Ductile prestressed concrete structure component and its production method

A concrete structure and prestressing technology, which is applied in the direction of manufacturing tools, building structures, ceramic molding machines, etc., can solve the problems of high-performance concrete quality environmental factors, reduced concrete ductility, poor ductility, etc., to increase ductility, improve The ultimate bearing capacity and the effect of improving the earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

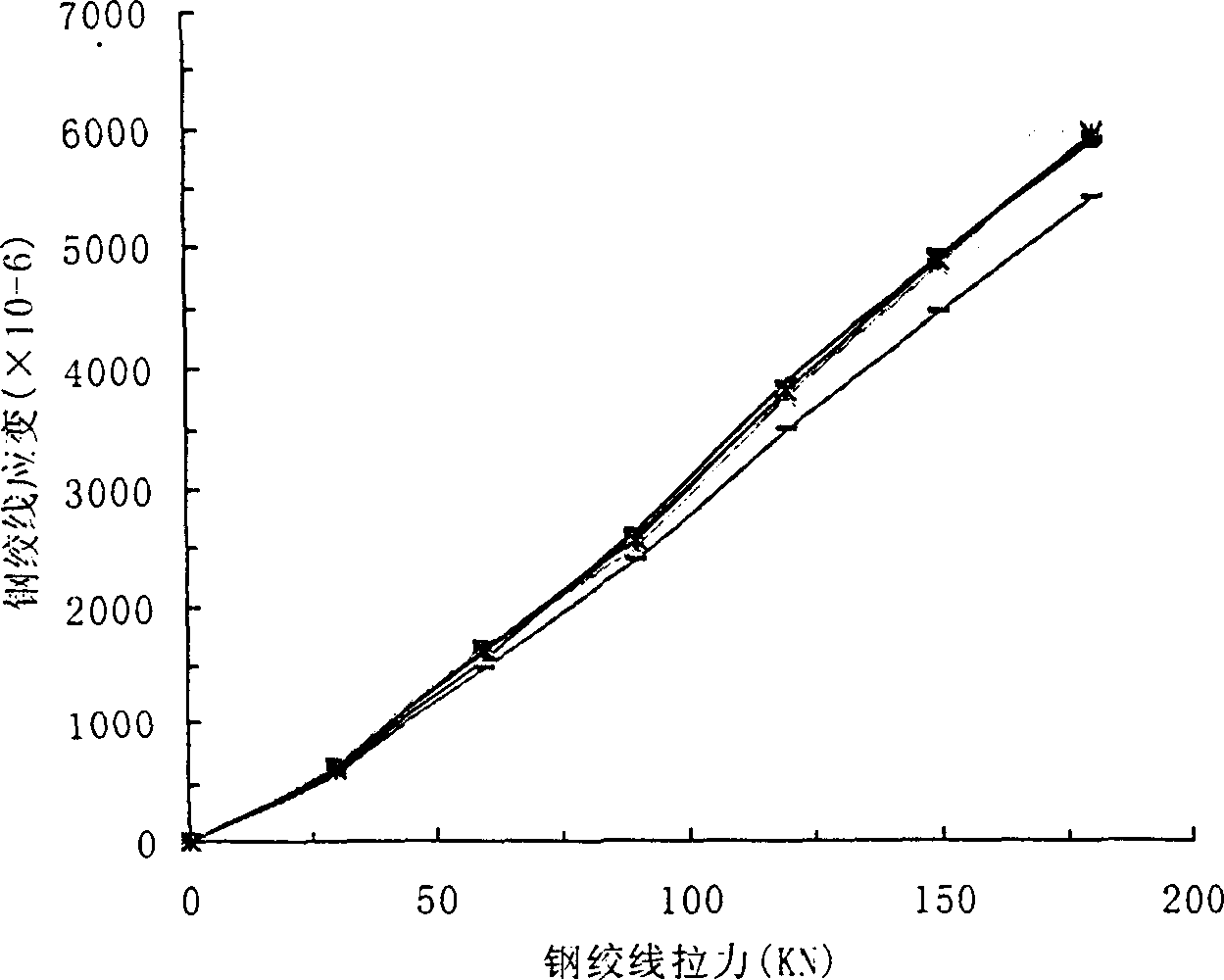

