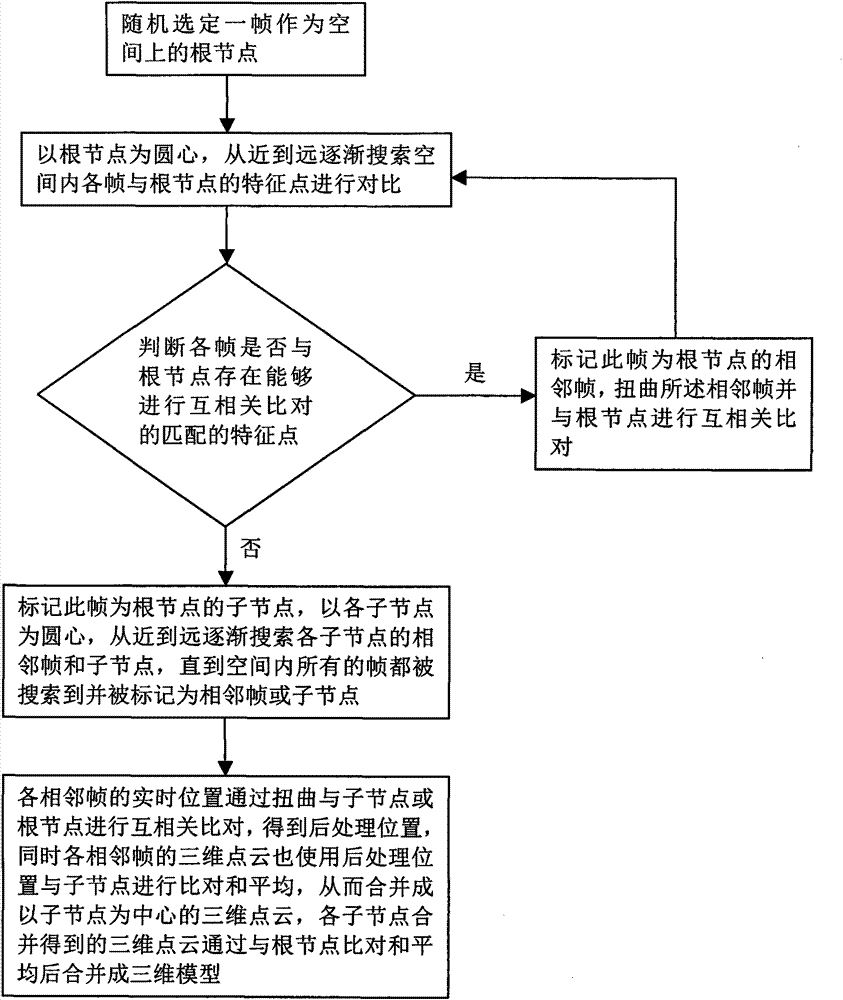

ActiveCN104517280AHigh precisionReduce precision errorImage analysis3D modellingThree dimensional modelThree dimensional data

The invention relates to a three-dimensional imaging method including real-time processing and post-processing. In the real-time processing, two-dimensional images are quickly processed in a computer when a camera moves for three-dimensional scanning, and the position of the camera and a three-dimensional model scanned are displayed in real time; in the post-processing, data acquired in the real-time processing are secondarily processed to obtain reconstructed three-dimensional data. The three-dimensional imaging method has the advantages that the relative position of the camera held by hand for scanning can be accurately measured, large precision errors of final three-dimensional images caused by stacking of multiple three-dimensional point cloud groups are greatly decreased, and thus, accuracy of the three-dimensional imaging is improved.

