Cloth printing equipment for garment production

A printing and fabric technology, applied in the field of fabric printing equipment for garment production, can solve the problems that the printing quality and effect cannot meet the expected requirements, the edges are prone to curling or wrinkles, and the flatness of the fabric cannot be guaranteed. Printing quality, optimized operation process, and the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

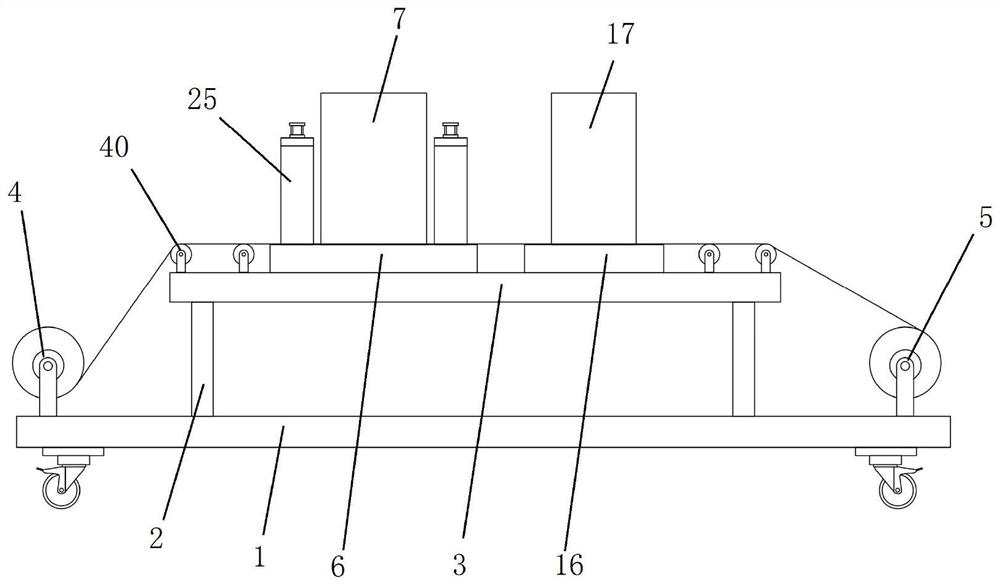

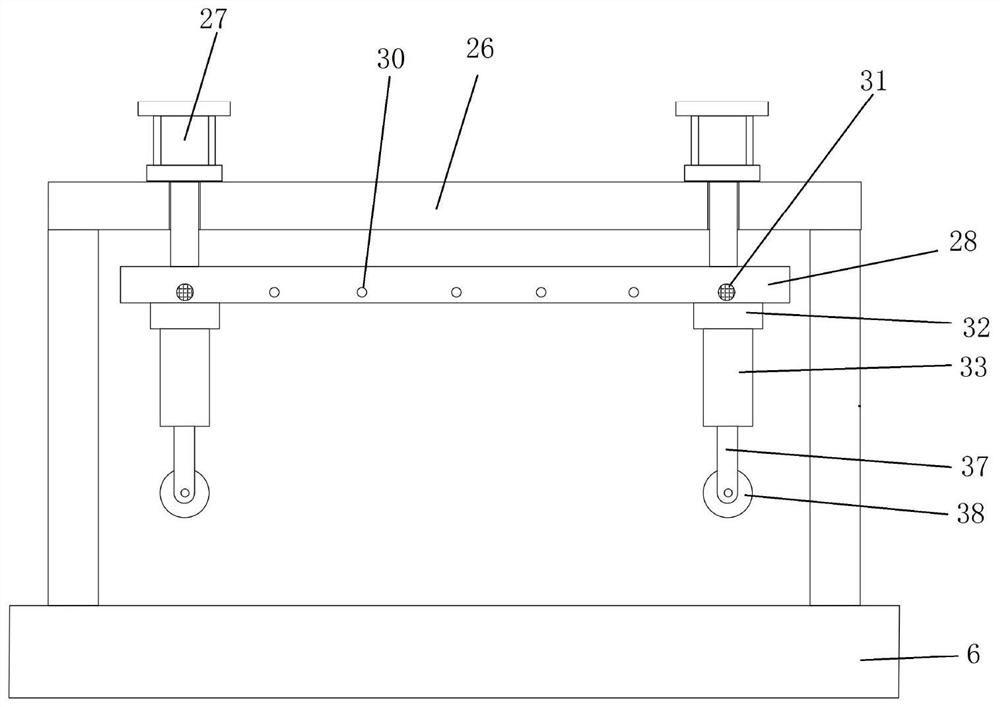

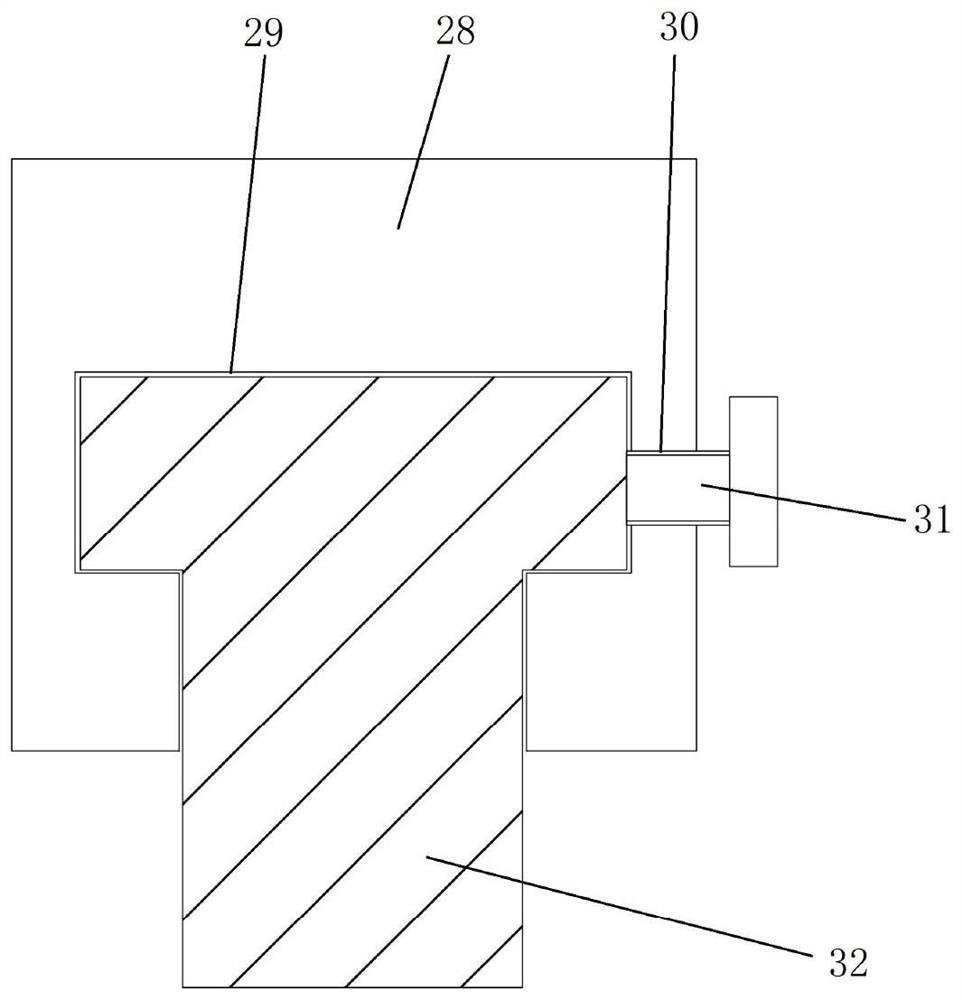

[0027] The embodiment of the present invention discloses a cloth printing equipment for garment production, such as figure 1 As shown, including the base 1, a frame body 2 is provided at the middle position of the top of the base 1, and a work table 3 is installed on the top of the frame body 2, and a printing operation table 6 and a drying operation table 16 are sequentially installed on the work table 3 along the length direction. The printing operation table 6 is provided with a printing mechanism 7, the drying operation table 16 is provided with a drying mechanism 17, and the base 1 is provided with a cloth releasing mechanism 4 and a cloth receiving mechanism 5 respectively located on both sides of the work surface 3 in the length direction. The top of the table top 3 is equipped with a plurality of guide rollers 40 along the cloth conveying direction by a support 39, such as Figure 5As shown, the outer side of the guide roller 40 is movably sleeved with two annular adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com