Patents

Literature

181results about How to "Flame retardant has" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength stretch-proof flame-retardant textile

InactiveCN101748549ASolve the difficulty of weavingSolve not easy to dyeWoven fabricsYarnCompound aEngineering

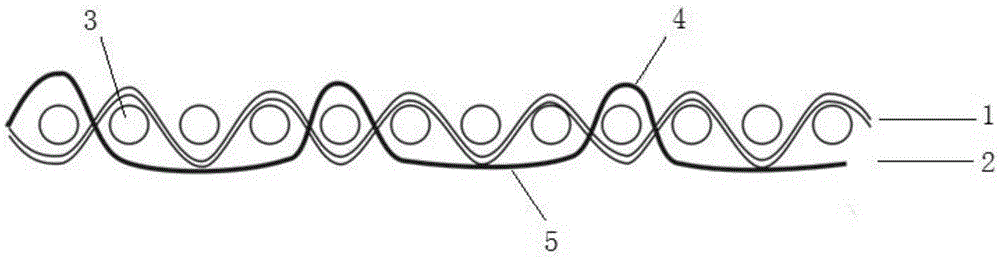

The invention provides a high-strength stretch-proof flame-retardant textile. The flame-retardant textile is formed by weaving a flame-retardant composite yarn, wherein the flame-retardant composite yarn is formed by compounding a core yarn and a leather yarn and is one of a covering yarn and a fasciated yarn; the core yarn adopts a flame-retardant filament yarn as a raw material; the leather yarn adopts a flame-retardant short fiber as a raw material; and the weight ratio of the flame-retardant filament yarn to the flame-retardant short fiber is 30-90:10-70. Compared with the conventional flame-retardant textile, the high-strength stretch-proof flame-retardant textile has higher strength and overcomes the defects of difficult weaving, difficult dyeing and uncomfortableness of the high-strength fiber; the high-strength stretch-proof flame-retardant textile has permanent flame retardance which cannot decrease after the textile is washed, and better textile strength; the textile has soft and comfortable handfeel, rich color and good strength, meets the requirements of various flame-retardant clothes and related standards; the product has rich and varied appearances and is durable; and the combustion performance of the textile can meet the national standards of flame-retardant products.

Owner:汕头市奥山服饰有限公司

Energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and preparation method thereof

ActiveCN102746784AExcellent performanceGood compatibilityAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryWetting

The invention discloses an energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and a preparation method thereof. The functional coating is prepared from the following raw materials: an aqueous polyurethane dispersion, a flame retardant, a flame-retardant antismoke agent, a hollow glass bead, a wetting dispersant, an anti-settling agent, a thickening agent, water, a leveling agent and a de-foaming agent, has the functions of heat preservation, flame retarding, water prevention and corrosion resistance and the like, is unlikely to become yellow when in use, is safe and reliable, is excellent in performance, is good in compatibility with pigment dyestuff, is unlikely to damage the coated surface, is easy to modify, is nontoxic, is safe to use, does not pollute environment and is suitable for the fields of inner and outer wall coating, pipeline coating, wood furniture coating, decoration coating, chemical corrosion-proof coating and the like.

Owner:江苏瑞丰科技实业有限公司

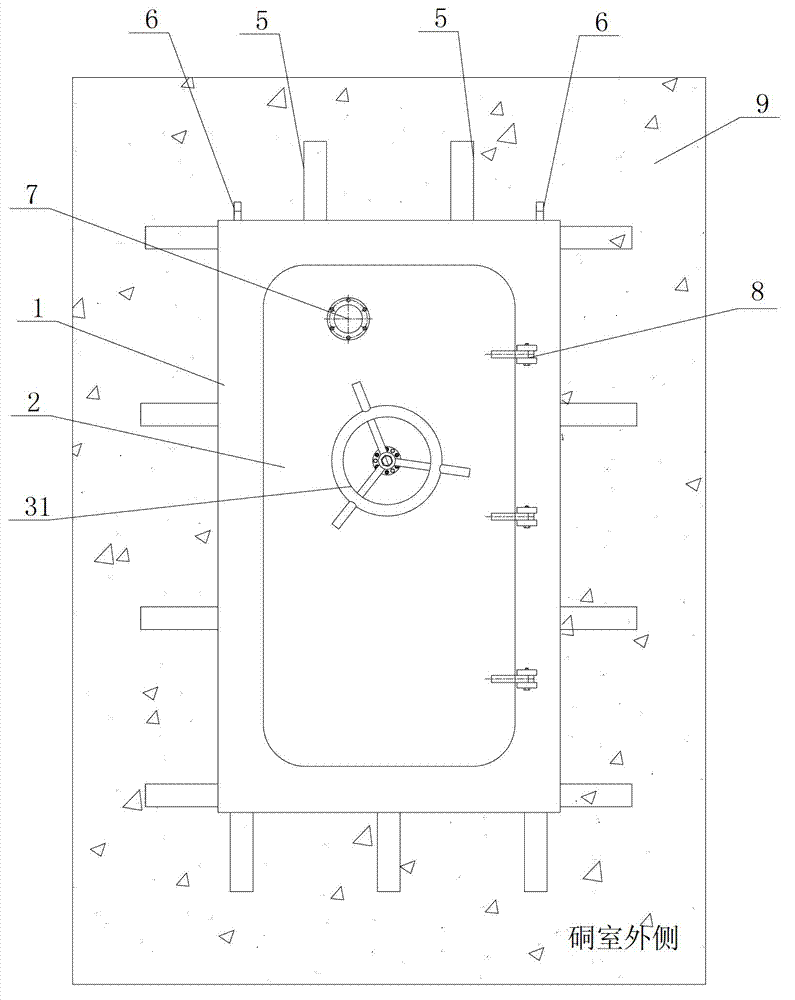

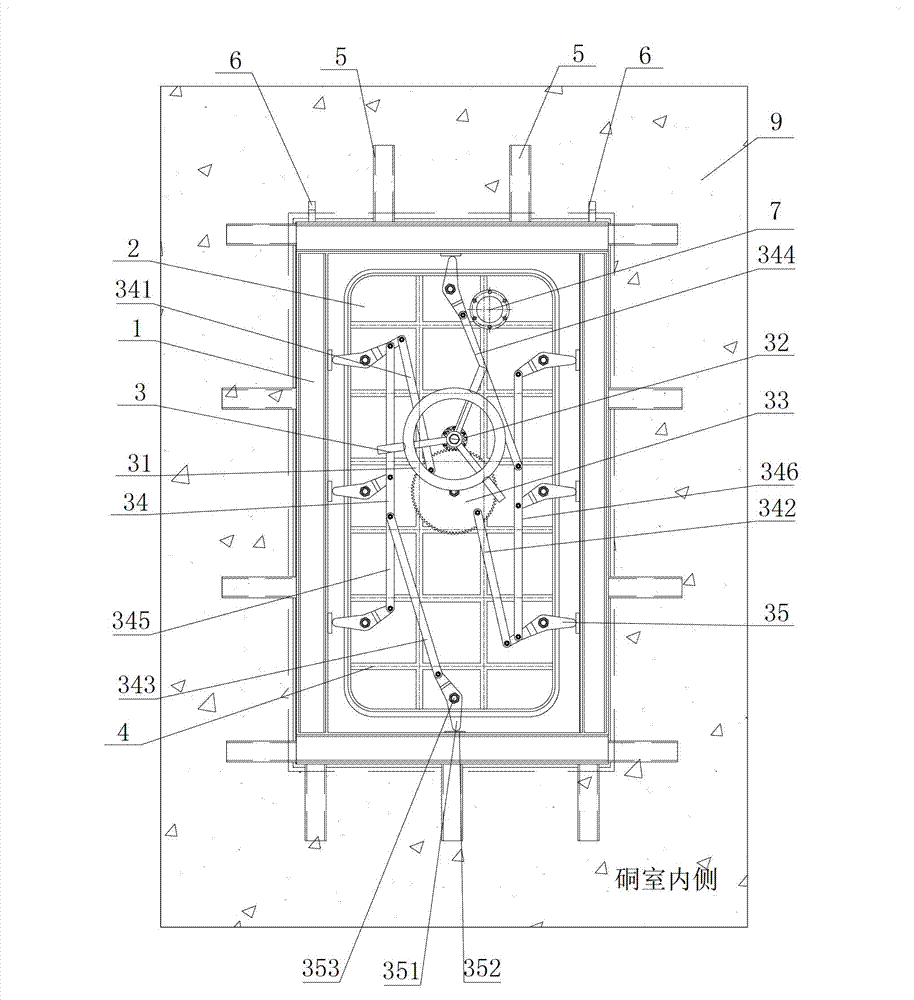

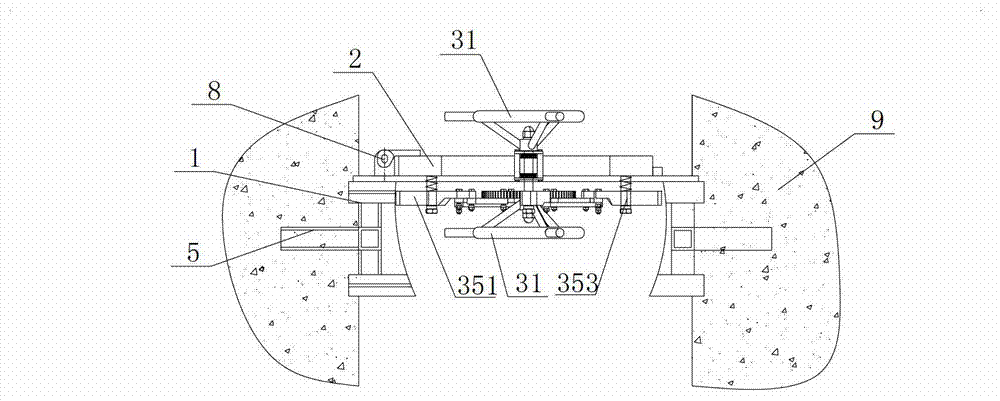

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

Flame-resistant and uvioresistant polyester composite material and method for preparing same