Owner:GUANGDONG LAUNCA MEDICAL DEVICE TECH

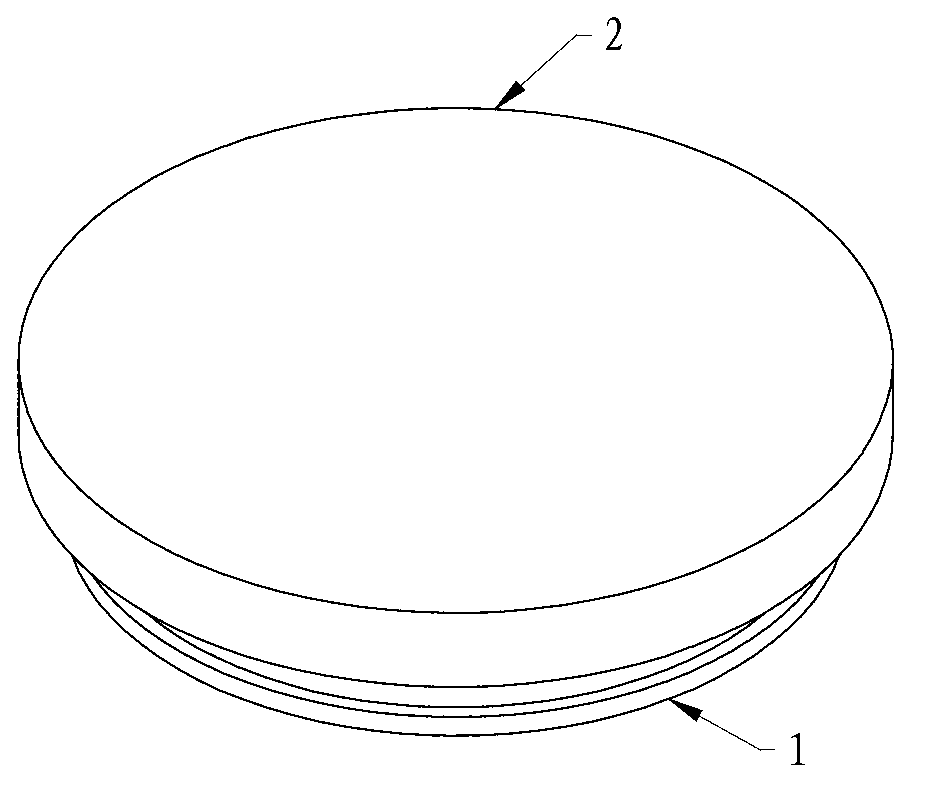

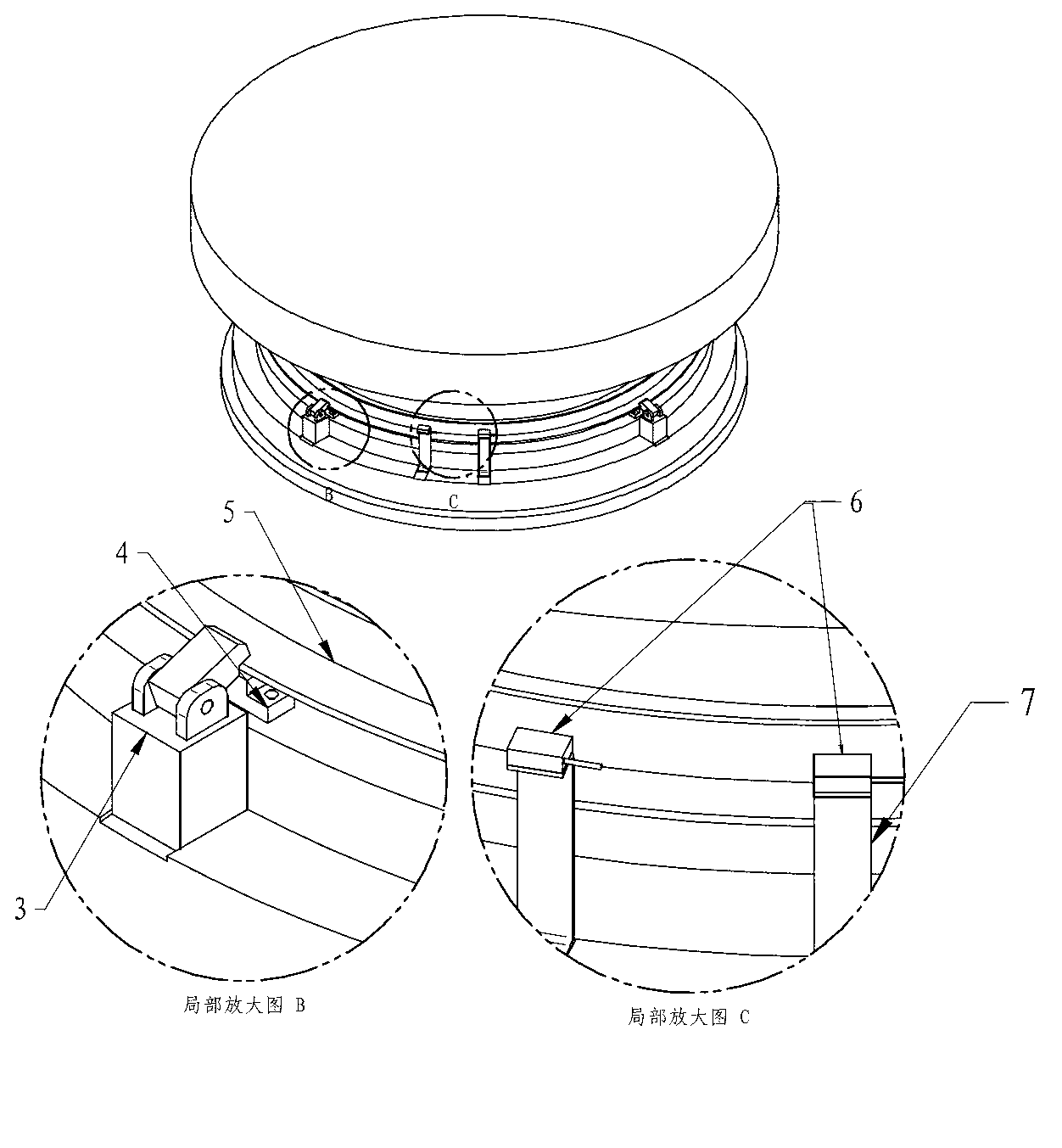

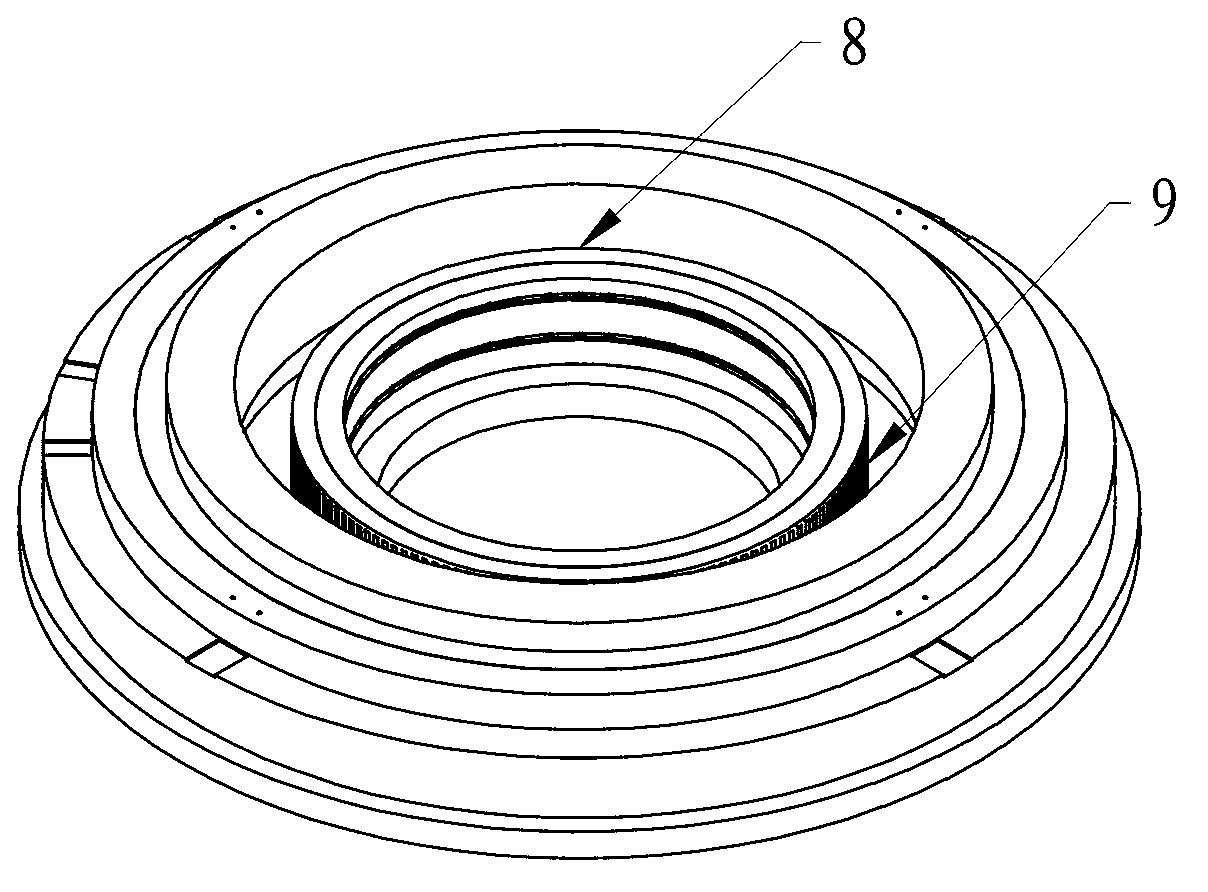

Large-moment direct-drive plane rotary platform device

InactiveCN102794755AEliminate Symptoms of Low AccuracyReduce precision errorWork benchesHydraulic cylinderWorking environment

The invention belongs to the technical field of an operation platform and relates to a large-moment direct-drive plane rotary platform device. A base, a core shaft, a coil winding, a hydraulic cylinder, a hydraulic seat, a reading head seat and a reading head are fixed through bolts to integrally form a stator; a rotor is formed by a tabletop, a hydraulic sheet, a magnet yoke and a magnetic railing ruler; the stator is coupled with the rotor through a bearing and is fixed in an inner ring of the bearing by a bolt; the rotor is fixed on an outer ring of the bearing by a bolt; glue is filled into the coiling winding to be encapsulated, and magnetic steel is stuck on the magnet yoke by glue; stamp gum is coated on the back face of the magnetic railing ruler, and magnetic railing rule is directly adhered to the tabletop; the hydraulic cylinder and the hydraulic seat are sequentially fixed on the base; the hydraulic sheet is fixed between the hydraulic seat and a pressing head of the hydraulic cylinder of the tabletop; the reading head and the reading head seat are sequentially fixed on the base; the coil winding is uniformly wound and fixed on the core shaft; and the magnetic railing ruler is fixed on the side face of the tabletop. The large-moment direct-drive plane rotary platform device disclosed by the invention has the advantages of simple structure, easiness in control, large moment, stability in rotation, high positioning precision, long service life and friendly working environment.

