Patents

Literature

101results about How to "Improve the seismic performance of structures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light cast-in-situs concrete wallboard

InactiveCN1530501AStrong and durable connectionImprove the seismic performance of structuresSolid waste managementWallsFiberglass meshGlass fiber

A light concrete wall slab cast in-situ is composed of main body and welded reinforcing steel bar net in said main body. Said main body is made up of water, cement, powdered coal ash, slag powder, silicon powder, efficient composite water-reducing agent, polypropylene fibres, glass fibre fabric or alkali-resistant plastic-coated glass staple, modified cement polymer emulsion (or powder), haydite, and sand. Its advantages are light weight, high strength, low shrinkage, not deforming and cracking, and low cost.

Owner:张英保

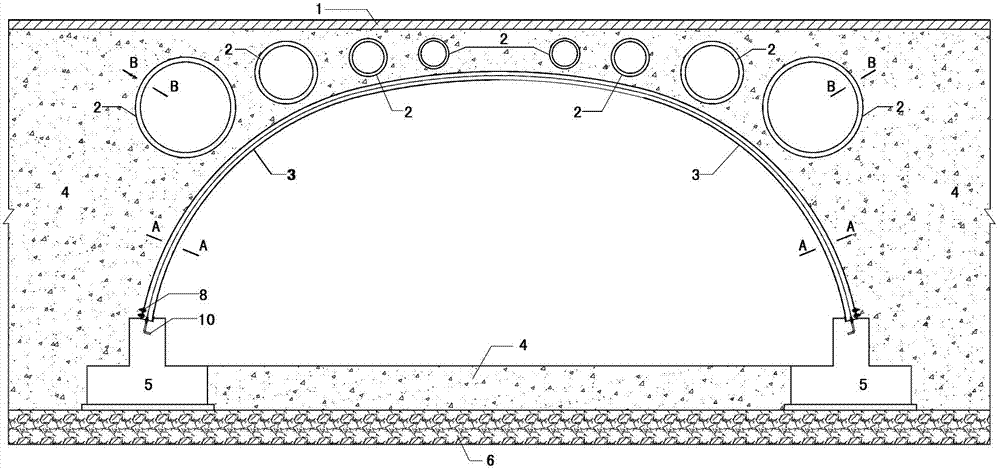

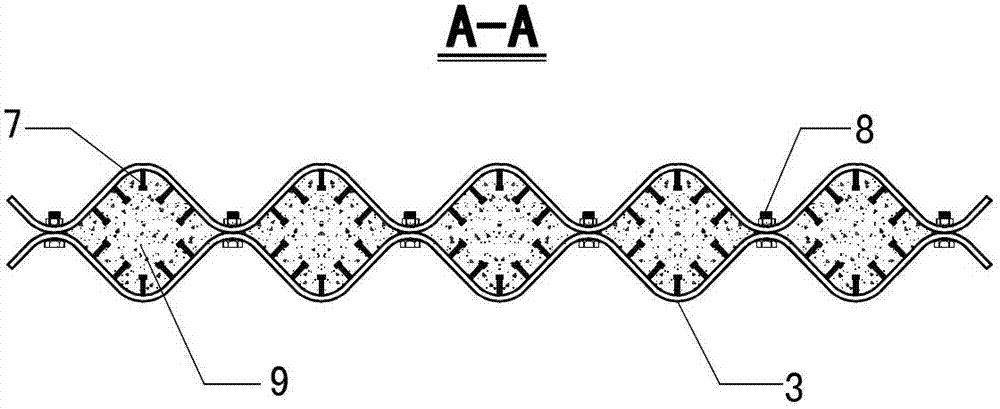

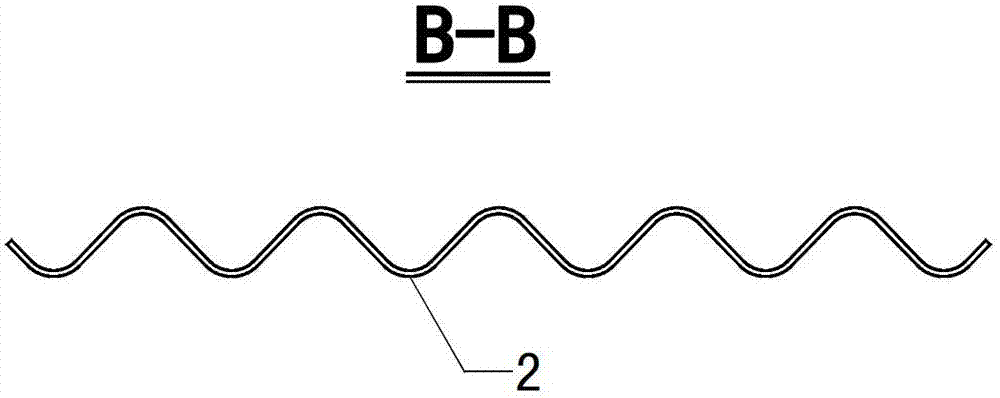

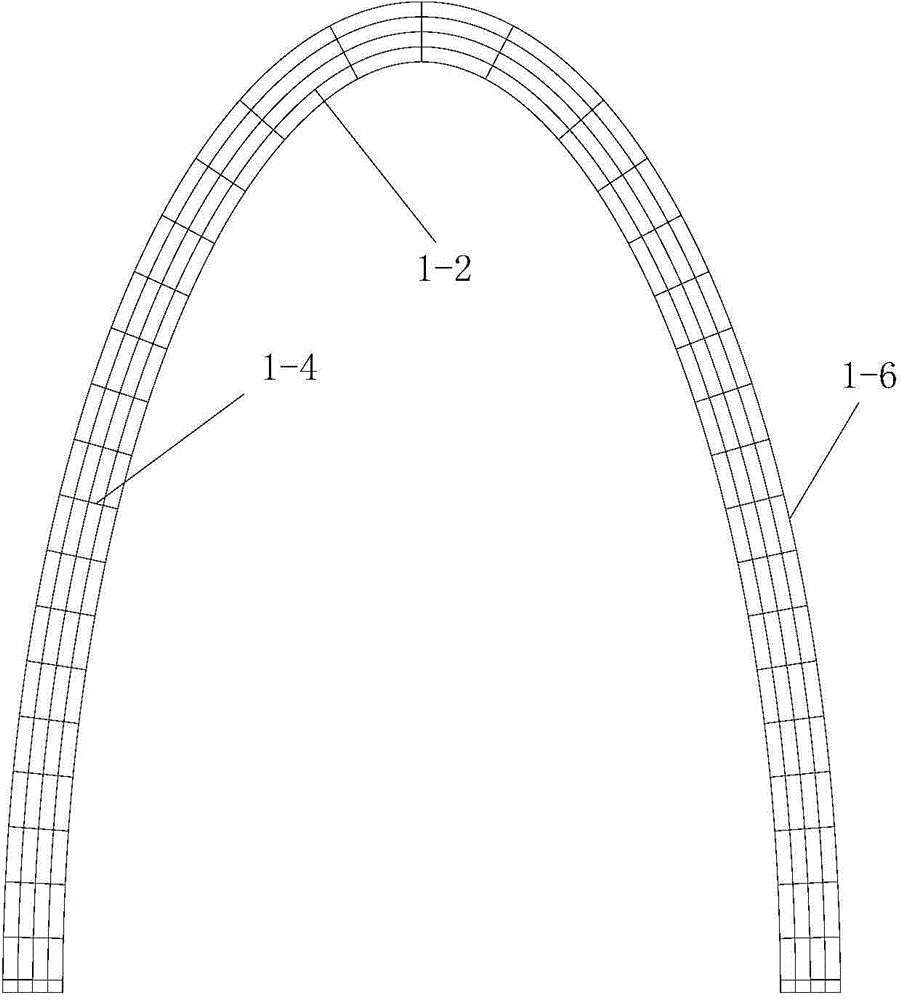

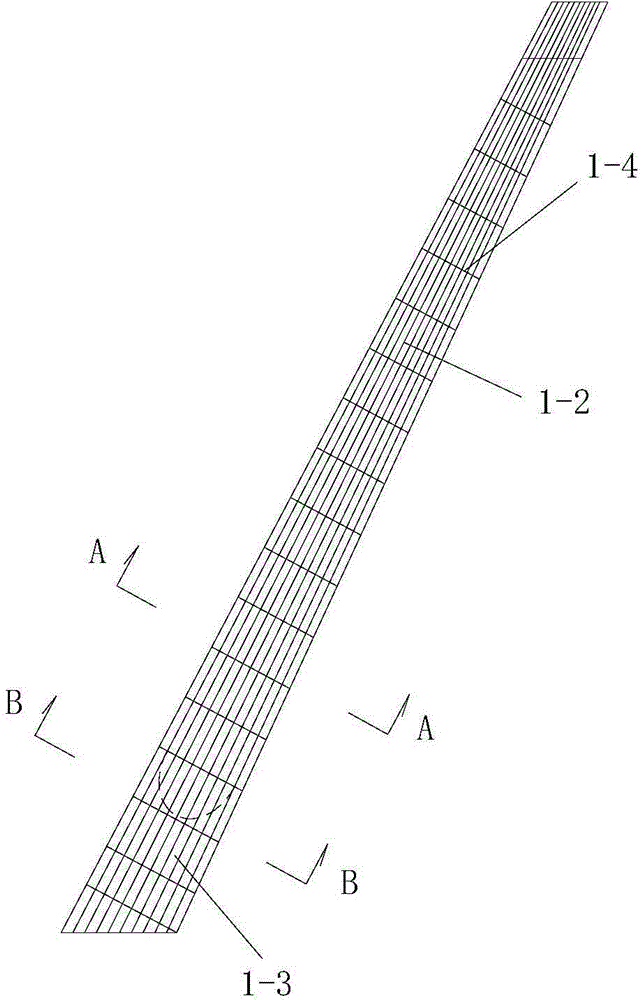

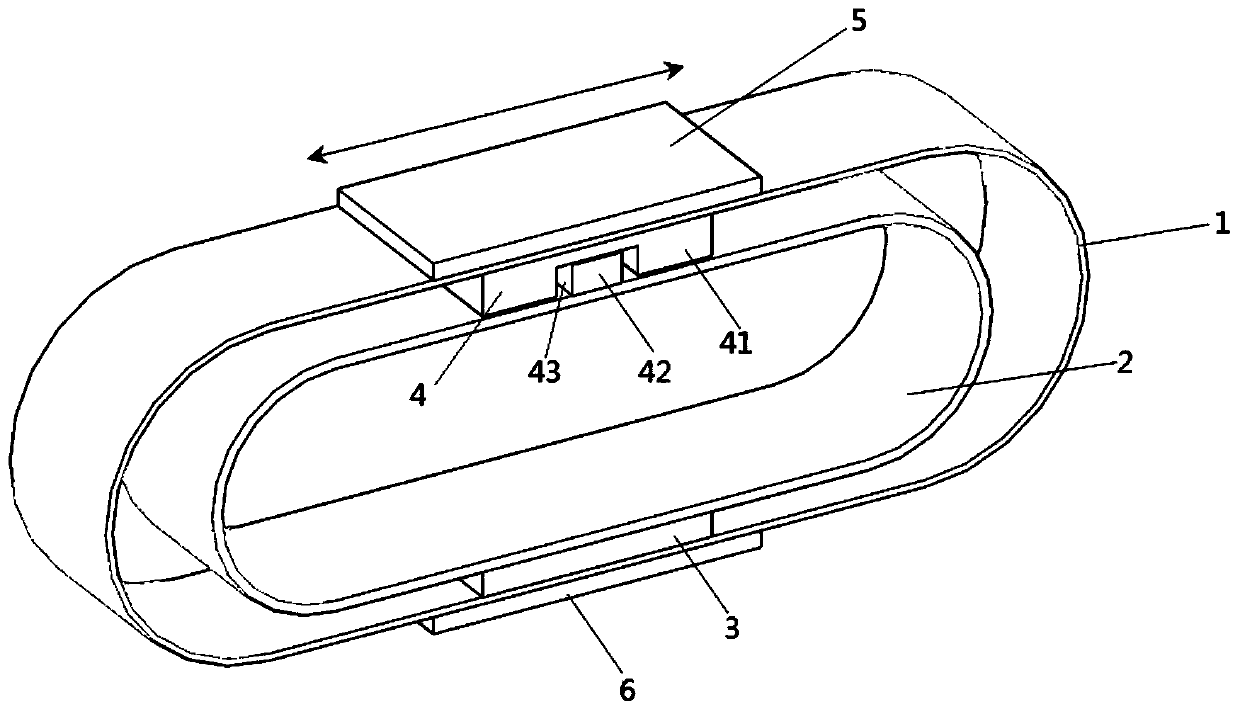

Lattice-type large-span soil-filling composite corrugated steel arch bridge structure

InactiveCN103114520ASimplify the assembly processReduce weightBridge erection/assemblyArch-type bridgeReinforced concreteEconomic benefits

The invention relates to a novel composite arc bridge structure, and particularly discloses a lattice-type large-span soil-filling composite corrugated steel arch bridge structure. Sandwich mortar composite corrugated steel plates are adopted as large-span main arch rings of the composite structure. The corrugated steel plates are connected to form a reversely arranged double-layer plate through bolts, studs are arranged in an interlayer, and filled high-strength mortar forms an integral sandwich composite corrugated steel plate. Corrugated steel tubes are adopted by gastropore. Load is conveyed between the main arch rings and the gastropore by filling soil. The lattice-type large-span soil-filling composite corrugated steel arch bridge structure has the advantages of being low in weight, durable, high in strength, good in flexibility, high in performance, rapid in construction, good in economic benefit and the like, is an ideal alternative to reinforced concrete bridges, can be widely used in the construction of middle-sized bridges (20-50m), and can certainly generate good social economic benefit.

Owner:HUNAN UNIV

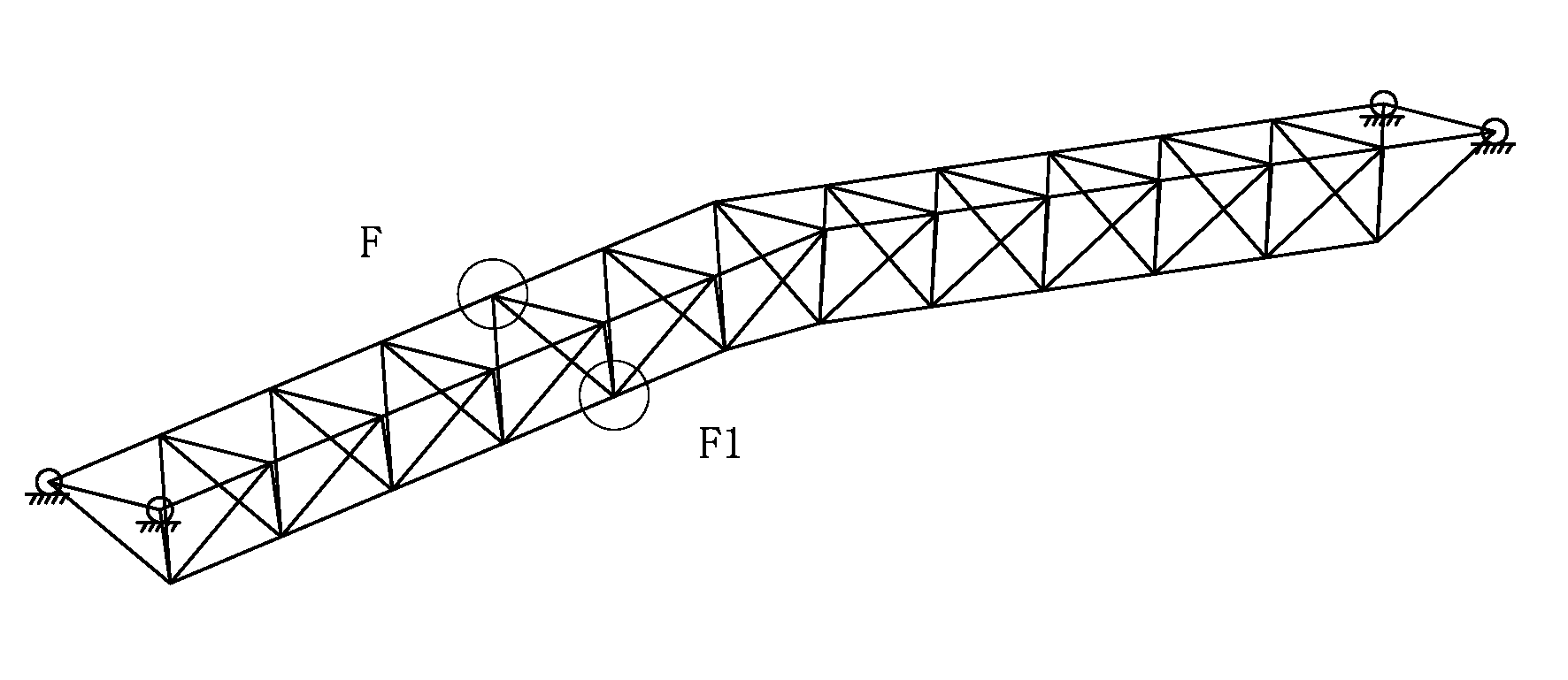

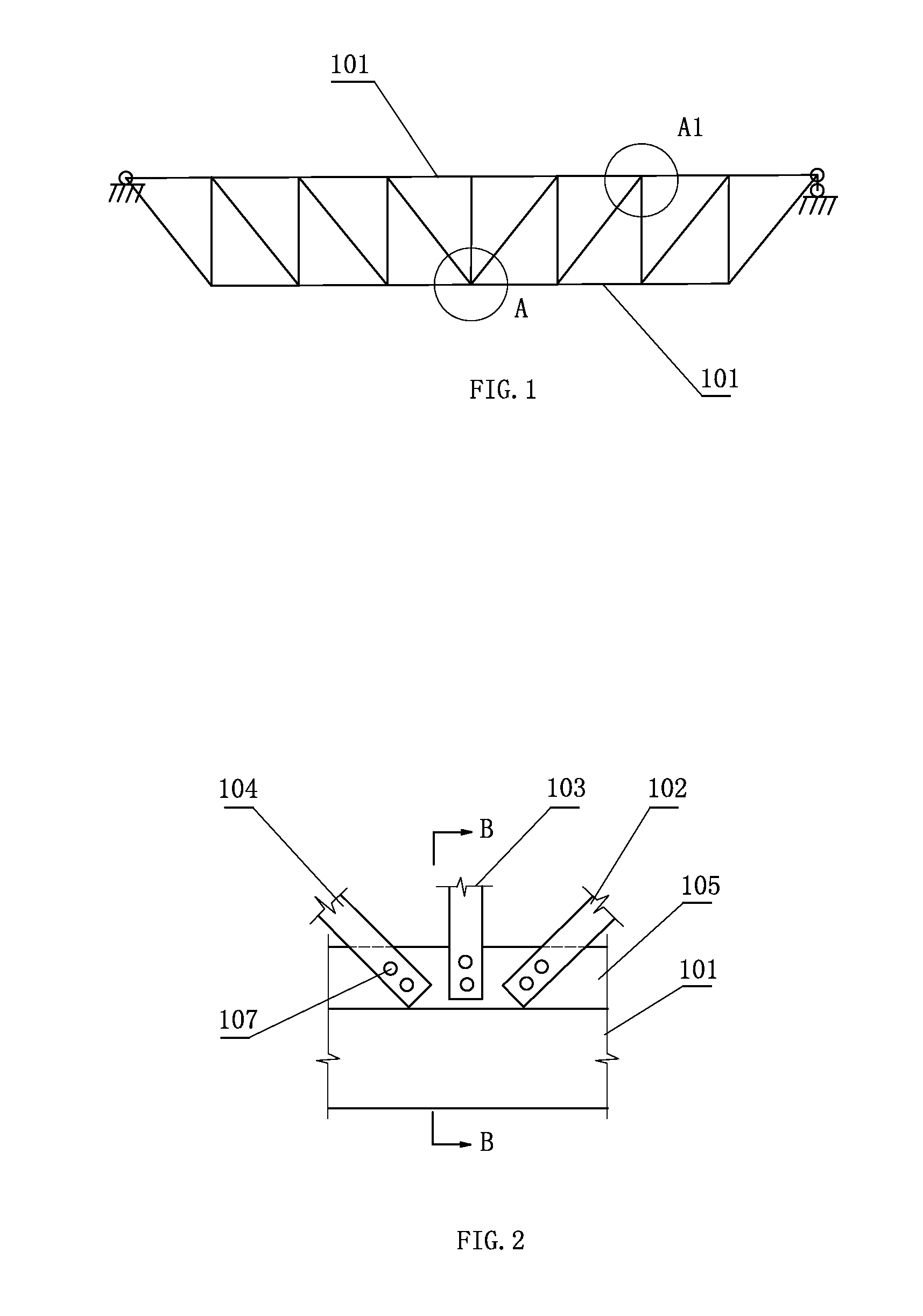

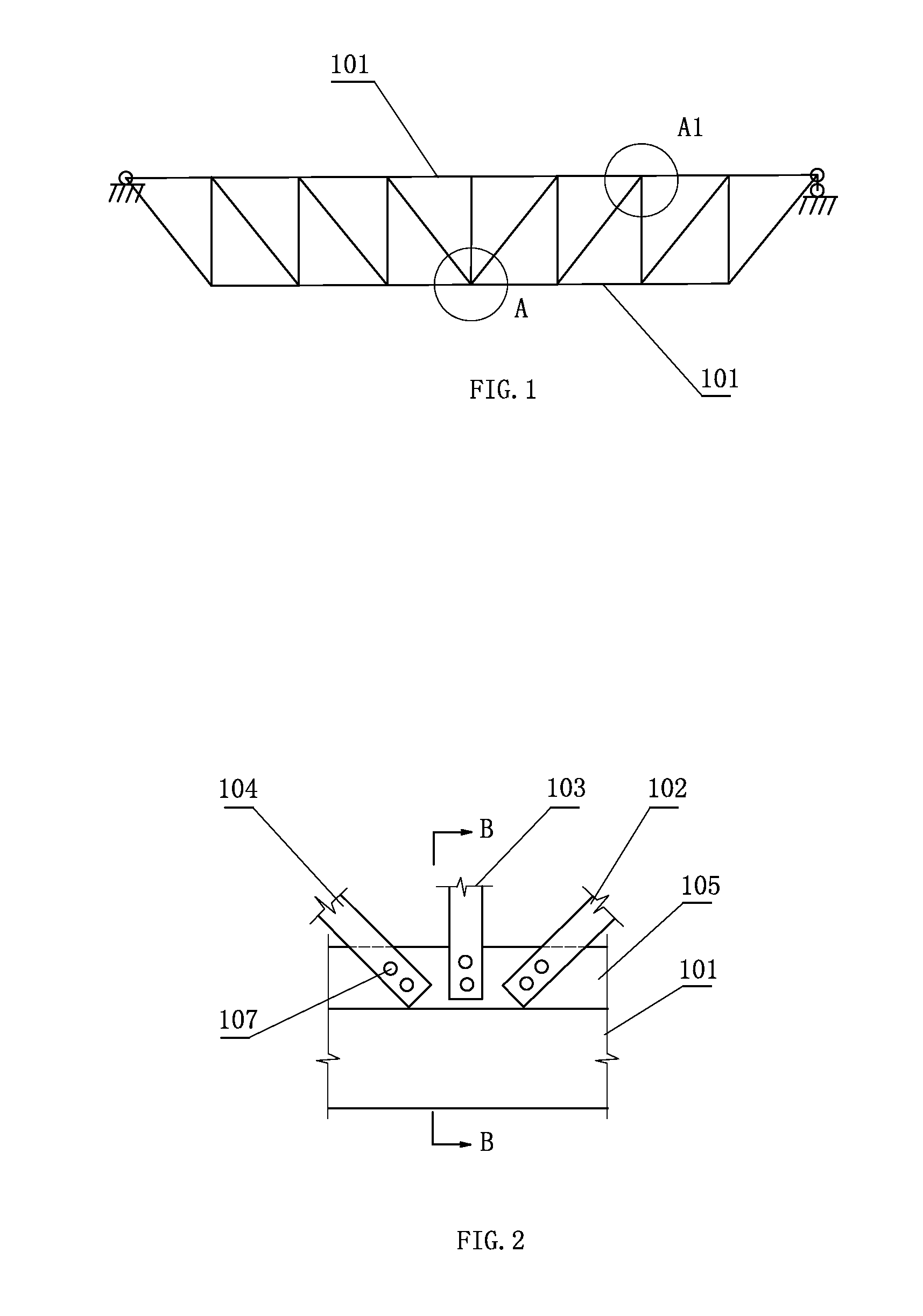

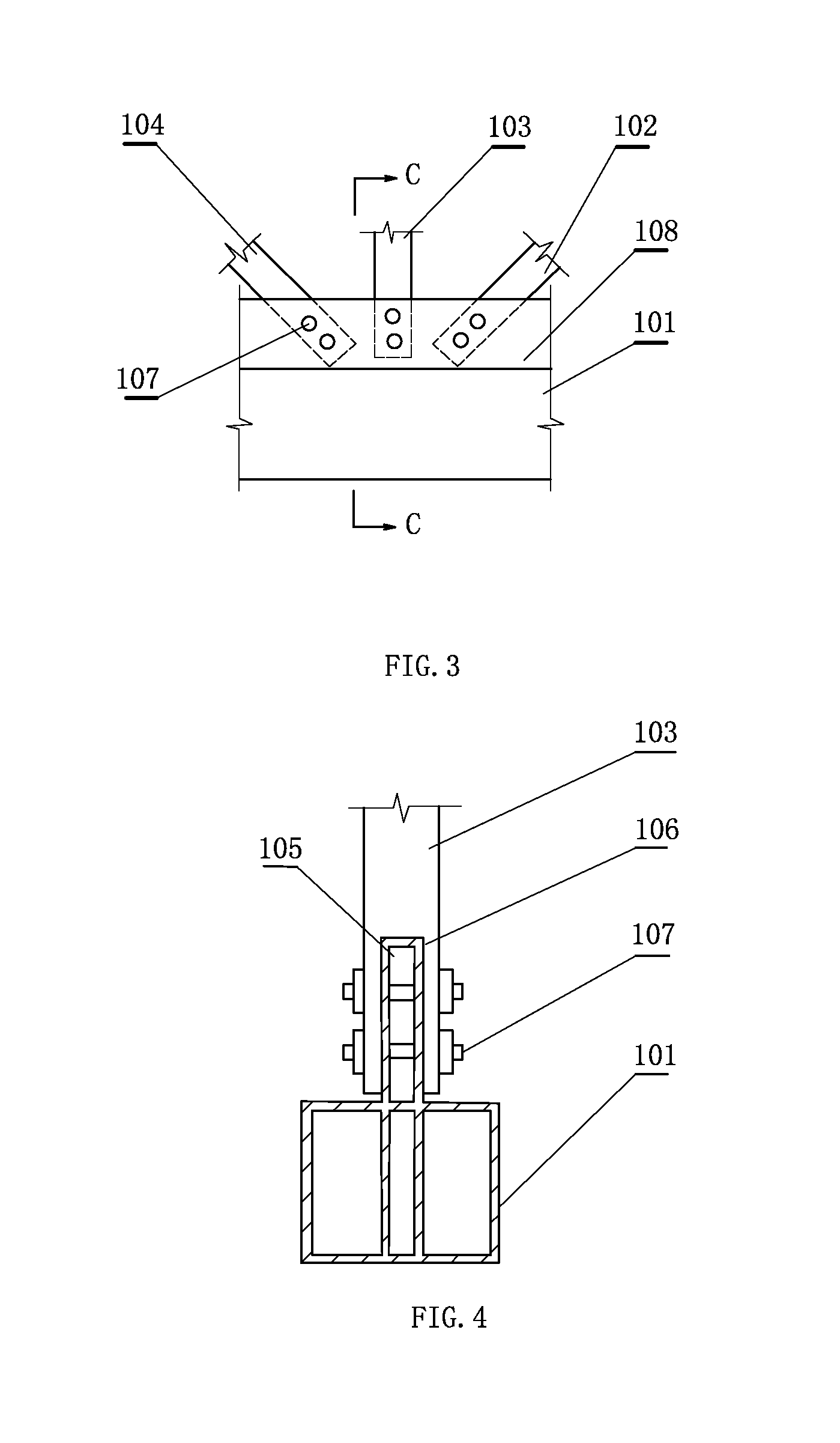

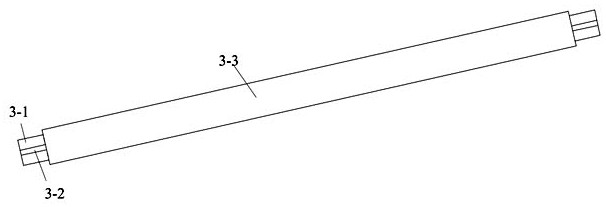

Aluminium alloy truss structure

InactiveUS20120255255A1Formed satisfactorilyEasy to makeArched girdersPortal framesEngineeringAluminium alloy

An aluminum alloy truss structure, comprising upper chord members, lower chord members, web members and all connection nodes by which the members are connected using riveting bolts, the chord members and web members being interconnected using tenons and mortise grooves that mate with each other respectively, each of the chord members being provided with a tenon plate at the end adjacent to the respective web members, each of the web members being correspondingly provided with a mortise groove at either end thereof, and the tenon plate on the chord members being implanted into the mortise groove on the web members; or, alternatively, each of the chord members being provided with a mortise groove at the end adjacent to the respective web members, each of the web members being correspondingly provided at either end thereof with a tenon that is to mate with the mortise groove.