ActiveCN101735578AFlame retardant hasHas anti-ultraviolet effectFlame-proof filament manufactureMonocomponent polyesters artificial filamentLow vacuumEsterification reaction

The invention relates to a flame-resistant and uvioresistant polyester composite material and a method for preparing the same. The composite material is prepared by performing an esterification reaction on ethylene glycol, terephthalic acid, uvioresistant agent pulp and a flame retardant and then performing low-vacuum condensation polymerization and high-vacuum condensation polymerization, wherein the added amounts of the uvioresistant agent pulp and the flame retardant are between 0.1 and 20 weight percent and between 0.1 and 20 weight percent respectively; the esterification reaction is performed at the temperature of between 200 and 290 DEG C and under a pressure of between 0.1 and 0.6 MPa for 1 to 4 hours; the low-vacuum condensation polymerization is performed at the temperature of between 200 and 290 DEG C and under the pressure of between 100,000 and 500 Pa for 10 to 90 minutes; the high-vacuum condensation polymerization is performed at the temperature of between 250 and 300 DEG C and under the pressure of between 500 and 50 Pa for 1 to 4 hours; and the uvioresistant agent pulp consists of 5 to 30 weight percent of inorganic nano-oxide and the ethylene glycol. Flame-resistant and uvioresistant polyester fiber fabrics prepared from the material have flame resistance and uvioresistant effect.

Owner:PETROCHINA CO LTD

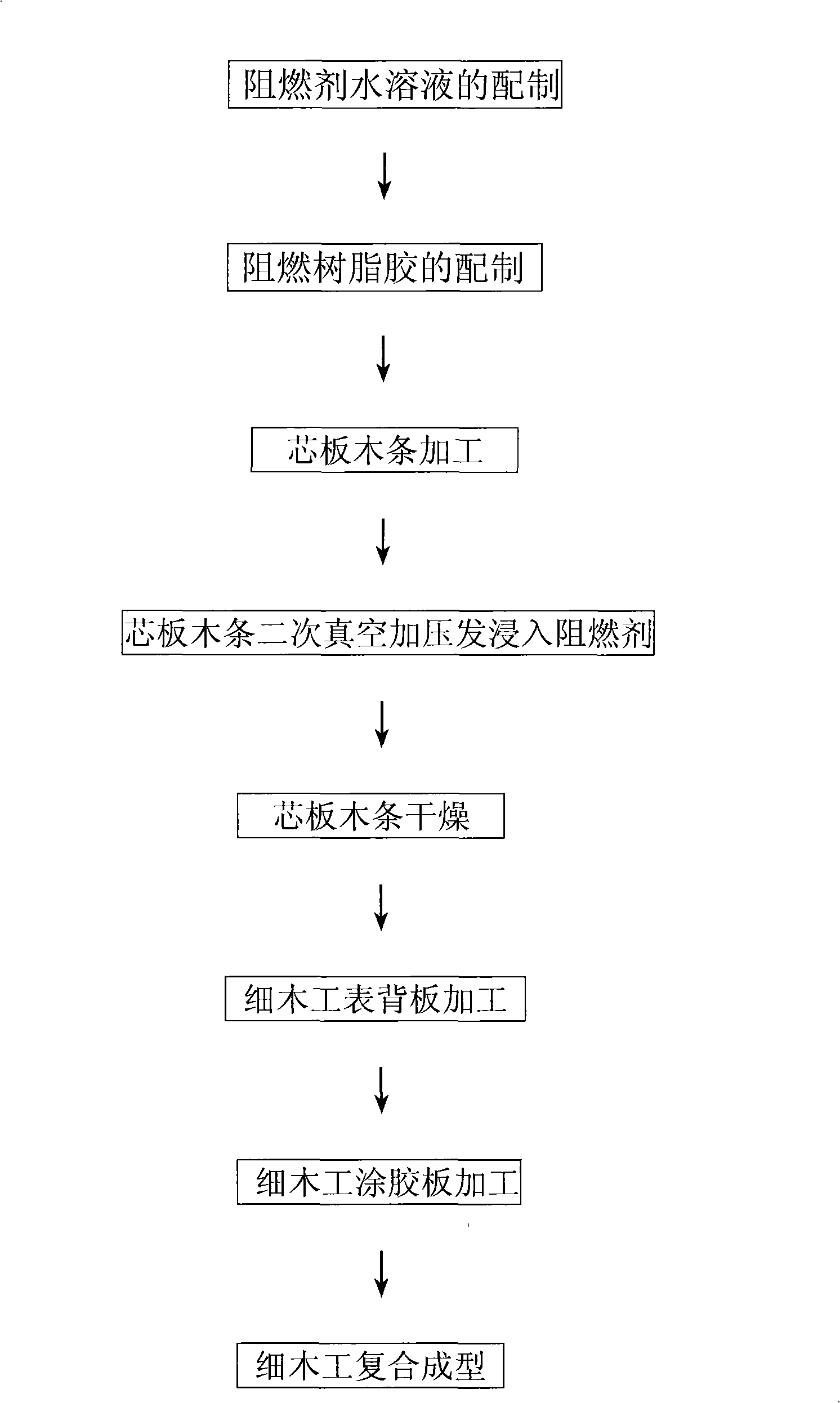

Preparation method for composite inflaming retarding core-board

InactiveCN101513745AFull immersionImprove flame retardant performanceWood treatment detailsWood veneer joiningWater basedLower grade

The invention relates to a preparation method for composite inflaming retarding core-board. The technology of filling a flame retardant by secondary vacuumizing / pressurizing is employed to lead the flame retardant to be more sufficiently dipped into the inside of a core-board strip and improve the inflaming retarding performance of the core-board strip. The flame retardant employs a non-halogen water-base environmental-friendly compound flame retardant which does not contain formaldehyde, has strong inflaming retarding performance, smoke inhibiting and mould-proof effects. The invention is a manufacture method for employing the low-grade wood or leftover materials after processing like undersized logs and removing the quality and processing defects to produce high-grade composite inflaming retarding core-board. The product of the invention has the characteristics of inflaming retarding, corrosion resistance, environment protection, heat preservation, sound isolation, and easy processing, and is an ideal fire-proof inflaming retarding material for the industries like furniture, door manufacture, and building decoration.

