Suction cup device for grabbing glass from lower surface of glass plate and control method

A glass plate and suction cup technology, used in transportation and packaging, conveyor objects, furnaces, etc., can solve problems affecting coating quality, glass impact, glass surface scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

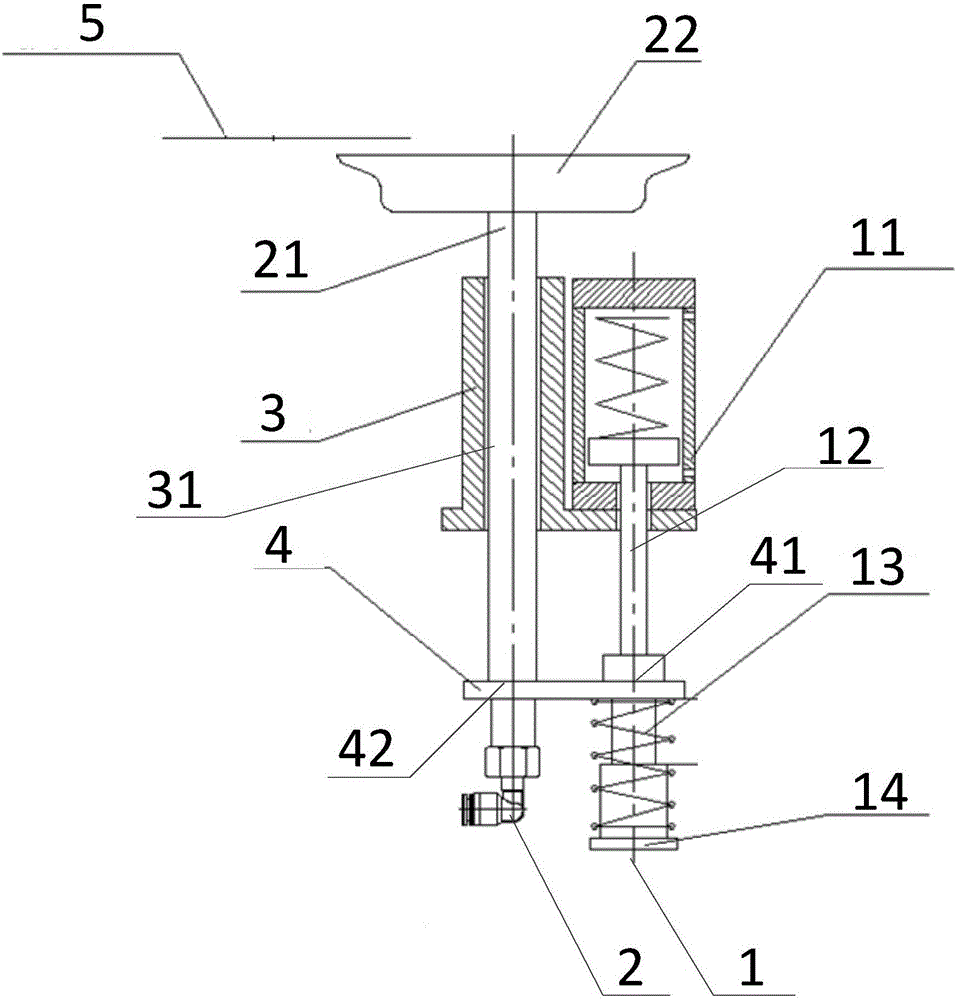

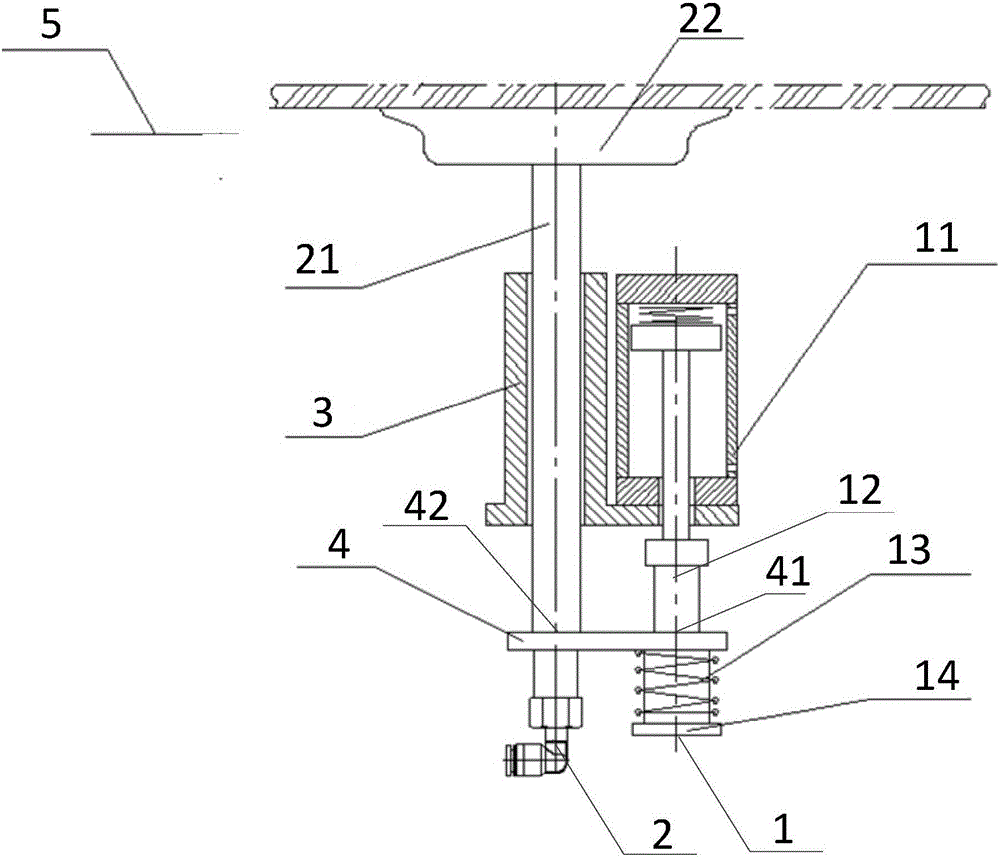

[0029] In order to better clearly express the technical solution of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

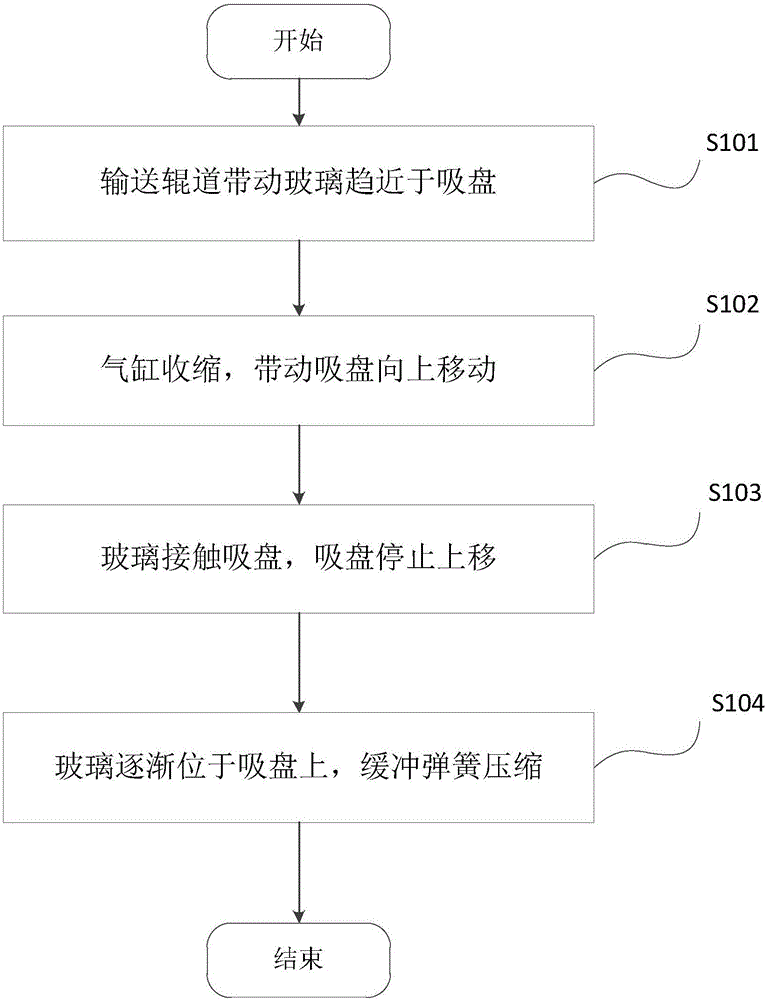

[0030] figure 1 It shows a specific embodiment of the present invention, in the initial state of work, a schematic structural view of a suction cup device for grabbing glass from the lower surface of a glass plate, and as a first embodiment of the present invention, figure 2 Showing the first embodiment of the present invention, in the working state, a schematic structural view of a sucker device for grabbing glass from the lower surface of a glass plate, those skilled in the art understand that the present invention will combine Figure 1 to Figure 2 To further describe the internal structure and connection relationship of the suction cup device, for a better understanding of the present invention, figure 1 as well as figure 2 The dynamics and working principle of the suction cup s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com