Owner:青岛同日电机有限公司

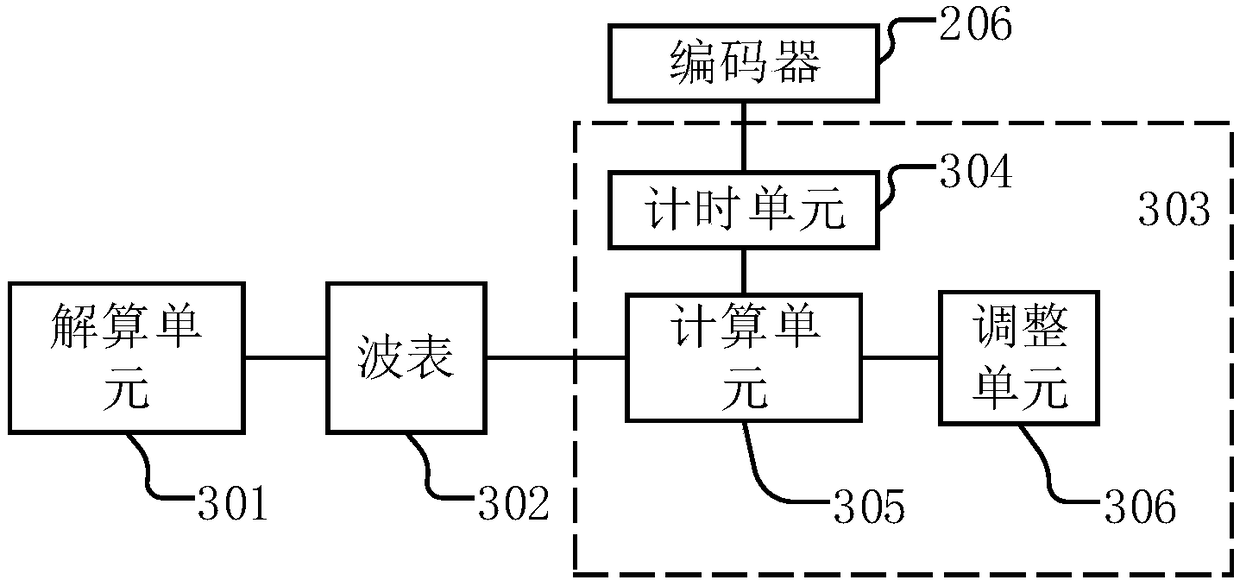

Robot and moving control part with precise control function, precise control method and medium

ActiveCN108481322AAchieve precise controlReduce precision errorProgramme-controlled manipulatorMovement controlControl function

The invention discloses a robot with the precise control function. The robot comprises a control part, a driving part, a moving part and an encoder; the control part comprises a resolving unit, a wavetable and a calculation adjusting unit; the resolving unit is used for resolving according to the motion parameters and the resolution of the encoder to obtain a set of wave table data and a theoretical micro-step value between two lines of the encoder, and the wave table data represents the theoretical time value between every two lines of the encoder; the wave table is used for storing the wavetable data; the calculation adjusting unit is used for calculating according to the wave table data between the current two lines of the encoder which is taken out from the wave table, the theoretical micro-step numerical value between the two lines of the encoder and the actual motion time between the current two lines which is detected by the encoder to obtain an actual period value corresponding to each micro step between the last two lines of the encoder, and the actual period value is used as an updated period value of the driving part. The robot does not need to be stopped, and then perform calculation and adjustment, so that the purpose of accurate control can be achieved, and the error is extremely small.

Owner:MEGAROBO TECH CO LTD

Gas chromatography for analyzing methane and nitrous oxide in air by one sample injection

InactiveCN102004133AReduce precision errorShort measuring cycleComponent separationHydrogenElectron capture detector

The invention relates to a gas chromatography for analyzing methane and nitrous oxide in air by one sample injection, which is characterized by comprising the following steps: enabling a carrier gas, of which the purity is lower than 10-5%, to pass through a purifier under the output pressure of 0.20-0.60 MPa, so that the purity of the purified carrier gas is lower than 10-6%; introducing the purified carrier gas into a chromatographic column of a gas chromatograph, in which a sample to be detected is placed, at the flow rate of 15-85 ml / min at the temperature of 15-40 DEG C, absorbing and desorbing at 20-90 DEG C, and after nitrous oxide and methane in the sample to be detected orderly enter an electron capture detector and a hydrogen flame ionization detector, carrying out detection at 110-350 DEG C; and finally, simultaneously inputting the data obtained by the electron capture detector and the hydrogen flame ionization detector into a chromatogram work station of the gas chromatograph, thereby obtaining the analytic result chromatogram. The invention is simple and easy to operate, can effectively lower the data accuracy error, and shortens the sample measurement period.

