Patents

Literature

79results about How to "Increase structural damping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

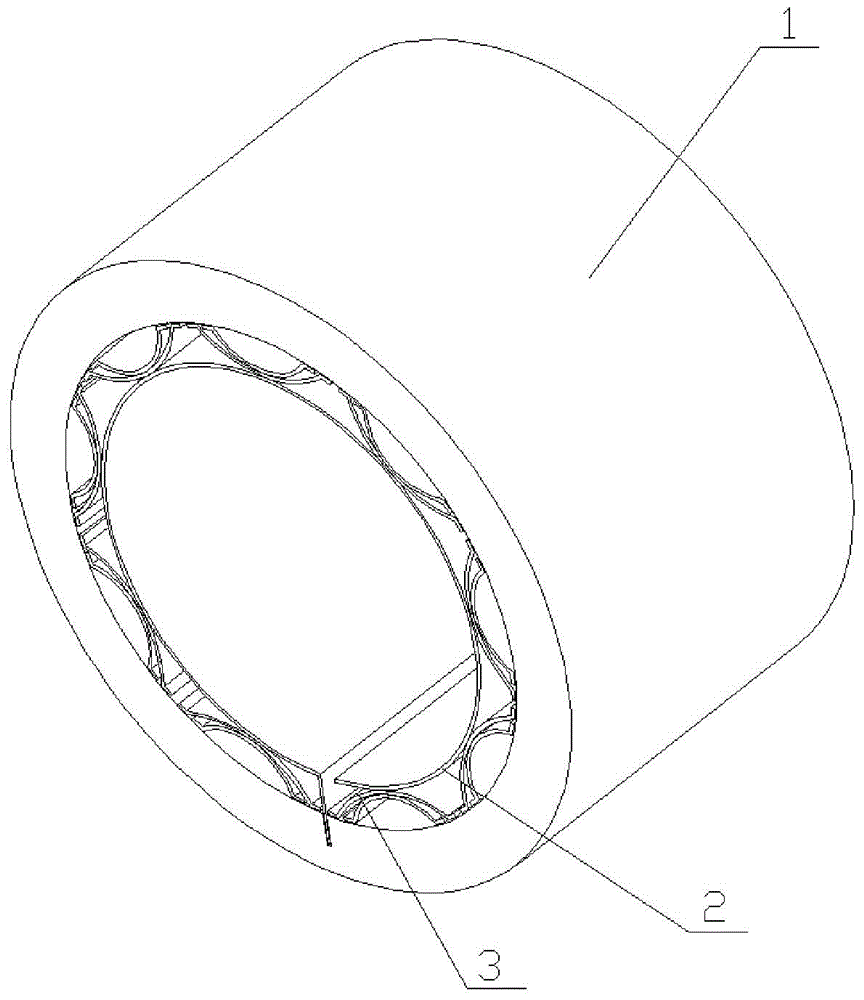

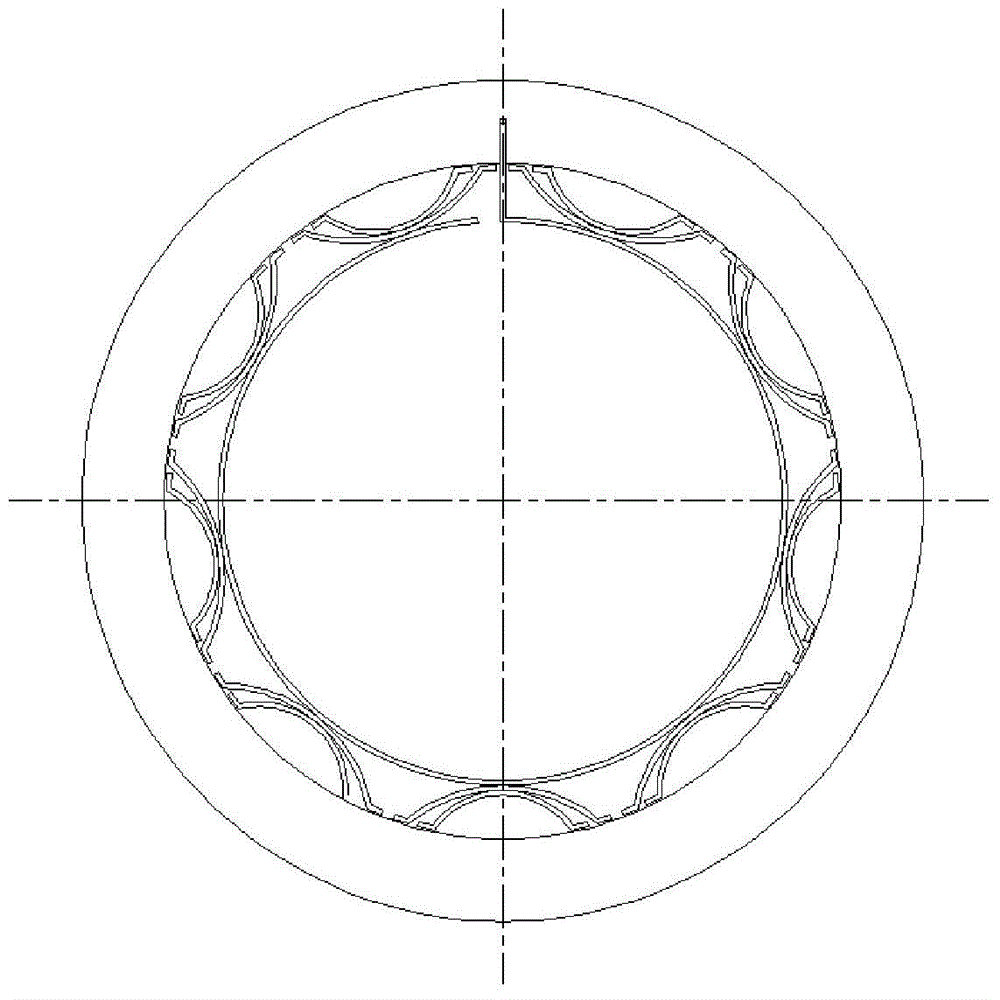

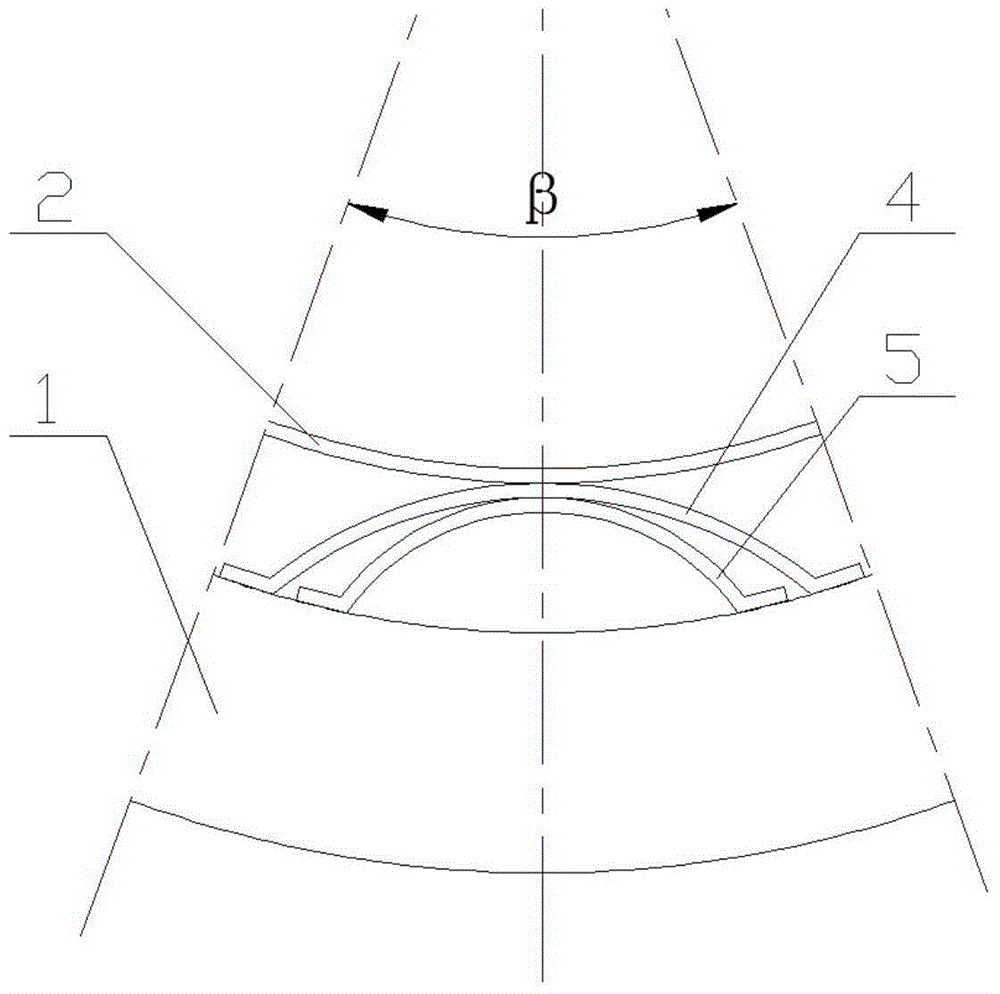

Minitype foil aerodynamic pressure bearing

InactiveCN104632871AQuality improvementImprove performance parametersSliding contact bearingsCushioningEngineering

The invention discloses a minitype foil aerodynamic pressure bearing. The minitype foil aerodynamic pressure bearing comprises a bearing body, a top layer foil and a composite elastic wave foil structure, wherein the composite elastic wave foil structure is connected with the top layer foil for circumferential location, the composite elastic wave foil structure comprises an outer elastic wave foil and an inner elastic wave foil, the convex surface of the inner side of the composite elastic wave foil structure is connected with the tangent position of the outer surface of the top layer foil, the convex surface of the outer side of the composite elastic wave foil structure is contacted with the inner surface of the bearing body, and the bearing body has mounting, protecting and supporting actions; and a matching surface of the bearing and a rotating shaft is formed on the inner surface of the top layer foil. According to the minitype foil aerodynamic pressure bearing, the surface quality and the performance parameters of the wave foil are improved, the bearing damping and stiffness characteristics are improved, the bearing capacity and the impact vibration cushioning capability of the bearing are improved remarkably, and the life and the stability of the bearing are prolonged and improved.

Owner:HUNAN UNIV

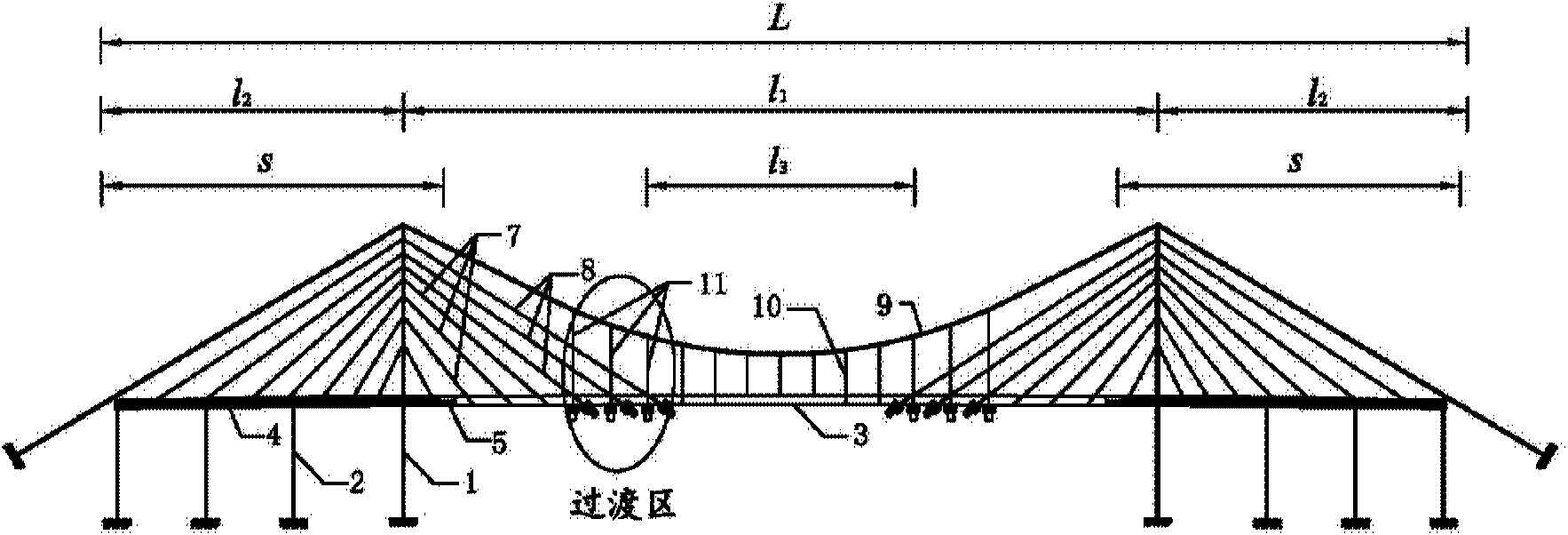

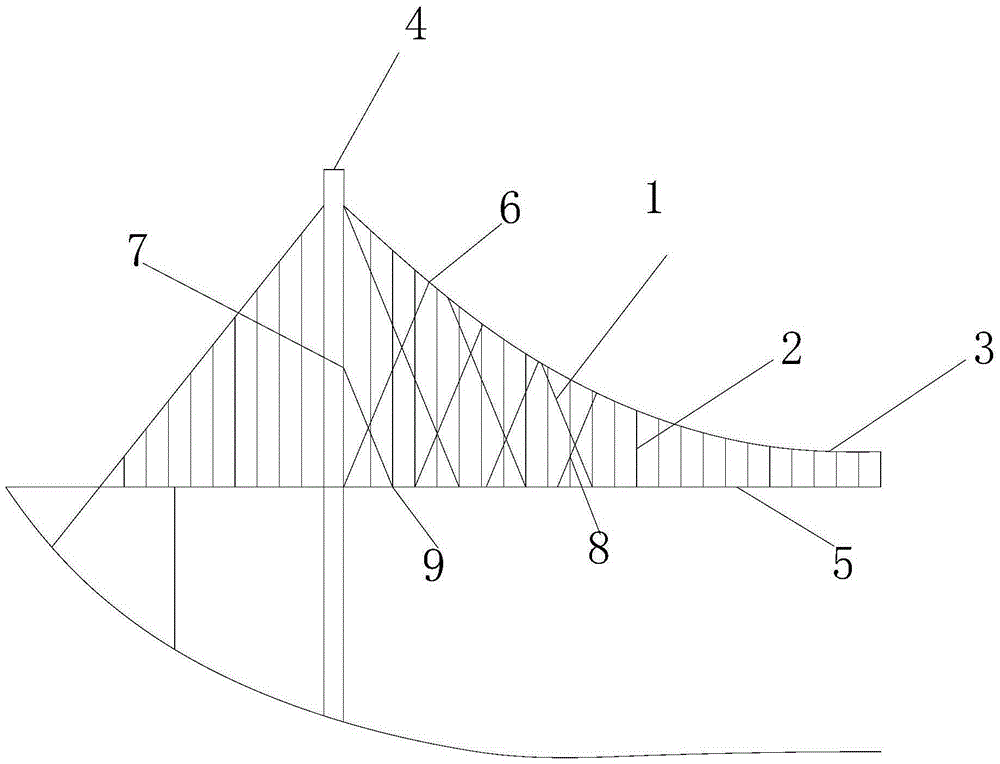

Composite beam stayed cable-suspension cable cooperation bridge

ActiveCN103850172AThe overall structure has large dampingIncrease stiffnessConstructionsStructural rigidityFatigue resistance

The invention discloses a composite beam stayed cable-suspension cable cooperation bridge which comprises a bridge head, auxiliary piers, a steel girder, a concrete girder, a combining part girder, a transition region girder, a stayed cable, a transition region stayed cable, a main cable, a suspension cable, a transition region suspension cable and a length regulating device, wherein the steel girder is positioned in the middle of a bridge body; two ends of the steel girder are sequentially and fixedly connected to the concrete girder by virtue of the transition region girder and the combining part girder; the concrete girder is adopted at the whole or partial length of side span parts 12 at two ends of the bridge, and the side span parts 12 are supported on the auxiliary piers; The midspan region 13 of the midspan part of the bridge is equal to 1 / 311-2 / 311 and the midspan region is suspended by virtue of the main cable. The novel stayed cable-suspension cable cooperation bridge provided by the invention is high in structural rigidity, high in damping, good in economical efficiency, uniform and smooth structural rigidity transition of a steel-concrete combining part and a stayed cable-suspension cable transition region, and good in fatigue resistance.

Owner:CCCC HIGHWAY CONSULTANTS +1

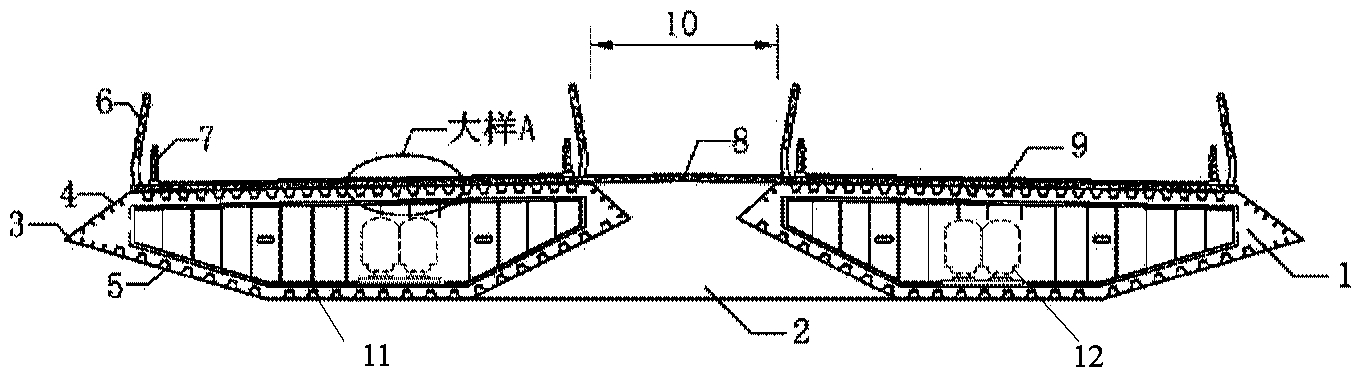

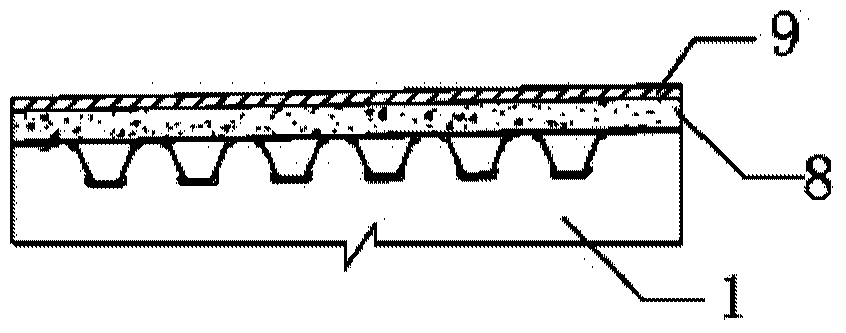

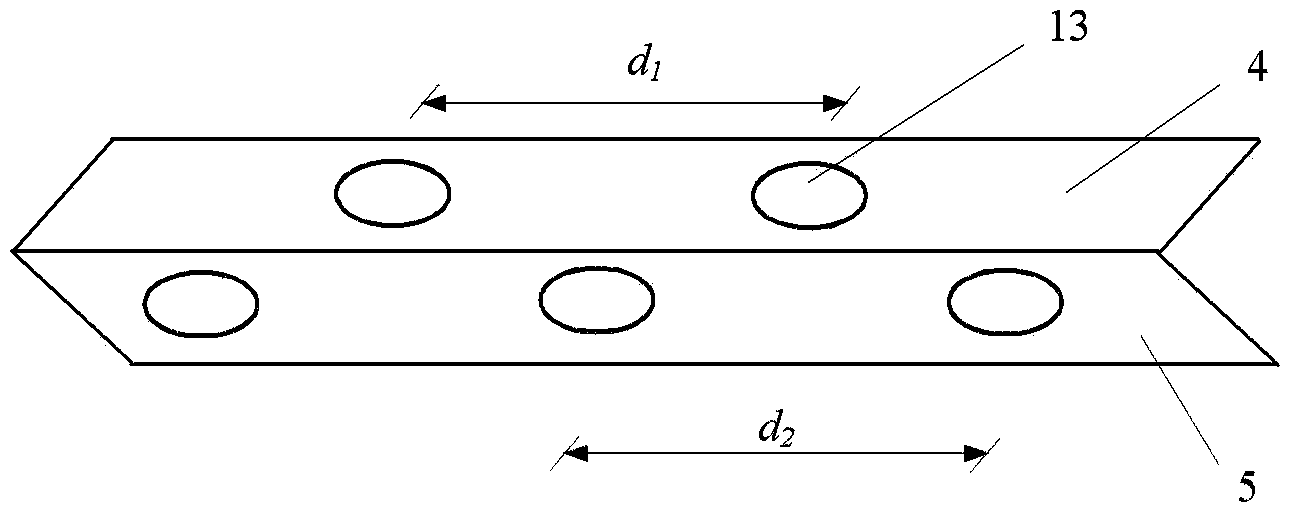

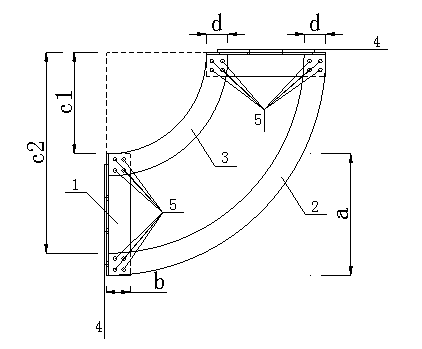

Split streamline steel-concrete composite box girder

ActiveCN103452036AGood aerodynamic shapeIncrease structural dampingBridge materialsBridge deckLight rail

The invention discloses a split streamline steel-concrete composite box girder comprising two or three horizontal steel-concrete composite box girder units. An air nozzle is disposed outside each steel-concrete composite box girder unit. A channel 4m-20m in horizontal width is formed between each two steel-concrete composite box girder units. Connecting beams are disposed at intervals of 4m-20m longitudinally along the channels. A top plat of each steel-concrete composite box girder unit is a concrete plate, and a bridge deck pavement for automobiles is paved on the top plate; a bottom plate and an oblique web in each girder unit are reinforced steel plates; rails for trains or light rail vehicles are arranged on the bottom plate; each oblique web is provided with round, elliptical or polygonal light holes. The split streamline steel-concrete composite box girder has the advantages that wind proofing stability of bridges can be improved effectively, vortex-induced vibration is suppressed, durability of the bridge deck pavement is improved, and the girder is applicable to highway bridges or highway and light-railway bridges and is simple in structure and well economical.