Owner:黑龙江省尚志国有林场管理局

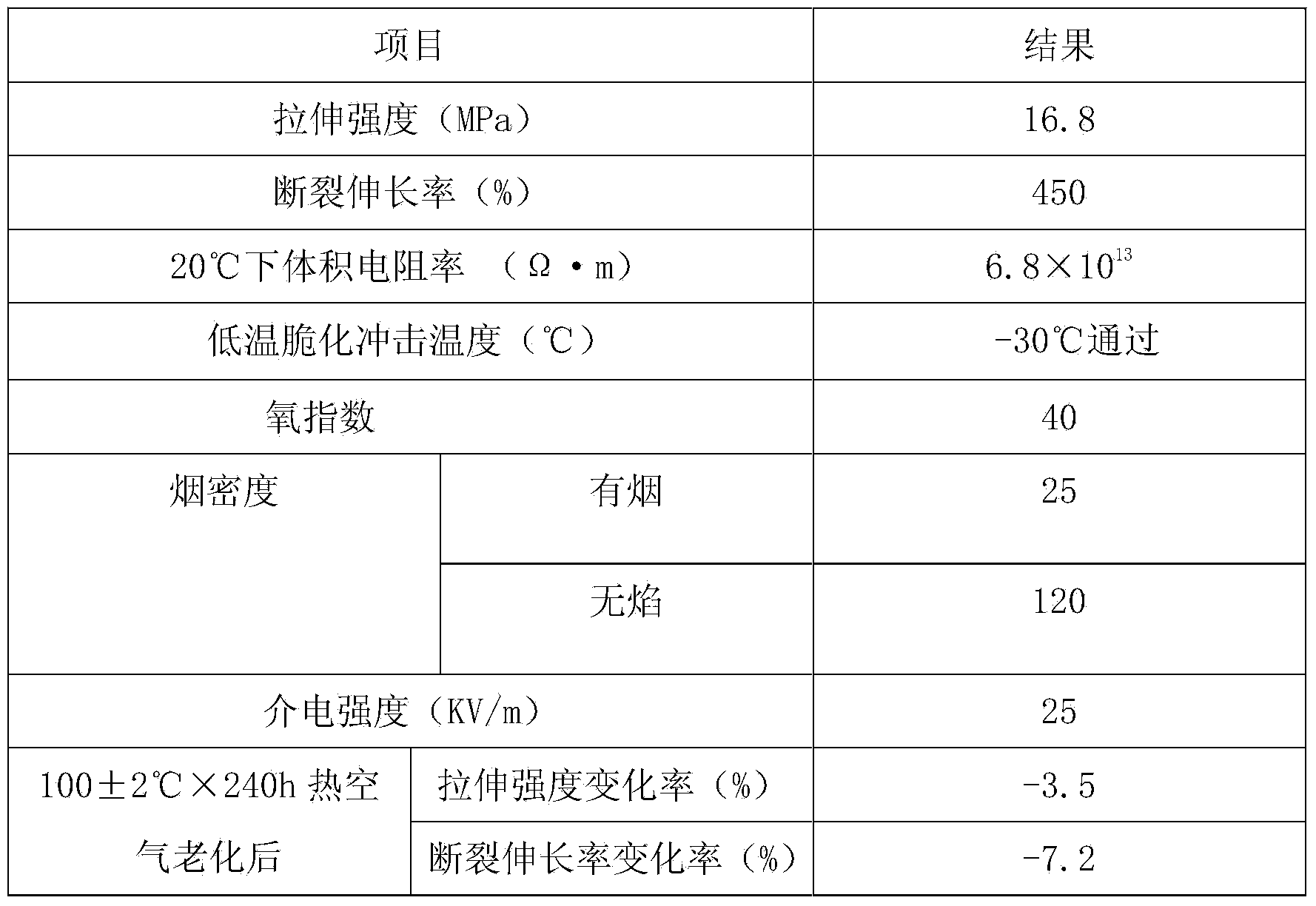

Flame-retardant oil-resistant aging-resistant thermoplastic elastomer cable material

ActiveCN103524913AFlame retardant hasFlame retardant and oil resistantPlastic/resin/waxes insulatorsInsulated cablesCalcium silicatePolyvinyl chloride

The invention provides a flame-retardant oil-resistant aging-resistant thermoplastic elastomer cable material prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride SG-3, 10-20 parts of nitrile rubber N26, 10-15 parts of polycarbonate, 10-15 parts of poly(ethylene terephthalateco-1,4-cylclohexylenedimethylene terephthalate), 15-20 parts of a silane coupling agent, 30-40 parts of bisphenol-A bis(diphenyl phosphate), 20-30 parts of calcium carbonate, 1-2 parts of calcium silicate, 30-50 parts of barium stearate, 10-15 parts of cresyl diphenyl phosphate, 3-4 parts of glycerol trioleate, 2-3 parts of a crosslinking agent TAIC, 2-3 parts of stearic acid, 1-2 parts of N,N'-m-phenylenedimaleimide, 5-8 parts of alcohol ester-12, 0.5-1.0 part of PE wax, 1-2 parts of aluminum nitride powder, 1-2 parts of jade powder, and 8-10 parts of a modified filler. The flame-retardant oil-resistant aging-resistant thermoplastic elastomer cable material has the characteristics of flame retardancy, oil resistance, aging resistance, and acid and alkali resistance, and has lower specific density and low manufacture cost.