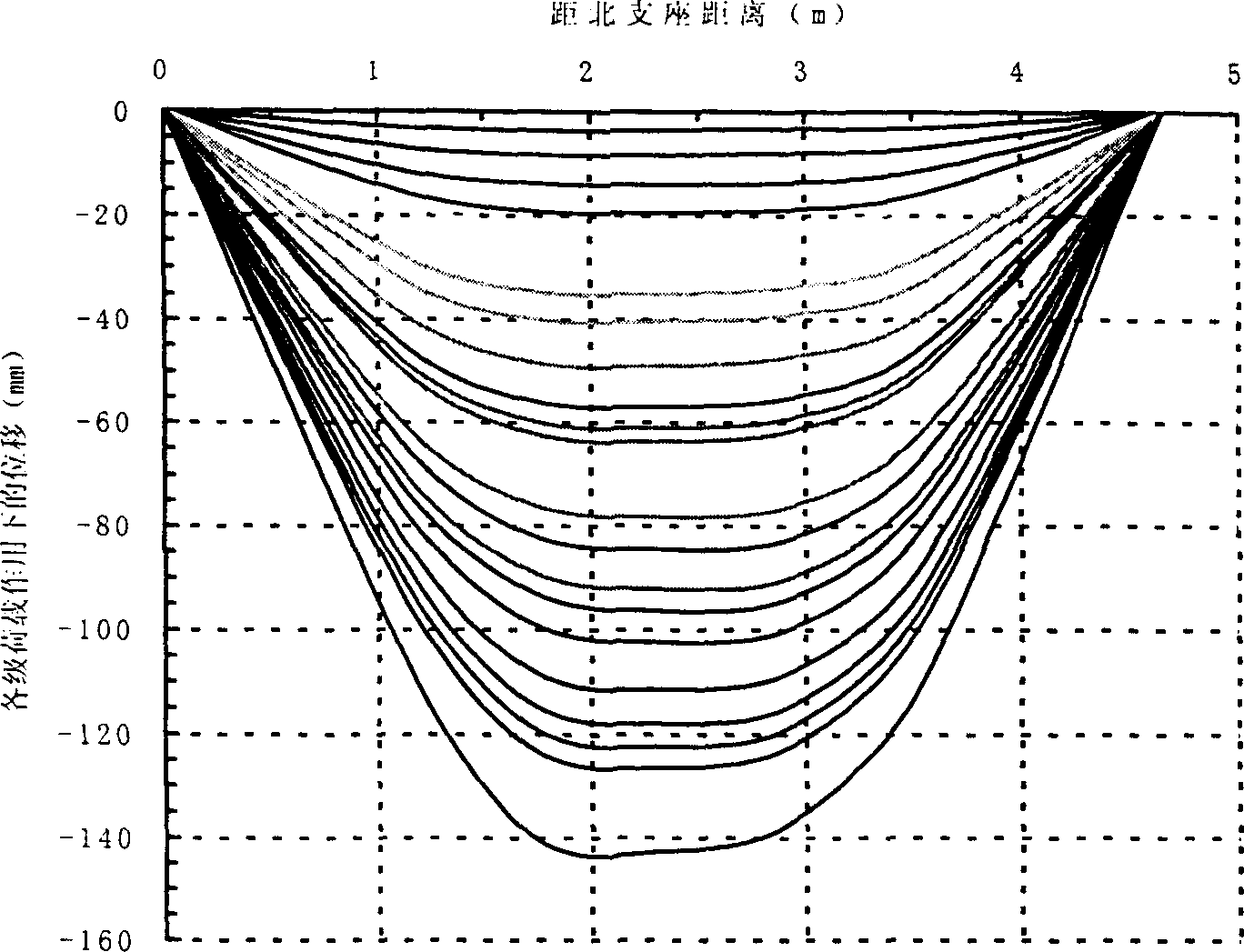

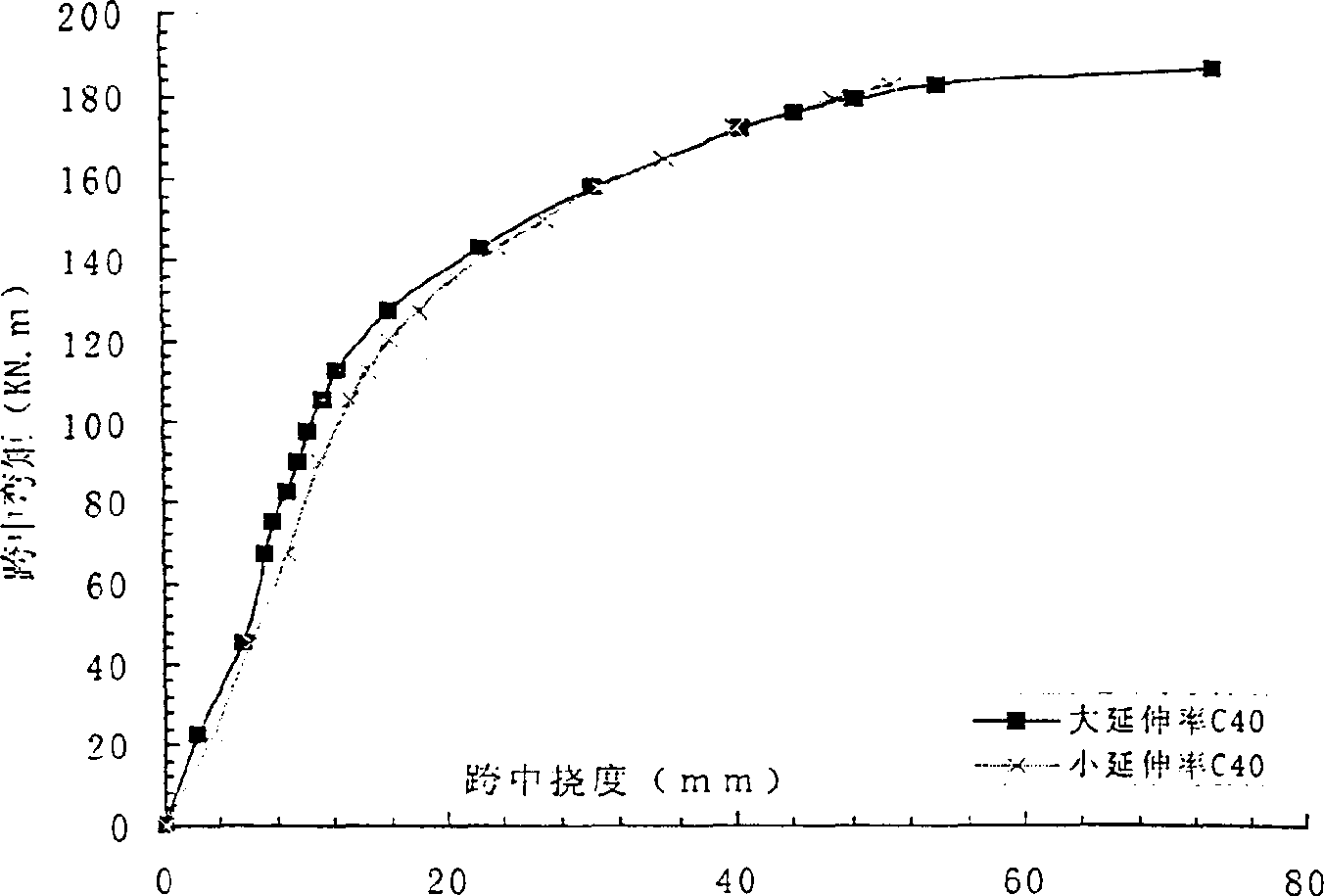

[0037] Specific implementation method: a new type of prestressed concrete structure, including concrete and prestressed tendons, the compressive strength of the concrete is greater than 60MPa, the prestressed tendons are prestressed steel strands, the strength is ≥ 1860MPa, and the relaxation rate is ≤ 2.5%, elongation ≥ 5%, and the flexural ductility ratio of the prestressed concrete structure conforming to the above process parameters is greater than 3.0. The manufacturing steps of described novel prestressed concrete structure are as follows: (1) formwork is laid (2) reinforced skeleton is set (3) concrete pouring strength is greater than 60mpa (4) strength is greater than 1860MPa, relaxation rate ≤ 2.5%, elongation ≥ 5% steel strands with high uniform elongation are in place, tensioned (5) the concrete is covered with sacks and watered for curing, when the strength of the concrete cube reaches the design required strength, the tensioned (post-tensioned) or pre-tensioned met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com