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT

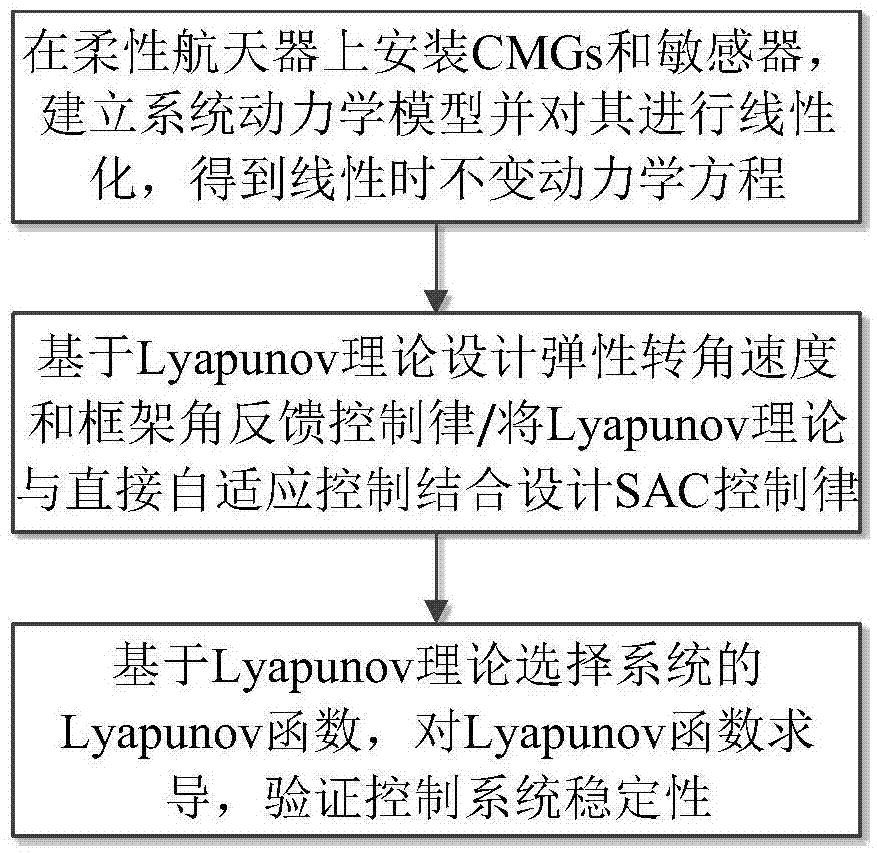

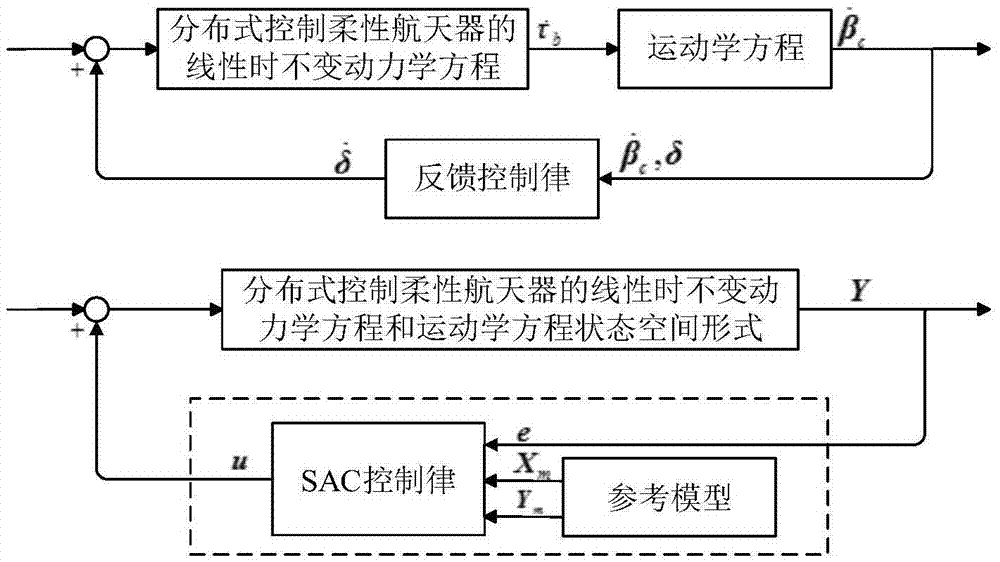

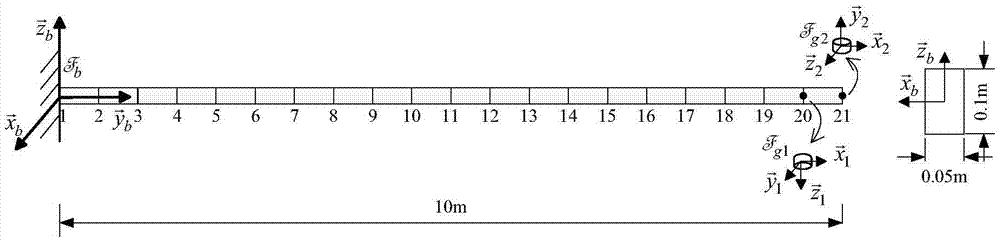

Distributed control method capable of improving control precision of flexible spacecraft

InactiveCN105446348AHigh control precisionIncrease structural dampingCosmonautic vehiclesCosmonautic partsKinematics equationsDynamic equation

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

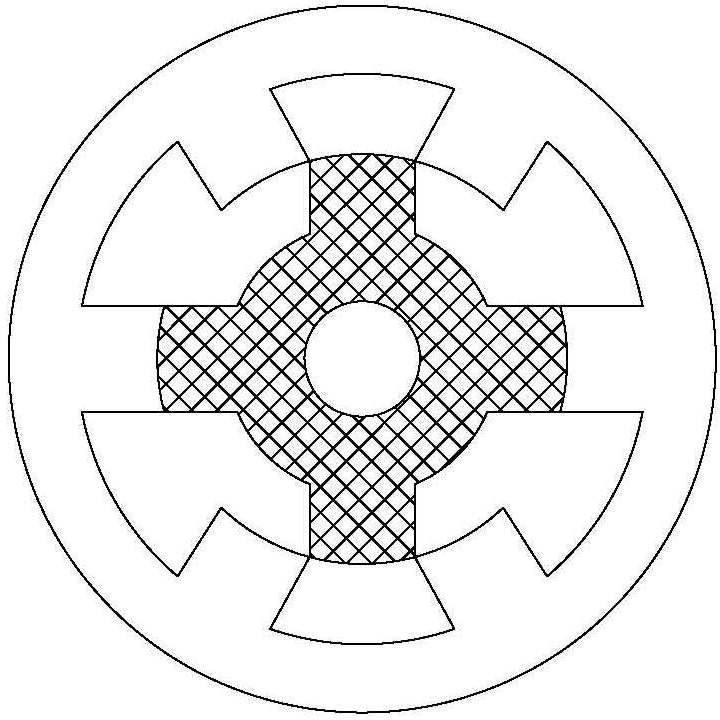

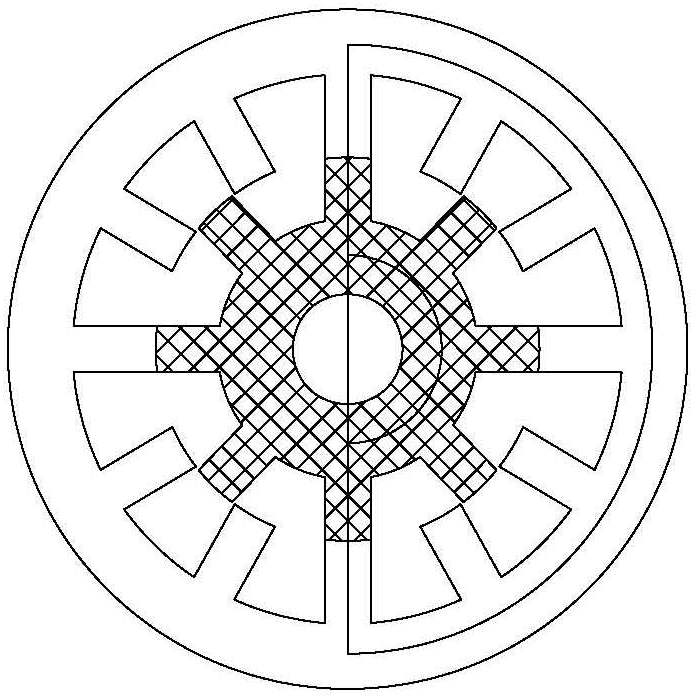

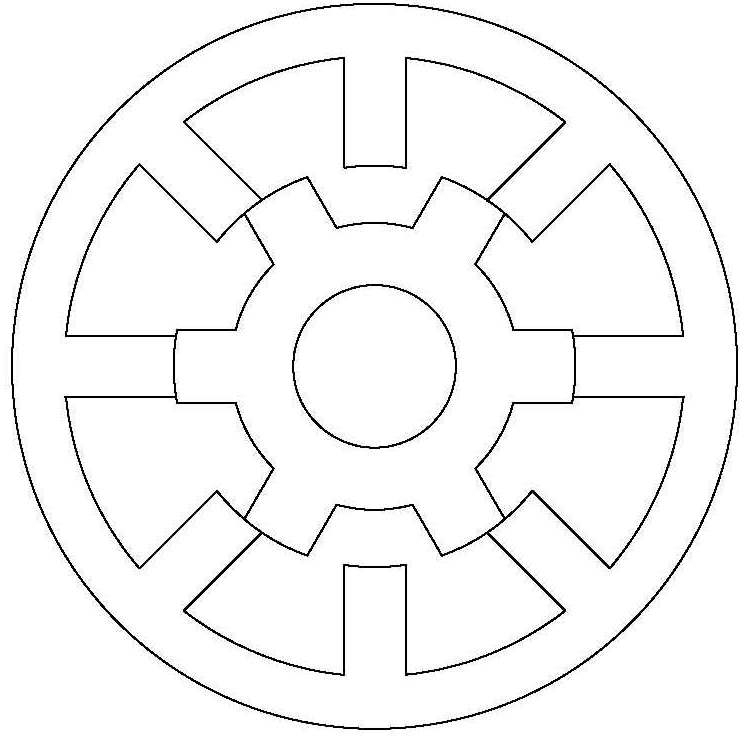

High-efficiency and large-torque disk type switching magnetoresistive motor

InactiveCN102545412AReduce temperature riseReduce noiseMagnetic circuit rotating partsMagnetic circuit stationary partsLow speedEngineering

The invention provides a high-efficiency and large-torque disk type switching magnetoresistive motor. The motor comprises a stator and a rotor, wherein both the stator and the rotor are in the shape of a yoke type round disk and comprise round disks and iron cores formed on the round disks; an integrated stator winding is wound on the iron core of the stator; and narrow magnetism isolating grooves which are arranged at intervals are radially formed in the iron core of the stator. The motor is simple in structure, high in efficiency and flexible in control method, can realize high-efficiency stepless speed regulation, and is very applicable to the application occasion requiring a short shaft, thin mounting, or low speed and large torque.

Owner:SHANGHAI DIANJI UNIV

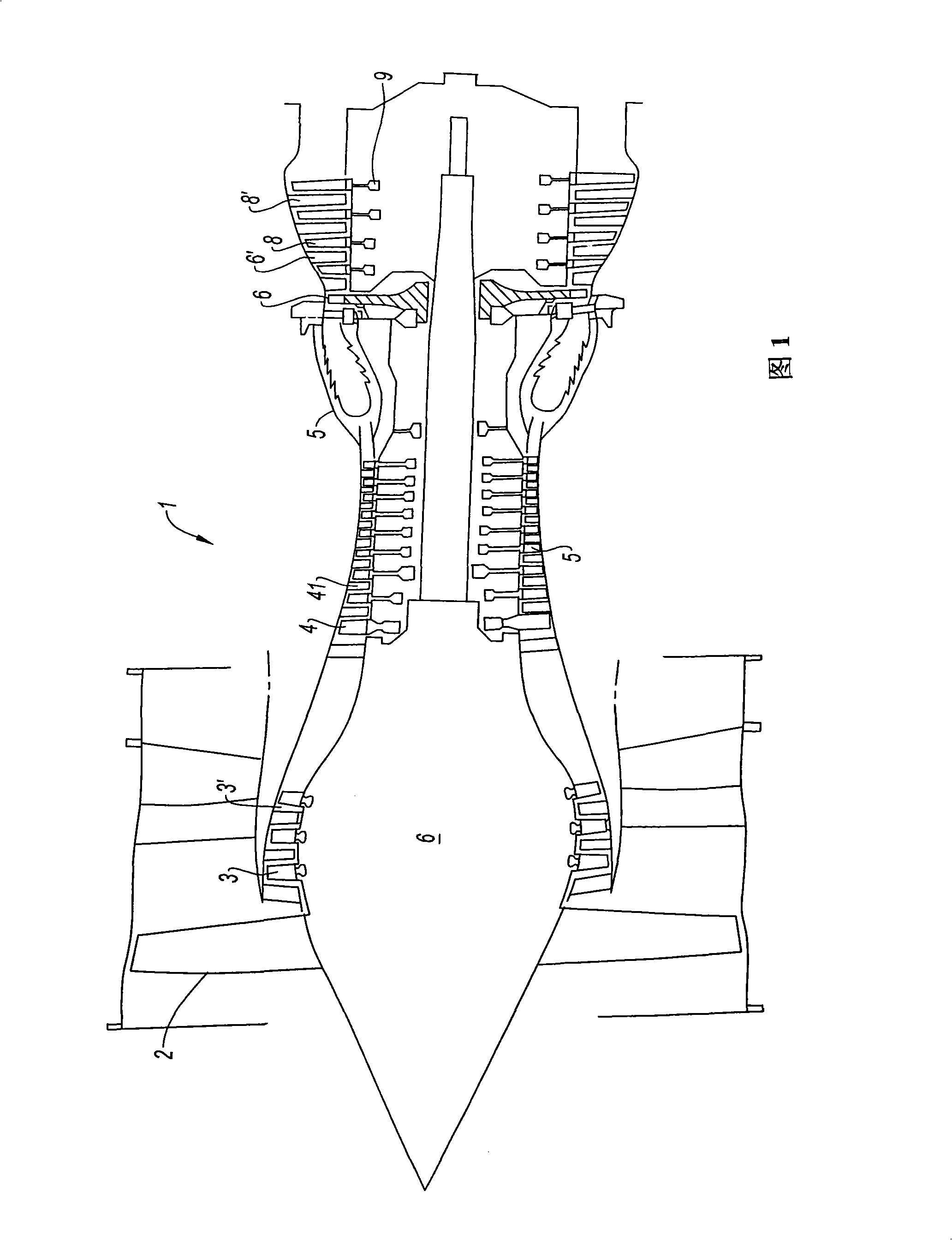

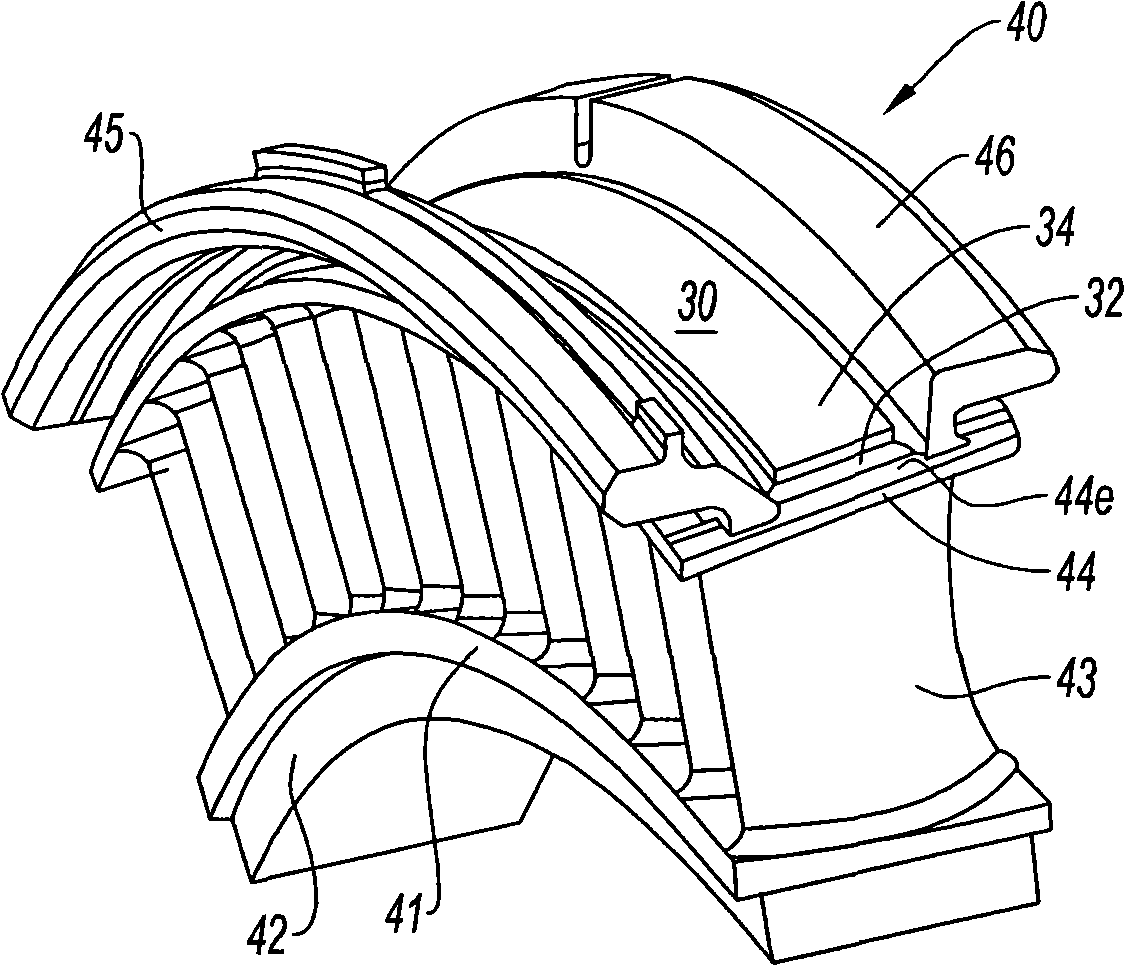

Turbomachine stator damper device

ActiveCN101333943ADissipate vibrational energyIncrease structural dampingSpringsEngine fuctionsEngineeringMechanical engineering

The invention relates to a damping device for a turbomachine stator. The turbomachine stator forming a stator vane ring or upstream guide vane element comprising a plurality of vanes placed radially between a first inner ring and a second outer ring, the two rings being concentric, the second ring having a cylindrical outer surface portion. The stator is characterized in that, on said outer surface portion, at least one vibration-damping laminate is attached, the laminate comprising at least one layer of viscoelastic material in contact with said surface portion and one counterlayer of rigid material.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

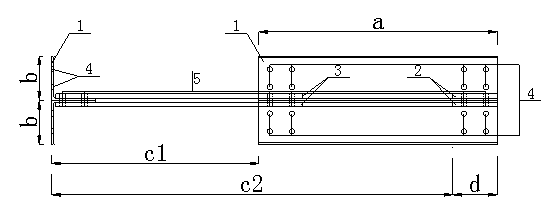

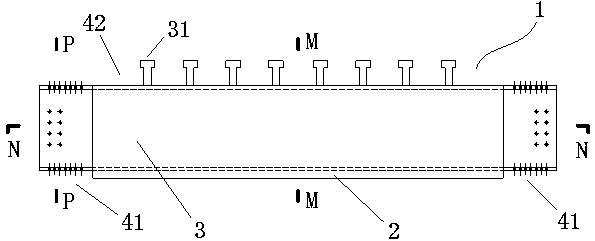

Anti-twisting novel soft steel energy dissipation device of plane irregular structure

An anti-twisting novel soft steel energy dissipation device of a plane irregular structure comprises a locating connector 1, a first energy dissipation soft steel strip set 2, a second energy dissipation soft steel strip set 3, a first bolt hole set 4 and a second bolt hole set 5. Installation positions of soft steel energy dissipation strips can be accurately fixed through the arrangement of the locating connector. The soft steel energy dissipation device can not only improve rigidity of a building structure and improve structural damping, but also have effects of deformation and energy dissipation when the structure encounters an earthquake action and improve an earthquake resistant property of the structure, and meanwhile the soft steel energy dissipation device has functions of corrosion resistance and rust resistance, an installable / detachable function and other functions. The anti-twisting novel soft steel energy dissipation device of the plane irregular structure can be applied to not only a new-built structure, but also a reinforced improvement of an old building, and satisfies double needs of a newly-built building and an old building. With increasing complexity of a building structure form and increasingly improved requirements of people for building performance, the anti-twisting novel soft steel energy dissipation device of the plane irregular structure has a wide development space and wide engineering application prospect.

Owner:CHINA MCC17 GRP

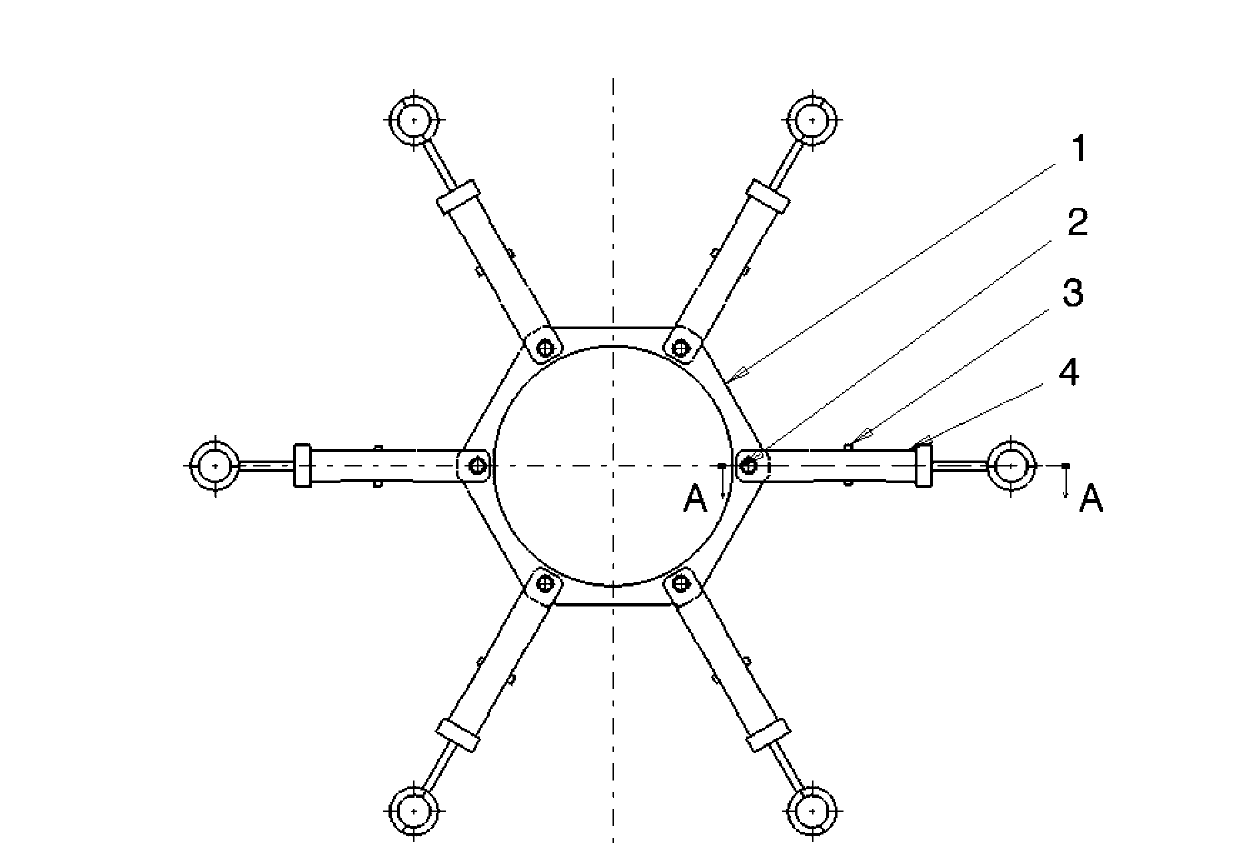

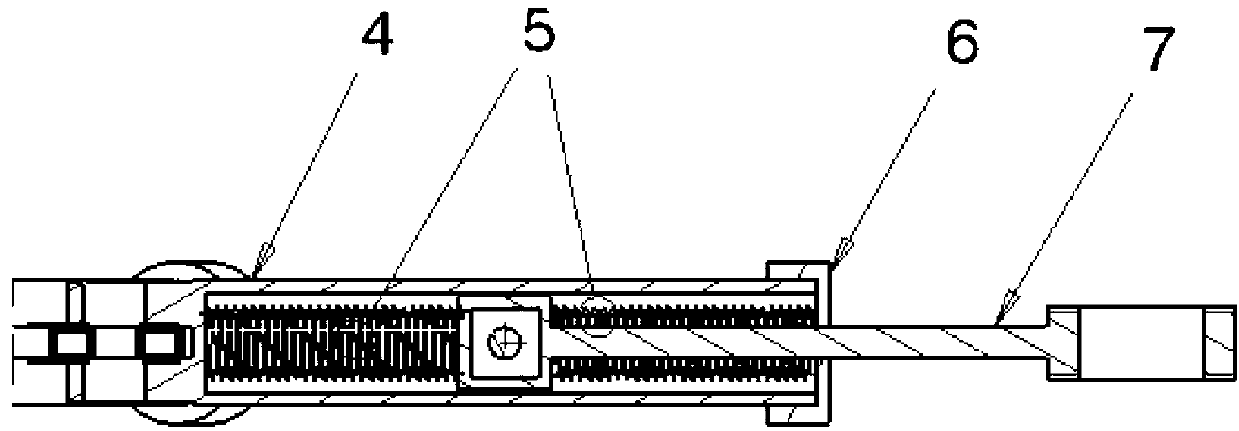

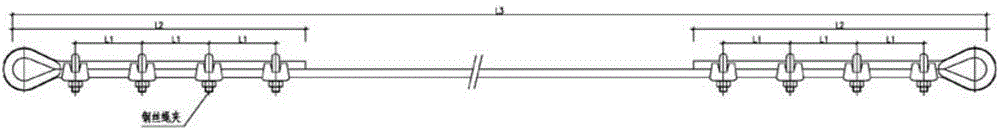

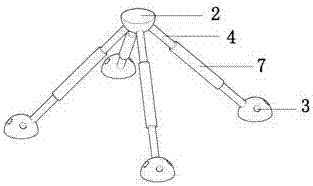

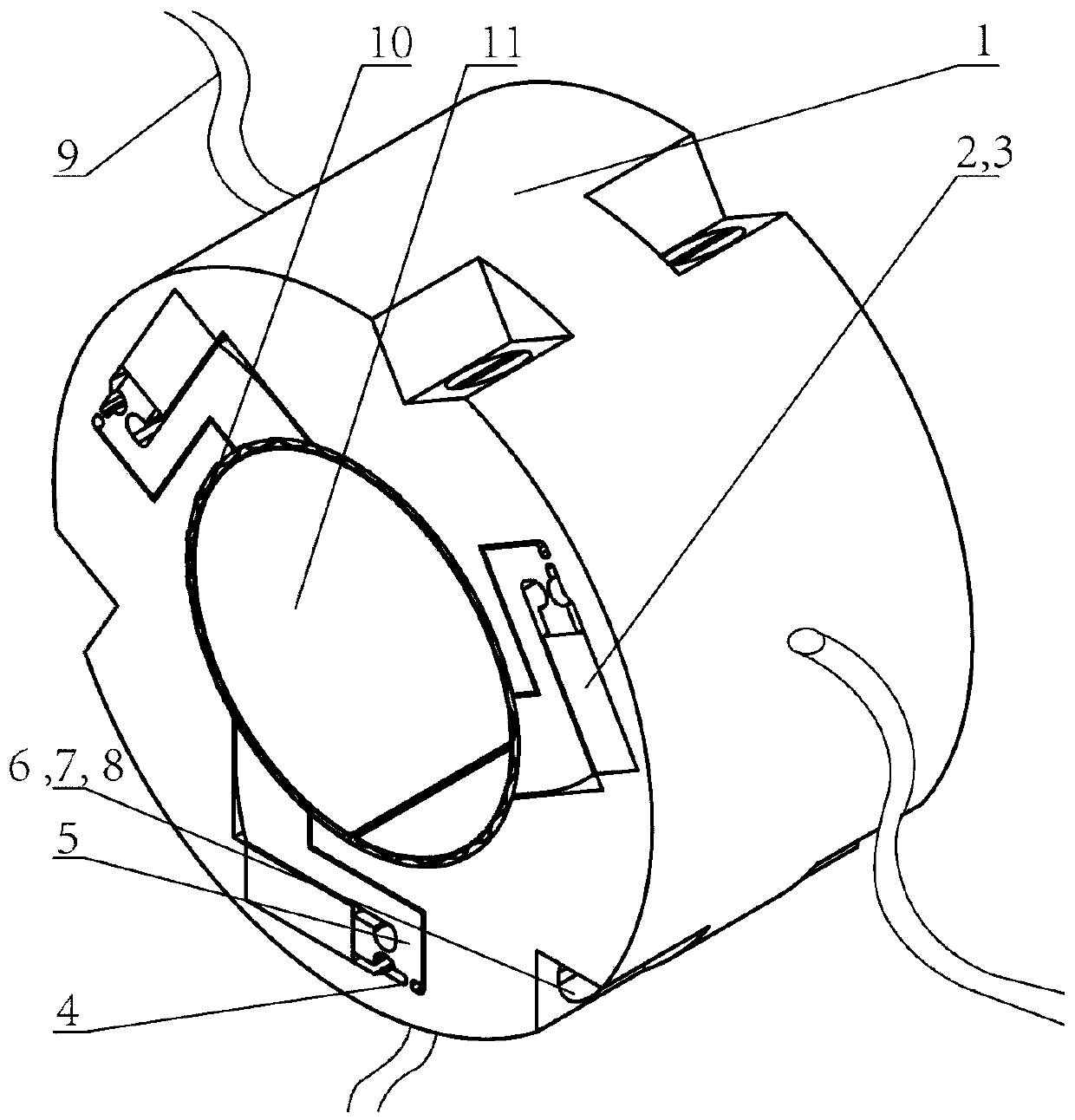

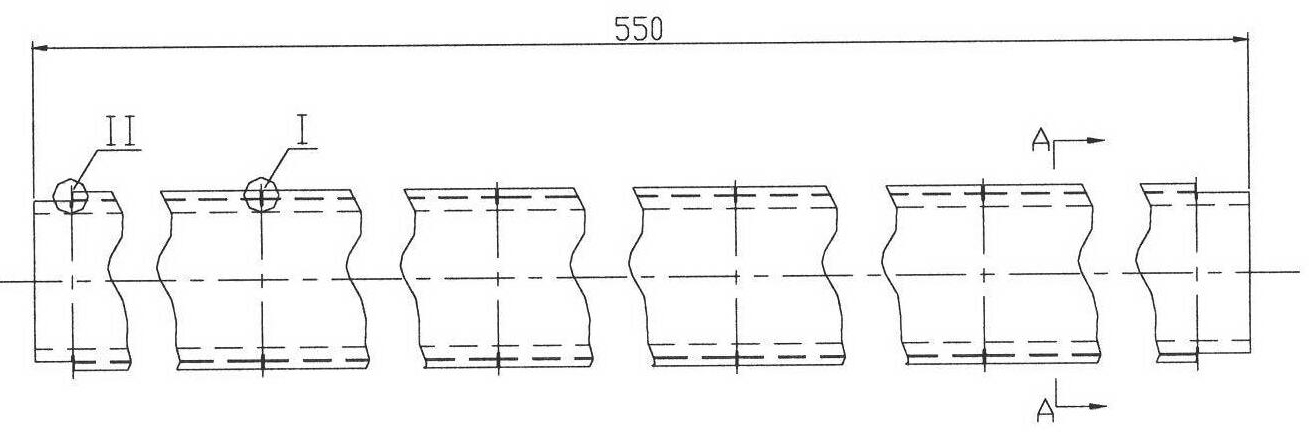

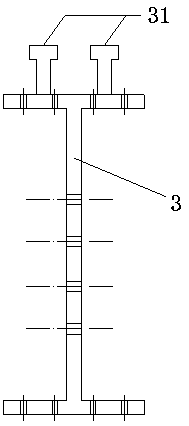

Rotary efficient damping anti-galloping spacer with wire clamps

InactiveCN103001163AIncrease structural dampingEffective absorption of vibration energyMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsEngineeringMechanical engineering

