Patents

Literature

33results about How to "Affect normal delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

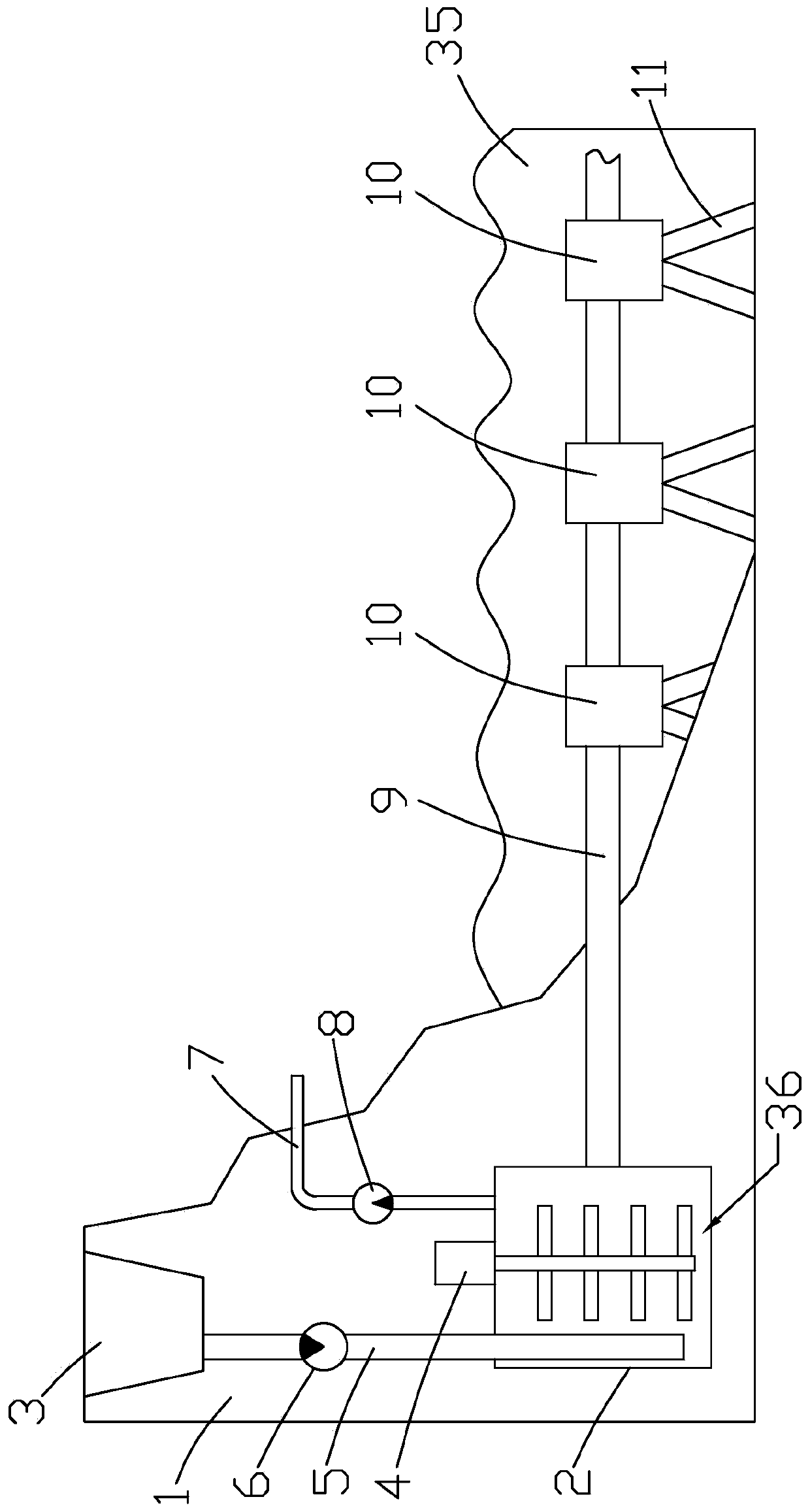

Intelligent urban rainwater storage regulation system and construction method thereof

ActiveCN106759781APrevent leakagePrevent waterloggingFatty/oily/floating substances removal devicesSewerage structuresResidenceEngineering

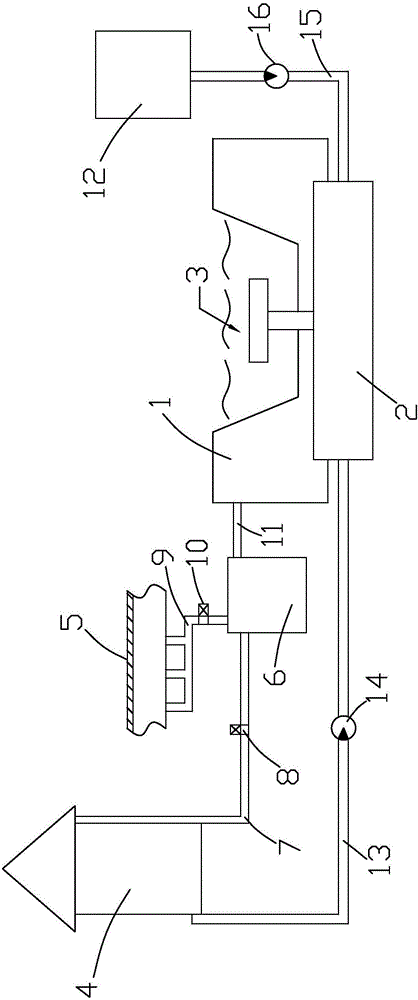

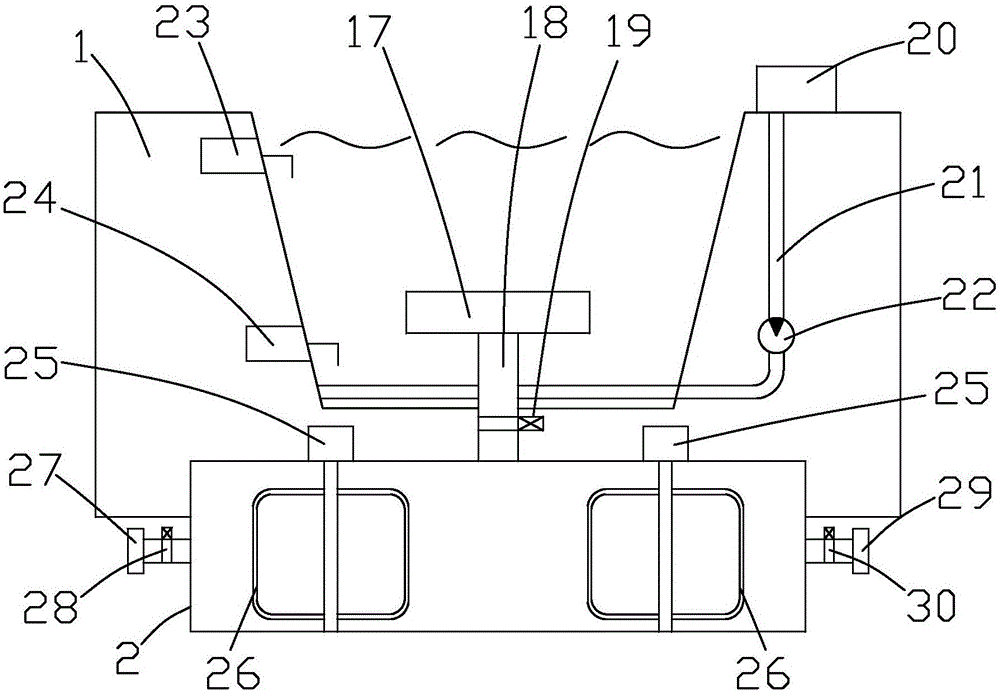

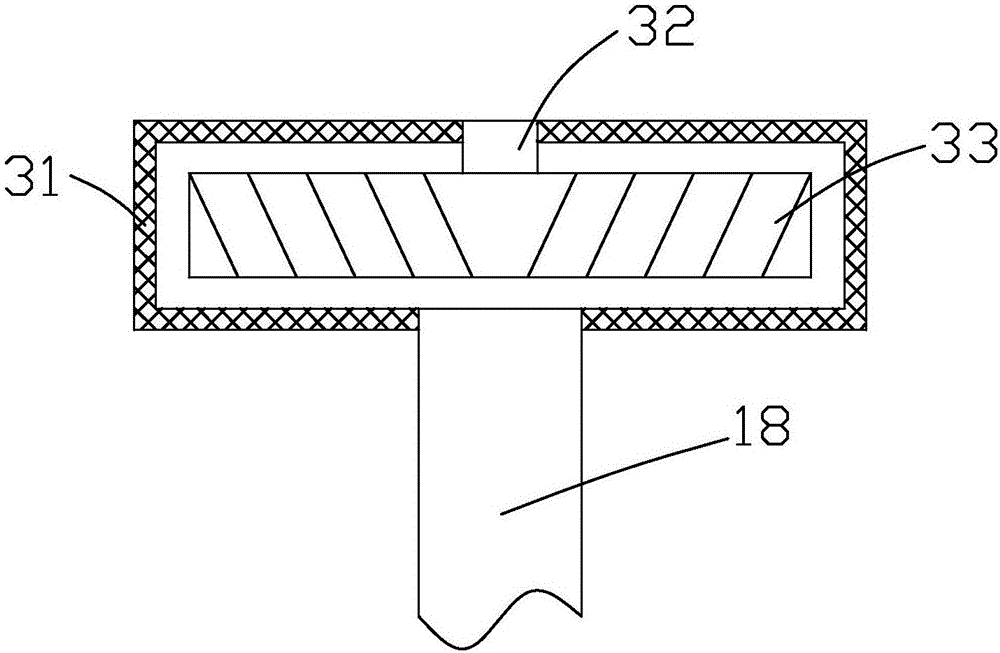

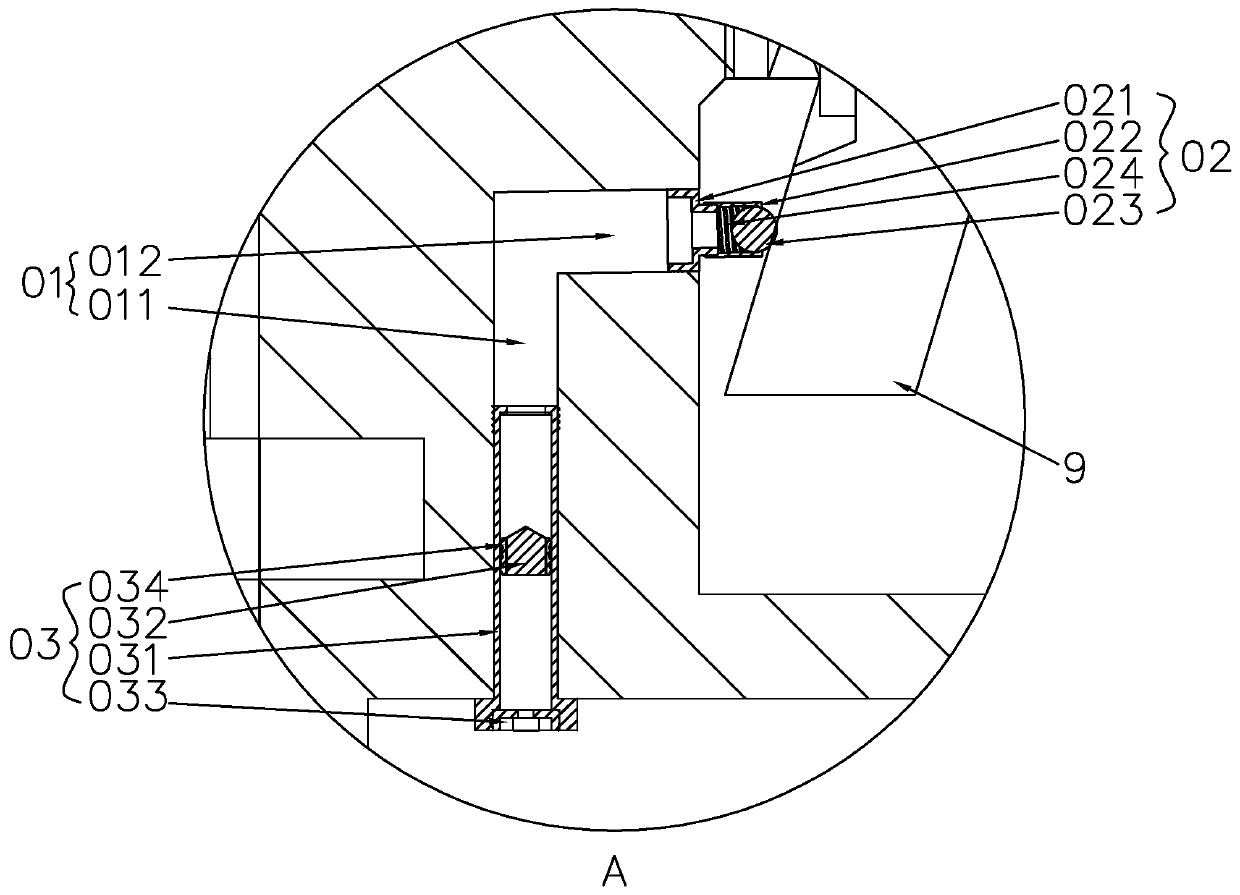

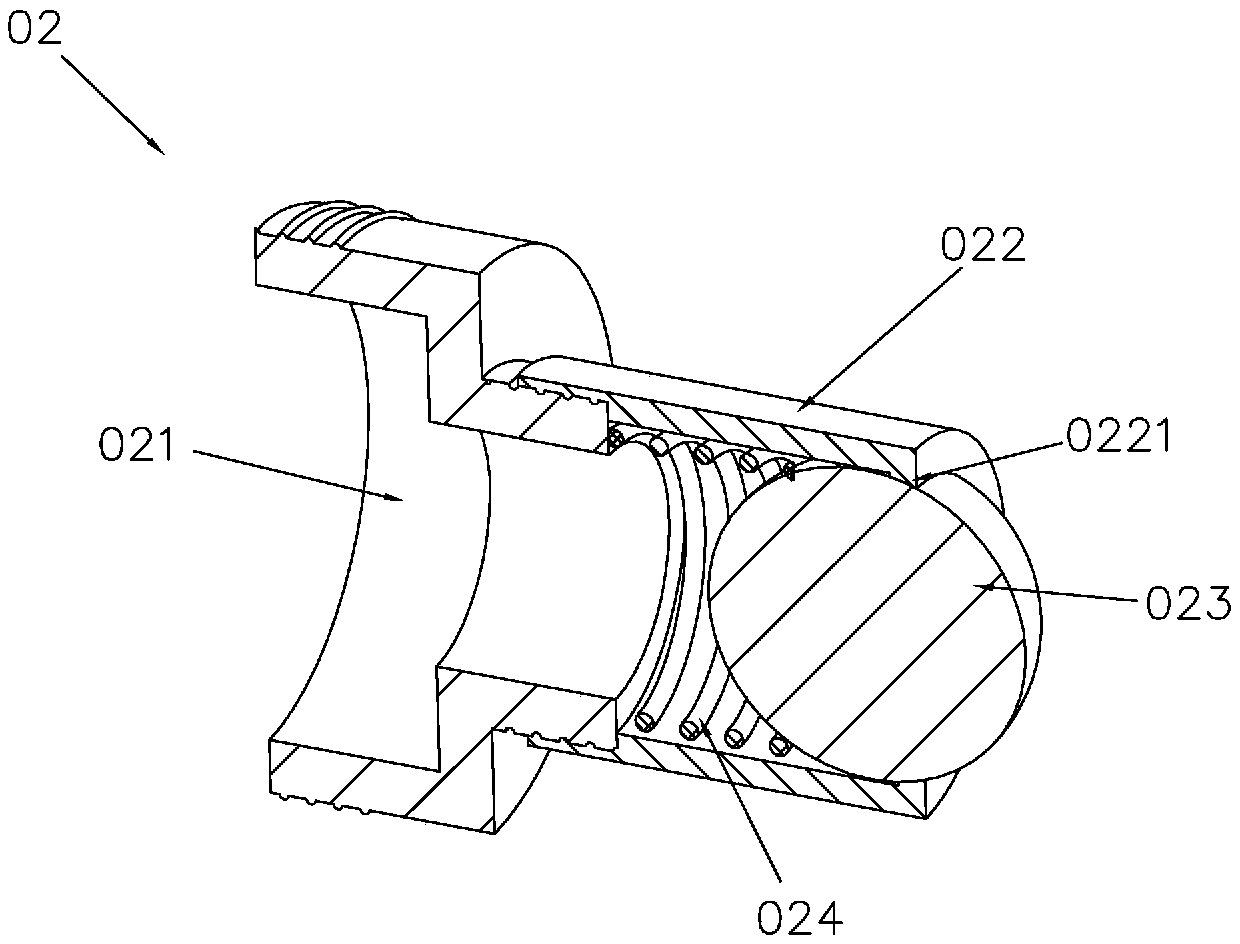

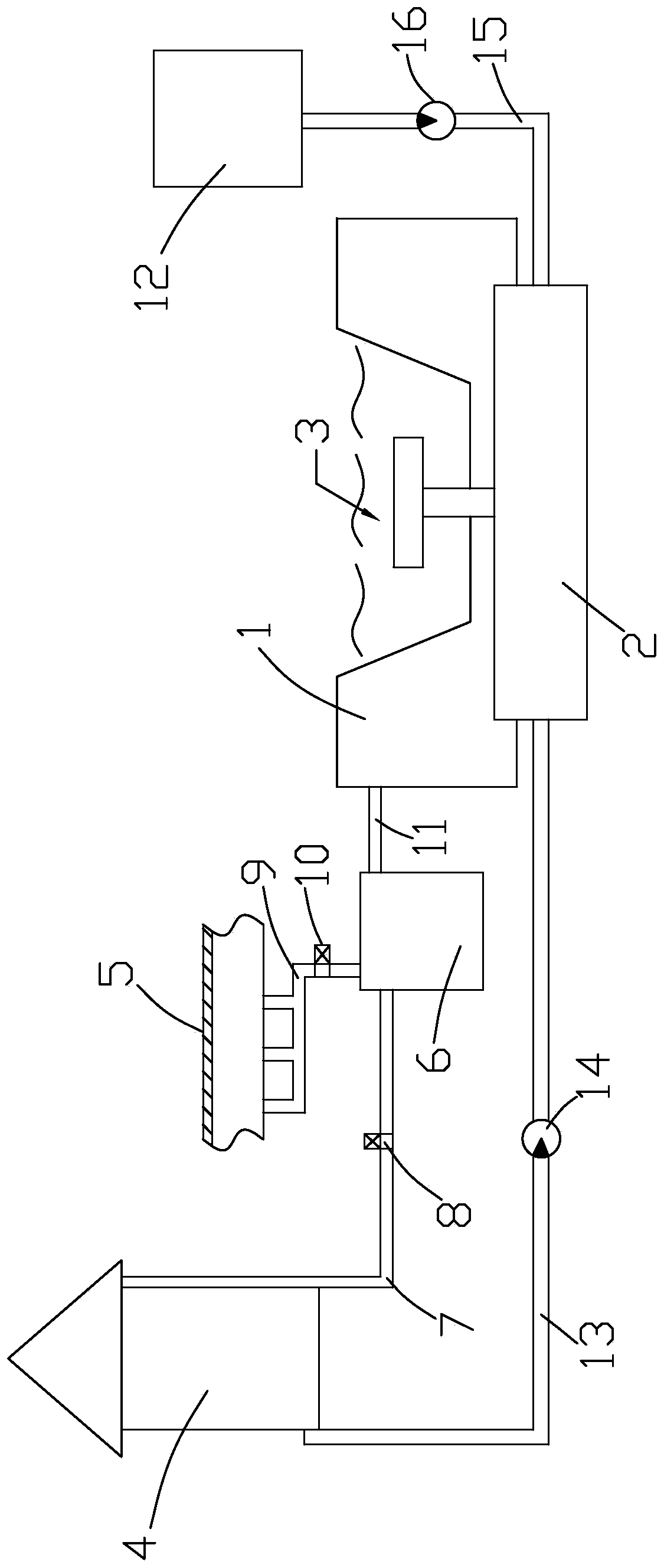

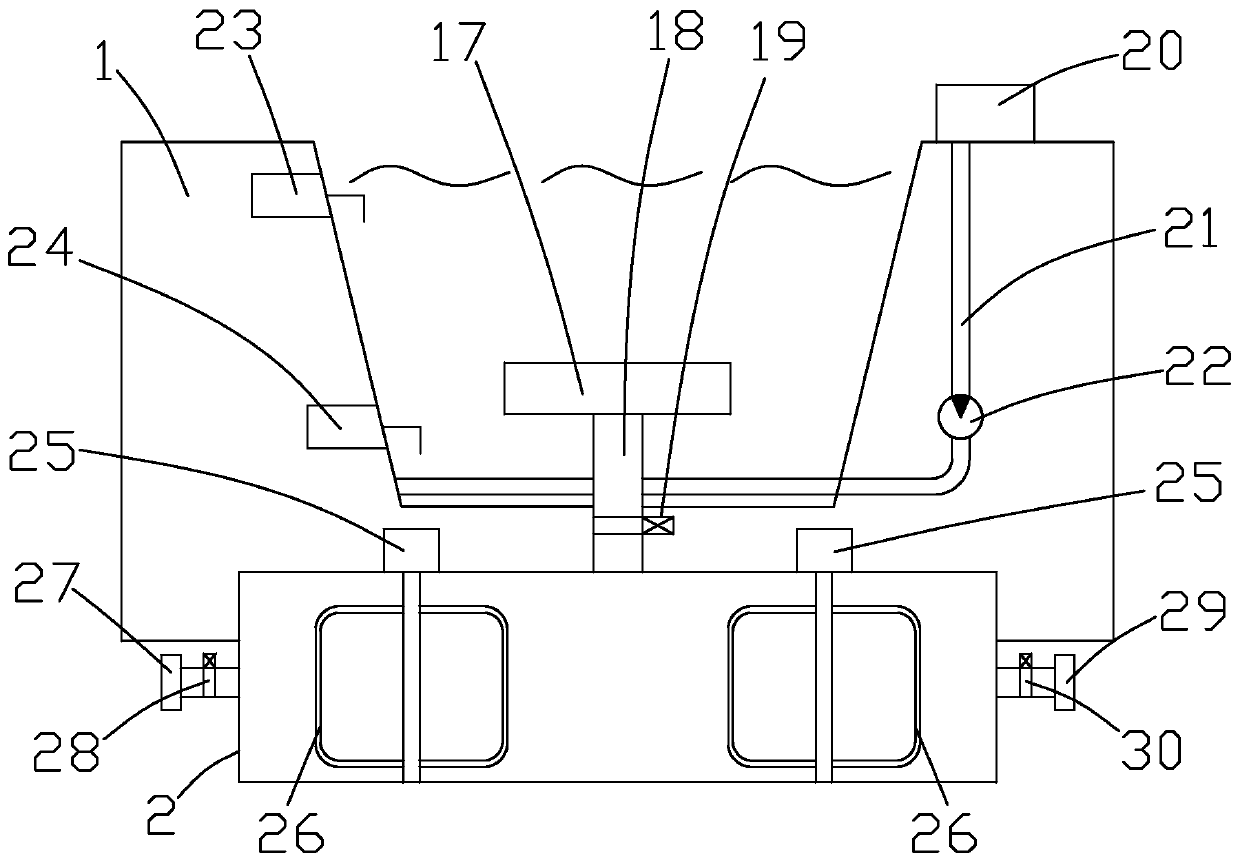

The invention discloses an intelligent urban rainwater storage regulation system and a construction method thereof. The system comprises a rainwater storage regulation tank, a water through device, a filter device and a water distribution tank. A first water level sensor and a second water level sensor are arranged on the inner side of a park pool, and the water through device is positioned between the first water level sensor and the second water level sensor and close to the second water level sensor. A silt clearing tank is arranged at the top of the park pool, the filter device is connected with a residence region and a road surface through a first water inlet pipe and a second water inlet pipe respectively, and the rainwater storage regulation tank is connected with the residence region and the water distribution tank through a first water drain pipe and a second water drain pipe respectively. The method includes steps of survey setting-out, rainwater storage regulation tank construction, filter device construction, water distribution tank construction, road surface construction, pipeline connection arrangement and rainwater storage regulation system commissioning. The construction method is simple in step, rainwater quick drainage and storage are facilitated, flood or waterlogging is prevented, and stored rainwater can be used for irrigation and domestic water.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