Owner:LIN JUAN +1

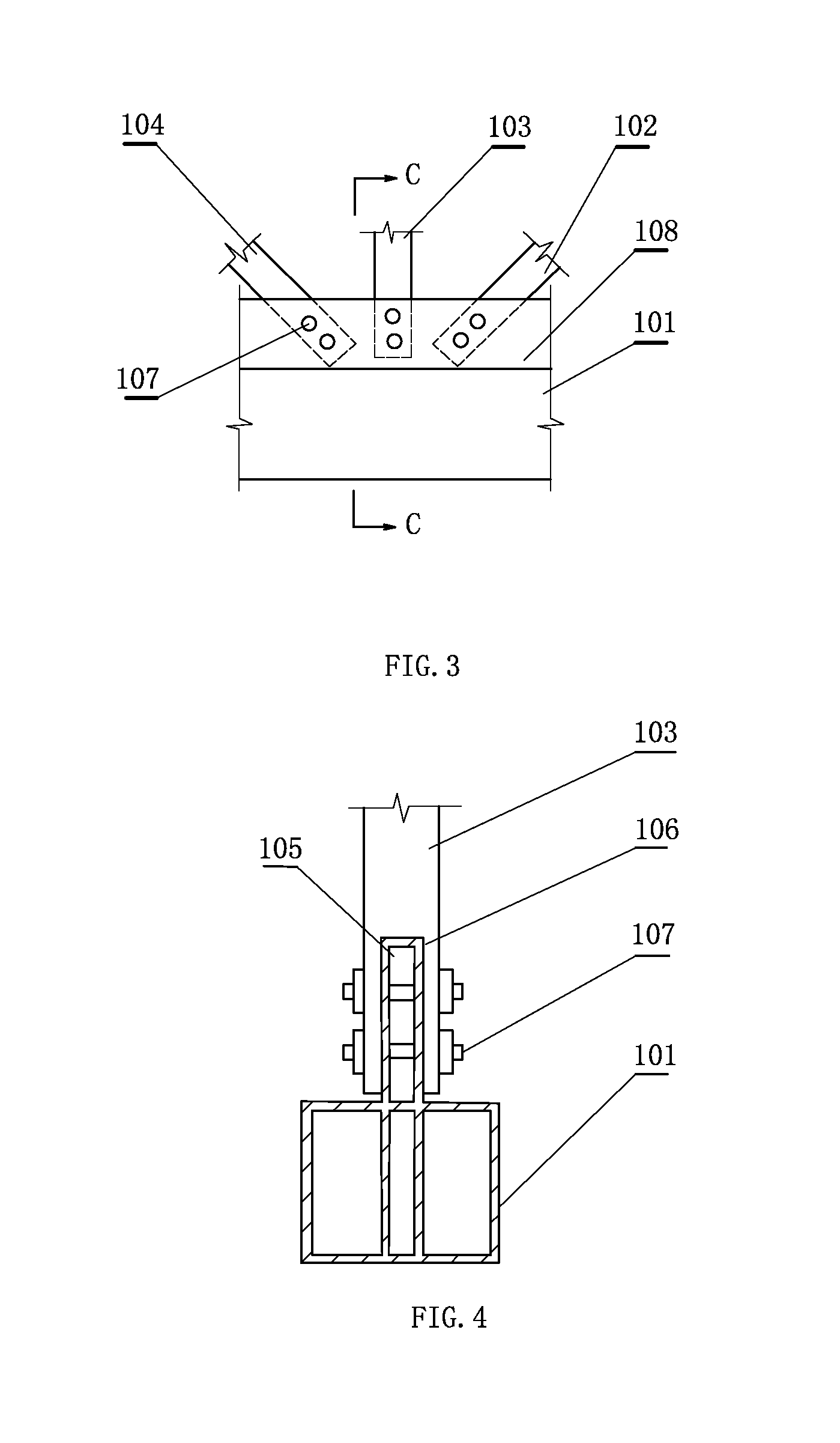

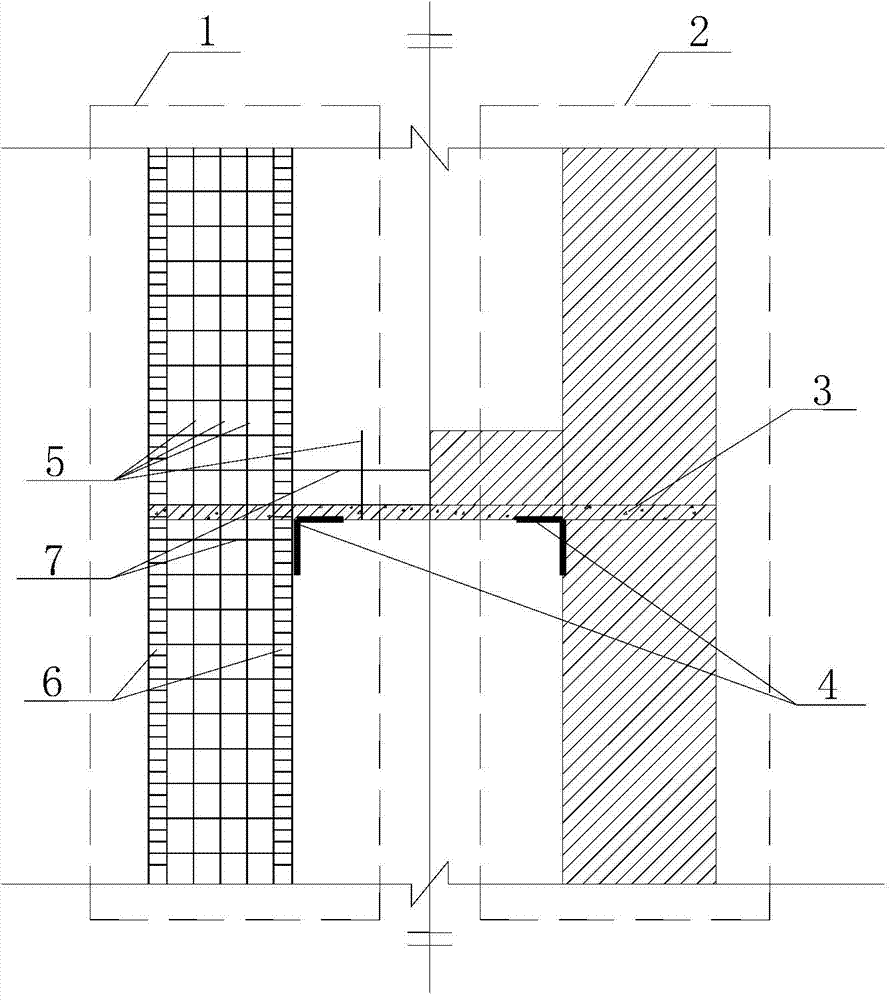

Hanging flexible connection of precast concrete infill wall

InactiveCN103556749AEnhanced horizontal and out-of-plane stiffnessPrevent out-of-plane collapseWallsShock proofingRebarPrecast concrete

The invention discloses a hanging flexible connection of a precast concrete infill wall. The hanging flexible connection of the precast concrete infill wall comprises precast concrete infill wall, frame columns / shear walls on both sides of the infill wall, a top beam / plate on the top of the infill wall and a bottom beam / plate at the bottom of the infill wall, wherein the precast concrete infill wall is connected with the frame columns / shear walls on both sides of the infill wall through snapping flexible pull rings, the precast concrete infill wall is connected with the top beam / plate of the infill wall through reserved joint bar grouting or cast-in-place of concrete, and a base slurry layer is arranged between the precast concrete infill wall and the bottom beam / plate of the infill wall. Vertical reinforcing steel bars are inserted into the middle and rear portions of the snapping flexible pull rings. The precast concrete infill wall can be made of light walls with anti-seismic energy dissipation structure. The hanging flexible connection of the precast concrete infill wall solves the technical and theoretical problems of heavy workload of cast-in-place or masonry construction, complex collaboration with a main structure, vulnerability and lack of anti-seismic energy dissipation capacity in earthquake and the like of an existing connection of the infill wall.

Owner:NANJING UNIV OF TECH

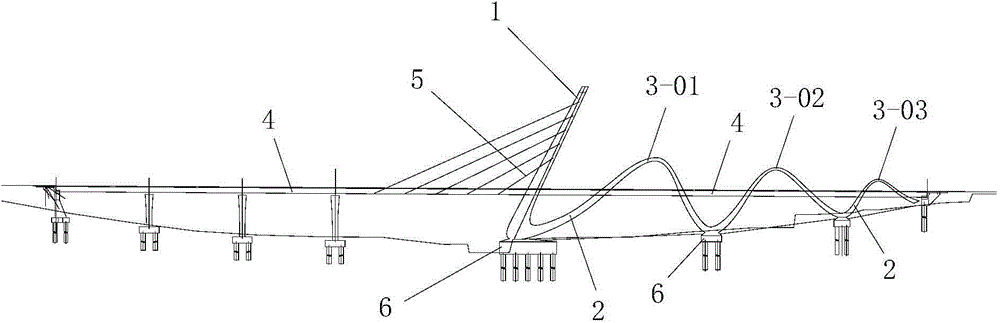

Ribbon-shaped single-tower cable-strayed-steel structure combined bridge and construction process thereof

ActiveCN104562913ASimple structureReasonable designCable-stayed bridgeBridge structural detailsCable stayedEngineering

The invention discloses a ribbon-shaped single-tower cable-strayed-steel structure combined bridge and a construction process thereof. The combined bridge comprises a lower supporting structure, a main beam, an arch-shaped main tower which is arranged on the main beam and gradually backwards inclined from bottom to top, and two ribbon-shaped supporting structures which are positioned at the rear side of the main tower; the two ribbon-shaped supporting structures are both integrally fixedly connected with the main beam; the two-ribbon-shaped supporting structures and the main beam are lengthways arranged along the bridge direction; a plurality of cable-strayed ropes are arranged between the main tower and the main beam; each ribbon-shaped supporting structure is divided into a lower ribbon-shaped supporting structure and an upper ribbon-shaped connecting structure through the main beam. The construction process of the combined bridge comprises the steps of 1, constructing the lower supporting structure; 2, constructing the lower ribbon-shaped supporting structure; 3, constructing the main beam; 4, constructing the main tower and the upper ribbon-shaped connecting structure. The combined bridge is reasonable in structural design, convenient to construct, outstanding in mechanical performance and a good in use effect; a non-back cable-stayed bridge and a continuous rigid structural bridge are effectively combined, and the advantages of the two bridges are brought into full play.

Owner:XIAN MUNICIPAL ENG DESIGN & RES INST +1

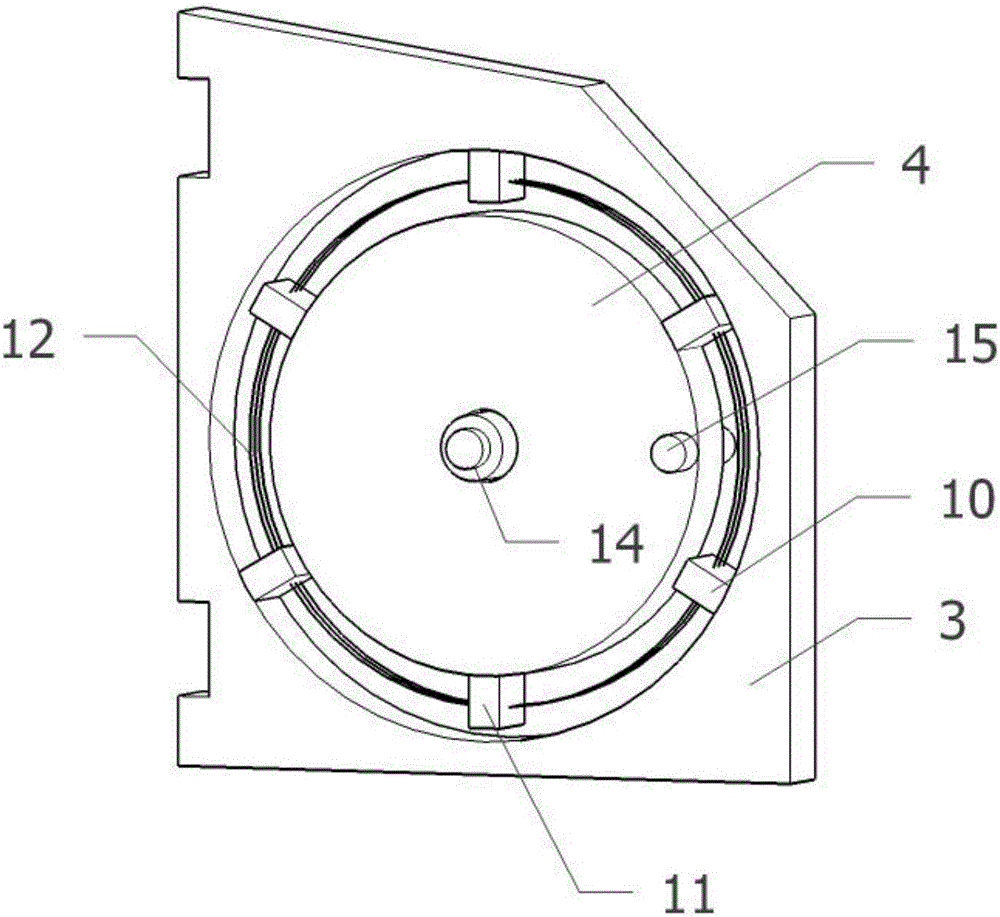

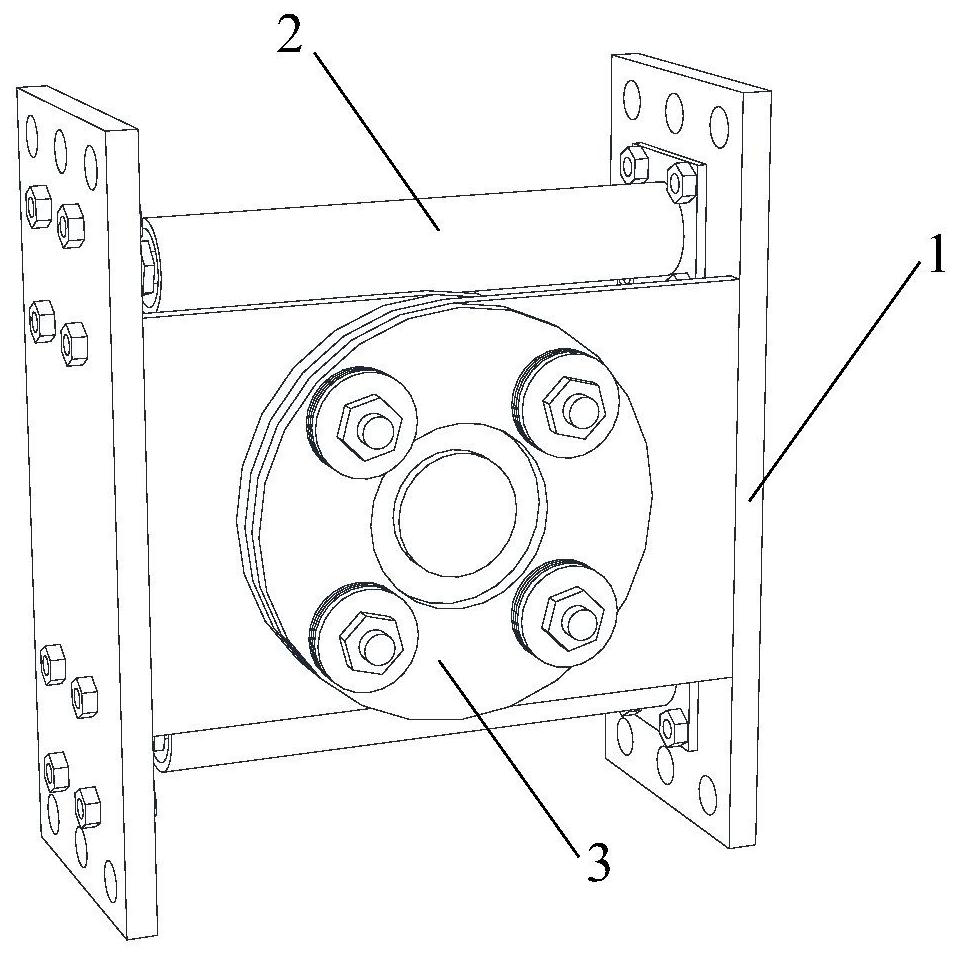

Disc-shaped memory alloy damper

ActiveCN106481132AIncreased shear capacityImprove the bending capacityProtective buildings/sheltersShock proofingCircular discShape-memory alloy

The invention discloses a disc-shaped memory alloy damper. The disc-shaped memory alloy damper comprises a wood column and a wood beam connected with the wood column and is characterized in that a base is connected to a corner where the wood column is connected with the wood beam, a rotary disc which can rotate along the base is arranged in the base, and the base is fixed on the inner side of the wood column through a vertical connecting steel plate and a wood column hoop; the rotary disc is respectively connected with the vertical connecting steel plate and the wood beam through an L-shaped fixing steel plate, the rotary disc is connected with the bottom surface of the wood beam through a rigid tie bar, a super-elasticity shape memory alloy wire is arranged at the gap between the base and the rotary disc, and the rotary disc is driven to move in a reciprocating manner through the vertical reciprocating movement of the rigid tie bar to allow the super-elasticity shape memory alloy wire to be repeatedly stretched and reset to bear the internal force the wood column and the wood beam. The disc-shaped memory alloy damper has the advantages that a node reinforcing manner is used to limit interlayer sidesway, the energy consumption and self-resetting ability of the structure under earthquake action are increased evidently, building inclination and collapse caused by the dynamic response generated by vibration, and secondary rectification and reinforcement of a building after the earthquake is avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

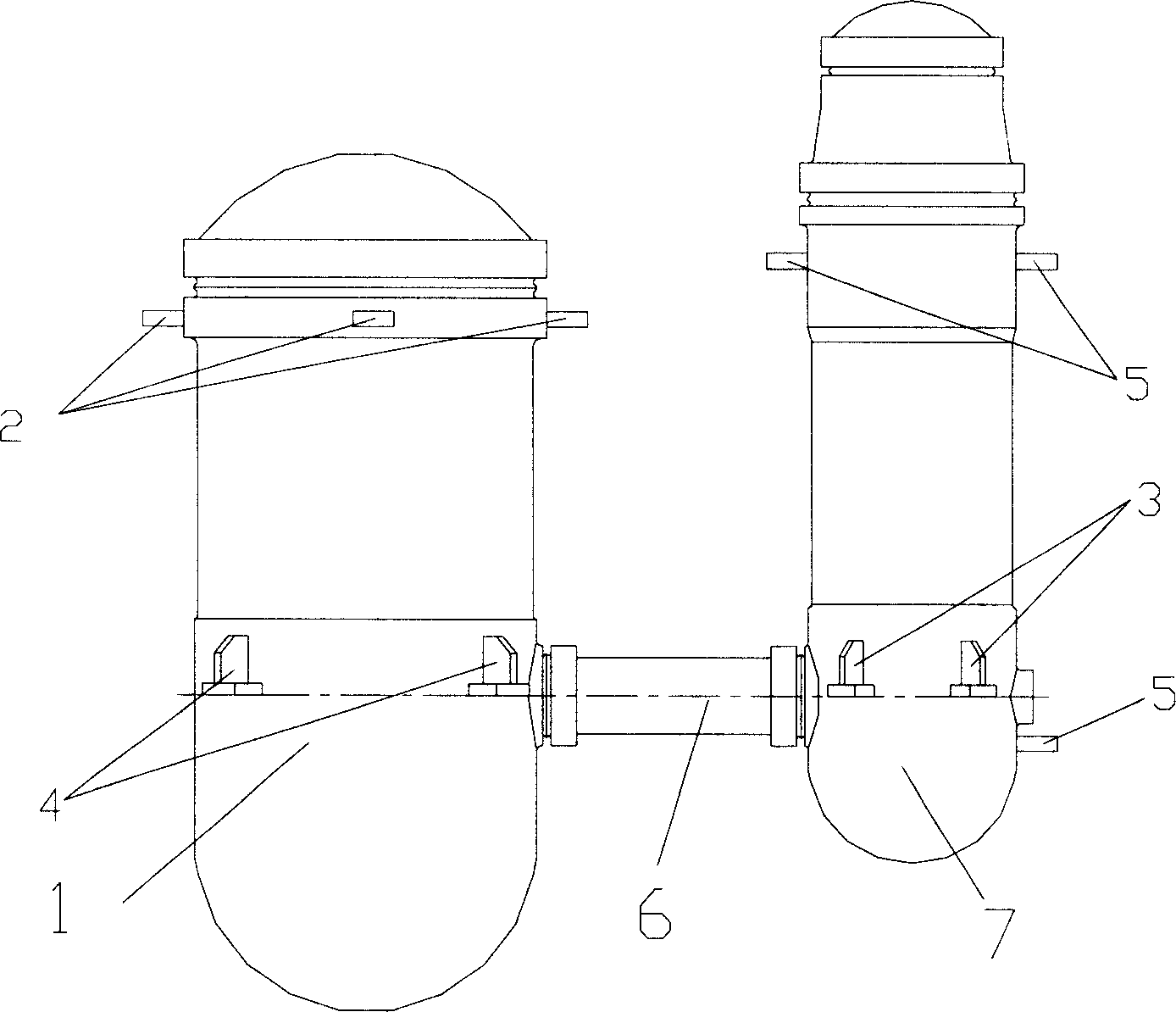

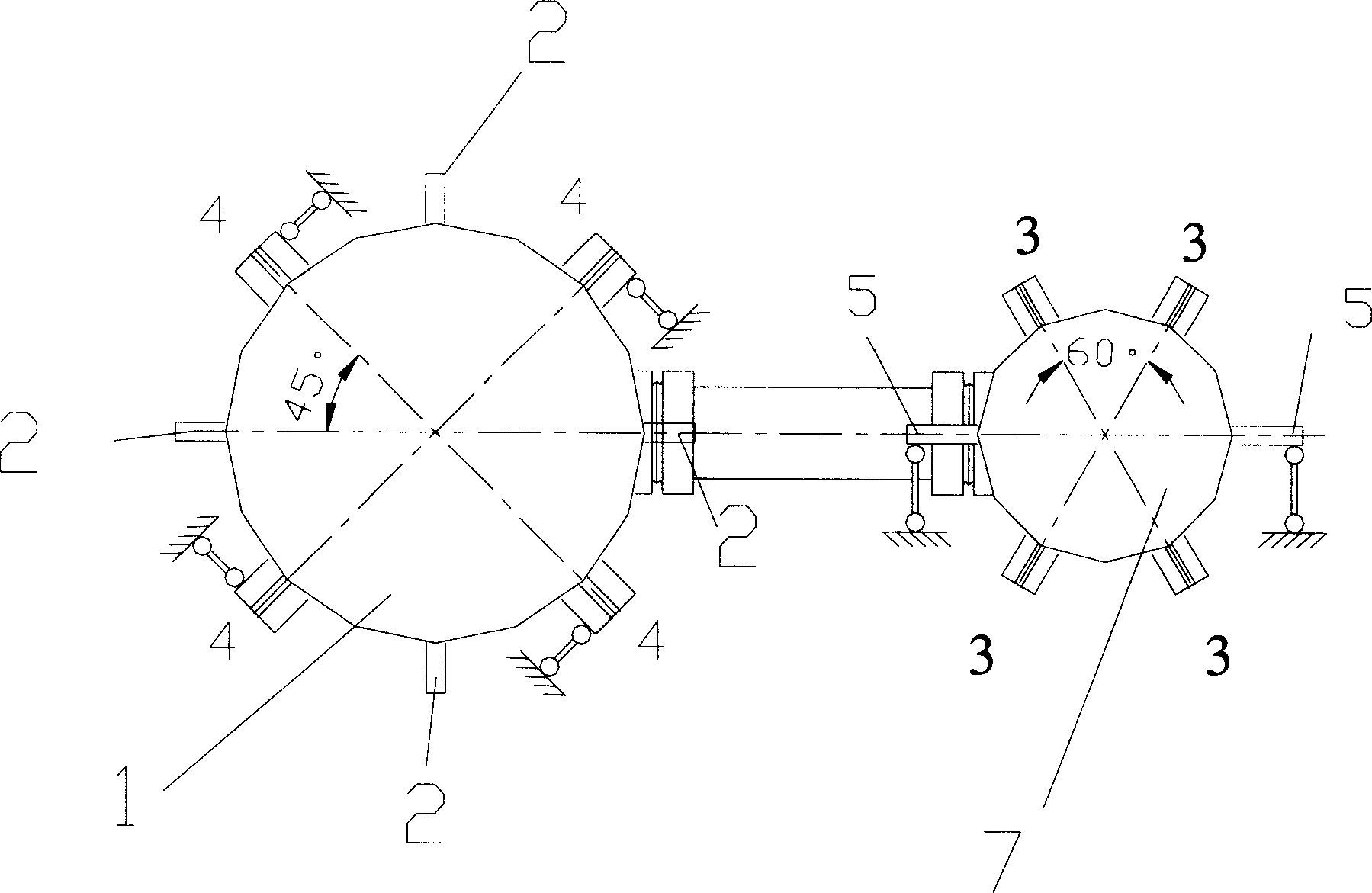

Damper-free support system for modular high temperature air-cooled pile pressure casing

ActiveCN1641797AFlexible rotationPrevent rotationNuclear energy generationContainmentEarthquake resistantMain bearing

The invention relates to a non-damper supporting system of module-type high temperature air-cooled reactor pressure vessel that is belonged to device technology field. The invention is used to solve the antimony between the unreliability of big damper and the high reliability of actor. The invention supplies a safe and reliable machine to take place of damper supporting system. It includes the first main bearing bracing, the second main bearing bracing, the first side direction bracing and the second side direction. Using the invention, the effective bearing and earthquake-resistant behavior would be ensured, and the fabrication cost is low.