The invention belongs to the technical field of safety protection for overhead power transmission lines, and particularly relates to a rotary efficient damping anti-galloping spacer with wire clamps. The anti-galloping spacer comprises a spacer body frame. The spacer body frame is of a regular polygon structure or a line structure, and a rotatable sleeve is connected to each of vertex angles or two ends of the spacer body frame; a slide groove is arranged in each sleeve, an end cover with a hole is fixedly connected to a free end of each sleeve, the wire clamps are mounted in the sleeves, and one end of each wire clamp is matched with the corresponding slide groove via a slider; springs are respectively mounted in each sleeve and are positioned on two sides of the slider of the corresponding wire clamp; and the sliders of the wire clamps are hollow, and a short pin is arranged in each slider and is fixedly connected with the corresponding sleeve. The anti-galloping spacer has the advantages that unevenness of icing can be eliminated or reduced via swinging of the rotary wire clamps; and as vibration damping is improved, vibration energy generated by wind excitation can be effectively absorbed, galloping occurring conditions are destroyed, and galloping is stopped.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Metal corrugated-metal rubber composite material and preparation method thereof

InactiveCN106808759AImprove performanceEasy to combine structureLamination ancillary operationsLaminationMetal rubberAdhesive

The invention discloses a metal corrugated-metal rubber composite material and a preparation method thereof. A matrix metal corrugated material and stamped type metal rubber are adhered together through adhesives to obtain a multifunctional composite porous material, and preparation of the metal corrugated-metal rubber composite material is realized; the metal corrugated-metal rubber composite material has wide application prospect in fields of transportation, mechanical manufacture and military, structural damping can be effectively increased, nonlinear and variable damping properties are achieved, earthquake, vibration and sound absorption of the structure can be improved, and high strength, high rigidity and excellent damping performance in machine-building industry can be exerted; in addition, the composite porous composite material has the advantages of total environmental adaptability, corrosion resistance, high-and low-temperature resistance, no ageing, vacuum non-volatilization and the like and is light, simple in manufacture, low in cost and long in service life.

Owner:XI AN JIAOTONG UNIV

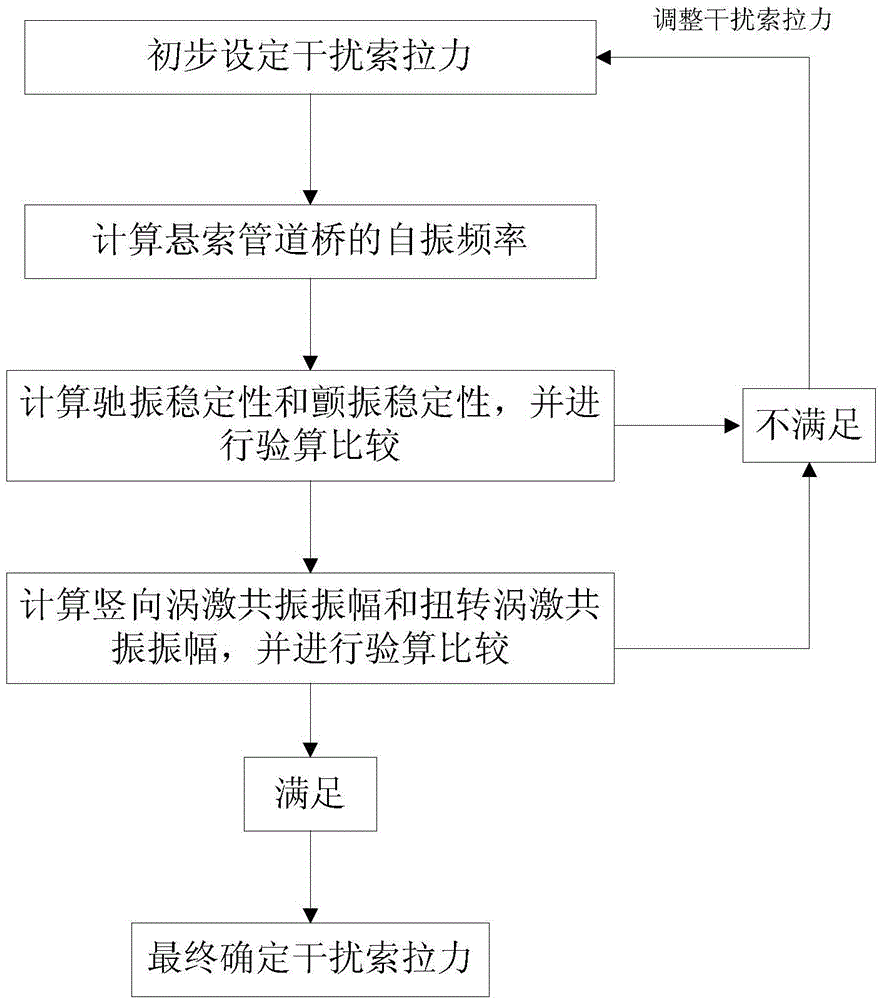

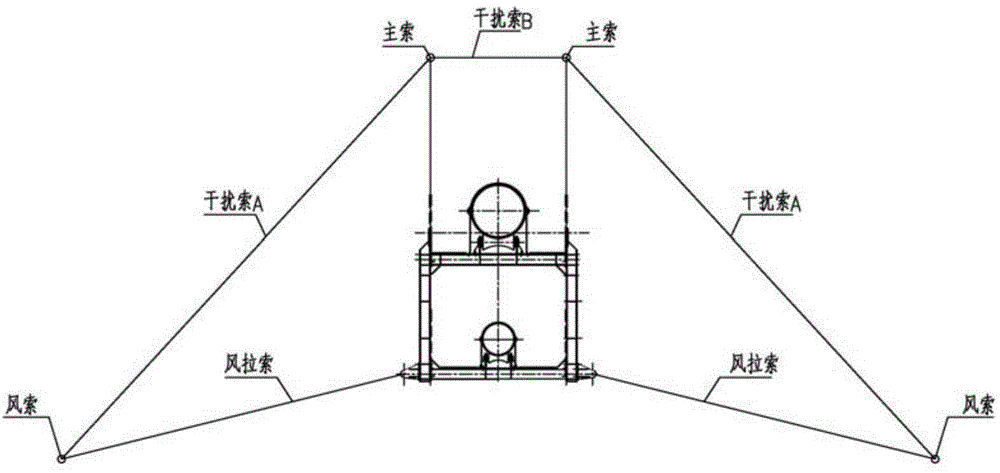

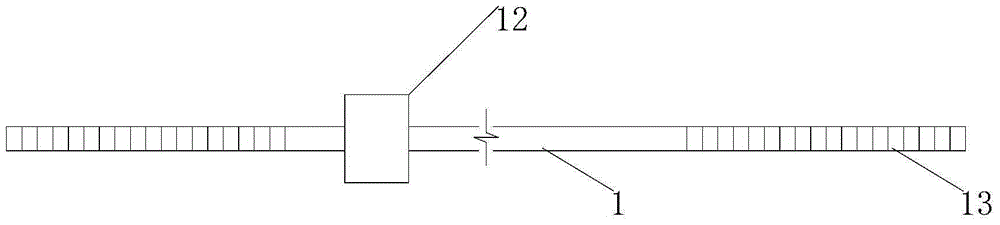

Long-span pipeline suspension bridge wind resisting method

ActiveCN104818665ARaise the natural frequencyAvoid divergent self-excited vibrationsBridge applicationsSuspension bridgeElement modelResonance amplitude

The invention relates to a long-span pipeline suspension bridge wind resisting method and belongs to the field of pipeline bridge wind resisting. The method comprises the following steps of, firstly, establishing a finite element model of a pipeline suspension bridge with interference cables, wherein the interference cables connect the main cables and the wind cables of the pipeline suspension bridge, and preliminarily setting the tension of the interference cables; secondly, calculating the natural vibration frequency of the pipeline suspension bridge; thirdly, according to the natural vibration frequency, calculating the galloping stability and the flutter stability and performing calculation comparison, and if Vcg>=1.2Vd and Vcr>=1.2 mu fVd, executing the fourth step, or, returning to the first step; fourthly, according to the natural vibration frequency, calculating the vertical vortex-induced resonance amplitude and the torsional vortex-induced resonance amplitude and performing calculation comparison, and if A, executing the fifth step, or, return the first step; fifthly, by means of the steps above, continuously adjusting the tension of the interference cables and finally determining the tension of the interference cables. The long-span pipeline suspension bridge wind resisting method can improve the wind resisting safety of the long-span pipeline suspension bridge.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

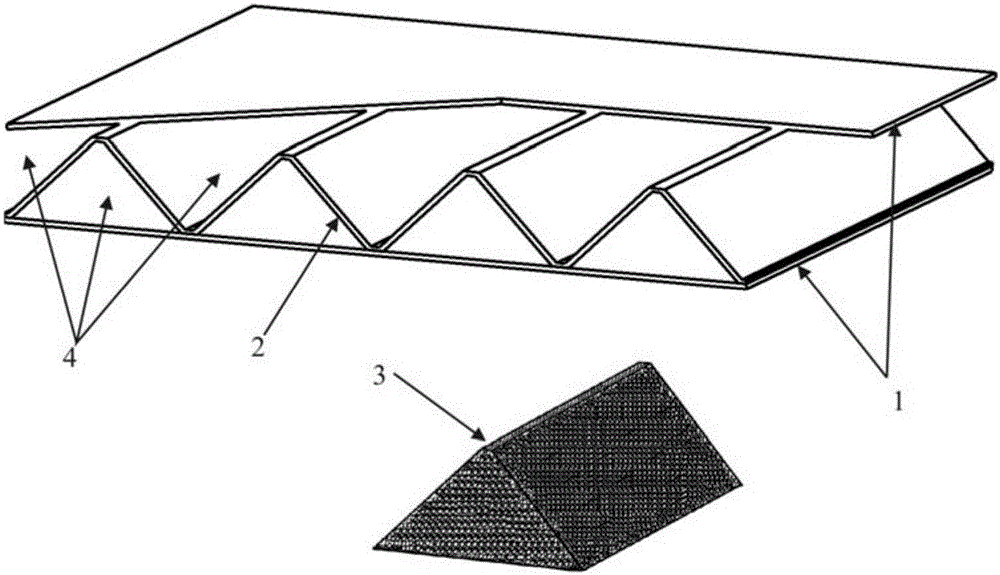

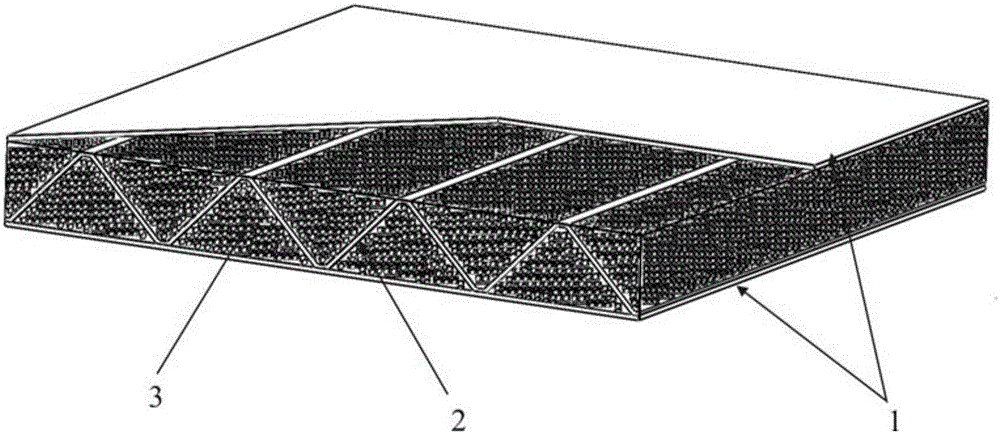

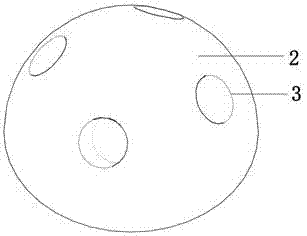

Telescopic type flexible rectangular pyramid sandwich structure for underwater explosion energy dissipation

InactiveCN106969678AHigh specific strengthImprove mechanical propertiesBlastingUnderwater explosionNetwork structure

The invention discloses a telescopic type flexible rectangular pyramid sandwich structure for underwater explosion energy dissipation. The structure is characterized by comprising two metal panels, multiple semispherical nodes arranged on the opposite surfaces of the two metal panels and sandwich rods. The semispherical nodes are steel hemispheres. The spherical face of each semispherical node is provided with four symmetrical connection points. One ends of the four sandwich rods are connected with the connection points on one semispherical node on one metal panel, and a rectangular pyramid unit with the semispherical node as the vertex is formed. The other ends of the four sandwich rods are connected with the connection points on the four semispherical nodes on the other opposite metal panel, and the four semispherical nodes on the other opposite metal panel are used as new vertexes to form a new rectangular pyramid unit with the other three sandwich rods. The operation is cycled and repeated till a rectangular pyramid network structure is formed between the two metal panels. According to the telescopic type flexible rectangular pyramid sandwich structure, the structure is simple and stable, and the damping and shock resistance are greatly improved through the simple structure.

Owner:WUHAN UNIV

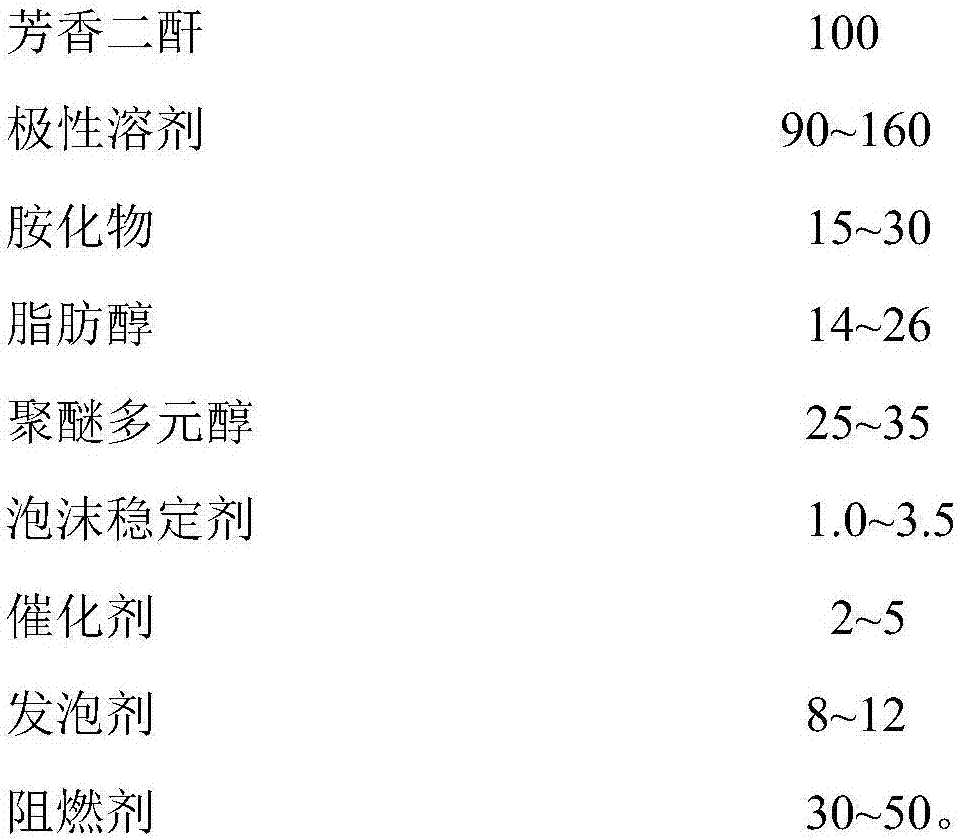

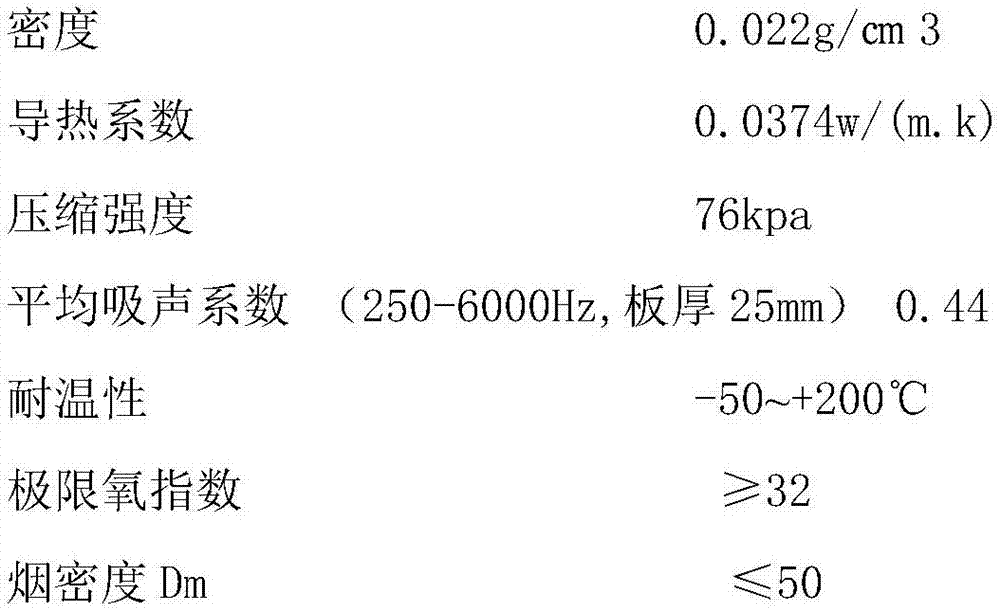

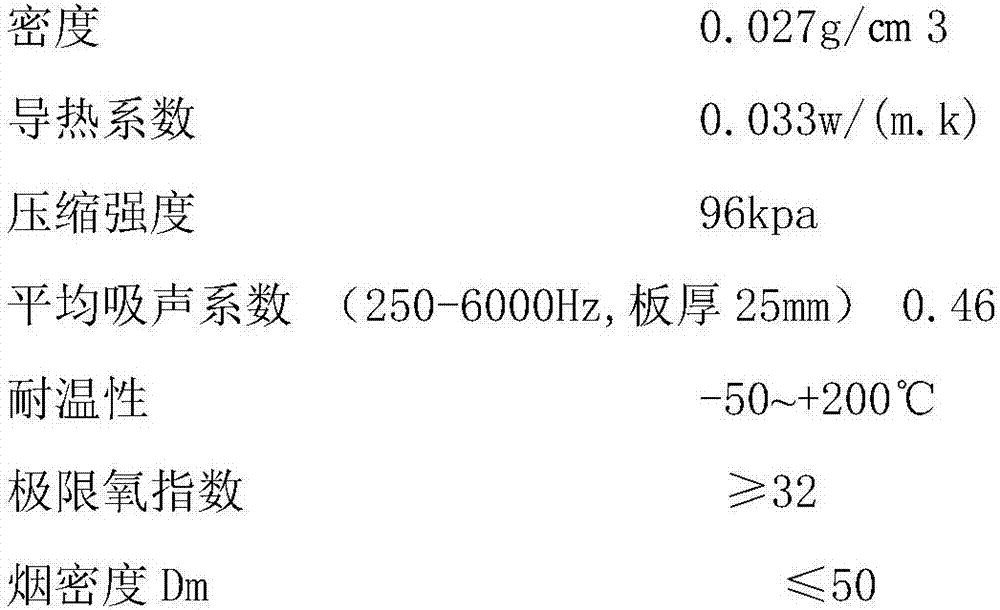

Sound-absorbing damping foam core sandwich composite material, and manufacturing method thereof

InactiveCN106945375AImprove practicalityLow densitySynthetic resin layered productsGlass fiberPolyurethane elastomer

The invention discloses a sound-absorbing damping foam core sandwich composite material, and a manufacturing method thereof. The sound-absorbing damping foam core sandwich composite material is composed of a core material, a surface material, and a damping coating layer; the core material is an open-cell polyurethane-polyimide foam board; the surface material is a flame-retardant glass fibre cloth coated with a waterproof polyurethane inner cabin coating; and the damping coating layer is polyether polyurethane elastomer. When the frequency ranges from 250 to 6000Hz, and the plate thickness is controlled to be 25mm, the average sound absorbing factor ranges from 0.42 to 0.46, the limit oxygen index is 32 or higher, the smoke density Dm is 50 or lower, the free damping loss factor is 1.0 or higher, and a foam material layer is destroyed when bonding strength N / 25mm.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