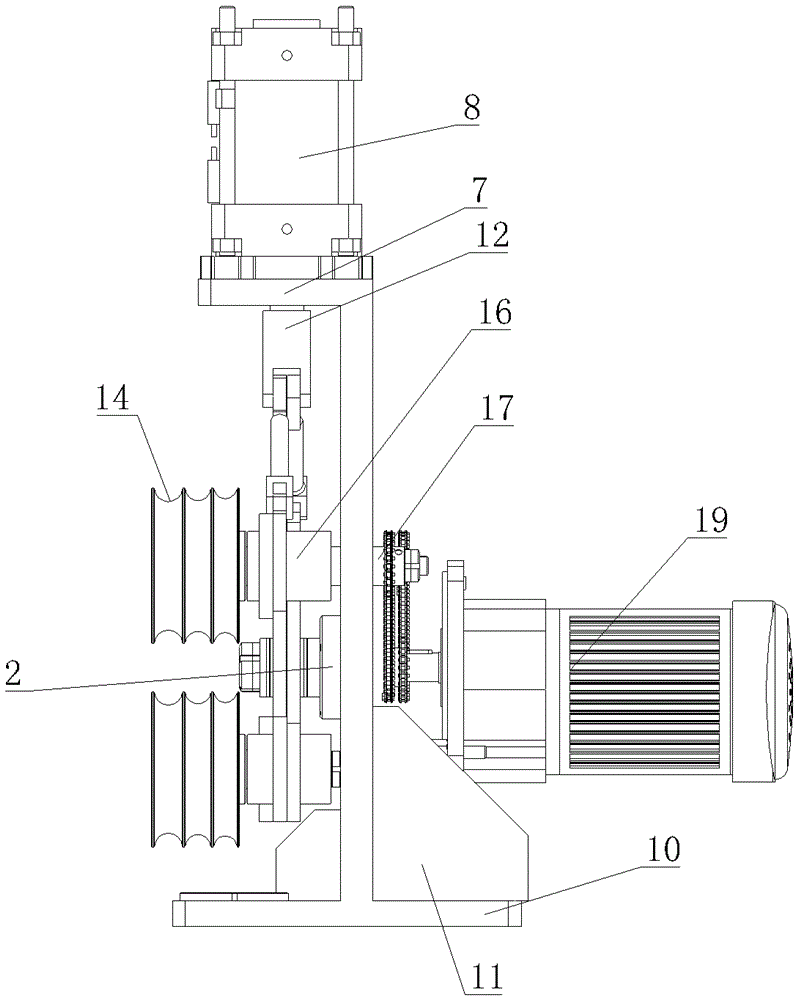

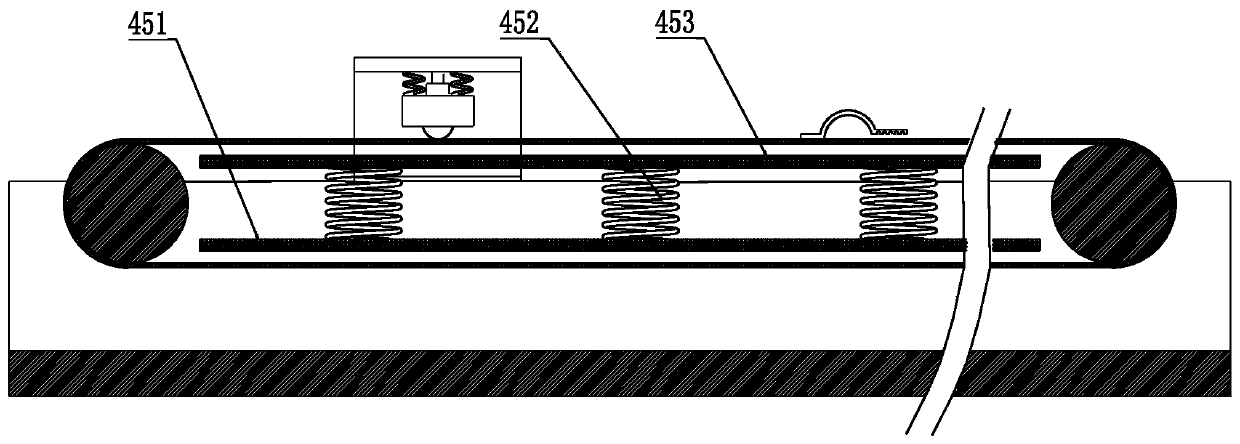

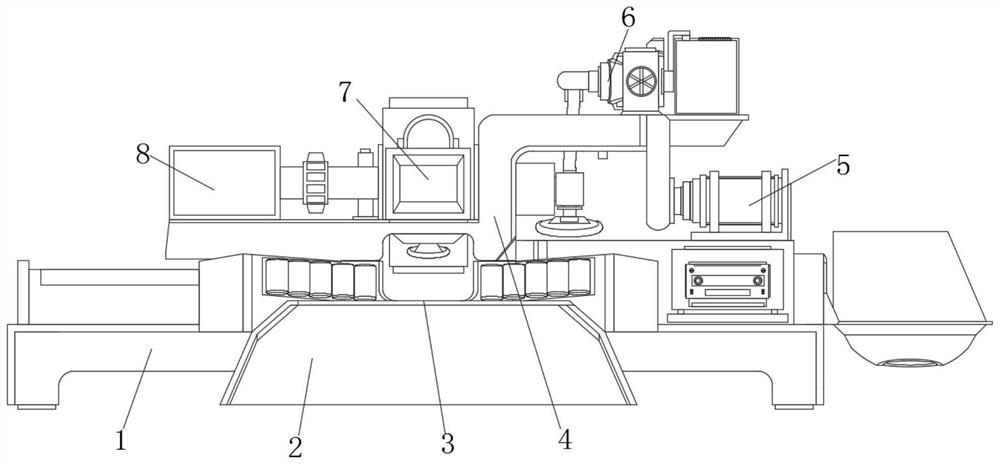

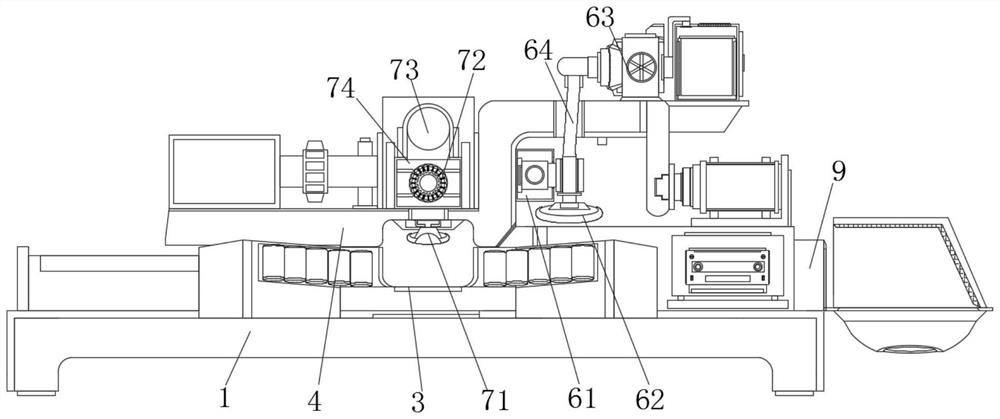

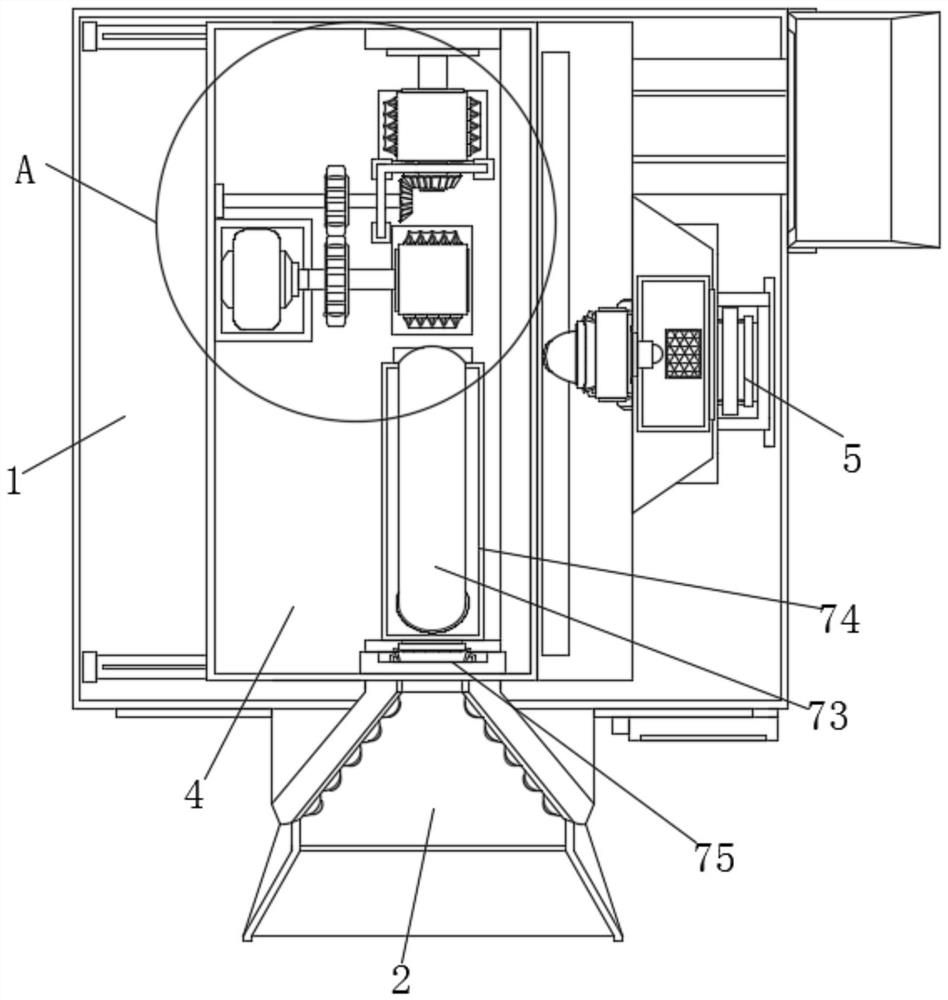

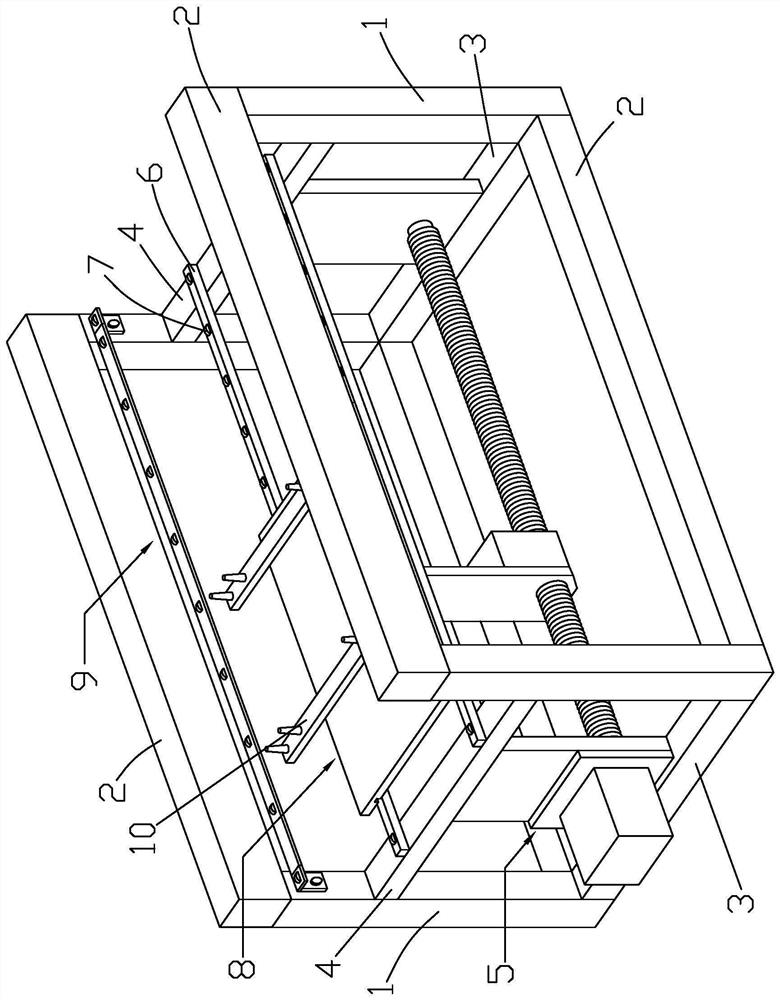

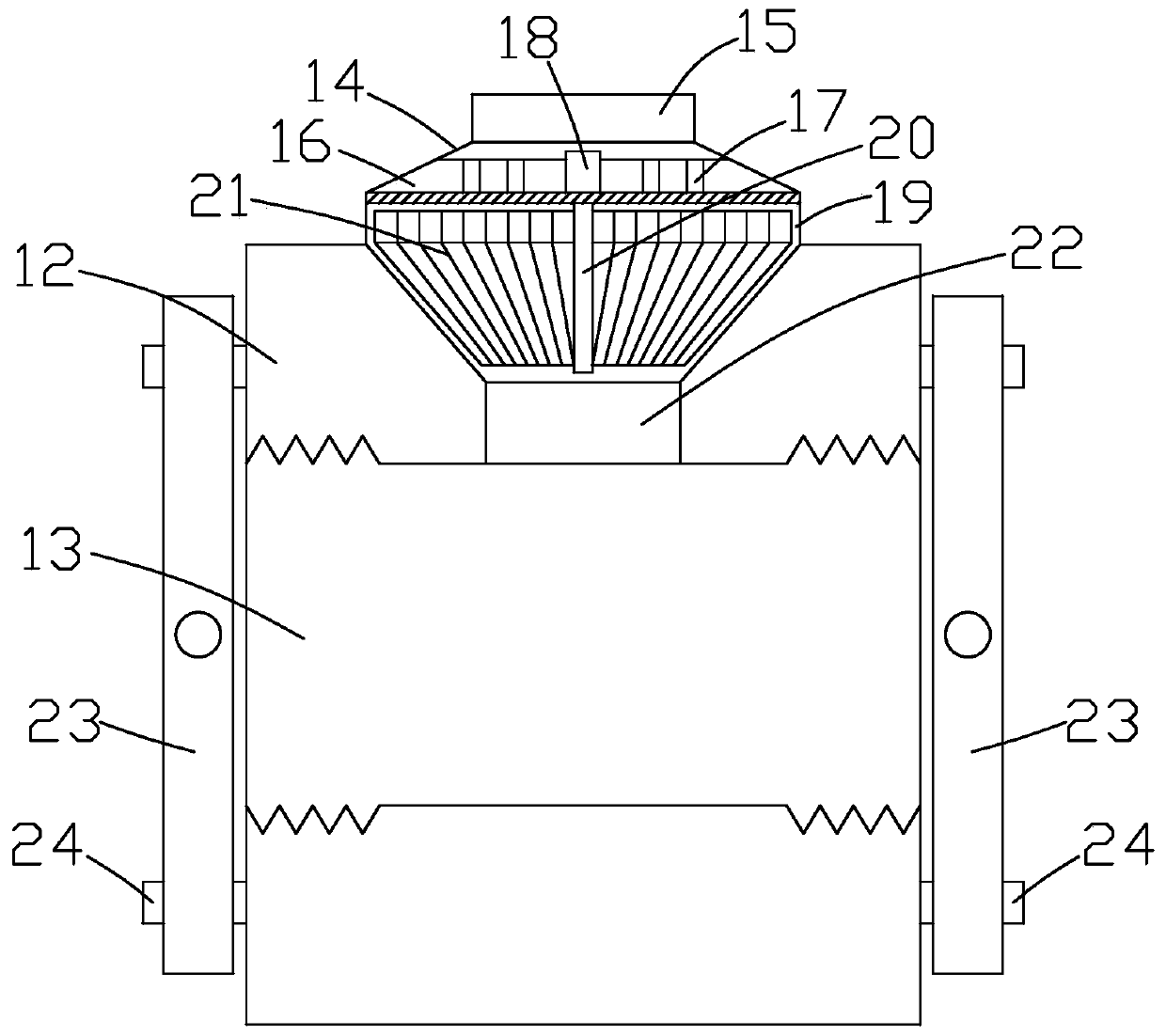

Silicon steel sheet punching machine for production of fan motor rotor

InactiveCN105449946AReduce impactAffect the service lifeMetal-working feeding devicesManufacturing stator/rotor bodiesHydraulic cylinderPunching

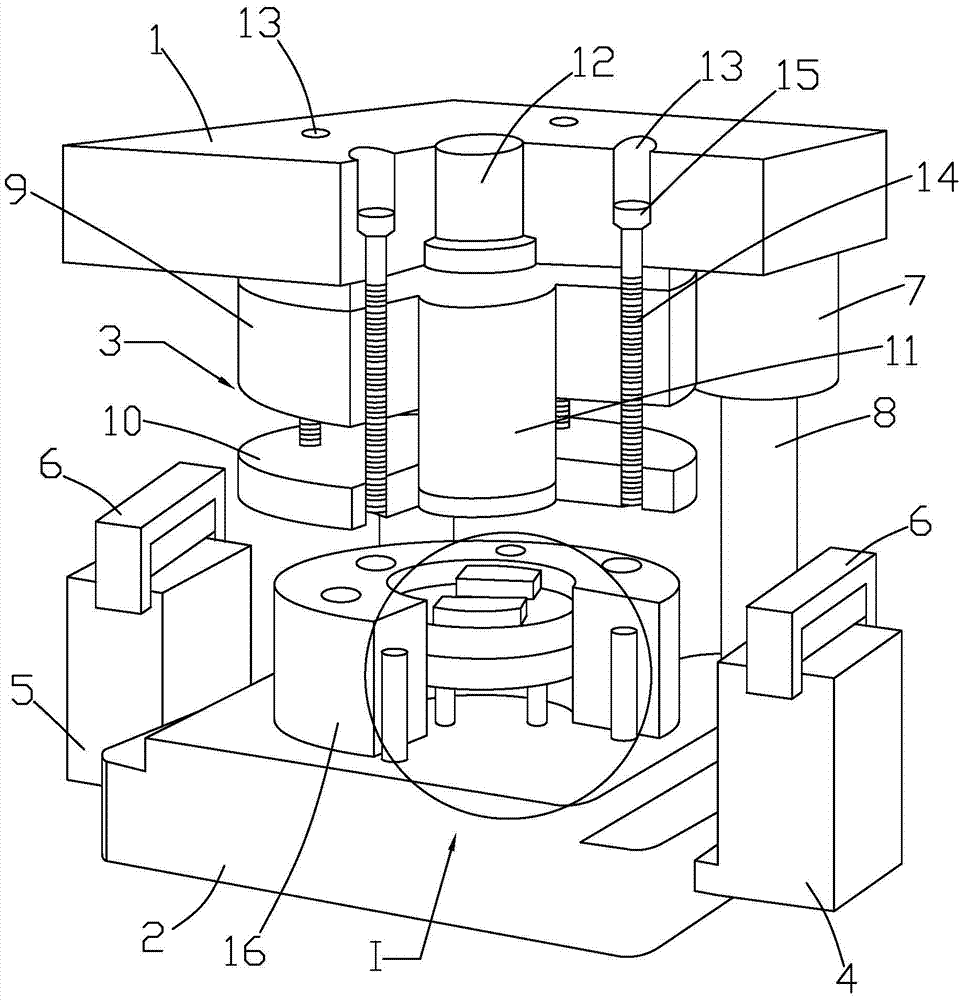

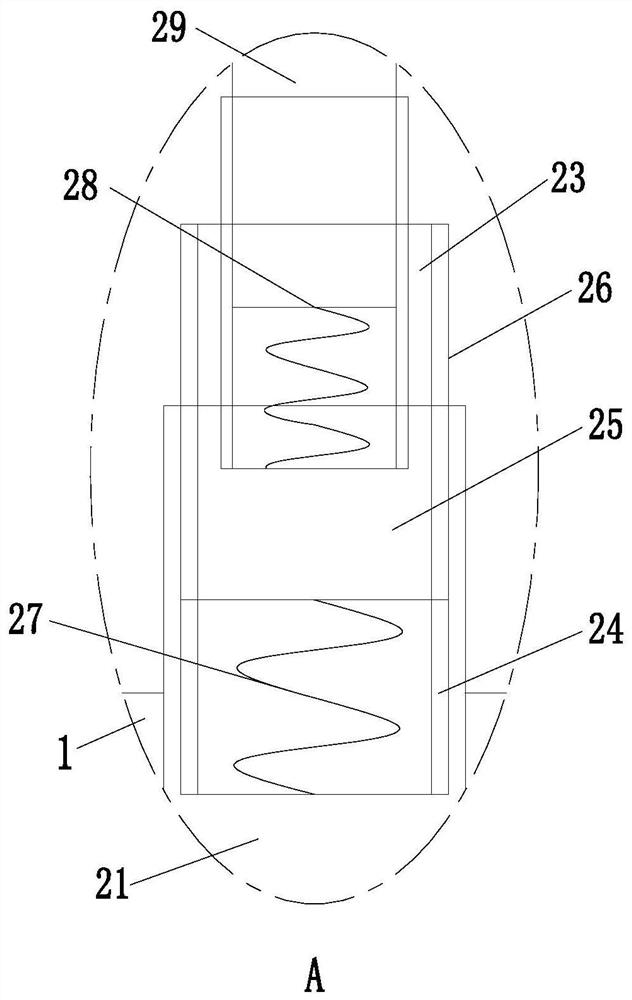

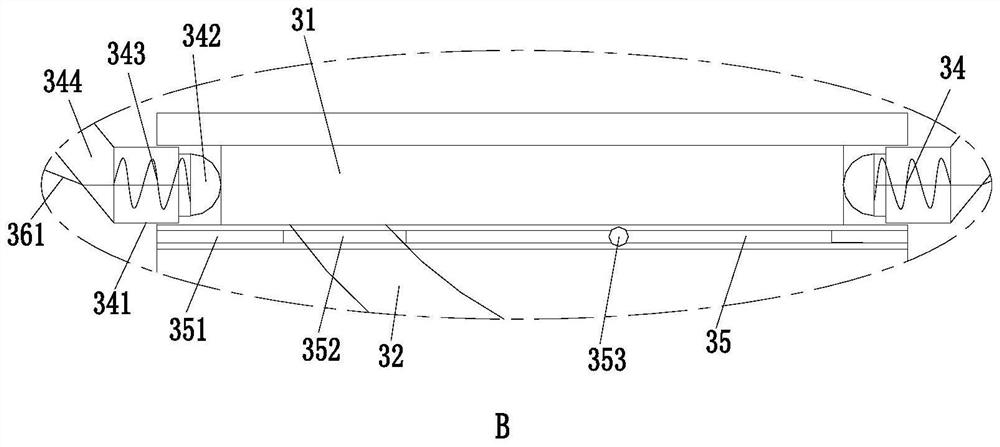

The invention discloses a silicon steel sheet punching machine for production of a fan motor rotor. The silicon steel sheet punching machine comprises an upper top plate, a base, a stamping mechanism, a feeding box body and a discharging box body, wherein a main hydraulic cylinder is arranged on the upper top plate, at least two lifting hydraulic cylinders are arranged on the bottom surface of the upper top plate and connected onto the top surface of the base via a piston rod, a punching processing table is arranged at the center of the top surface of the base and fixedly connected onto the base via a limitation rod, a stamping through hole is formed in the center of the punching processing table, a buffer mechanism is arranged in the stamping through hole, the feeding box body and the discharging box body are respectively arranged at the two sides of the base, and feeding positioning devices are arranged on the top surfaces of the feeding box body and the discharging box body. The silicon steel sheet punching machine is simple in structure and has high practicability, continuous transmission of silicon steel sheets can be fulfilled, and the transmission efficiency of the silicon steel sheets is improved; and moreover, the punching process of the silicon steel sheets with different sizes and types can be met, the silicon steel sheets after being punched are automatically stacked and formed, and the production process of the rotor is simplified.

Owner:SHENGZHOU BEIYULING MOTOR FACTORY

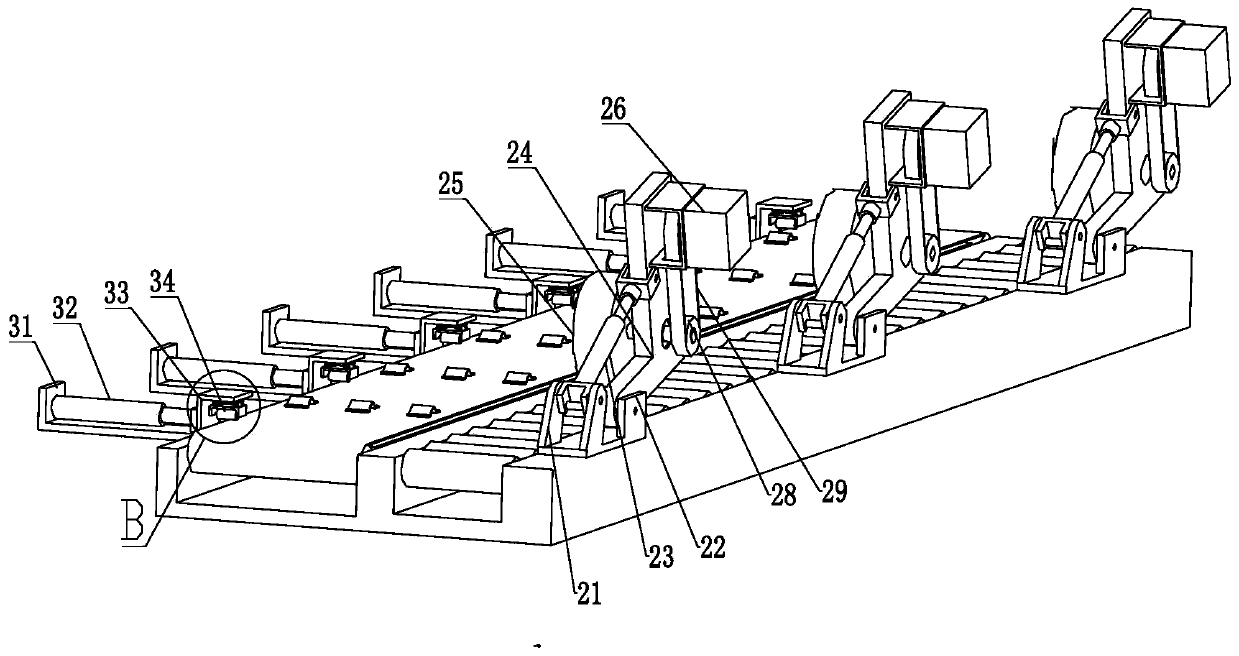

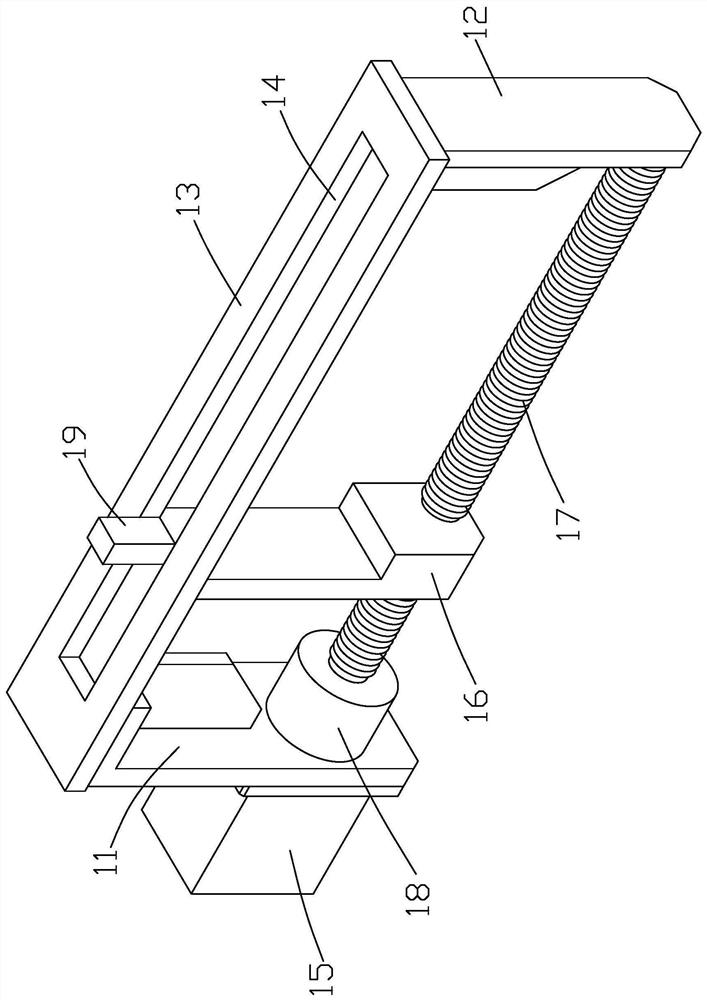

Full-automatic punching device for production of vehicle fittings

InactiveCN104923601AReduce labor costsImprove molding efficiencyMetal-working feeding devicesPositioning devicesEngineeringPunch press

The invention discloses a full-automatic punching device for production of vehicle fittings. The device comprises a conveying mechanism, a punching machine and a material shifting mechanism, wherein multiple forming molds are mounted on the punching machine; the conveying mechanism and the material shifting mechanism are both mounted on the punching machine; and the material shifting mechanism can transfer workpieces conveyed by the conveying mechanism into the forming molds for molding, and can transfer the workpieces in the previous forming molds into the next forming molds. The device continuously molds the vehicle fittings to greatly improve the molding efficiency, and needs no labor to largely reduce the labor usage amount so as to reduce the enterprise labor cost.