Owner:滁州君越高分子新材料有限公司

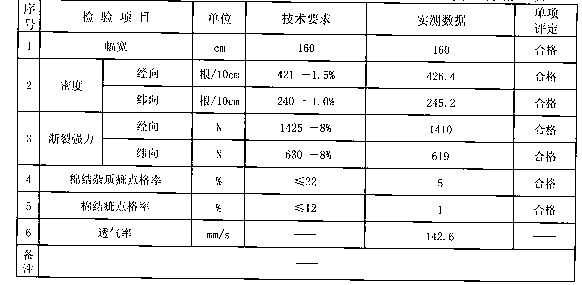

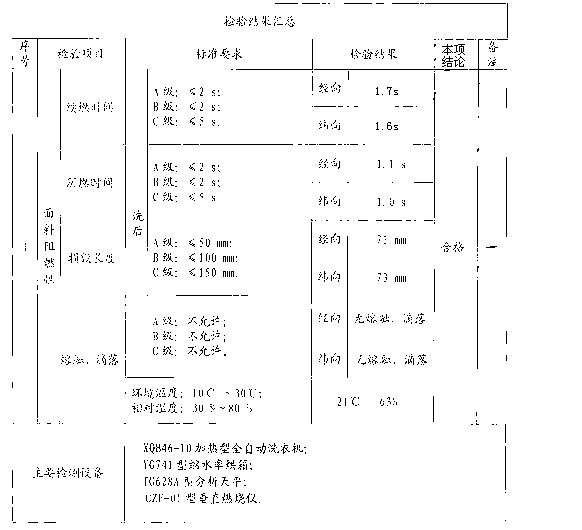

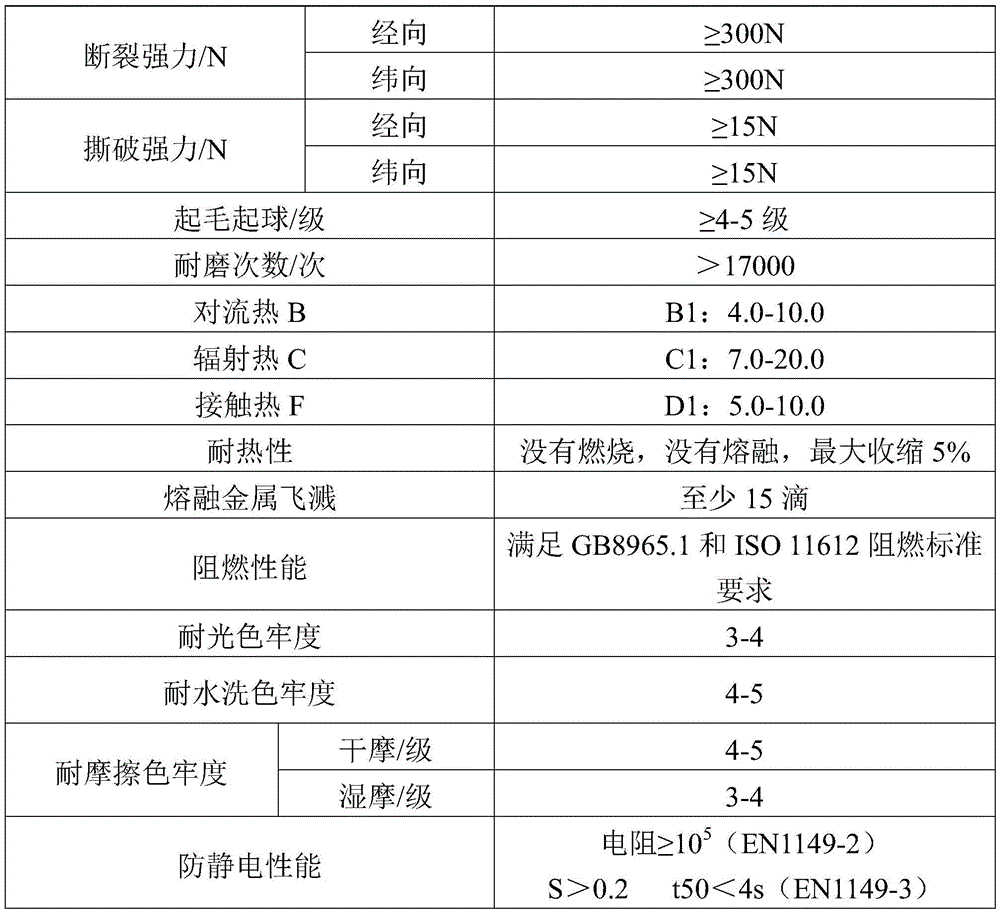

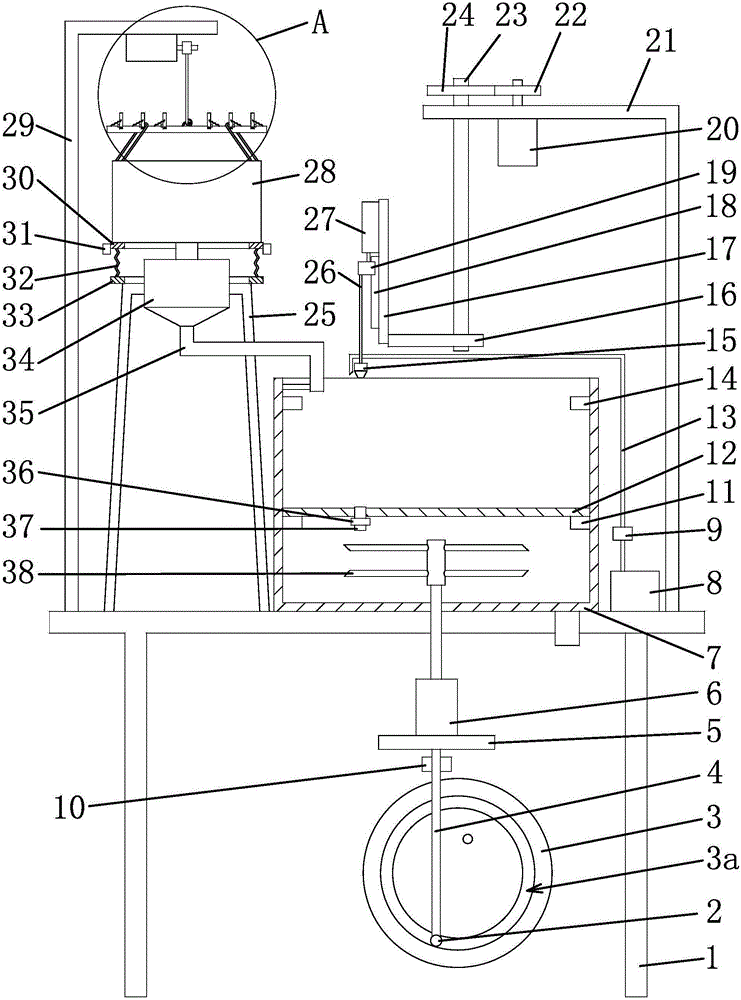

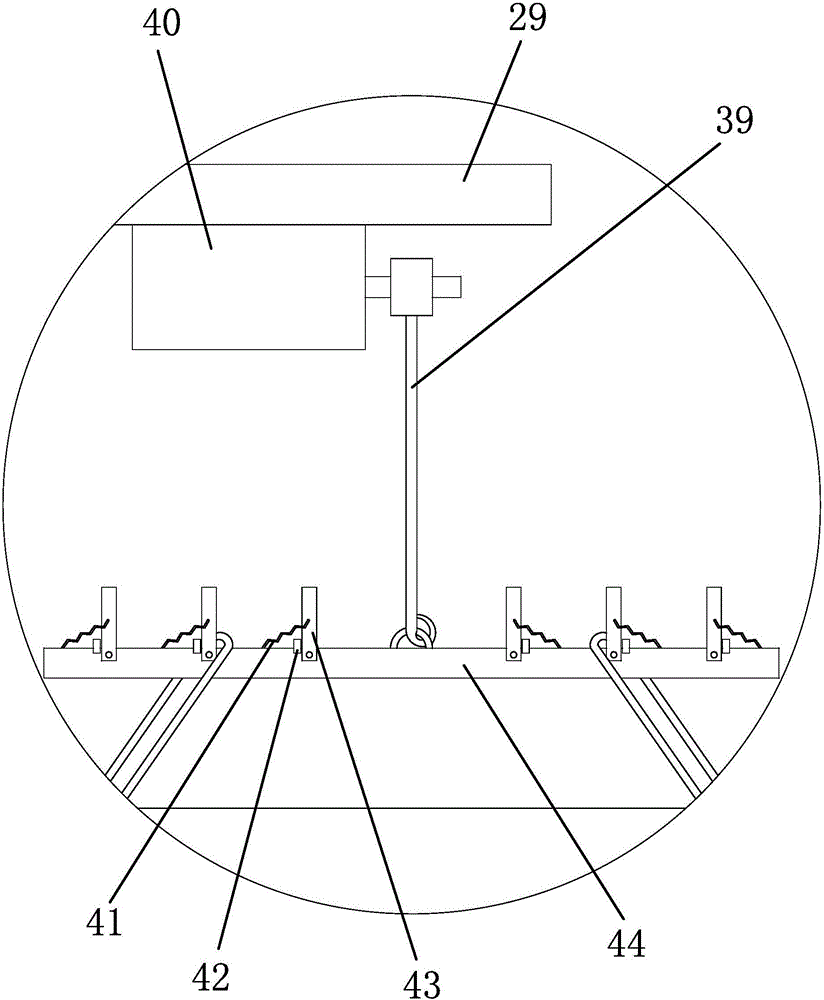

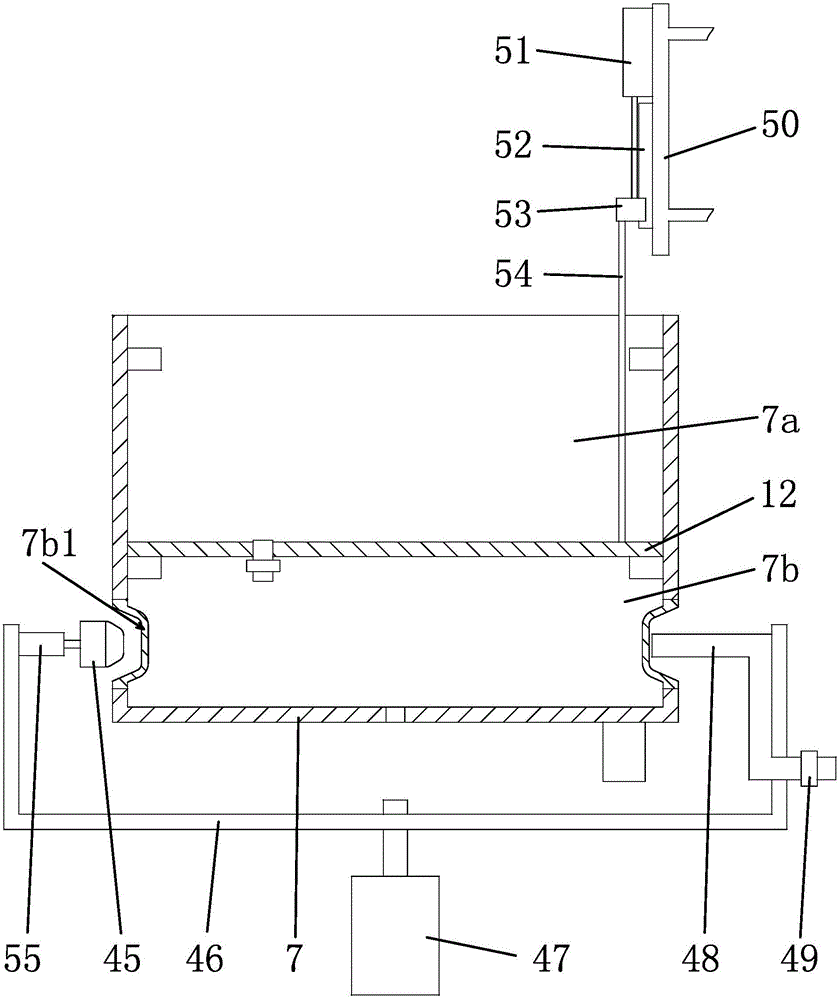

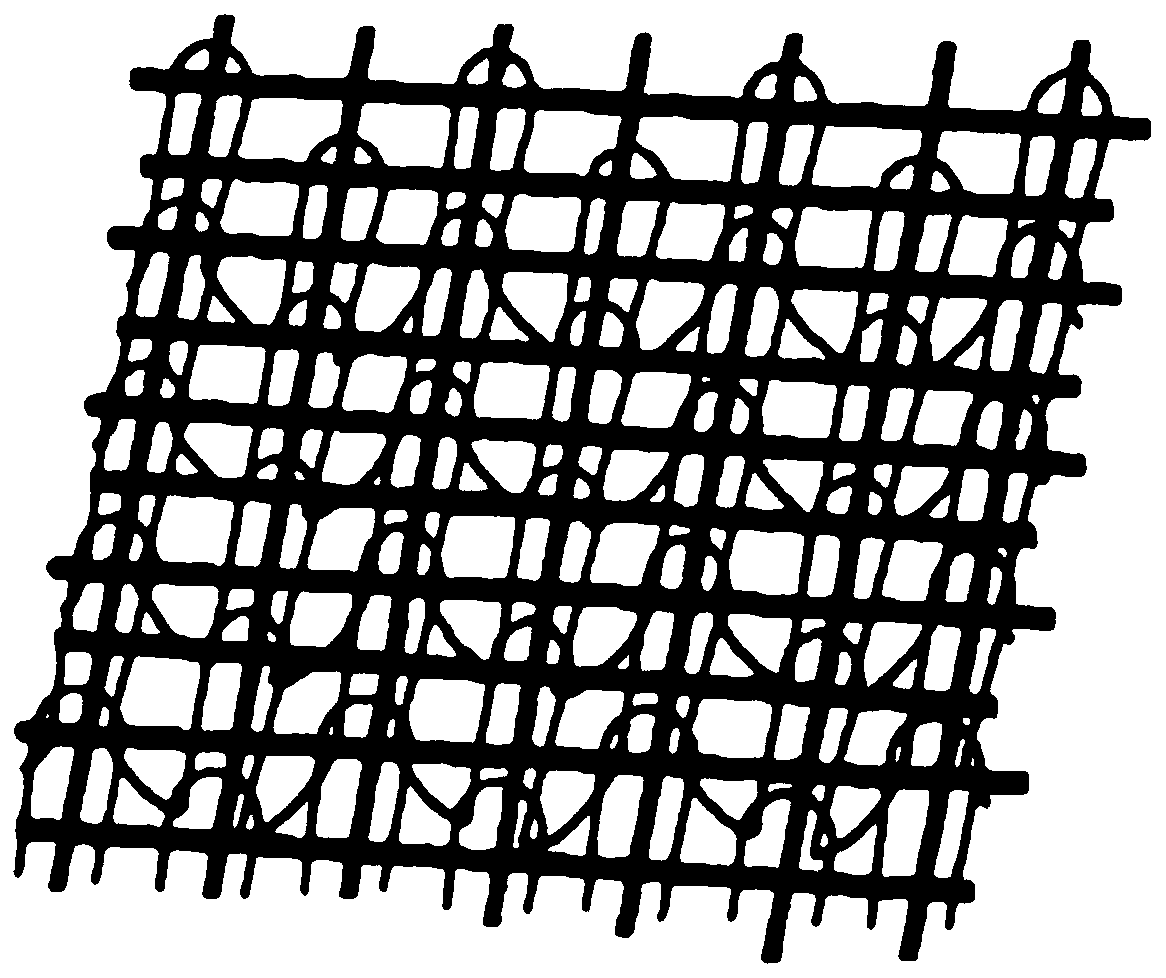

Coal mine protective clothing fabric and preparation method thereof

InactiveCN103061000ALess hairyGuarantee the basic protection requirementsWoven fabricsVegetal fibresEngineeringFire retardant

The invention provides a coal mine protective clothing fabric which is durable and comfortable to wear, flame-retardant, anti-static, oil-proof, waterproof, good in antifouling performance and low in price. The coal mine protective clothing fabric is prepared from warp yarns and weft yarns by embedding a PET100D conductive filament every 2cm in the warp direction, wherein each warp yarn is a vortex spinning all-cotton MVS CM18.2texX2 two-fold yarn, each weft yarn is a vortex spinning all-cotton MVS CM32.4tex single yarn, warp density is 421 pieces / 10cm, and weft density is 240 pieces / 10cm. The preparation method of the coal mine protective clothing fabric includes the steps: a, spinning; b, weaving including warping, sizing and drafting; c, printing and dyeing; and d, afterfinish including flame-retardant finish and tri-proof finish, wherein during flame-retardant finish, Pyrovatex CP new serves as fire retardant, and RUCOSTAR EEE serves as tri-proof finish agent.

Owner:JIANGSU YDTEX GRP LTD

Halogen-free flame-retardant dicyclopentadiene material and preparation method thereof

ActiveCN101792505AImprove appearance qualityImprove mechanical propertiesPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPhosphateAluminium hydroxide

The invention discloses a halogen-free flame-retardant dicyclopentadiene material and a preparation method thereof. The material consists of polydicyclopentadiene, flame retardant, modifier and catalyst, wherein the flame retardant is silane coupling agent, titanate coupling agent, aluminium zirconate coupling agent, organic chromium coupling agent, higher fatty acid and salt thereof, phosphate, unsaturated