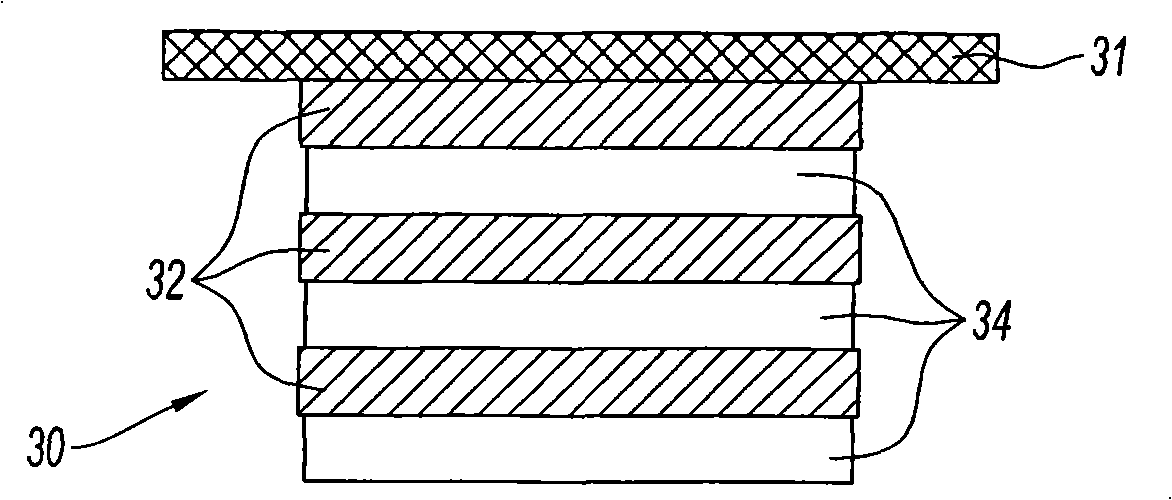

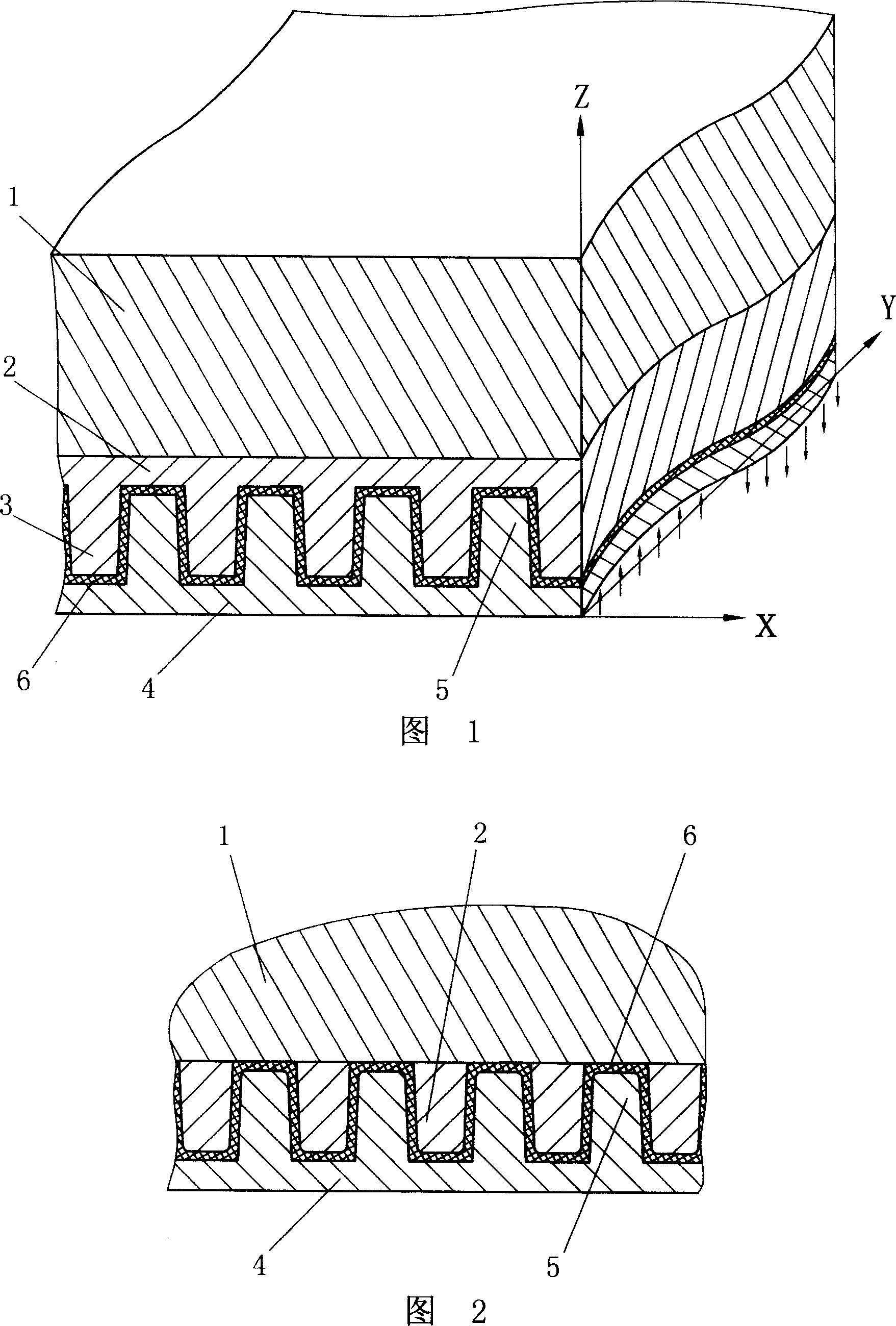

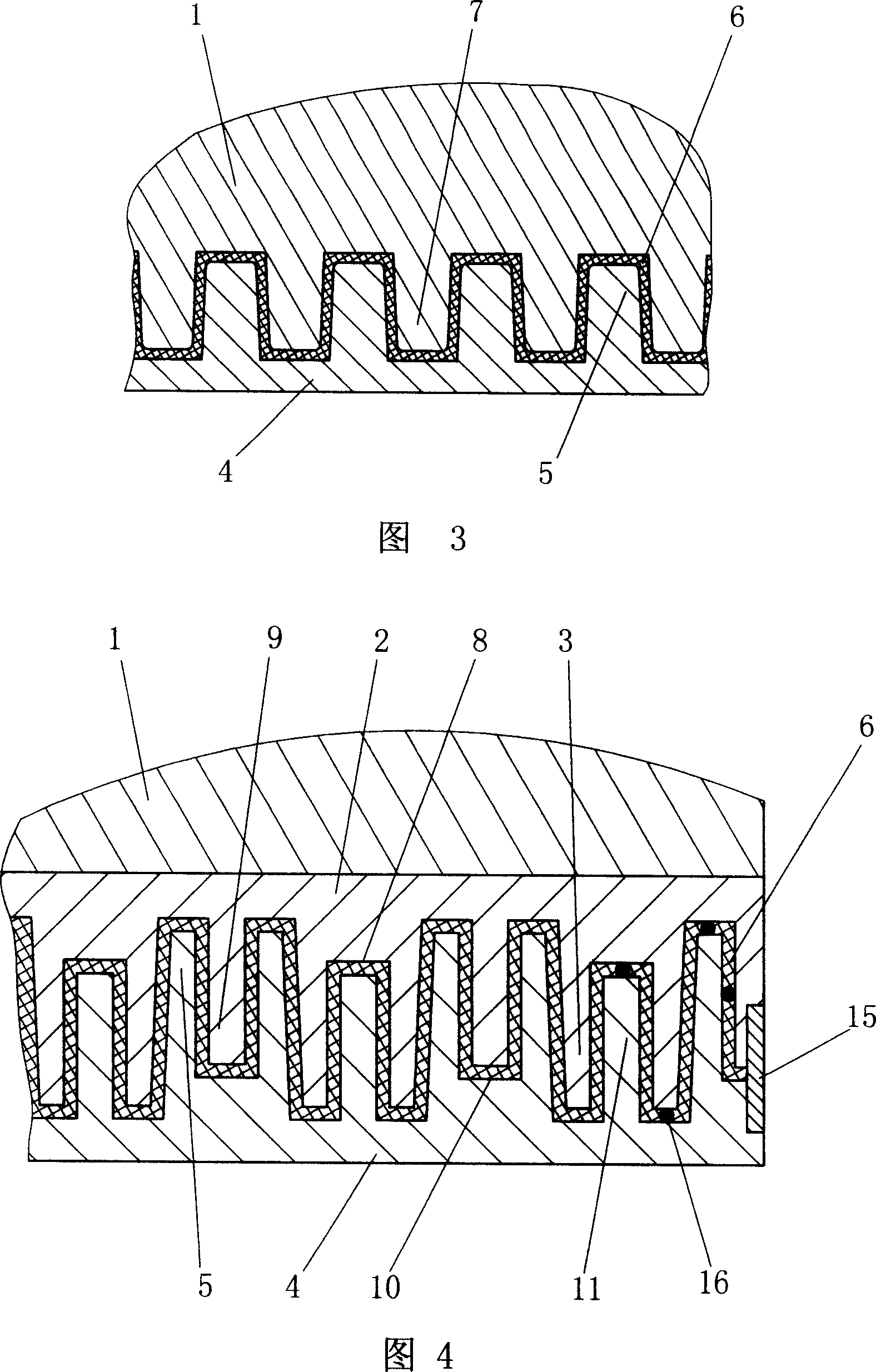

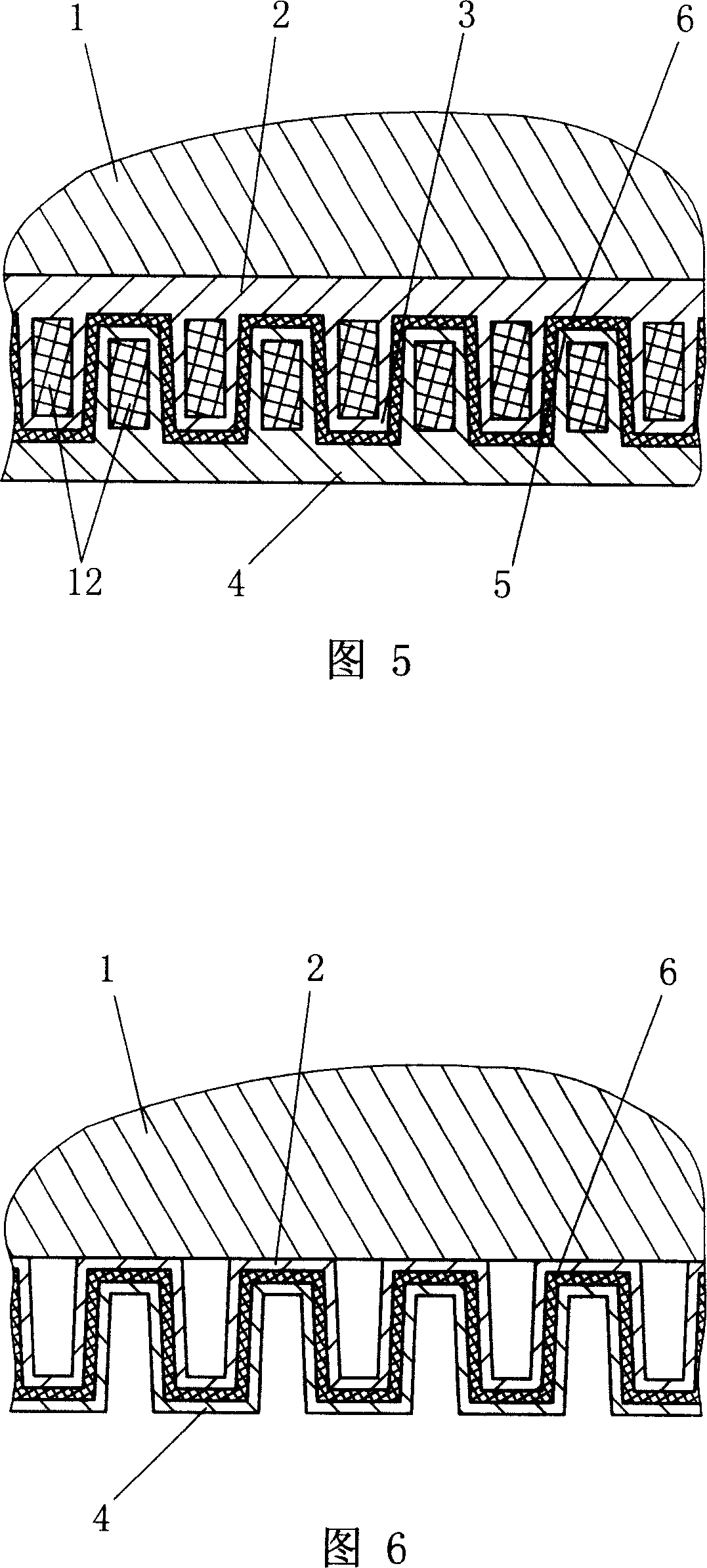

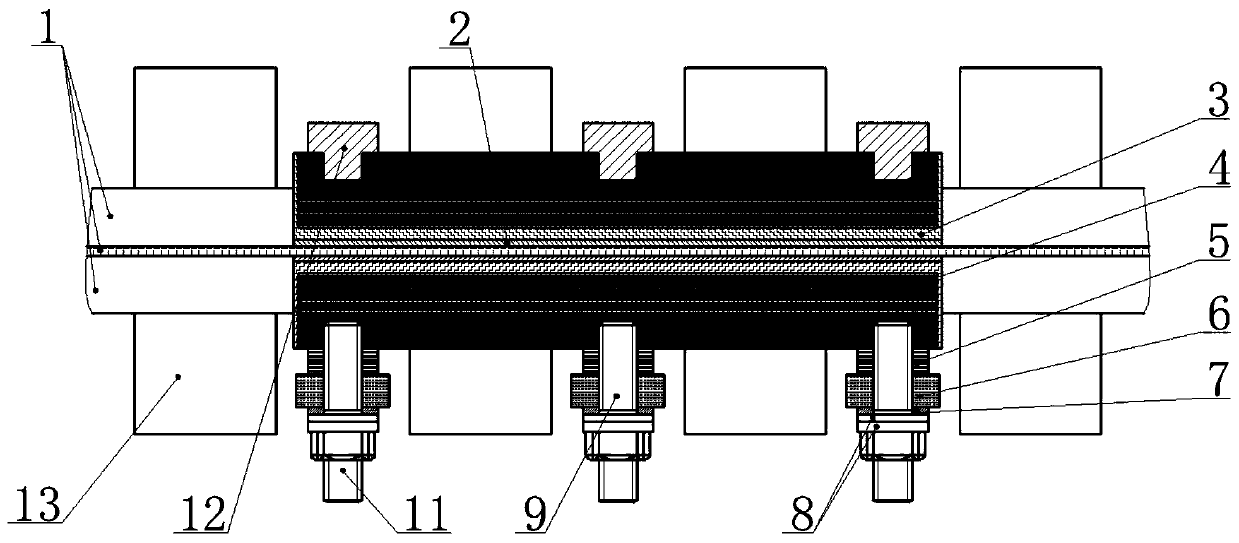

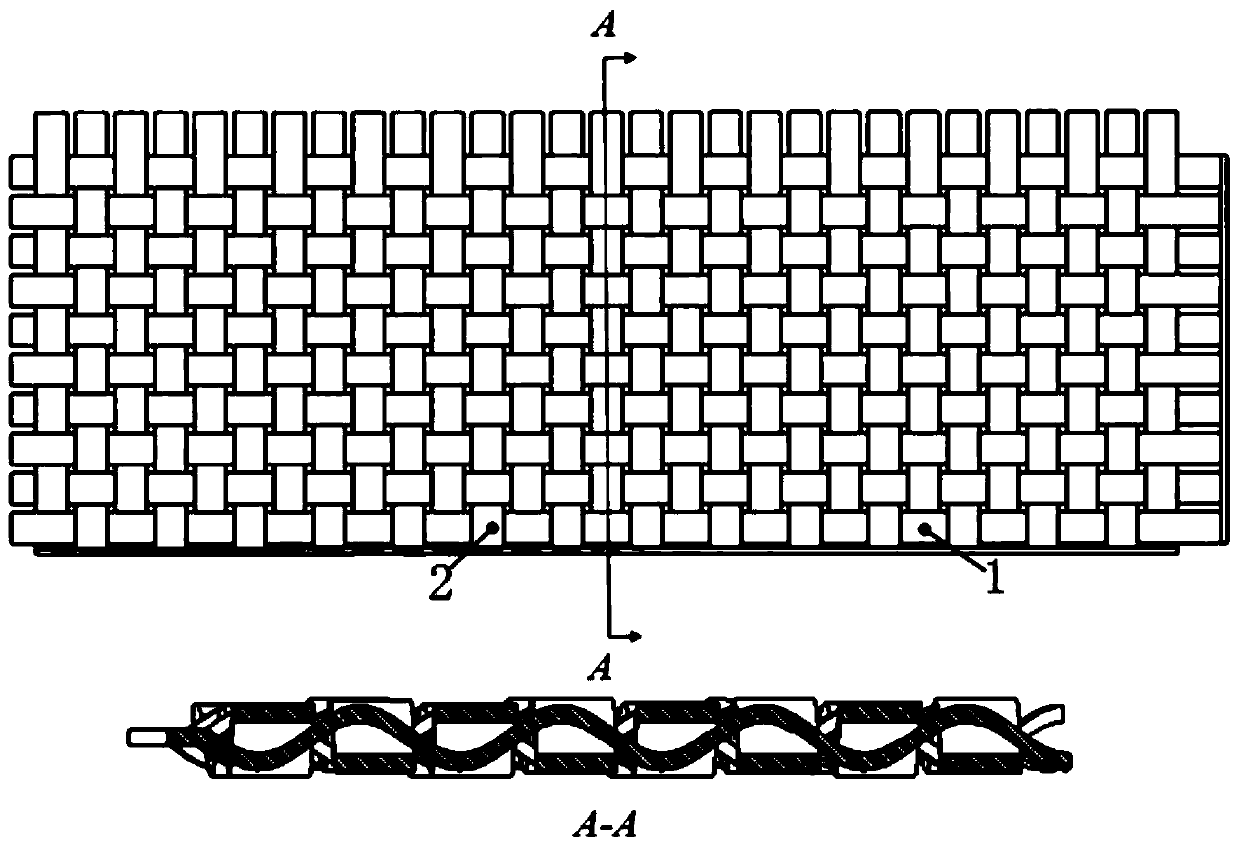

Damping structure and composite material

ActiveCN101101038AIncrease structural dampingIncrease contactLayered productsRubber-like material springsConvex structureNoise control

This invention relates to vibration and noise control field, especially structure which can increase common component self damping and composite material using this structure. The component surface is continuously or alternately fixed with connector with concavo convex structure. The connector and binding body with corresponding concavo convex structure are cooperated. There is damping material between connector and binding body. This invention greatly increases the contacted and working area between damping material and component as well as binding body. It also increases applied moment the damping action applied on component bend neutral plane and bend axes. Thus, this invention can increase structural damping of components.

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH

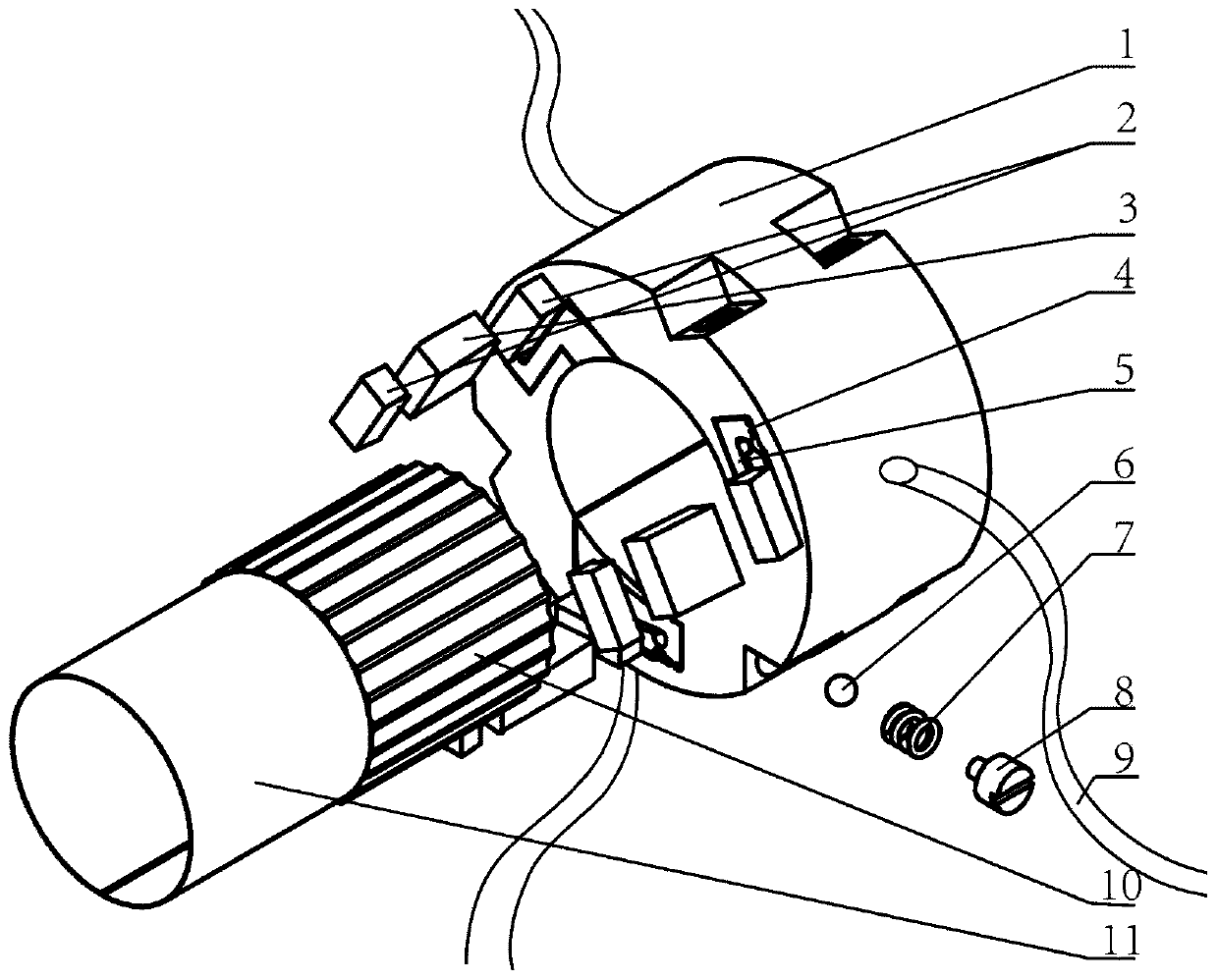

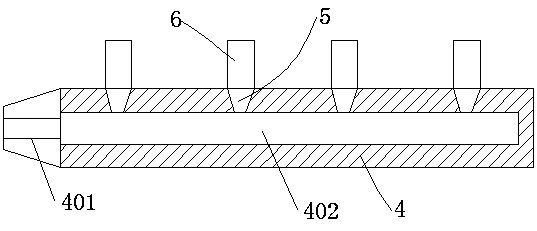

Novel active air foil bearing based on PZT and SMA

InactiveCN111457007AStable jobEnhance the dynamic pressure effectBearing componentsSliding contact bearingsEngineeringMechanical engineering

The invention discloses a novel active air foil bearing based on PZT and SMA. The novel active air foil bearing comprises a shaft sleeve, piezoelectric ceramics (PZT), a memory alloy wire mesh block (SMA block), flexible hinges, a rigid push rod, pre-pressure applying devices, a cooling pipe, a wave foil and a top foil; the PZT and the SMA block are installed in pre-machined through grooves, the corresponding pre-pressure applying devices are designed for the PZT and SMA block, the wave foil is formed by pressing an elastic material, one end of the wave foil is welded, and the other end of thewave foil is free. The top foil overlies the wave foil. Power supply signals of the PZT are controlled, the flexible hinges are coupled, PZT deformation is amplified, the wave foil is supported by the rigid push rod, the wedge-shaped space is enlarged, therefore, the crossed coupling effect is weakened, the dynamic pressure effect of the bearing is enhanced, and the rigidity characteristic of thebearing is improved; by controlling the temperature of the SMA block, the SMA block expands and contracts to generate larger structural damping, and the damping characteristic of the bearing is improved; and finally, the rigidity and damping characteristics of the bearing are actively controlled, and the stability of the system is improved.

Owner:HUNAN UNIV

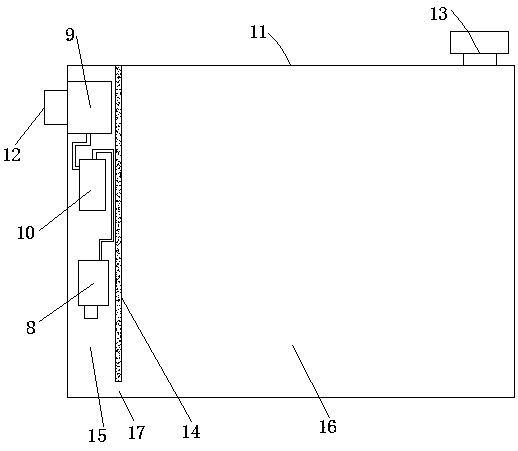

Cold-formed thin-walled steel-structure house outer wall structure system

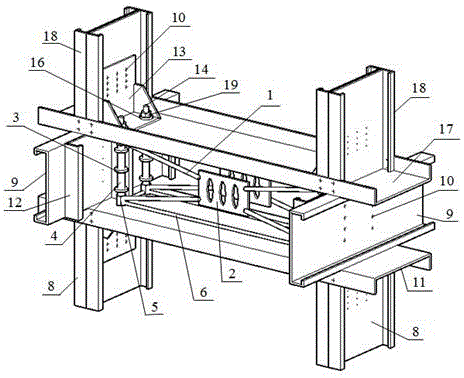

A cold-formed thin-walled steel-structure house outer wall structure system comprises beams and wall frame pillars, and the beams and the wall frame pillars are in cooperation with one another. The cold-formed thin-walled steel-structure house outer wall structure system is characterized in that the wall frame pillars comprise lower layer pillars (8) and upper layer pillars (18); the beams comprise floor beams (9), a top beam (11) and a bottom beam (17); the tops of the two adjacent lower layer pillars (8) are fixedly embedded in the top beam (11); pulling resistant pieces (13) are connected between the inner walls of the lower layer pillars (8) and the top beam (11), the floor beams (9) are fixed above the top beam (11), and the bottom beam (17) is fixed above the floor beams (9); the bottoms of the two adjacent upper layer pillars (18) are fixedly embedded in the bottom beam (17); pulling resistant pieces (13) are connected between the inner walls of the upper layer pillars (18) and the bottom beam (17); and a truss type strengthening part is installed between the top beam (11) and the bottom beam (17), and the truss type strengthening part is fixed to the top beam (11) and the bottom beam (17) through spacers (16) and nuts (19) after pulling resistant anchor bolts (14) penetrate through bolt holes (15), the top beam (11), steel sleeves (4) and the bottom beam (17).