Owner:LANZHOU CENT FOR OIL & GAS RESOURCES INST OF GEOLOGY & GEOPHYSICS CAS

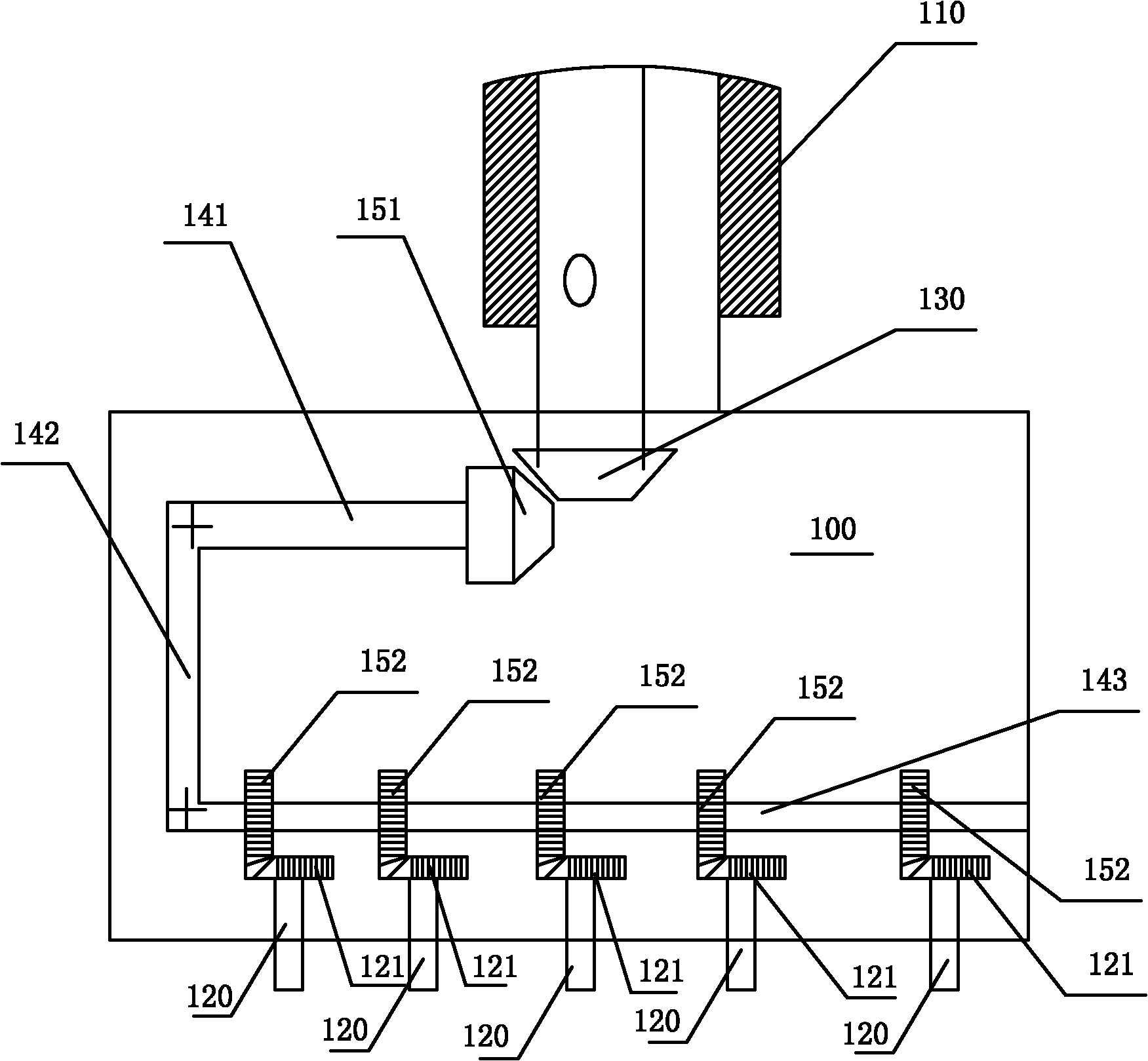

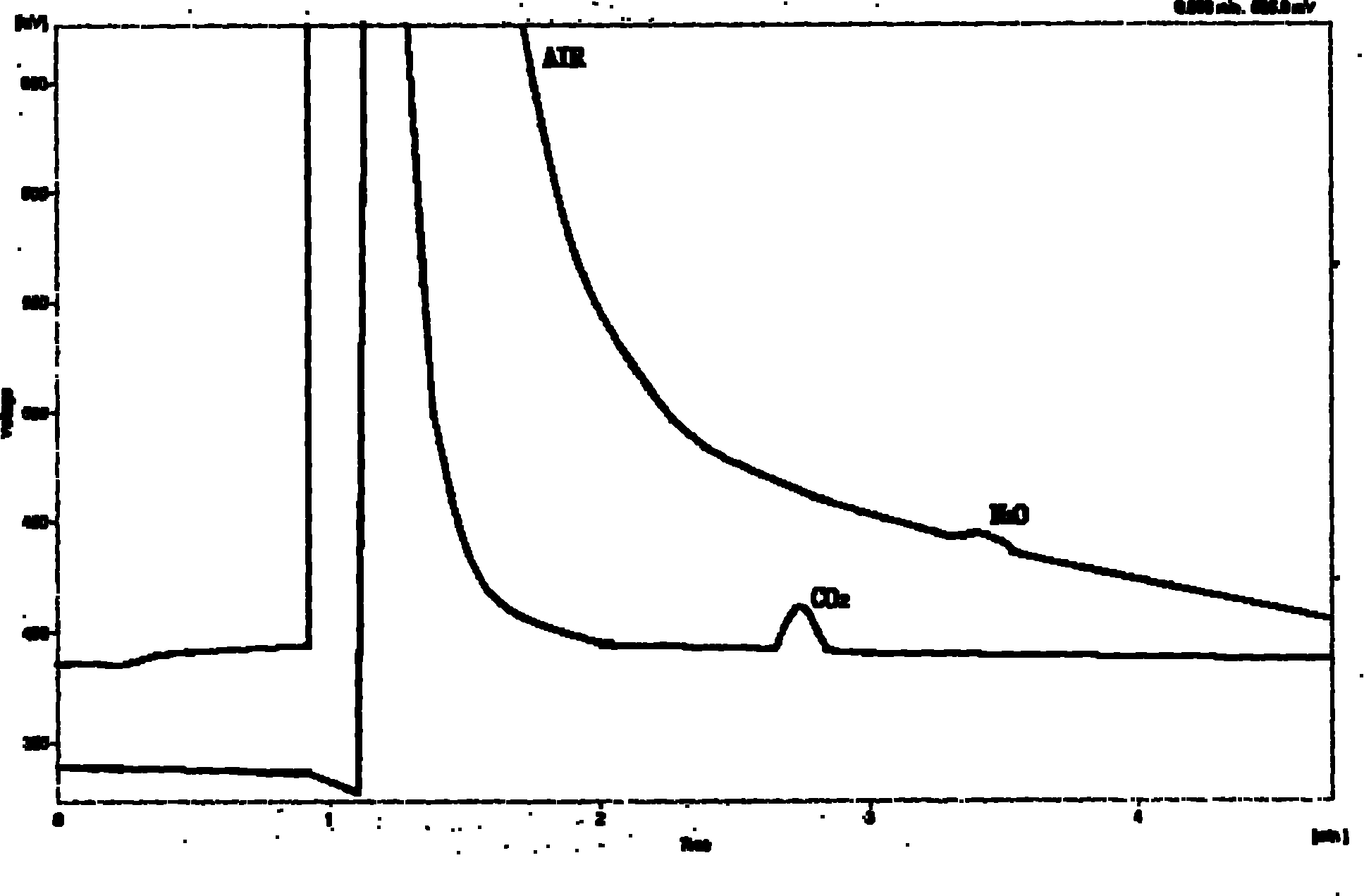

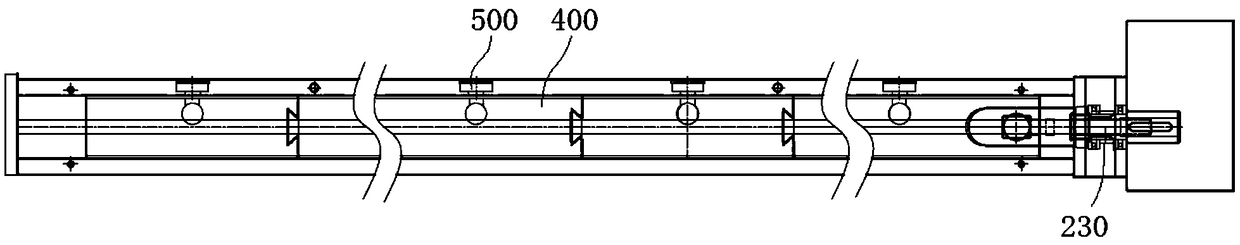

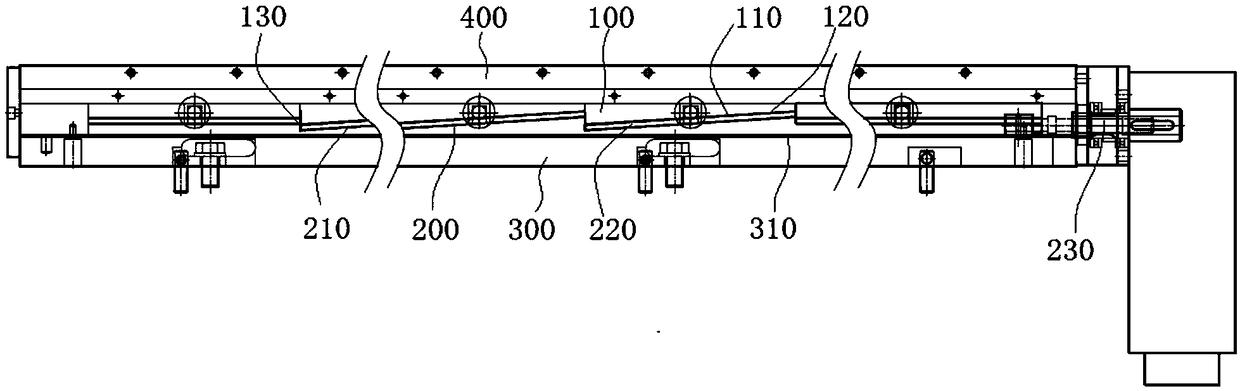

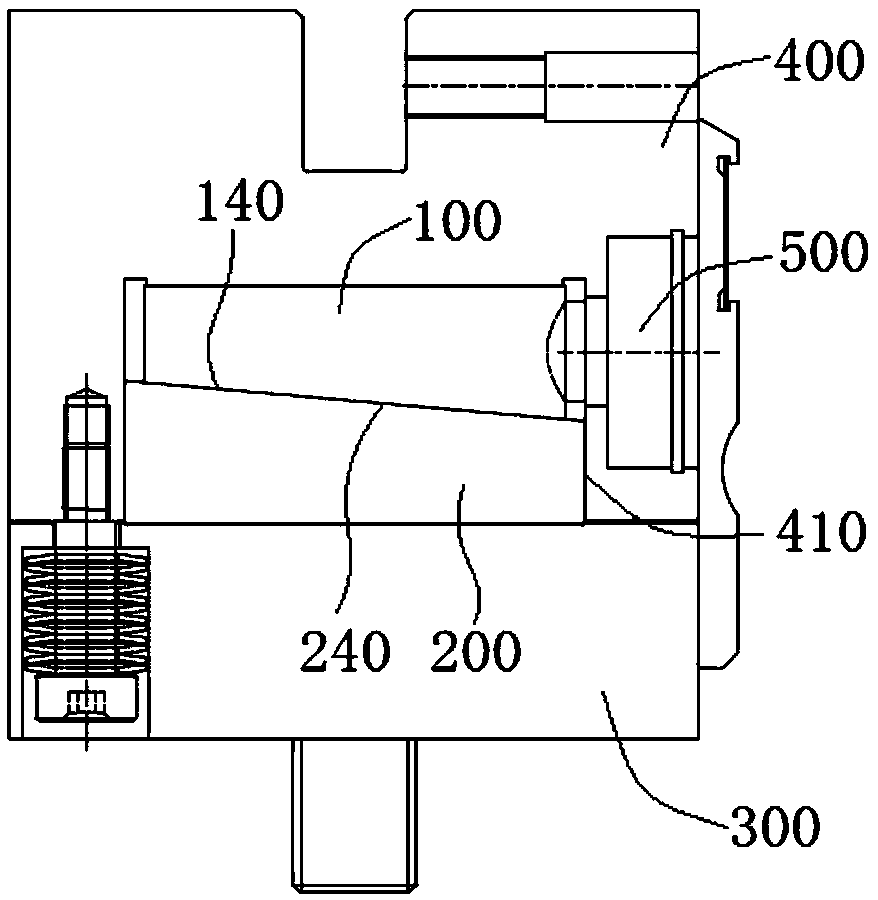

Group hole drilling system

ActiveCN102009199AReduce the number of mobile positioningIncrease productivityTransportation and packagingBoring/drilling machinesDrilling systemTwist drill

The invention provides a group hole drilling system. The system comprises drilling equipment and cutters; the drilling equipment is provided with a main shaft and a plurality of terminal output shafts in the vertical direction, and the terminal output shafts are arranged in one row and driven to link by the main shaft through a transmission device; the group hole drilling system is provided with a plurality of cutters, and the plurality of cutters are connected on different terminal output shafts respectively; and the cutter is provided with a twist drill cutter section, a hole expanding cutter section and a reaming cutter section. The system can process a row of straight-bottom and conical-upside holes processed by multiple processes and multiple cutters at one time, and has significance for processing products of large batch, high precision requirement and many hole positions; and the system can greatly reduce the moving and positioning frequency of workpieces and reduce the precision errors of products due to multiple clamping and multiple moving.

Owner:NINGBO ANCHOR FASTENERS INDAL

Method for analyzing nitrous oxide and carbon dioxide in atmosphere by adopting gas chromatography through one sampling

InactiveCN101968466AReduce precision errorShort measuring cycleComponent separationElectron capture detectorDesorption

The invention relates to a method for analyzing nitrous oxide and carbon dioxide in atmosphere by adopting gas chromatography through one sampling, which is characterized by firstly purifying the carrier gas with purity being less than 10-3% in a purifier under the output pressure of 0.20-0.60MPa to ensure the purity of the purified carrier gas to be less than 10-4%; secondly pumping the purifiedcarrier gas into a chromatographic column with samples to be detected in a gas chromatograph under the conditions of flow of 15-75ml / min and temperature of 15-40 DEG C and the nitrous oxide and carbon dioxide in the samples to be detected entering into an electron capture detector and a thermal conductivity cell detector in sequence after adsorption and desorption at 25-50 DEG C to be detected at90-350 DEG C; and finally simultaneously inputting the data obtained by the electron capture detector and the thermal conductivity cell detector into a chromatographic working station in the gas chromatograph, thus obtaining the analysis result chromatogram. The method is simple and easy to operate and can effectively reduce the data accuracy error and shorten the sample measuring period.

