Energy-saving high-precision BGA chip tin removing machine for intelligent welding system

A welding system and energy-saving technology, applied in welding equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of difficult cleaning, difficult cleaning, increased chip damage and collection difficulty, etc., to improve the precision and efficiency of tin removal and improve efficiency. Sexual and comprehensive, avoiding the effect of rapid heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

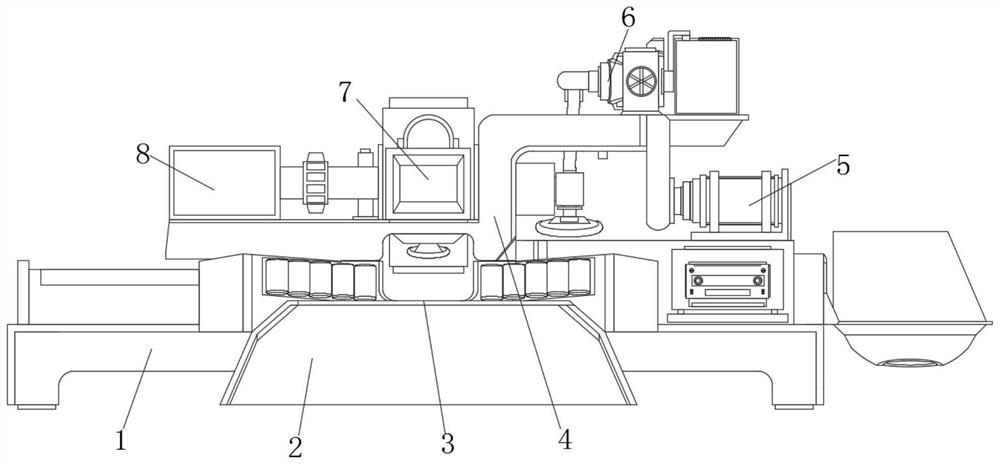

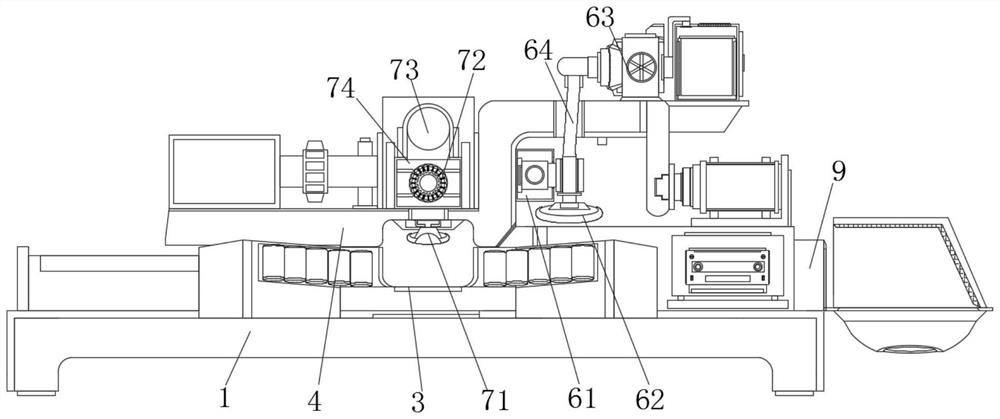

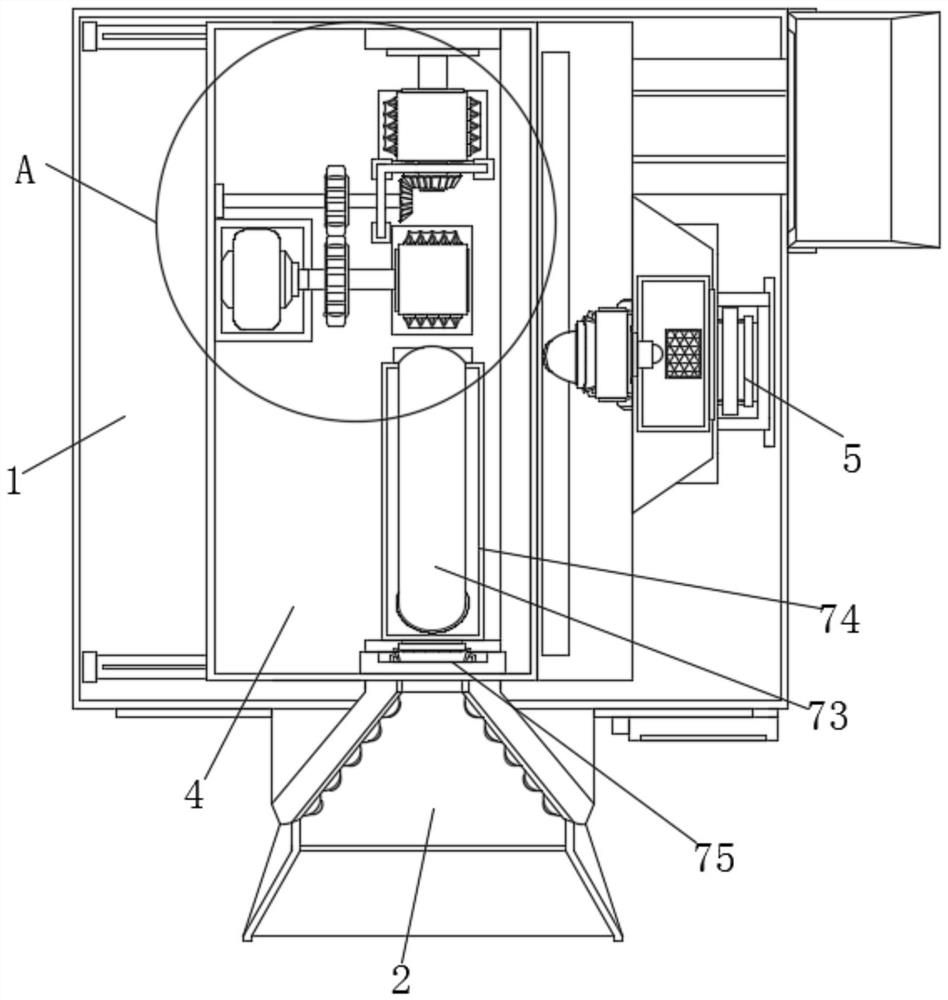

[0040] Example 1, such as Figure 1-4 As shown, when the chip is placed on the surface of the material guide device 2, the chip can be pushed into contact with the guide roller of the inclined plate along with the material guide table through the cooperation of the inclined plate and the guide roller joined to the notch of the tin removal guide groove 3 surface, and with the limit of the guide roller, the chips are pushed into the notch of the tin removal guide groove 3 more orderly and smoothly, and then each group of chips is advanced one by one, so that multiple chips are pulled in the tin removal guide groove 3 Slide for automatic tin removal.

Embodiment 2

[0041] Example 2, such as Figure 1-4 As shown, when the chip is detinned, the electric push rod 5 can be activated to push the installation frame 4 as a whole under the guidance of the guide rail and the guide block so that the exhaust port 71 is canceled and opposed to the vertical surface of the detinning guide groove 3, and then The movement of the installation frame 4 can drive the first brush roller 83 and the second brush roller 85 to slide in the preset extension groove, thereby canceling the connection between the first brush roller 83 and the second brush roller 85 and the tin removal guide groove. 3 corresponds to the vertical surface, and after the installation frame 4 moves to the designated position, the dust suction port 62 can be made to be opposite to the vertical surface of the tin removal guide groove 3, and at this time, the vacuum cleaner 63 and the servo motor 65 can be started. The screw rod 66 is driven by the servo motor 65 to rotate, forcing the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com