Owner:SOUTHWEAT UNIV OF SCI & TECH

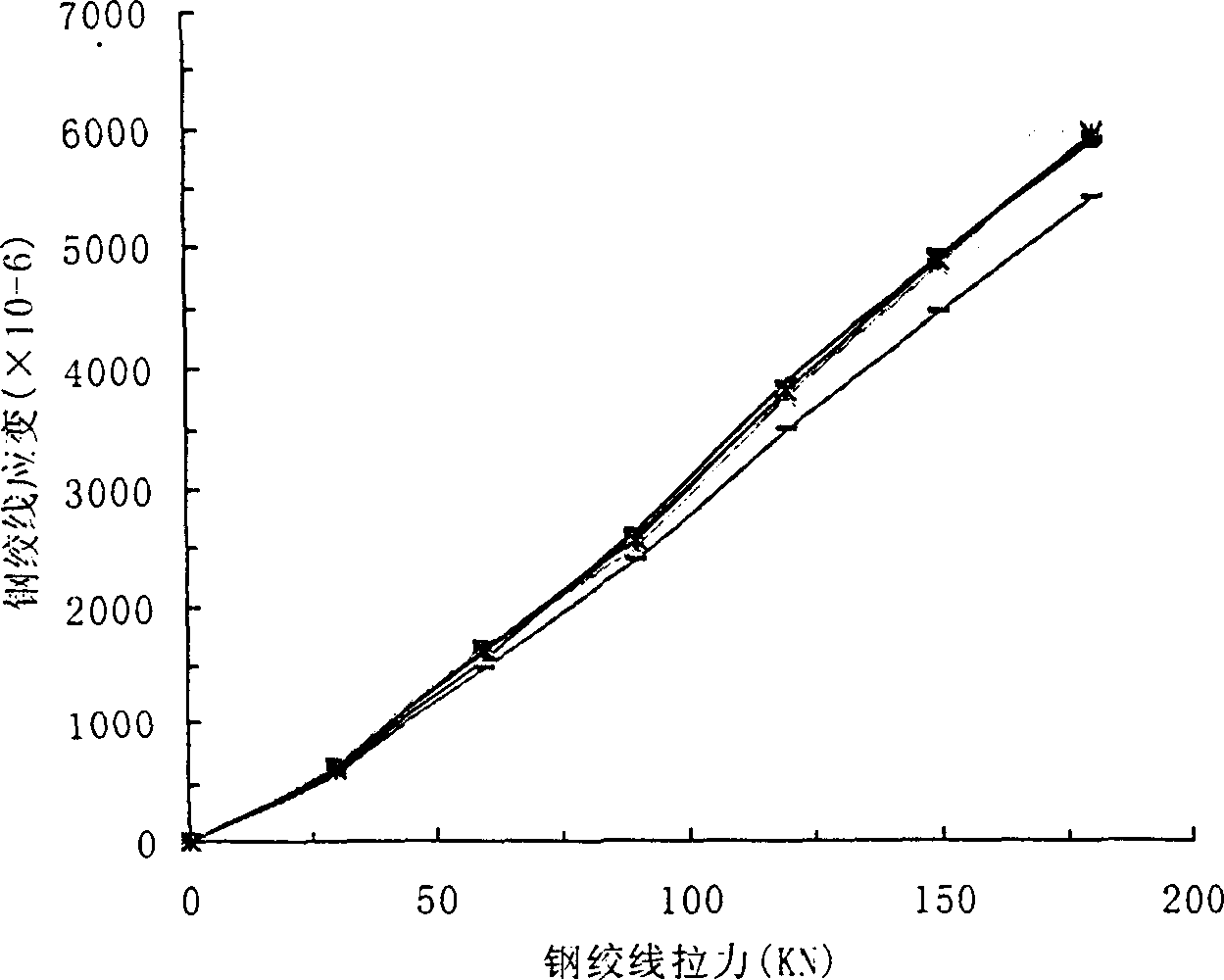

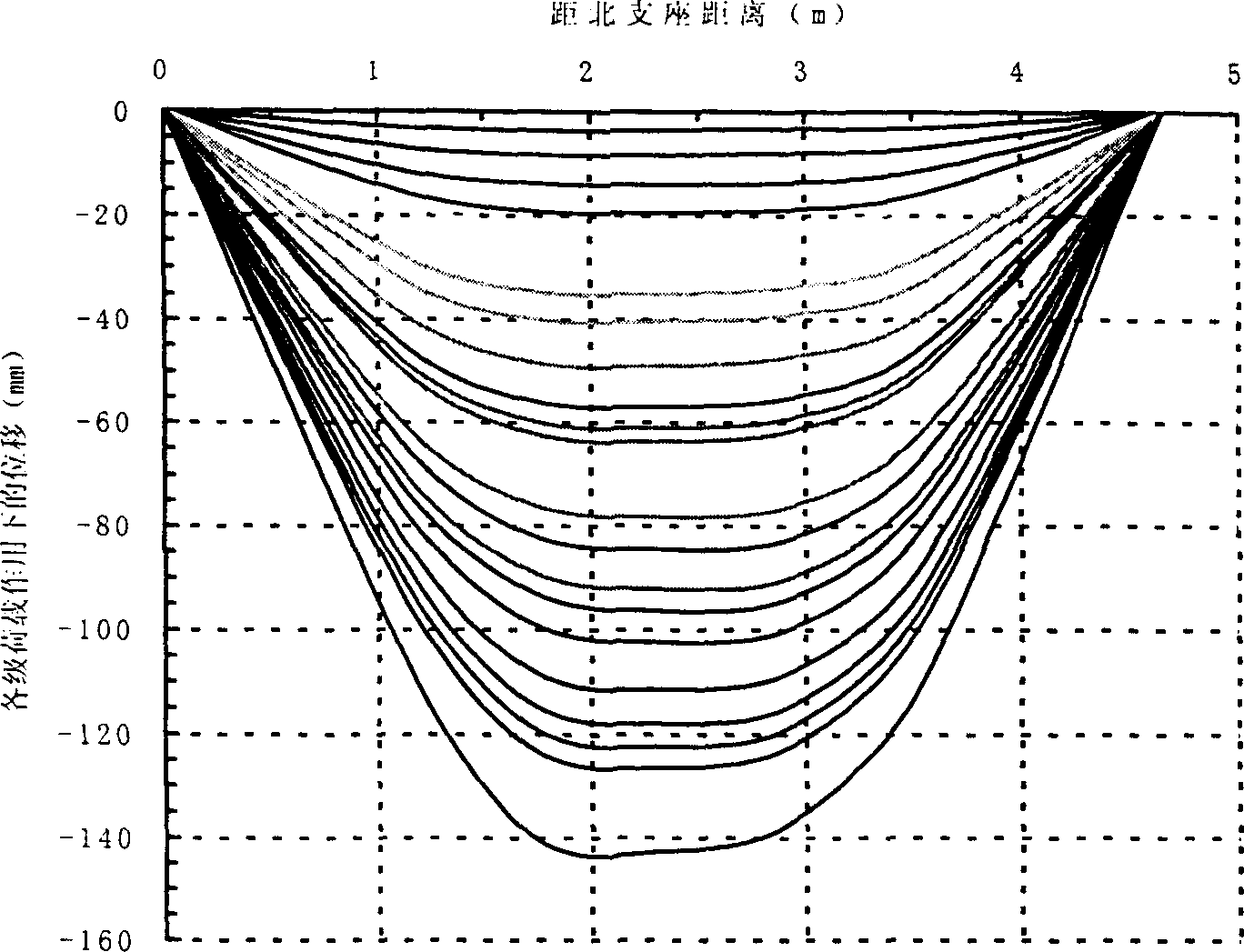

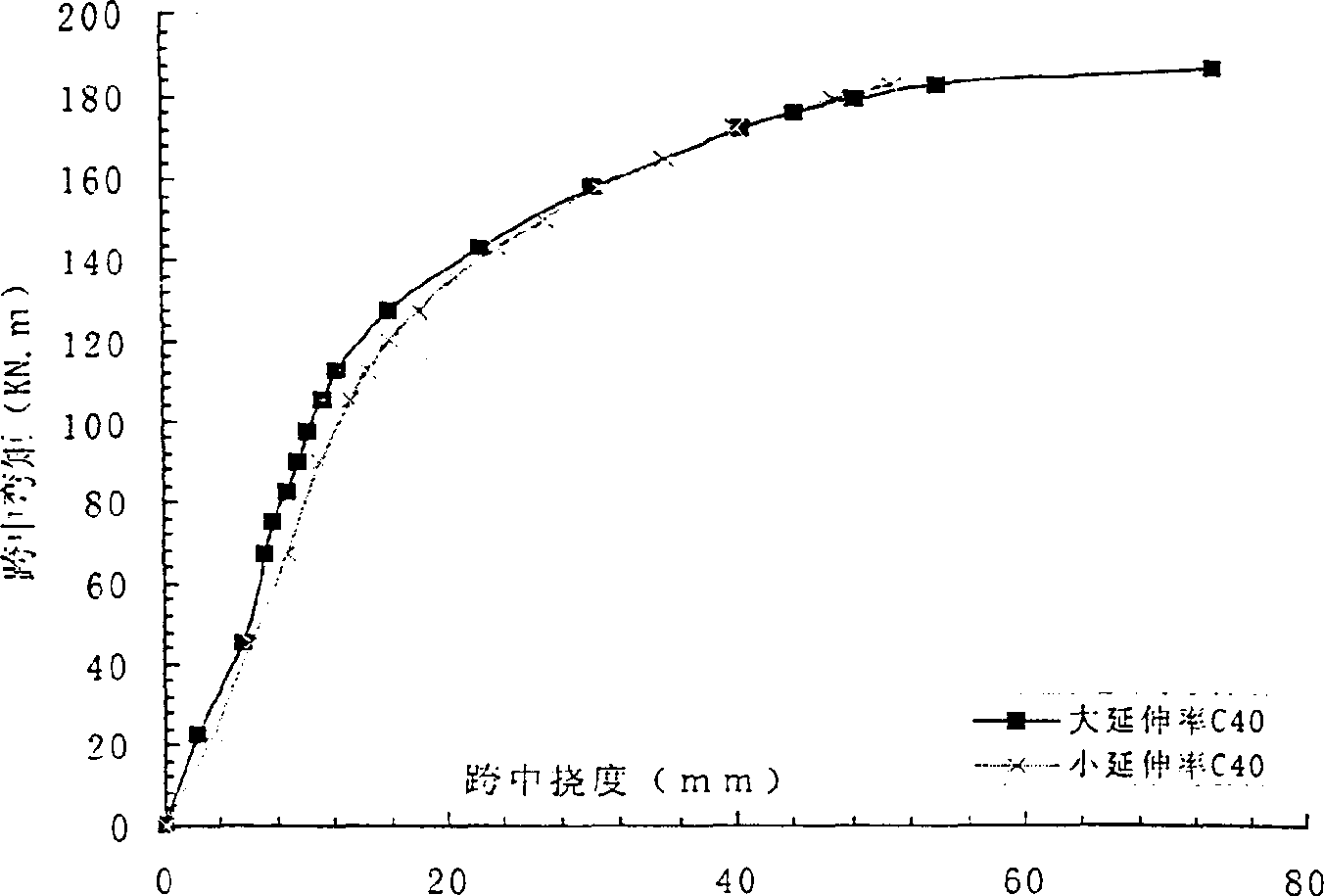

Ductile prestressed concrete structure component and its production method

InactiveCN1395012AImprove ductilityImprove securityCeramic shaping apparatusBridgesPre stressCompressive strength

The present invention discloses a ductile prestressed concrete structural member and its production method. Said member includes concrete and prestressed reinforcement, the described concrete compression strength is greater than 60MPa, and the described prestressed reinforcement is prestressed stranded wire, its strength is greater than or equal to 1860 MPa, its relaxation rate is less than or equal to 2.5% and percentage elongation is greater than or equal to 5%. The bending deflection ductility ratio of the prestressed concrete structure meeting the above-mentioned technological parameters is greater than 3.0, and said prestressed concrete structure is superior to general concrete structure in ductility.

Owner:王用中 +3

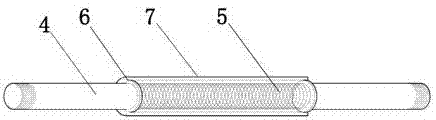

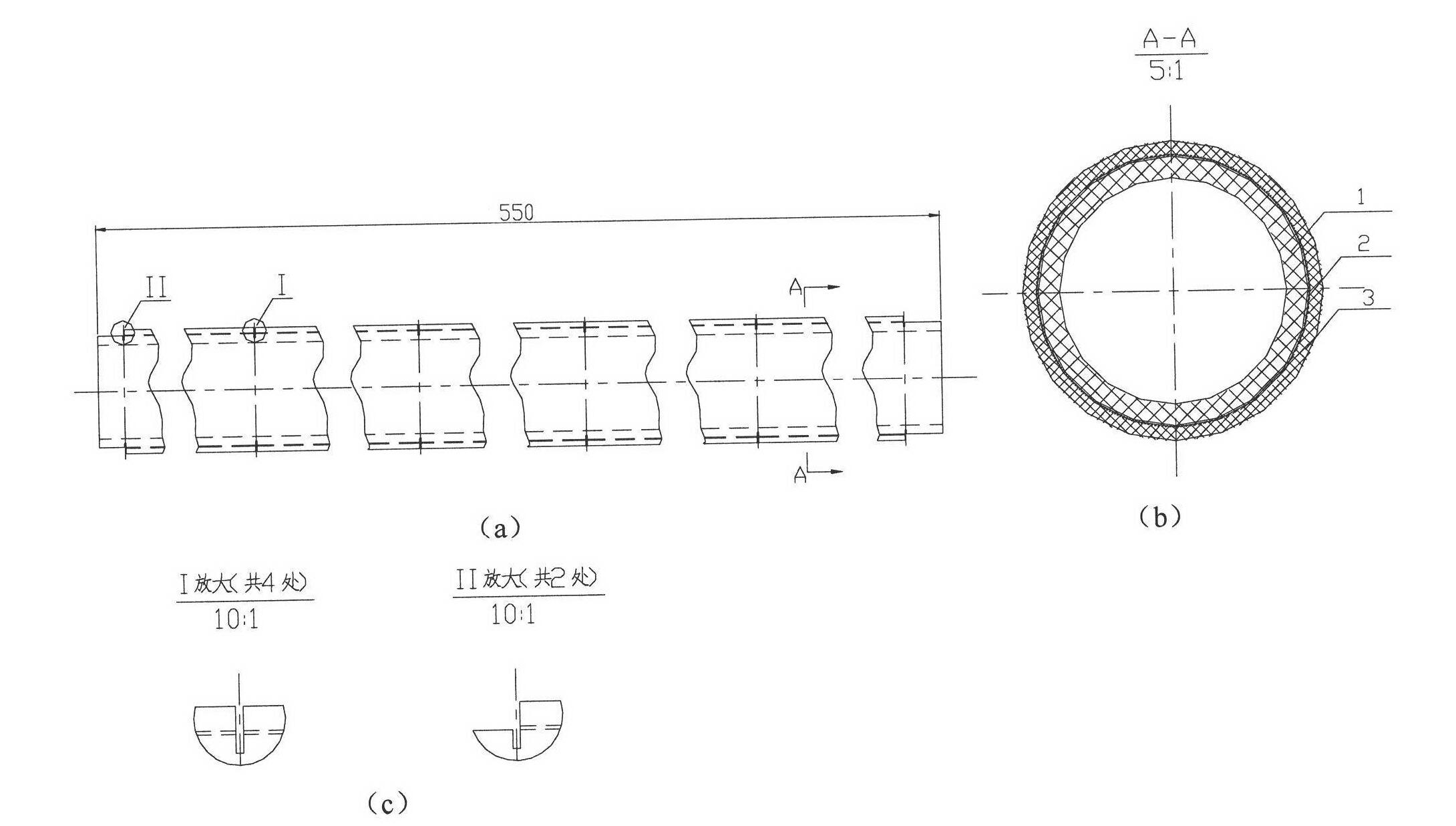

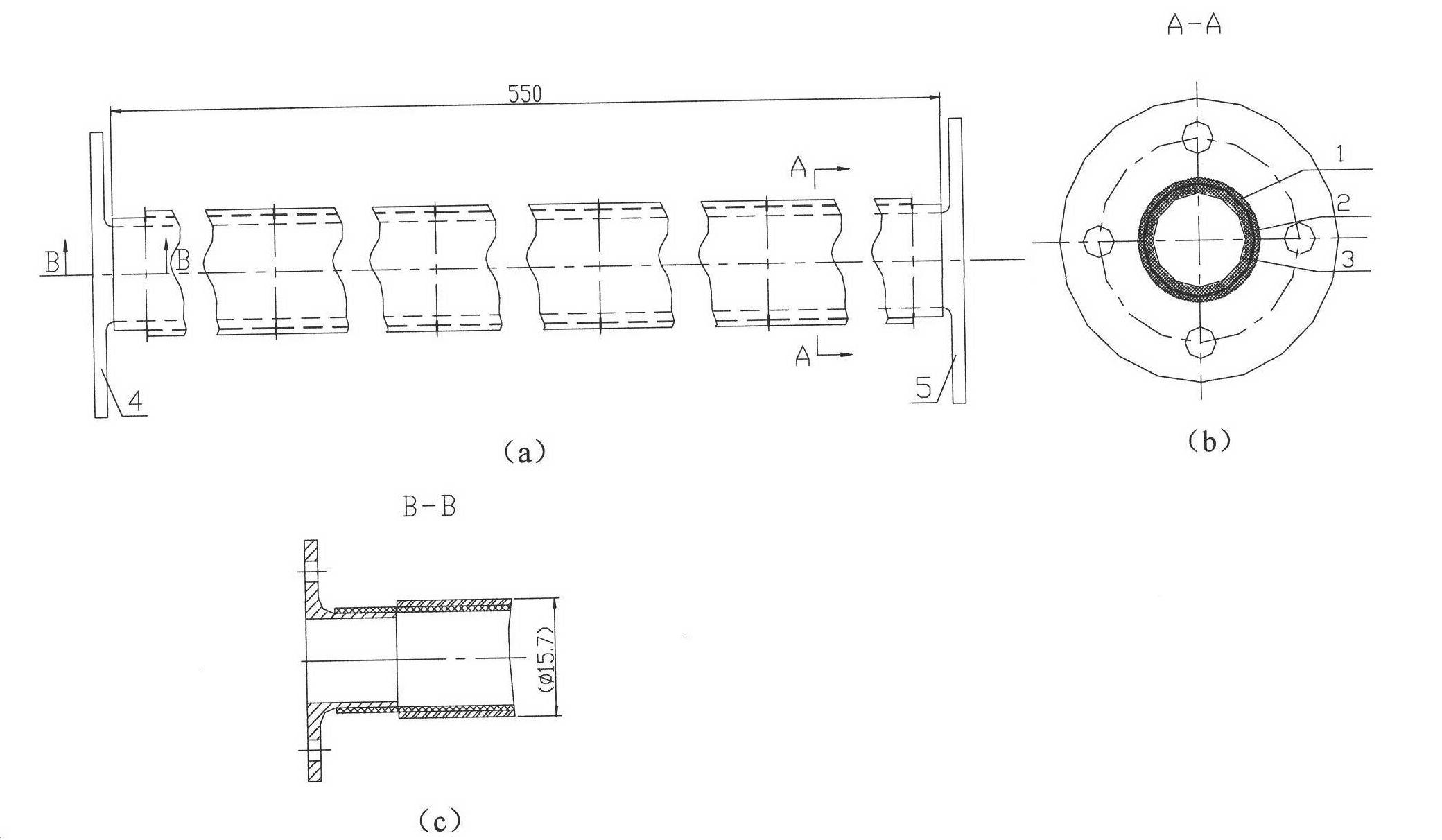

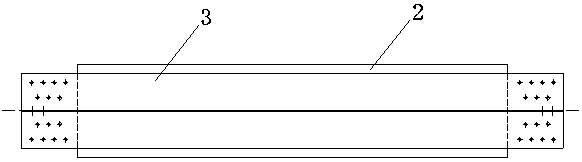

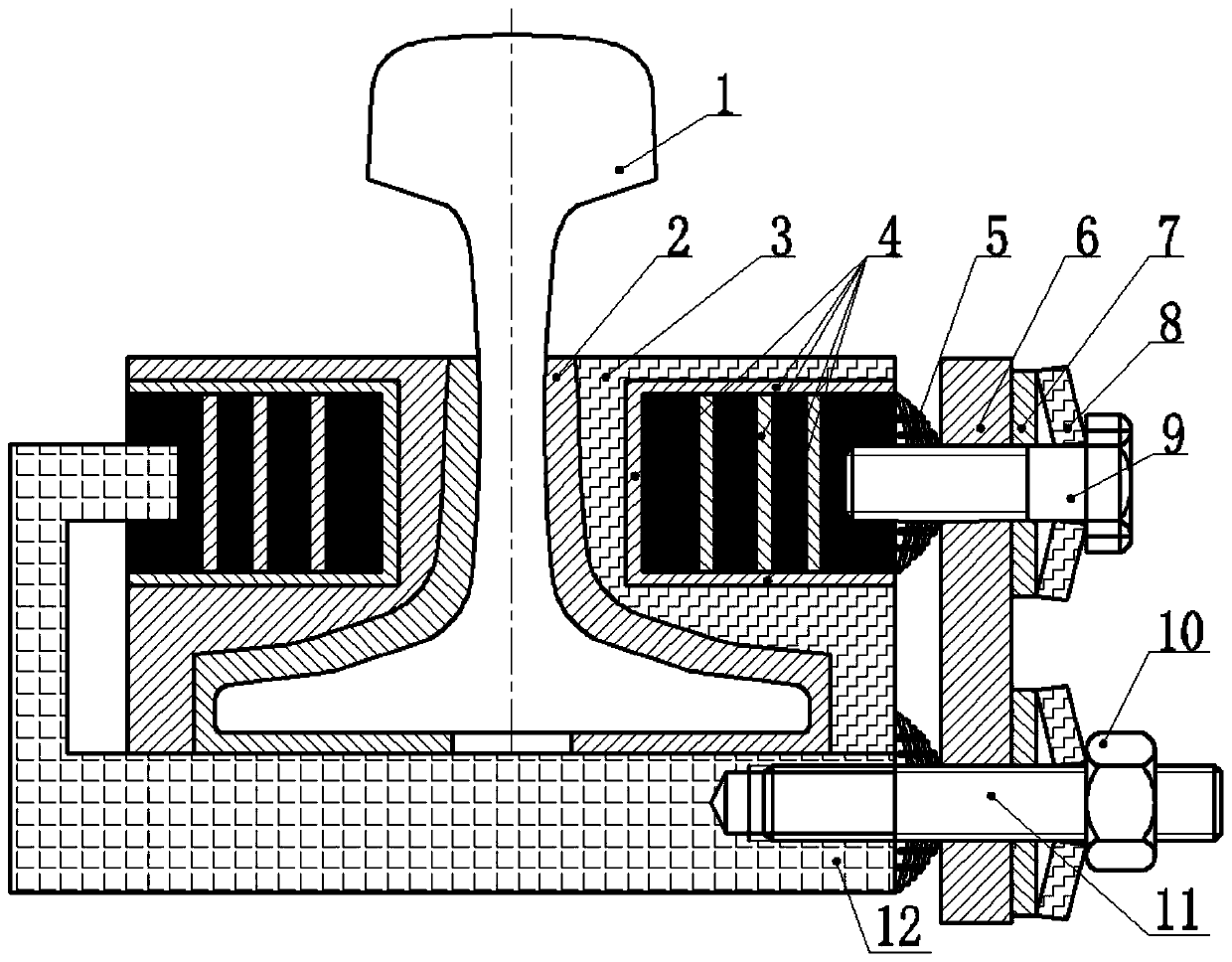

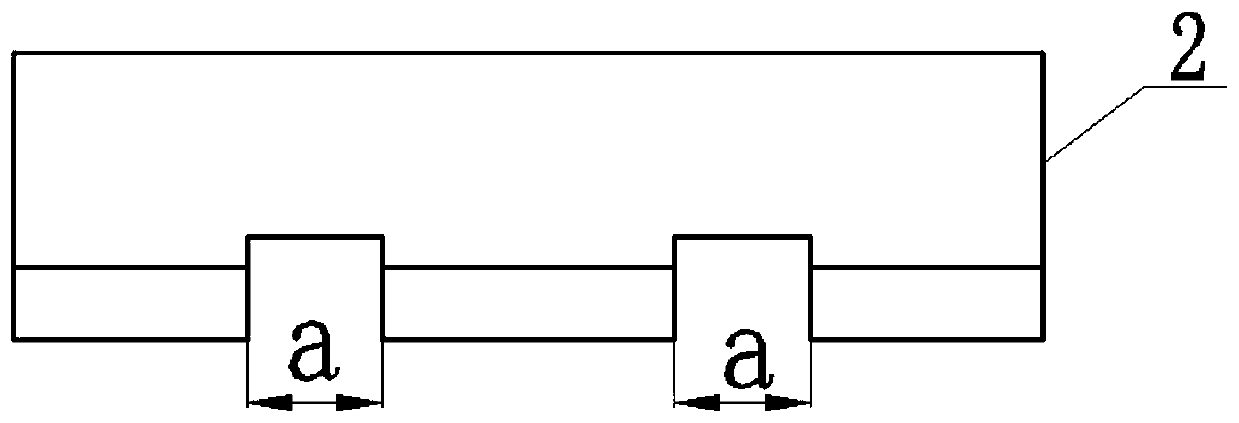

Composite material viscoelastic damping rod

ActiveCN102322493AGuaranteed axial strengthIncreased axial dampingSynthetic resin layered productsRubber-like material springsRubber materialViscoelastic damping

The invention relates to a composite material viscoelastic damping rod which comprises mounting flanges at two ends and an intermediate rod between the mounting flanges, wherein the intermediate rod comprises three layers which are a rod body (1), a viscoelastic damping layer (2) and a restraint layer (3) of T series high-intensity carbon fiber composite materials from inside to outside sequentially, and the length of the intermediate rod is 200-1000mm; a damping rubber material with the dissipation factor greater than 1 is selected for the viscoelastic damping layer (2) to be pasted to the outer part of the rod body (1); M series high-modulus carbon fiber composite materials are selected for the restraint layer (3), and the damping layer (2) and the restraint layer (3) are molded by adopting a co-curing technology; and the intermediate section is divided through opening a U-shaped groove out of the restraint layer (3), and the number of the sections of the intermediate rod at the length direction is 3-12.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