Owner:HUZHOU IRON FORCE METAL PROD

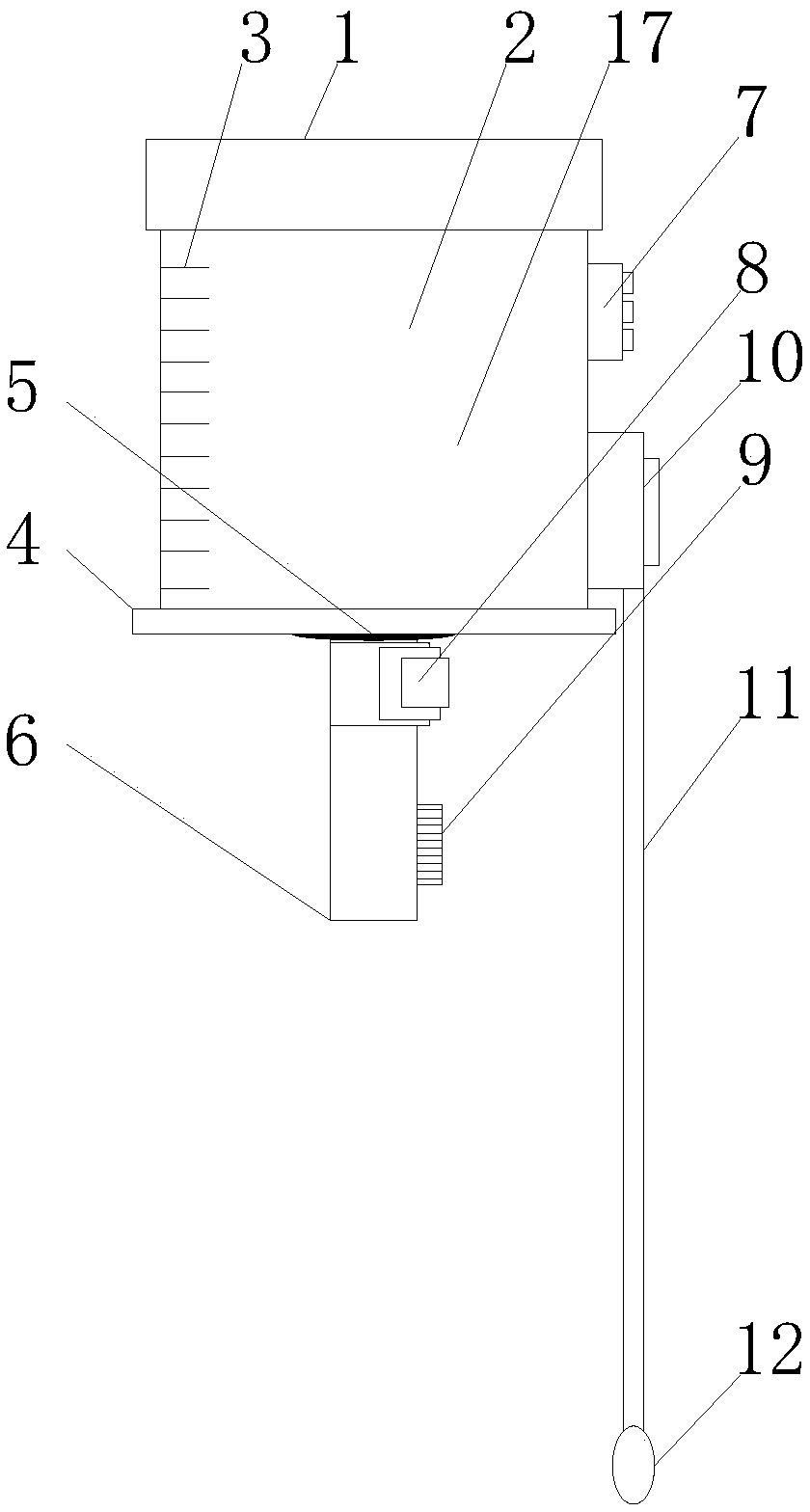

Metering type feeding device for ornamental fish

InactiveCN108935264AStable installationReduce gapMeasurement devicesClimate change adaptationEngineeringElectromagnetic valve

The invention discloses a metering type feeding device for ornamental fish. The device comprises a storage can, the storage can comprises an upper cover and a can body, the lower end of the upper cover sleeves the upper end cornice of the can body, a drying box is installed at the top of the interior of the upper cover, a controller is installed on the right side outer wall of the can body, a display is installed at the lower end of the controller, a temperature sensor is installed at the lower end of the display, a pressure sensor is installed at the lower end of the can body, and a discharging tube is installed at the lower end of the middle of the pressure sensor. By the arrangement of the drying box, the pressure sensor, the controller, an electromagnetic valve, a vibration motor, thedisplay, the temperature sensor and a sensing end, the problems that the healthy condition of fish is affected by the easy mildewing of feed caused by moisture, the feeding device is easily blocked when discharging is conducted, the feeding device has a single function, the ornamental fish eat excessive feed and irregular deaths are caused, timely and quantitative feeding cannot be conducted, andmetering cannot be conducted on the feed are solved.