organic acid or organic ammonium salt modified aluminium hydroxide. The preparation method prepares the flame-retardant material by using reaction injection moulding. The oxygen index of the obtained material is 22 to 26 percent, and the horizontal combustion test can reach HB level; and the bending strength is 40 to 45MPa, the bending modulus is 1,400 to 1,700MPa, the tensile strength is 34 to 37MPa, the impact strength is 26-80kJ / m<2>, and the hardness is 74 to 76 Shaw D. The material does not contain halogen flame retardant, and has high flame-retardant performance and high mechanical property.

Owner:LIMING RES INST OF CHEM IND

Fluorescent inflaming-retarding multifunctional double-layer fabric and preparing method thereof

ActiveCN105483898AFlame retardant hasHigh temperature resistantFibre typesMulti-ply fabricsYarnSurface layer

The invention discloses a fluorescent inflaming-retarding multifunctional double-layer fabric. The surface layer of the fabric is woven from inflaming-retarding yarn capable of being dyed with fluorescence color, and the inner layer of the fabric is woven from non-melting inflaming-retarding yarn incapable of being dyed with fluorescence color. The warps of the inner layer are lifted to be interwoven with the wefts of the surface layer to form a binding texture so that the two layers can be connected. The fabric is prepared in the way that the warps of the inner layer are lifted to be interwoven with the wefts of the surface layer to form the binding texture so that the two layers can be connected, and then dyeing treatment is conducted to generate the fluorescent inflaming-retarding multifunctional double-layer fabric. Specifically, the two layers of the fabric are connected in the way that when surface wefts are put in for surface layer weaving, all inner warps must sink to the space below a shed and can not be interwoven with surface wefts; when inner wefts are put in for inner layer weaving, all surface warps must be lifted and can not be interwoven with inner wefts. The double-layer fabric can have different spaces and can be used for making protection garments in a plurality of fields.