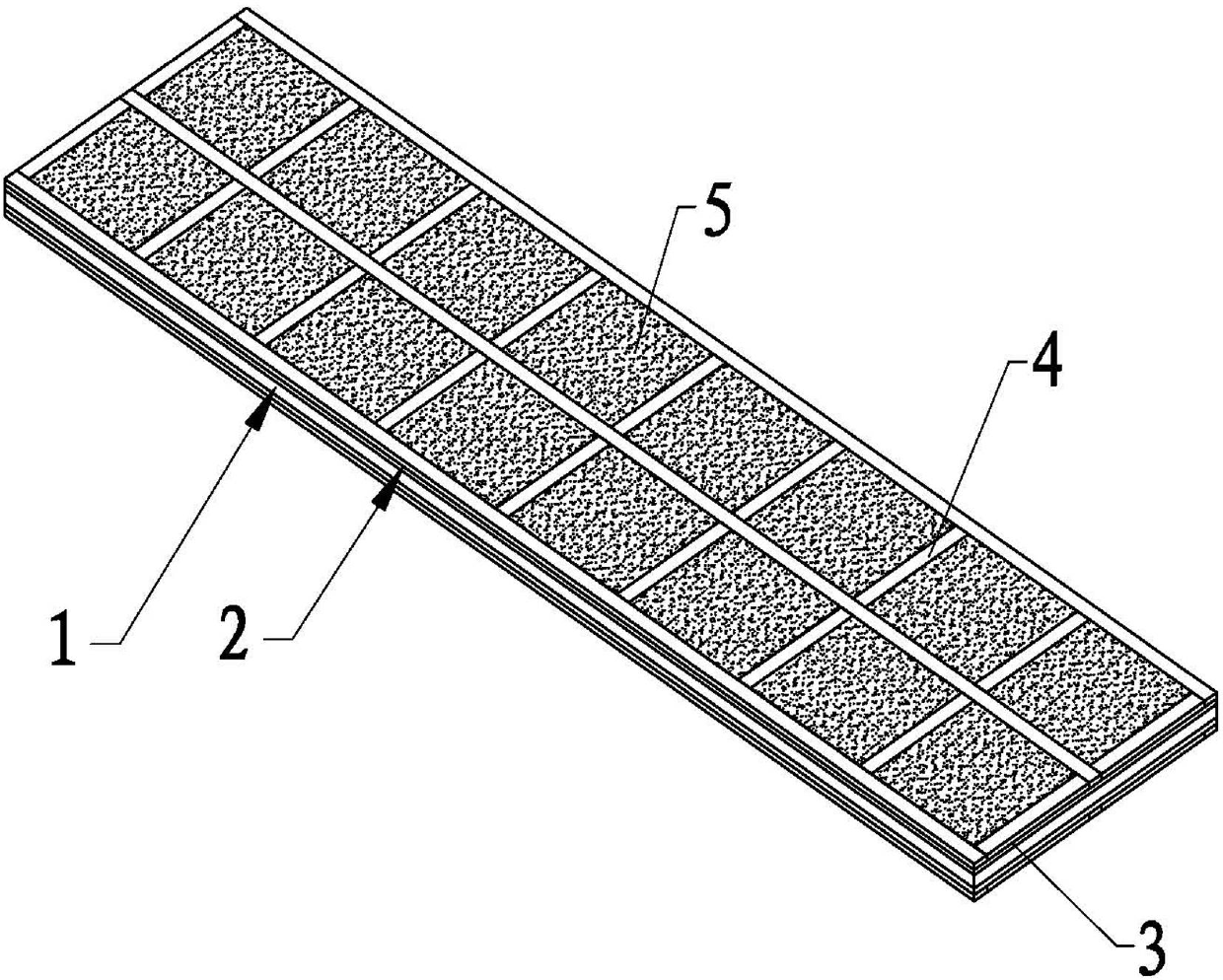

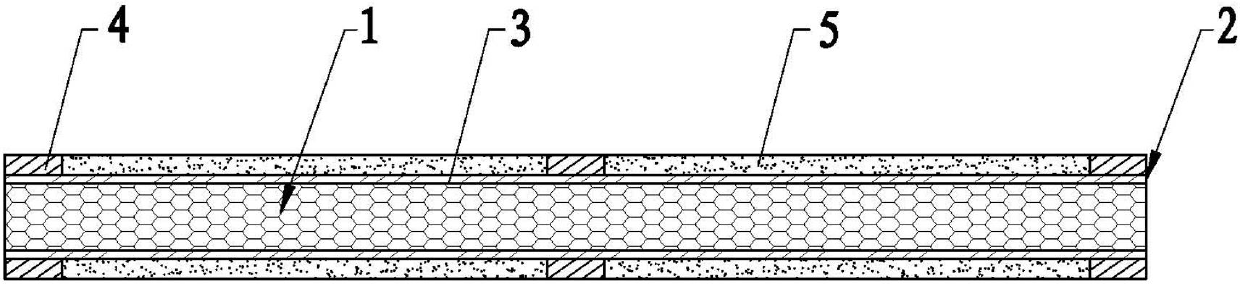

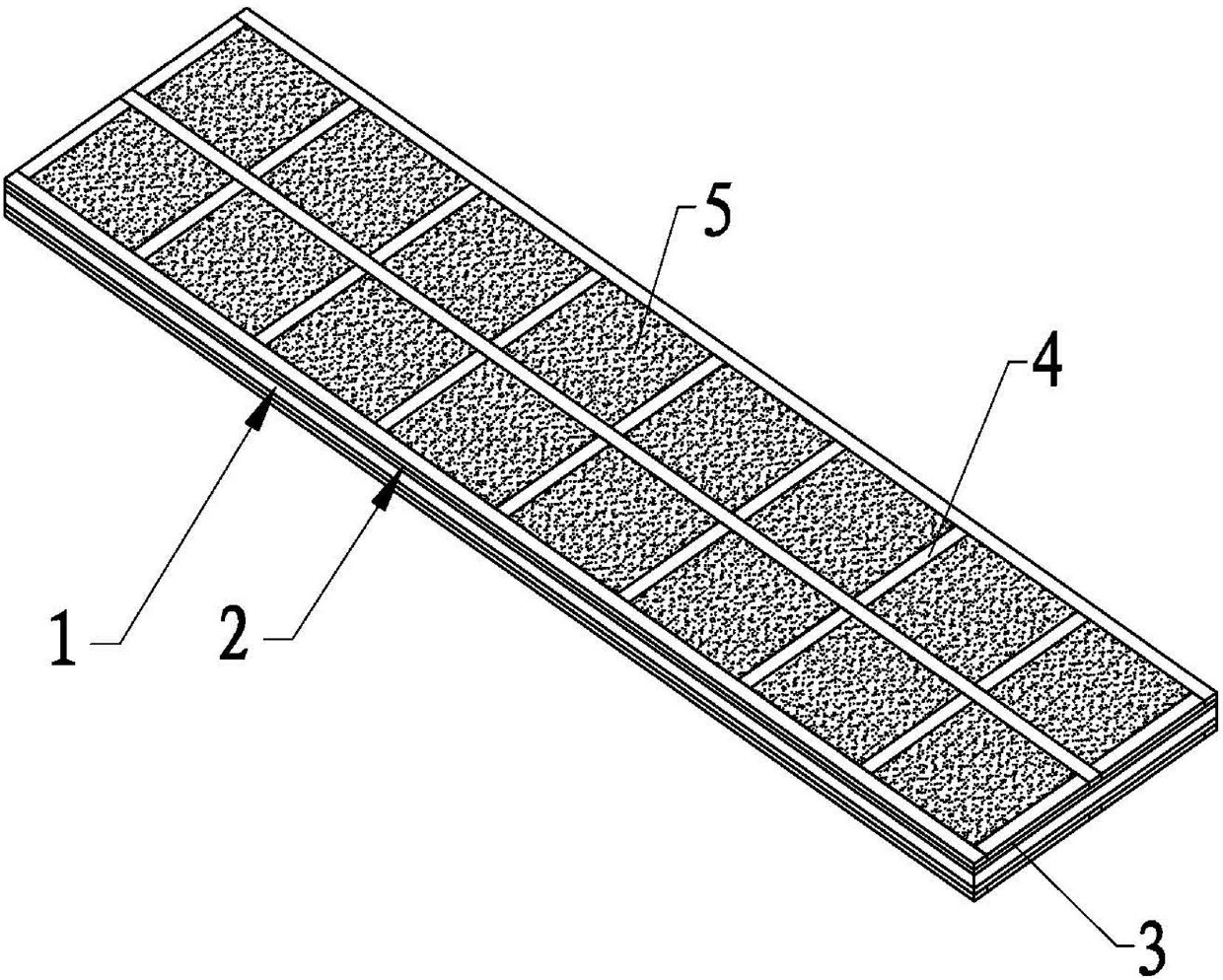

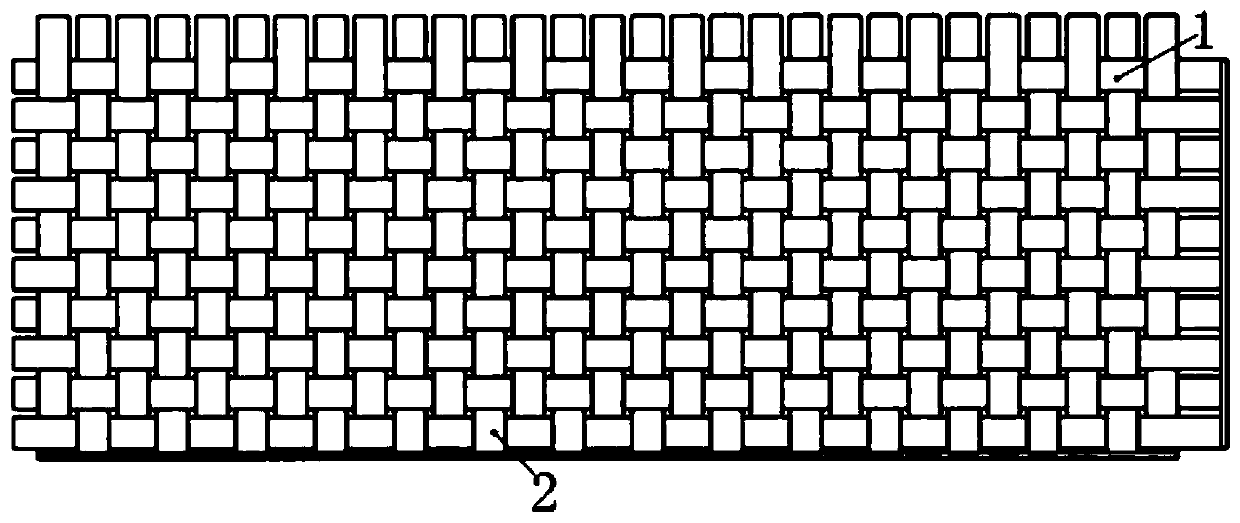

Novel composite partition wall board and production technology thereof

InactiveCN102433957AGive full play to the characteristicsReduce the burden onCeramic shaping apparatusShock proofingFiberEngineering

The invention discloses a novel composite partition wall board and a production technology of the novel composite partition wall board. The novel composite partition wall board comprises a core board (1) and side boards (2) arranged two sides of the core board (1), wherein the core board (1) is adhered to the side boards (2) by resins, each side board (2) comprises a lining board (3), a rib strip (4) and a fiber reinforced gypsum board (5), the rib strip (4) has a frame-shaped structure and is fixed on the outer side face of the lining board (3), and the fiber reinforced gypsum board (5) is arranged in the frame-shaped structure formed by the rib strip (4). The production technology of the novel composite partition wall board comprises the following steps of: firstly, machining a wood board into the lining board (3) and the rib strip (4), and combining the lining board (3) with the rib strip (4); secondly, producing the side boards (2) by the means that the fiber reinforced gypsum board (5) is cast in the rib strip (4); and finally, obtaining a finished product by the means that the gluing, the pre-pressing and the cold-pressing operations are preformed to the core board (1) and the side boards (2). The invention is applicable to the inner partition wall with a frame structure, has the characteristics of being light in weight, high in deformation capability and suspension capability, and good in vibration resistance and thermo-technical performance, and is convenient and fast to construct, thereby being suitable for popularization and use.

Owner:NANJING UNIV OF TECH

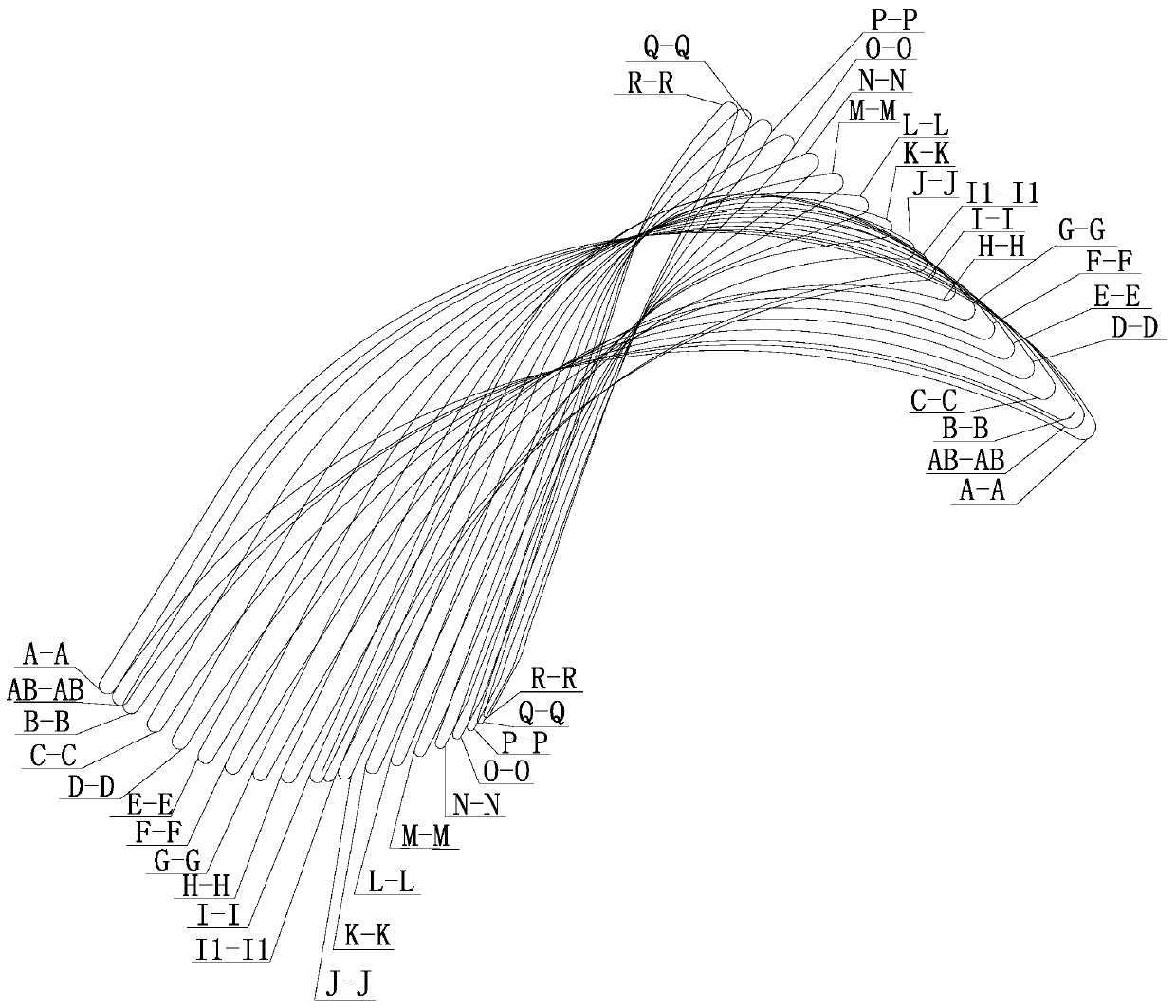

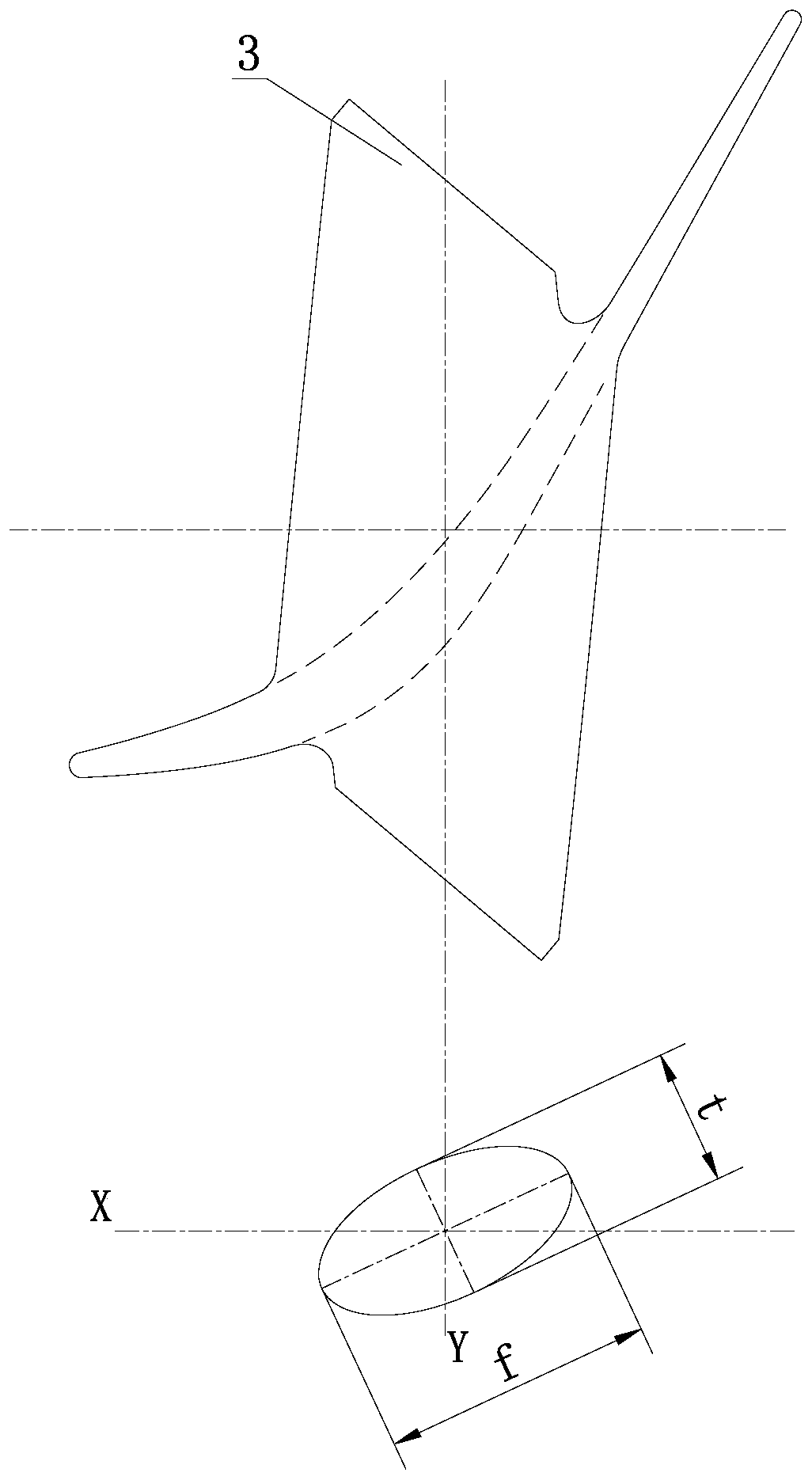

835mm last-stage moving blade suitable for running under low-load working condition

PendingCN110566282AStatic stress reductionLarge amount of intensity domainBlade accessoriesMachines/enginesLow loadPulp and paper industry

The invention provides a 835mm last-stage moving blade suitable for running under a low-load working condition and relates to a last-stage moving blade. The 835mm last-stage moving blade comprises a blade working part and a blade root and further comprises a lug boss pull rib and a hole passing pull rib; the blade working part, the lug boss pull rib and the blade root are subjected to die forgingfrom top to bottom to form an integrated structure; the hole passing pull rib is positioned at the middle part of the blade working part and is in a half-split form; the molded line of the blade working part is a variable-section twisted blade; relative torsion exists between two adjacent sections; the area of the section, from the root to the top, of the blade working part is gradually reduced; the height of the blade working part is 835 mm; the axial width of the root part of the blade working part is 160 mm; the steam discharging area of the blade working part is 6.65 m<2>; the blade root is a circular arc type fir-shaped blade root; and the axial width of the blade root is 190 mm. The 835mm last-stage moving blade provided by the invention is applied to a turbine of a heavy duty gas turbine engine. The last-stage moving blade provided by the invention improves the safety of the overall blade structure and guarantees safe and stable running of the unit under the low-load working condition.

Owner:HARBIN TURBINE

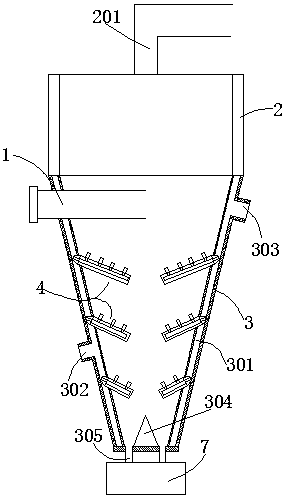

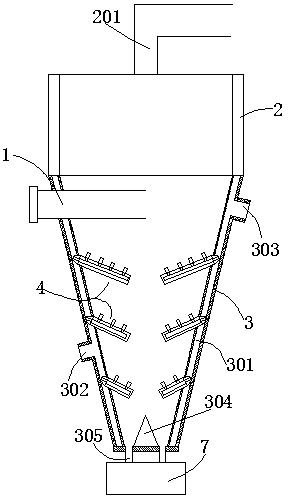

Gas treatment device for electric control room under coal mine

The invention relates to a gas treatment device for an electric control room under a coal mine. The gas treatment device comprises a hollow shell and an airflow guide pipe used for guiding the airflow, wherein the shell comprises a cylindrical part and a circular cone part, wherein the upper end of the cylindrical part is in a cylindrical shape, and the lower end of the circular cone part is in acircular cone shape; the shell wall of the circular cone part is internally provided with a cold airflow channel; the inner wall of the circular cone part is provided with a plurality of aeration spacer plates which incline downwards; the plurality of aeration spacer plates are arranged up and down at intervals and are arranged on the inner wall of the circular cone part at the equal intervals; each aeration spacer plate is internally provided with an airflow channel I, and the airflow channels I are communicated with the cold airflow channel of the circular cone part; the aeration spacer plates are separately provided with an air nozzle structure used for discharging cold air; a material dispersing cone is arranged at the middle lower part of an inner cavity of the circular cone part, andthe bottom end of the circular cone part is provided with a plurality of outlet pipes. The gas treatment device can be arranged at a gas inlet of the electric control room in a matching way, so thatthe external oily and dusty gases can be effectively treated by purifying, the air quality in the electric control room is improved, the safety of electrical equipment of the coal mine is improved, and the service life of the electrical equipment of the coal mine is prolonged.

Owner:XUCHANG YONGXIN ELECTRIC

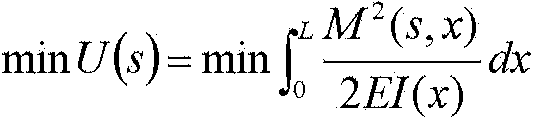

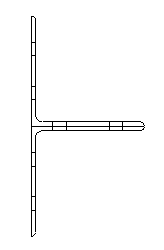

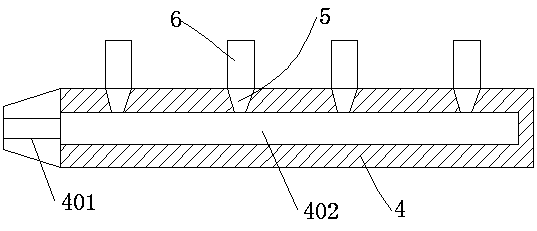

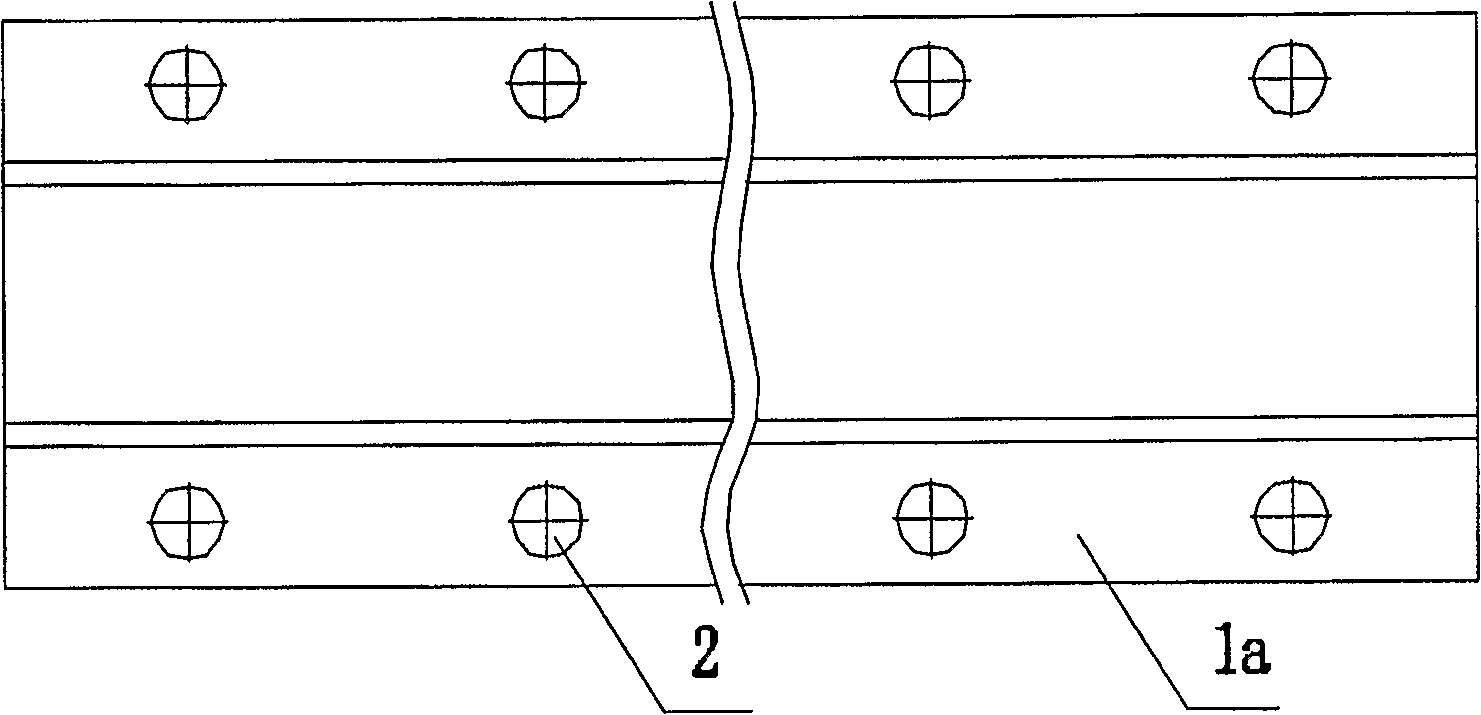

Semi-assembled prefabricated beam and preparation method and design method thereof

The invention discloses a semi-assembled prefabricated beam and a preparation method and design method thereof. The semi-assembled prefabricated beam comprises an H-shaped steel beam and an outer protection coating. The outer protection coating is arranged on the outer surface of the H-shaped steel beam. Flanges of two ends of the H-shaped steel beam and a web are provided with bolt holes. Two ends of the H-shaped steel beam are respectively provided with end connection joint uncoated zones for connecting a steel column. The upper flange of the H-shaped steel beam is welded to a bolt. The outer surface of the upper flange of the H-shaped steel beam is provided with an upper connection joint uncoated zone for connecting a concrete floor. The semi-assembled prefabricated beam retains the load and construction advantages of the traditional fabricated steel beam, solves the problem that the conventional assembled steel structural beam needs anti-corrosion and fireproof treatment and regular maintenance, reduces the comprehensive cost of the steel structure system and improves the overall rigidity, anti-seismic properties and construction and use convenience of the steel structure.

Owner:ARCHITECTURAL DESIGN INST FUKIEN PROV

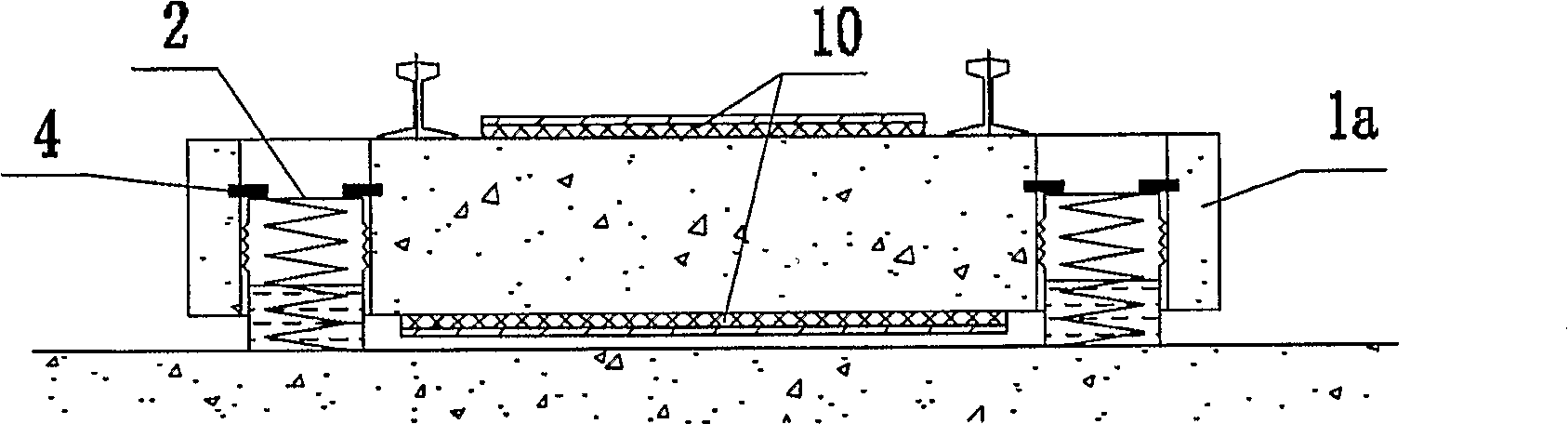

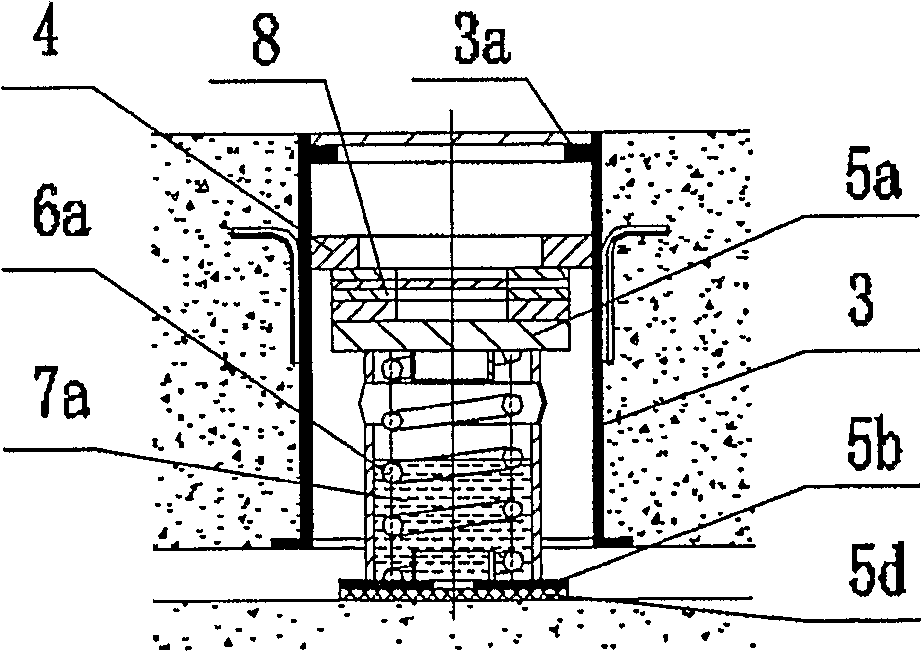

Floating roadbed

The present invention relates to absorption of vibration structure of the railway track bed, which comprises floating slab (1) and spring absorption of vibration apparatus (2). Thereinto, the floating slab (1) is mount on the spring absorption oaf vibration apparatus (2) elastically, so the vibration which transferring to the basement of the track bed from the rail (16) wi11 be decreased greatly by the spring absorption of vibration apparatus (2).

