A Saddle-type Bypass of Rear Cloth Electrofusion

A saddle type, electric fusion technology, applied in the direction of pipeline connection arrangement, pipe/pipe joint/fitting, mechanical equipment, etc., can solve the problems of insufficient welding strength, easy air leakage during use, monotonous structure, etc., to achieve optimal welding strength, Guaranteed sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described in detail below through embodiments and in conjunction with the accompanying drawings.

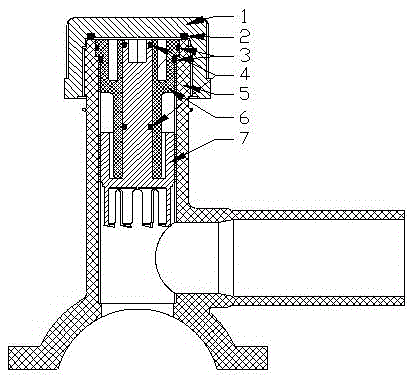

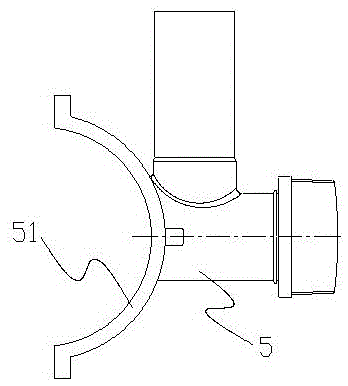

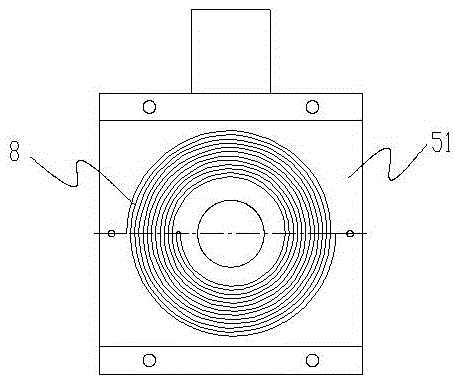

[0022] In the present embodiment, there is a saddle-type bypass with a rear wire mesh, and the main casing is a saddle-shaped bypass body 5, such as figure 1 , figure 2 As shown, the bypass main body 5 is provided with two mutually perpendicular short pipes, one of which is an external pipe, and the other short pipe is used as a hole-forming drilling tool seat. The hole cutter 7 is coaxially provided with a saddle seat, that is, a saddle arc welding surface 51 in the bypass body 5 .

[0023] The drilling tool 7 is assembled in the hole drilling tool seat of the bypass main body 5, and the drilling tool 7 is provided with an upper handle, such as Figure 5 As shown, the upper handle is in transition fit with the inner hole of the transition pressure ring 6, and two tool sealing rings 4 are arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com