Owner:SHAANXI YUANFENG TEXTILE TECH RES

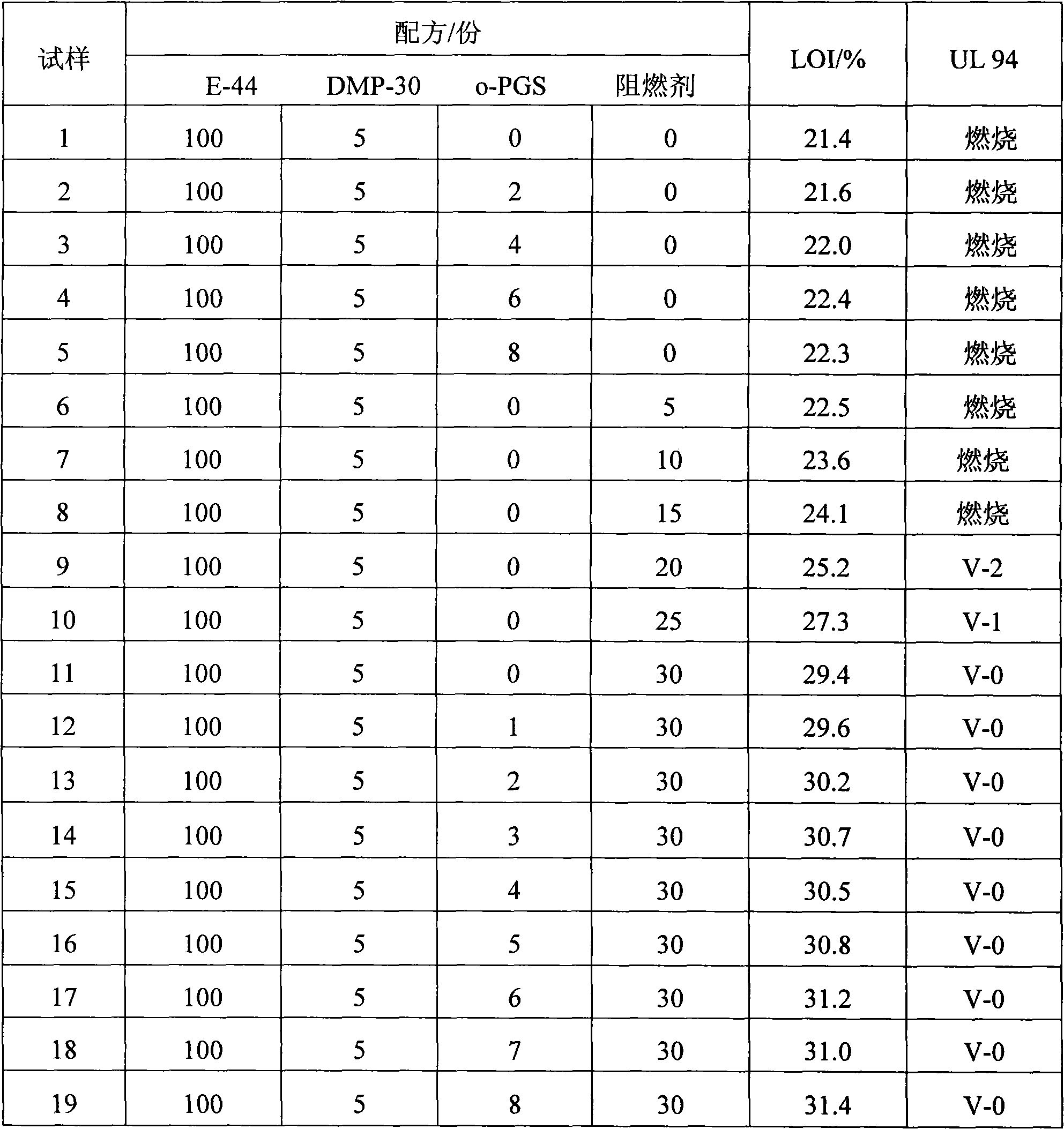

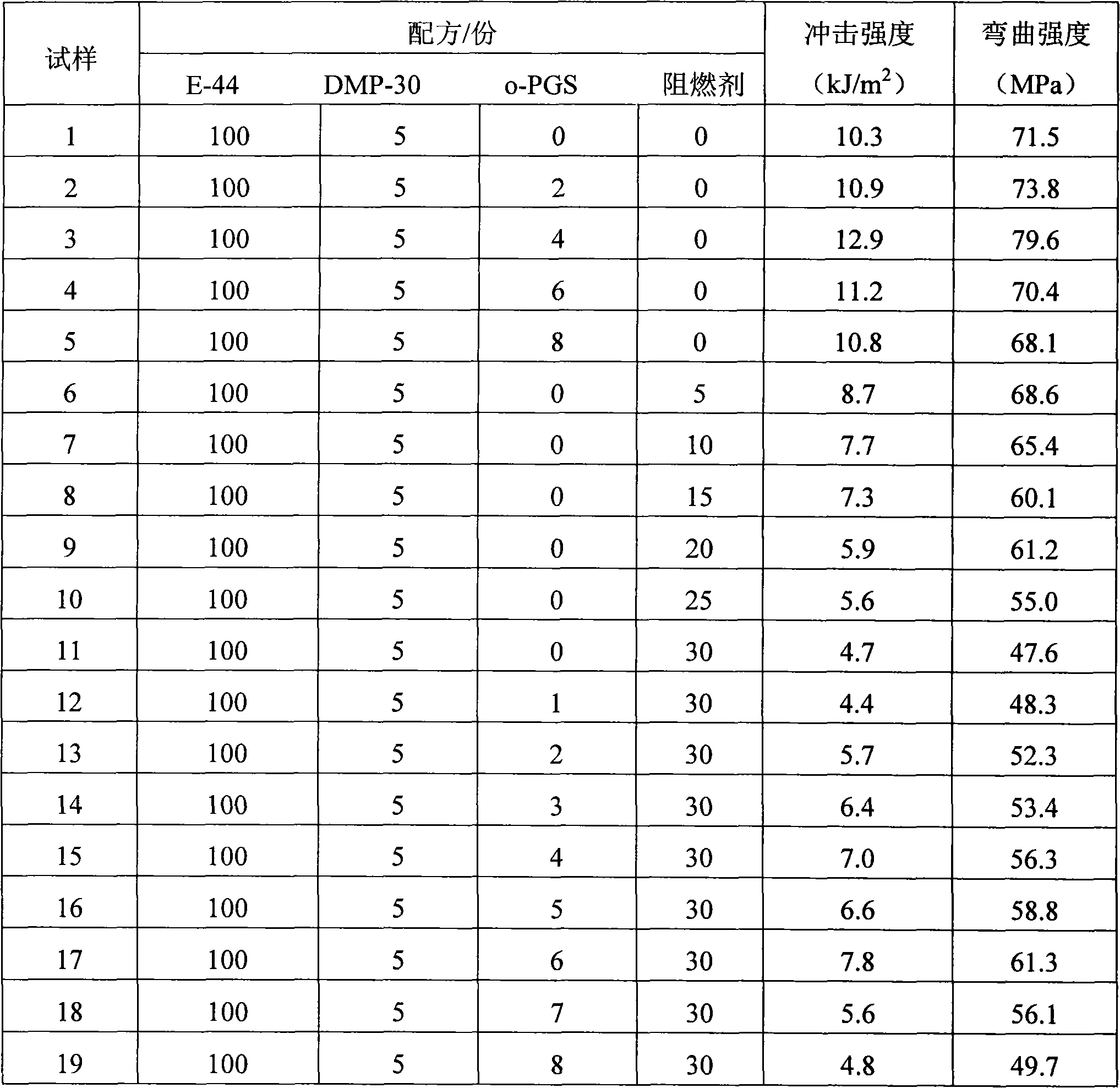

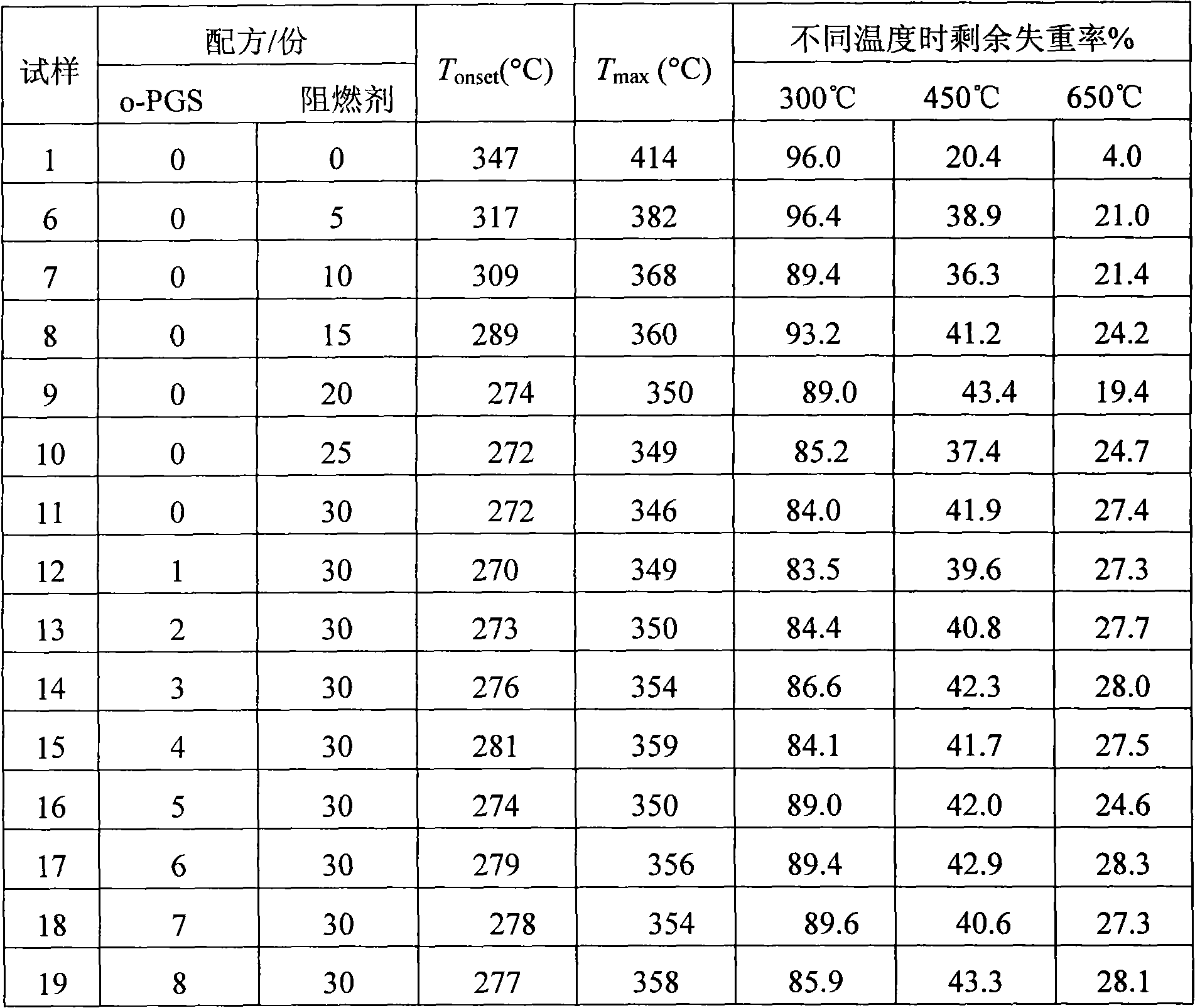

Nanometer grade paligorskite-flame retardant epoxide resin composite material

The invention provides a nano-palygorskite reinforced flame retarding epoxy resin composite material which disperses the nano-palygorskite into epoxy resin matrix by means of ultrasonic dispersion by mass ratio between 1:100 and 8:100 after surface treatment is carried out to the nano-palygorskite, then mix the obtained palygorskite epoxy resin mixture with a reactive-type flame retardant by the mass ratio between 100:5 and 100:30, and casting and curing are carried out. A plurality of P-N bond intermediates formed in the reactive-type flame retardant of the invention are phosphorylating agents better than routine phosphorus compounds, and water vapor generated from nano-palygorskite acting as a synergistic flame retardant during burning is in great favor for a phosphorous flame retardant, and the reinforcement of appropriate amount of nano-palygorskite compensates for the reduction of the mechanical property of the epoxy resin caused by adding the flame retardant to some extent, serving double effect of flame retardation and reinforcement, thus, the flame retarding epoxy resin composite material of the invention has the advantages of high oxygen index, good smoke suppression effect and excellent physical and mechanical properties.