Owner:芜湖佩林郁松计量科技有限公司

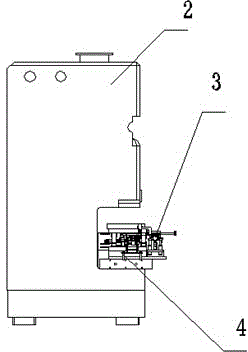

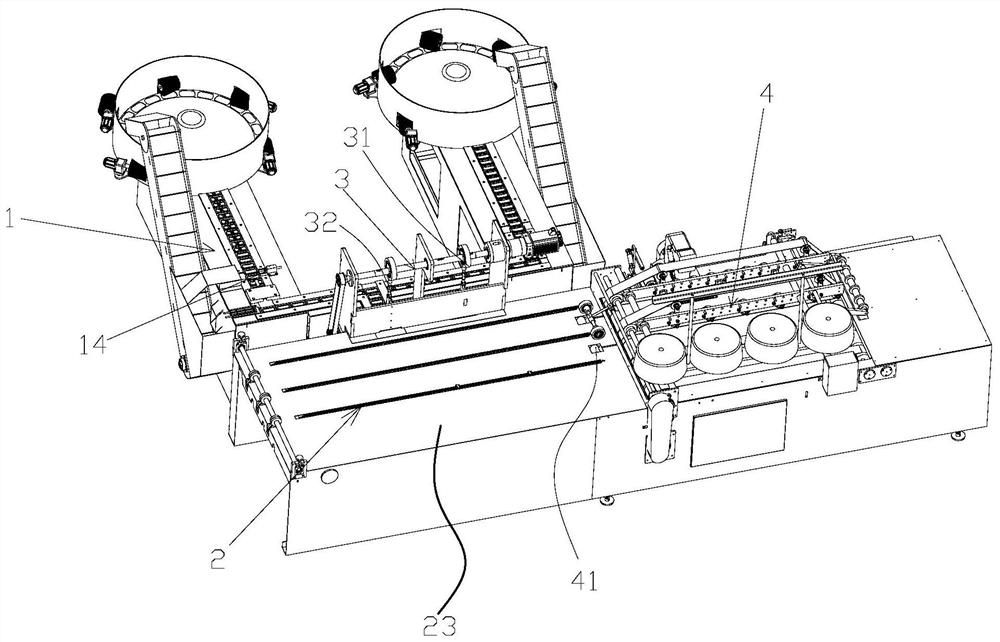

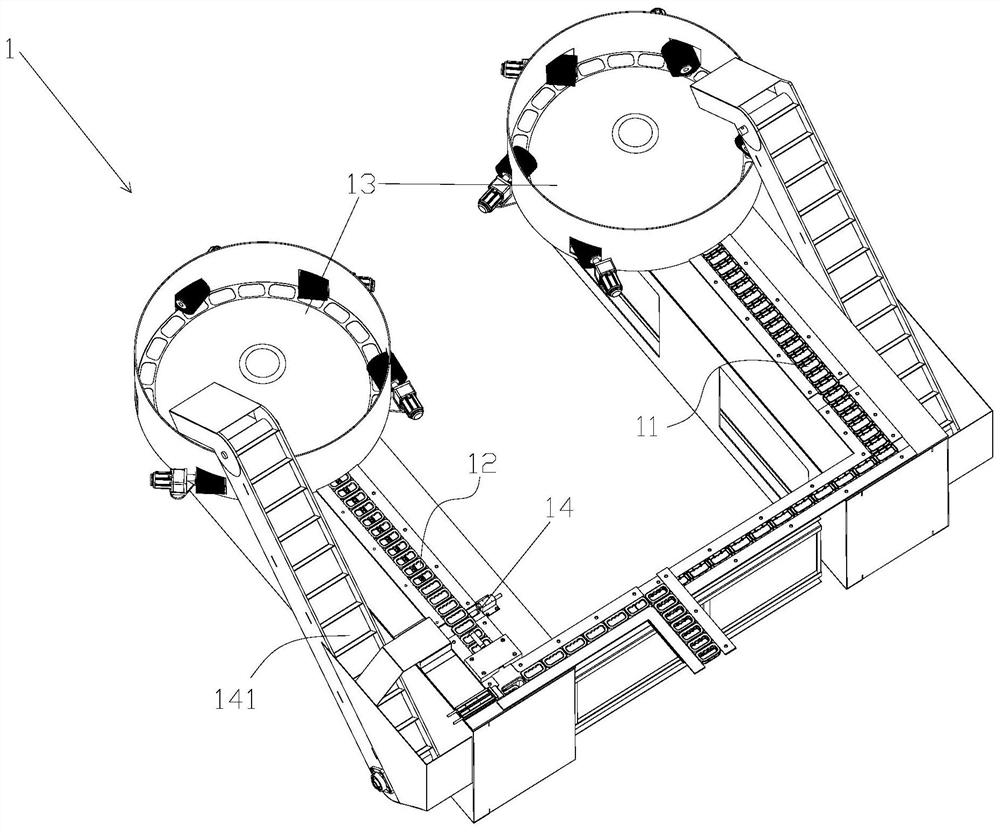

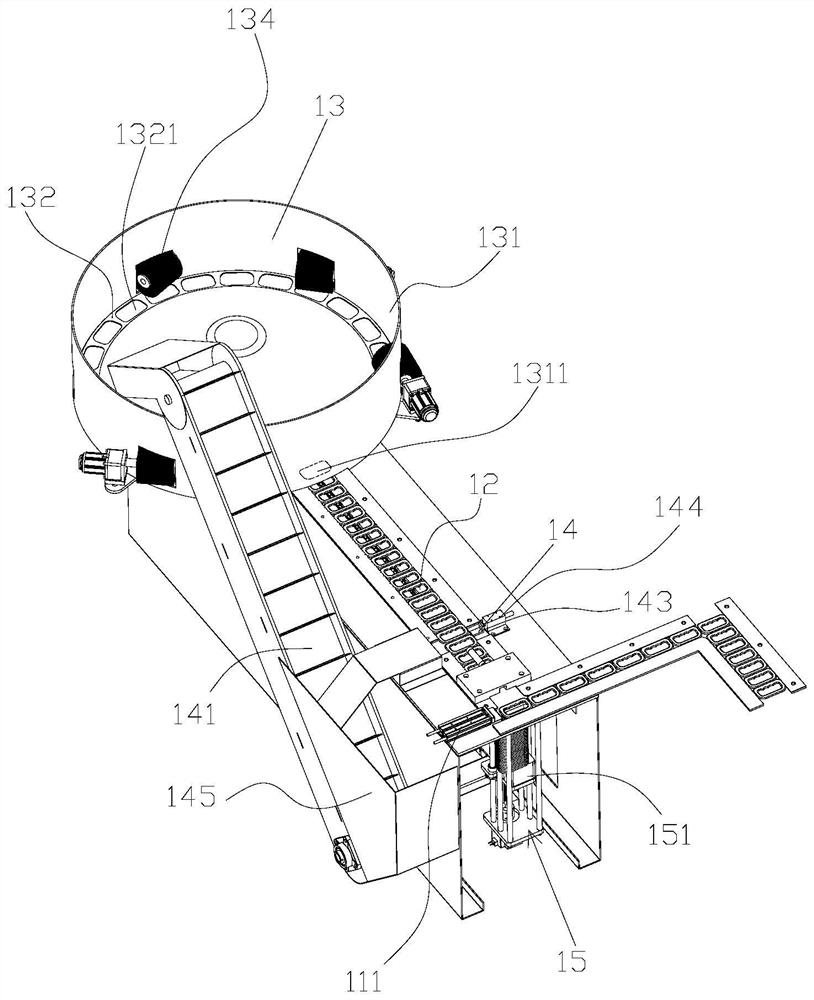

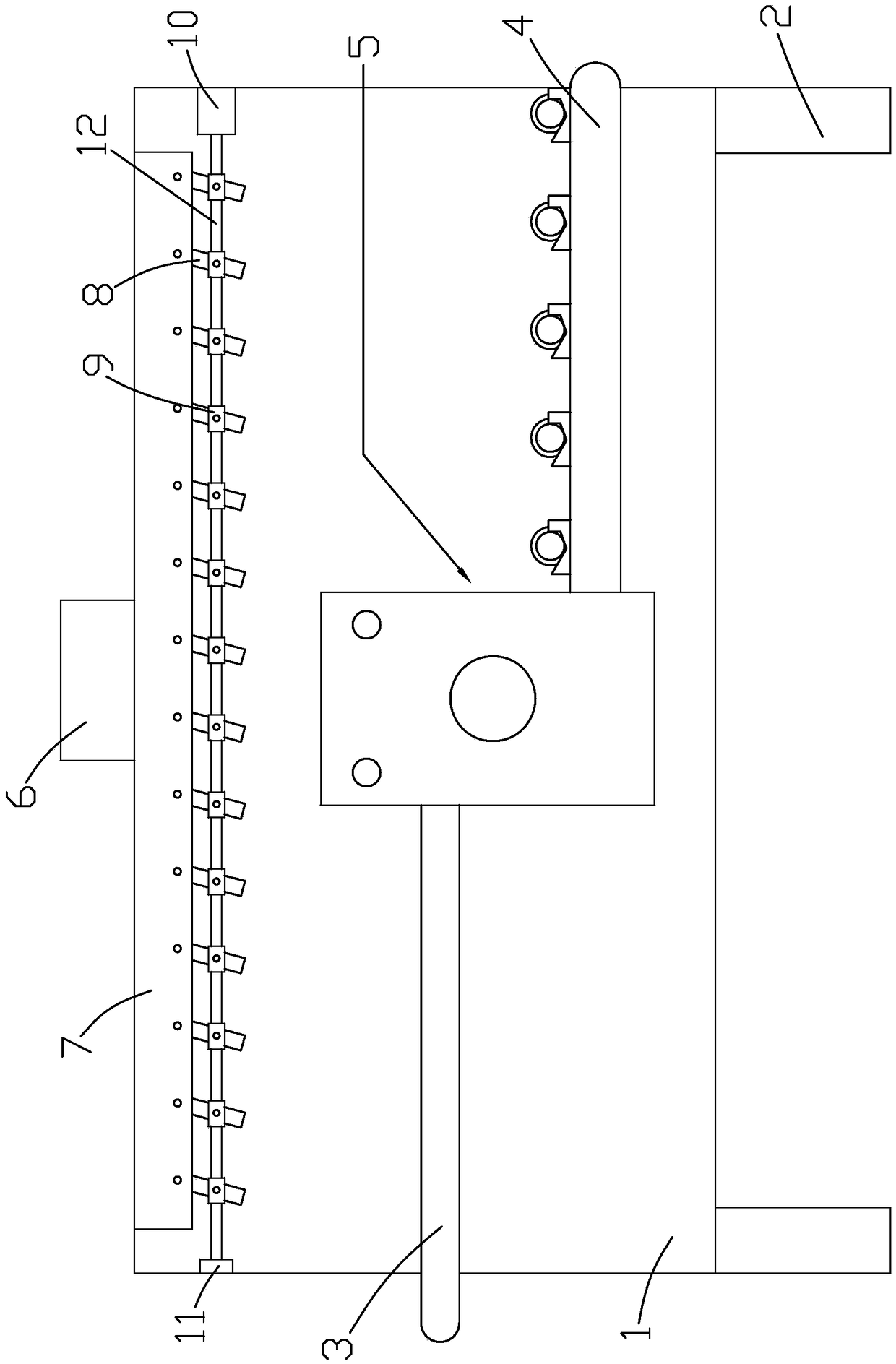

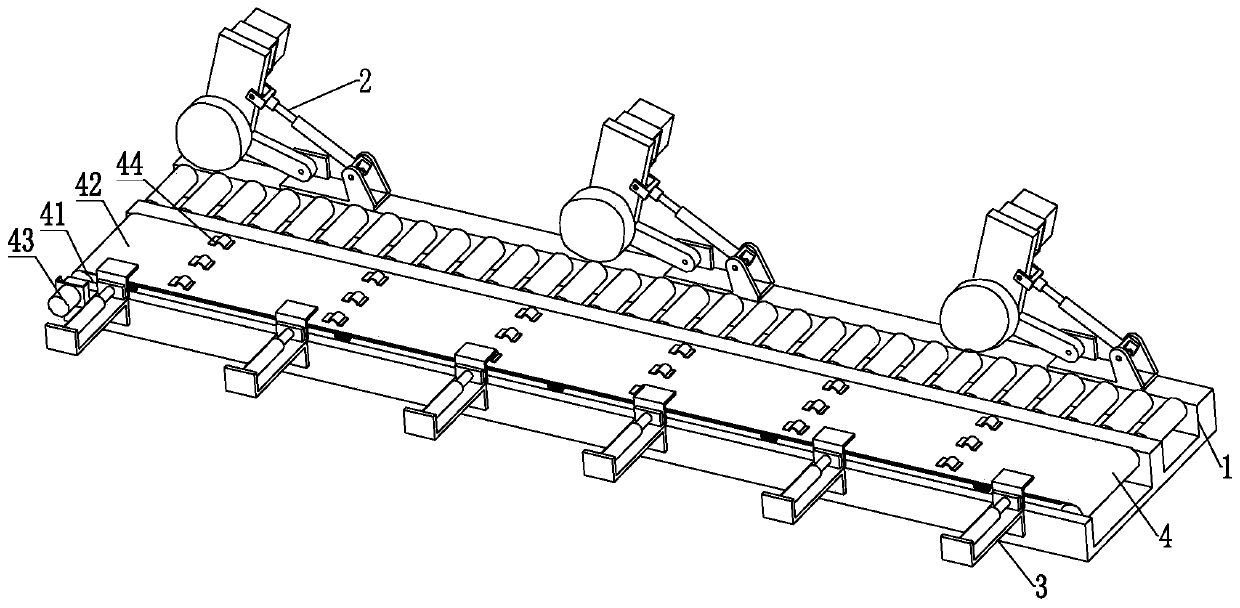

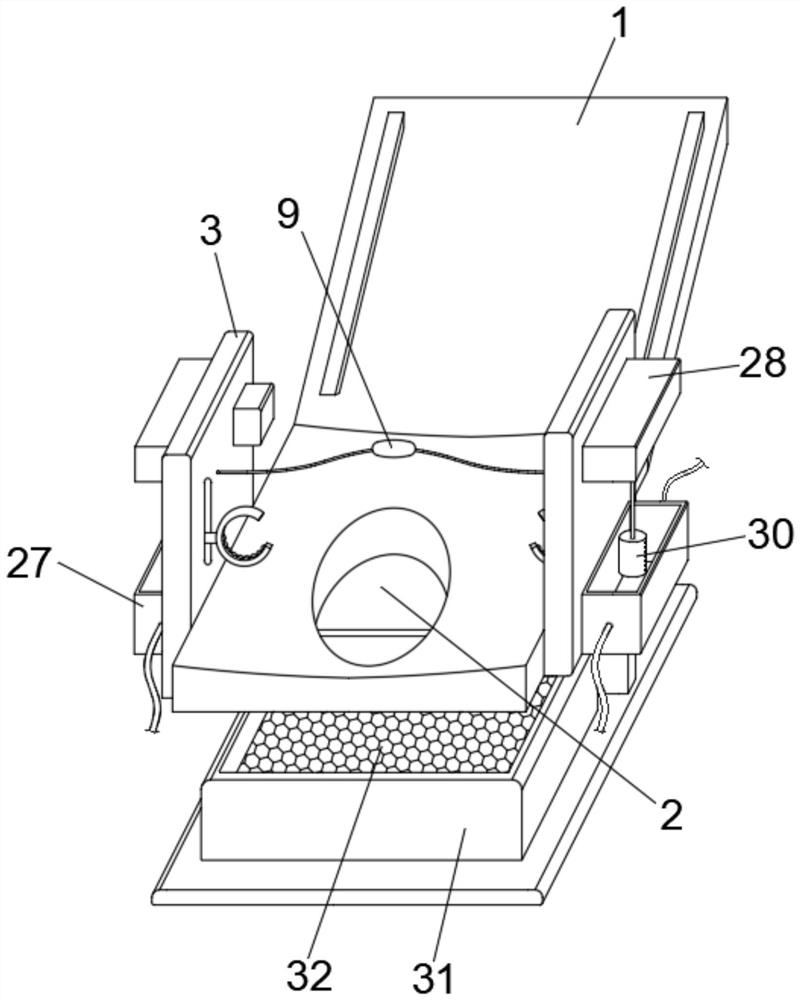

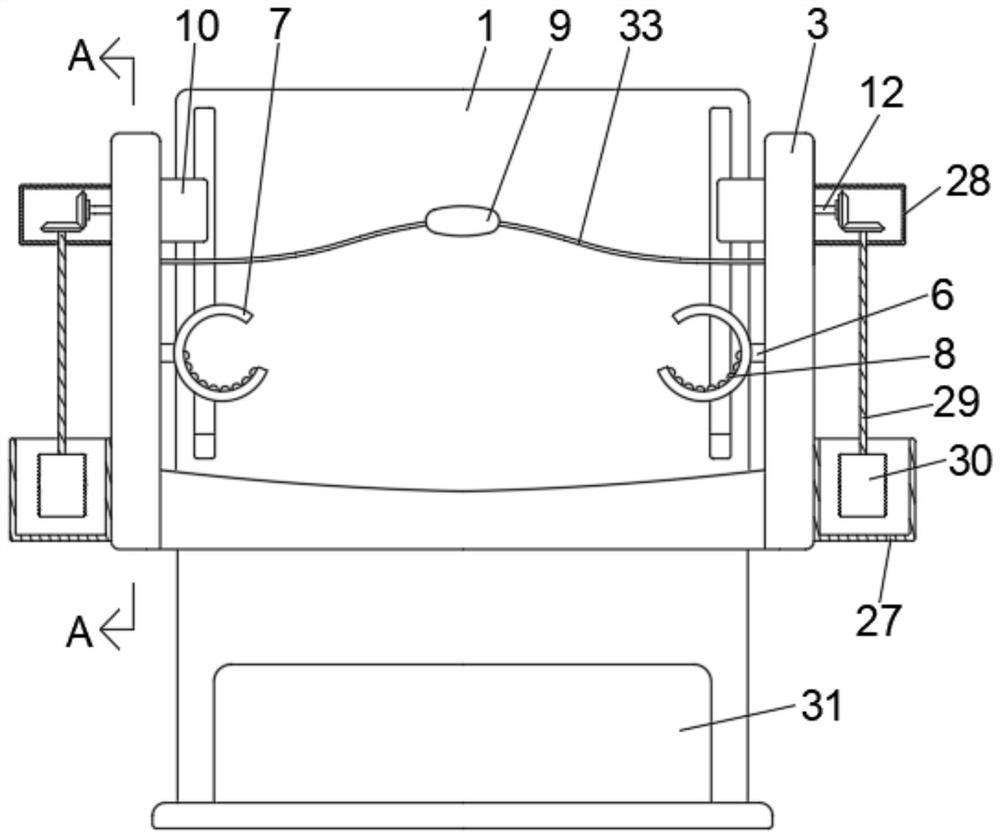

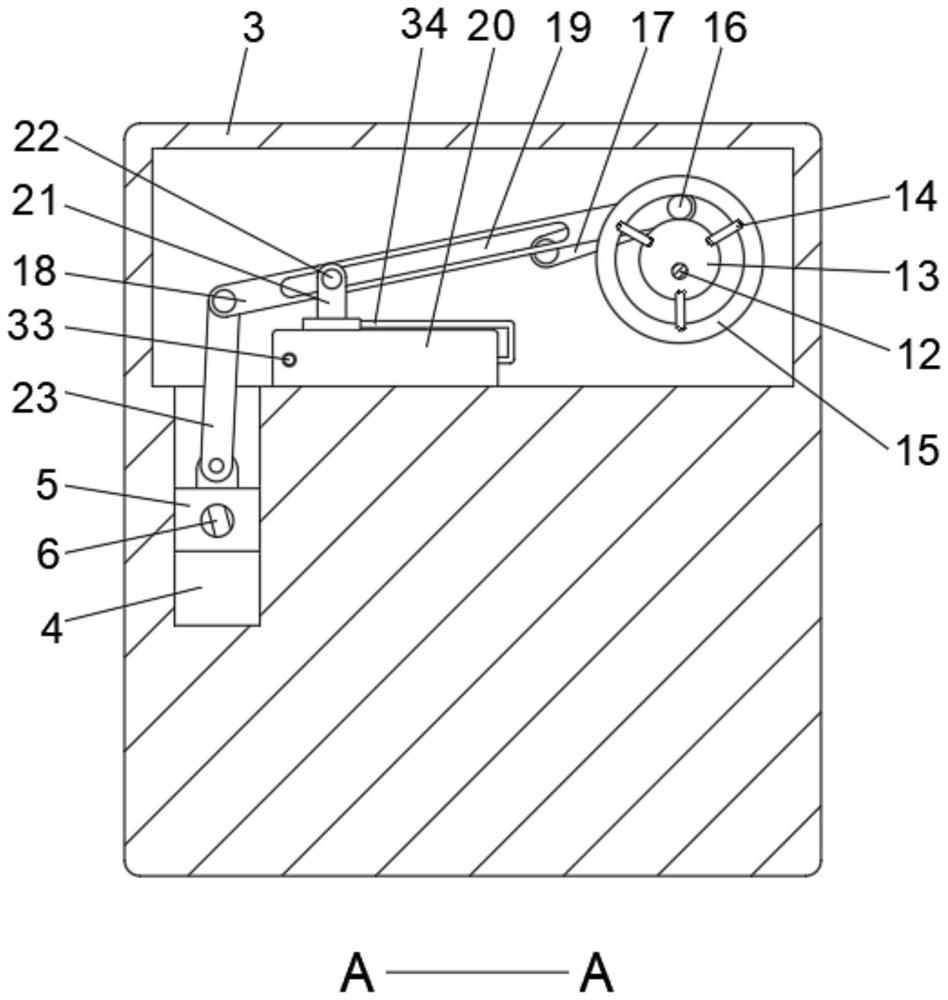

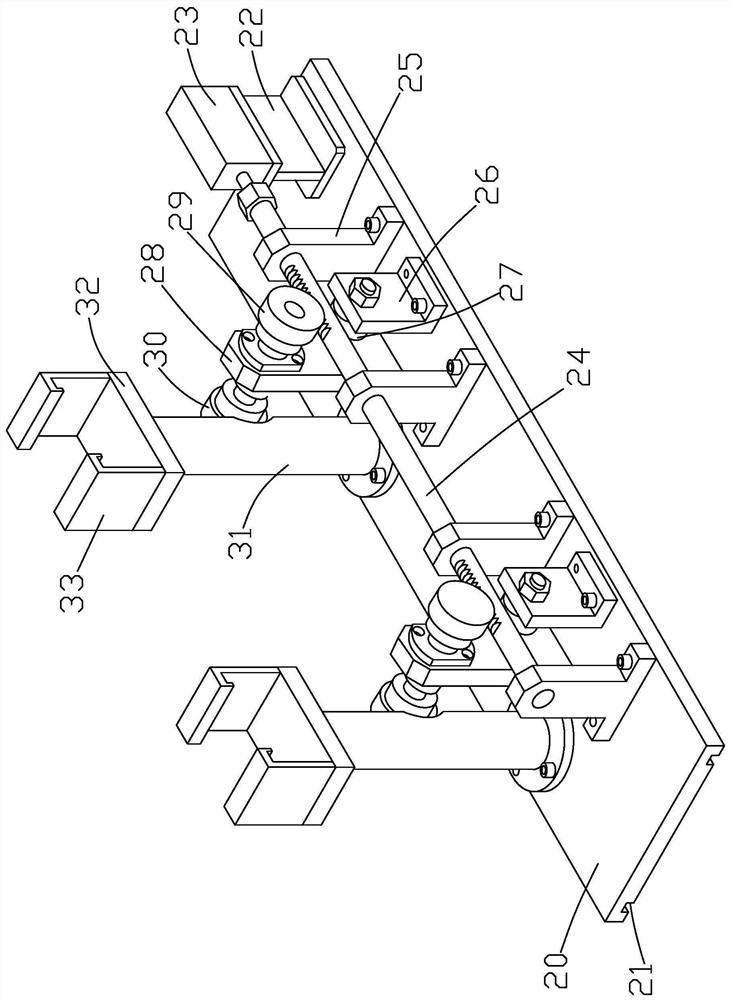

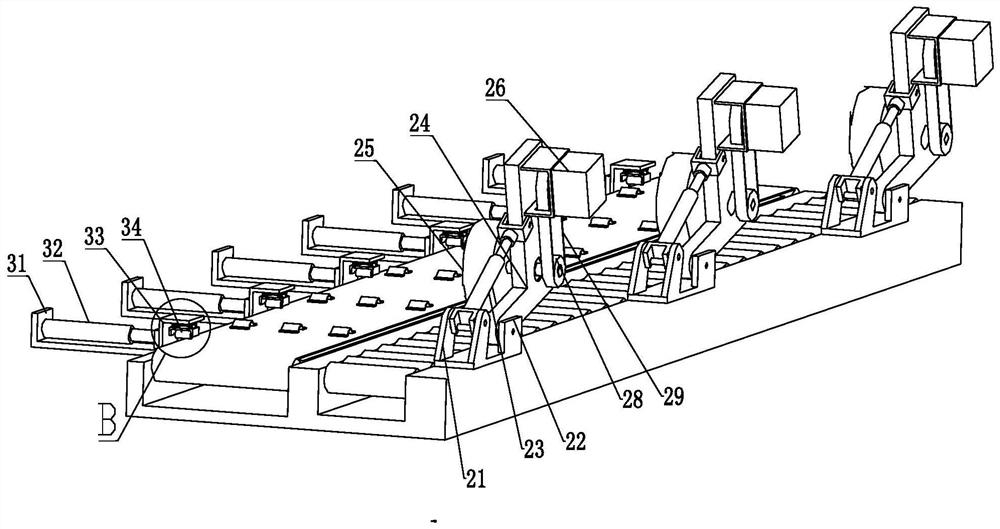

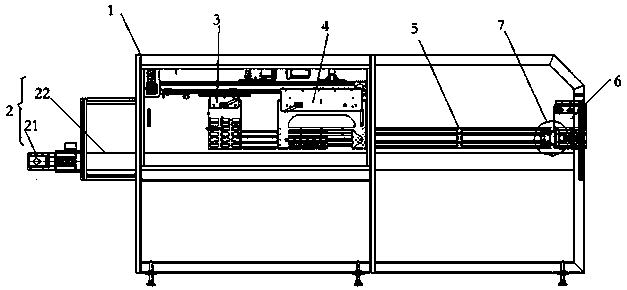

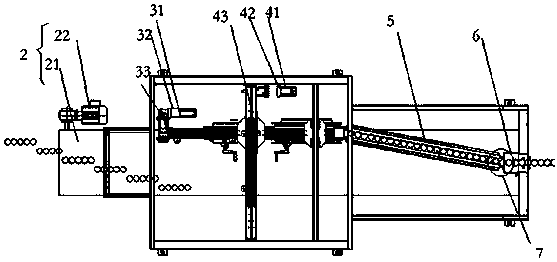

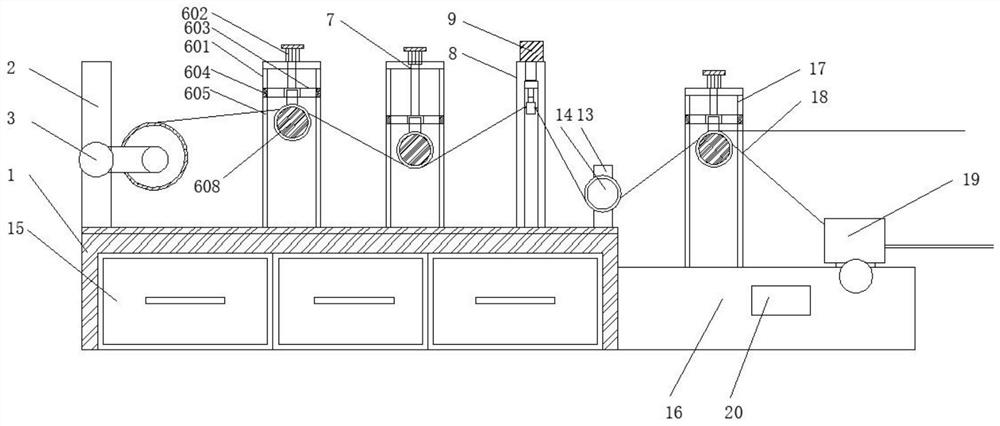

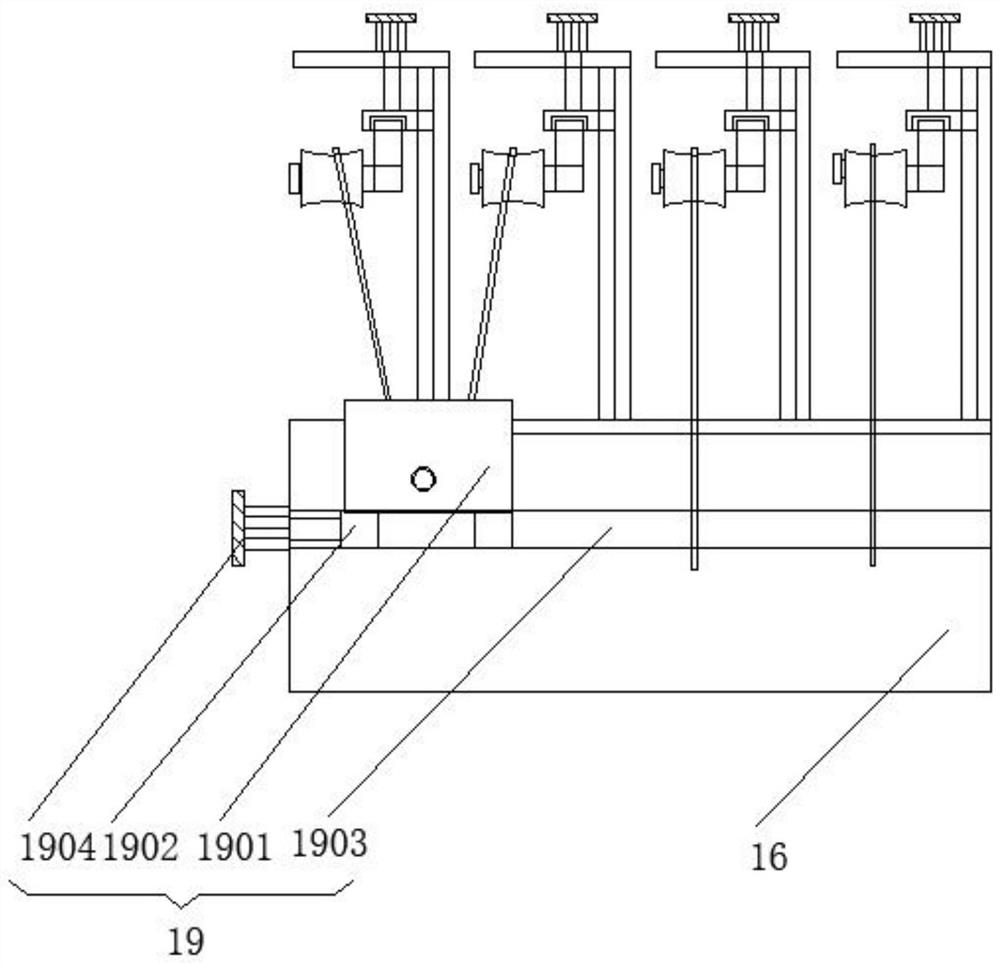

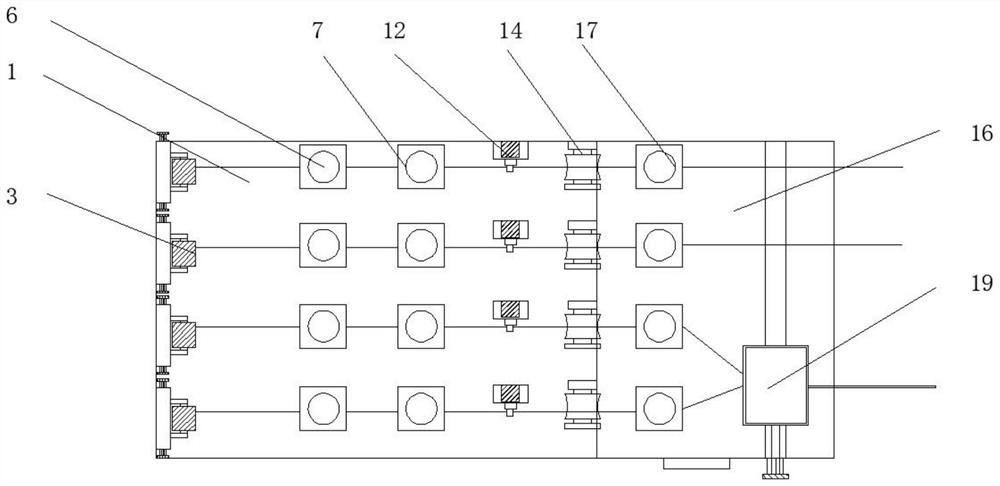

Automatic hand buckle buckling and pressing equipment

PendingCN112009028AAffect normal deliveryNormal delivery does not produceBag making operationsPaper-makingStructural engineeringIndustrial engineering

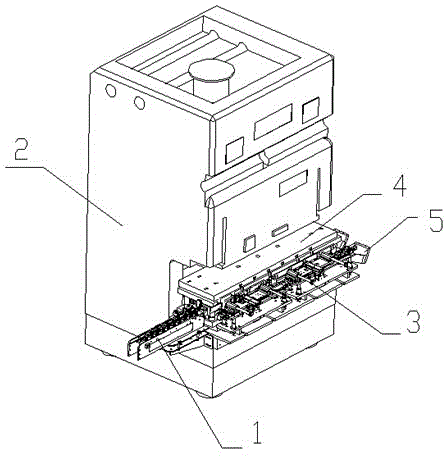

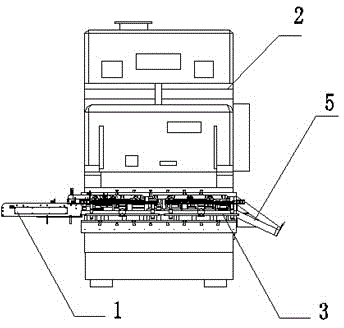

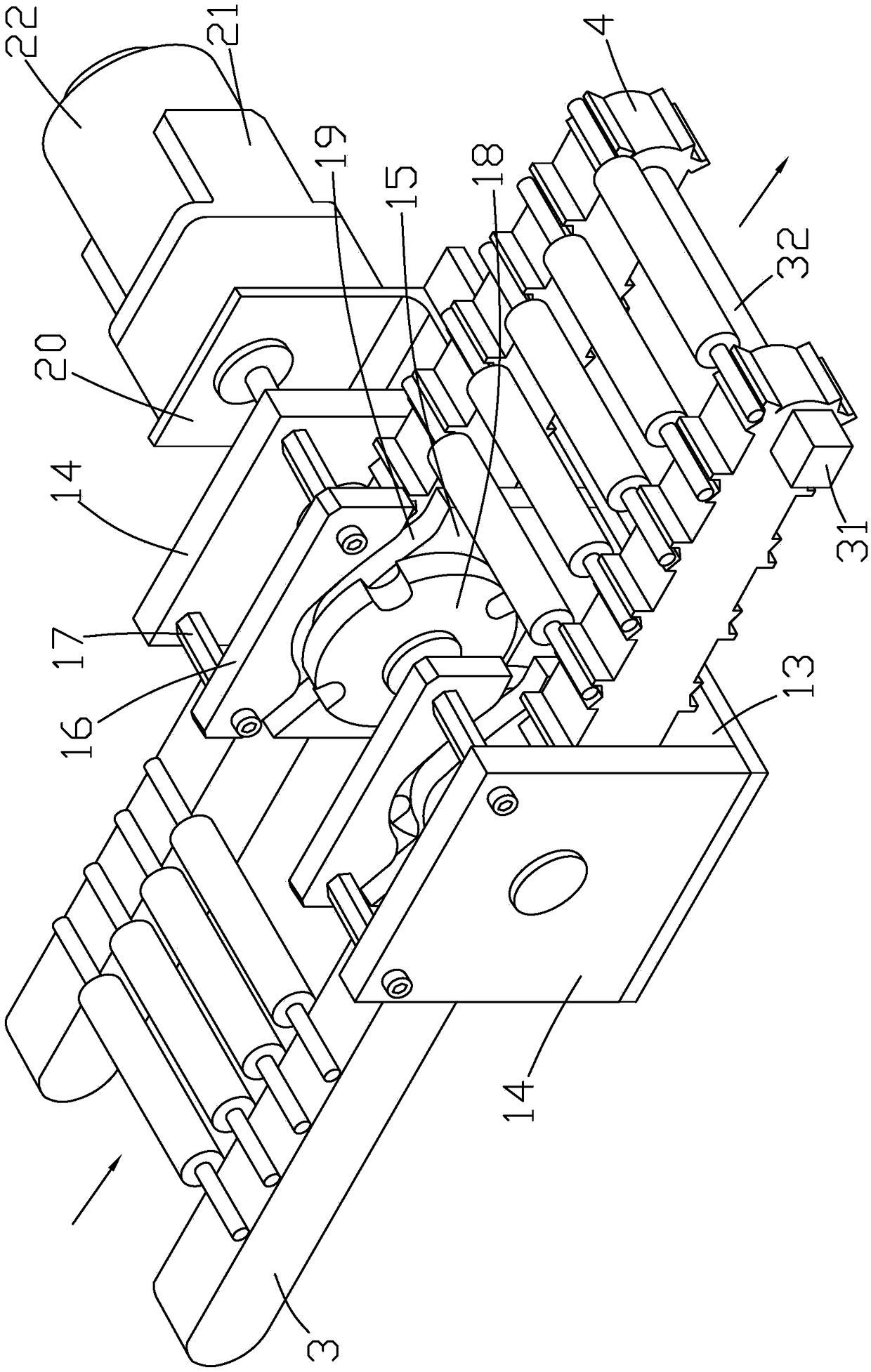

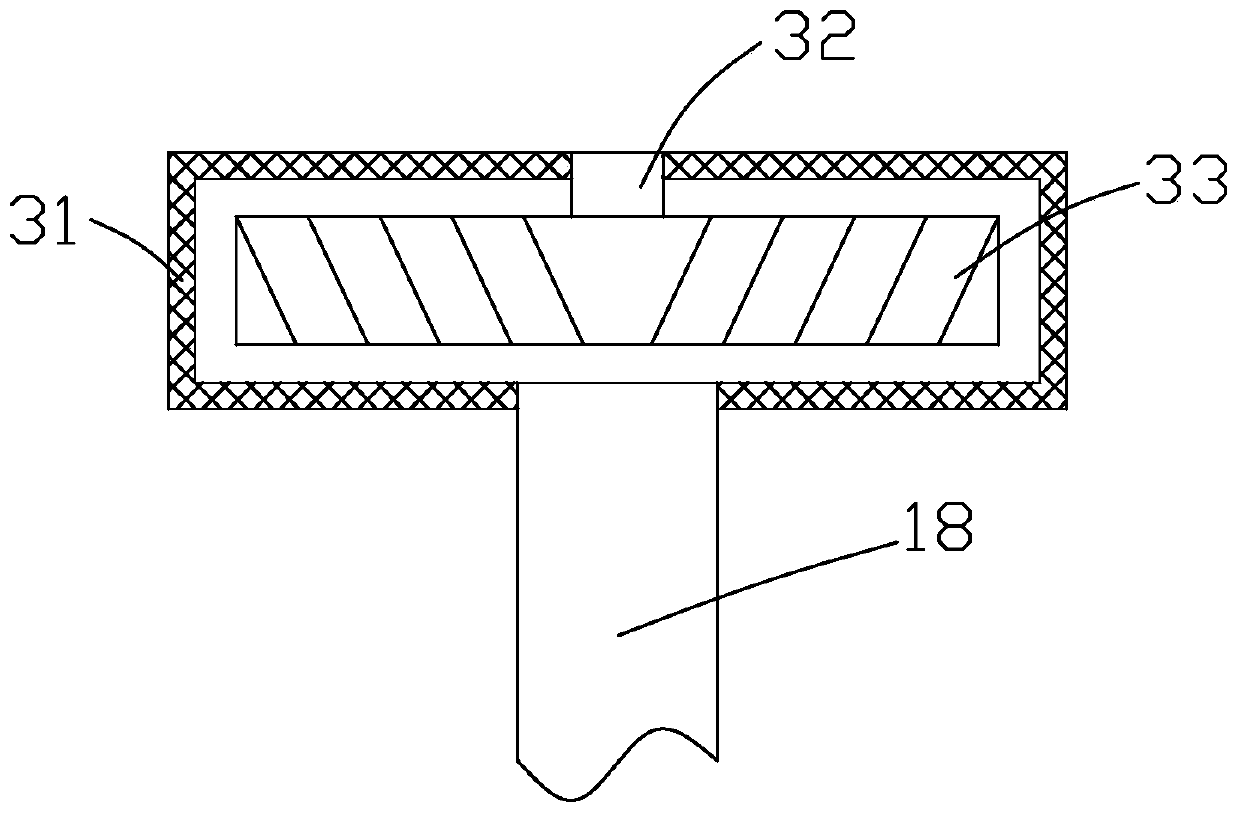

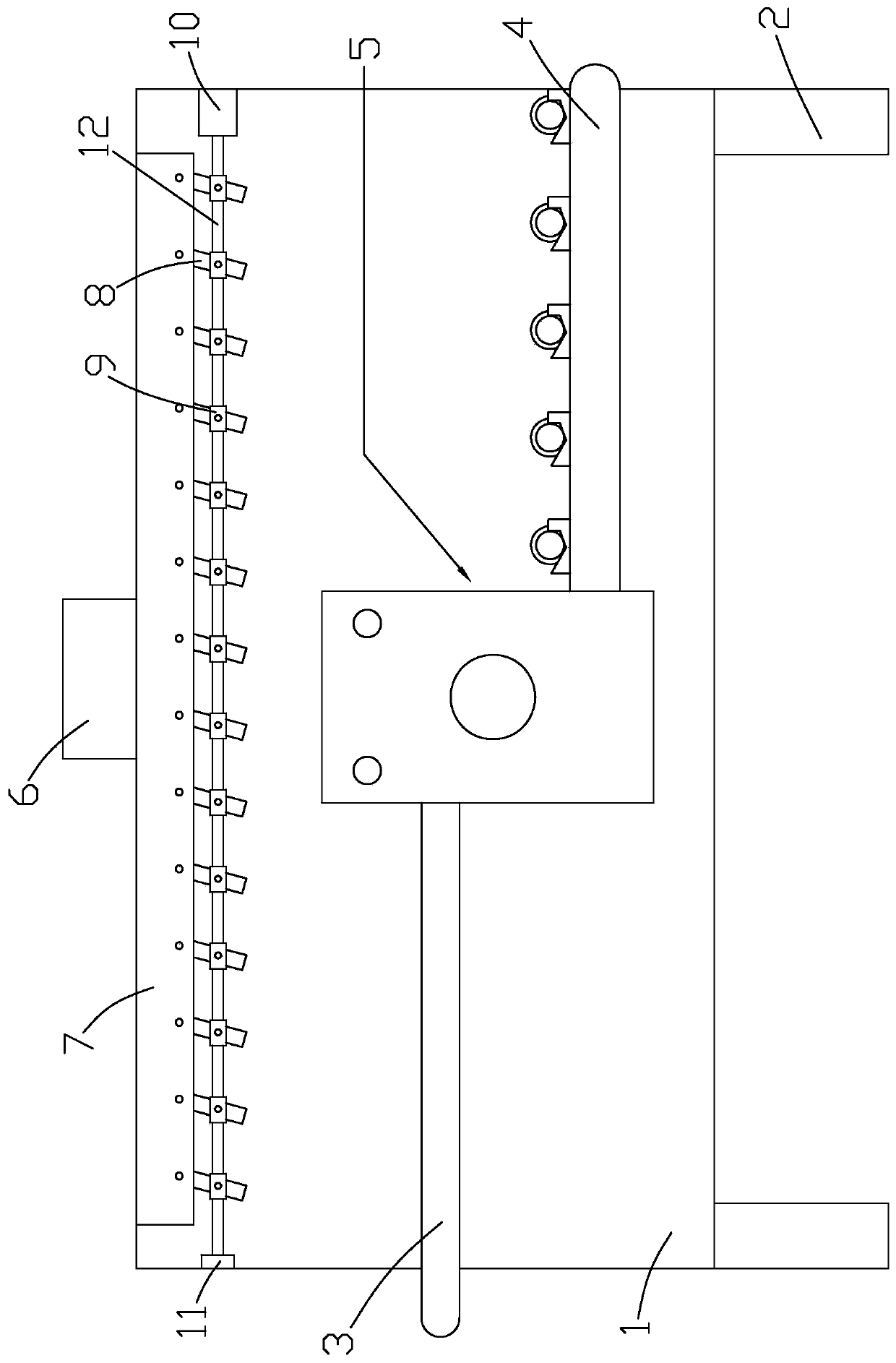

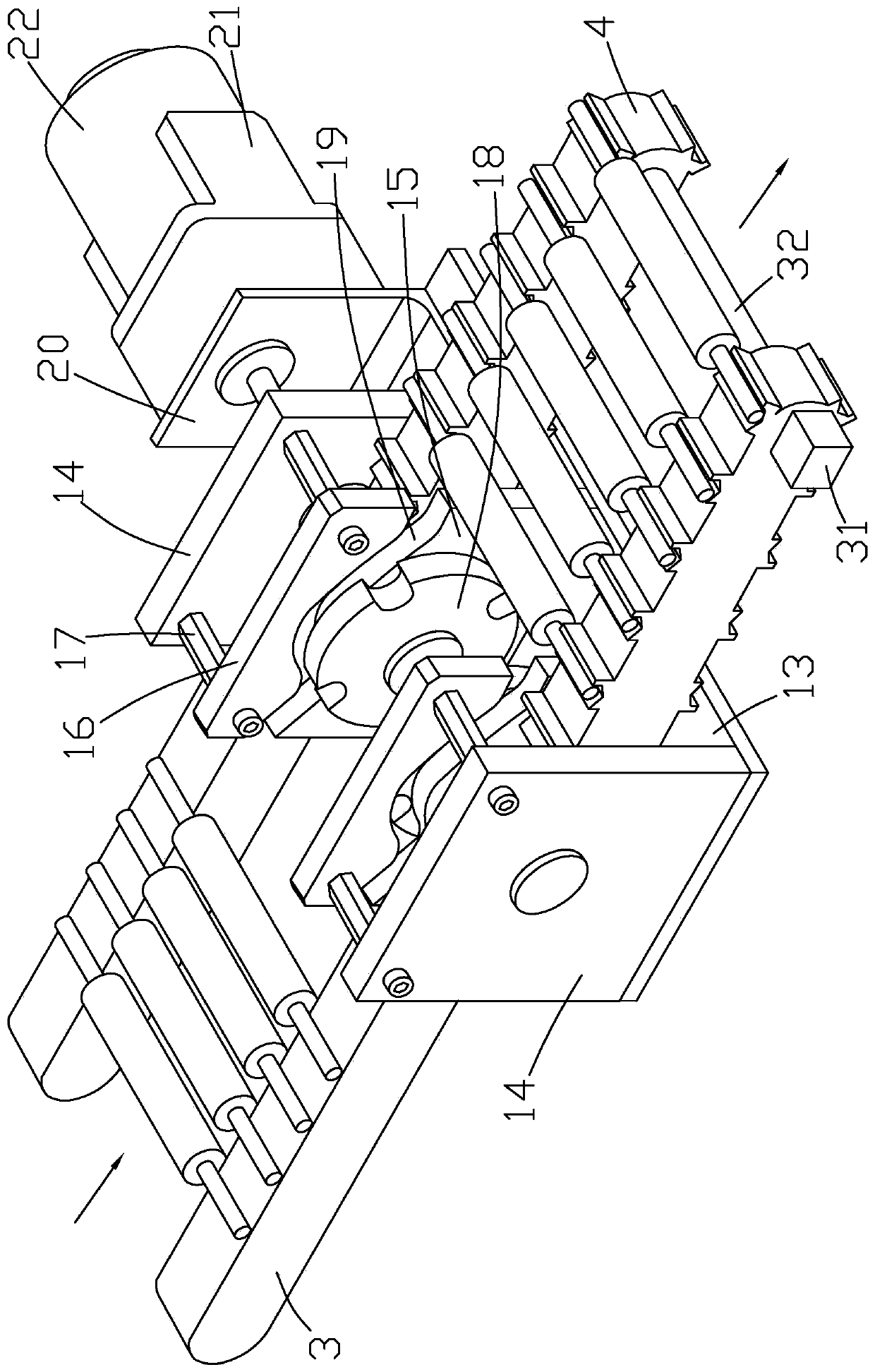

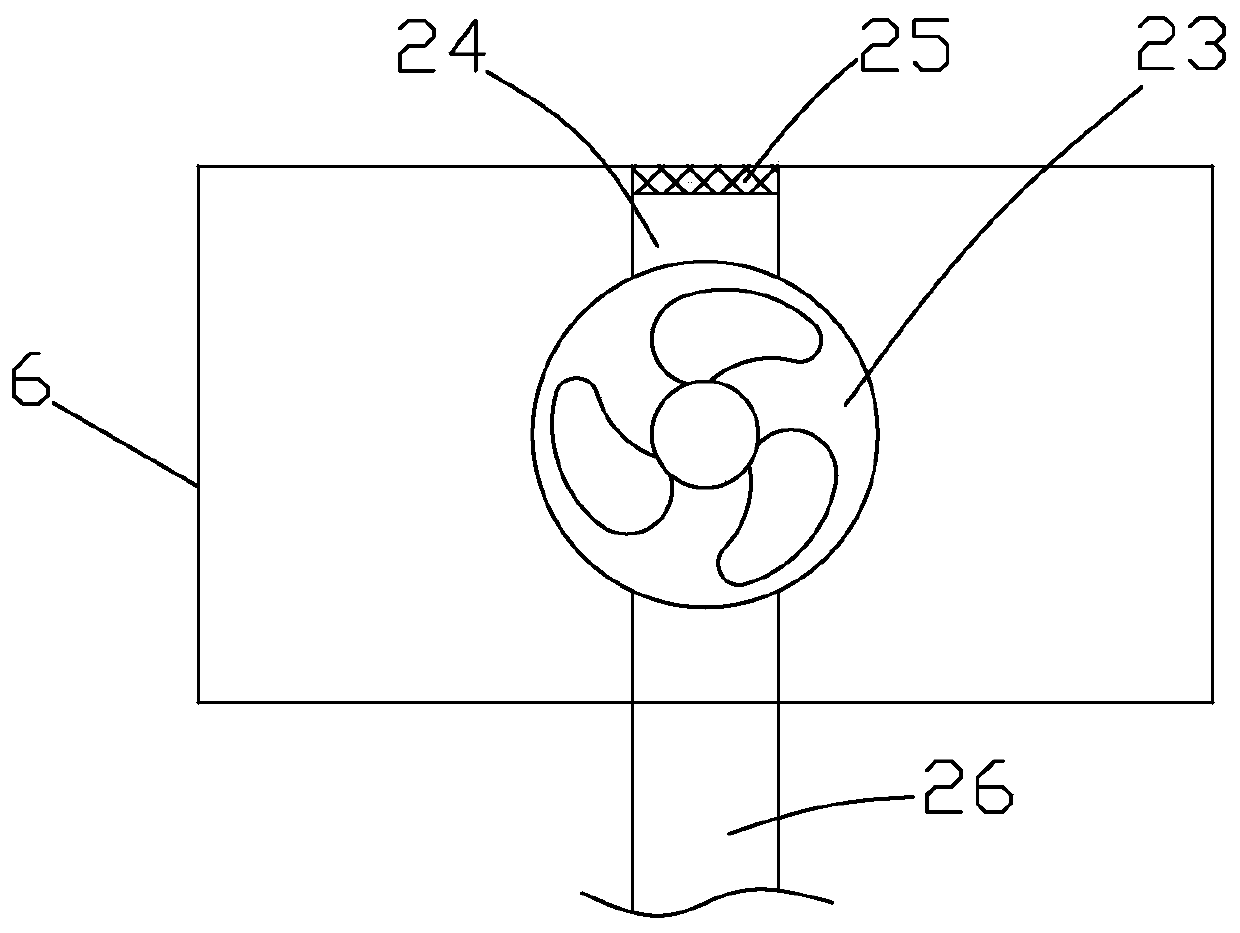

The invention discloses automatic hand buckle buckling and pressing equipment. The automatic hand buckle buckling and pressing equipment comprises a frame, wherein a hand buckle feeding device, a woven bag feeding device and a stamping device are arranged on the frame; the stamping device is provided with a stamping station and a pressing and buckling station; a primary buckle feeding track and asecondary buckle feeding track are respectively arranged on the upper end surface and the lower end surface of a woven bag, corresponding to the pressing and buckling station, of the hand buckle feeding device; the primary buckle feeding track and the secondary buckle feeding track are respectively provided with filling mechanisms for feeding primary buckles into the primary buckle feeding track and feeding secondary buckles into the secondary buckle feeding track; and sorting mechanisms used for distinguishing and sorting the front faces and the back faces of the primary buckles and the frontfaces and the back faces of the secondary buckles are arranged on track paths of the primary buckle feeding track and the secondary buckle feeding track respectively. The automatic hand buckle buckling and pressing equipment provided by the invention can perform automatic production, improves the production efficiency and is used for automatic processing and assembling of woven bag punching and automatic buckling of hand buckles.