Owner:TSINGHUA UNIV

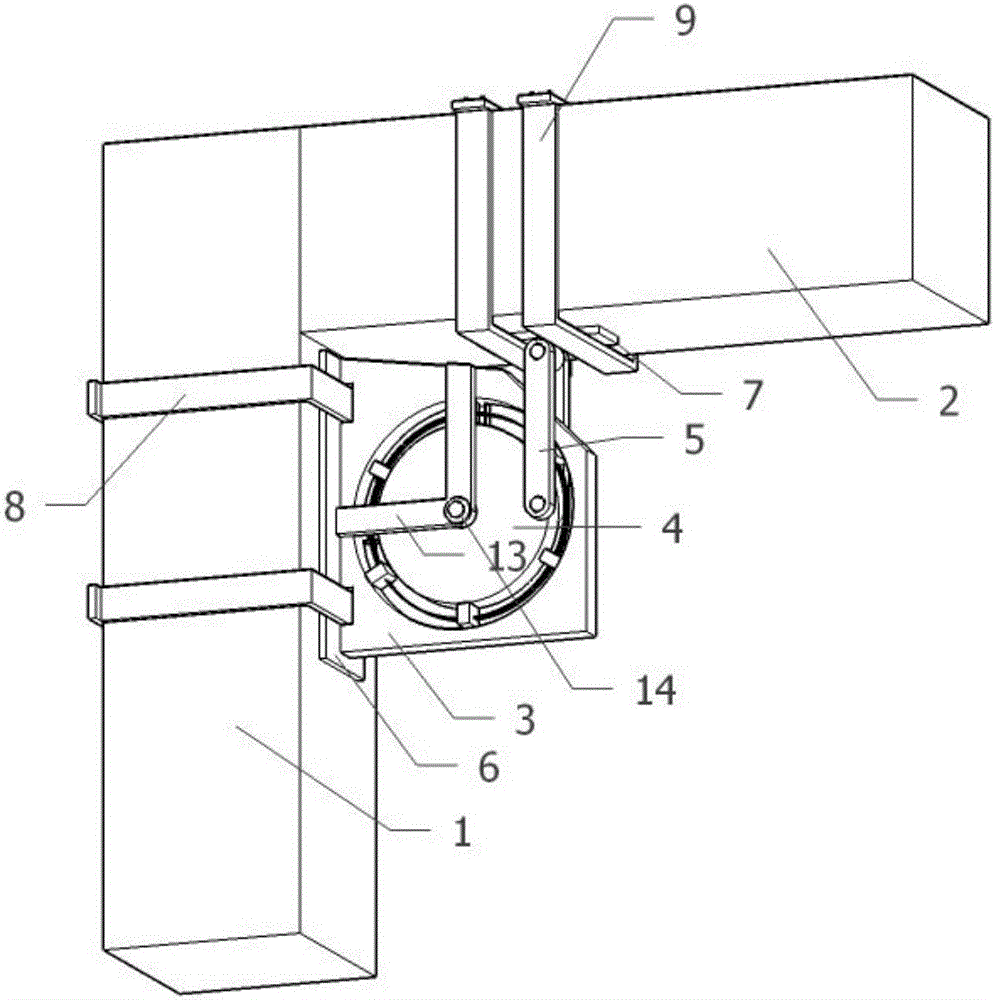

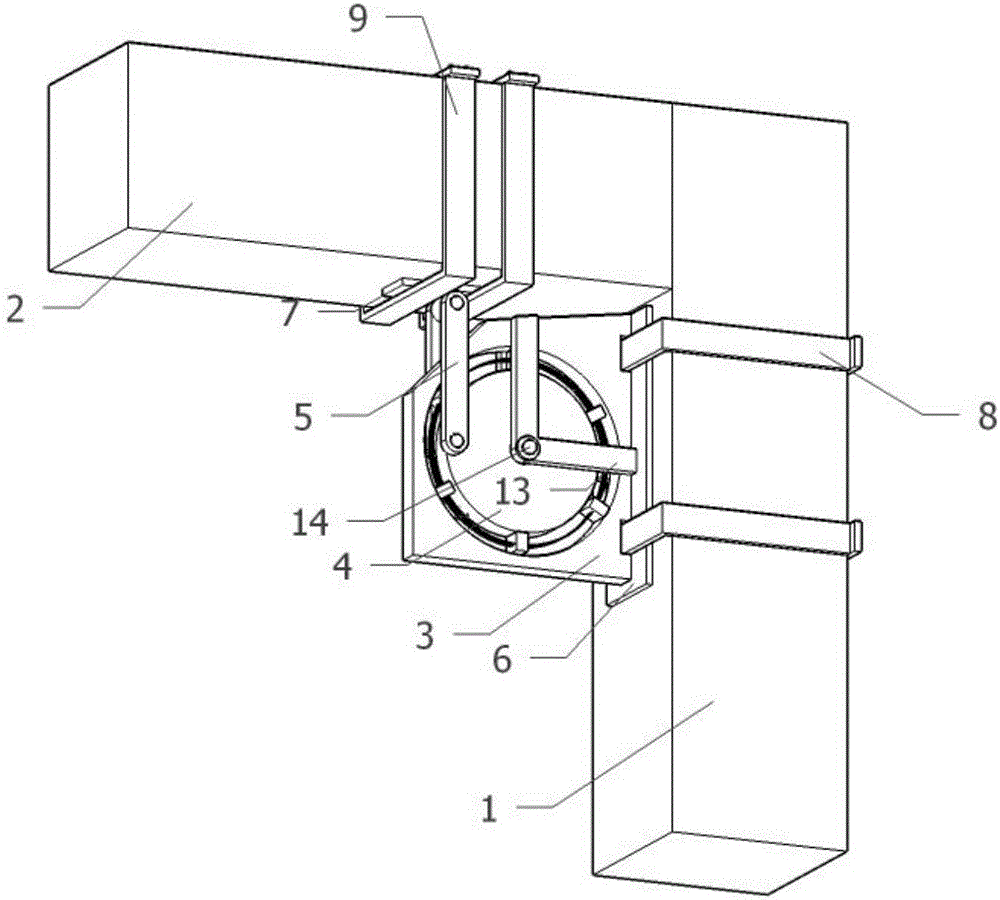

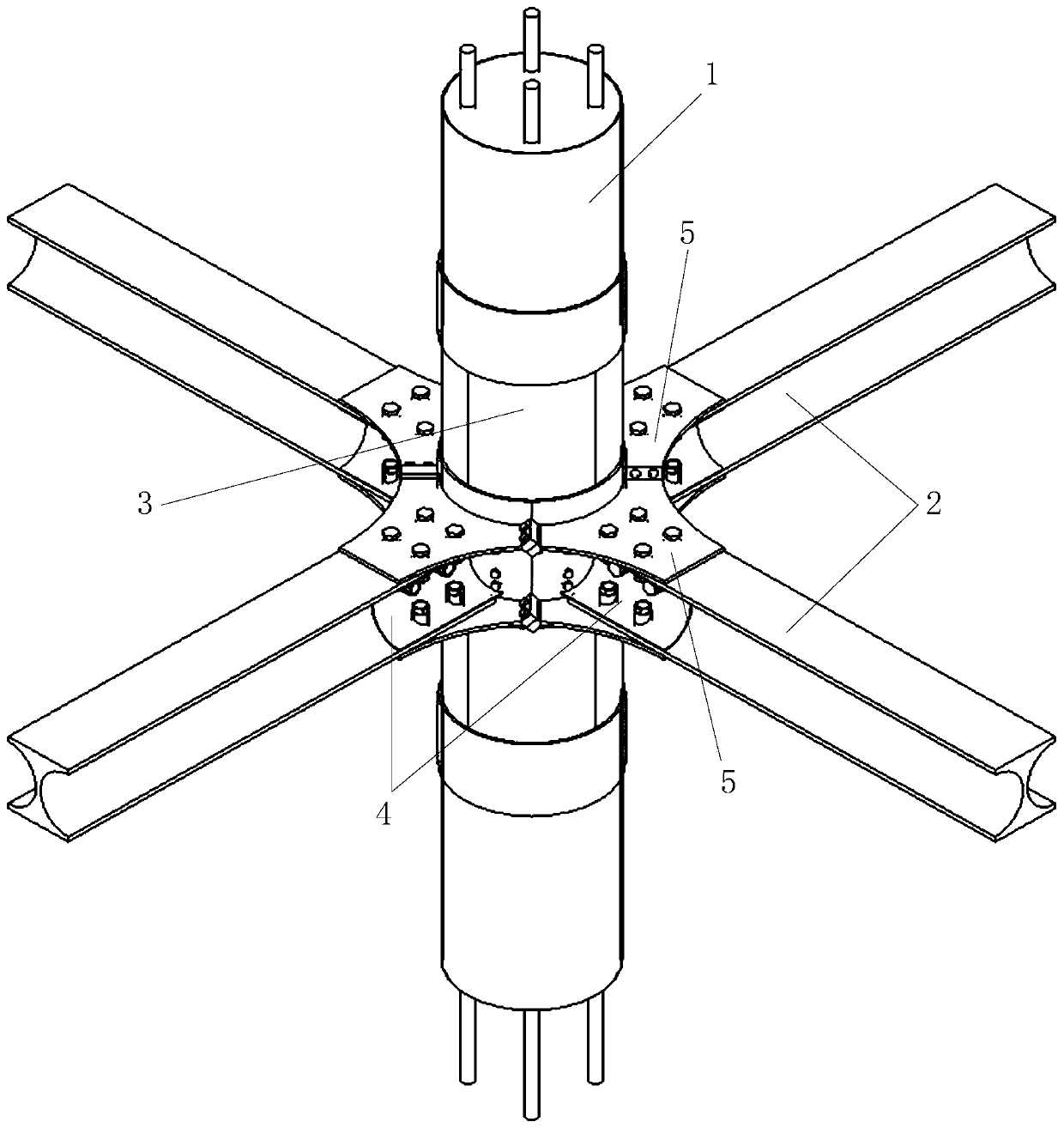

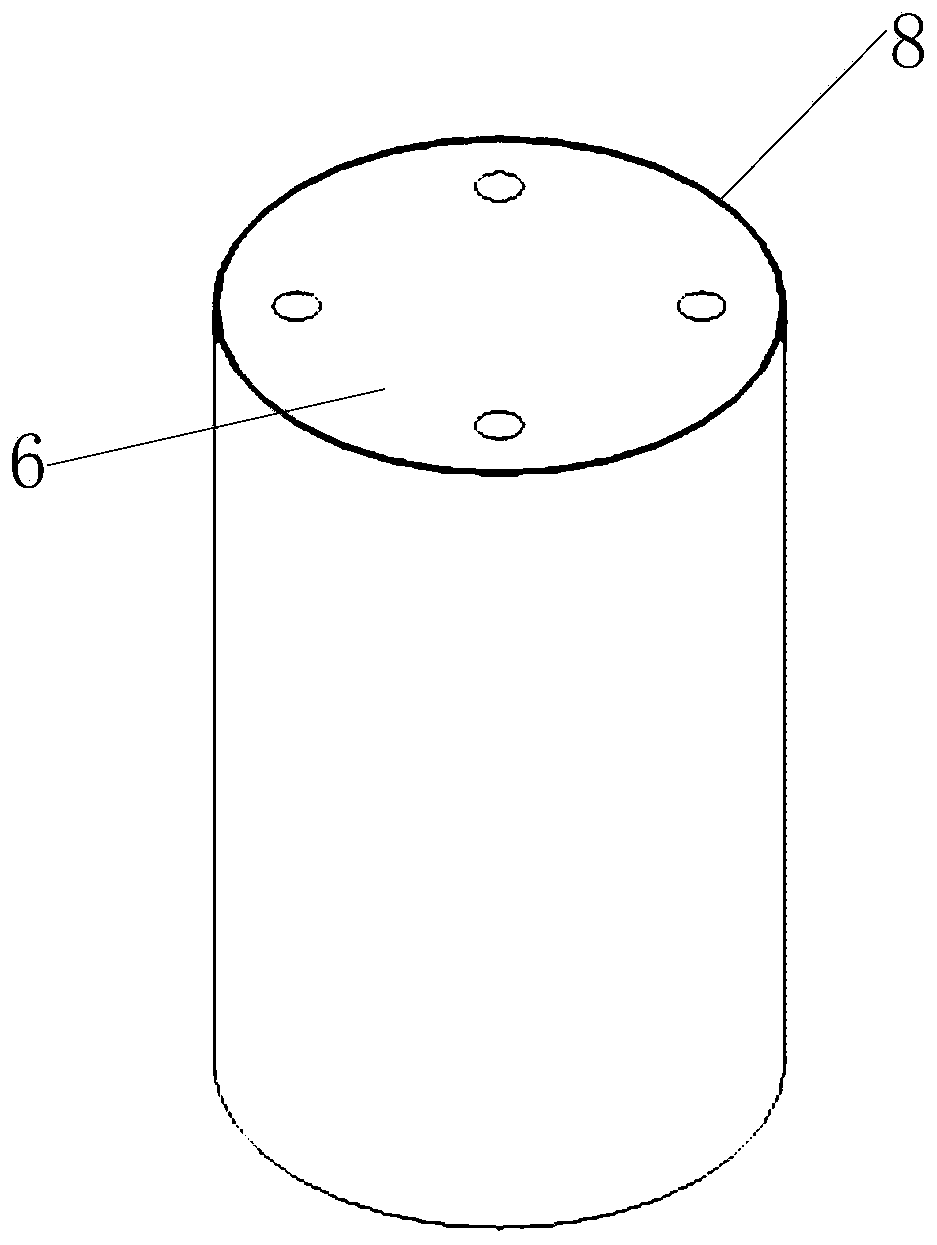

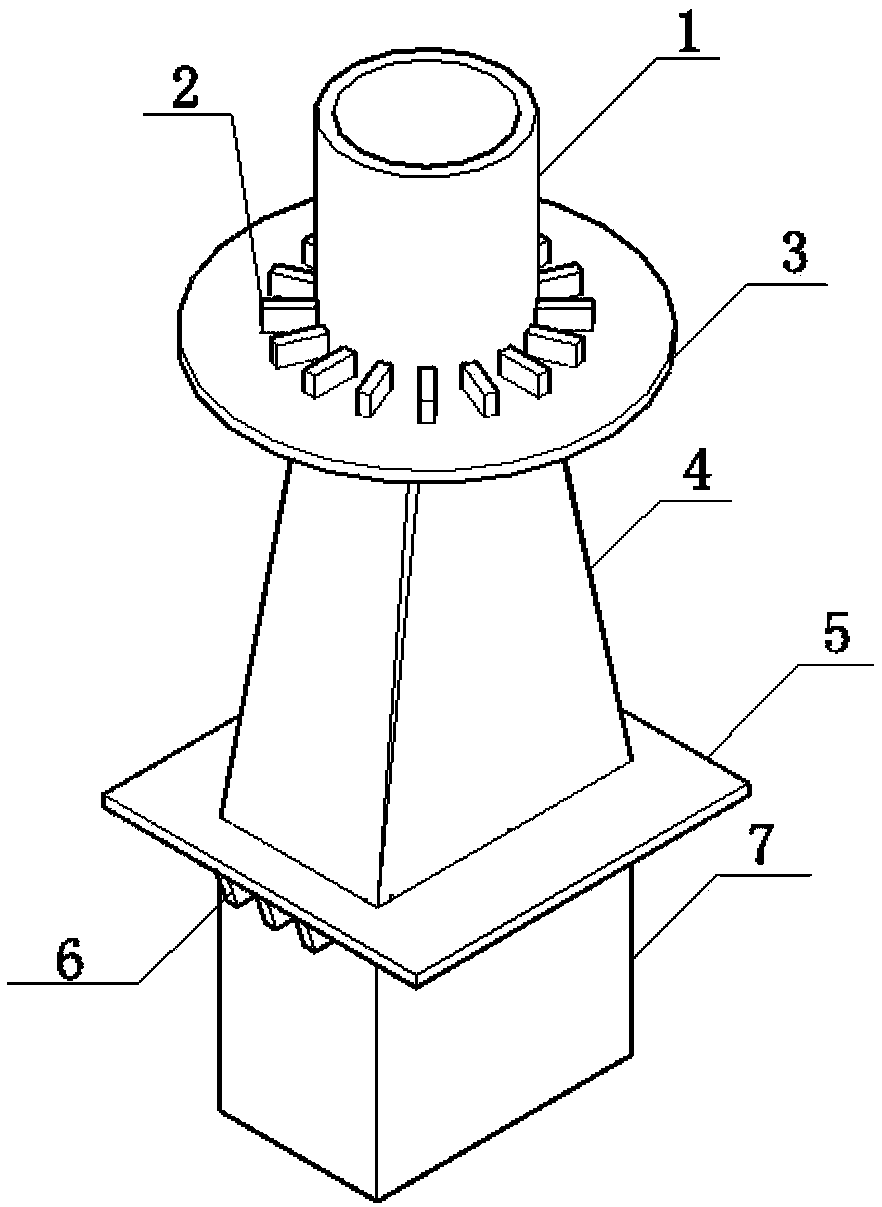

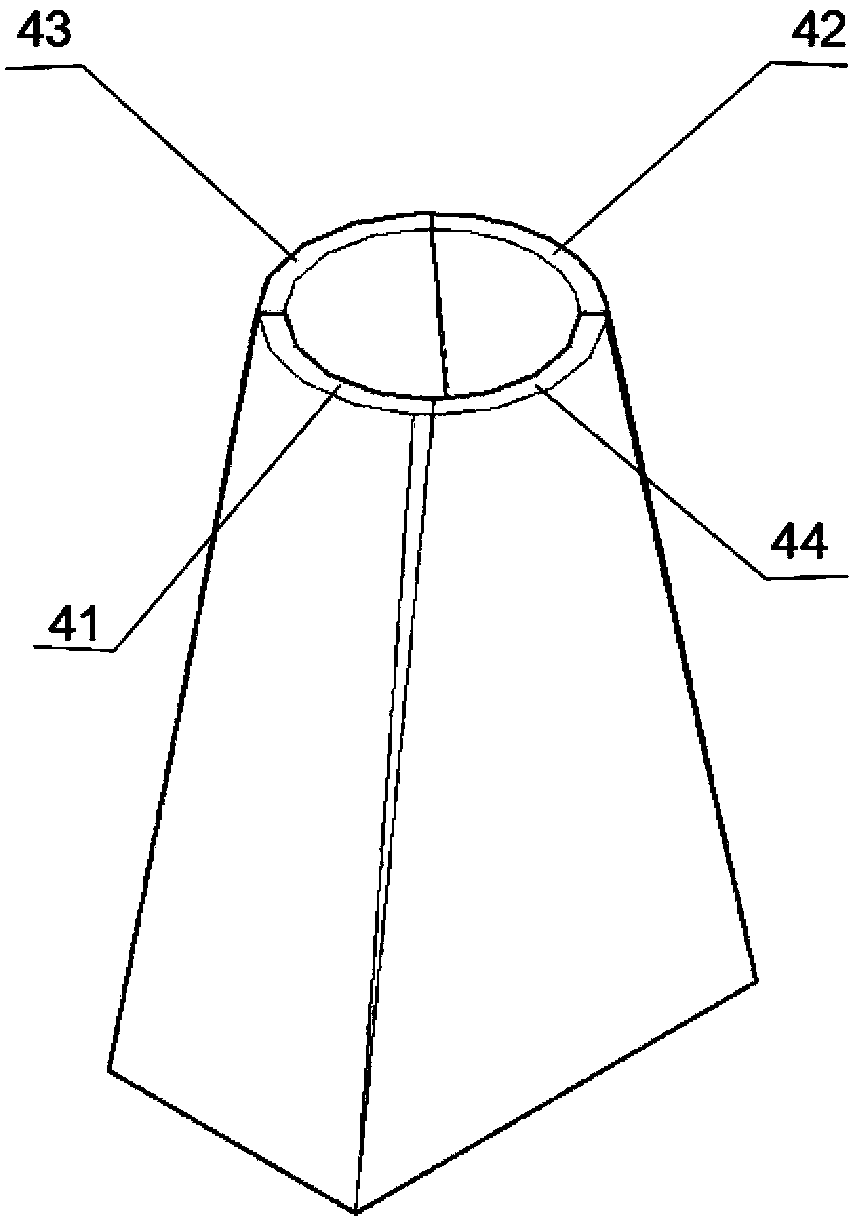

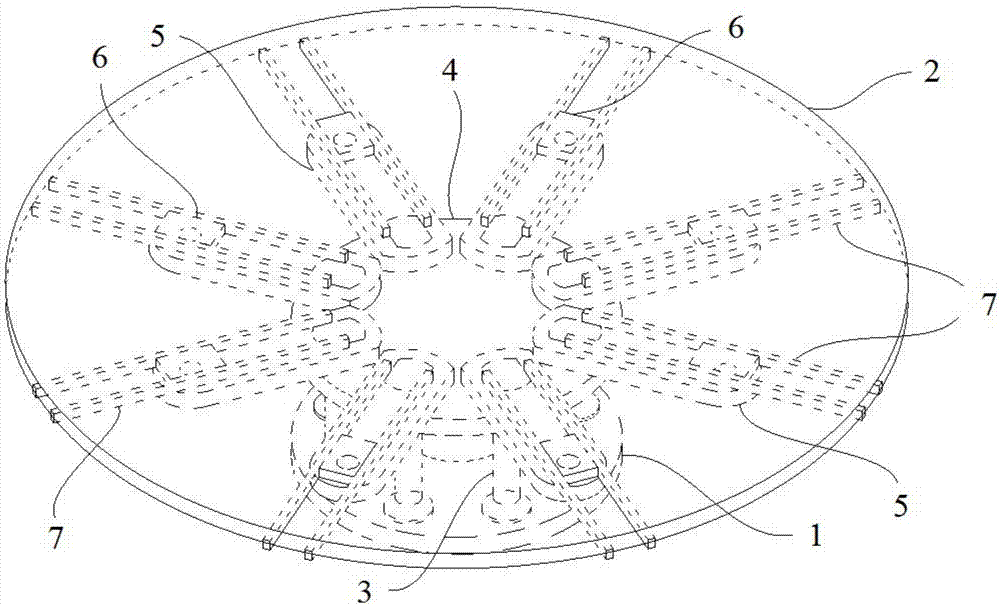

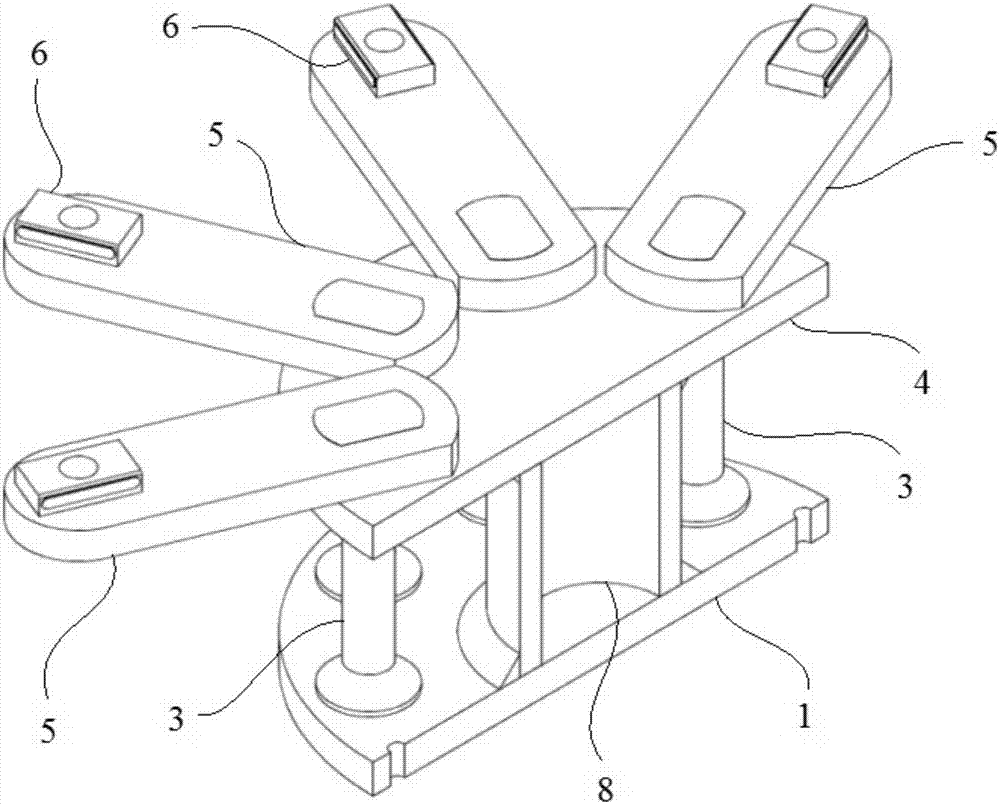

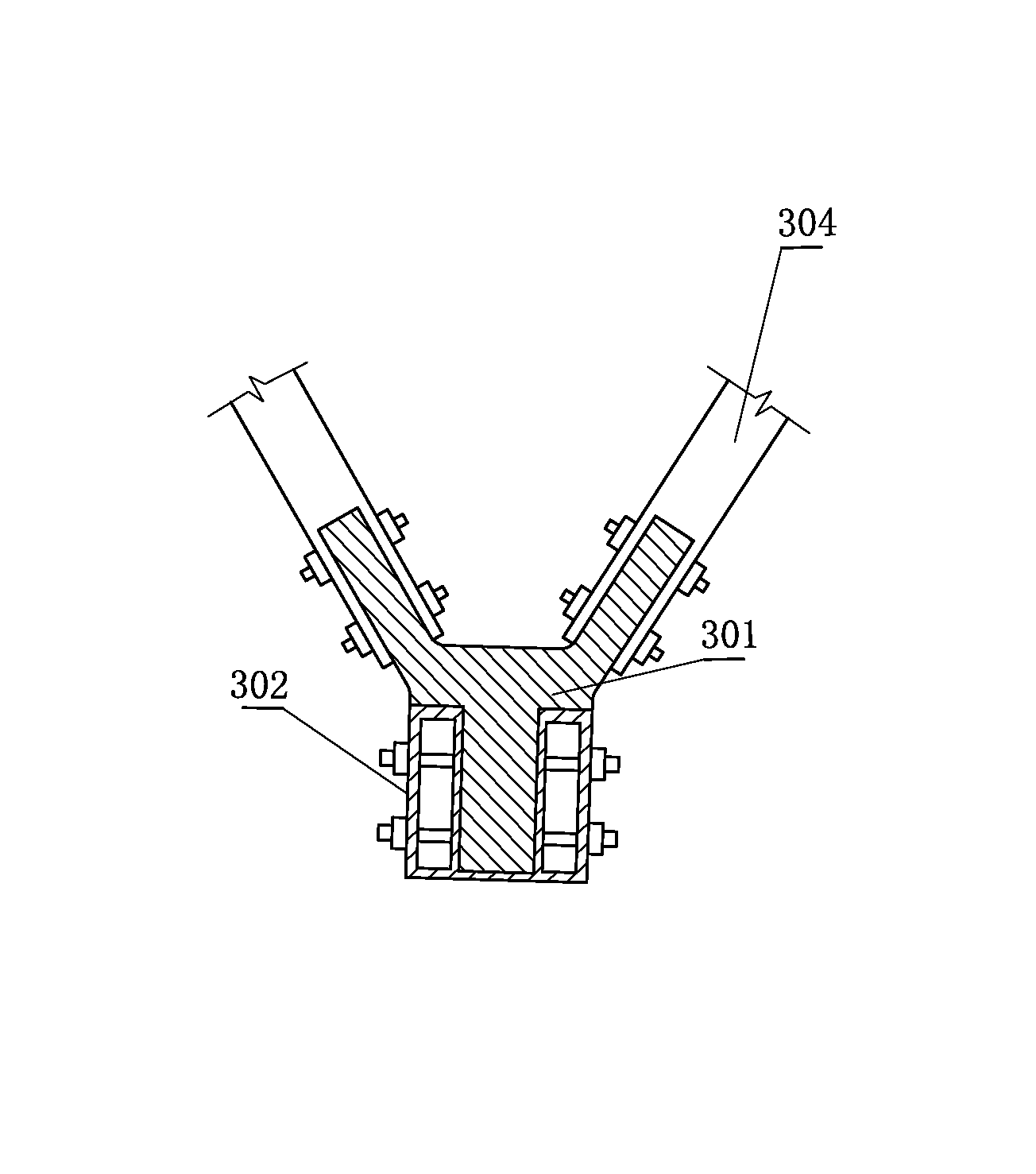

Round sleeve steel-wood assembly node and mounting method thereof

ActiveCN110331782AGuaranteed vertical bearing capacityImprove the seismic performance of structuresBuilding constructionsSolid woodHorizontal force

The invention discloses a round sleeve steel-wood assembly node. The round sleeve steel-wood assembly node comprises an FRP round wood column, an X-shaped wood beam, a core connecting component, splicing outer ring plates and an arc-shaped connector, wherein the core connecting component consists of upper and lower round steel sleeve plates, a connecting sleeve, round solid wood, filling wood blocks, and the like; the FRP round wood column and the core connecting component are connected, are plugged through circular steel sleeve plates in a mode of penetrating through reinforcing steel bars, and are connected by injecting glue into gaps of the reinforcing steel bars; the X-shaped wood beam is connected to the core connecting component through the arc-shaped connector; and the splicing outer ring plates and bolts are fixed to realize assembly connection. According to the scheme adopted by the invention, the node structure adopts a connecting sleeve design, so that bearing force is high,vertical force transmission is guaranteed to be free of influences, and a horizontal force transmission way and a vertical force transmission way are not crossed; during field construction mounting,glue connection and glue bonding are adopted, so that operation is simple, mounting is quick, assembly type mounting is complete, and design requirements of a wood structure building with special vertical load can be met, and therefore, the round sleeve steel-wood assembly node has great market potential in a medium and high-rise wood building.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

