Graphite electrode nanometer antioxidant and preparation method thereof

An anti-oxidant and graphite electrode technology, which is applied in the field of graphite electrodes, can solve the problems of reduced conductivity of graphite electrodes, cracks in the anti-oxidation layer, and low anti-oxidation temperature, so as to achieve improved anti-oxidation performance, not easy to fall off, and improved physical and chemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

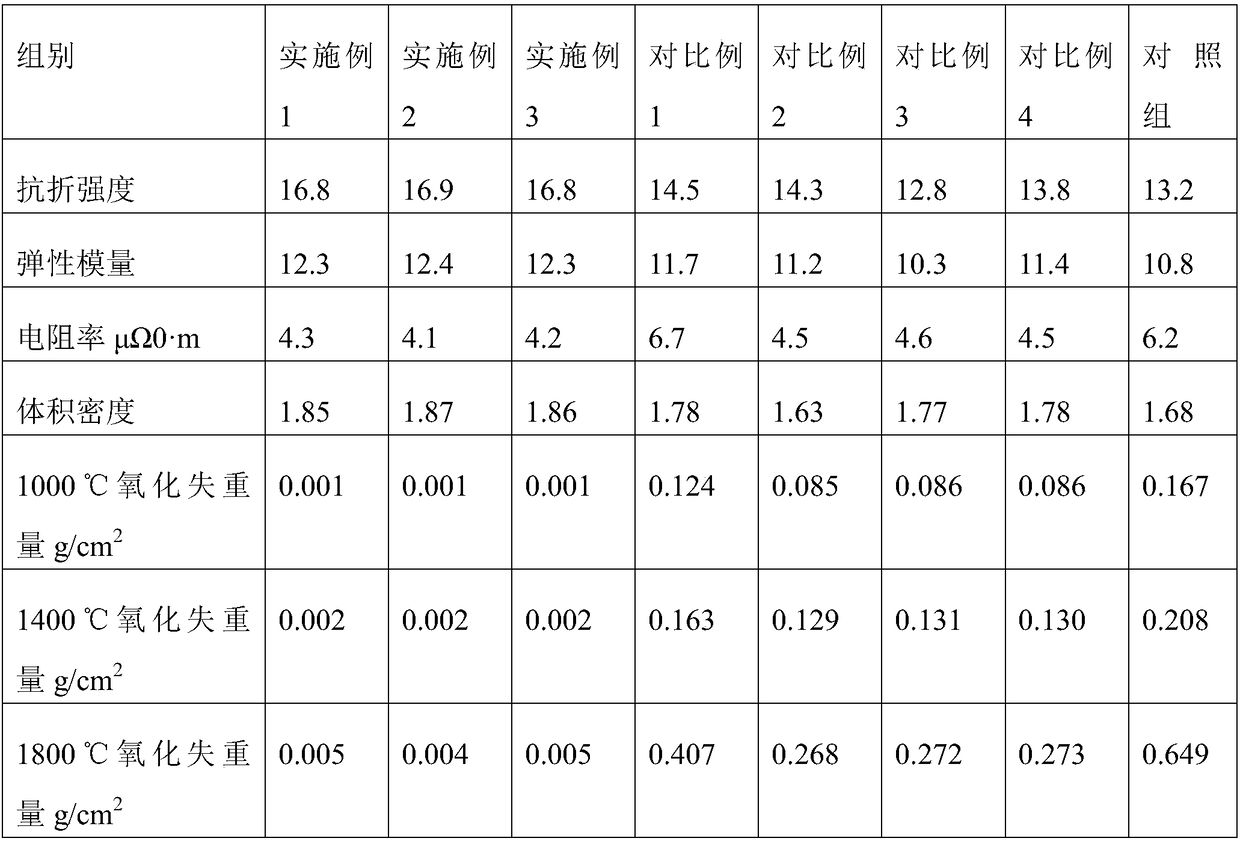

Examples

Embodiment 1

[0032] A graphite electrode nano-antioxidant, consisting of the following components by weight: 20 parts of water, 20 parts of nano-oxide ceramic powder, 15 parts of graphene, 10 parts of polyethylene glycol, 10 parts of mercaptochitosan, and a stabilizer 6 parts, polyhedral oligomeric silsesquioxane 5 parts,

[0033] Wherein, the nano-oxide ceramic powder consists of the following components by weight:

[0034] 30 parts of silicon dioxide, 25 parts of aluminum oxide, 25 parts of phosphorus pentoxide, 20 parts of diboron trioxide, 15 parts of tin dioxide, 10 parts of titanium dioxide, and 5 parts of zirconia.

[0035] The stabilizer is a mixture of zinc borate and polyetherimide with a mass ratio of 2:1.

[0036] Wherein, mercapto-chitosan is prepared as follows: take 10 parts of chitosan, 7 parts of 1-hydroxybenzotriazole (HOBt), add 100 parts of distilled water, stir to dissolve it, add 20 parts of 1-(3- Add 20 parts of N-acetyl-L-cysteine (NAC) to the aqueous solution o...

Embodiment 2

[0043] A graphite electrode nano-antioxidant, consisting of the following components by weight: 25 parts of water, 25 parts of nano-oxide ceramic powder, 18 parts of graphene, 15 parts of polyethylene glycol, 12 parts of mercaptochitosan, and a stabilizer 9 parts, polyhedral oligomeric silsesquioxane 7 parts,

[0044] Wherein, the nano-oxide ceramic powder consists of the following components by weight:

[0045] 33 parts of silicon dioxide, 28 parts of aluminum oxide, 27 parts of phosphorus pentoxide, 22 parts of diboron trioxide, 18 parts of tin dioxide, 13 parts of titanium dioxide, and 7 parts of zirconia.

[0046] The stabilizer is a mixture of zinc borate and polyetherimide with a mass ratio of 2:1.

[0047] Its preparation method is with embodiment 1.

Embodiment 3

[0049] A graphite electrode nano-antioxidant, consisting of the following components by weight: 30 parts of water, 30 parts of nano-oxide ceramic powder, 20 parts of graphene, 20 parts of polyethylene glycol, 15 parts of mercapto-chitosan, and a stabilizer 12 parts, polyhedral oligomeric silsesquioxane 10 parts,

[0050] Wherein, the nano-oxide ceramic powder consists of the following components by weight:

[0051] 35 parts of silicon dioxide, 30 parts of aluminum oxide, 30 parts of phosphorus pentoxide, 25 parts of diboron trioxide, 20 parts of tin dioxide, 15 parts of titanium dioxide, and 10 parts of zirconia.

[0052] The stabilizer is a mixture of zinc borate and polyetherimide with a mass ratio of 2:1.

[0053] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com