Owner:NORTHWEST NORMAL UNIVERSITY

Flame-resistant and uvioresistant polyester composite material and method for preparing same

ActiveCN101735578BFlame retardant hasHas anti-ultraviolet effectFlame-proof filament manufactureMonocomponent polyesters artificial filamentLow vacuumEsterification reaction

The invention relates to a flame-resistant and uvioresistant polyester composite material and a method for preparing the same. The composite material is prepared by performing an esterification reaction on ethylene glycol, terephthalic acid, uvioresistant agent pulp and a flame retardant and then performing low-vacuum condensation polymerization and high-vacuum condensation polymerization, wherein the added amounts of the uvioresistant agent pulp and the flame retardant are between 0.1 and 20 weight percent and between 0.1 and 20 weight percent respectively; the esterification reaction is performed at the temperature of between 200 and 290 DEG C and under a pressure of between 0.1 and 0.6 MPa for 1 to 4 hours; the low-vacuum condensation polymerization is performed at the temperature of between 200 and 290 DEG C and under the pressure of between 100,000 and 500 Pa for 10 to 90 minutes; the high-vacuum condensation polymerization is performed at the temperature of between 250 and 300 DEG C and under the pressure of between 500 and 50 Pa for 1 to 4 hours; and the uvioresistant agent pulp consists of 5 to 30 weight percent of inorganic nano-oxide and the ethylene glycol. Flame-resistant and uvioresistant polyester fiber fabrics prepared from the material have flame resistance and uvioresistant effect.

Owner:PETROCHINA CO LTD

Flame-retardant sound insulation composite material and sound insulation component

ActiveCN101735530AFlame retardant hasGood sound insulation effectSound producing devicesIron powderPlasticizer

The invention relates to a flame-retardant sound insulation composite material. The flame-retardant sound insulation composite material comprises the following components in percentage by weight: 5 to 30 percent of PVC, 5 to 30 percent of chlorinated polyethylene, 15 to 80 percent of iron powder of which the grain diameter is 10 to 100 microns, 0.5 to 2 percent of coupling agent and 9.5 to 23 percent of aid. The invention provides the flame-retardant sound insulation composite material, which is prepared from the PVC, the chlorinated polyethylene, the iron powder with the grain diameter of 10 to 100 microns, the coupling agent and the aid, has good flame-retardant sound insulation effect, and also has the characteristics of flame retardancy, innocuity, no lead, high strength, good construction property and low cost. Because the chlorinated polyethylene is particularly introduced into the material components of the flame-retardant sound insulation composite material, the using amount of a plasticizer of the material is reduced, and the composite material has better softness and can be widely applied to sound insulation treatment in the construction industry, decoration field and the like; and the sound insulation composite material can effectively reduce the noise, and the sound insulation index of the material can reach 25 to 32 decibels.

Owner:深圳洛赛声学技术有限公司

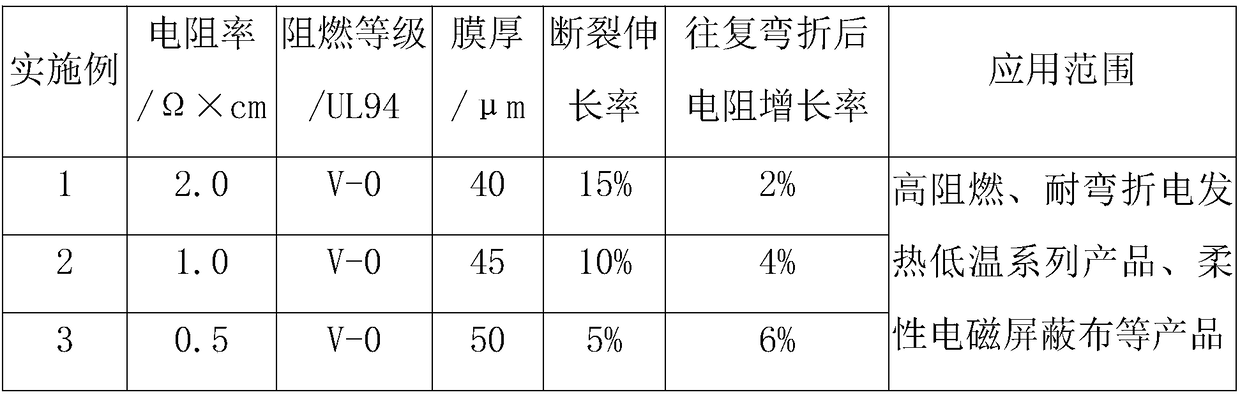

Graphene flame-retardant elastic composite, composite film and preparing method of composite film

The invention provides a graphene flame-retardant elastic composite. The composite is characterized by being prepared from, by mass, 0.5-10% of graphene microchips, 20-35% of fire retardant, 10-30% ofthermoplastic elastomer, 30-60% of solvent and 0.1-1.5% of auxiliaries. In addition, the invention further provides a composite film containing the graphene flame-retardant elastic composite and a preparing method of the composite film. The composite obtained with the thermoplastic elastomer, the fire retardant and the solvent with different elasticity moduli as the film forming materials and thegraphene microchips as the conductive filler has the advantages of flame retardance, high conductivity, bendability, high adhesiveness and the like, and therefore the composite film prepared from thecomposite also has the advantages of flame retardance, high conductivity, bendability, high adhesiveness and the like, and the composite film can be applied in the fields of electromagnetic shielding, far infrared electric heating products, flexible conductive electrodes and the like, is wide in application range, and effectively overcome the problems that an existing electric heating film product is poor in bending resistance and potential safety hazards such as spontaneous combustion are caused by local overheating.

Owner:中金态和(武汉)石墨烯科技股份有限公司

Siliconless fire-retardant type quick solidifying covering film for flexible circuit and its preparation method

InactiveCN1537906AGuaranteed stabilityLower volatility pointLiquid surface applicatorsEpoxy resin coatingsEpoxyElastomer

A flame-retarded quickly solidified silicon-free covering film for flexible circuit contains brominated epoxy resin, liquid phenolic epoxy resin, high-activity low-viscosity epoxy resin, acrylate copolymer, diaminodiphenyl sulfone (or methane), aluminium hydroxide, Sb2O3, and toluene / acetone. Its advantages are high adhesion and fire resistance.