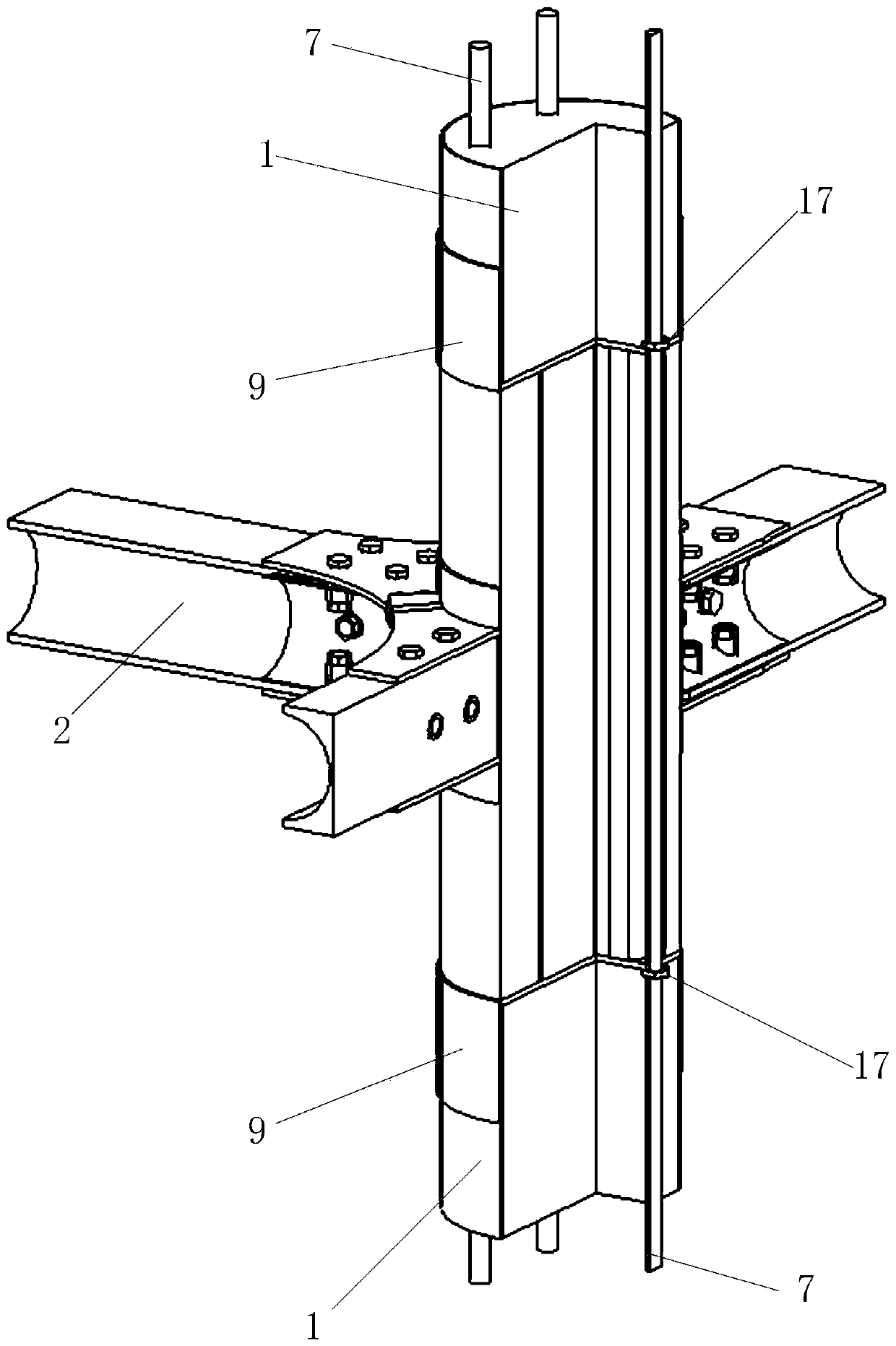

Discontinuous cross-section column transferring joint and construction method thereof

ActiveCN108661174AChange the cross-sectional areaReduce gravityBuilding constructionsPhotovoltaic energy generationSquare cross sectionStress concentration

The invention discloses a discontinuous cross-section column transferring joint and a construction method thereof. The discontinuous cross-section column transferring joint comprises a joint body which is of a column structure with hollow inside, a cross steel column connected into a column structure of the joint body, an upper end circular cross-section column transition plate connected to the upper end of the joint body, an upper end circular cross-section column connected to the upper part of the upper end circular cross-section column transition plate, a stiffening rib plate I connected between the upper end circular cross-section column and the upper end circular cross-section column transition plate, a lower end square cross-section column transition plate connected to the lower endof the joint body, a lower end square cross-section column connected to the lower part of lower end square cross-section column transition plate, and a stiffening rib plate II connected between the lower end square cross-section column and the lower end square cross-section column transition plate, wherein the outer edge of the cross steel column is connected with the inner wall of the column structure. The discontinuous cross-section column transferring joint has good cross section transition, and the occurrence of stress concentration phenomenon and the generation of anti-seismic weak partscaused by the transition of discontinuous joint steel columns only by single-layer steel plates are avoided.

Owner:CHINA RAILWAY CONSTR GROUP

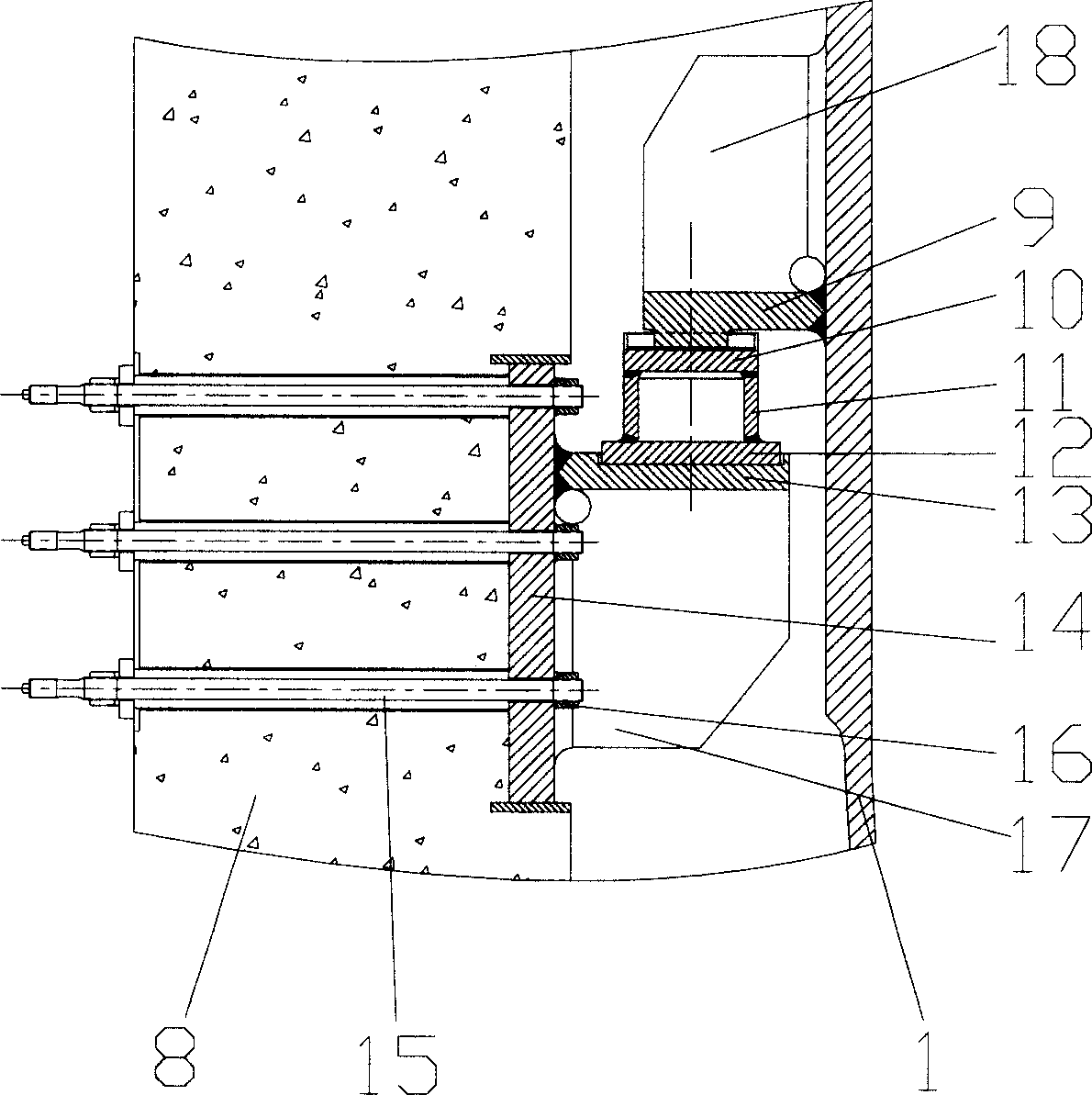

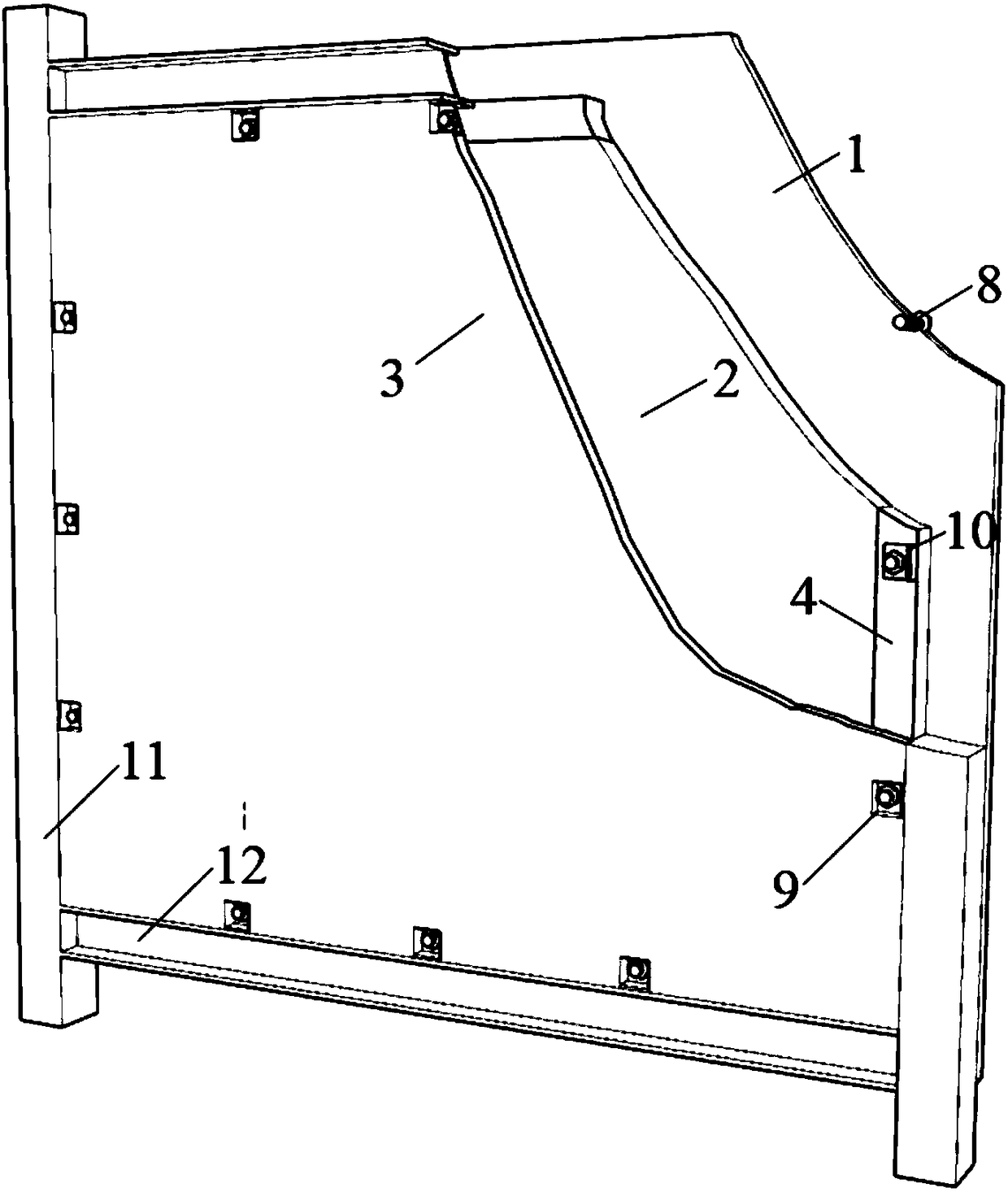

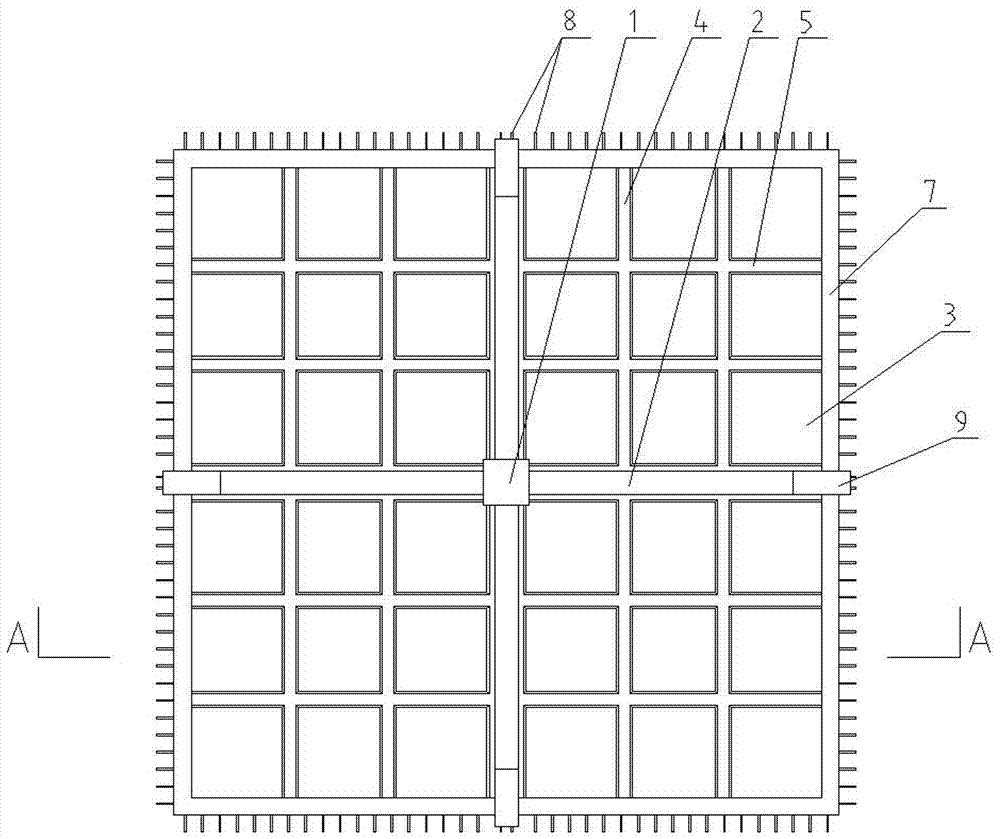

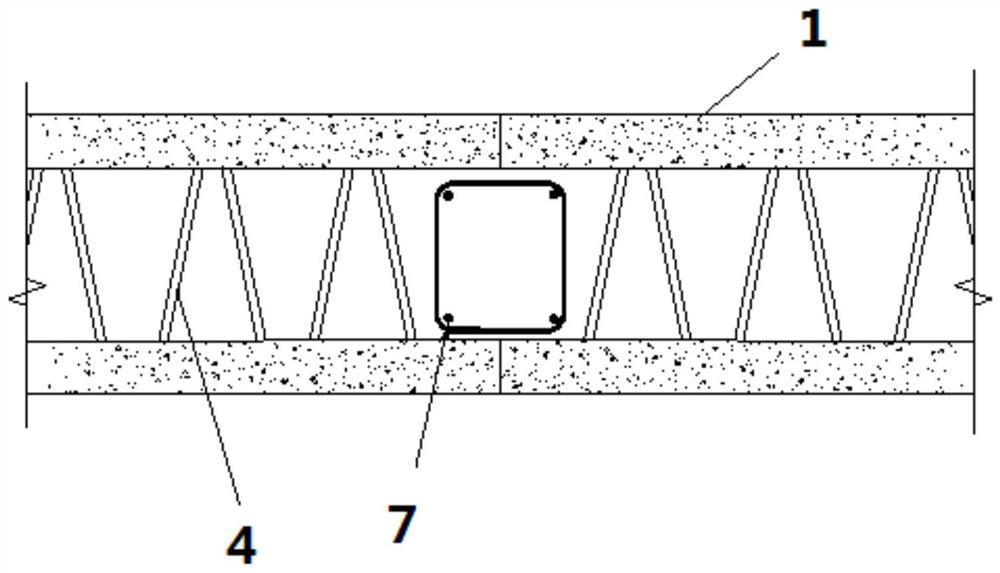

Connecting joint of fabricated concrete composite wall with built-in thermal insulation layer and light steel frame

PendingCN108277887AImprove seismic performanceHigh design strengthWallsHeat proofingThermal insulationSteel frame

The invention belongs to the technical field of connecting and manufacturing of wall joints in building structure engineering and particularly relates to a connecting joint of a fabricated concrete composite wall with a built-in thermal insulation layer and a light steel frame. The composite wall is mounted in a semi-embedded mode, and the built-in thermal insulation layer and inner sheet concreteare embedded into the light steel frame. Beam columns of the light steel frame are externally wrapped with outer sheet concrete. Compared with a traditional fabricated wall, the wall can serve as a structural force-bearing component, transmits loads with the frame beam columns, and participates in house structural force bearing, the house bearing capacity and anti-seismic capacity are improved, wallboards are wrapped with the frame beam columns, and thus steel corrosion is effectively reduced. The joint of the composite wall and the frame achieves bolted connection by means of the methods that bolts are pre-buried into the composite wall and connecting angle steel is welded to the frame structure beam columns, the structure form of the joint is simple, connecting is reliable, constructionis easy, the joint is applied to practical engineering, the building period can be effectively shortened, and the joint is suitable for being applied and popularized in low-rise and high-rise light steel frame structures.

Owner:BEIJING UNIV OF TECH

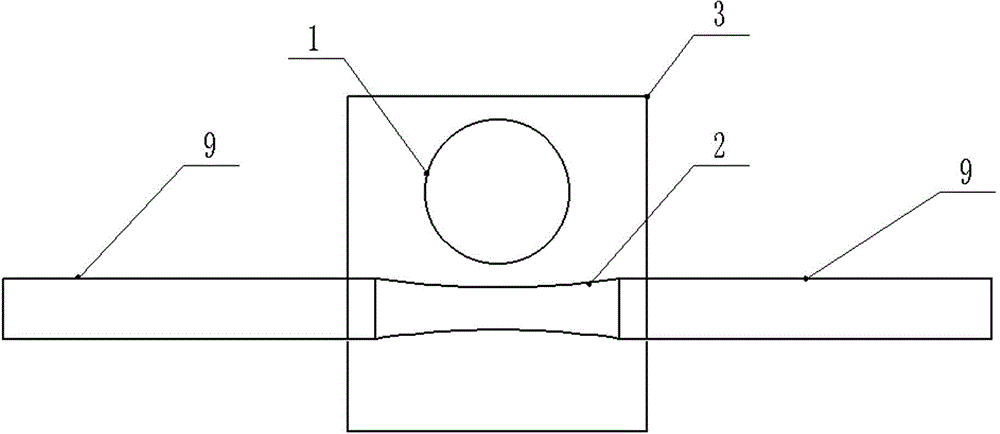

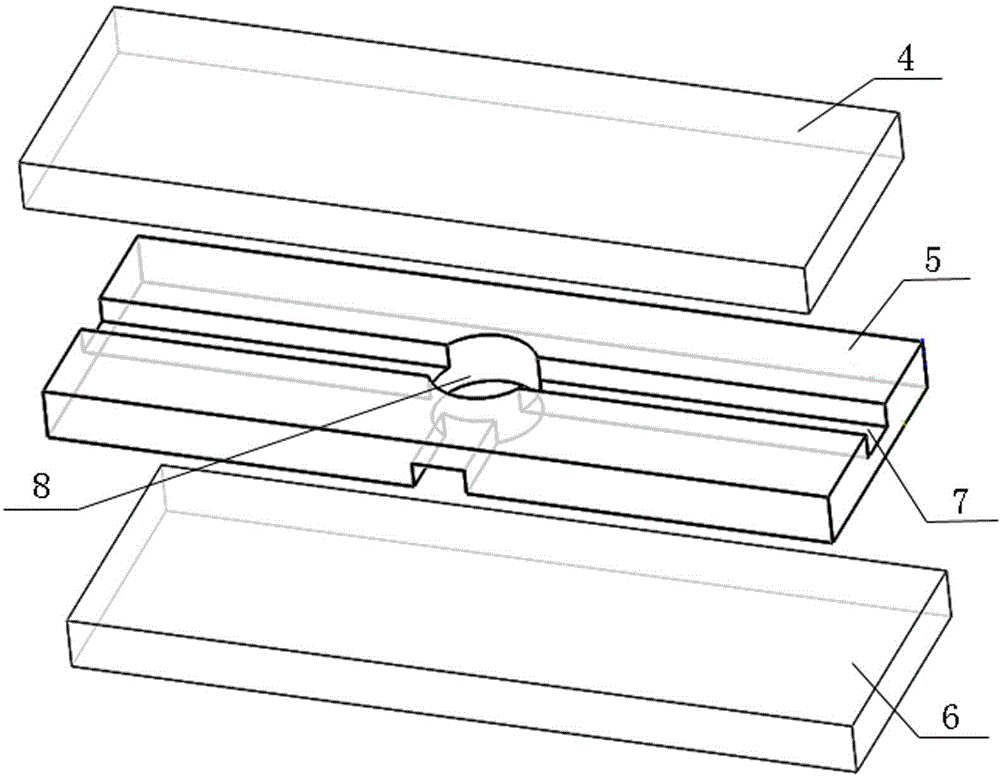

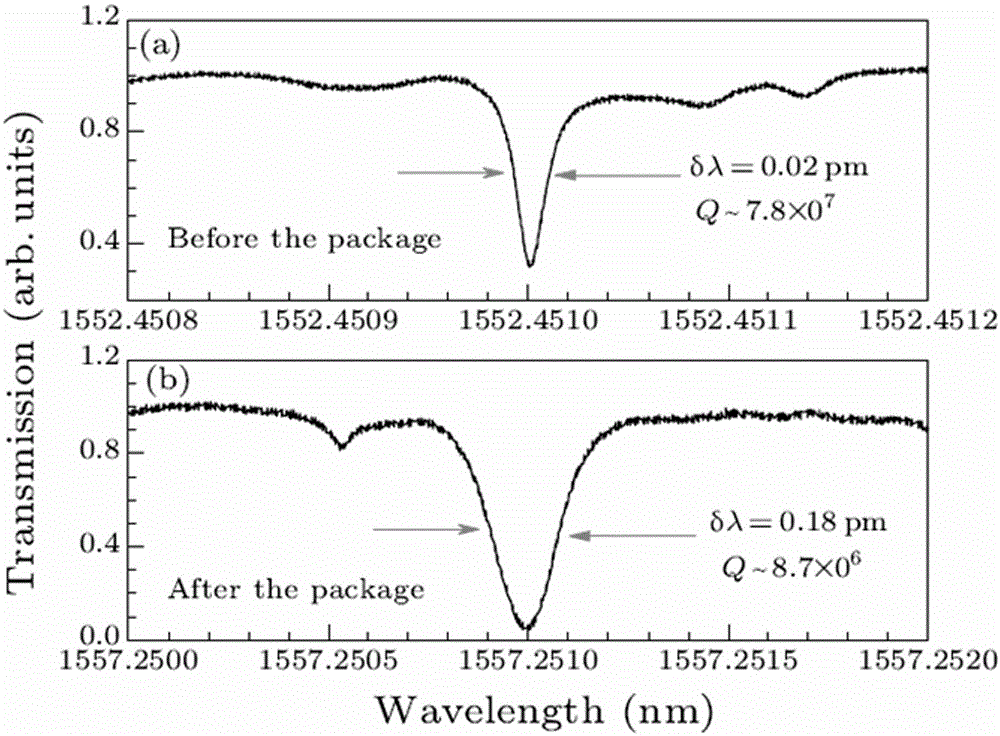

Encapsulating structure and encapsulating method of high-Q-value optical micro-cavity coupling system based on LTCC (Low Temperature Co-Fired Ceramic)

InactiveCN104635301AImprove the earthquake resistance of the structureImprove temperature stabilityCoupling light guidesSecondary layerCo-fired ceramic

The invention relates to an encapsulating structure and an encapsulating method of a high-Q-value optical micro-cavity coupling system based on LTCC (Low Temperature Co-Fired Ceramic). The encapsulating structure comprises an optical micro cavity, a coupler and a two-layer encapsulating body, wherein the first layer of the encapsulating body is formed by condensing an optical transparent encapsulating material accommodating the whole optical micro cavity and the coupler, so that the shock resistance of the system is enhanced; the second layer of the encapsulating body is partitioned into upper, middle and lower parts made of a ceramic material; the first layer of the encapsulating body is fully embedded into a middle layer through technical operation; the upper and lower layers are tightly bonded with the middle layer through a bonding agent at a high temperature, so that the defect that the first layer of the encapsulating material tends to be influenced by the environmental temperature is overcome, and the temperature stability is enhanced. The optical transparent encapsulating material of which the refractive index is lower than the refractive index of the optical micro-cavity coupling system is used for accommodating a coupling structure constructed by the whole optical micro cavity and the coupler, and a layer of ceramic material with a special structure is added outside, so that errors caused by the environmental temperature change are controlled. By adopting the encapsulating structure and the encapsulating method, the optical micro-cavity coupling system becomes more stable.