Owner:LANZHOU CENT FOR OIL & GAS RESOURCES INST OF GEOLOGY & GEOPHYSICS CAS

Bending machine workbench precision bidirectional mechanical deflection compensation device and fabrication method thereof

PendingCN109332435AImprove bending accuracyEasy to control longitudinal deflection compensation curveShaping toolsOther manufacturing equipments/toolsEngineeringWorkbench

The invention discloses a bending machine workbench precision bidirectional mechanical deflection compensation device and a fabrication method for the bending machine workbench precision bidirectionalmechanical deflection compensation device and belongs to the technical field of bending machines. The bending machine workbench precision bidirectional mechanical deflection compensation device comprises an upper inclined plate, a lower inclined plate and an adjusting mechanism, wherein the upper surface of the lower inclined plate is provided with second longitudinal inclined planes matched withfirst longitudinal inclined planes, slopes of the first longitudinal inclined planes and the second longitudinal inclined planes both decrease from the middle to two ends, two adjacent second longitudinal inclined planes are connected through arc surfaces, and the radian of the arc surfaces increases from the middle to two ends; the lower surface of the upper inclined plate and the upper surfaceof the lower inclined plate are provided with a pair of a first horizontal inclined plane and a second horizontal inclined plane which are of the same slope in the horizontal direction; and the adjusting mechanism is used for changing the relative positions of the upper inclined plate and the lower inclined plate in the longitudinal direction and the horizontal direction. According to the bendingmachine workbench precision bidirectional mechanical deflection compensation device and the fabrication method for the bending machine workbench precision bidirectional mechanical deflection compensation device, by means of longitudinal moving of a lower inclined block with overall double slopes and horizontal moving of an upper inclined block with segmented double slopes, compensation of different deflection value for all points of a workbench is realized to meet the molding requirements for different-precision sheet metal parts.