Owner:WENZHOU KEWANG MACHINERY

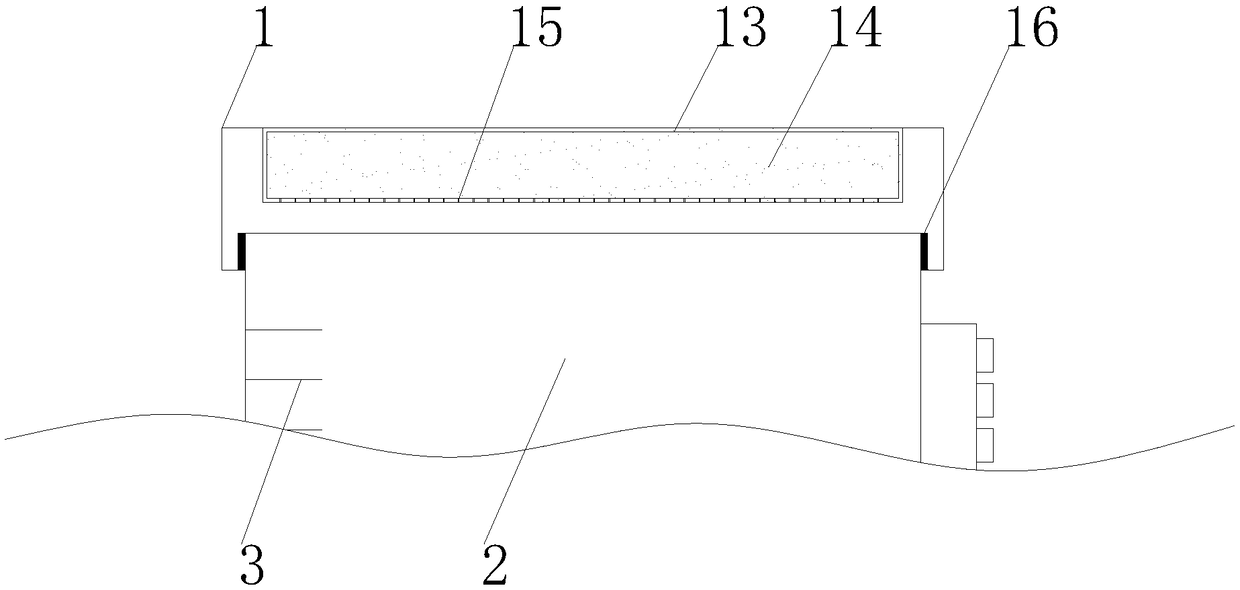

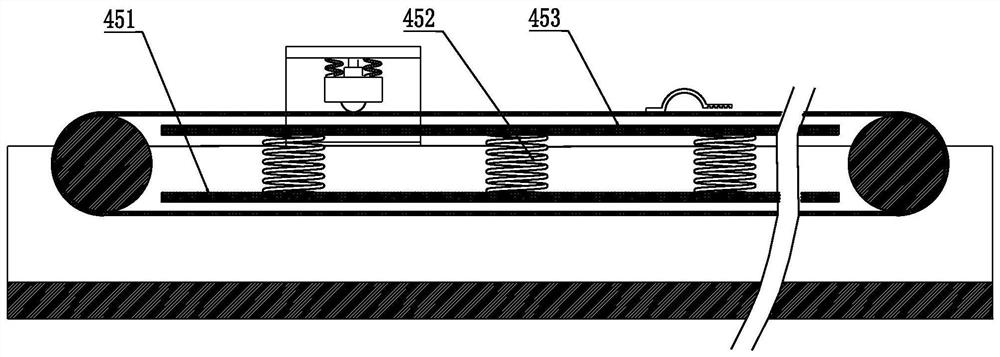

Cloth conveying device used for textile machine

ActiveCN109399113AImprove delivery efficiencyControl packing timeCleaningMechanical conveyorsEngineeringMechanical engineering

The invention discloses a cloth conveying device used for a textile machine. A box body is included, and is internally provided with an intermittent conveying mechanism; the left side and the right side of the intermittent conveying mechanism are provided with two feeding belts and two discharging belts correspondingly; the intermittent conveying mechanism comprises a base, side plates, intermittent rotating disks and a second motor; two lower supporting plates are arranged between the two side plates; upper supporting plates are arranged above the lower supporting plates; a guiding groove isformed between the upper supporting plates and the lower supporting plates; a rotating shaft is connected to the second motor; the two intermittent rotating disks are fixedly connected to the rotatingshaft, and are located on the side close to the side plates; and a dust clearing mechanism is arranged on the top face of the box body. The cloth conveying device used for the textile machine is simple in structure and high in practicability, conveying can be achieved on the discharging belts through the intermittent conveying mechanism, the labor intensity of manual carrying is greatly lowered,the cloth conveying efficiency is improved, the conveying interval between all cloth conveying rollers can be controlled, and then the binning time of cloth is controlled.