Owner:ZHONGBEI UNIV

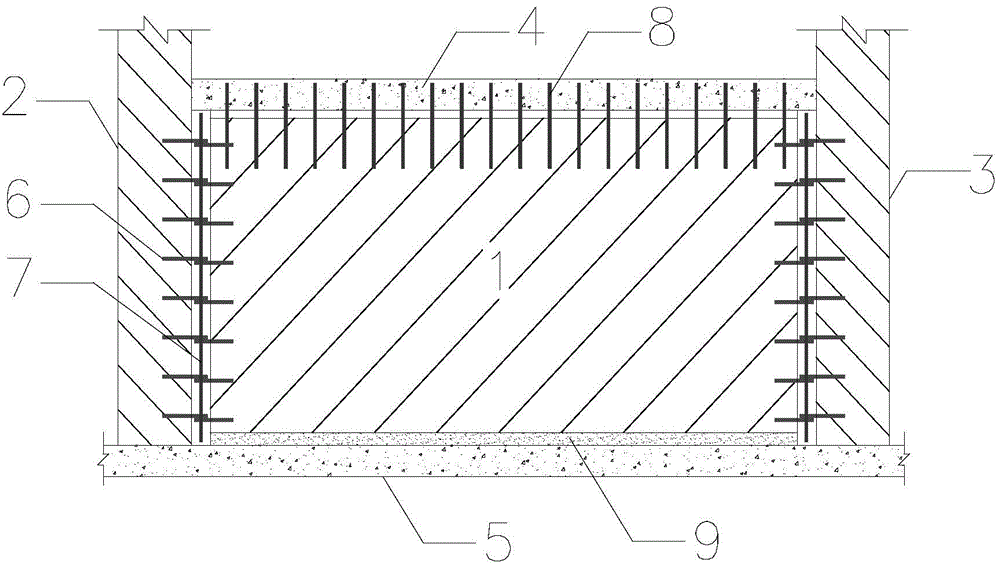

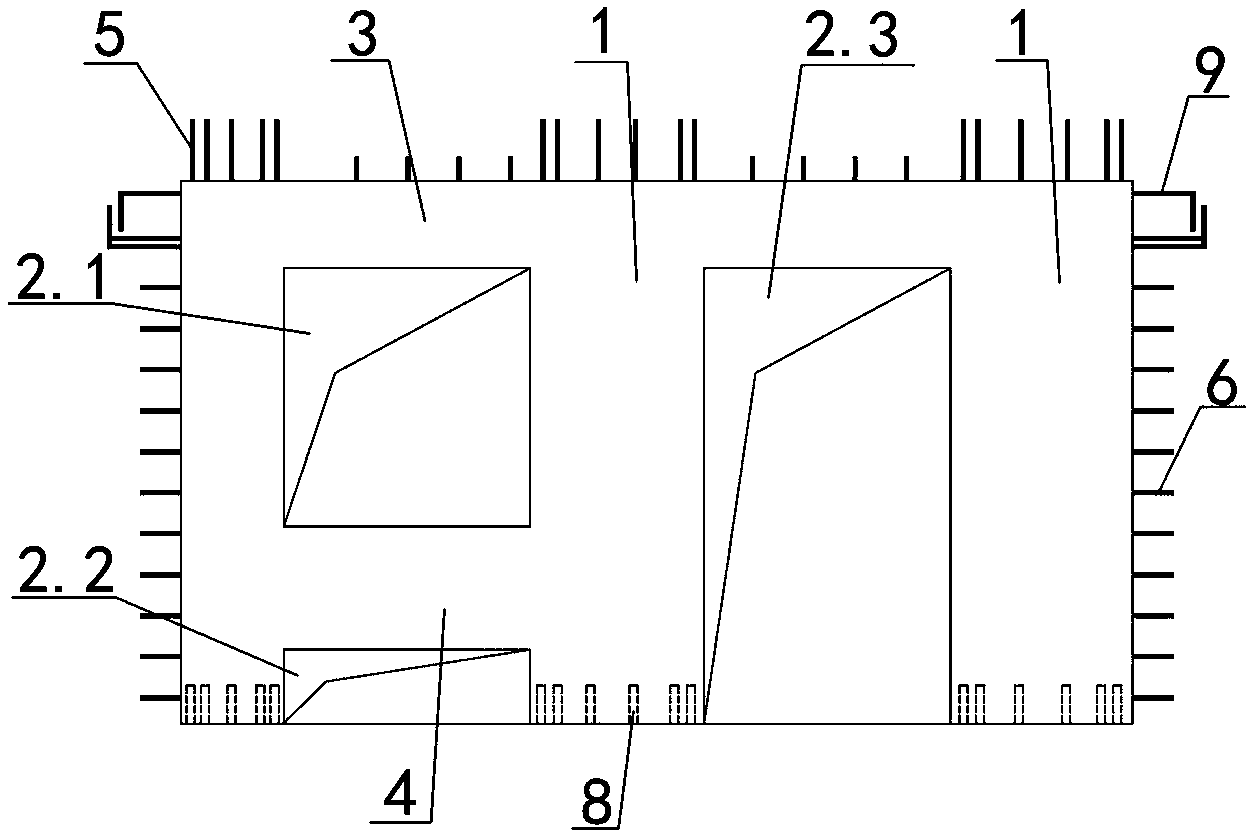

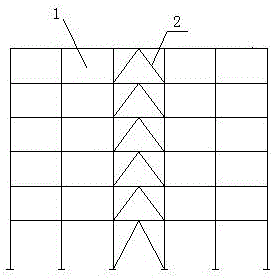

Fireproof composite wall for building protection

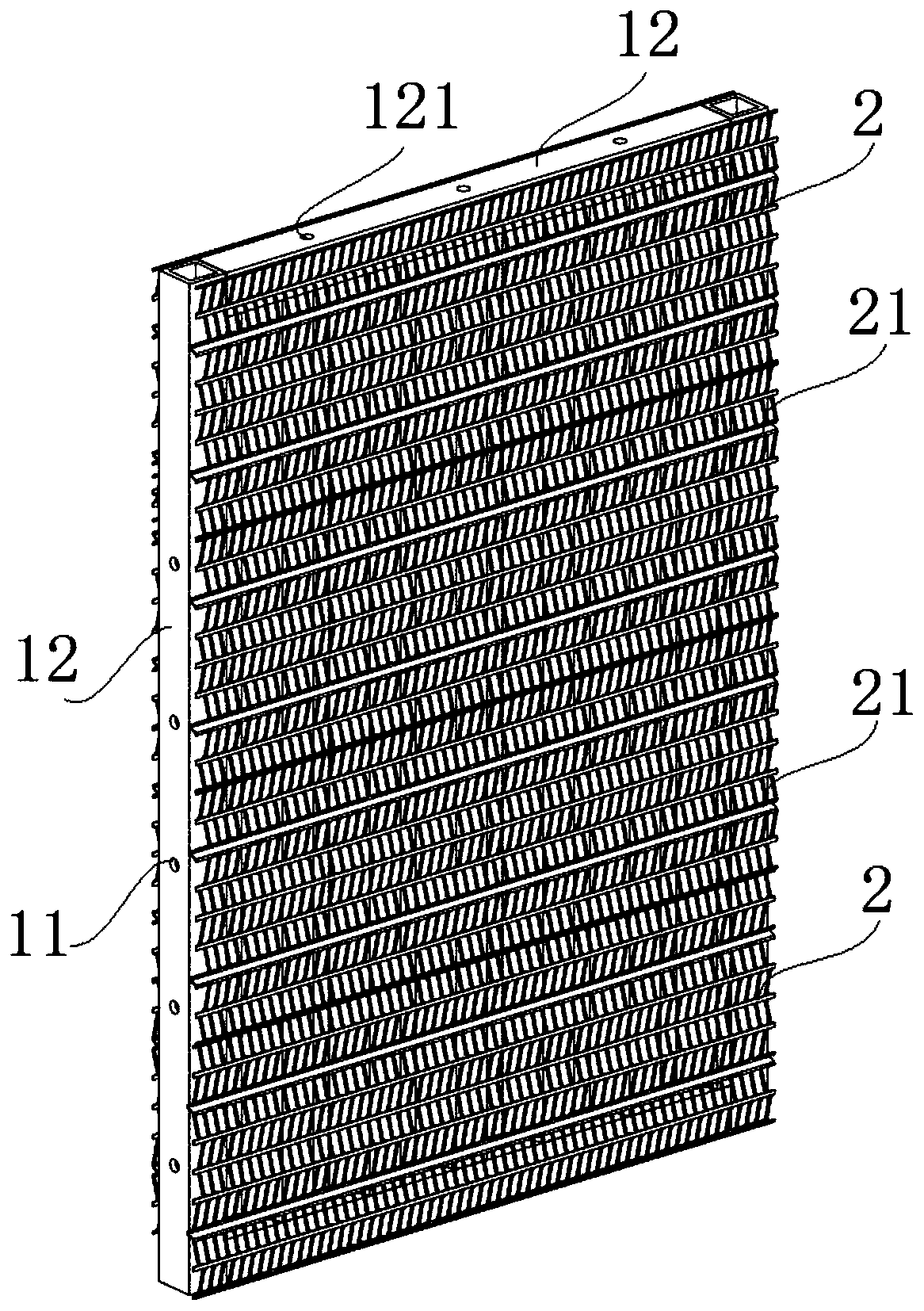

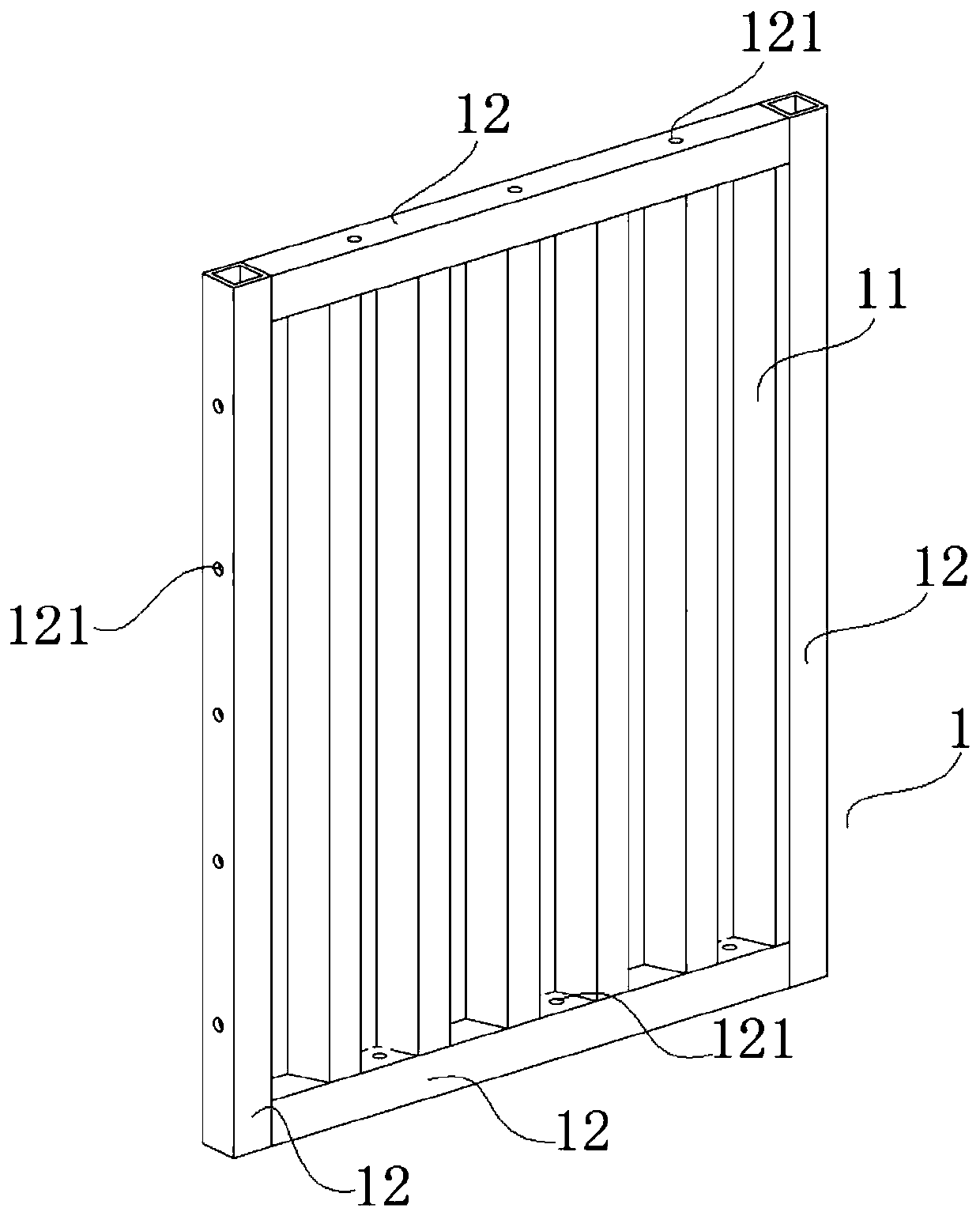

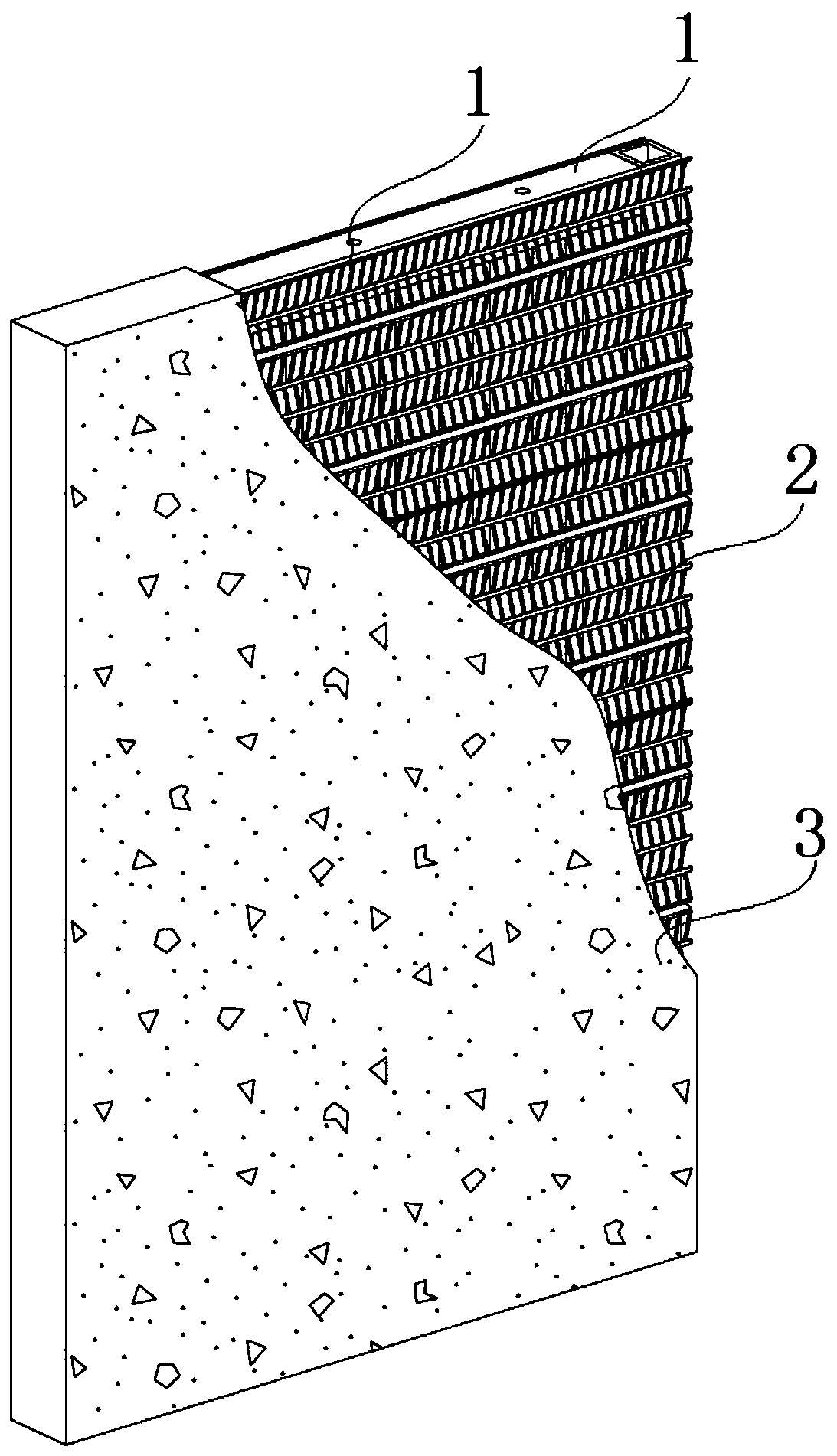

PendingCN110607853AReduce thicknessSmall thickness, can increase the use of small spaceWallsHeat proofingEarthquake resistancePre stress

The invention discloses a fireproof composite wall for building protection. The simple wall comprises a bearing wall (1); multiple prestress dispersion layers (2) are transversely bonded on the two sides of the bearing wall (1) end to end; sandwich layer fillers (3) are cast in two space formed by the prestress dispersion layers (2) and the bearing wall (1); the sandwich layer fillers (3), the prestress dispersion layers (2) and the bearing wall (1) are integrally injected to form a simple wall main body. The simple wall is simple in structure and novel in design, improves the earthquake resistance of the overall wall structure, reduces the design strength and cost of wall components, meanwhile, greatly improves the shear resistance and the integrity, and has such advantages as excellent integrity, excellent earthquake resistance, higher bonding and anti-shearing capacity and excellent finished wall molding effect.

Owner:金国洪

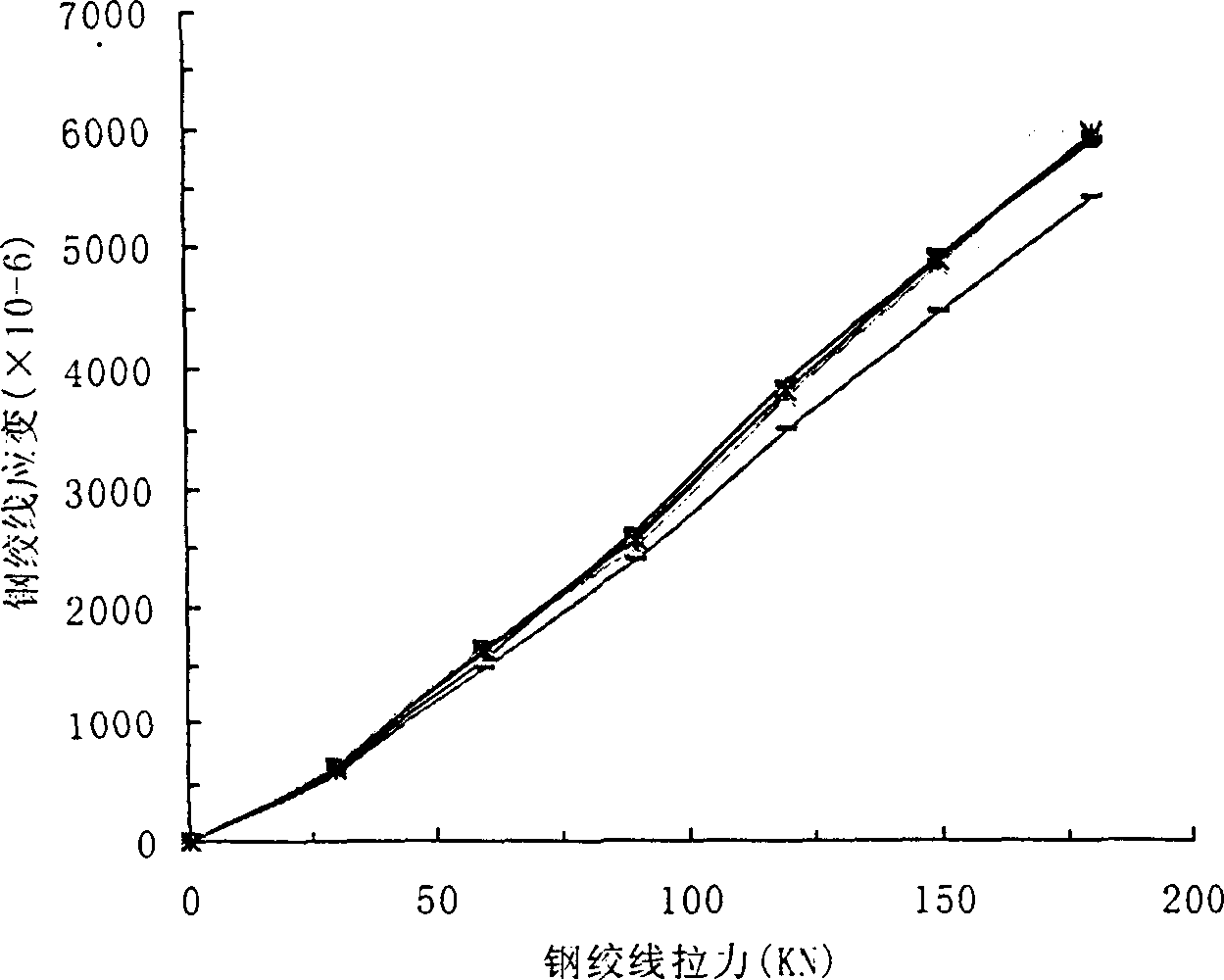

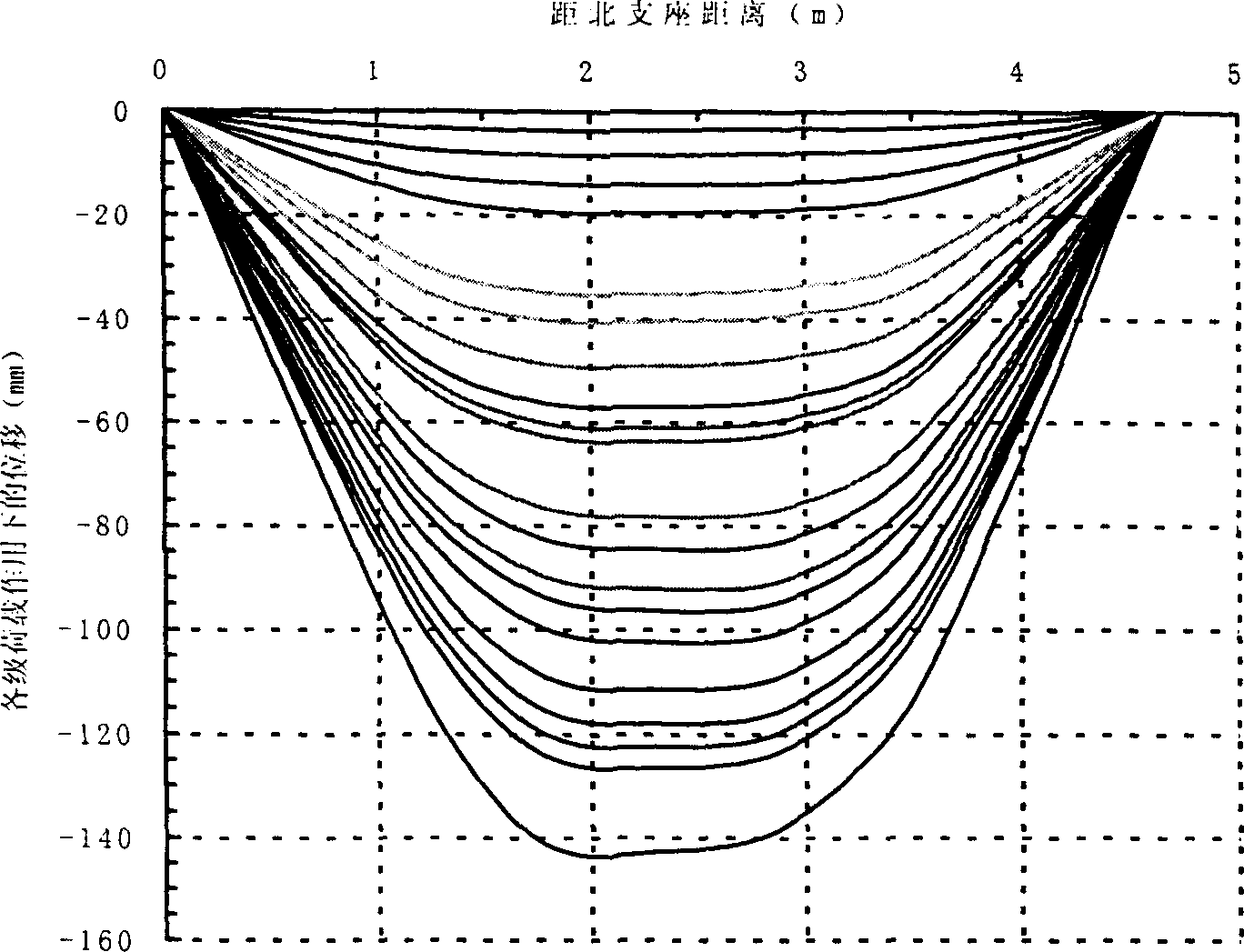

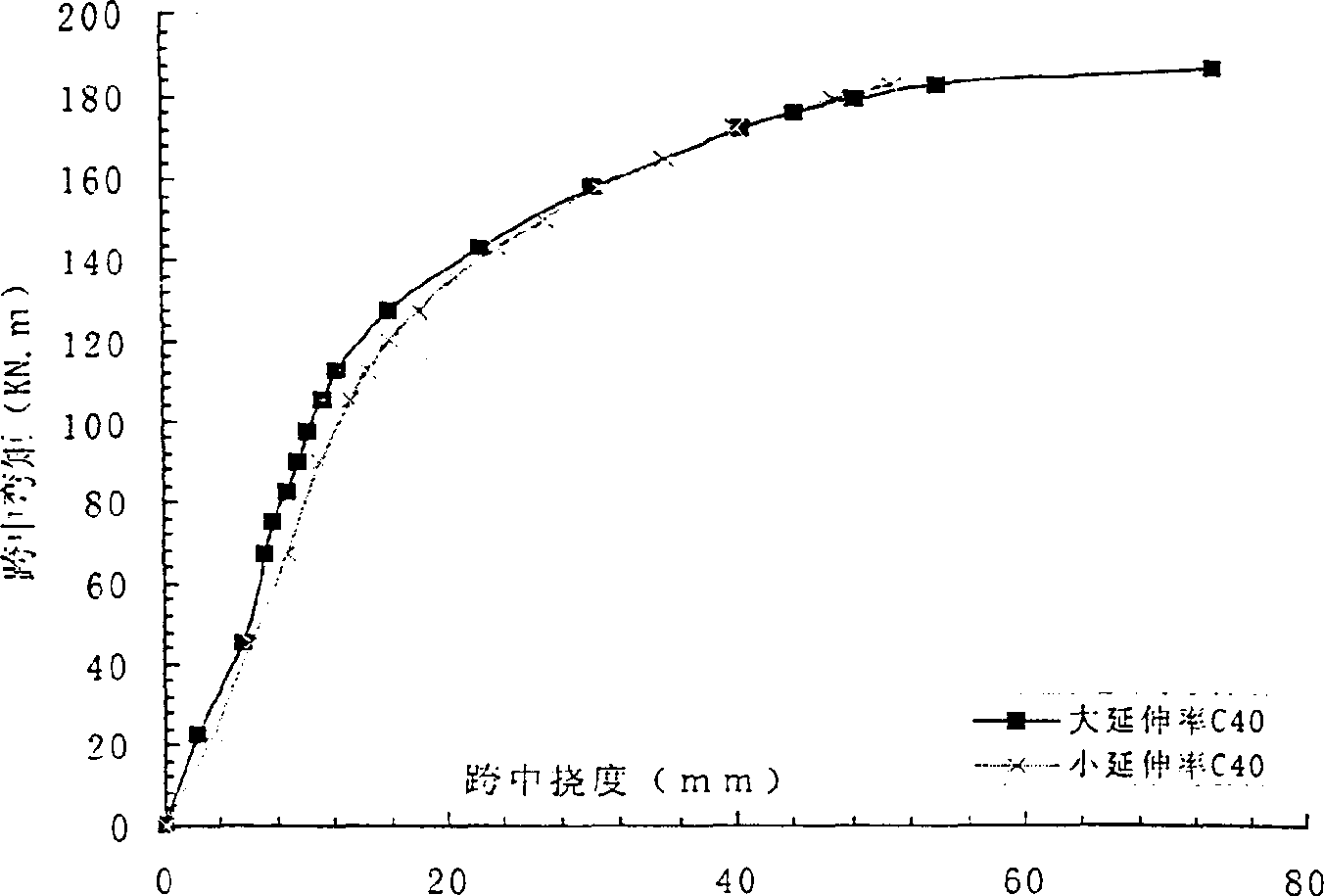

Ductile prestressed concrete structure component and its production method

InactiveCN1395012AImprove ductilityImprove securityCeramic shaping apparatusBridgesPre stressCompressive strength

The present invention discloses a ductile prestressed concrete structural member and its production method. Said member includes concrete and prestressed reinforcement, the described concrete compression strength is greater than 60MPa, and the described prestressed reinforcement is prestressed stranded wire, its strength is greater than or equal to 1860 MPa, its relaxation rate is less than or equal to 2.5% and percentage elongation is greater than or equal to 5%. The bending deflection ductility ratio of the prestressed concrete structure meeting the above-mentioned technological parameters is greater than 3.0, and said prestressed concrete structure is superior to general concrete structure in ductility.