Owner:ANHUI LIYUAN NUMERICAL CONTROL CUTTING TOOL & PATTERNS MFG

Combined calibration method for determining photographing scale after three-dimensional reconstruction

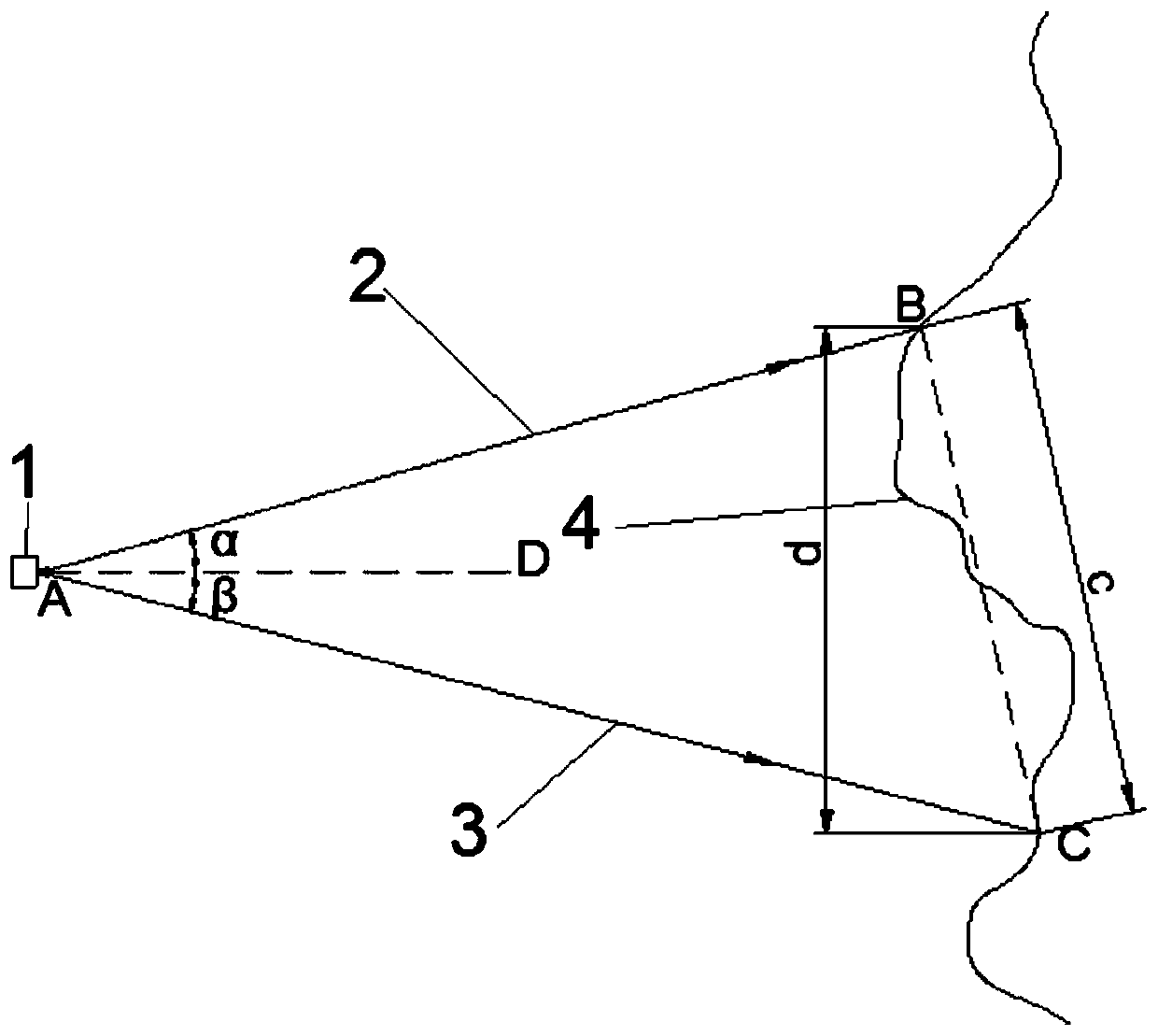

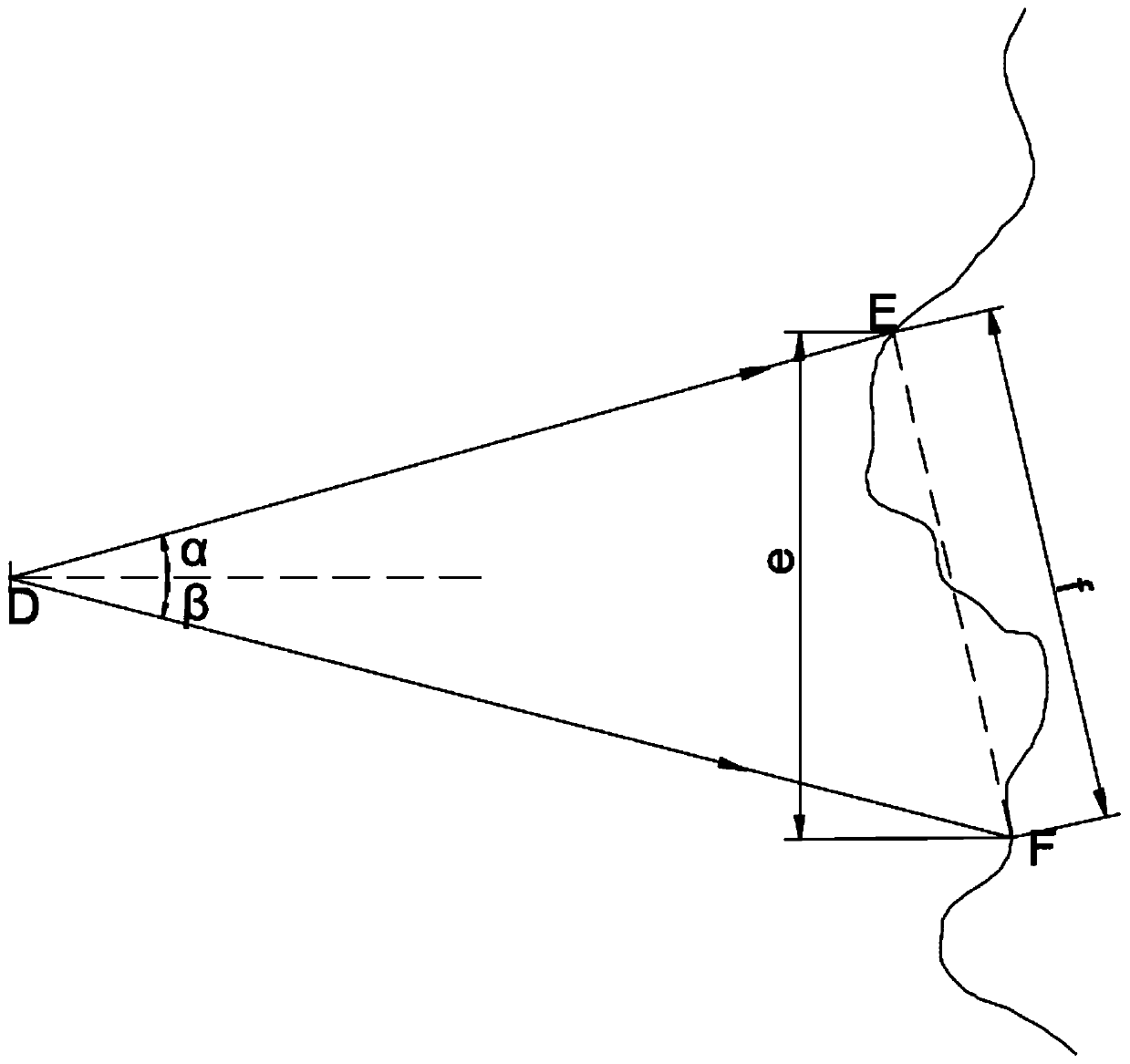

InactiveCN109708618AReduce precision errorEasy to makePhotogrammetry/videogrammetryUsing optical meansLaser rangingMeasurement device

Provided in the invention is a combined calibration method for determining the photographing scale after three-dimensional reconstruction. The method comprises the following steps: step one, selectinga scene needing image collection; and step two, setting an image acquisition device, two laser range finders and an angle measurement device in the scene. To be specific, the image acquisition deviceis horizontally fixed in the scene and the laser range finders and the angle measurement device are arranged in front of the image acquisition device; when collection is carried out for the first time, the position level of the image acquisition device is kept, the plane formed by the two laser range finders is in a parallel relationship with the bottom surface of the image acquisition device, and the two laser range finders measure that included angles between the finders and the normal direction AD of the lens of the image acquisition device are alpha and beta by the angle measurement device. According to the invention, A photo pose position parameter and an image control point parameter of a static object can be provided in multi-eye three-dimensional reconstruction; and since the ranging in the process is performed by the laser range finders directly, the precision error occurrence caused by the manual operation is reduced.