Owner:佛山市南海区赛宏毡业有限公司

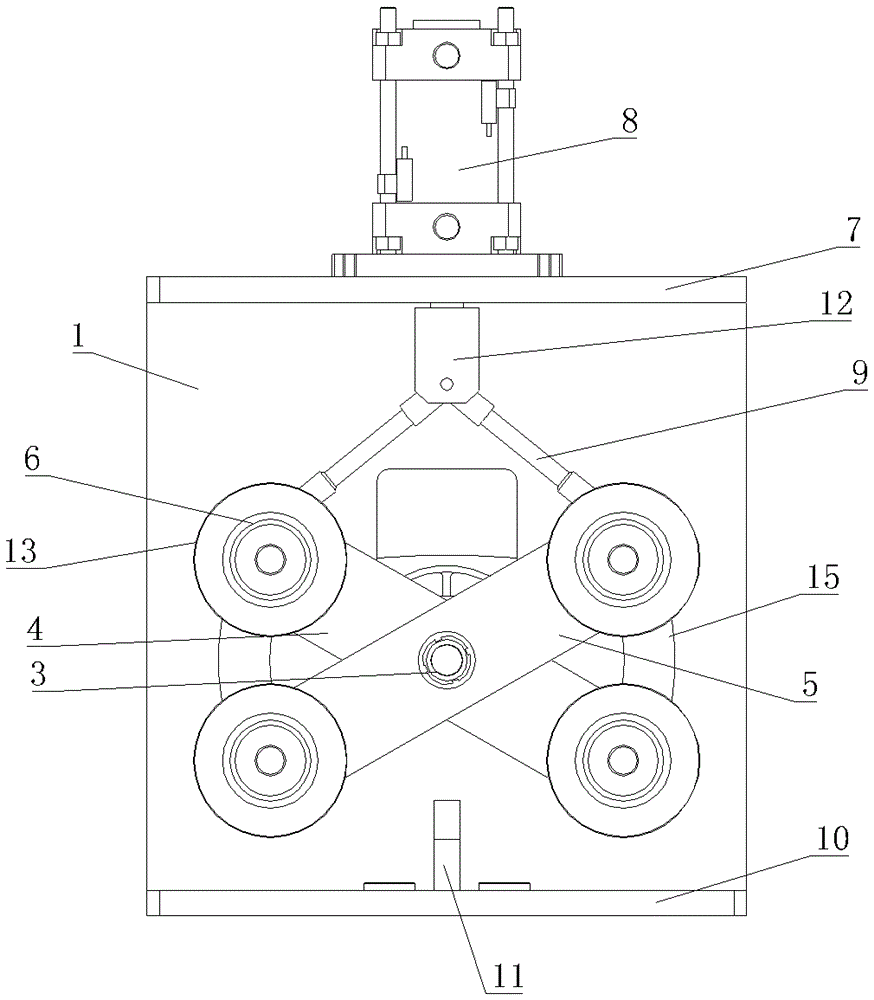

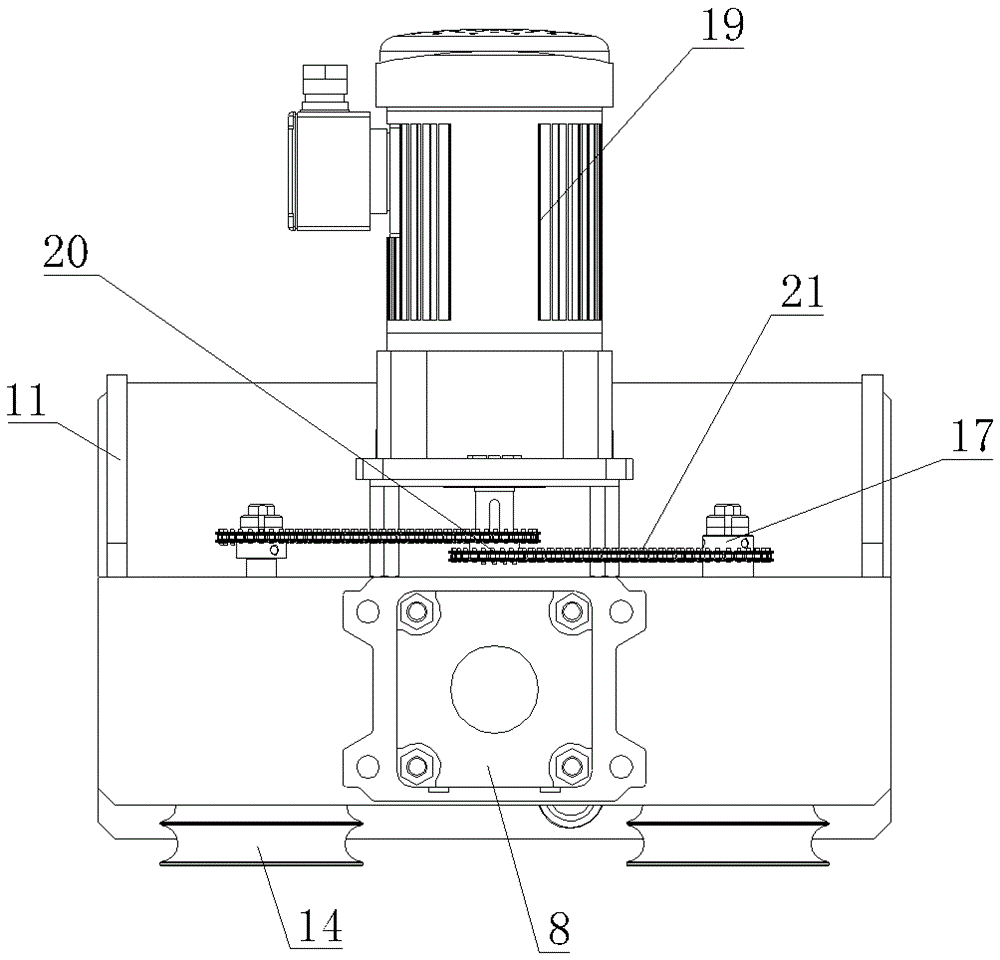

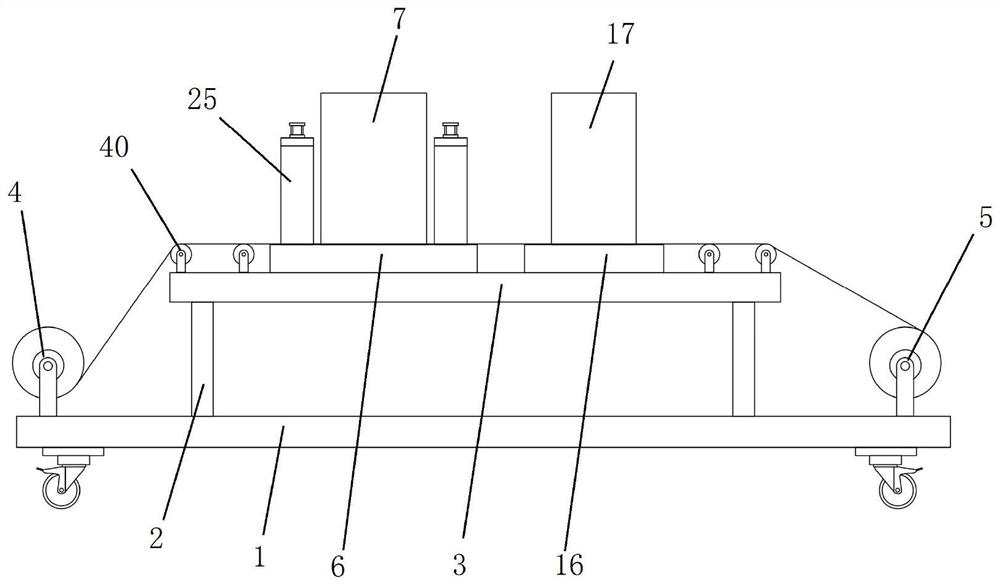

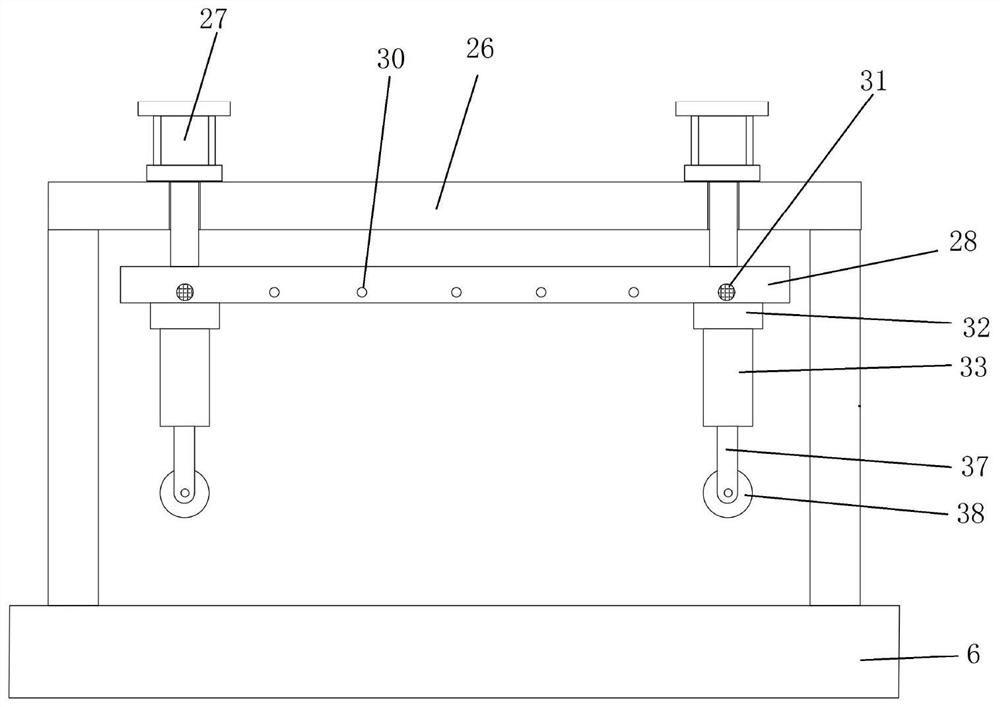

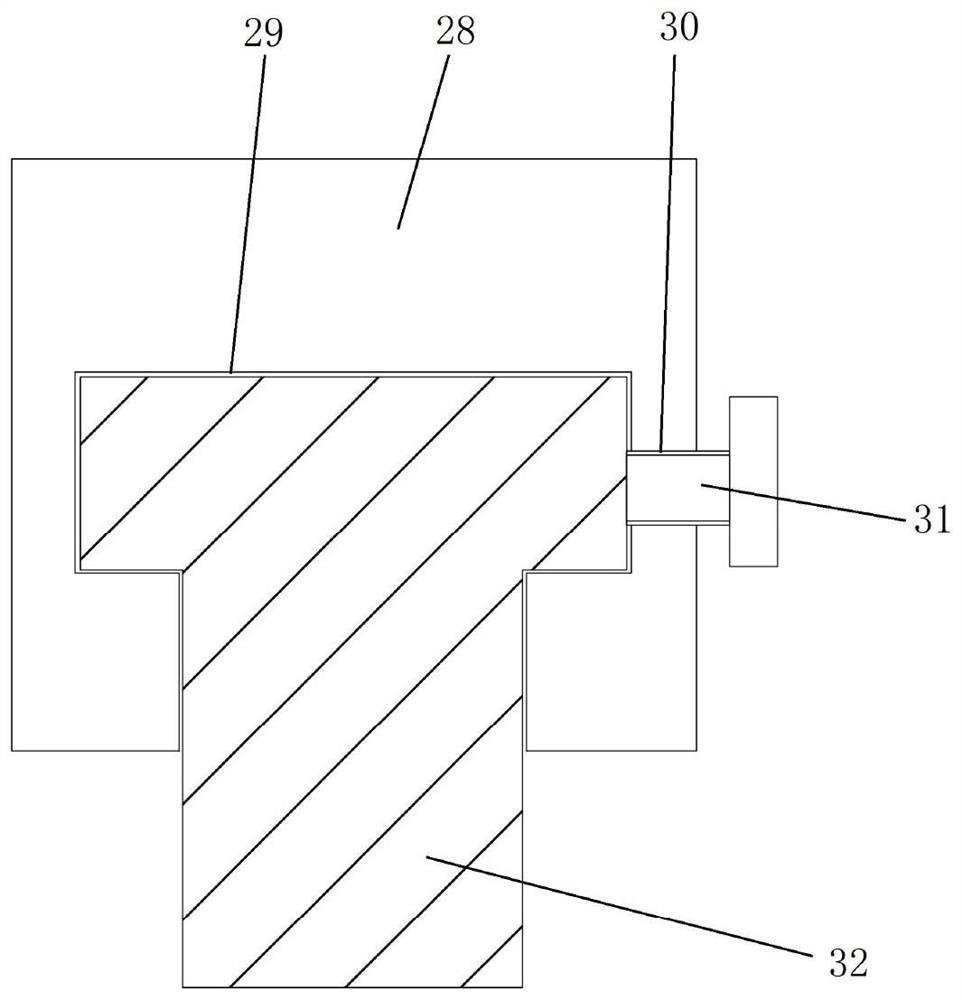

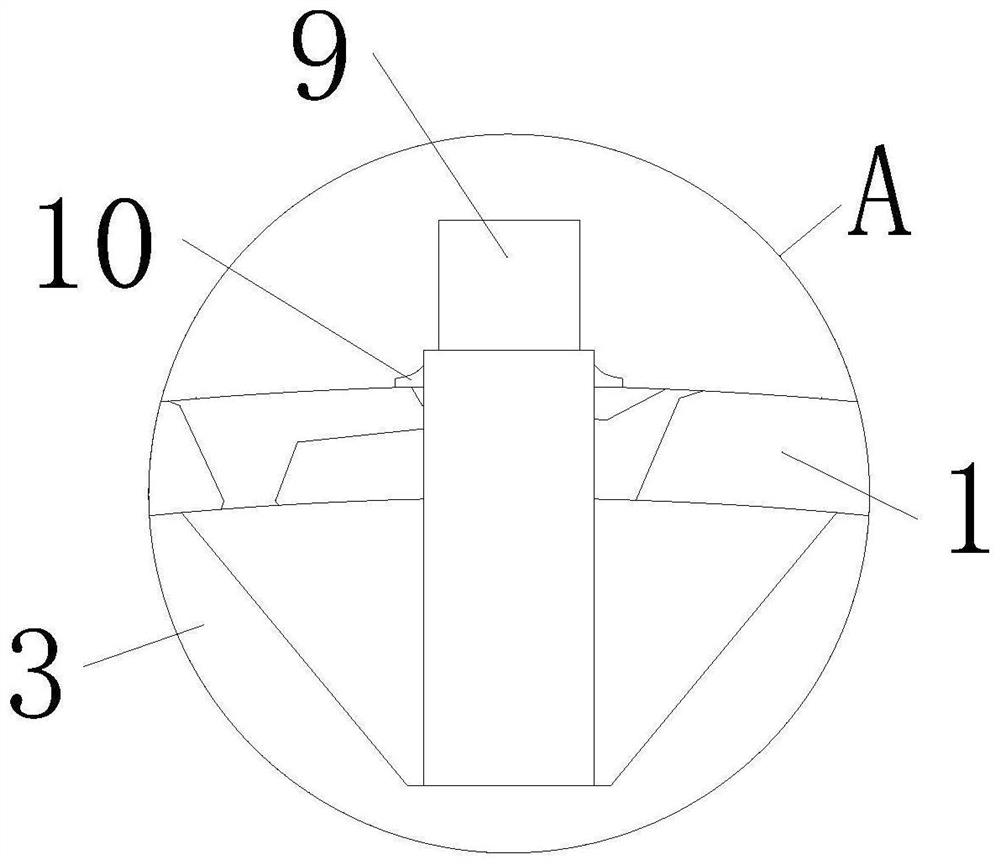

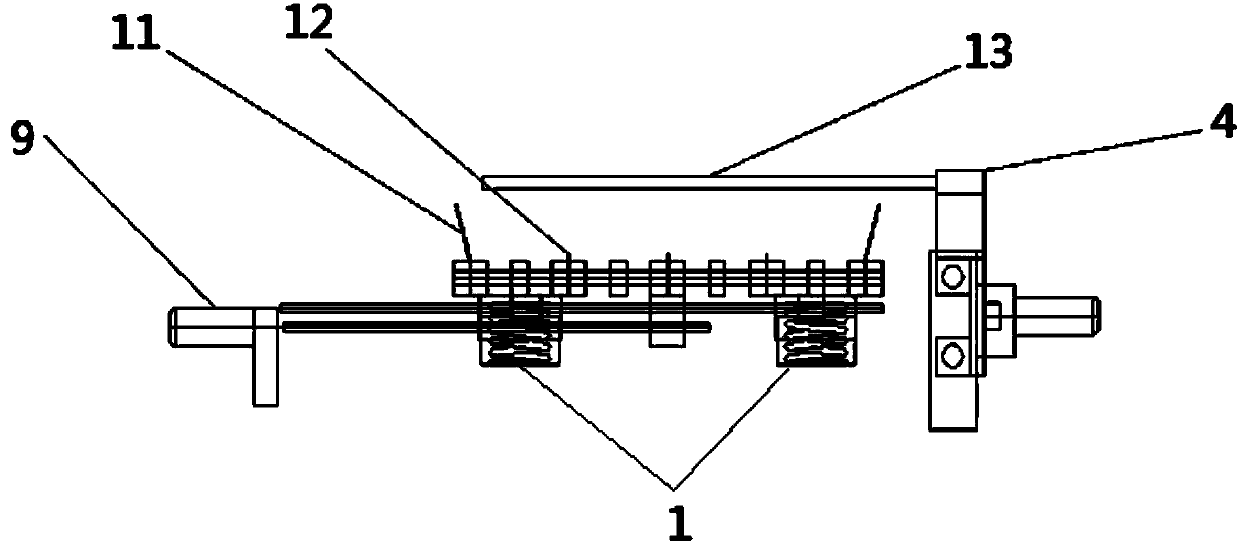

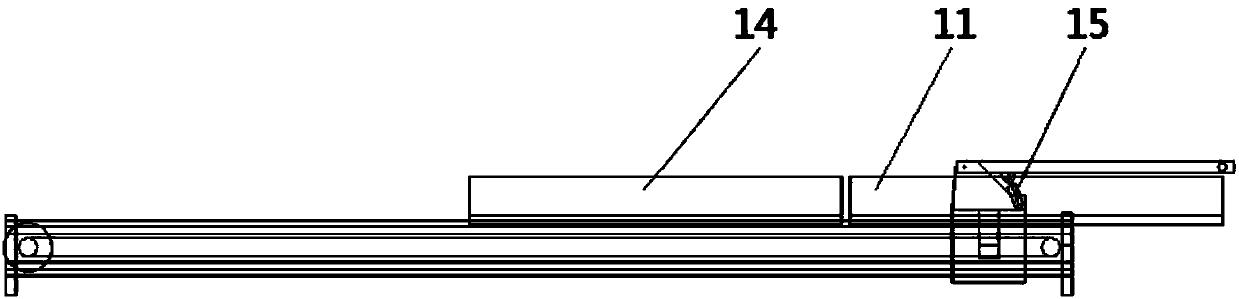

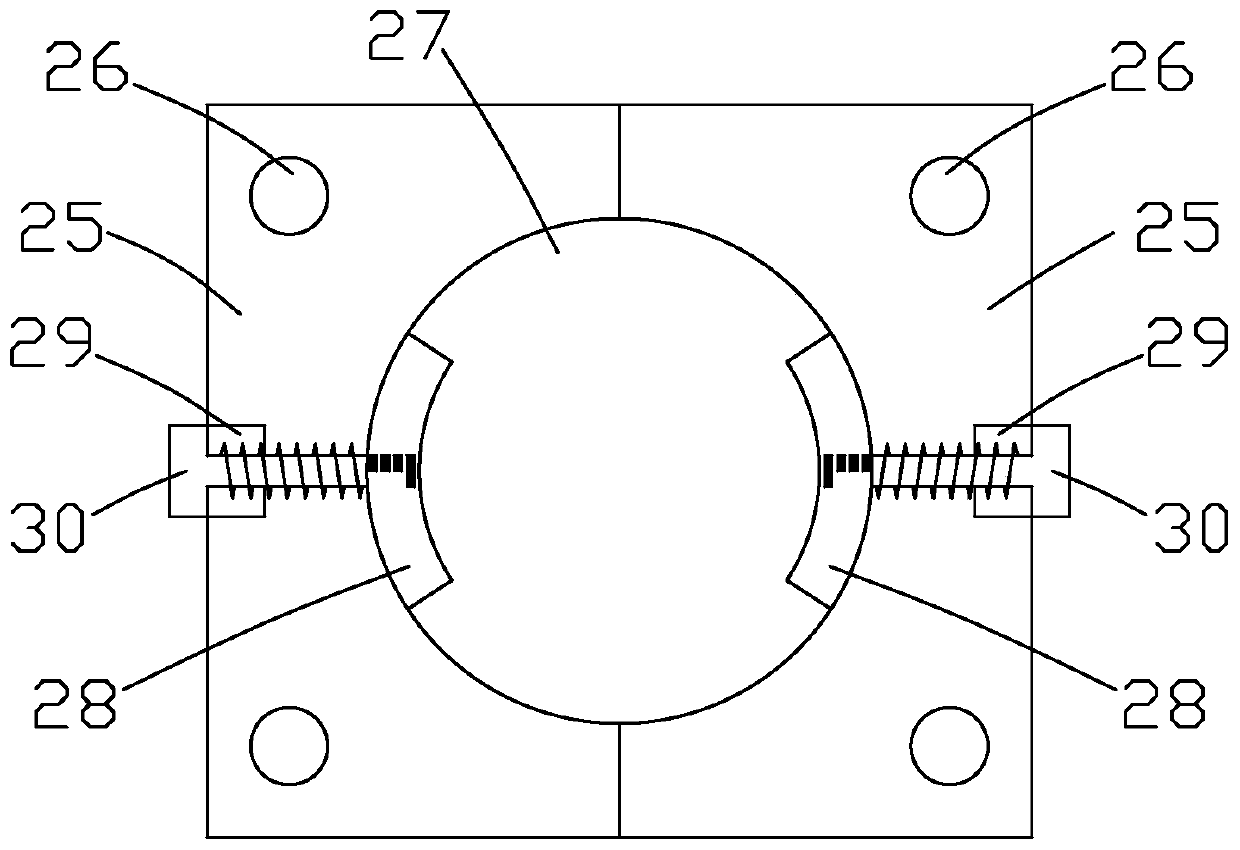

Tube stock conveying and clamping device

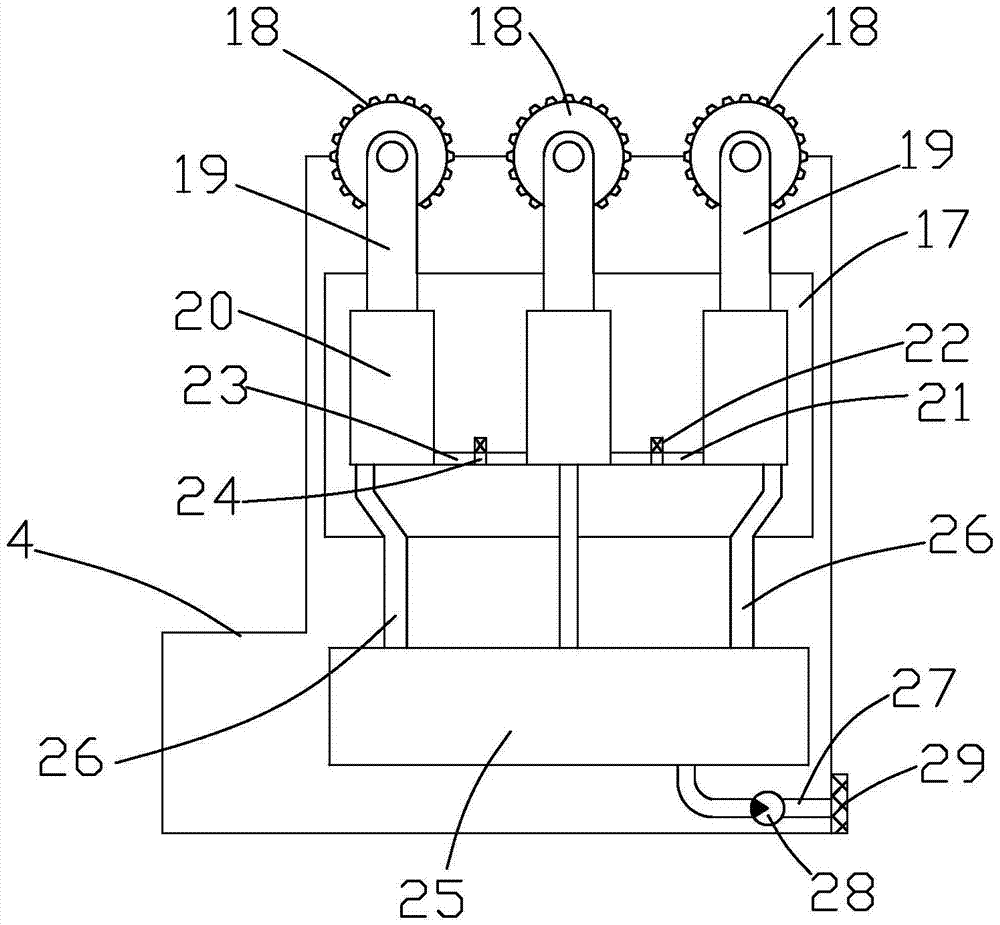

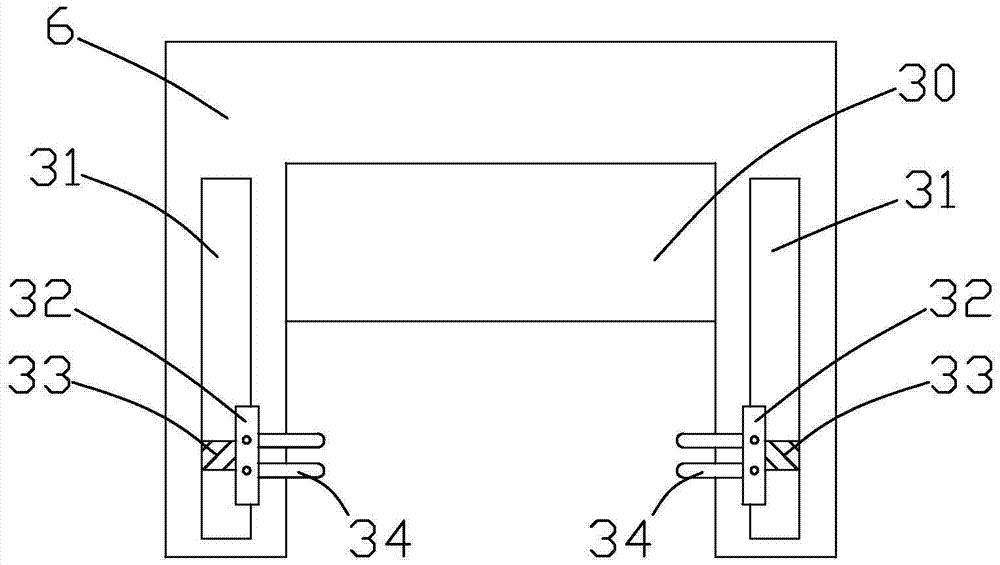

The invention provides a tube stock conveying and clamping device. The tube stock conveying and clamping device can drive a tube stock to be conveyed, can also press the tube stock tightly when conveying the tube stock and is good in control coordination and high in regulating and clamping efficiency. The tube stock conveying and clamping device comprises a rack. The rack is provided with a bearing pedestal, and a main shaft is arranged on the bearing pedestal. A first installation plate and a second installation plate are rotatably arranged on the main shaft and arranged in a staggered manner. Guide wheel devices are arranged at the two ends of the first installation plate and the two ends of the second installation plate. An air cylinder is arranged at the upper end of the rack and arranged over the main shaft. A piston rod of the air cylinder is vertically and downwards arranged and connected with a connecting rod in a hinged manner, and the connecting rod is connected with the upper end of the first installation plate and the upper end of the second installation plate in a hinged manner. Rotating grooves are formed in the rack, rotating shafts which are arranged on guide wheel bearing pedestals and used for driving the guide wheels to rotate backwards extend out to penetrate the corresponding rotating grooves and are provided with driven sprockets, a gear motor is arranged on the rear side of the rack, and a drive sprocket is arranged on the gear motor and connected with the driven sprockets through chains.

Owner:WUXI MINGZHU TURBOCHARGER MFG

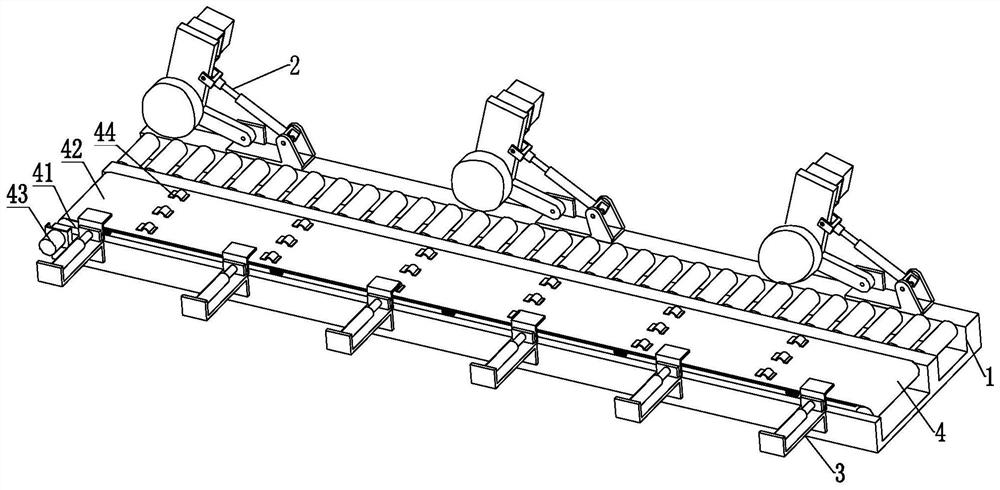

Woven plastic bag pressing manufacturing forming machine

ActiveCN110884220AImprove efficiencyHigh degree of automationBag making operationsPaper-makingManufactured formMolding machine

The invention relates to a woven plastic bag pressing manufacturing forming machine, which comprises a base, roll forming mechanisms, pressing mechanisms and conveying devices, and is characterized inthat the pressing mechanisms are uniformly mounted on the front side of the base; the roll forming mechanisms are uniformly mounted on the rear side of the base; a conveying groove and a pressing groove are sequentially formed in the middle of the base from front to back; rollers which are uniformly distributed are arranged in the pressing groove through bearings; the conveying device is mountedin the conveying groove. By means of the multiple roll forming mechanisms and the multiple pressing mechanisms arranged on the base, multiple woven bag materials can be automatically pressed and formed at the same time in the conveying process, the purpose of accurate folding is achieved, and therefore, the problems that in the prior art, due to manual pressing, knitting materials are sewn in a staggered mode, labor intensity is high, time and labor are consumed, production cost is high, efficiency is low, and the automation degree is low are solved.

Owner:广西安得塑业有限公司

Cloth printing equipment for garment production

PendingCN114104811AFully automatedConvenient self-winding storagePrinting press partsWebs handlingTextile printerWorkbench

The invention discloses cloth printing equipment for garment production, which comprises a base, a frame body is arranged in the middle of the top of the base, a working table is mounted at the top of the frame body, a printing operation table and a drying operation table are sequentially mounted on the working table in the length direction, a printing mechanism is arranged on the printing operation table, and a drying mechanism is arranged on the drying operation table. The base is provided with a cloth releasing mechanism and a cloth collecting mechanism which are located on the two sides of the working table in the length direction respectively, a plurality of guide rollers are installed on the top of the working table through a support in the cloth conveying direction, and the outer sides of the guide rollers are movably sleeved with two annular adjusting plates which can be close to or away from each other in the length direction. The distance between the two annular adjusting plates is matched with the width of the cloth, and the two sides, in the cloth conveying direction, of the printing operation table are each provided with a flattening mechanism used for flattening the edge of the garment cloth.

Owner:苏州元润服饰有限公司

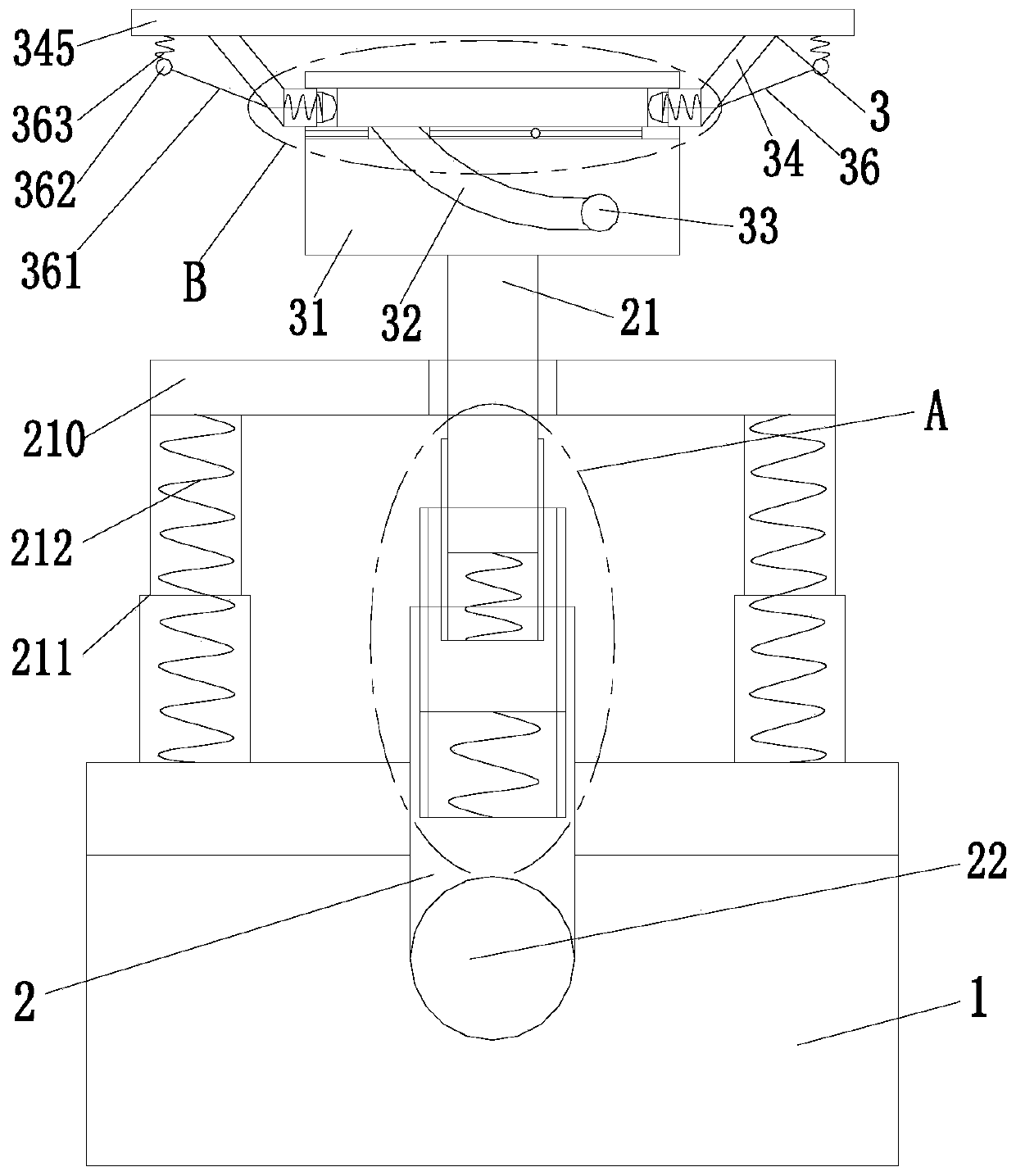

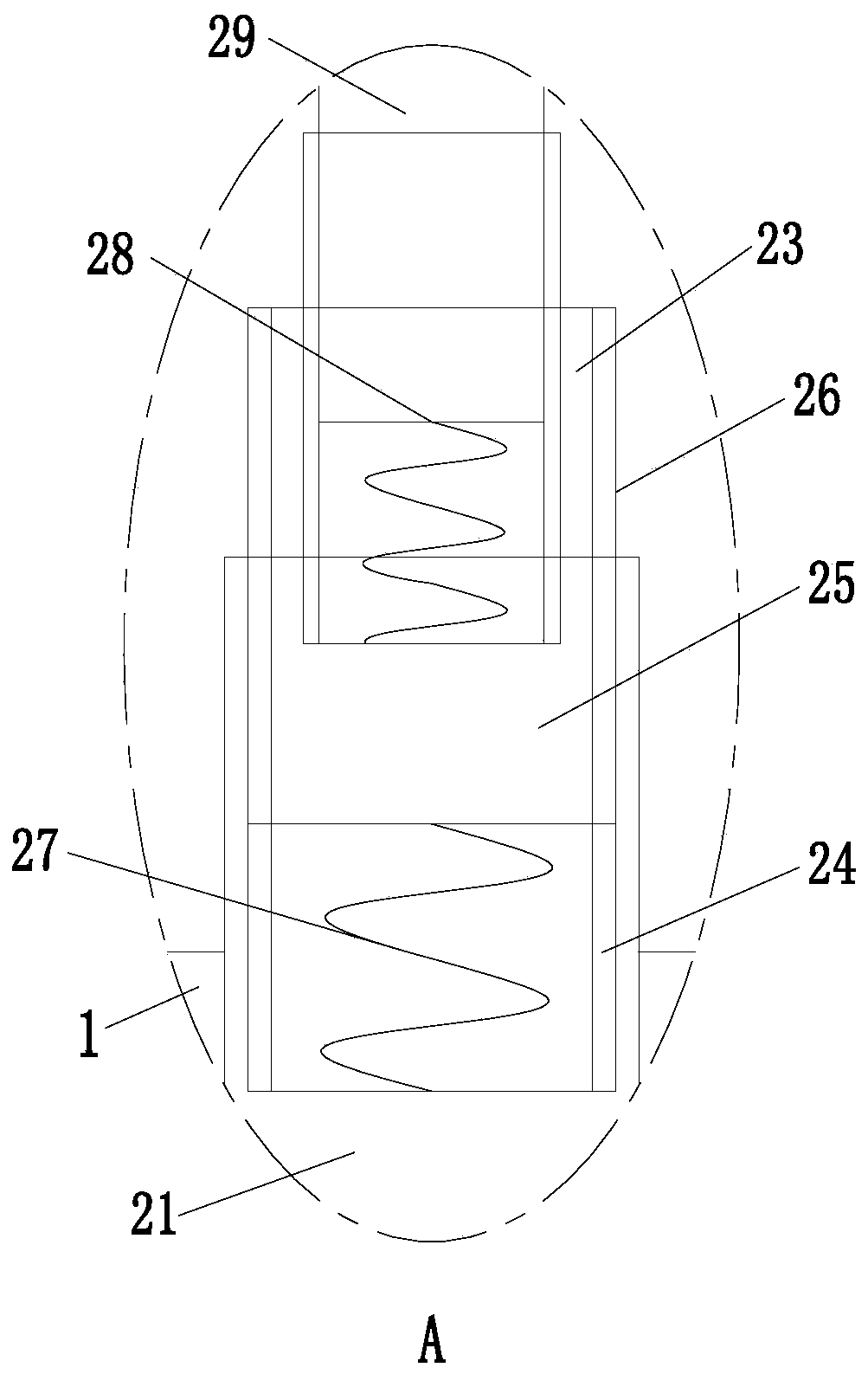

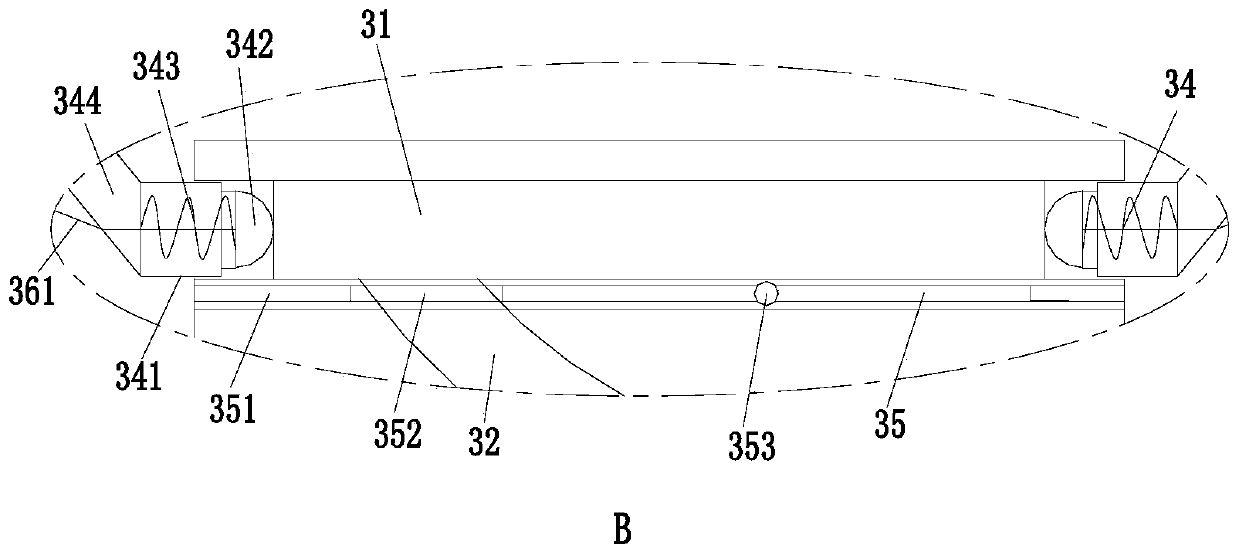

Delivery assisting device for obstetrics and gynecology department

PendingCN114767459APrevent muscle crampsIncrease the shaking of the legsOperating chairsDental chairsFetus fetusAssistive device

The invention discloses a delivery assisting device for obstetrics and gynecology department, and relates to the technical field of delivery assisting devices.The delivery assisting device comprises a chair body, a delivery channel is arranged on the surface of the chair body in a penetrating mode, limiting plates are fixedly connected to the two sides of the chair body, first limiting grooves are formed in the surfaces of the limiting plates, and sliding blocks are slidably connected to the inner walls of the first limiting grooves; a transmission rod is fixedly connected to the surface of the sliding block, a limiting ring is fixedly connected to the end of the transmission rod, and massage balls are fixedly installed on the inner wall of the limiting ring. Through mutual cooperation of the structures, a puerpera can be subjected to abreaction when feeling painful in the delivery process, the two legs of the puerpera are kept in a diverging state all the time, normal delivery of a fetus is prevented from being affected due to the fact that the two legs of the puerpera are closed in the follow-up delivery process, calf muscle groups of the puerpera are automatically massaged to prevent cramp, and the puerpera can feel comfortable. And when the puerpera feels pain and leg muscles are tightened, the effect of correspondingly increasing the leg shaking amplitude is achieved.

Owner:AIR FORCE MEDICAL UNIV

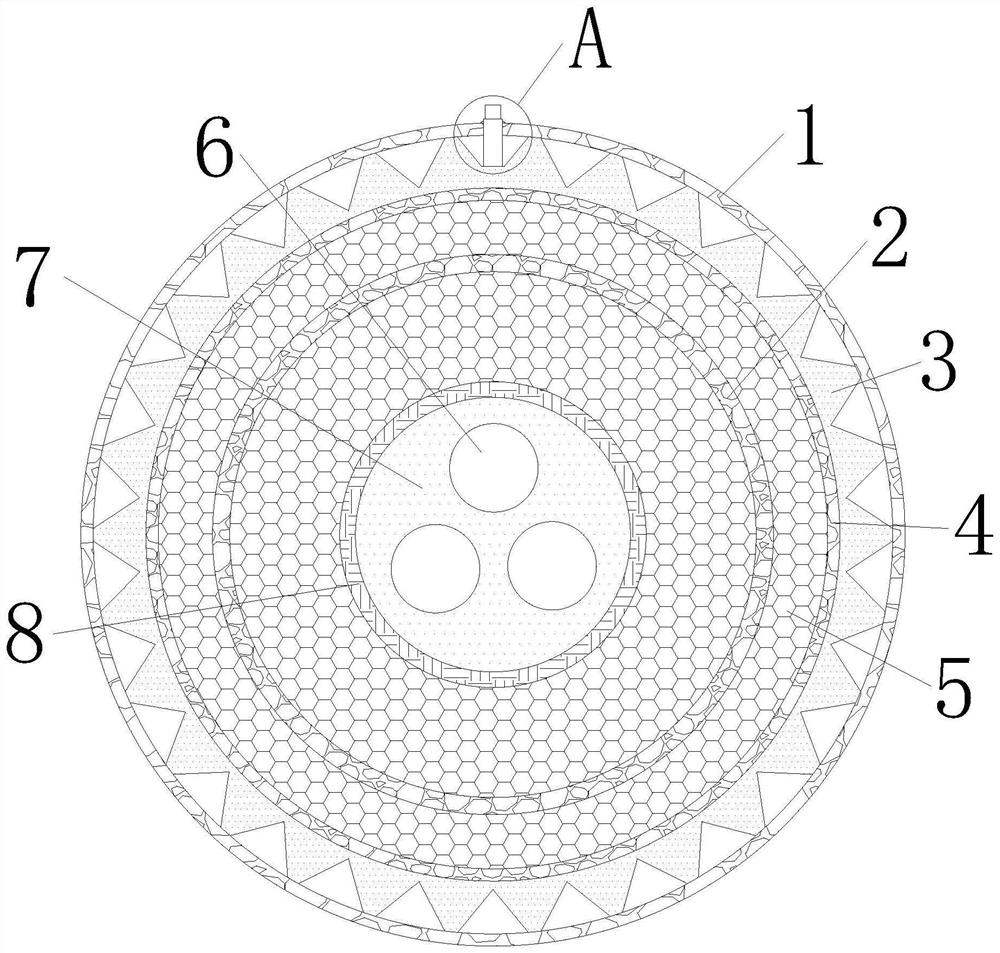

Super-strong electromagnetic compatibility and antistatic protection design

ActiveCN112466523AAvoid fireImprove shielding effectElectrostatic discharge protectionClimate change adaptationRubber materialEngineering

The invention provides a super-strong electromagnetic compatibility and antistatic protection design, and relates to the technical field of cable antistatic enhanced electromagnetic compatibility. Thesuper-strong electromagnetic compatibility comprises an electromagnetic compatibility enhancing device, wherein the electromagnetic compatibility enhancing device is divided into a first shielding layer and a second shielding layer, the first shielding layer is shielding protection paper, and the shielding protection paper is a copper paper material. The specific manufacturing method of the second shielding layer comprises the steps of 1, weighing a rubber material and a lead powder material, wherein the ratio of the rubber material to the lead powder material is 1.5: 1; and 2, melting the rubber material weighed in the step 1, adding the weighed lead powder into the molten rubber material, and fully mixing the rubber material with the lead powder in a high-temperature state. According tothe invention, the electromagnetic compatibility and the electrostatic performance of the cable are good, so that the cable is prevented from being subjected to electromagnetic interference in signalin the use process, and fire disasters are avoided.