Owner:王用中 +3

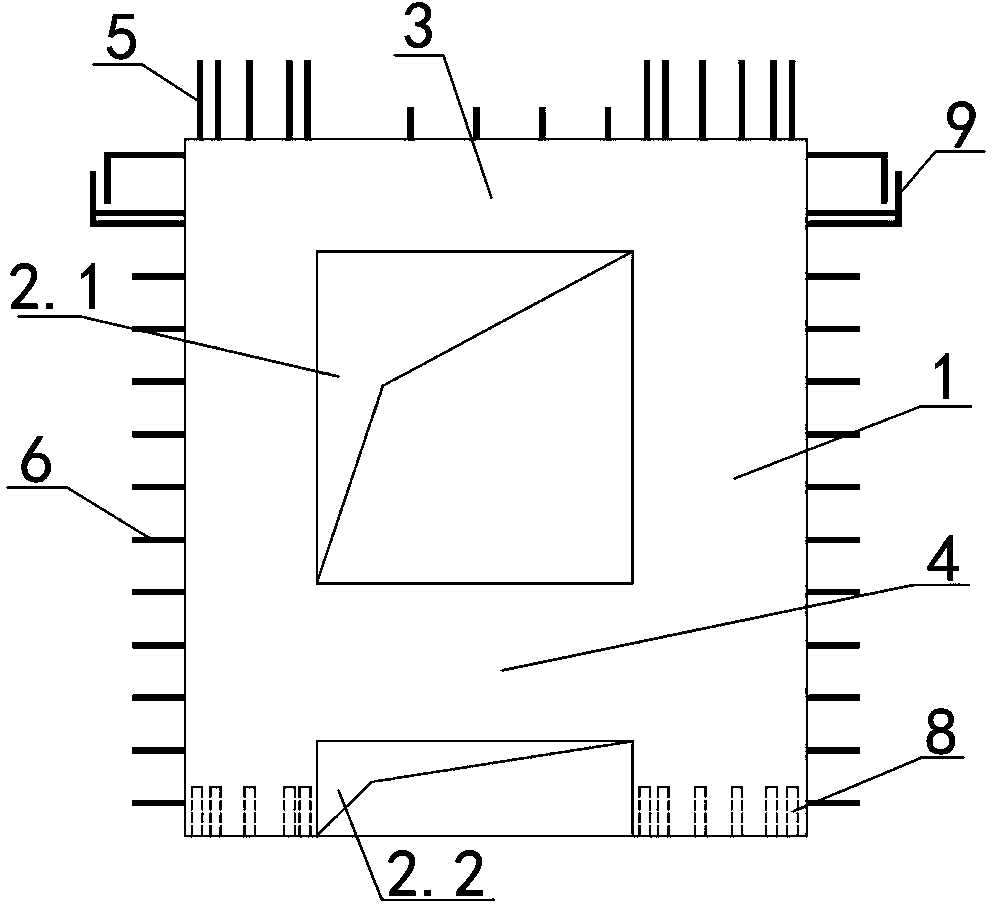

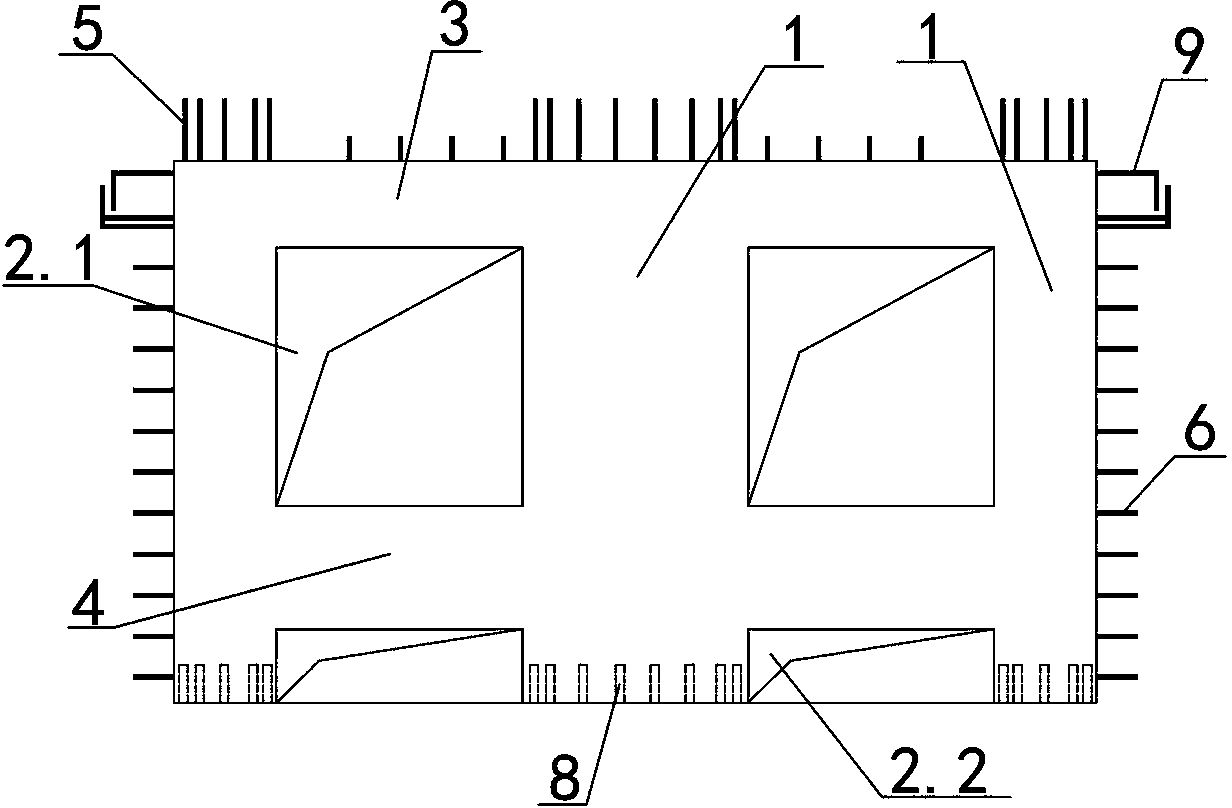

Precast assembled integrated type concrete shear wall panel with bottom hole containing multiple coupling beams

The invention discloses a precast assembled integrated type concrete shear wall panel with a bottom hole containing multiple coupling beams. The precast assembled integrated type concrete shear wall panel comprises lateral connection rebars of the precast concrete shear wall panel, top connection rebars and bottom installation sleeves corresponding to the top connection rebars. The middle of the wall panel is provided with window holes. The lower end of the wall panel is provided with structure holes corresponding to the window holes, wall limbs, a general coupling beam, energy consumption coupling beams A and energy consumption coupling beams B. The width of the window holes is the same as that of the structure holes. The structure holes are filled with light non-structural materials. The portions, on the wall limbs, of the top coupling rebars are stretched out upwards to connect upper layers of shear wall rebars and lower layers of shear wall rebars. By means of the precast assembled integrated type concrete shear wall panel, the number of connected rebars is reduced, self weight is reduced, construction transportation and hoisting are facilitated, the concrete shear wall panel is good in anti-seismic performance, multiple seismic fortification lines are formed for a building, the energy-dissipation capacity of a wall body is enhanced, and the purpose of reducing repair cost is achieved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Multi-yield-point metal shear damper facing multiple disasters and multiple performance targets

ActiveCN111364635AImprove the seismic performance of structuresMeet the needs of multiple performance objectivesProtective buildings/sheltersShock proofingEarthquake resistantEngineering

The invention relates to the technical field of building, in particular to a multi-yield-point metal shear damper facing multiple disasters and multiple performance targets. The multi-yield-point metal shear damper comprises a first energy dissipation piece and a second energy dissipation piece, the first energy dissipation piece sleeves the outer side of the second energy dissipation piece, and afixing piece and a stopping assembly are arranged between the first energy dissipation piece and the second energy dissipation piece; the first energy dissipation piece and the second energy dissipation piece are fixedly connected through the fixing piece, and the stopping assembly comprises a first stopping block and a second stopping block matched with the first stopping block; and the first stopping block is connected with one of the first energy dissipation piece and the second energy dissipation piece, and the second stopping block is connected with the other one of the first energy dissipation piece and the second energy dissipation piece, and used for making contact with the first stopping block and pushing the first stopping block to move in the shear force direction. When a structure suffers the disasters of different types and different levels, multi-stage energy dissipation and vibration reduction capability can be provided according to the deformation state of the structure, demands of the multiple performance targets of the building structure under the multiple disasters are met, seismic performance of the structure is improved, and the multi-yield-point metal shear damper adapts to the stiffness, carrying capacity and energy dissipation capacity required by the structure.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

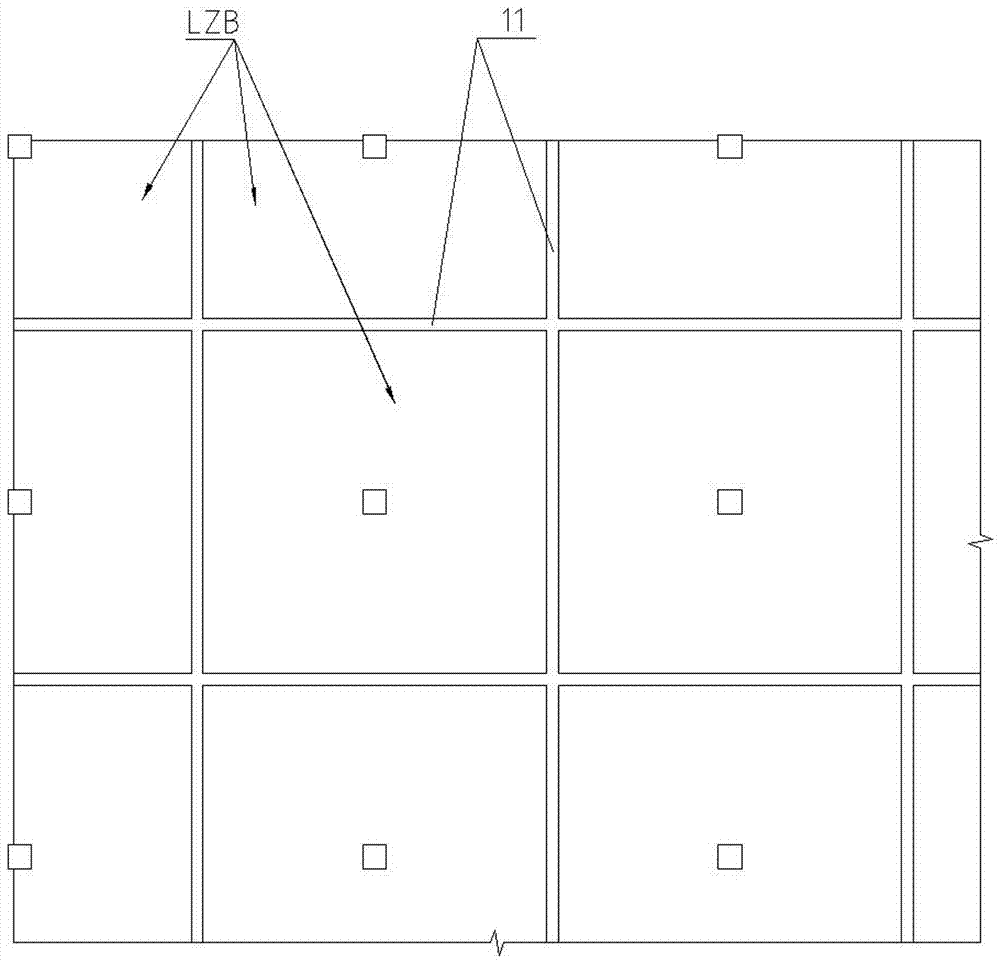

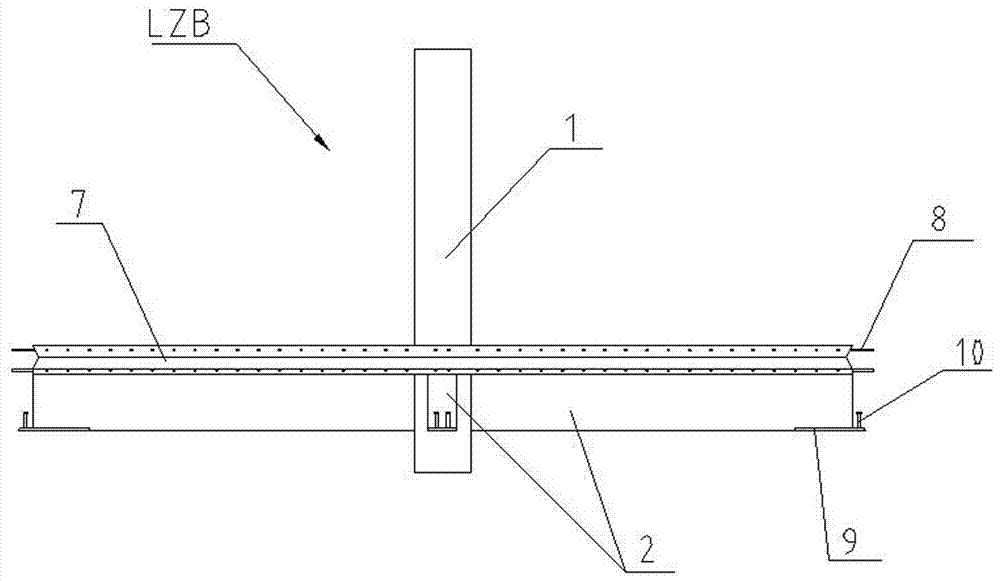

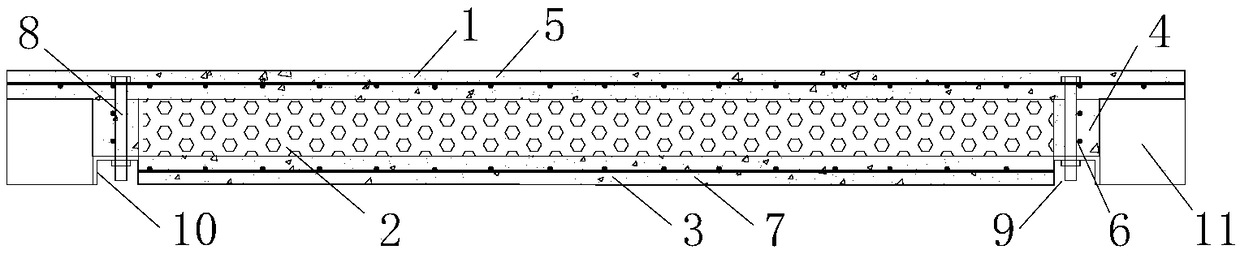

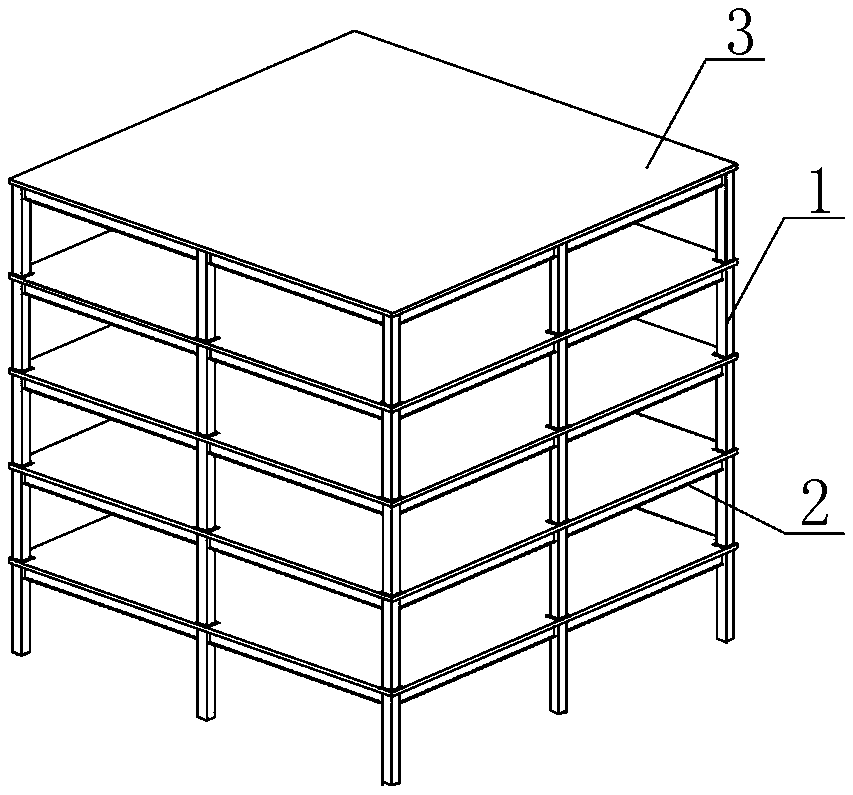

Super-high performance concrete frame structure fabricated building and construction method thereof

The invention discloses a super-high performance concrete frame structure fabricated building and a construction method thereof. A splicing unit at least comprises beam, column and floor integrated pieces prefabricated by super-high performance concrete. The height of each column is the height of a building storey; the beams are perpendicular to the side walls of the columns; the floors are located on the upper surfaces of the beams; connecting parts are arranged on the side edges of the floors; and the two ends of the columns stretch out of the end faces of the floors and the beams. When fabricating is constructed, after the prefabricated integrated pieces adjacent to the building plane, the super-high performance concrete is poured into joints between the connecting parts of the side edges of the floors to enable the prefabricated integrated pieces to form a whole. The upper storey and the lower storey of the building are connected through the columns of the beam, column and floor integrated pieces. The prefabricated integrated pieces adopt the super-high performance concrete as structure materials, and the reasonable connecting arrangement is configured, so that the average thickness of the floor and the amount of connectors and the joints between prefabricated members both are decreased substantially. The self-weight of the building is reduced substantially under the premise of guaranteeing the rigidity and strength of the building, and construction difficulty is reduced.

Owner:HUNAN UNIV

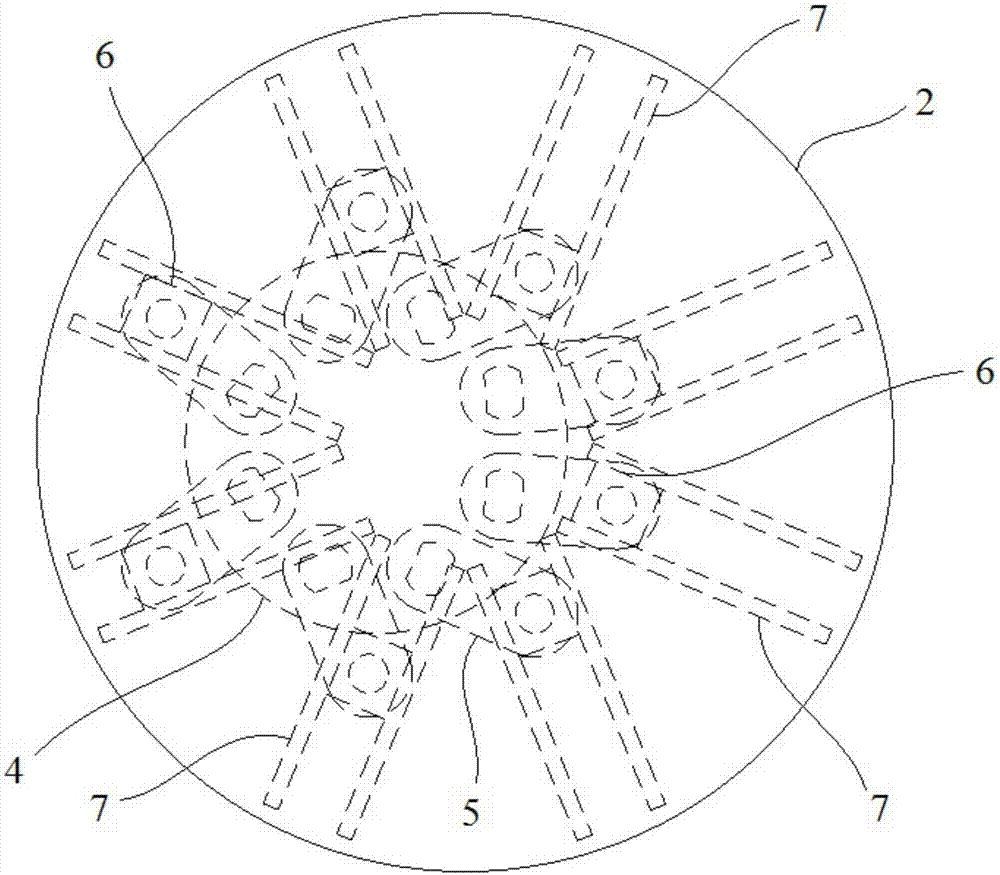

Novel all-dimensional twisting energy dissipation damping supporting seat

PendingCN108004916AImprove energy consumptionGood effectBridge structural detailsBridge materialsEngineeringKinetic energy

The invention discloses a novel all-dimensional twisting energy dissipation damping supporting seat. The novel all-dimensional twisting energy dissipation damping supporting seat includes a base and atop seat, the base is provided with at least three energy dissipation supporting columns, the energy dissipation supporting columns are provided with limiting parts which are connected with the base,and the energy dissipation supporting columns are connected with connecting parts which are rotatably provided with sliding blocks in a connecting mode; each of the sliding blocks is suitably matchedwith a corresponding sliding groove, the sliding grooves are connected at the lower surface of the top base, and the sliding blocks can slide in correspondence with corresponding sliding grooves; andthe sliding grooves are located at the same plane, at least two sliding grooves are not mutually parallel, and the energy dissipation supporting columns are mild steel members. According to the novelall-dimensional twisting energy dissipation damping supporting seat, the principle of a traditional supporting seat energy dissipation due to friction can be broken, deformation capability of materials can be fully played, earthquake kinetic energy amount can be effectively consumed, the blindness and the directionality in present designing and installing process can be avoided, the energy dissipation effect of the supporting seat is improved, and the entire anti-quake performance and safety of a structure can be improved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Aluminium alloy truss structure

An aluminum alloy truss structure, comprising upper chord members, lower chord members, web members and all connection nodes by which the members are connected using riveting bolts, the chord members and web members being interconnected using tenons and mortise grooves that mate with each other respectively, each of the chord members being provided with a tenon plate at the end adjacent to the respective web members, each of the web members being correspondingly provided with a mortise groove at either end thereof, and the tenon plate on the chord members being implanted into the mortise groove on the web members; or, alternatively, each of the chord members being provided with a mortise groove at the end adjacent to the respective web members, each of the web members being correspondingly provided at either end thereof with a tenon that is to mate with the mortise groove.

Owner:LIN JUAN +1

Energy dissipation type coupled anti-seismic wall with reinforcing bars, grouting holes, building blocks and combined coupling beam and manufacturing method

InactiveCN104775544AAvoid instant collapseGood for load bearingWallsBuilding material handlingEarthquake resistanceEngineering

The invention belongs to the technical field of earthquake resistance of building structures, and particularly relates to an energy dissipation type coupled anti-seismic wall with reinforcing bars, grouting holes, building blocks and a combined coupling beam and a manufacturing method. The energy dissipation type coupled anti-seismic wall is adopted by a bearing wall of a multi-storey building in a town. The energy dissipation type coupled anti-seismic wall comprises a building block wall body, a coupling beam, soft steel dampers, single-reinforcement core columns, construction core columns and horizontal pull connecting ribs. According to the invention, due to the combined action of the core columns and the horizontal pull connecting ribs, the building block wall body is effectively constrained, and the integrity and the anti-seismic performance of a coupling wall column are improved. The coupling beam and a constraint building block wall beam on the top of the coupling beam are combined to form the shear type combined coupling beam, and the soft steel dampers are arranged on the portions of connection between the coupling beam and the coupling wall column, so that multiple energy dissipation and seismic resistance defense lines of the coupled anti-seismic wall are formed, and the ductility and the energy dissipation capacity of the wall body are enhanced.

Owner:ANHUI XINHUA UNIV

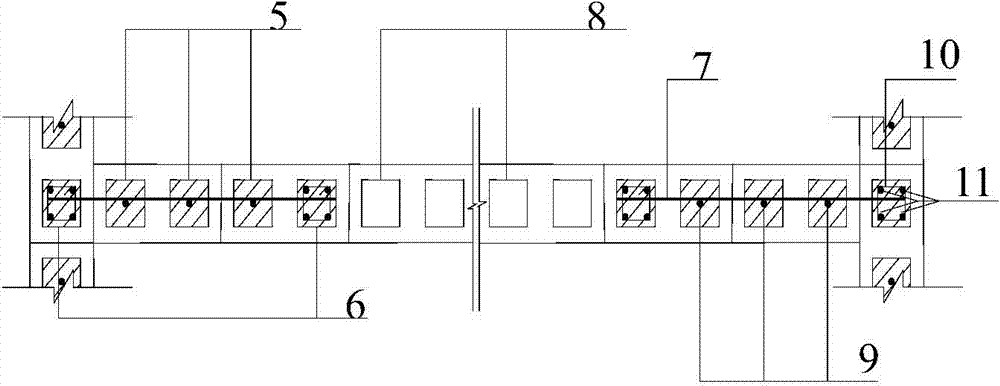

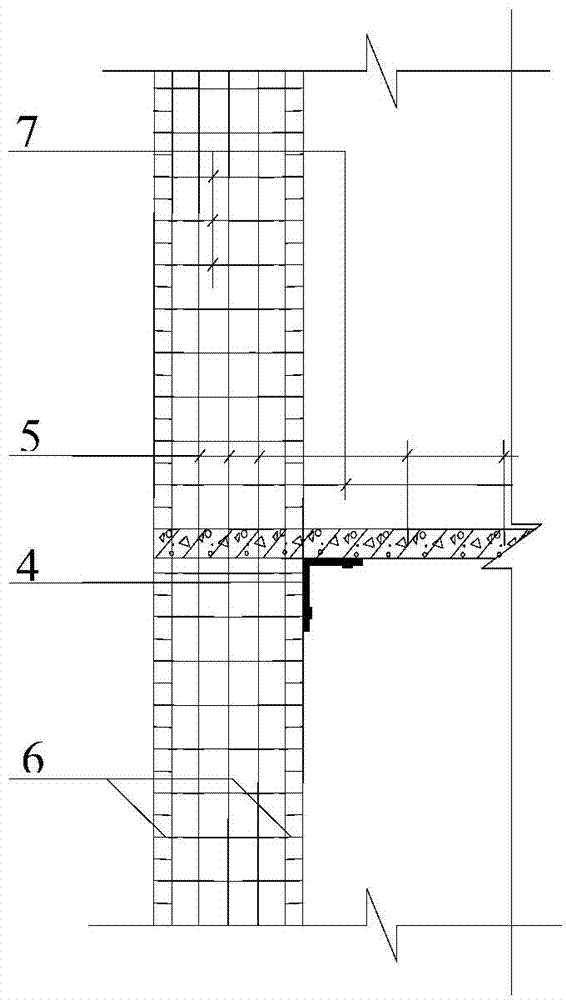

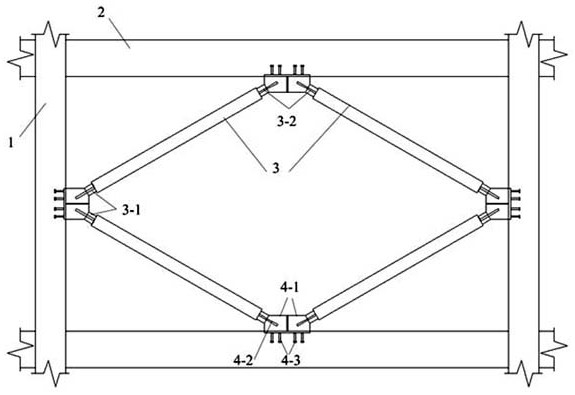

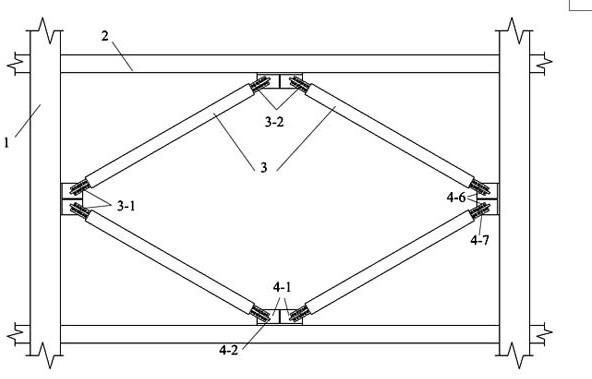

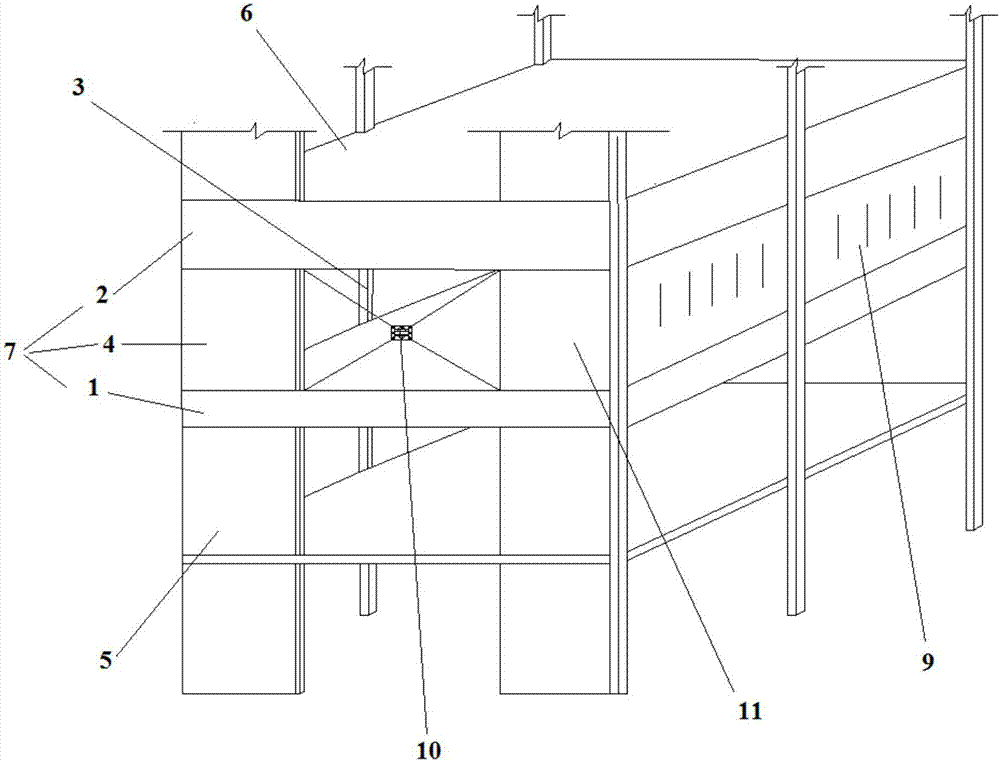

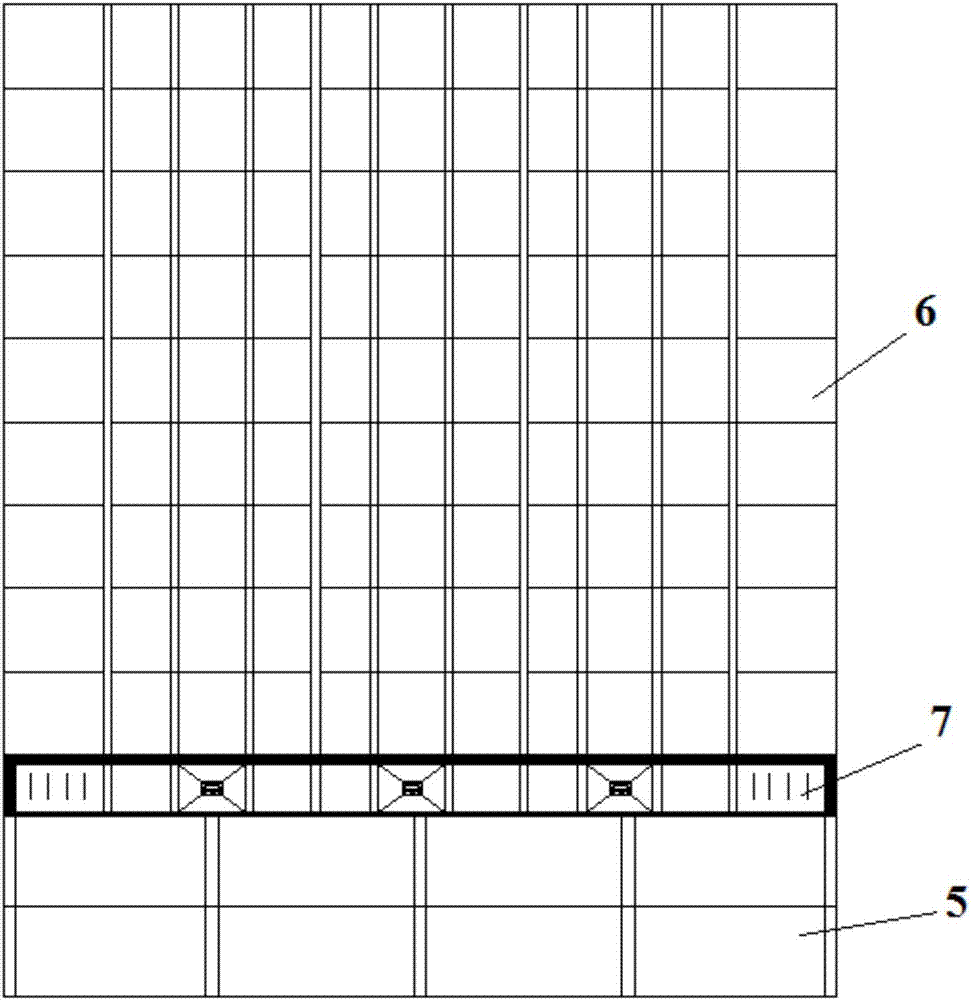

Buckling restrained brace structure arrangement system for building

PendingCN114134994AImprove seismic performanceExcellent lighting functionProtective buildings/sheltersShock proofingEarthquake resistantBuckling-restrained brace

The invention discloses a buckling restrained brace structure arrangement system for a building, which comprises a frame column, a frame beam, four buckling restrained braces and a connecting node element, a rectangle is enclosed between the frame column and the frame beam, and the connecting node element is arranged between the frame column and the frame beam. The two ends of each buckling restrained brace are fixed to the middle of the frame column and the middle of the frame beam through connecting joint elements respectively, and a rhombic building window opening is defined by the four buckling restrained braces. The buckling restrained brace arranged in the rhombus mode is adopted, the good anti-seismic performance is achieved, construction is convenient and fast, the steel using amount of embedded parts is reduced, good feasibility and practicability are achieved, and the buckling restrained brace can be used for concrete structures, steel structures and combined structures. The structure is simple, force transmission is clear, and construction is fast.

