Novel flow valve for fuel gas conveying

A flow valve, a new type of technology, applied in the direction of valve details, safety valves, balance valves, etc., can solve the problems of low self-protection ability, loose connection of flow valve, single structure of flow valve, etc., to improve self-protection ability and avoid loose connection , the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

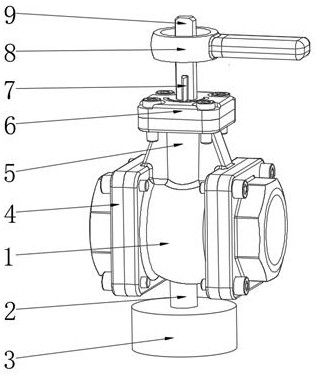

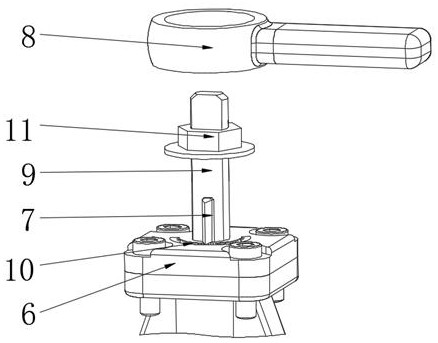

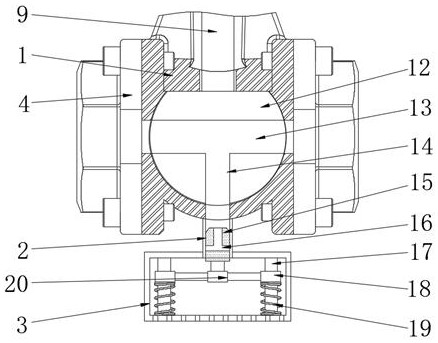

[0019] As shown in the attached picture: see Figure 1~3 , in the embodiment of the present invention, a new type of flow valve for gas transportation, including a valve body 1, the two sides of the valve body 1 are symmetrically screwed with a connecting flange 4, and the lower part of the valve body 1 is connected with a The decompression mechanism, the decompression mechanism includes a decompression pipeline 2 connected at the middle position below the valve body 1, the bottom end of the decompression pipeline 2 is connected with an exhaust cylinder 3, and the inner side of the decompression pipeline 2 is engaged with a sealing plug 15 , the inner side of the sealing plug 15 is embedded with a pressure relief channel 16, the sealing plug 15 is made of NBR material, and the pressure relief channel 16 is a T-shaped structure. The matching combination of the pressure passage groove 14 can prevent the flow valve from being loosely connected and blasted due to excessive impact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com