Owner:深圳特朗达照明股份有限公司

Buried pipeline dredger

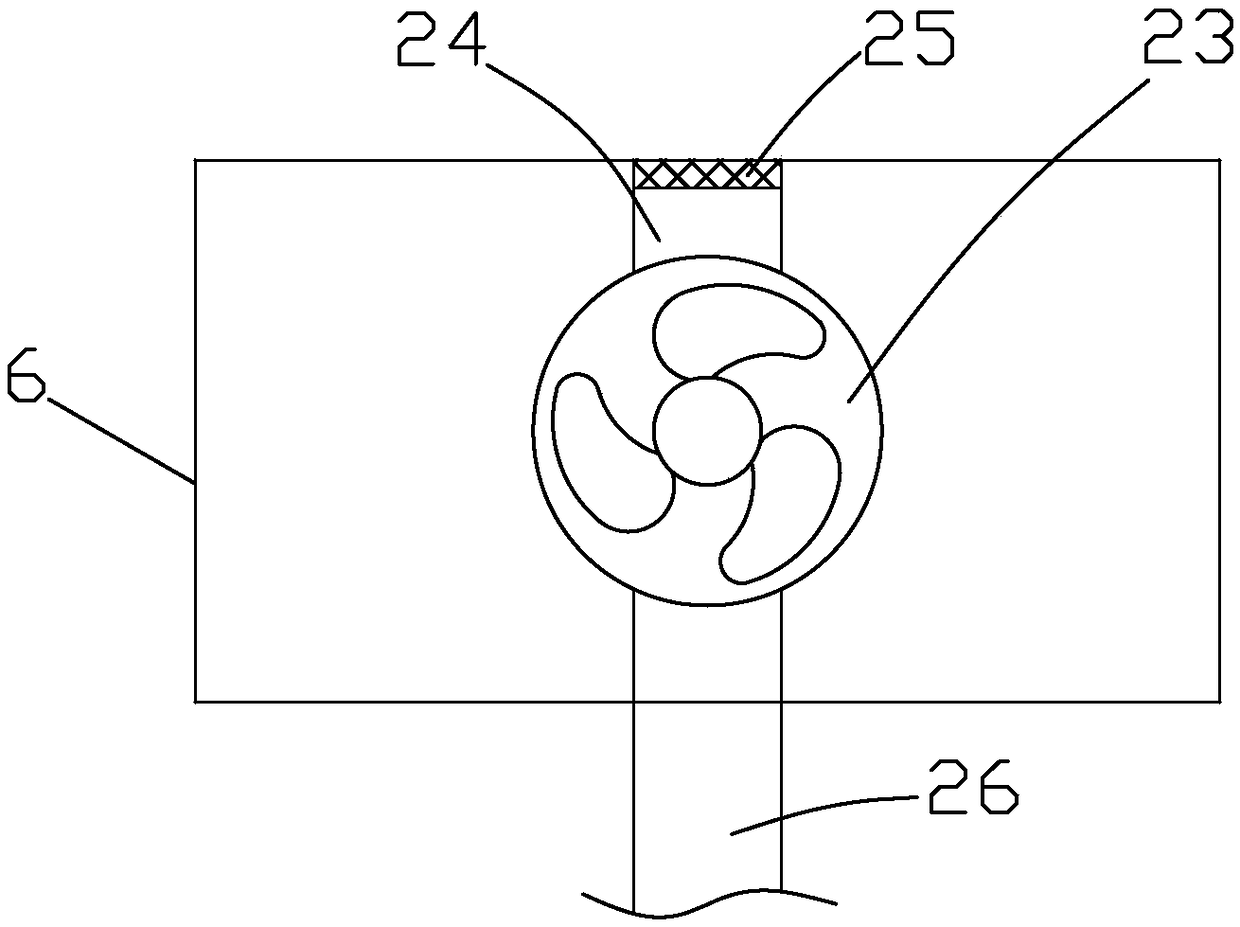

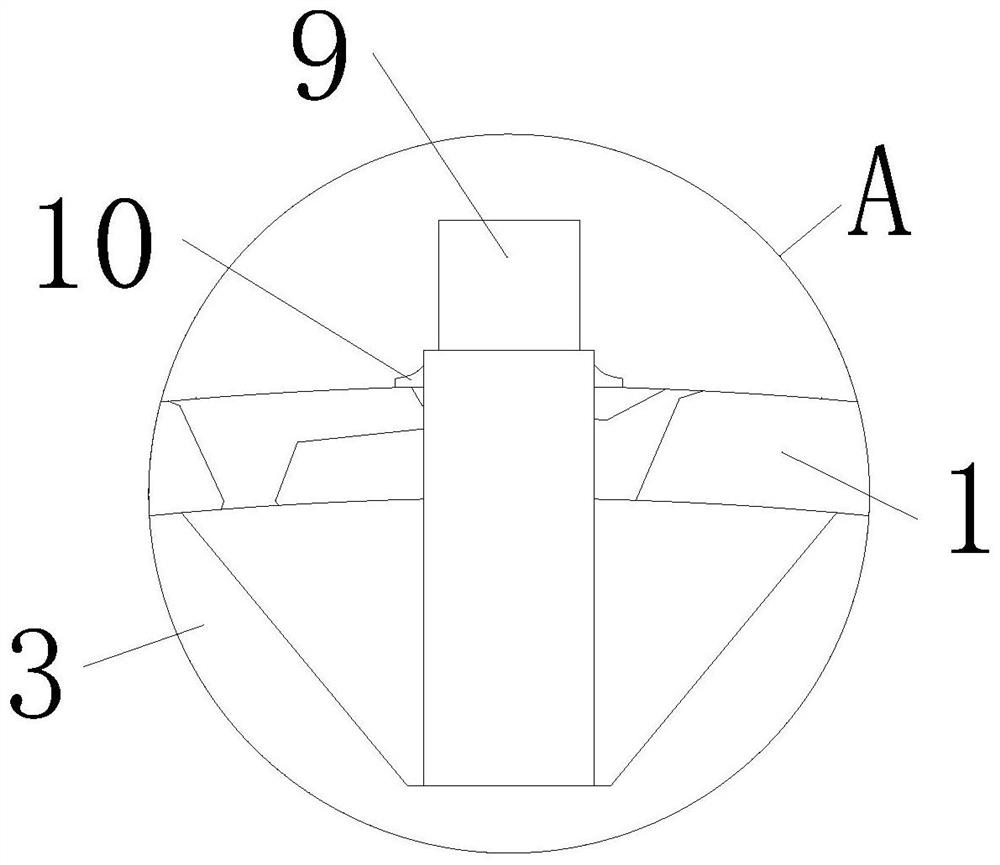

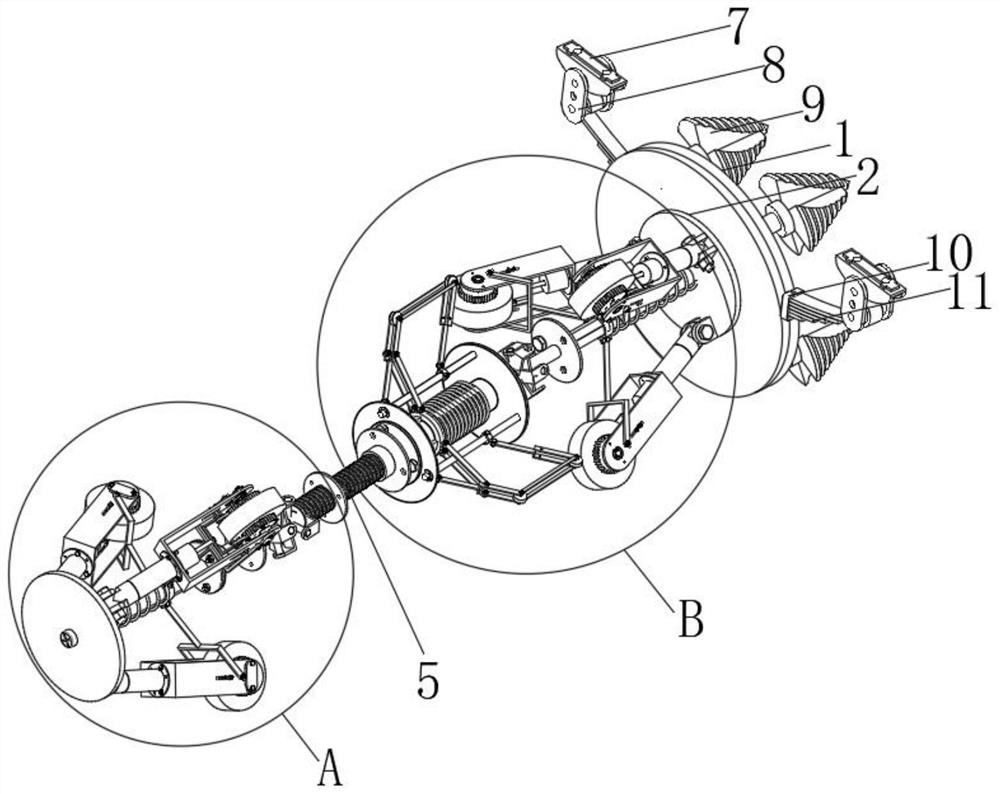

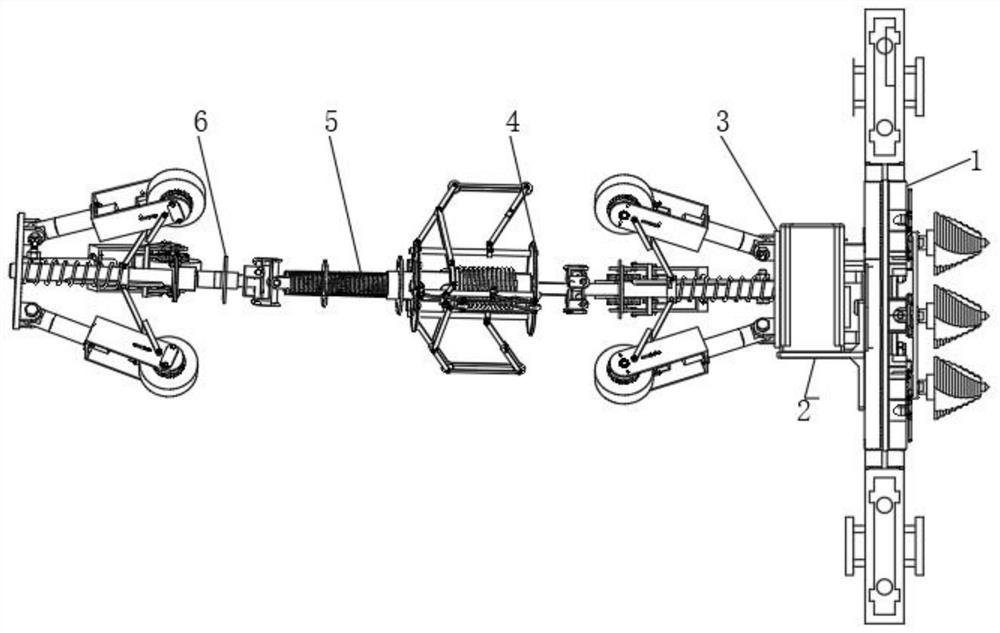

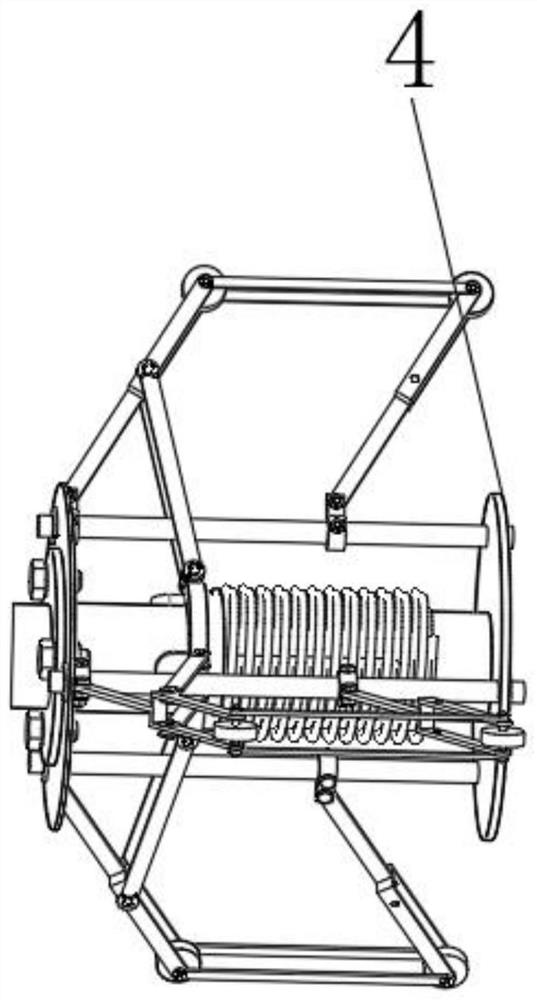

PendingCN113000506AAffect normal deliveryImprove cleanlinessHollow article cleaningClassical mechanicsElectric machinery

The invention discloses a buried pipeline dredger. The buried pipeline dredger comprises a crushing structure, wherein a driving source structure is arranged on one side of the crushing structure, a first driving structure is fixedly installed on the side, away from the crushing structure, of the driving source structure, and a guiding structure is fixedly connected to the side, away from the driving source structure, of the first driving structure. According to the buried pipeline dredger, a first driving motor drives a rotating plate to rotate through a worm and worm gear transmission part, then a drill bit is driven to rotate, the drill bit can crush obstacles inside a pipeline while rotating so as to prevent the obstacles from influencing normal conveying of the pipeline, and meanwhile, a circular ring plate can drive a grinding block to rotate while rotating, and the friction end surface of the grinding block makes contact with the inner wall of the pipeline so that the grinding block can rub the interior of the pipeline, objects adhering to the inner wall of the pipeline are further ground and removed, and the effect of removing the obstacles inside the pipeline is improved.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

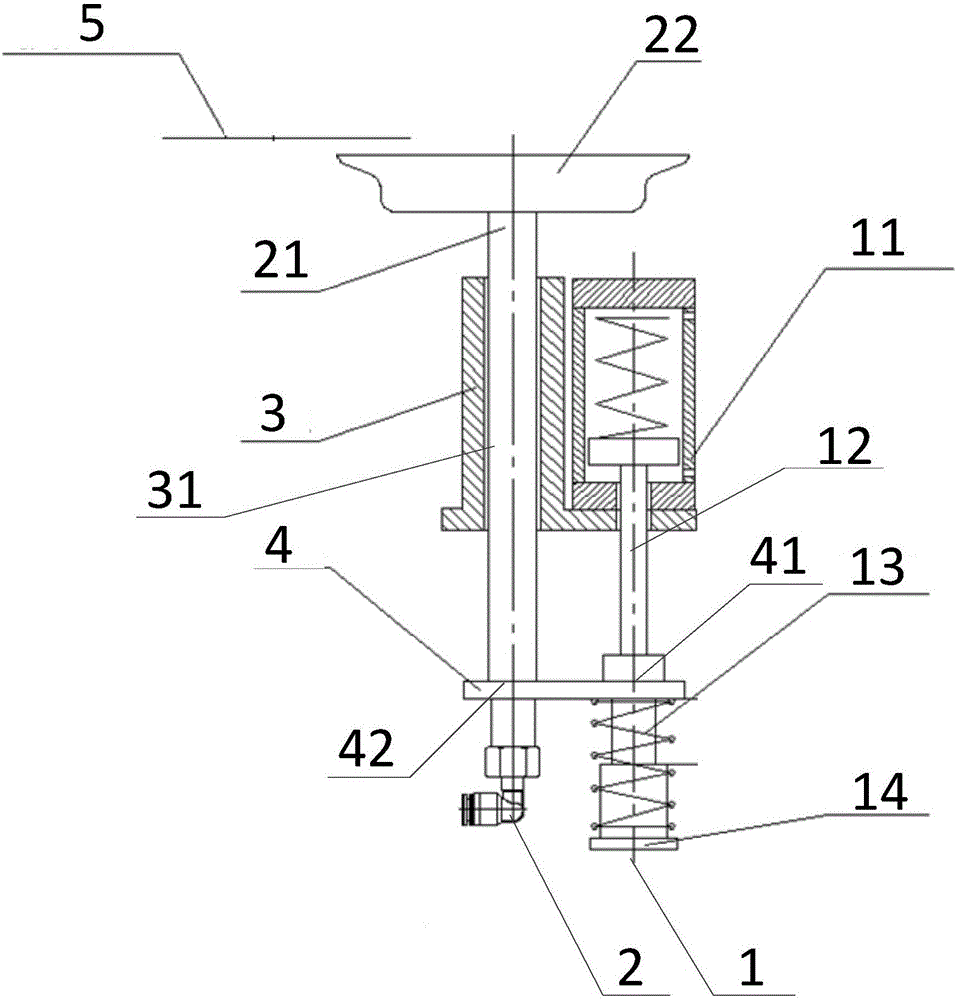

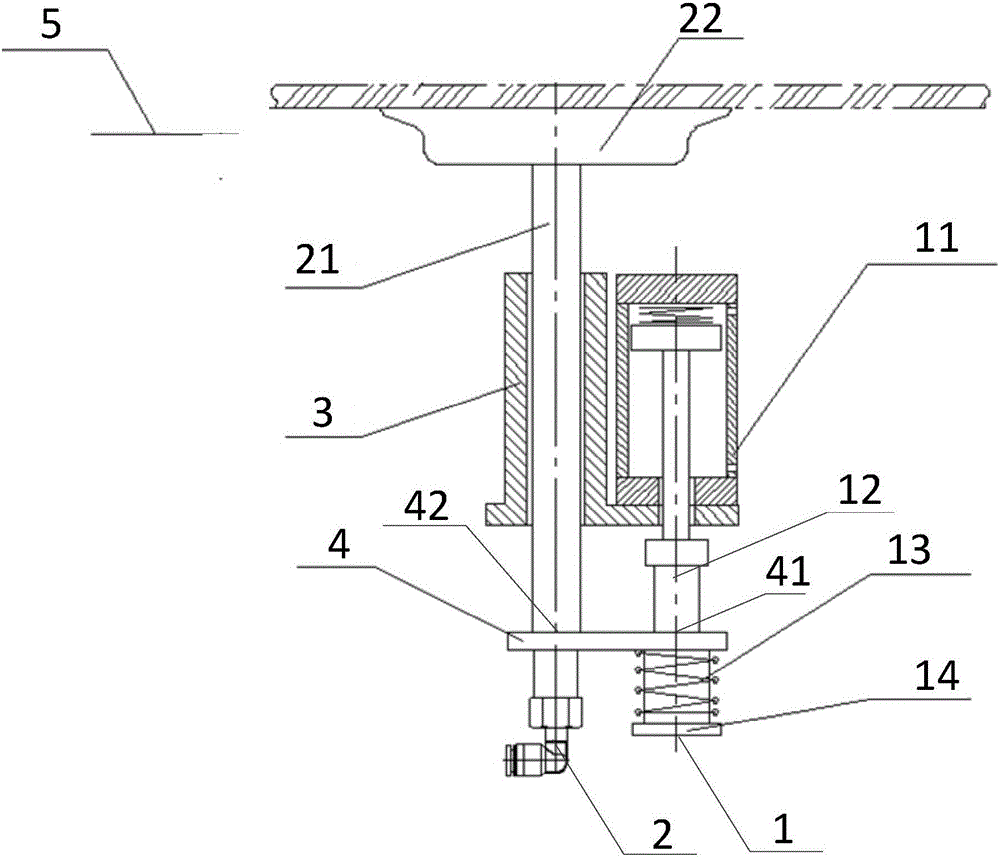

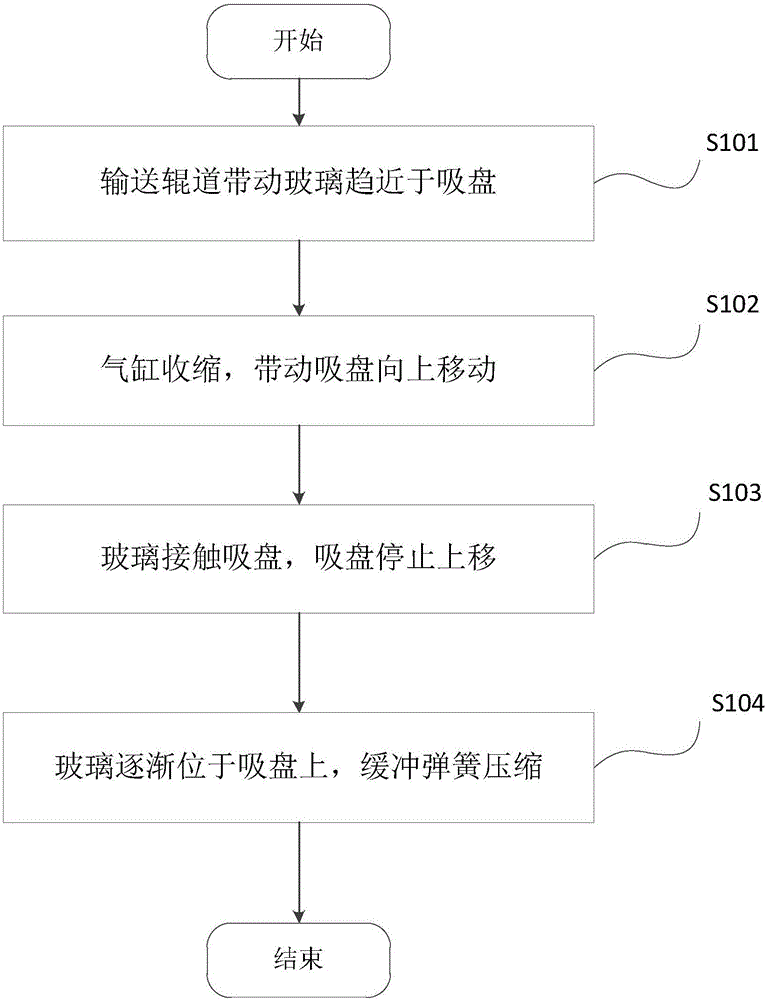

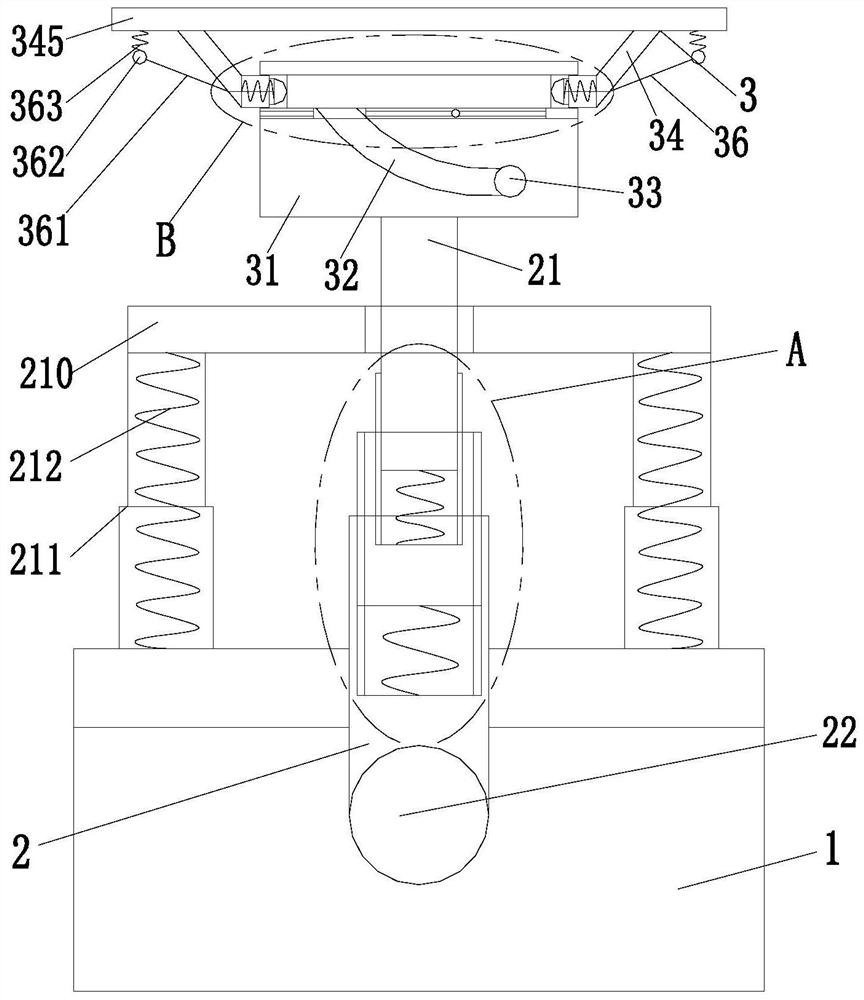

Suction cup device for grabbing glass from lower surface of glass plate and control method

PendingCN106629058AWith self-resetting functionAffect normal deliveryCharge manipulationConveyor partsEngineeringMechanical engineering

Owner:CHINA TRIUMPH INT ENG

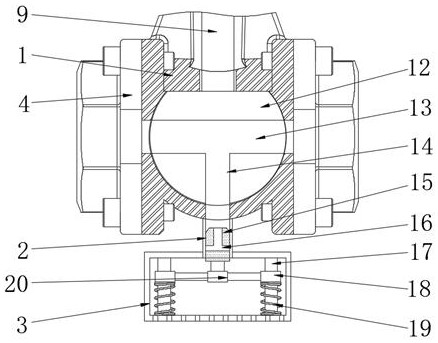

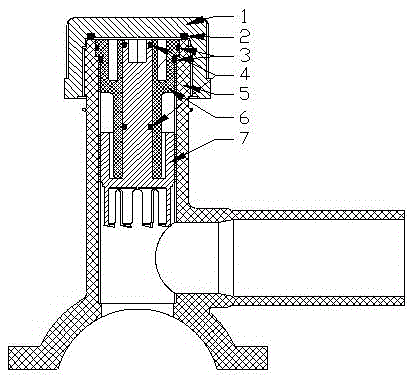

a shut-off valve

ActiveCN110206896BIncrease flexibilityAvoid bendingOperating means/releasing devices for valvesLift valveClassical mechanicsStructural engineering

Owner:ZHUJI HAIDAO MACHINERY CO LTD

Novel flow valve for fuel gas conveying

InactiveCN112145738AImprove convenienceAvoid loose connectionsPlug valvesOperating means/releasing devices for valvesPhysicsEngineering

The invention relates to the technical field of fuel gas conveying, and discloses a novel flow valve for fuel gas conveying. Connecting flanges are symmetrically screwed to two sides of a valve body,a pressure reducing mechanism is connected to the middle of the lower portion of the valve body, a valve rod is connected with a rotating handle in a clamped mode through a regular hexagonal screw base, a valve ball is fixed to the bottom end of the valve rod, and a circulation groove is formed in the middle of one side of the valve ball in a penetrating mode. According to the novel flow valve, the valve rod is connected with the rotating handle in a clamped mode, under one-to-one correspondence of identification pointers and scale identifications, a worker can conveniently and accurately adjust a flow circulation size of the flow valve, and then the convenience of adjusting and using the flow valve is improved; and in a fuel gas conveying process, through matching and combining of a pressure reducing mechanism and a pressure reducing through groove, the situations that connection of the flow valve is loosened and the flow valve is exploded and damaged due to too large barometric impact strength can be avoided, and then the self-protection capacity of the flow valve is improved.

Owner:祁东中燃城市燃气发展有限公司

Energy-saving high-precision BGA chip tin removing machine for intelligent welding system

ActiveCN114160902AEntry is smoothHigh precisionSoldering auxillary devicesEngineeringStructural engineering

The energy-saving high-precision BGA chip tin removing machine for the intelligent welding system comprises a platform, an electric push rod is arranged in the middle of one side of the top of the platform, a mounting frame is arranged at the output end of the electric push rod, and a tin removing guide groove is formed in the middle of the top of the platform; one end of the back surface of the tin removal guide groove is provided with a row guide groove which is communicated with the tin removal guide groove, and the row guide groove and the tin removal guide groove form an L-shaped structure; according to the invention, the tin removal guide groove and the row guide groove are matched to form the L-shaped groove body, and the material guide device is arranged at the port of the tin removal guide groove to guide the chip entering the groove, so that the chip can enter the groove of the tin removal guide groove more orderly and smoothly for tin removal; and meanwhile, the first brush roller and the second brush roller which are crisscrossed are arranged at the tail end of the tin removal guide groove and the front end of the row guide groove correspondingly, secondary brushing work of different faces is conducted on the guided-in chip, and the tin removal precision and efficiency of the chip are greatly improved.

Owner:深圳市维佳芯片返修科技有限公司

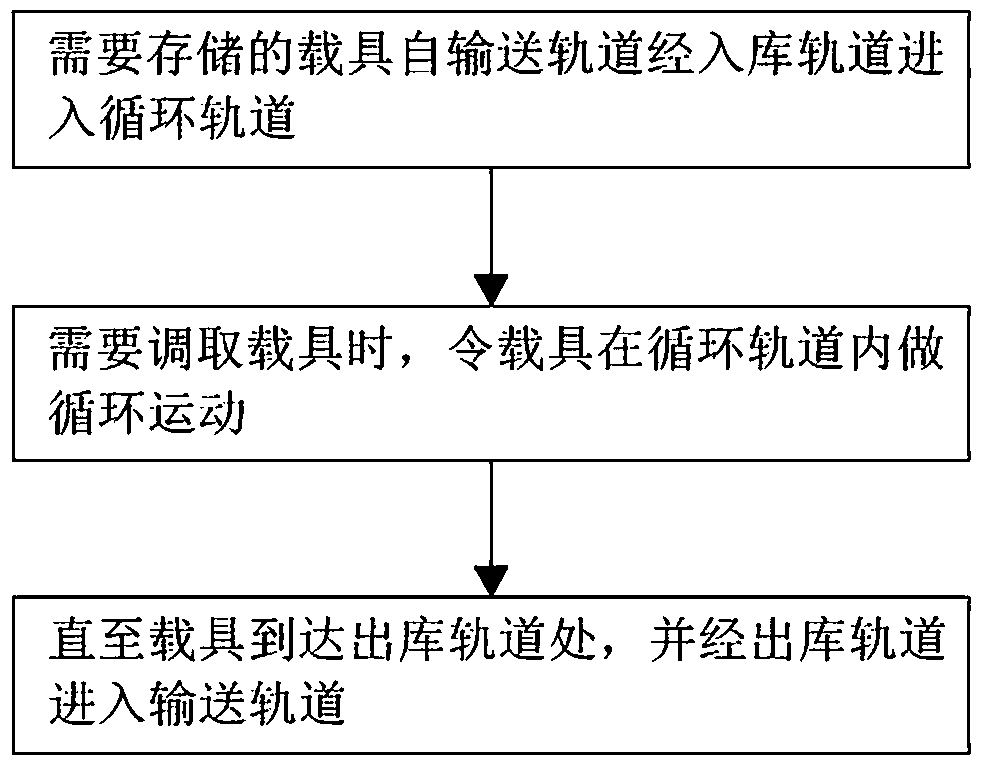

Warehouse circulating system and control method thereof

InactiveCN111409987ASimplify outbound operationsImprove delivery efficiencyStorage devicesMechanical engineeringDelivery efficiency

The invention discloses a warehouse circulating system and a control method thereof, and belongs to the technical field of clothing manufacturing warehouses. The warehouse circulating system comprisesa circulating rail, a conveying rail, a storage rail, a delivery rail and carriers. The storage rail and the delivery rail are both arranged between the circulating rail and the conveying rail. The control method includes the steps that the carriers needing to be stored enter the circulating rail from the conveying rail through the storage rail, when the carriers need to be transferred, the carriers are made to do circulating movements in the circulating rail until arriving at the delivery rail, and the carriers enter the conveying rail through the delivery rail. By means of the warehouse circulating system, the delivery operation is greatly simplified, and the cargo delivery efficiency is effectively improved.