Owner:GERB QINGDAO VIBRATION CONTROL +1

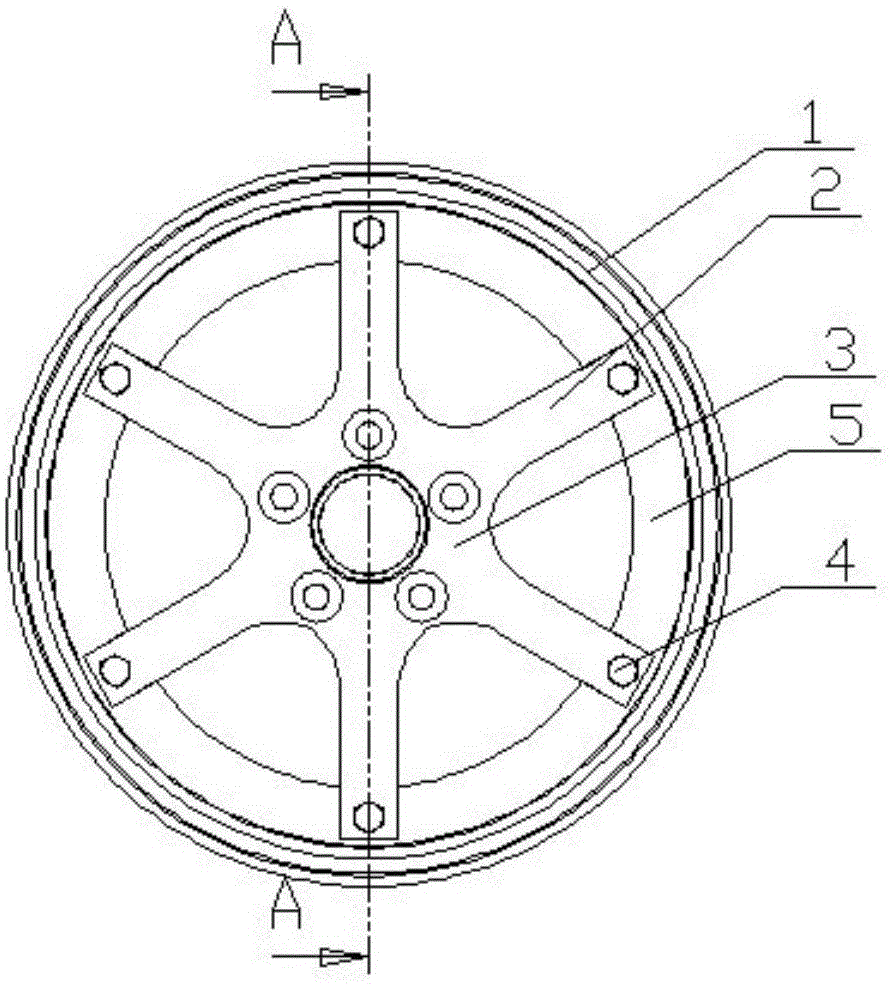

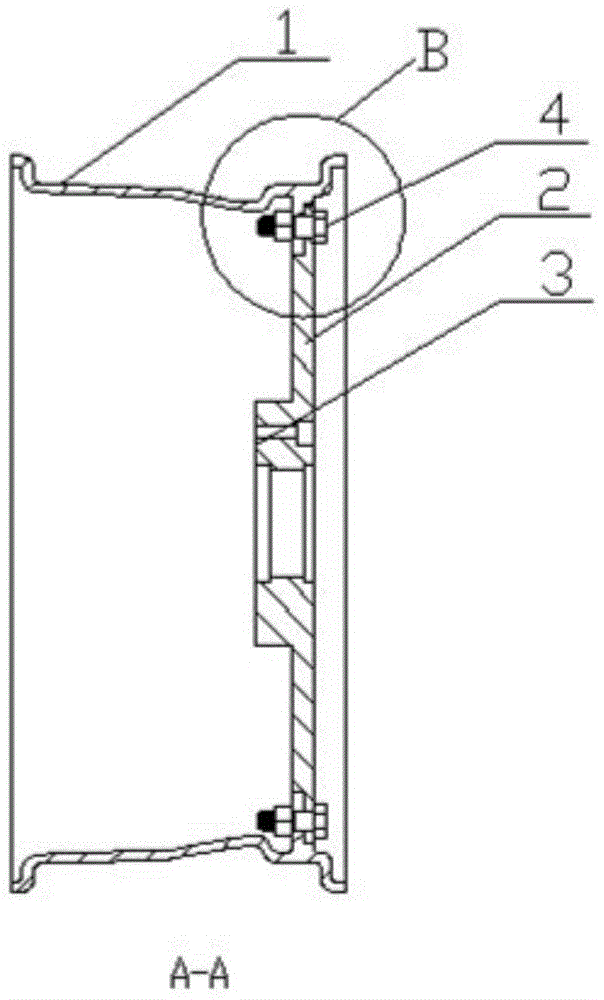

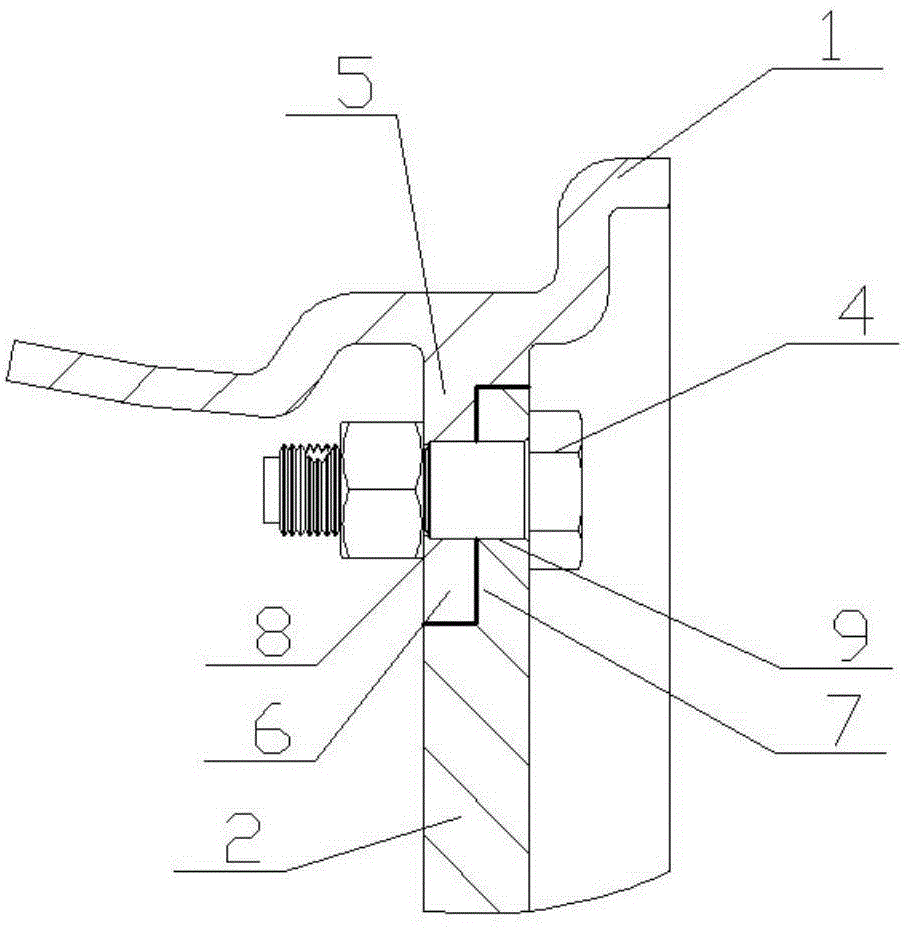

Lightweight magnesium-aluminum alloy assembled wheel

ActiveCN103950350ALarge damping capacityImprove shock absorptionRimsSpoked wheelsUltimate tensile strengthBolt connection

The invention discloses a lightweight magnesium-aluminum alloy assembled wheel and relates to a wheel structure. According to the lightweight magnesium-aluminum alloy assembled wheel, the problems that the maintenance cost is high and the waste is generated due to the fact that the existing structure of the wheel is a rim and spoke integrated structure and the whole wheel is required to be changed if the wheel is damaged are solved. The lightweight magnesium-aluminum alloy assembled wheel comprises a rim, a spoke and a hub, wherein an annular boss is arranged on the inner side of the rim; positioning grooves and mounting holes are uniformly distributed in the annular boss along the circumferential direction and are used for being connected with the spoke; the hub and the spoke are integrated; a radial positioning spigot and a mounting hole are distributed in the outer edge of the spoke. According to the lightweight magnesium-aluminum alloy assembled wheel, the spoke made of a magnesium alloy is protected by a tire, and the exposed area of the rim on the outer side of the wheel is small, so that the possibility of scratch is reduced and the defect that the magnesium alloy is poor in corrosion resistance is overcome; the spoke is made of an aluminum alloy, and thus high strength is obtained; the rim and the spoke form an assembled structure and are connected by bolts, so that the rim and the spoke can be respectively changed after being damaged; the convenience in maintenance is realized, the scrappage of the whole wheel is avoided, the manufacturing process is greatly simplified, the die cost is reduced and the manufacturing efficiency is increased.

Owner:JILIN UNIV

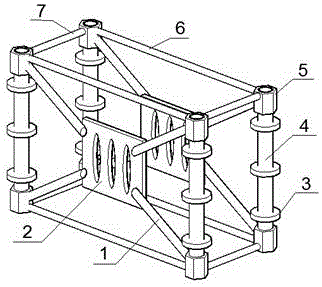

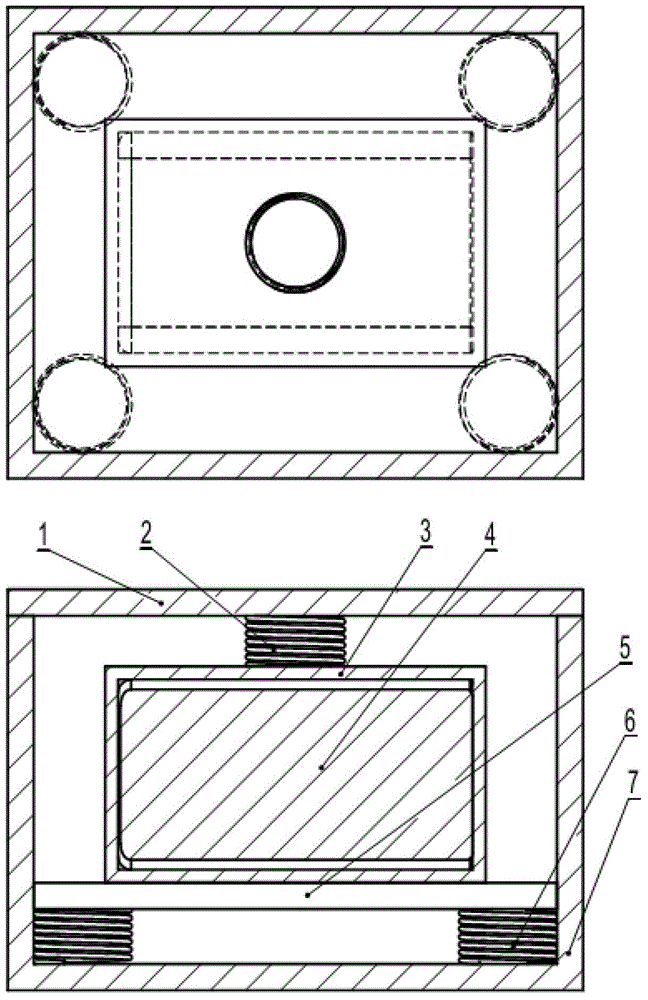

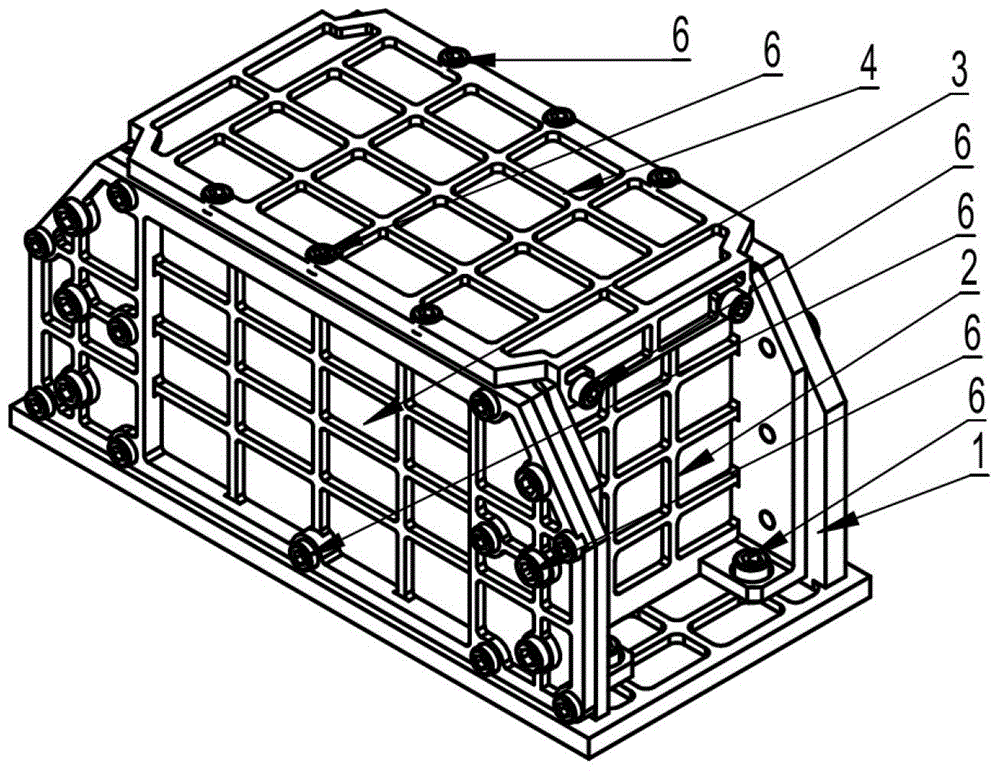

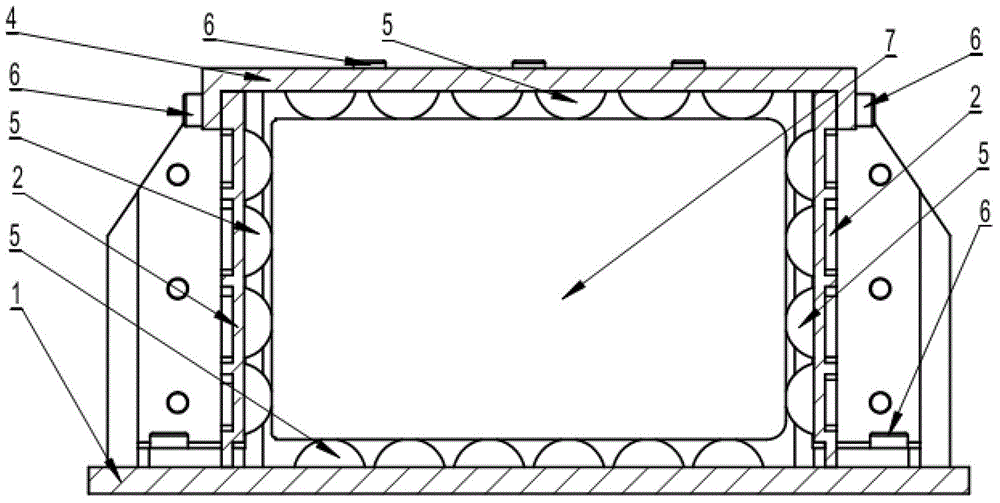

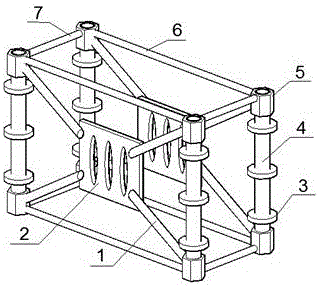

Impact-resisting damping device with multi-freedom-degree high-damping viscoelastic damping semi-spheres

ActiveCN103557267ASmall additional weightImprove structural strengthNon-rotating vibration suppressionElastic dampersViscoelastic dampingEngineering

An impact-resisting damping device with multi-freedom-degree high-damping viscoelastic damping semi-spheres is characterized in that the damping device is a sealed hexahedron device combined by a damping base, two damping cavity lateral covers, a damping cavity front cover and a damping cavity upper cover. A mechanical structural component inner cavity is formed in the vibration damper. The damping semi-spheres are attached to the entire inner wall of the mechanical structural component inner cavity. A damping cavity for mounting damping parts is formed in vibration damper. The damping base comprises a front positioning seat, a damping cavity base plate and a damping cavity rear plate. Each semi-sphere is made of high-viscoelasticity, high-damping and multi-freedom-degree polyether urethane materials. By the damping device, normal operation of highly-sensitive equipment under vibration and impact can be guaranteed.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Gas purifying chamber for coal mine electrical equipment

InactiveCN108543399AImprove air qualityImprove securityCombination devicesEngineeringElectric control

The invention relates to a gas purifying chamber for coal mine electrical equipment. The gas purifying chamber for the coal mine electrical equipment comprises a sealed cavity body structure with an internal space formed by abutting a plurality of wall plates, wherein a sound insulating plate is arranged in a sealed cavity body, and a certain ventilation gap is arranged between the lower end surface of the sound insulating plate and the bottom wall plate of the sealed cavity body; the other end surfaces of the sound insulating plate are sealingly connected with the inner wall of the sealed cavity body, and the space of the sealed cavity body is divided by the sound insulating plate into a ventilation cavity and a purification cavity; the ventilation cavity is communicated with an air inlet, and the air inlet in the ventilation cavity is sequentially connected with a coarse filter, a purifier and a drying box through connecting pipelines; the dirty air discharged through the air inlet is sequentially processed by the coarse filter, the purifier, the drying box, and enters the purification cavity through the ventilation gap to realize the air circulation. The gas purifying chamber can coarsely filter, purify and dry the external oily and dusty gas effectively, thereby improving the air quality in an electric control room, improving the safety of the coal mine electrical equipmentand prolonging the service life.

Owner:XUCHANG YONGXIN ELECTRIC

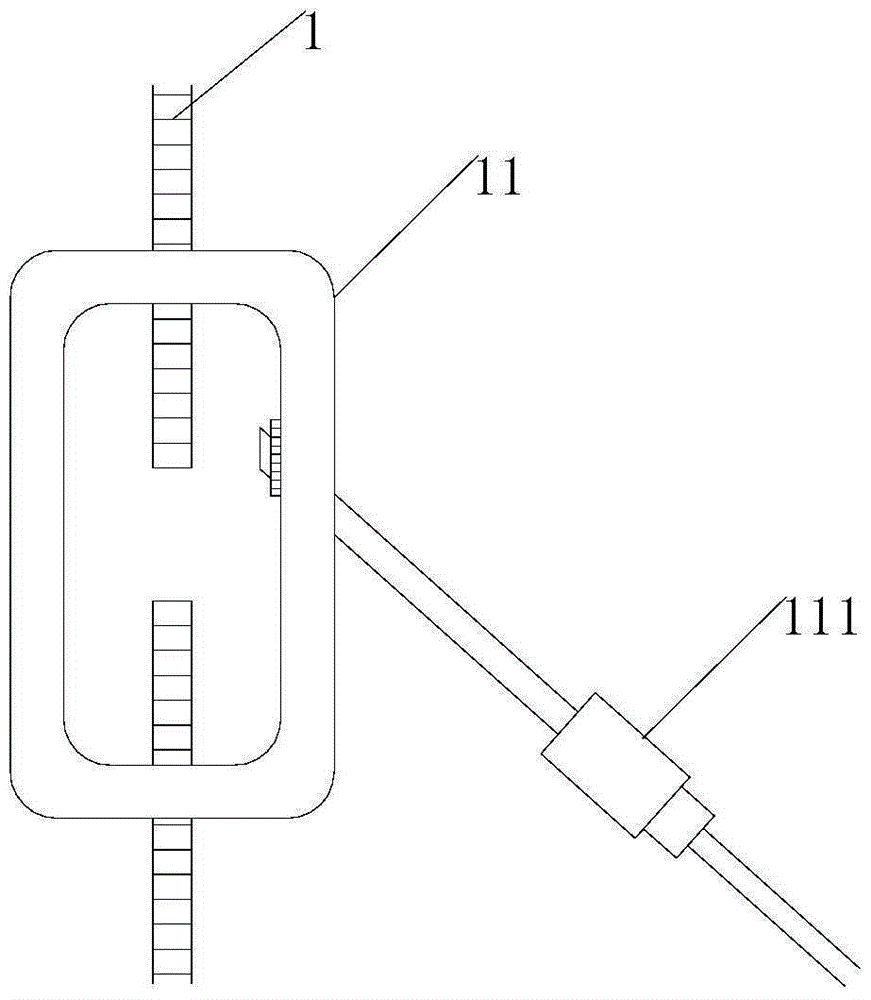

Vibration reducing device for restraining wind-induced vibration of lifting rod of large-span suspension bridge

ActiveCN105220615AReduce free lengthReduce vibrationSuspension bridgeBridge structural detailsCable netMechanical engineering

The invention discloses a vibration reducing device for restraining wind-induced vibration of a lifting rod of a large-span suspension bridge, which is an auxiliary cable net system arranged on a suspension bridge lifting rod (2); the auxiliary cable net system is a netty structure formed by across arranging multiple auxiliary cables (1); included angles between the auxiliary cables (1) and the lifting rod (2) are 30-70 degrees; and in a connecting area (8) of the auxiliary cables and the lifting rod, the auxiliary cables (1) and the lifting rod (2) are fixedly connected by bolts through two second connecting devices (10) at two sides of the lifting rod (2), connecting clamping pieces (81) of two auxiliary cables at two sides of the two second connecting devices (10) and the lifting rod and rubber washers between the connecting clamping pieces (81) of the auxiliary cables and the lifting rod and the lifting rod (2). The vibration reducing device is simple in connecting structure, has the advantages of convenience for installation and maintenance construction, and can be convenient to replace cable bodies in the use period.

Owner:TONGJI UNIV

Portable electronic apparatus vibration damping structure and notebook-type computer

ActiveCN101211199ACompact vibration-absorbing structureEffectively absorb external impactDigital data processing detailsSolid based dampersLaptopEngineering

The invention relates to a vibration damping structure for portable electronic equipment and a laptop. The vibration damping structure for portable electronic equipment comprises a casing, a damping cavity arranged on the casing, a cover board covering the damping cavity and damping parts arranged in the damping cavity. The damping cavity can be independent or a plurality of sub-aspect damping cavity divided by a separator and the damping parts can be particles, small rods or plates. When the vibration damping structure for portable electronic equipment of the invention vibrates periodically or non-periodically especially randomly due to vibration, drop and other external shocks, the damping parts enclosed in the cavity will move and lose a large amount of energy by mutual collision, thus absorbing and consuming a substantial amount of vibration energy and reducing the harm caused by vibration. The damping structure is compact, thin and light weighted and the damping does not change within a temperature range of minus forty DCG to eighty DCG, which represents the excellent property of the damping structure.