Owner:成都天佑智隧科技有限公司

Three-degree-of-freedom micro-positioning platform based on symmetrical double compliant hinge

ActiveCN105174210AEffective Asymmetry CompensationReduce precision errorMicrostructural devicesThree degrees of freedomEngineering

The invention provides a three-degree-of-freedom micro-positioning platform based on a symmetrical double compliant hinge. The three-degree-of-freedom micro-positioning platform comprises fixed platforms, a movable platform, drivers and three lever amplifying mechanisms, wherein the drivers are arranged on the fixed platforms; the three lever amplifying mechanisms are used for connecting the fixed platforms with the movable platform; the three lever amplifying mechanisms are uniformly distributed on the periphery of the movable platform, and connected with the fixed platforms, the movable platform and the drivers respectively; each lever amplifying mechanism comprises a movable lever, a double compliant hinge and a guide mechanism which is provided with the double compliant hinge; the movable levers are connected with the fixed platforms and the drivers respectively through the double compliant hinges, and connected with the movable platform through the guide mechanisms; and the double compliant hinges are symmetrical double compliant hinges. Through adoption of the micro-positioning platform, the displacement positioning accuracy can be increased and travel being as large as possible is obtained on the premise thatvarious conditions such as installation space and fixed frequency are satisfied. The micro-positioning platform has a function of correcting a displacement output, and displacement is output as linearly as possible, so that coupled displacement is reduced.

Owner:珠海市和信致美建筑科技有限公司

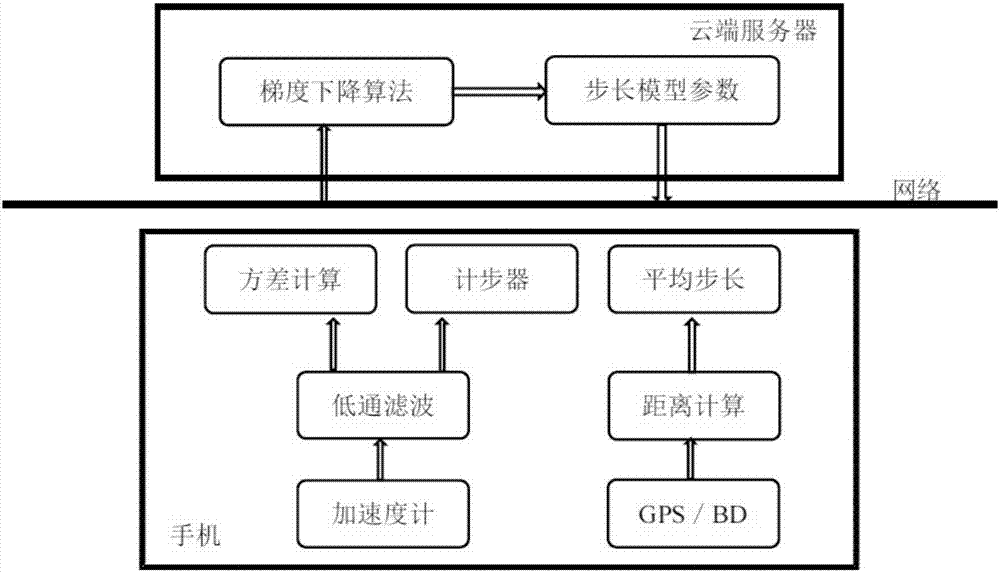

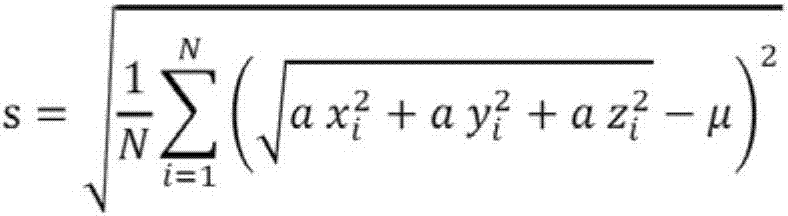

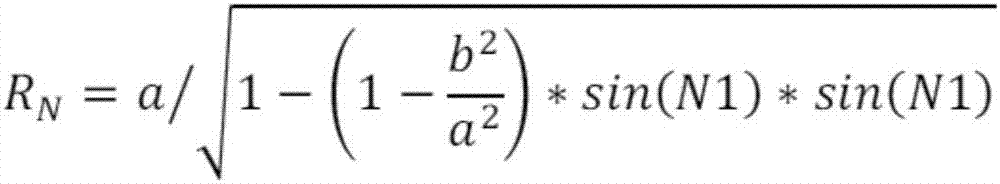

Cloud step length estimation method

ActiveCN107167129AReduce precision errorNavigational calculation instrumentsNavigation by speed/acceleration measurementsReal-time computingEstimation methods