Owner:INA INTELLIGENT TECH (ZHEJIANG) CO LTD

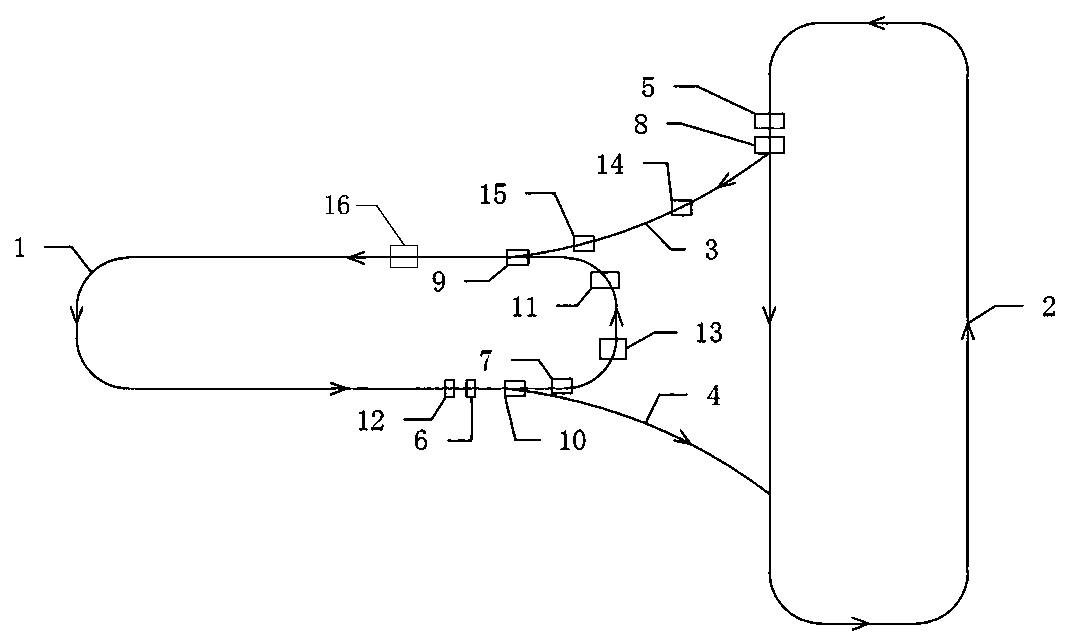

Method for removing hemp thread and hemp velvet from threshing and redrying

InactiveCN109619652AGood adsorption and adhesionSimple structureTobacco preparationEngineeringImpurity

The invention relates to a method for removing hemp thread and hemp velvet from threshing and redrying, which belongs to the technical field of threshing and redrying and impurity removal. The methodcomprises seven steps of weighing, mixing, pressing, air drying, cutting, processing and hanging. By the adoption of the method for removing the hemp thread and hemp velvet from threshing and redrying, a characteristic of mutual adhesion of the hemp thread and the hemp velvet is utilized, the hemp thread and the hemp velvet are mixed and pressed, a prepared hemp thread and hemp velvet impurity-removing board is firm and durable; the hemp thread and the hemp velvet are manufactured into a hemp thread and hemp velvet impurity-removing board according to a mass ratio of 1 to 3, so that the hemp velvet provided by a surface of the prepared impurity-removing board has good adsorption and bonding effects; in a process of conveying tobacco leaves, the hemp thread and hemp velvet impurity-removingboard is in contact with the tobacco leaves and rubs with the tobacco leaves to generate static electricity, so that impurities such as the hemp thread, the hemp velvet and the like mixed in the tobacco leaves are absorbed; the structure is simple, a removal rate of the hemp thread and the hemp velvet is high, and cleaning is convenient.

Owner:HONGTA TOBACCO GRP

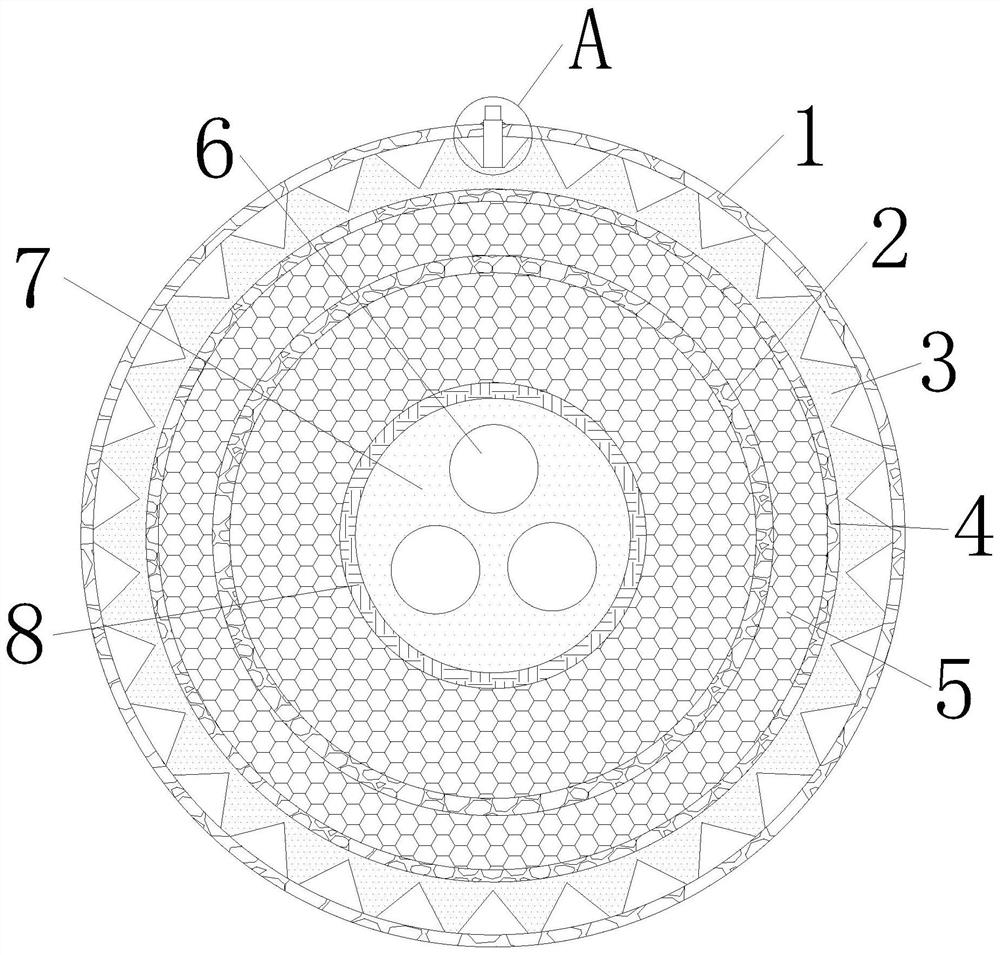

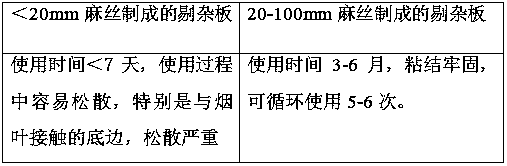

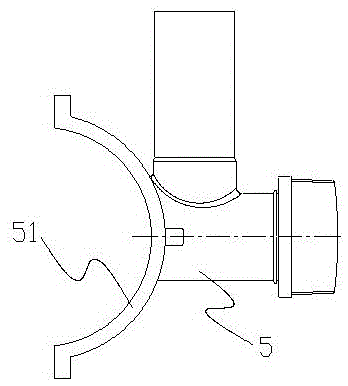

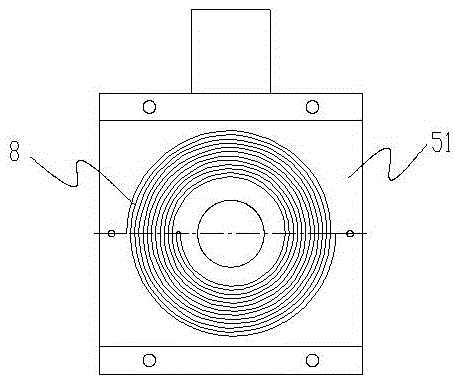

Compressor

InactiveCN111594409AReduce wearReduce frictionPositive displacement pump componentsMulti-stage pumpsThermodynamicsEngineering

The invention relates to a compressor, and relates to the technical field of fluid conveying. The compressor comprises a front cylinder body and a rear cylinder body mounted on the front cylinder body, wherein an oil supplementing passage is formed in the front cylinder body and / or the rear cylinder body; the oil supplementing passage is filled with a lubricant; the oil supplementing passage comprises an oil inlet hole section and an oil outlet hole section communicating with the oil inlet hole section; an oil outlet piece is mounted on an oil outlet of the oil outlet hole section; and the surface of a swash plate rotates to be propped against or separated from the oil outlet piece. When the swash plate rotates to enable the surface to be propped against the oil outlet piece, the swash plate can dip the lubricant from the oil supplementing passage through the oil outlet piece, and then the position, dipped with the lubricant, of the swash plate rotates to enter a connecting cavity toreduce friction between the connecting cavity and the swash plate, so that abrasion of the swash plate is reduced, and the compressor has the advantage of protecting the swash plate.

Owner:黄山双桦动林压缩机有限公司

An intelligent urban rainwater regulation and storage system and its construction method

ActiveCN106759781BAchieve recyclingRealize savings and utilizationFatty/oily/floating substances removal devicesSewerage structuresWater useEnvironmental engineering

The invention discloses an intelligent urban rainwater storage regulation system and a construction method thereof. The system comprises a rainwater storage regulation tank, a water through device, a filter device and a water distribution tank. A first water level sensor and a second water level sensor are arranged on the inner side of a park pool, and the water through device is positioned between the first water level sensor and the second water level sensor and close to the second water level sensor. A silt clearing tank is arranged at the top of the park pool, the filter device is connected with a residence region and a road surface through a first water inlet pipe and a second water inlet pipe respectively, and the rainwater storage regulation tank is connected with the residence region and the water distribution tank through a first water drain pipe and a second water drain pipe respectively. The method includes steps of survey setting-out, rainwater storage regulation tank construction, filter device construction, water distribution tank construction, road surface construction, pipeline connection arrangement and rainwater storage regulation system commissioning. The construction method is simple in step, rainwater quick drainage and storage are facilitated, flood or waterlogging is prevented, and stored rainwater can be used for irrigation and domestic water.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

A cloth conveying device for textile machinery

ActiveCN109399113BImprove delivery efficiencyControl packing timeCleaningMechanical conveyorsElectric machineryCotton material

The invention discloses a cloth conveying device used for a textile machine. A box body is included, and is internally provided with an intermittent conveying mechanism; the left side and the right side of the intermittent conveying mechanism are provided with two feeding belts and two discharging belts correspondingly; the intermittent conveying mechanism comprises a base, side plates, intermittent rotating disks and a second motor; two lower supporting plates are arranged between the two side plates; upper supporting plates are arranged above the lower supporting plates; a guiding groove isformed between the upper supporting plates and the lower supporting plates; a rotating shaft is connected to the second motor; the two intermittent rotating disks are fixedly connected to the rotatingshaft, and are located on the side close to the side plates; and a dust clearing mechanism is arranged on the top face of the box body. The cloth conveying device used for the textile machine is simple in structure and high in practicability, conveying can be achieved on the discharging belts through the intermittent conveying mechanism, the labor intensity of manual carrying is greatly lowered,the cloth conveying efficiency is improved, the conveying interval between all cloth conveying rollers can be controlled, and then the binning time of cloth is controlled.

Owner:佛山市南海区赛宏毡业有限公司

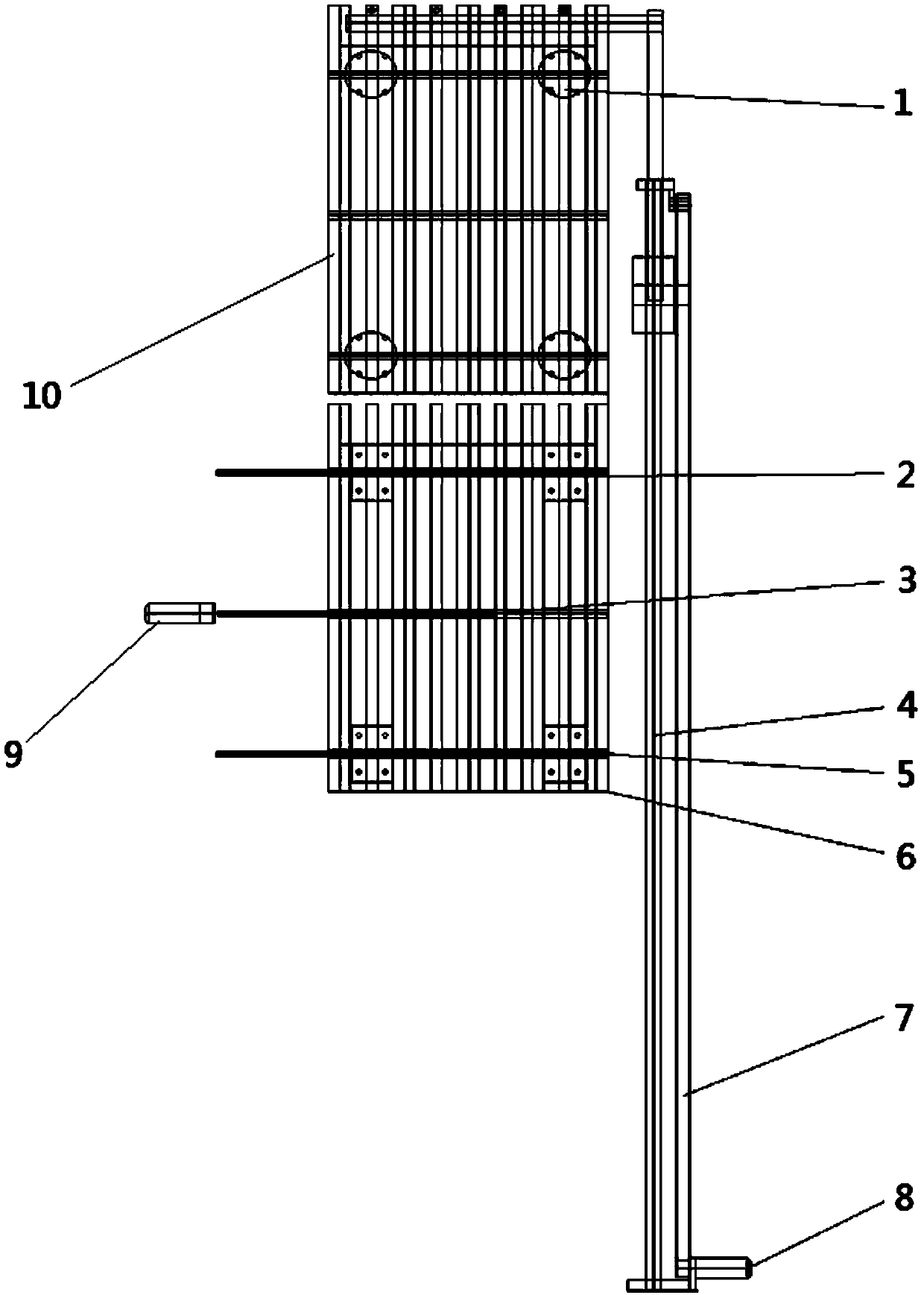

A reciprocating cocoon harvesting propulsion mechanism for industrial farming

ActiveCN111096304BImprove stabilityImprove reliabilityAnimal husbandryAgricultural engineeringStructural engineering

The invention discloses a reciprocating cocoon harvesting propulsion mechanism for industrial farming, which includes a column, a booster mechanism, a jacking mechanism and a cocoon cage guiding mechanism, and the top and bottom surfaces of two columns on the same side are fixedly connected by a beam , a lower support rod and an upper support rod are arranged in parallel between the two opposite columns, the booster mechanism is arranged between the two upper support rods and the two lower support rods parallel to each other, and between the top surfaces of the two upper support rods There are two guide rails in parallel between them, the jacking mechanism is connected to the guide rails, the jacking mechanism is connected with the booster mechanism, and at least two sets of limit mechanisms are arranged above the jacking mechanism, which are located inside the two columns on the same side of the beam. A cocoon cage guiding mechanism is arranged between the sides. The invention is simple in structure and strong in practicability, not only improves the stability and reliability of cocoon cage transportation, but also reduces noise and wear between parts, facilitates maintenance and improves the efficiency of cocoon picking.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

A woven plastic bag compression molding machine

ActiveCN110884220BImprove efficiencyHigh degree of automationBag making operationsPaper-makingMolding machineIndustrial engineering

The invention relates to a compression forming machine for woven plastic bags, which includes a base, a rolling forming mechanism, a compression mechanism and a conveying device, and is characterized in that the compression mechanism is evenly installed on the front side of the base, and the rear side of the base is evenly installed. There is a rolling forming mechanism, and the middle part of the base is provided with conveying grooves and pressing grooves sequentially from front to back. In the pressing grooves, evenly distributed rollers are provided through bearings, and a conveying device is installed in the conveying grooves. The present invention passes through the base The multiple rolling forming mechanisms and pressing mechanisms set up on the machine realize the purpose of automatically pressing and shaping multiple woven bag materials at the same time during the conveying process, and the purpose of accurate folding, thereby solving the suture dislocation of woven materials caused by manual pressing in the prior art, High labor intensity, time-consuming and labor-intensive, high production cost, low efficiency, and low degree of automation.

Owner:广西安得塑业有限公司

Super electromagnetic compatibility and anti-static protection device

ActiveCN112466523BAvoid fireImprove shielding effectElectrostatic discharge protectionClimate change adaptationRubber materialElectromagnetic interference

The invention provides a super-strong electromagnetic compatibility and antistatic protection device, and relates to the technical field of cable antistatic enhancement of electromagnetic compatibility. The super electromagnetic compatibility includes an electromagnetic compatibility enhancement device, the electromagnetic compatibility enhancement device is divided into a first shielding layer and a second shielding layer, the first shielding layer is shielding protection paper, and the shielding protection paper is copper paper material, the specific manufacturing method of the second shielding layer is as follows: Step 1: Weigh rubber material and lead powder material, and the proportioning ratio of rubber material and lead powder material is 1.5:1; Step 2: Weigh in step 1 Melt a certain amount of rubber material, add weighed lead powder into the melted rubber material, and fully mix the rubber material and lead powder under high temperature. The invention makes the electromagnetic compatibility and electrostatic performance of the cable good, prevents the signal from being interfered by electromagnetic interference during the use of the cable, and avoids the occurrence of fire.

Owner:深圳特朗达照明股份有限公司

A Saddle-type Bypass of Rear Cloth Electrofusion

ActiveCN104061397BGuaranteed tightnessAvoid accidental failurePipe connection arrangementsTool bitEngineering

Owner:ZHEJIANG QINGFA PIPE TECH

Stop valve

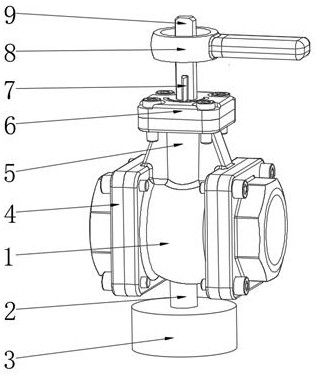

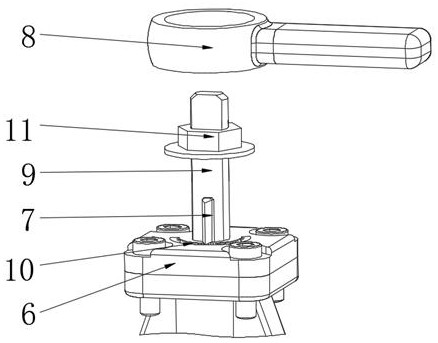

ActiveCN110206896AIncrease flexibilityAvoid bendingOperating means/releasing devices for valvesLift valveJoystickEngineering

The invention relates to a stop valve. The stop valve comprises a connecting pipe, a control assembly and a rotating assembly; the upper end of the connecting pipe is in threaded connection with the control assembly; the upper end of the control assembly is provided with the rotating assembly; the rotating assembly comprises a rotating base mounted on the upper end surface of an extension rod; a sliding groove is formed in the side wall of the upper end of the rotating base; the side wall of the rotating base is evenly provided with arc grooves in the circumferential direction; the upper endsof the arc grooves communicate with the sliding groove; and the lower ends of the arc grooves are provided with a clamping groove. The problems that during usage of existing stop valves, control rodsare stressed and are prone to being bent or slipping when the stop valves are buried, rotation plates are prone to being rotated by non-operating person when the stop valves are exposed to the surface, and the normal pipeline conveying is affected can be solved; the function of enhancing the protection performance of the stop valve can be achieved; and the stop valve has the advantages that a control rod is not prone to be bent and slipping when being stressed, a control plate is not prone to being rotated by the non-operating person, and normal pipeline conveying is not affected.

Owner:ZHUJI HAIDAO MACHINERY CO LTD

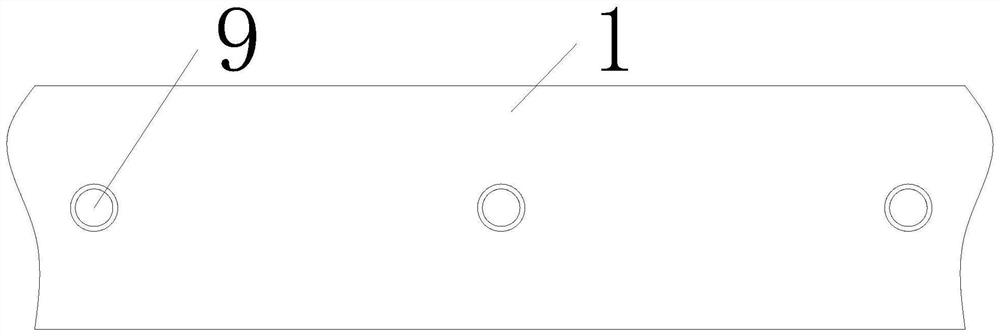

Article conveying device and drug production equipment

PendingCN109956309AAffect normal deliveryImprove delivery efficiencyConveyor partsMechanical engineeringDrug production

The invention relates to an article conveying device and drug production equipment. The article conveying device comprises a first platform (10) used for receiving articles, wherein the first platform(10) is provided with an auxiliary falling structure, and the auxiliary falling structure is used for assisting the articles to smoothly fall onto the first platform (10). According to the article conveying device, the auxiliary falling structure is arranged on the first platform, when skewing or deformation and other problems occur to the articles, the articles can be guided to smoothly fall onto the first platform by means of the auxiliary falling structure, the situation that the articles cannot smoothly fall onto the first platform or smash other articles, so that normal conveying of thearticles is influenced is prevented, and the article conveying efficiency can be improved.

Owner:BEIJING WBL PEKING UNIV BIOTECH

An adjustable dynamic tracking bottle divider

The invention discloses an adjustable dynamic tracking bottle distributor comprising a framework. A conveying device, a forward and backward movement guardrail, a leftward and rightward movement guardrail, a swing guardrail, an inlet width adjusting mechanism and a controller are arranged in the framework; the conveying device comprises a chain net conveying belt and a driving motor; the controller controls the driving motor to operate; a conveying motor is provided with an encoder; the signal output end of the encoder is electrically connected with the controller; the forward and backward movement guardrail is arranged on the left side of the leftward and rightward movement guardrail; and the swing guardrail is arranged on the right side of the leftward and rightward movement guardrail and connected with the inlet width adjusting mechanism through a rotating joint. The adjustable dynamic tracking bottle distributor is reasonable in structural design and high in practicability, conveyed bottles continuously moving on a single conveying channel can be distributed to several channels as required through the coordinative work of the leftward and rightward movement guardrail and the forward and backward movement guardrail, and the automation degree is high.

Owner:NANJING F&P LIGHT IND MACHINERY

Yarn feeding mechanism for spinning

PendingCN113371529AHeight adjustableAvoid affecting the quality of post-processingFilament handlingYarnSpinning

The invention discloses a yarn feeding mechanism for spinning, which comprises a first base, a drawing box, a second base and a control box, wherein a first supporting plate, a first sliding adjusting assembly, a second sliding adjusting assembly, a third supporting plate and a fourth supporting plate are fixed to the upper side of the first base, and the first supporting plate is located on the leftmost side of the first sliding adjusting assembly; the third supporting plate is located on the left side of the fourth supporting plate, the first supporting plate is connected with an adjusting assembly in a sliding way, a buzzer is fixed to the upper side of the third supporting plate, a yarn breaking reminding assembly is fixed to the lower side of an electric telescopic rod, and the drawing box is used for storing different yarns; and a third sliding adjusting assembly is fixed to the upper side of the second base. The yarn feeding mechanism for spinning has the advantages that yarn rollers of different lengths can be fixed in an auxiliary mode, the height of the yarns can be adjusted, reminding can be conducted when the yarns are broken, and multiple groups of yarns can be directly doubled.

Owner:徐州天虹银联纺织有限公司

A device for monitoring and treating bottom mud at a river channel construction section and its construction method

ActiveCN106592673BImprove water qualityReduce contentMechanical machines/dredgersStream regulationSludgeTreatment pond

The invention discloses a monitoring treatment device for riverway construction fracture surface bottom mud and a construction method of the monitoring treatment device. The monitoring treatment device comprises bottom mud monitoring boxes, a bottom mud treatment pond and a bottom mud recycling pond; the bottom mud treatment pond is connected with the bottom mud recycling pond through a sludge output pipe which is provided with a mud pumping pump; a water inlet pipe is arranged on the top face of the bottom mud treatment pond and is communicated into water of a riverway; a stirring mechanism is arranged in the bottom mud treatment pond; the bottom mud monitoring boxes are connected with the bottom mud treatment pond through conveying pipes; and every two adjacent bottom mud monitoring boxes are connected through the corresponding conveying pipe. The construction method of the monitoring treatment device includes staking out in survey, foundation pit excavation, bottom mud treatment pond construction, bottom mud recycling pond construction, bottom mud monitoring box arrangement and bottom mud monitoring pilot running. The monitoring treatment device is simple in structure and remarkable in effect of riverway construction fracture surface bottom mud monitoring and clearing, the riverway construction fracture surface strength is improved, the bottom mud high in pollutant content can be conveniently treated, and secondary pollution formed by release of pollutants in bottom mud is prevented.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com