Owner:上海史狄尔建筑减震科技有限公司

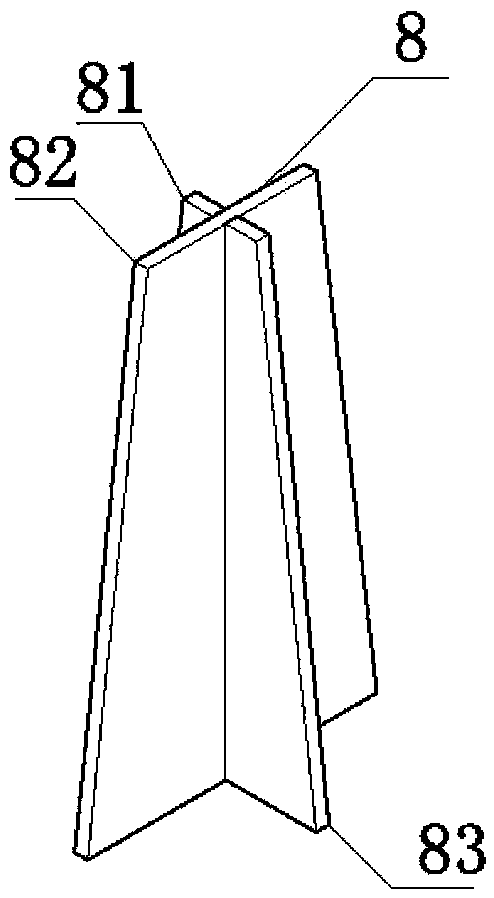

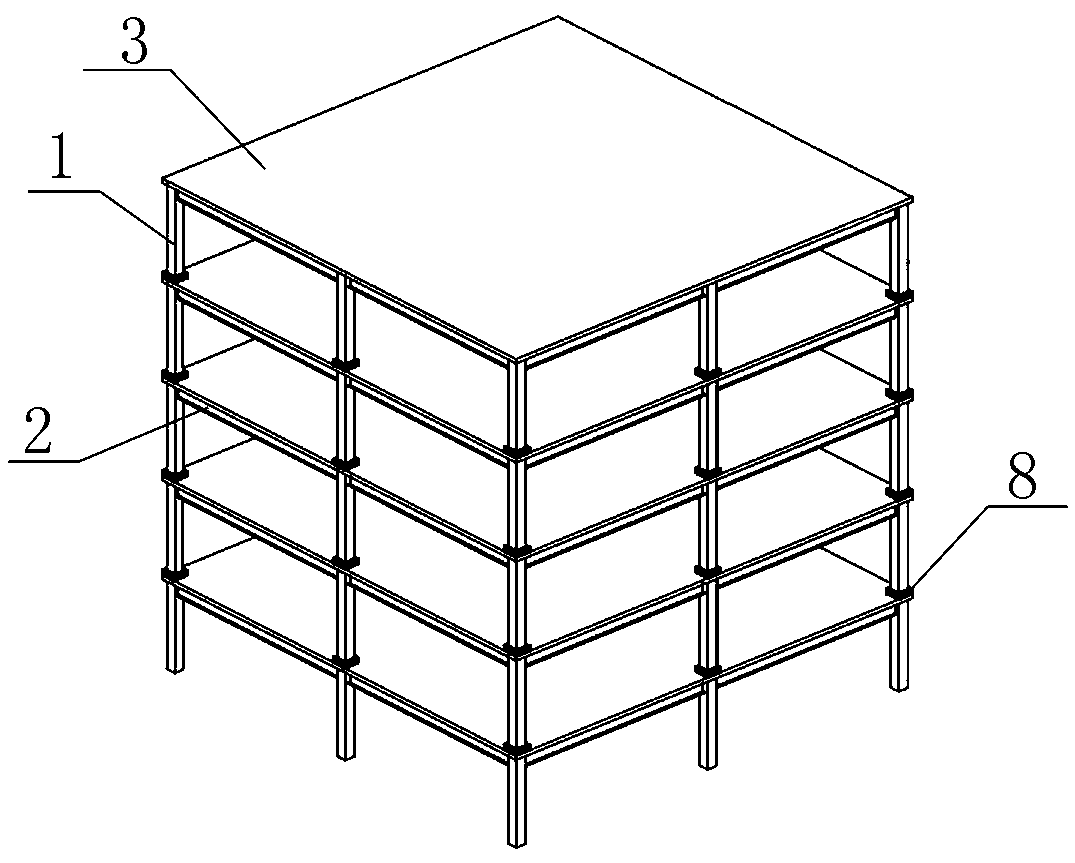

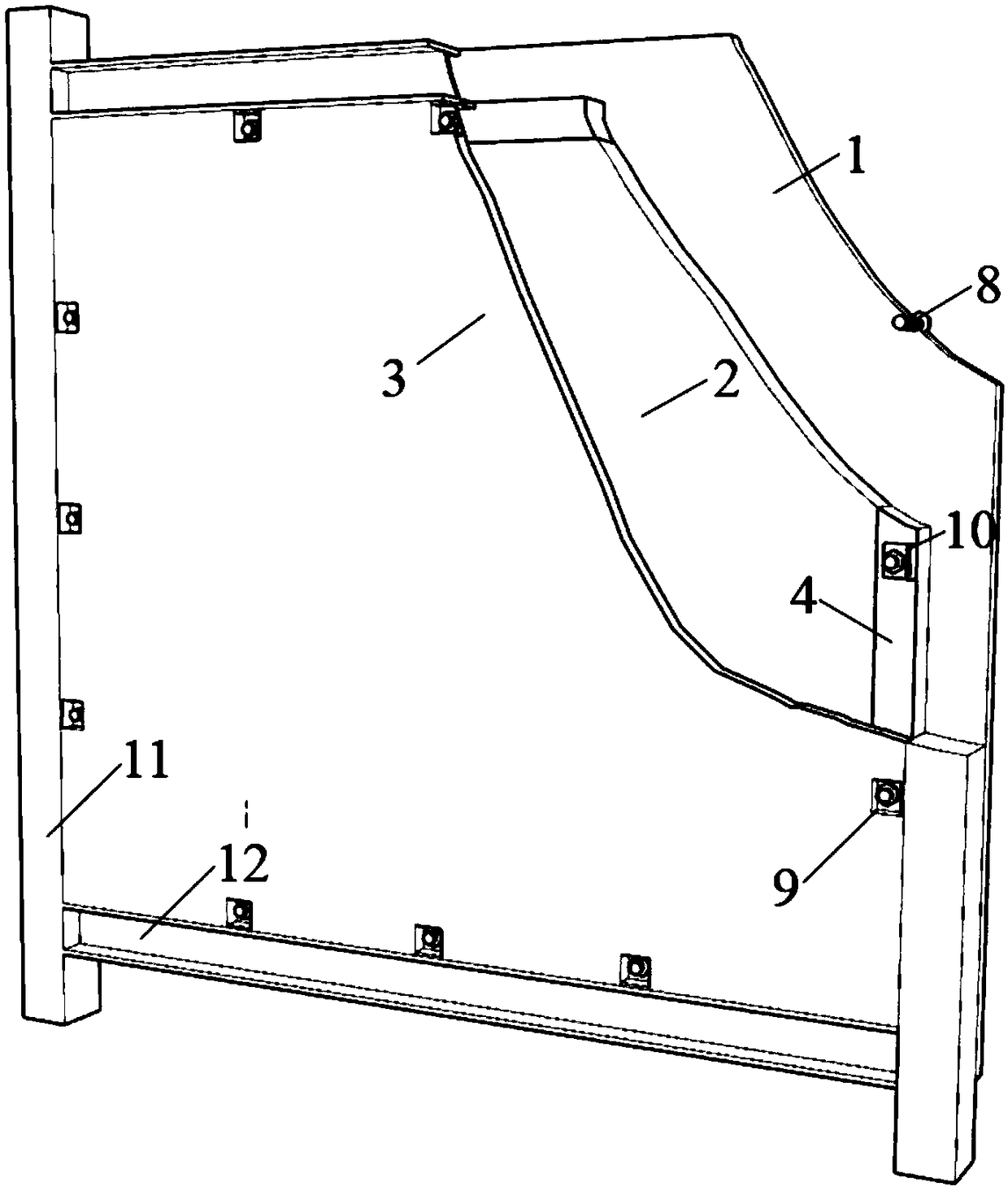

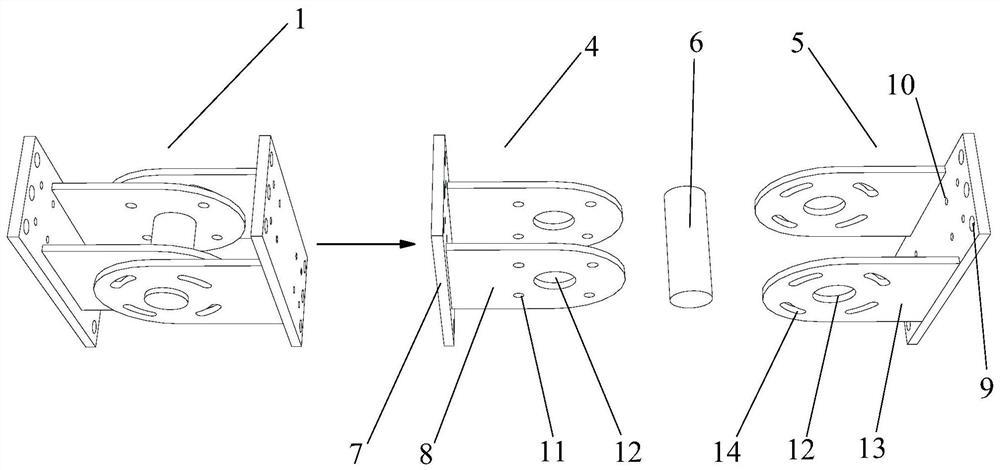

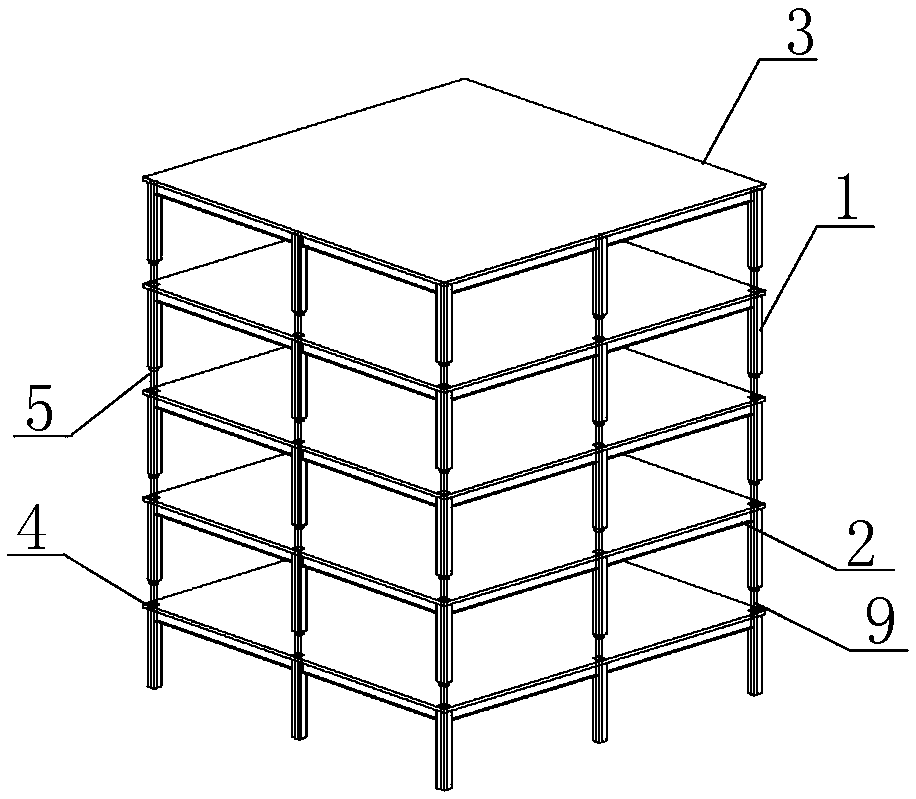

Assembling integral type framework buckling-prevention supporting structure

InactiveCN106401209AReduce the weight of the structureLow costShoresShock proofingHigh riseStructure system

The invention provides an assembling integral type framework buckling-prevention supporting structure. The structure comprises a building framework body. The building framework body is a multi-truss framework which is composed of framework beams and framework columns. The building framework body further comprises a plurality of buckling-prevention supports arranged in the building framework body. According to the buckling-prevention supports, every two buckling-prevention supports are crossed in a triangle shape; the two buckling-prevention supports which are in the triangle shape are connected with the building framework body through connecting joints; the top ends of the two buckling-prevention supports are fixedly connected to the corresponding framework beams arranged transversely; and the bottom ends of the two buckling-prevention supports are fixedly connected with the corresponding framework columns separately. A shear wall is replaced with the structure, and the problems of field concrete pouring construction required by the shear wall and pre-cast shear wall assembling construction are solved, so that prefabrication assembling of all components of a high-rise framework-buckling-prevention supporting structure system is achieved, the prefabrication assembling rate of similar structures is increased, and an assembling building technology of a high-rise framework-buckling-prevention supporting structure is developed.

Owner:NANJING YANGTZE RIVER URBAN AGCHITECTURAL DESIGN

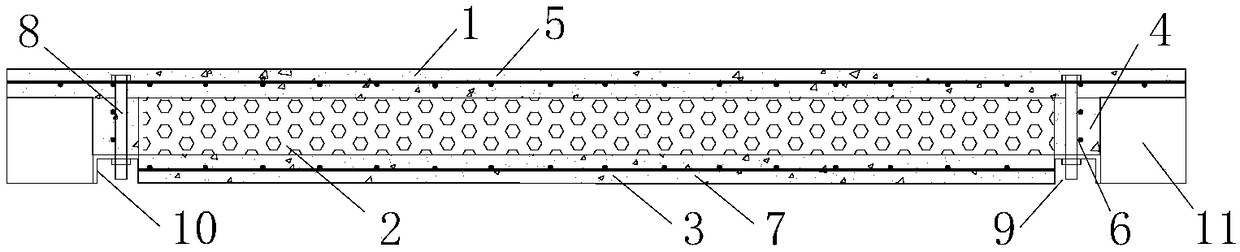

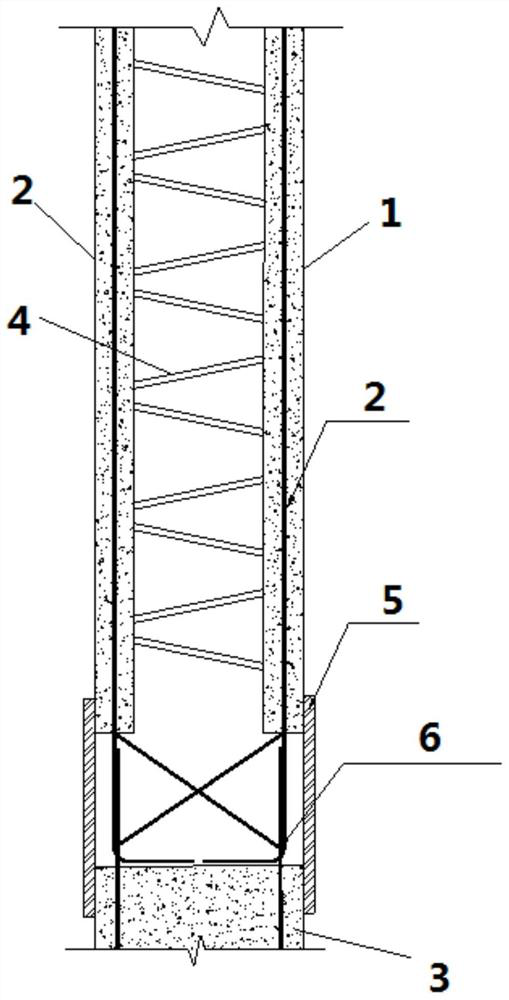

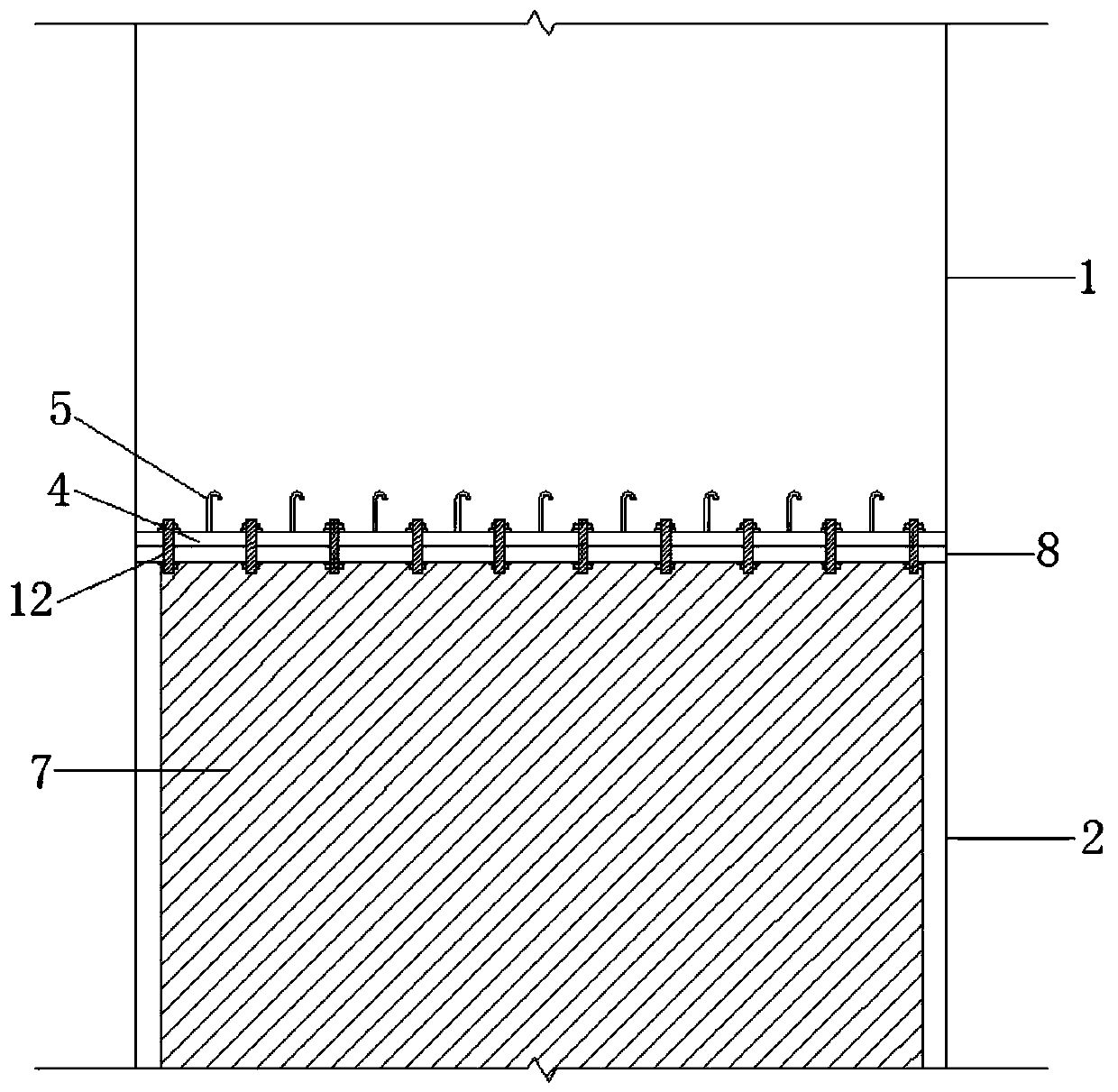

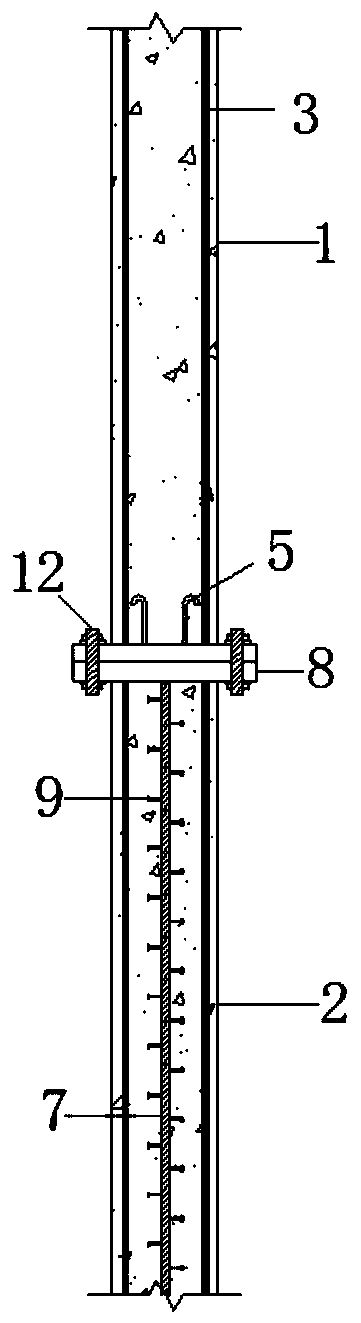

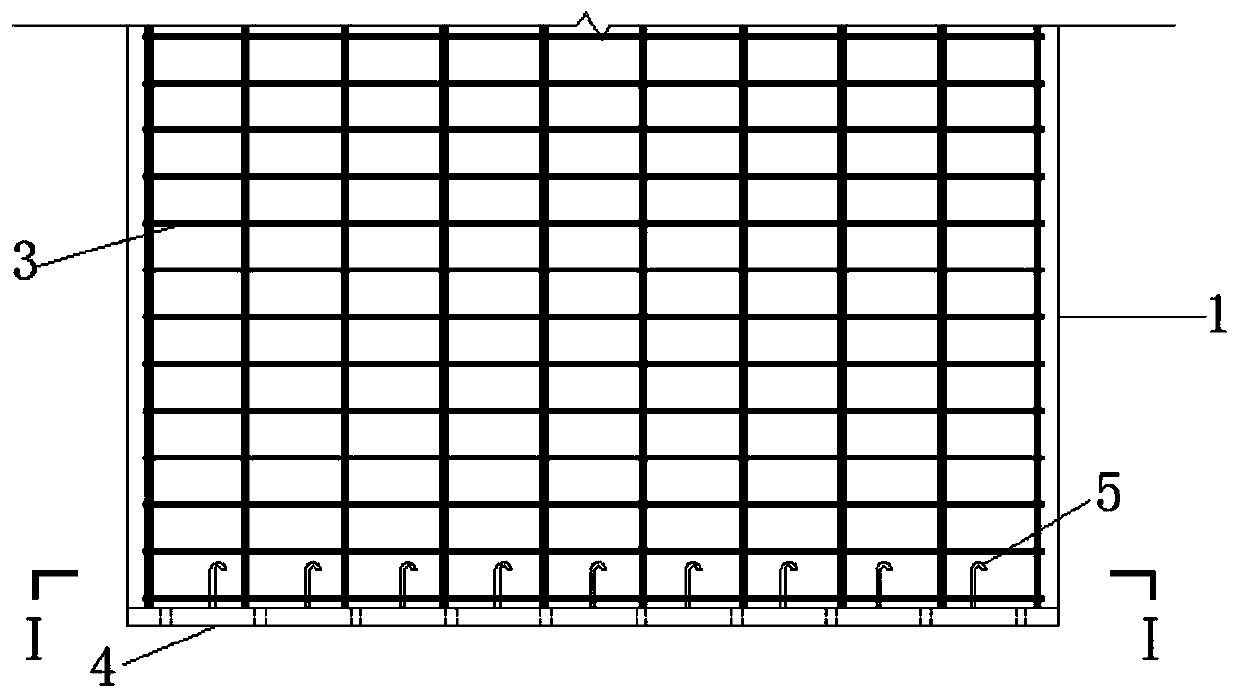

Self-supporting type double-faced laminated shear wall and construction method

PendingCN113404190AEfficient connection methodEasy to tieWallsForms/shuttering/falseworksEarthquake resistanceArchitectural engineering

The invention provides a self-supporting type double-faced laminated shear wall and a construction method. The self-supporting type double-faced laminated shear wall comprises each laminated shear wall body, wherein each laminated shear wall body comprises two prefabricated wall bodies which are oppositely arranged in parallel at an interval, a vertical reinforcing steel bar penetrates through each prefabricated wall body, the extension part of each vertical reinforcing steel bar extends out of each prefabricated wall body, and the extension part is in lap joint with a ground beam or a pre-embedded vertical reinforcing steel bar of a lower-layer shear wall; the vertical reinforcing steel bars extending out of wall columns suspend the wall body, reinforcing steel bar binding or UHPC short lap joint is facilitated, the effective height of the section of the double-face laminated shear wall is increased, and the structural anti-seismic performance is improved. The prefabricated shear wall structure connected through a horizontal joint is high in assembly rate and easy to construct, long-time operation of large hoisting equipment is not needed, only inclined struts need to be adopted for fixing, the construction period can be greatly shortened, and the construction efficiency can be improved.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