Owner:LENOVO (BEIJING) CO LTD

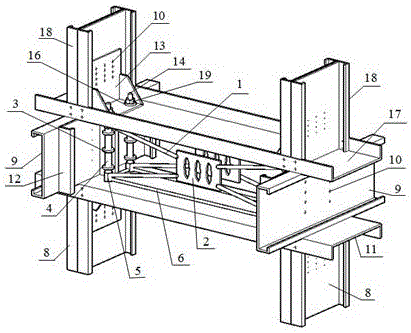

Interlayer reinforcement component of cold-bent thin-wall type steel house

The invention discloses an interlayer reinforcement component of a cold-bent thin-wall type steel house. The interlayer reinforcement component is characterized by being of a truss type structure and comprising four upright steel bushings (4) with rectangular projections, and hollow supports (5) which are fixed at two ends of the steel bushings (4) and are coaxial with the steel bushings (4), wherein horizontal transverse steel bars (6) or horizontal longitudinal steel bars (7) are welded between every two adjacent hollow supports (5); oblique steel bars (1) with equal lengths are welded on the hollow supports (5) at four corners of each of front and rear side walls formed by the horizontal transverse steel bars (6) and the steel bushings (4) along the diagonal direction; the far end of each oblique steel bar (1) is welded on a perforated steel plate (2); reinforcement hoops (3) are welded alternately on the steel bushings (4). The reinforcement component is applicable to the cold-bent thin-wall type steel house which is of a multilayer house beam column structure; the force transmission path is direct and reliable; the lateral resistant ability and the capability of bearing the vertical load action of the whole structure can be obviously improved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

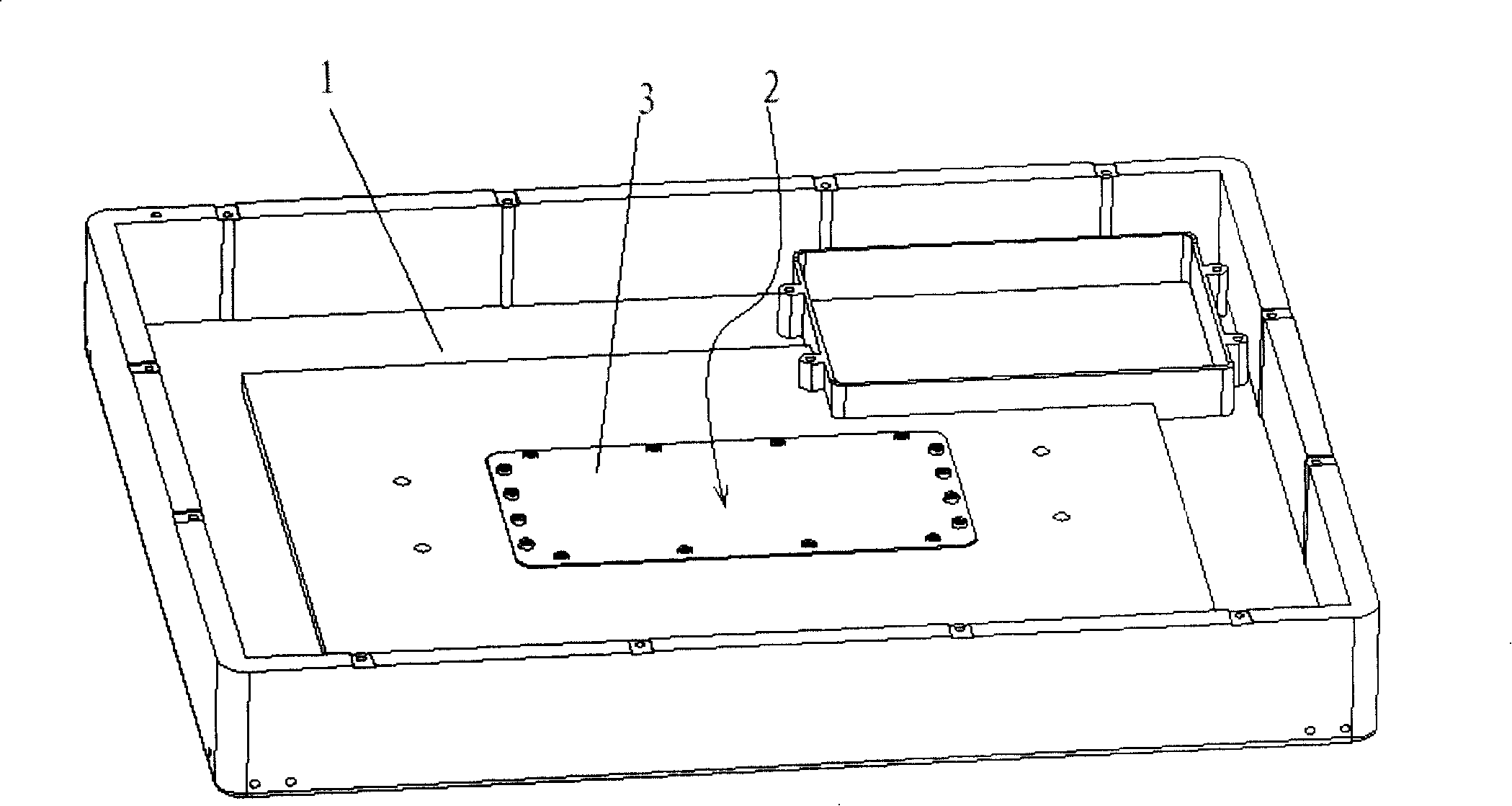

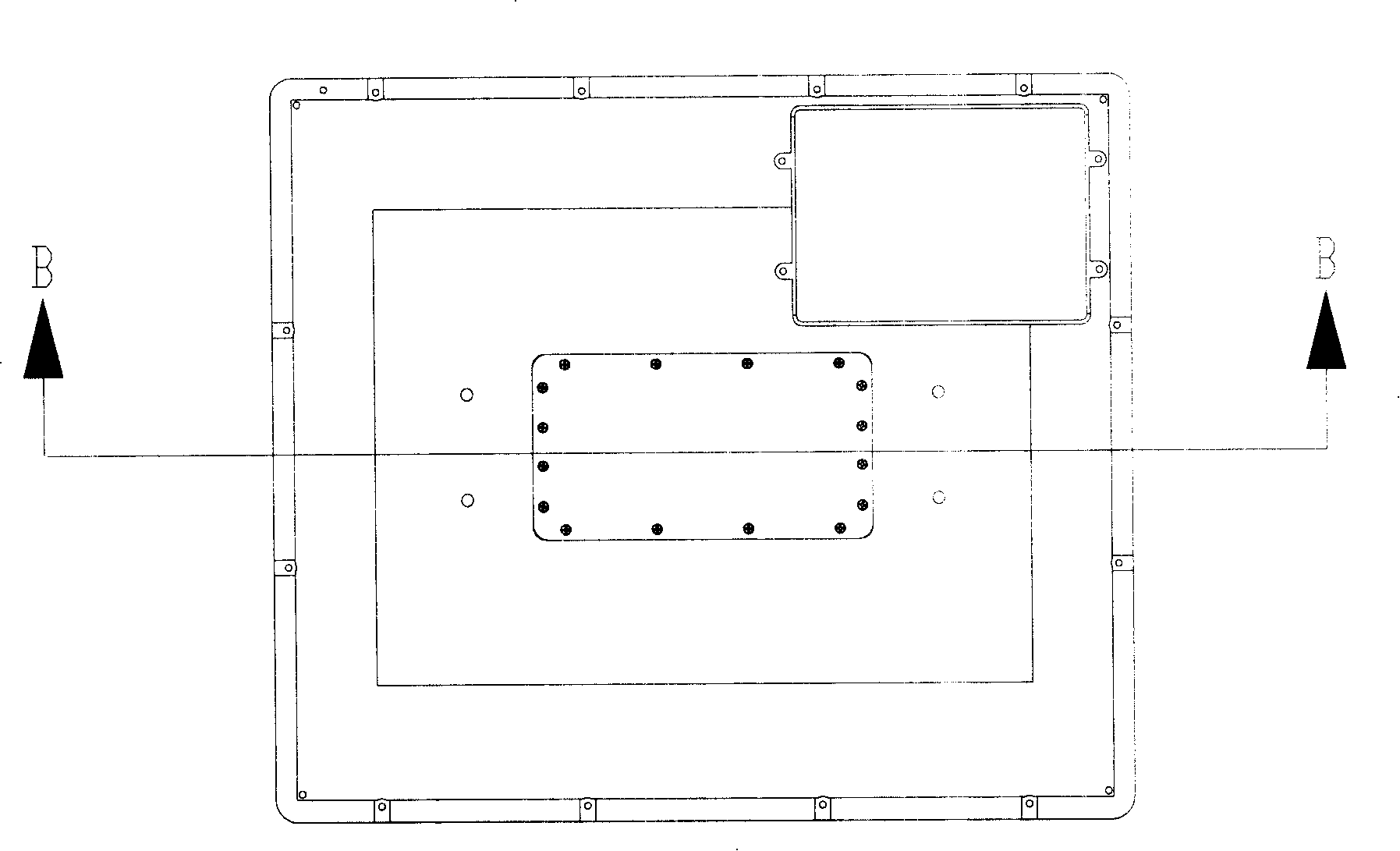

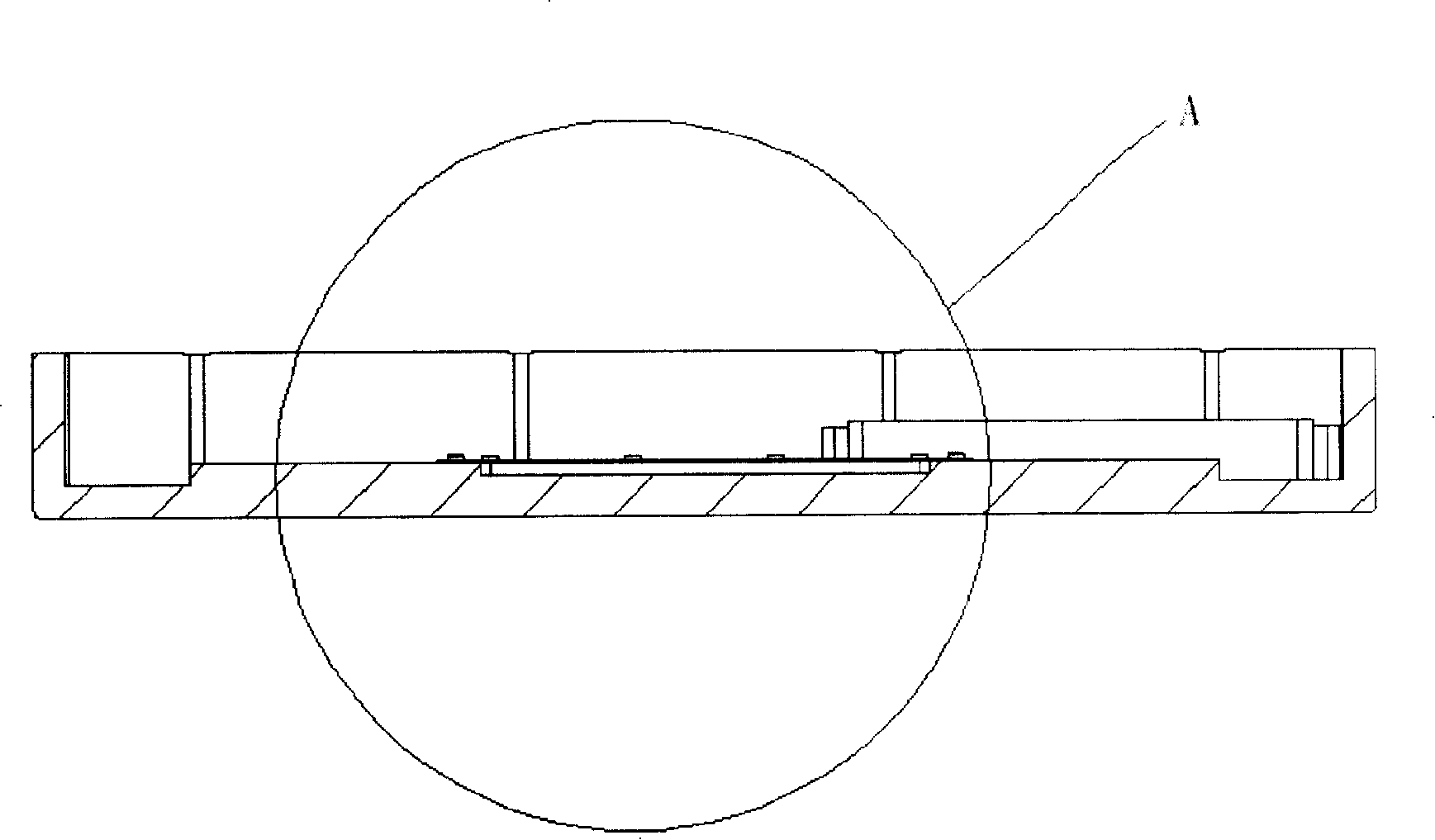

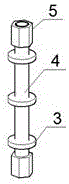

Multi-mass-sheet two-side clamping device for rail vibration reduction

The invention discloses a multi-mass-sheet two-side clamping device for rail vibration reduction. The multi-mass-sheet two-side clamping device comprises elastomers, supports, elastomer-steel member assemblies, pressing plates, first locking pieces, second locking pieces, pressing bars with pressing ends, leaf springs and rail gaskets, wherein the elastomers, supports, the elastomer-steel member assemblies, the pressing plates, the first locking pieces, the second locking pieces and the pressing bars with pressing ends are arranged on the first side and the second side of a rail, and the leafsprings and the rail gaskets are located on the pressing plates and the elastomer-steel member assemblies; the spring gaskets and the elastomer-steel member assemblies are attached to the rail, so that the vibration impact of a train on the rail is retarded; the elastomer-steel member assemblies increase structural damp of the rail and adjust the vibration frequency of the rail to be close to thefrequency of a main structure, and the resonance characteristic of the structure is changed, so that the vibration reduction and noise reduction effects are achieved. The multi-mass-sheet two-side clamping device can greatly reduce the energy transmitted by wheels and the rail, prevents the generation of vibration and noise, greatly prolongs the service life of the wheels and the rail, is beneficial to reduction of the use cost of a railway and noise pollution, is convenient to replace and disassemble, and has a very strong practical value and application prospect.

Owner:SOUTHWEST JIAOTONG UNIV

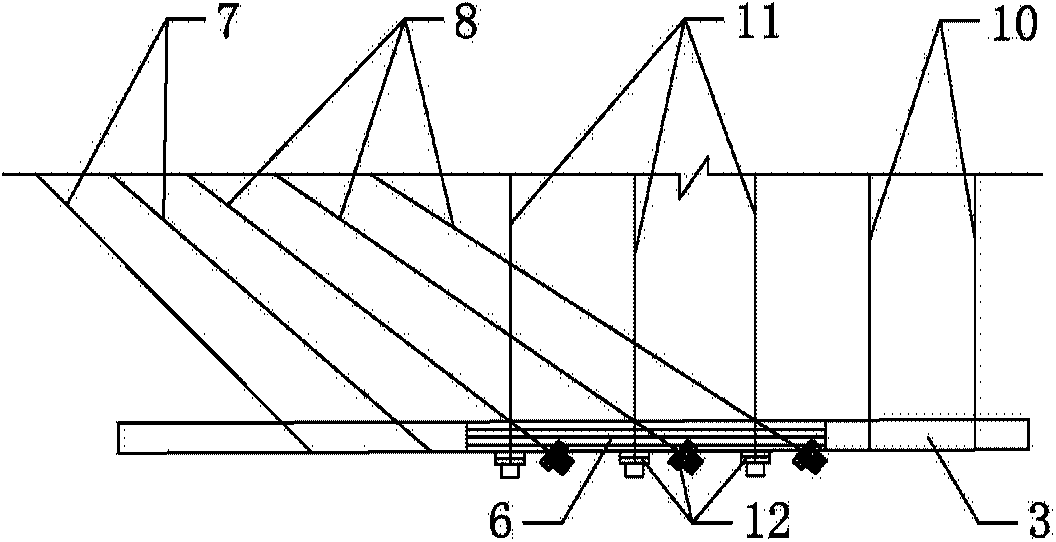

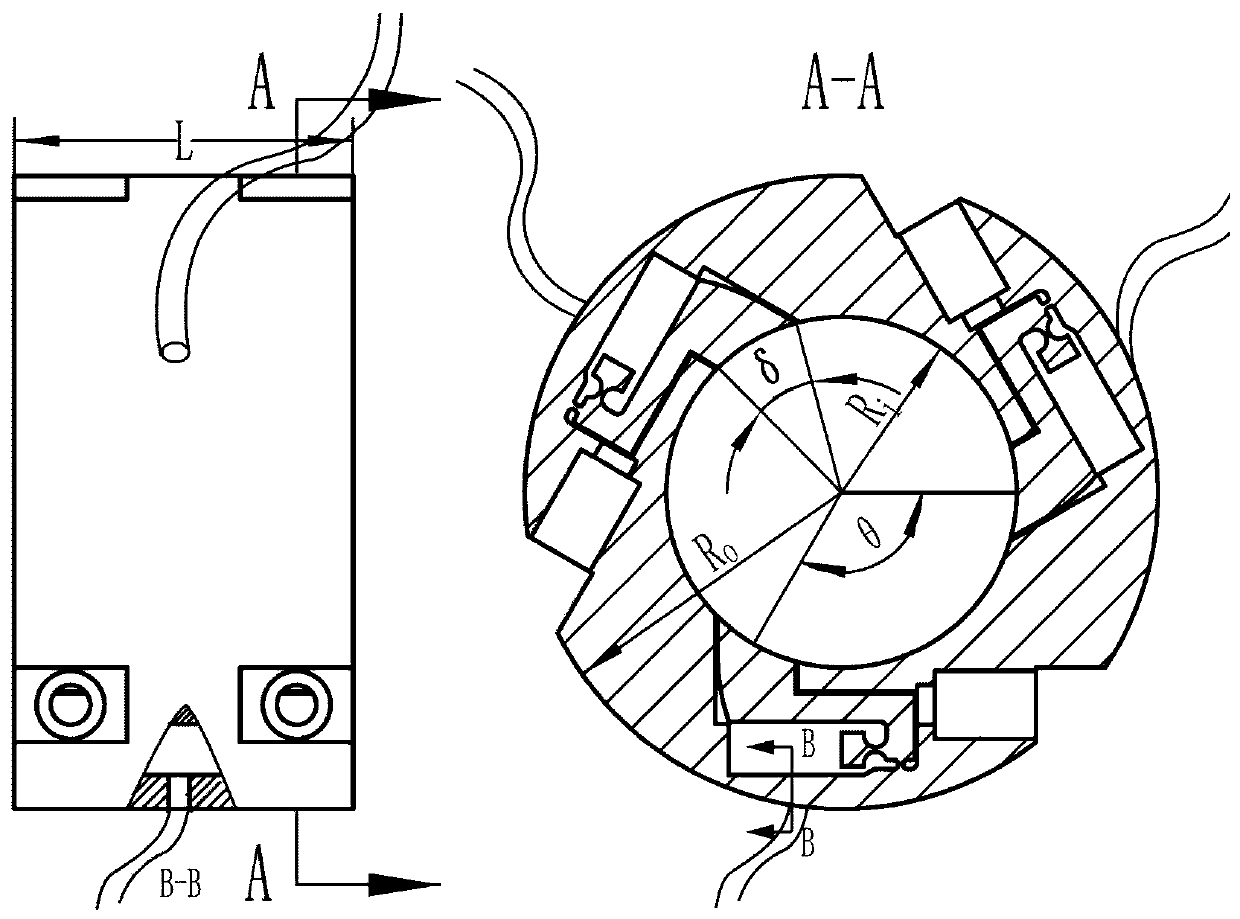

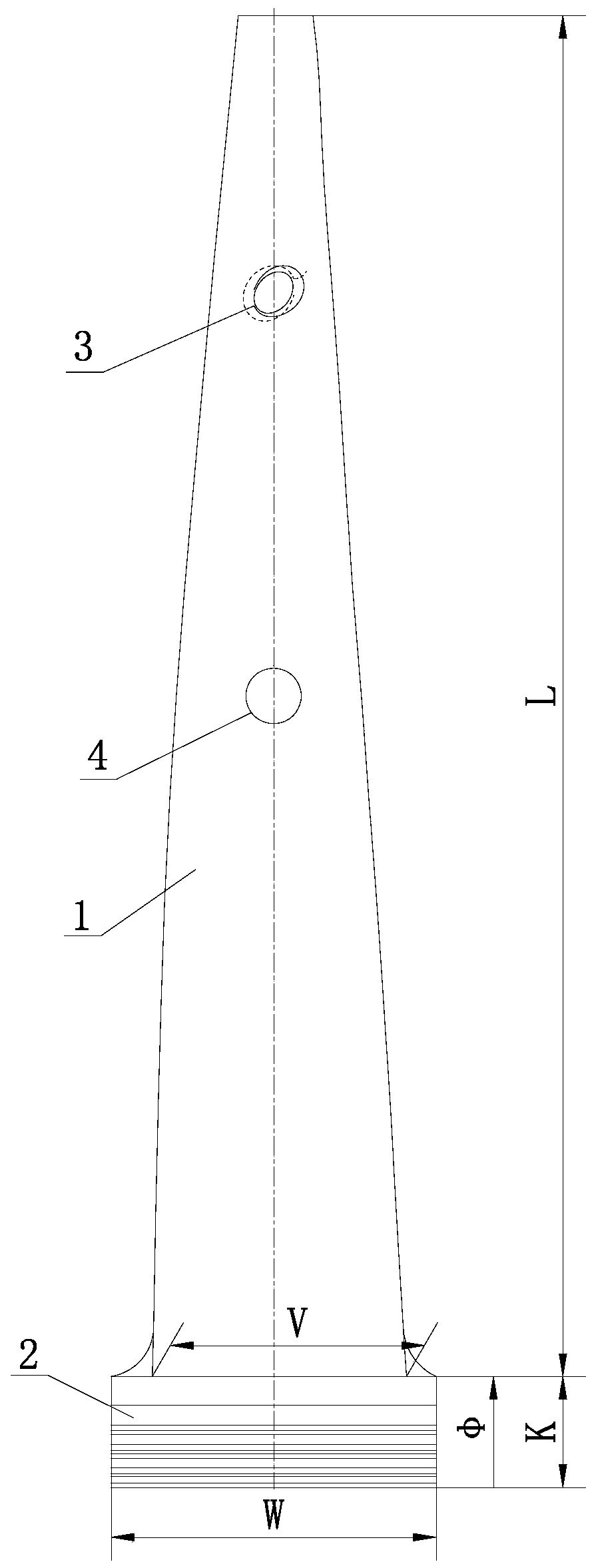

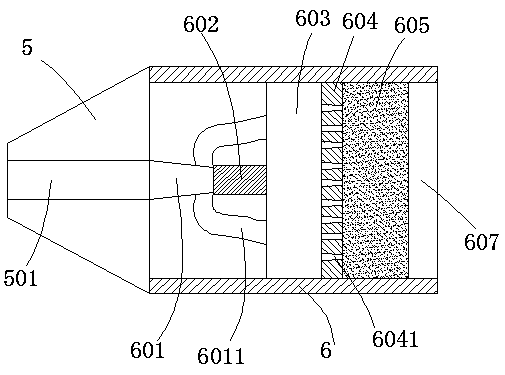

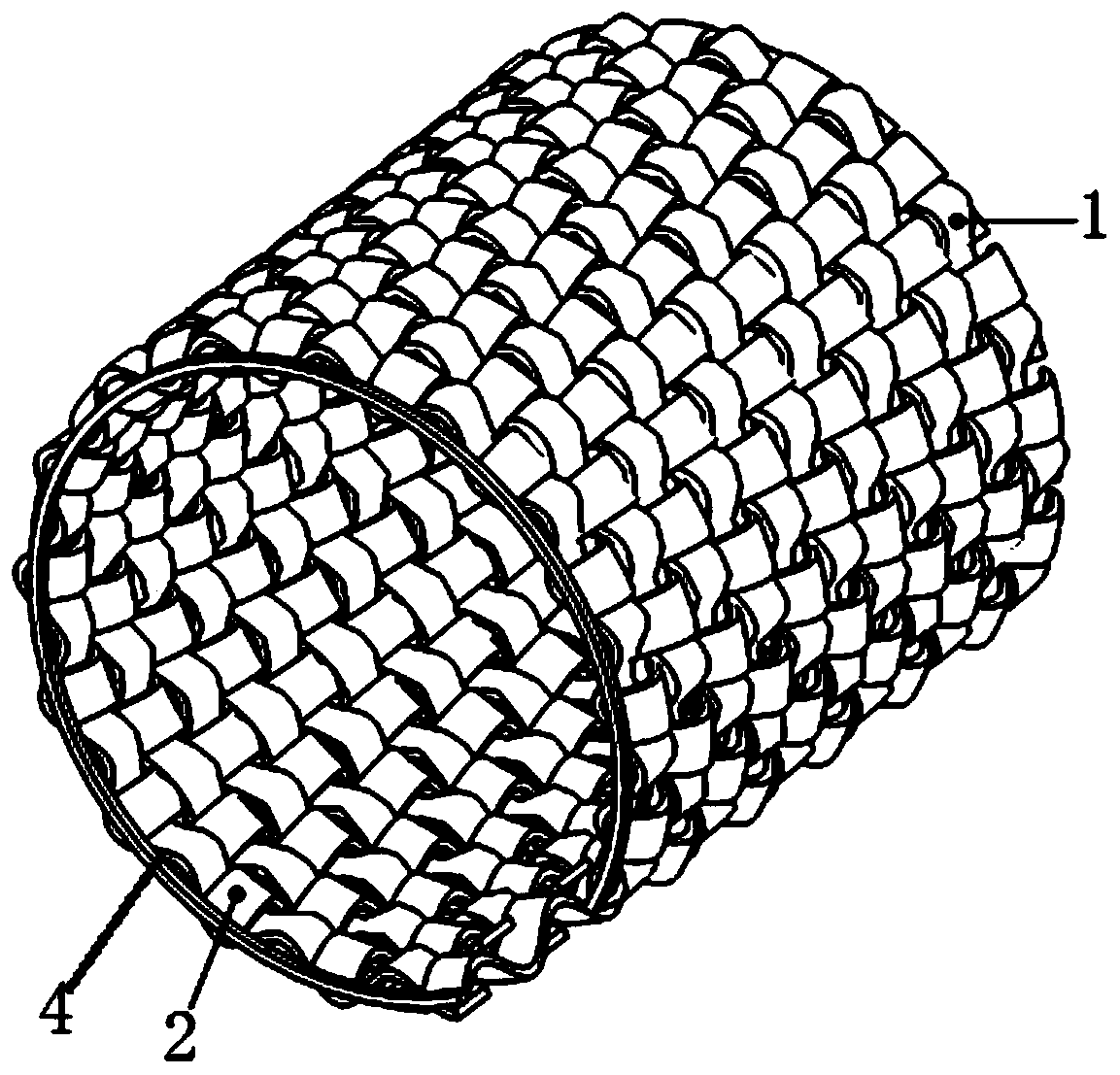

Flexible assembly and dynamic pressure radial gas bearing

InactiveCN109780051AIncrease structural dampingIncrease frictional dampingSliding contact bearingsBearing unit rigid supportProduct gasEngineering

The invention belongs to the technical field of mechanical equipment, and in particular relates to a flexible assembly and a dynamic pressure radial gas bearing. The variable range of stiffness is limited due to the fact that in a traditional foil bearing structure, the wave foil arch bottom only contacts with the upper surface of a bearing seat in one direction; and at the same time, the effect of friction damping on energy dissipation is poor due to the fact that the space of a wave foil bearing structure is not fully utilized. The flexible assembly comprises a first foil group and a secondfoil group, the first foil group intersects with the second foil group, and the space phase of the first foil group is opposite to the space phase of the second foil group; and the flexible assembly is provided higher structural damping. According to the dynamic pressure radial gas bearing, by adopting the flexible assembly, the limited working space of the foil bearing is fully utilized, the contact area among the flexible assembly and the flat foil surface and the bearing seat surface is increased, bearing friction damping is improved, thus energy dissipation in the bearing is enhanced, andthe stability of a rotor-bearing system is effectively maintained.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com