Silicon steel sheet punching machine for production of fan motor rotor

A technology for fan motors and silicon steel sheets is applied in the manufacture of stator/rotor bodies, metal processing equipment, feeding devices, etc. The effect of increased machining efficiency, increased flexibility and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

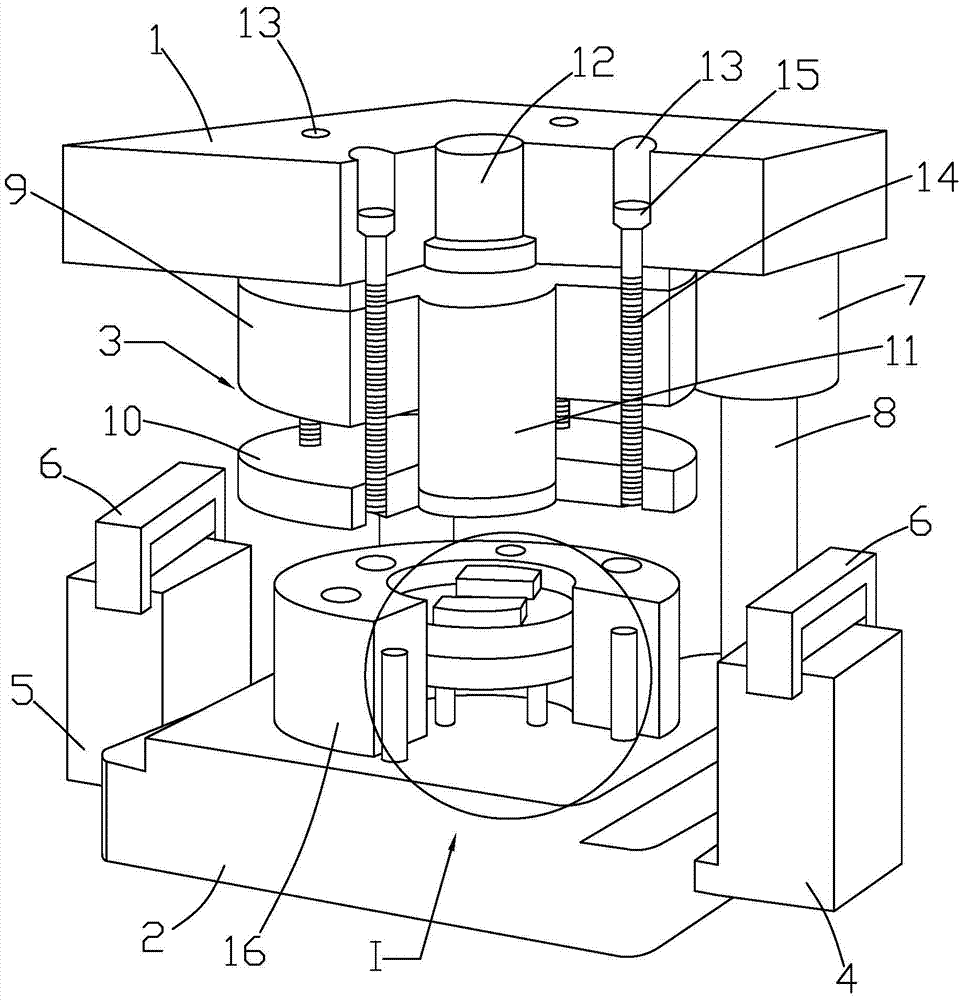

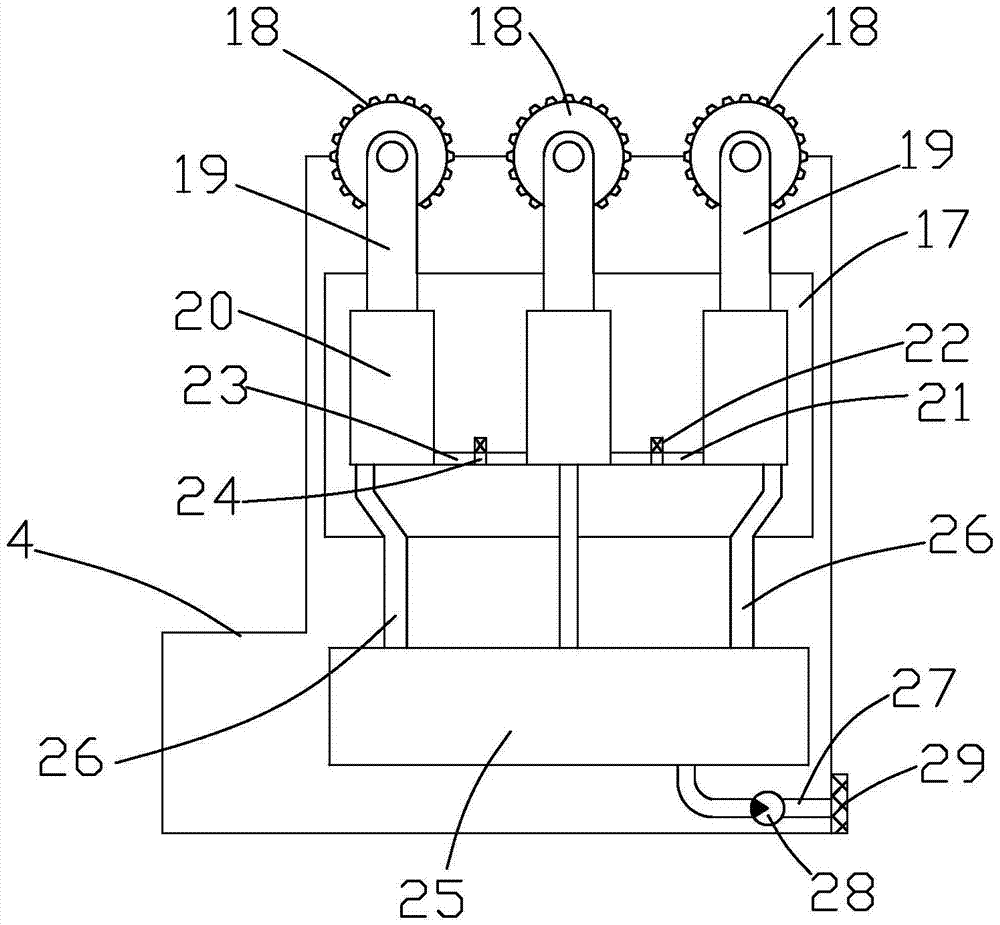

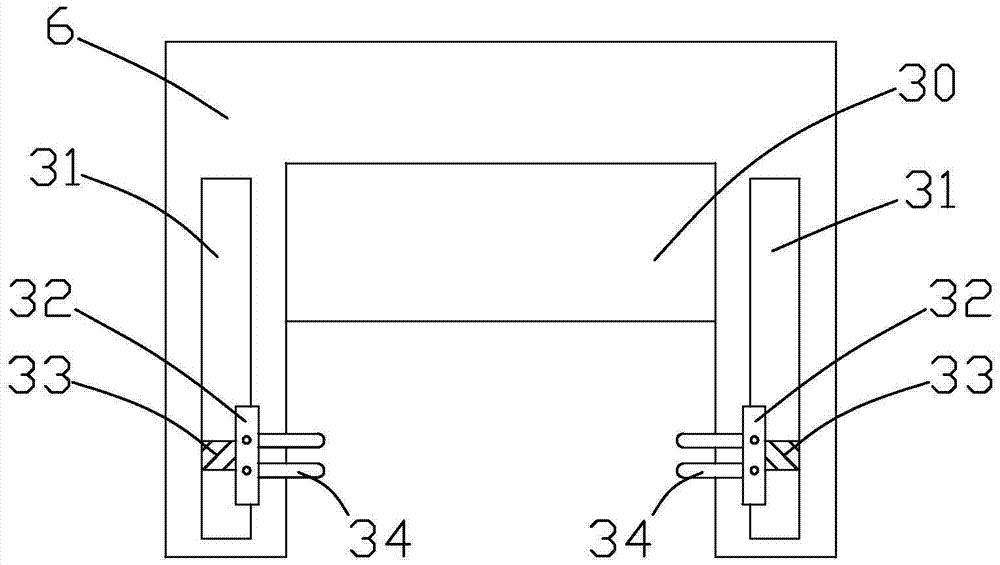

[0031] Such as Figure 1 to Figure 6 As shown, it is a silicon steel sheet punching machine for producing fan motor rotors according to the present invention, which includes an upper top plate 1, a base 2, a stamping mechanism 3, a feed box 4 and a discharge box 5, and the upper top plate 1 is provided with a main Hydraulic cylinder 12, limit hole 13 is uniformly arranged around the main hydraulic cylinder 12, stamping mechanism 3 is located on the bottom surface of upper top plate 1, stamping mechanism 3 includes upper positioning column 9 and lower positioning column 10, upper positioning column 9 is fixedly connected to the upper On the bottom surface of the top plate 1, the lower positioning column 10 is connected to the upper positioning column 9 through the stamping column 11, the stamping column 11 is connected with the main hydraulic cylinder 12, and the upper top plate 1 passes through the upper positioning column 9 through the spring rod 14 and is connected to the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com