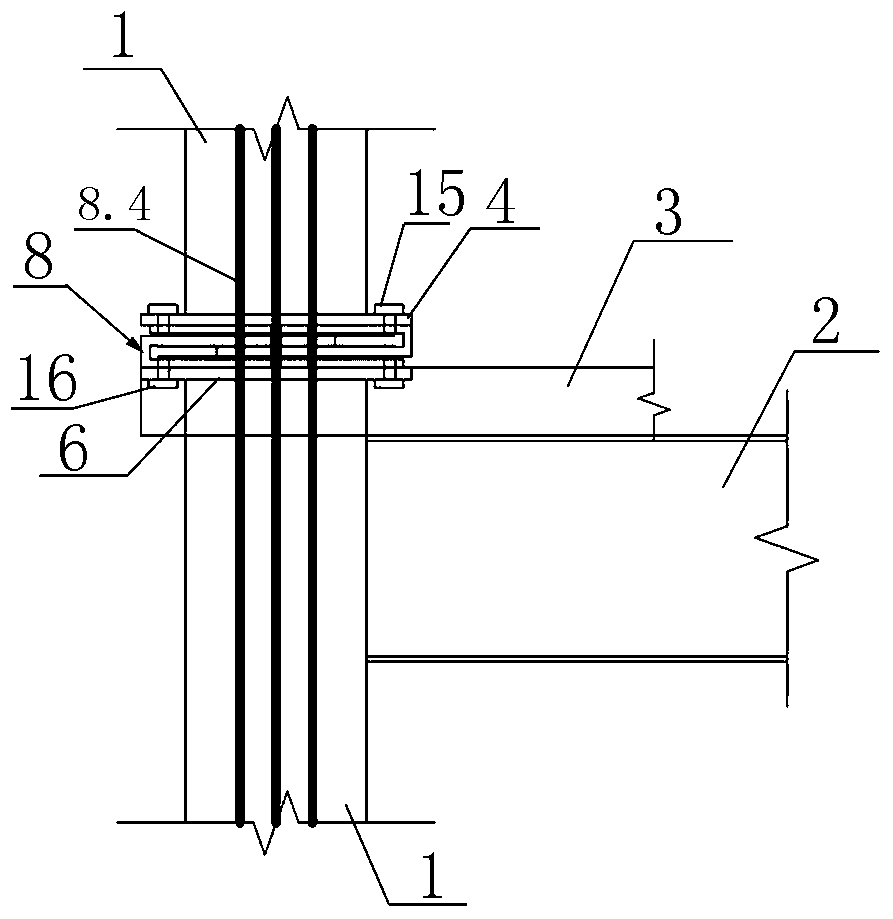

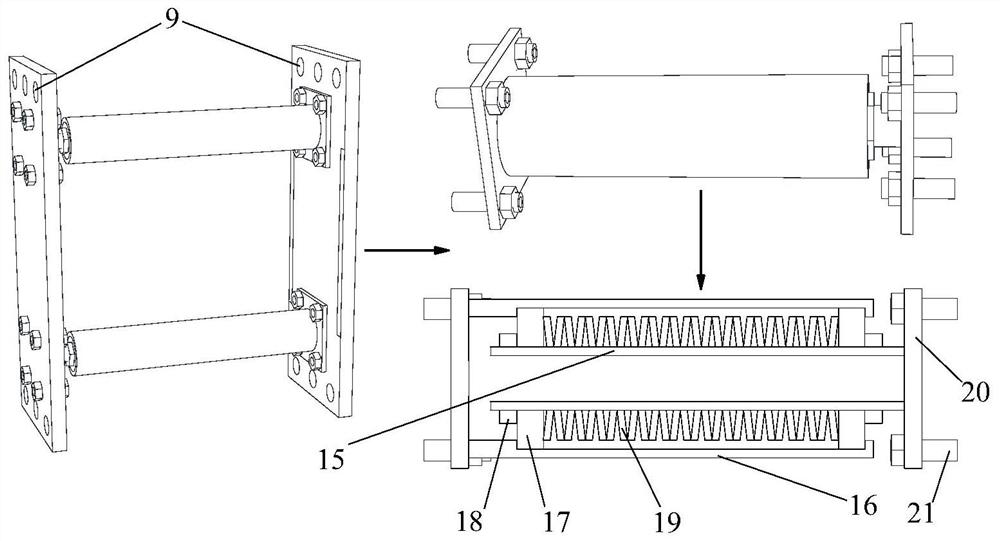

Prestressed assembly type steel frame friction damping structure system and design method thereof

ActiveCN110409604AAvoid damageReduce pollutionProtective buildings/sheltersSpecial data processing applicationsFloor slabPre stress

A prestressed assembly type steel frame friction damping structure system and a design method thereof comprise at least two layers of steel frame structures, wherein adjacent steel frame structures are disconnected at the joint of an upper-layer column and a lower-layer floor slab; the adjacent steel frame structures are connected in a sliding manner through a bidirectional sliding friction connecting device; the bidirectional sliding friction connecting device comprises an upper C-shaped plate, a lower C-shaped plate, a friction plate and a connecting piece; the plate surface of the upper C-shaped plate is provided with a first transverse strip hole; the plate surface of the lower C-shaped plate is provided with a first longitudinal strip hole; the upper C-shaped plate and the lower C-shaped plate are mutually inserted and connected with the connecting pieces in the corresponding first longitudinal strip holes through the first transverse strip holes; the upper C-shaped plate is connected with a bottom connecting plate; the lower C-shaped plate is connected with a top connecting plate; and friction plates are arranged between a first top plate and a second top plate, between a second top plate and a first bottom plate and between the first bottom plate and a second bottom plate. The prestressed assembly type steel frame friction damping structure system solves the technical problems of poor energy consumption performance and difficult construction of connecting joints of the traditional assembly type structural steel column connecting structure.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

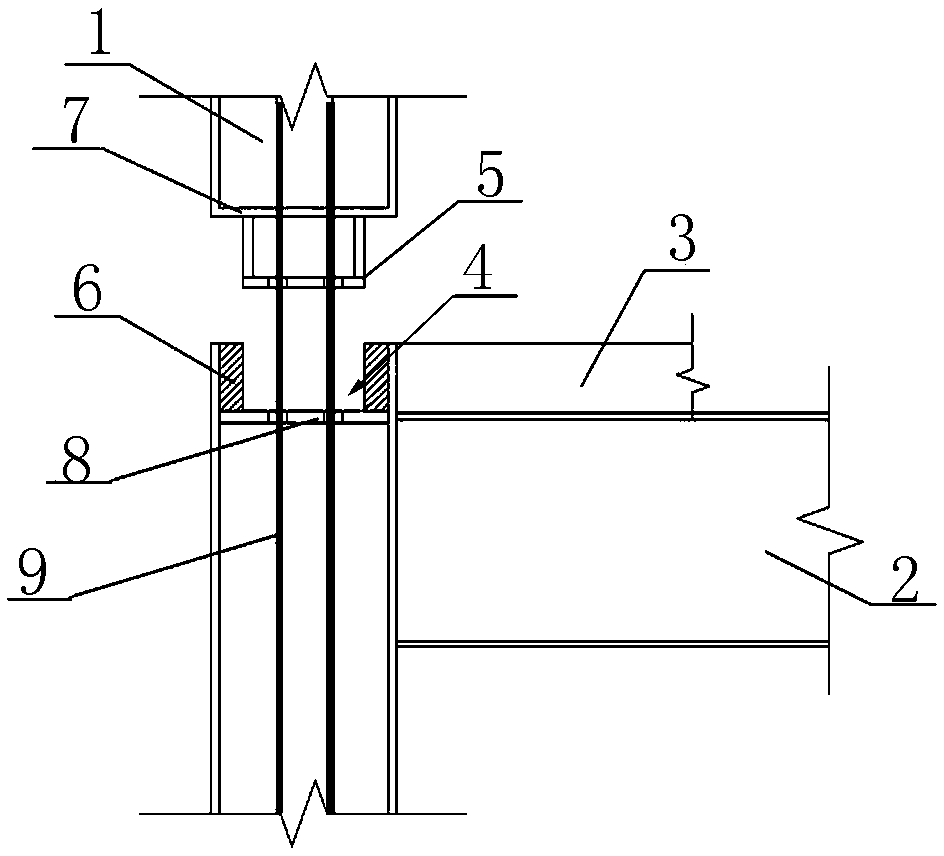

Prefabricated built-in insulating layer foamed concrete composite wall-light steel frame connection joint

The invention belongs to the technical field of wall joint connecting and manufacturing in building structure engineering, and particularly relates to a prefabricated built-in insulating layer foamedconcrete composite wall-light steel frame connection joint. A composite wall is installed in a half-embedded mode, a built-in insulating layer and inner sheet foamed concrete are embedded into a lightsteel frame, and external sheet foamed concrete externally covers a light steel frame beam-column. Compared with a traditional prefabricated wall, a wall body of the prefabricated built-in insulatinglayer foamed concrete composite wall-light steel frame connection joint can be used as a structural stress member, mutually transfers the load with the frame beam-column, participates in the structure stress of a building, and improves bearing capacity and anti-seismic capacity of the building, and a wallboard externally covers the steel frame beam-column to effectively reduce the corrosion of steel. The composite wall-frame joint realizes the bolt connection by pre-embedding bolts in the composite wall and welding connection angle iron on the frame structure beam-column; and the prefabricated built-in insulating layer foamed concrete composite wall-light steel frame connection joint is simple in structure form, reliable in connection and easy to construct, can effectively shorten the construction period when applied to practical engineering, and is suitable for wide popularization and application in low multi-layer light steel frame structures.

Owner:BEIJING UNIV OF TECH

Double-layer PC plate type conversion layer of post-poured upper-portion structure and construction method

ActiveCN107460948AReduce thicknessLow costProtective buildings/sheltersBuilding material handlingType conversionEngineering

The invention provides a double-layer PC plate type conversion layer of a post-poured upper-portion structure and a construction method. The double-layer PC plate type conversion layer comprises a first-layer RC conversion plate and a second-layer RC conversion plate, and the first-layer RC conversion plate and the second-layer RC conversion plate are supported through frame columns to form a hollow layer. The thickness of the first-layer RC conversion plate is smaller than that of the second-layer RC conversion plate, and hidden beams are arranged in the second-layer RC conversion plate. A post-poured shearing wall, an energy consumption shearing wall and a friction damp mechanism are mounted in the hollow layer. A certain quantity of steel bars are configured in the upper and lower plates of the conversion layer, an energy consumption device is arranged between layers, thus the mass of the conversion layer plates is decreased, and the conversion layer plates have the enough bearing capacity to meet the upper-portion post-poured building structure. Through arrangement of interlayer special components, the structural integrity is reinforced, the structural seismic performance is reinforced, and thus the upper-down adjacent layers of the conversion layer do not become the anti-seismic weak layers.

Owner:CHANGAN UNIV

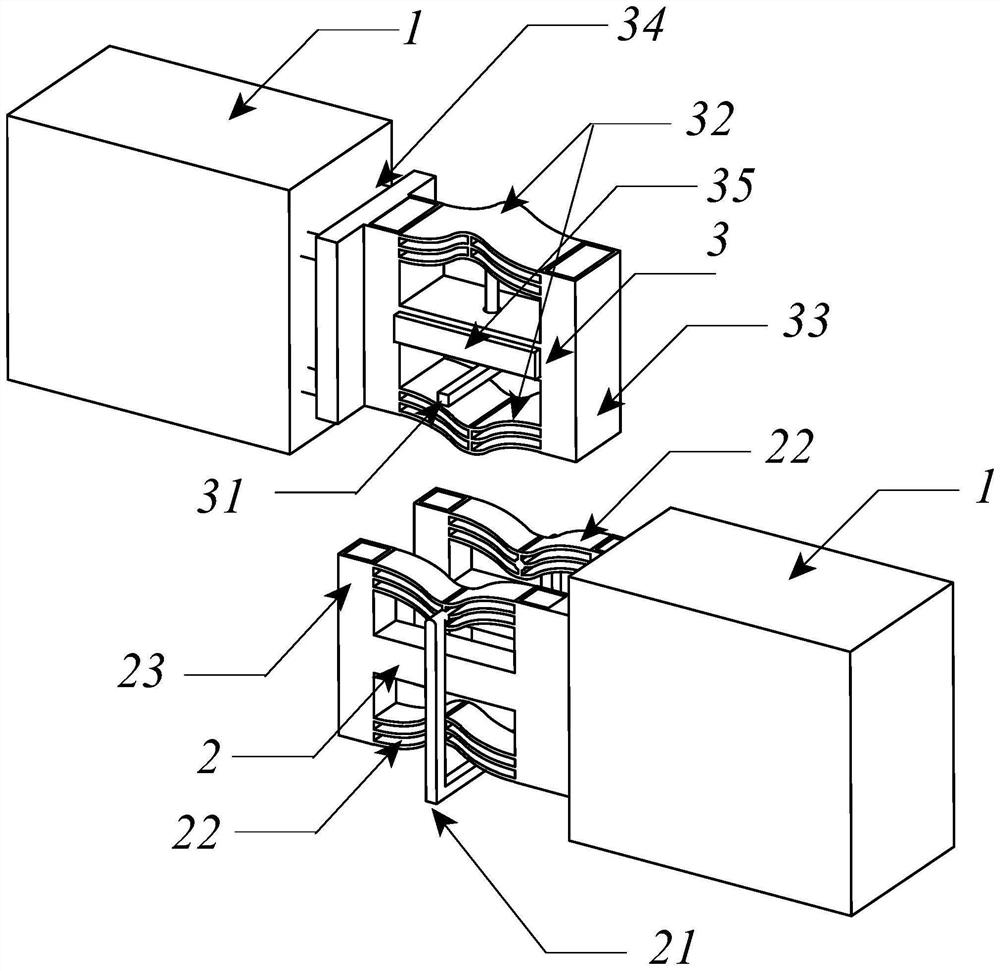

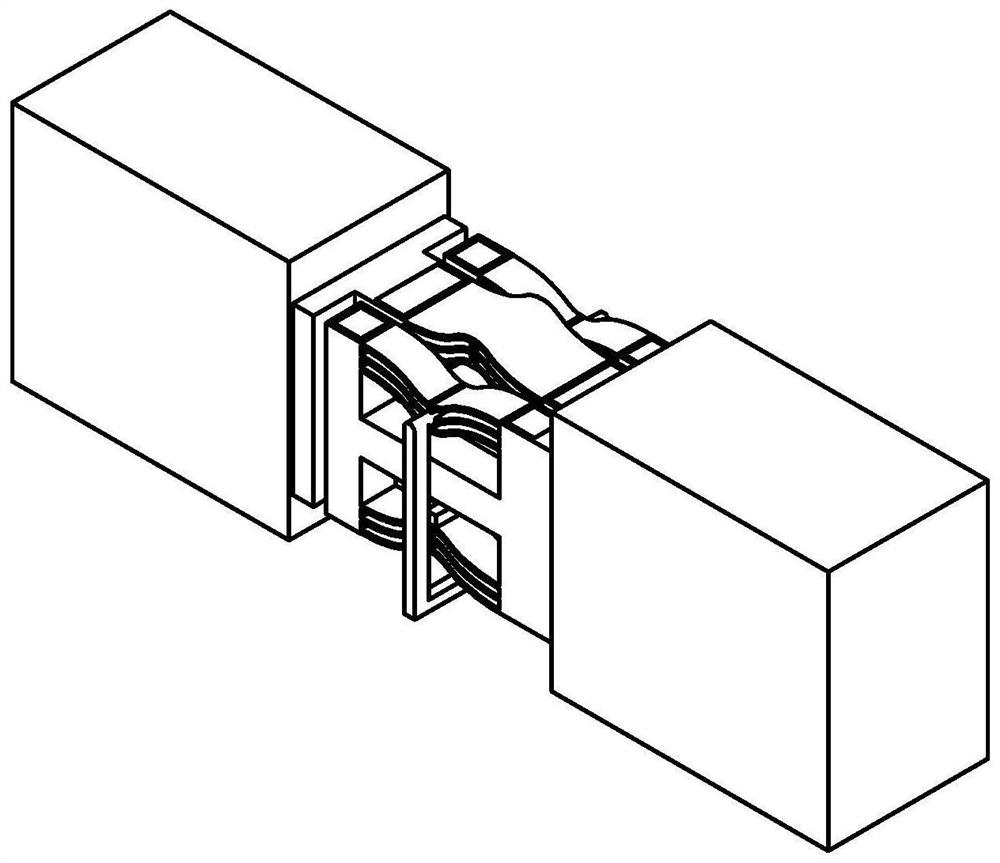

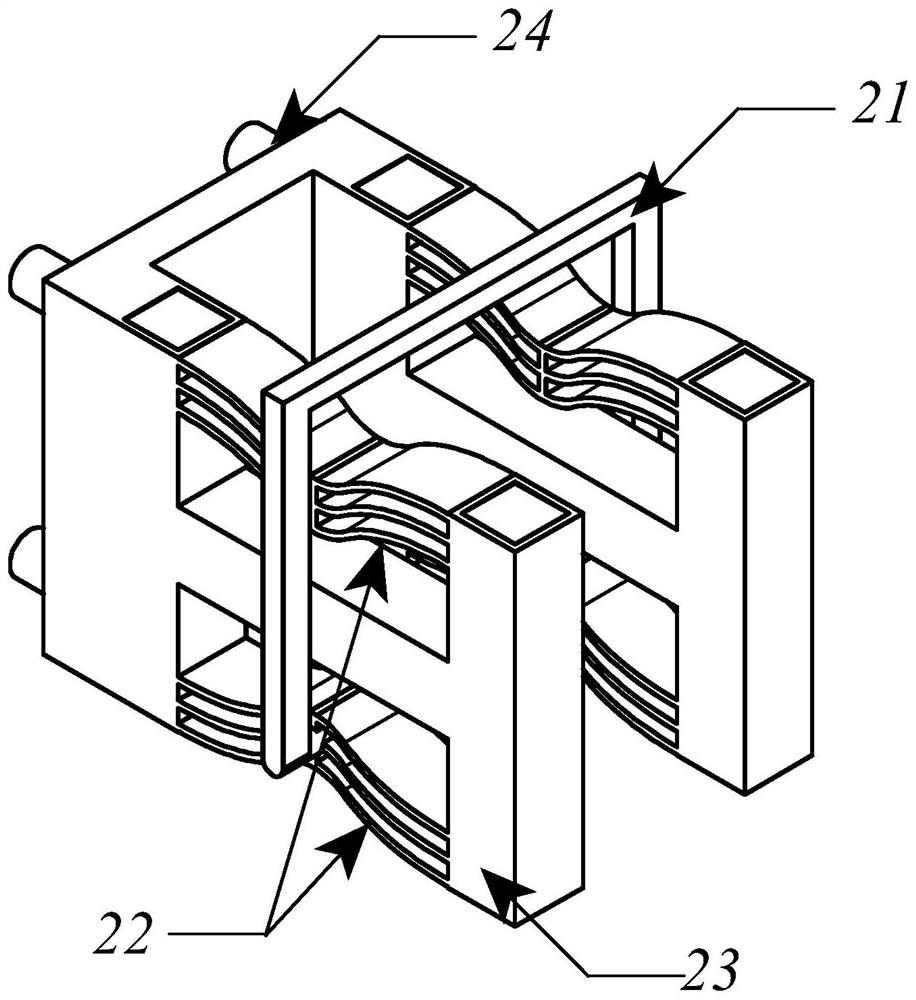

Variable stiffness shock absorption device with embedded connecting beam and working method thereof

ActiveCN111779148AReduce the structural eigenfrequencyIncreased structural damping ratioWallsProtective buildings/sheltersExternal energyEngineering

The invention discloses a variable stiffness shock absorption device with an embedded connecting beam and a working method thereof. The device comprises a U-shaped joint, a T-shaped joint, hyperbolicspring steel sheets located at the upper end and lower end of the joints, and internal and external connecting elements for connecting the two joints, wherein the U-shaped joint and the T-shaped jointare respectively connected to cut-off connecting beams on two sides; a slotted hole of the U-shaped joint and a bulge of the T-shaped joint are matched with each other; and the misalignment displacement of the U-shaped joint and the T-shaped joint is restricted by the hyperbolic spring steel sheets at the upper ends and lower ends of the joints and the internal and external connecting elements. The device can passively adjust the stiffness and damping characteristics of the connecting beam greatly and accurately, optimally controls the dynamic response of high-rise structures for different environmental excitations such as earthquakes and wind vibrations, does not need plastic deformation and external energy, and has relatively high application prospect.

Owner:SOUTHEAST UNIV

Beam end controllable energy consumption plastic hinge

PendingCN113187299ARealize passive controlImprove the seismic performance of structuresProtective buildings/sheltersShock proofingEarthquake resistanceClassical mechanics

Disclosed is a beam end controllable energy dissipation plastic hinge. The beam end controllable energy dissipation plastic hinge comprises a mechanical hinge; disc spring self-resetting devices are arranged on the inner sides of the upper end and the lower end of the mechanical hinge; and friction energy dissipation devices are arranged on the front end face and the rear end face of the mechanical hinge. The structure can be induced to form a reasonable damage mechanism under the earthquake action, the anti-seismic performance of a fabricated concrete frame structure is improved, passive control over the structure under the earthquake action is achieved, the purpose that the structure function can be recovered is achieved, and rapid development of the fabricated concrete frame structure is promoted.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

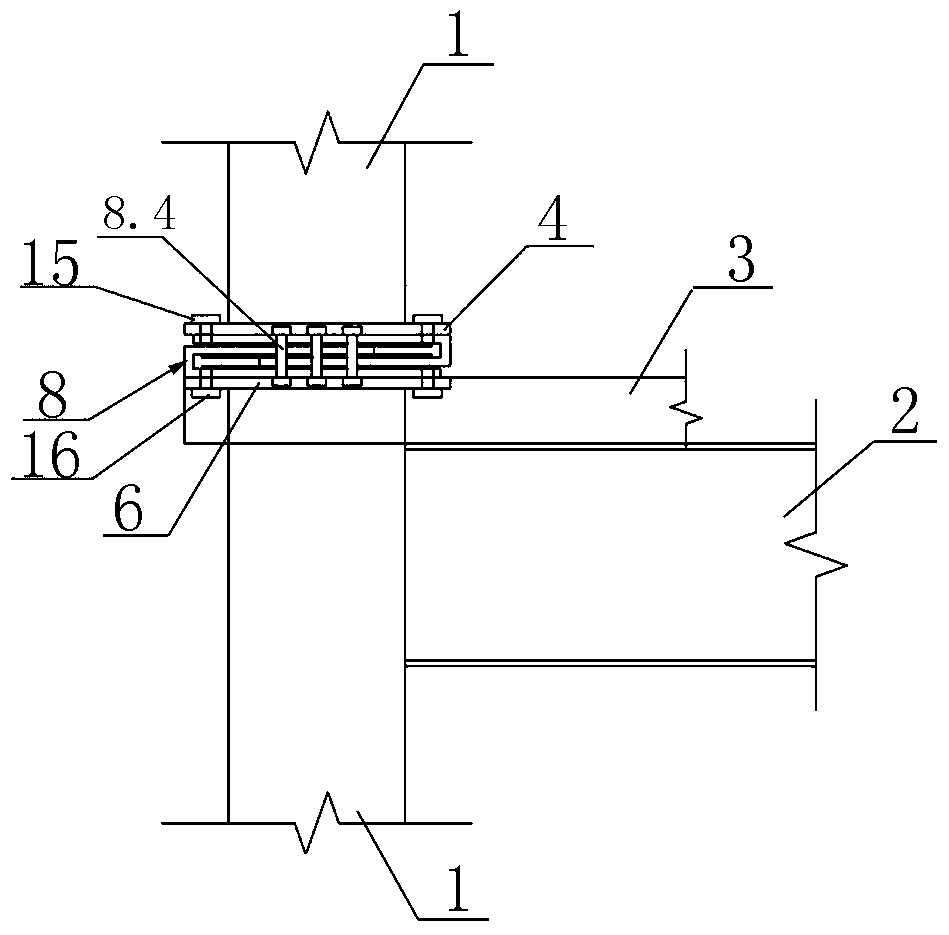

Prestress column tenon connection steel structure system and design method thereof

ActiveCN110409605AImprove seismic performanceEfficient assemblyProtective buildings/sheltersSpecial data processing applicationsFloor slabSteel columns

The invention provides a prestress column tenon connection steel structure system and a design method thereof. The prestress column tenon connection steel structure system comprises at least two layers of steel-frame structures stacked in the vertical direction; steel columns of each layer of the steel-frame structure are broken at the connecting parts between the steel columns and the lower layers of floor slabs; adjacent steel-frame structures are connected through prestress column tenon connection structures; the prestress column tenon connection structures comprise through holes, top sleeving tenons, elastic materials and high-strength pulling cables; the through holes are formed in the tops of the steel columns of the lower layers of the steel-frame structures; the top sleeving tenonsare connected with the bottoms of the steel columns of the upper layers of the steel-frame structures; the top sleeving tenons at the bottoms of the steel columns are correspondingly inserted into the through holes in the tops of the steel columns; gaps are reserved between the side walls of the top sleeving tenons and the side walls of the through holes; gaps are reserved between the tops of thethrough holes and the bottoms of the steel columns of the upper layers of the steel-frame structures; the elastic materials are arranged in the gaps between the top sleeving tenons and the through holes; and the high-strength pulling cables penetrate through the steel columns vertically corresponding in the steel structure system. The technical problem that a traditional steel structure is low inconstruction efficiency, severe in environmental pollution and poor in connecting joint anti-seismic property is solved.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

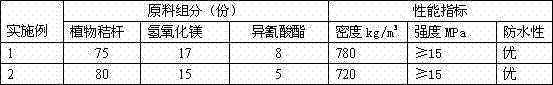

Production method of insulating brick containing plant straws

ActiveCN103539387AGood fire performanceSolve the problem of environmental pollutionSolid waste managementElectromagnetic inductionIsocyanate compound

The invention relates to a preparation method of an insulating brick containing plant straws. The preparation method is characterized in that the insulating brick is produced from the raw materials in parts by weight: 70-80 parts of the plant straws, 13-25 parts of magnesium hydroxide and 5-10 parts of isocyanate and comprises the steps: crushing the plant straws to obtain crushed plant straws with the fiber length of 5-10mm, drying the crushed plant straws until the moisture content is 8 percent according to the weight percentage, weighing the plant straws according to the parts by weight, adding the magnesium hydroxide and the isocyanate as a binder according to the parts by weight, carrying out mixing and burdening, then carrying out prepressing with the precompression of 500 tons, then carrying out compression molding with the die pressure of 1.2 kilotons, heating to 110 DEG C by virtue of a high-frequency electromagnetic induction method, and carrying out hot pressing for 3-6 minutes to form the insulating brick. According to the production method disclosed by the invention, with the plant straws as main raw materials, the produced insulating brick has a good fireproof performance without needing secondary insulation; in addition, the insulating brick is rapid in construction, has a favorable anti-seismic effect and has the shock strength according with the stipulations of a national standard in wall materials.

Owner:李伟

Spliced shear wall with steel-plate concrete and reinforced concrete arranged inside and construction technology

PendingCN110872872AReduce labor intensitySave materialWallsProtective buildings/sheltersReinforced concreteArchitectural engineering

The invention discloses a spliced shear wall with steel-plate concrete and reinforced concrete arranged inside and a construction technology. There are two types; the first type includes a prefabricated reinforced concrete shear wall and a prefabricated steel-plate concrete shear wall, the prefabricated reinforced concrete shear wall comprises a reinforcement cage I, a connecting steel plate I, aplurality of embedded pieces and a post-pouring concrete zone, and the prefabricated steel-plate concrete shear wall comprises a reinforcement cage II, a built-in steel plate I, a connecting steel plate II, a plurality of connecting pieces, embedded bolts and connecting bolts; the second type includes a prefabricated reserved-groove reinforced concrete shear wall and a prefabricated bulging built-in steel-plate concrete shear wall, the prefabricated reserved-groove reinforced concrete shear wall comprises a reinforcement cage III, a reserved groove and a plurality of reserved holes, and the prefabricated bulging built-in steel-plate concrete shear wall comprises a built-in steel plate II, a reinforcement cage IV, a round hole, a grouting device, an injection nozzle and transverse split bolts. The spliced shear wall has the advantages of very high construction speed, low labor intensity of workers and low environmental pollution.

Owner:辽宁省城乡市政工程集团有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com