Owner:QIANXUN SPATIAL INTELLIGENCE INC

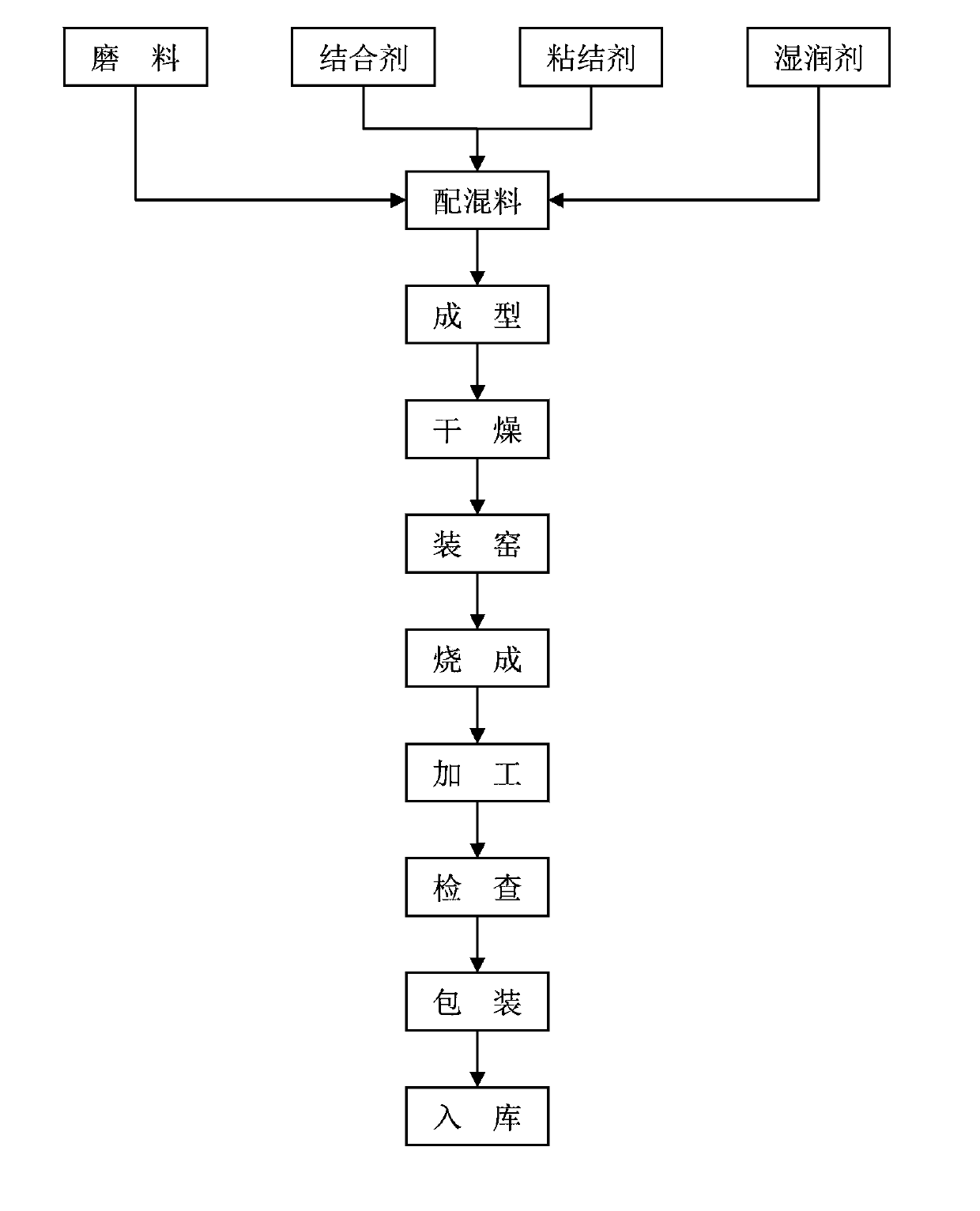

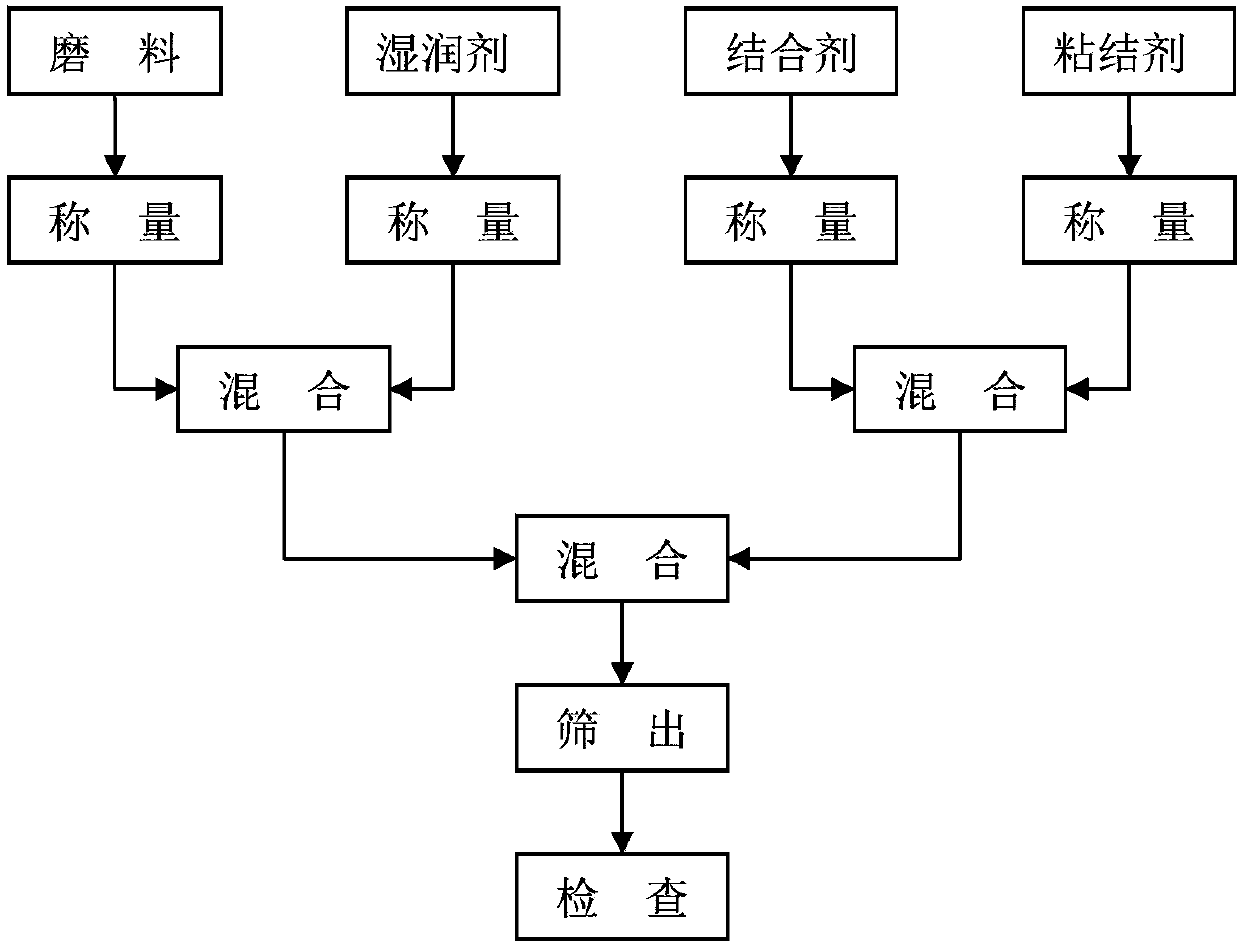

Ceramic microcrystal abrasive powerful grinding wheel and processing method thereof

ActiveCN103862390ALower firing temperatureIncrease the amount of cutAbrasion apparatusGrinding devicesGrinding wheelCeramic

The invention belongs to the field of grinding wheels and particularly relates to a high-precision ceramic microcrystal abrasive powerful grinding wheel and a processing method thereof. The grinding wheel comprises a center reinforcement part and a grinding use part. The high-precision ceramic microcrystal abrasive powerful grinding wheel is characterized in that the center reinforcement part comprises, by weight, 100 parts of WA80#, 10-24 parts of bonding agent, 0.5-3.5 parts of adhesion agent and 2.5-4.5 parts of wetting agent; the grinding use part comprises, by weight, 10-50 parts of CA80#, 50-90 parts of WA80#, 8-15 parts of bonding agent, 0.5-3.5 parts of adhesion agent, 2.5-4.5 parts of wetting agent and 2-12 parts of pore-forming agent; the forming density is 1.6-1.95kg / cm3; the adhesion agent is dextrin, and the wetting agent is latex. The processing method is characterized by comprising a first step of material mixing, a second step of forming, a third step of drying and a fourth step of firing. The high-precision ceramic microcrystal abrasive powerful grinding wheel has the advantages of being large in cutting amount, high in grinding efficiency and grinding precision and low in grinding wheel firing temperature.

Owner:山东鲁信四砂泰山磨具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com