Method for removing hemp thread and hemp velvet from threshing and redrying

A technology of threshing and re-roasting and hemp silk, which is applied in the direction of tobacco preparation, application, tobacco, etc. It can solve the problems that the drum cannot be cleaned, the hook is not strong enough, and the hooking function is lost, so as to achieve flexible and automatic height adjustment and low processing cost. Low cost, simple structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

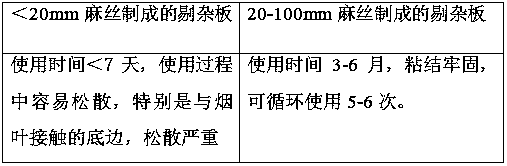

[0025] Mix hemp silk and hemp velvet with a mass ratio of 1:3 to prepare hemp silk and hemp velvet tow with a diameter of 0.15-0.3mm and a length of 100-1500mm, preferably 20-100mm in length to prepare hemp silk and hemp velvet Tow, after mixing the prepared hemp silk and hemp velvet tow, add a food-grade binder and mix again, put the mixed hemp silk and hemp velvet into a pressing machine and press it into a plate shape with a thickness of 10-20mm. Air-dry the hemp and hemp velvet pressing board, and cut the air-dried hemp and hemp velvet board into a 1600mm long and 150mm wide hemp and hemp velvet picking board according to the width of the tobacco leaf conveyor belt, Drill circular hanging holes with a diameter of 50mm at the two end corners on the same side along the length direction, take two punched hemp silk and velvet scrap boards, and place the two hemp silk and hemp velvet scrap boards side by side. And the two are connected together along the length without perforat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com