Sound-absorbing damping foam core sandwich composite material, and manufacturing method thereof

A composite material and foam technology, which is applied in the field of polymer-based lightweight composite materials and foam sandwich composite materials, can solve problems that are not related to temperature resistance, flame retardancy, low smoke, low toxicity, sound absorption, damping, and vibration reduction. , Noise-reducing polyurethane-polyimide foam sandwich composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment provides a kind of preparation of open-cell polyurethane-polyimide foam:

[0050] Put 170 grams of 1,2,4,5 pyromellitic dianhydride (PMDA) and 240 grams of dimethylformamide into a 1000ml three-neck flask equipped with a stirrer, a thermometer and a reflux condenser, stir well and slowly raise the temperature When the solid particles of 1,2,4,5 pyromellitic dianhydride are completely dissolved at 90-100°C, add 25 grams of 4,4, diaminodiphenyl ether and raise the temperature to 120°C to react to a clear solution. Cool down to 65°C and put in 25 grams of anhydrous methanol, carry out esterification reaction to a reddish-brown transparent solution, cool down to below 60°C, add 2.5 grams of isoquinoline, stir evenly, and prepare a precursor solution.

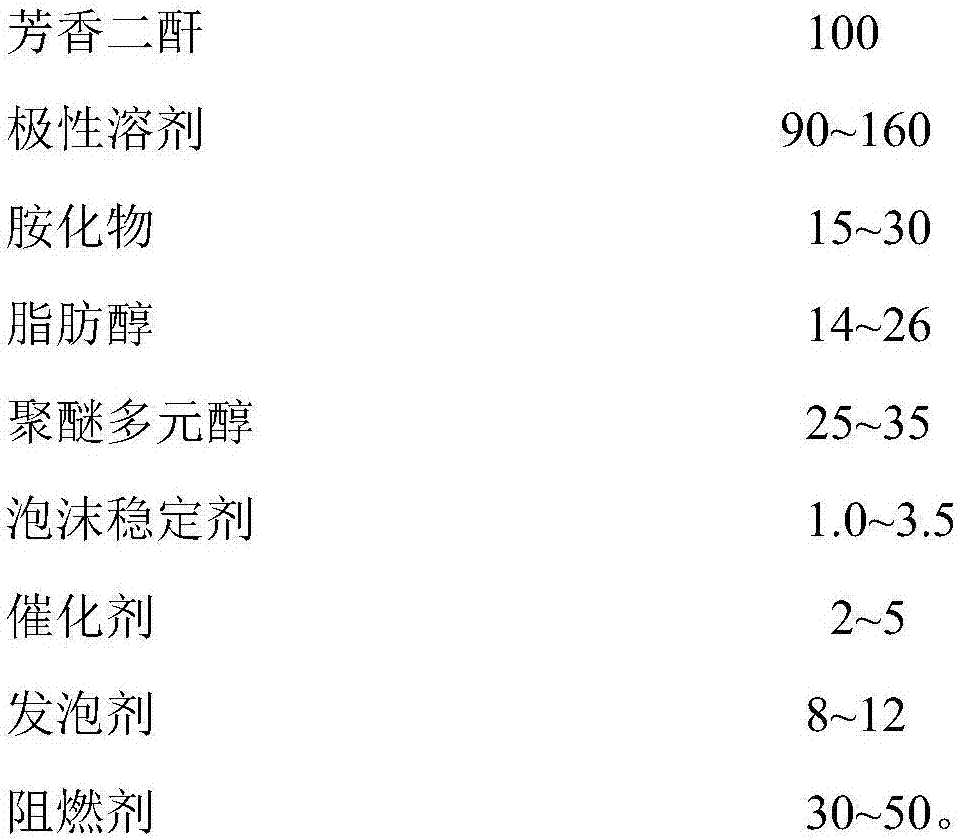

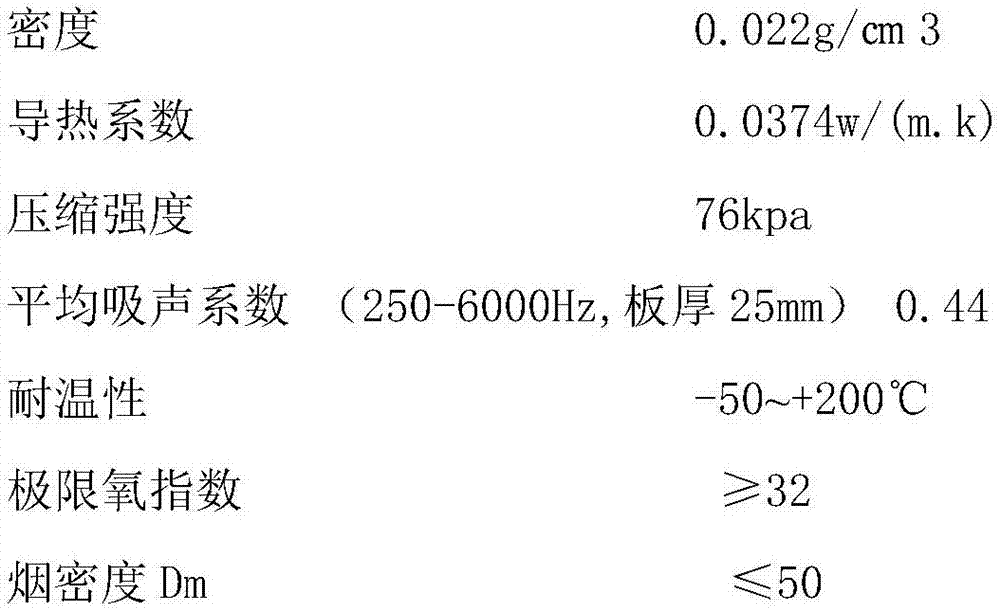

[0051] Weigh 100 grams of the above precursor solution and add 12 grams of blowing agent deionized water, 1.5 grams of triethylenediamine, 0.5 grams of bis(dimethylaminoethyl) ether catalyst, 30 grams o...

Embodiment 2

[0057] The present embodiment provides a kind of preparation of open-cell polyurethane-polyimide foam:

[0058] In the 1000ml there-necked flask equipped with stirrer, thermometer and reflux condenser, drop into 150 grams of 3,3,,4,4,, benzophenone tetracarboxylic dianhydride (BTDA) and 210 grams of dimethylformamide, Stir well and slowly raise the temperature to 100-110°C. After the solid particles of 3,3,,,4,4,, benzophenone tetracarboxylic dianhydride (BTDA) are completely dissolved, add 25 grams of 4,4,, diaminodiphenyl Ether (4,4,,-ODA) was heated up to 120°C and reacted to a clear solution solution, cooled to 65°C and put into 38 grams of anhydrous methanol for esterification reaction, and the solution was clear and transparent, and the temperature was lowered to below 60°C. Add 2.5 g of isoquinoline, and stir the solution evenly to obtain a light yellow transparent precursor solution.

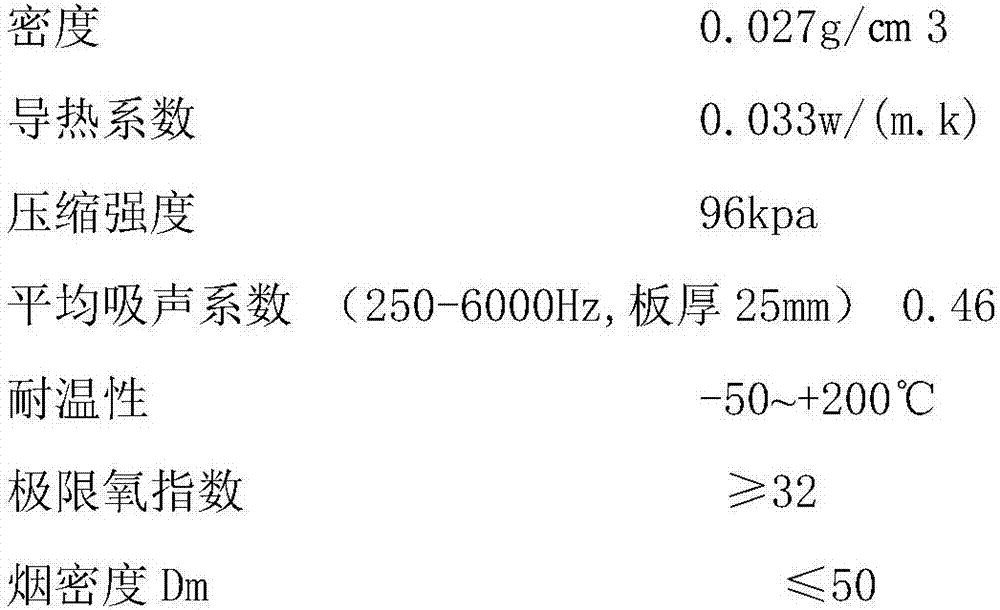

[0059] Weigh 100 grams of the above precursor solution and add 12 grams of deionize...

Embodiment 3

[0064] The present embodiment provides a kind of preparation of open-cell polyurethane-polyimide foam:

[0065] Put 170 grams of 1,2,4,5 pyromellitic dianhydride (PMDA) and 260 grams of dimethylformamide into a 1000ml three-neck flask equipped with a stirrer, a thermometer and a reflux condenser, stir well and slowly raise the temperature To 90 ~ 100 ℃, when the solid particles of 1,2,4,5 pyromellitic dianhydride are all dissolved and the solution becomes clear, drop the temperature to 65 ℃ and put in 25 grams of anhydrous methanol to carry out esterification reaction. Clear and transparent, cooling down to below 60°C. Add 2.5 grams of isoquinoline, 30 grams of polyoxypropylene diamine (D-2000). Stir the above solution to a constant temperature to obtain a brown-red transparent viscous precursor solution.

[0066] Weigh 100 grams of the above precursor solution and add 12 grams of foaming agent deionized water, 1.5 grams of triethylenediamine, 0.5 grams of bis(dimethylaminoe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com