Owner:SHENZHEN DANBOND TECH

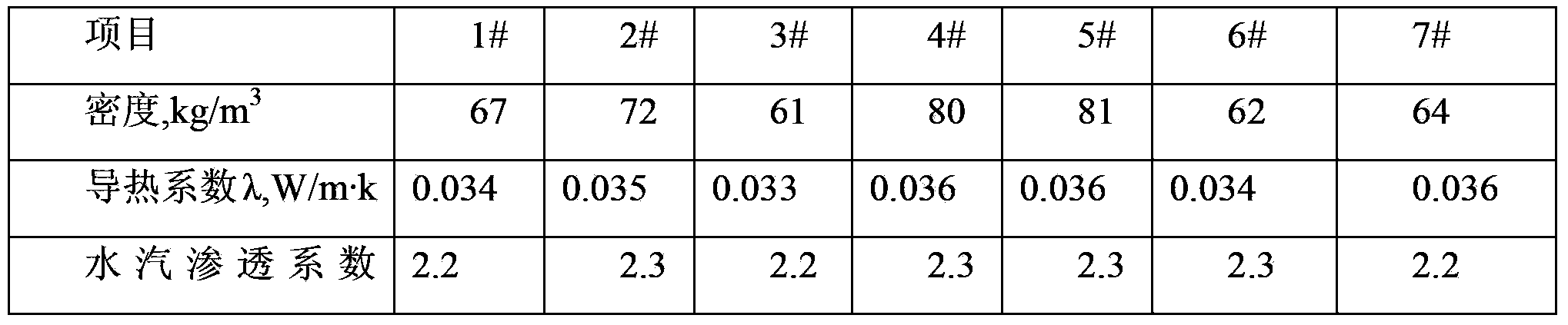

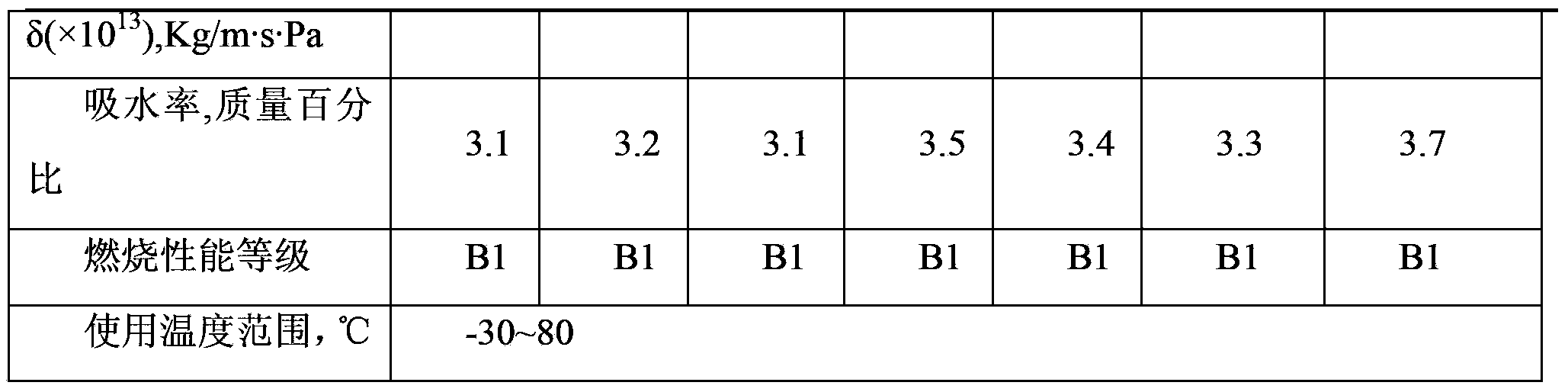

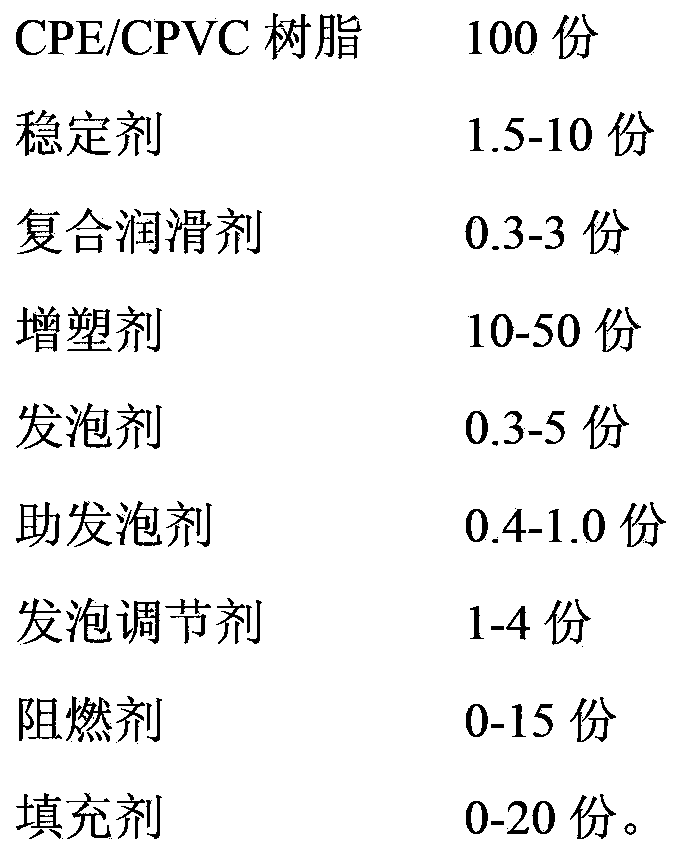

CPE/CPVC rubber-plastic thermal-insulation material and preparation method thereof

The invention relates to a CPE / CPVC rubber-plastic thermal-insulation material and a preparation method thereof and belongs to the field of polymer synthesis and processing application. The CPE / CPVC rubber-plastic thermal-insulation material is prepared from 100 parts by mass of CPE / CPVC resin, 1.5-10 parts by mass of a stabilizing agent, 0.3-3 parts by mass of a composite lubricant, 10-50 parts by mass of a plasticizer, 0.3-5 parts by mass of a foaming agent, 0.4-1.0 part by mass of a foaming aid, 1-4 parts by mass of a foaming adjustment agent, 0-15 parts by mass of a fire retardant and 0-20 parts by mass of a filling material. The CPE / CPVC rubber-plastic thermal-insulation material has excellent performances such as softness, flexing damage resistance, cold resistance, heat resistance, flame retardation, water resistance, low heat-conduction coefficient, cushioning effect and sound absorption and has ideal use effects in the aspect of thermal insulation for heat loss prevention. The preparation method of the CPE / CPVC rubber-plastic thermal-insulation material is simple and continuous, has high production efficiency, is suitable for streamline batch production and can be widely used in industries of building, light textile, medicine, chemical engineering, metallurgy and ship-building.

Owner:CHINA PETROLEUM & CHEM CORP

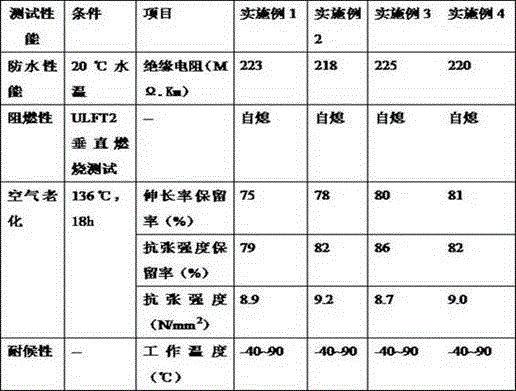

Waterproof flame-retardant cable material and preparation method thereof

ActiveCN106519521AImprove performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsTetrafluoroethyleneAgricultural engineering

The invention discloses a waterproof flame-retardant cable material. The waterproof flame-retardant cable material is prepared from the following raw materials by weight: 30 to 60 parts of tetrafluoroethylene-propylene rubber, 25 to 40 parts of EPDM, 20 to 35 parts of chlorinated polyethylene, 10 to 30 parts of ammonium polyphosphate, 10 to 20 parts of kaolin, 20 to 30 parts of nanometer carbon black, 1 to 5 parts of sulfur, 15 to 30 parts of a fire retardant, 1 to 5 parts of an anti-oxidant and 1 to 5 parts of a lubricant. The invention also discloses a preparation method for the waterproof flame-retardant cable material. The preparation method is simple and is easy to operate. The prepared waterproof flame-retardant cable material has the characteristics of water resistance, damp resistance, flame retardation, aging resistance and the like, appears to be smooth and fine, can adapt to specific application environment condition and has broad market application prospects.

Owner:XITIANQI SUZHOU ELECTRONICS

Novel low-carbon veneer and manufacture method thereof

InactiveCN101941218AAddress resource scarcityImprove protectionWood veneer joiningWood layered productsEnvironmental resistanceFiber

The invention discloses a novel low-carbon veneer formed by the lamination of at least one wood layer and at least one magnesite gelation flame-retardant layer. The magnesite gelation flame-retardant layer mainly comprises the contents of magnesium chloride and magnesium oxide, plant fibers, such as sawdust or peanut shell powder, as well as glass fibers, modifiers and other mineral extractives are also added, and the wood layer and the magnesite gelation flame-retardant layer are laminated and adhered through an adhesive or cemented by a cementing material. The invention also discloses a manufacture method of the veneer. The novel low-carbon veneer of the invention is fireproof, moistureproof, non-toxic, environment-friendly without inducing insect pests, high-temperature-resistant, sound-absorbing, shockproof, light-quality and antiseptic, can be sawed, planed, nailed or processed otherwise and can favorably solve the problem of wood shortage and protect the environment.

Owner:庄启程 +2

Forming method of resin matrix composite with double layers of foam sandwich structures

The invention discloses a forming method of a resin matrix composite with double layers of foam sandwich structures, the entire forming preparation of the resin matrix composite with double layers of foam sandwich structures is realized by adopting a liquid forming method, the forming method comprises the following steps: on a mold which can heat, employing a step-by-step dipping technology, dipping a lower-layer pre-formed body in a pre-formed body of the double layers of sandwich structures in a Z direction by using a resin film infusion method, and then guiding fluid resin by using a vacuum infusion molding process to dip upper-layer pre-formed body and a middle layer pre-formed body in the pre-formed body of the double layers of sandwich structures; after dipping, carrying out co-curing forming on the upper, middle and lower layers of pre-formed bodies and two foam sandwiches clamped between the upper, middle and lower layers of pre-formed bodies, so as to obtain the resin matrix composite with double layers of foam sandwich structures, wherein the upper, middle and lower layers of pre-formed bodies and the two foam sandwiches are thoroughly dipped by resin. The forming method has the advantages of simplicity in operation, environment protection, low cost, high functionality and the like, and is especially suitable for the forming preparation of a large-size composite material component.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing flame-retardant luminous polyethylene glycol terephthalate

The invention relates to a method for preparing flame-retardant luminous polyethylene glycol terephthalate. The flame-retardant luminous polyethylene glycol terephthalate is prepared from 0.1 to 20 weight percent of radiant agent, 0.1 to 20 weight percent of fire retardant and the balance of the polyethylene glycol terephthalate, wherein in an esterification reaction, the temperature is between 200 and 290 DEG C and the pressure is between 0.1 and 0.5 MPa; in a low-vacuum polycondensation reaction, the temperature is between 200 and 290 DEG C and the pressure is between 500 and 100,000 Pa; in a high-vacuum polycondensation reaction, the temperature is between 250 and 300 DEG C and the pressure is between 50 and 500Pa; the radiant agent accounts for 5 to 30 percent of the weight of slurry; the grain diameter of the radiant agent is between 1 nm and 1 micron; and the radiant agent with the grain diameter more than 760 nm accounts for 5 percent of the total weight of the radiant agent. The fiber fabric of the flame-retardant luminous polyethylene glycol terephthalate prepared from the composite materials has fire-retardant and luminous effects and is used for fire-fighting working clothes, marine working clothes and camping tents.

Owner:PETROCHINA CO LTD

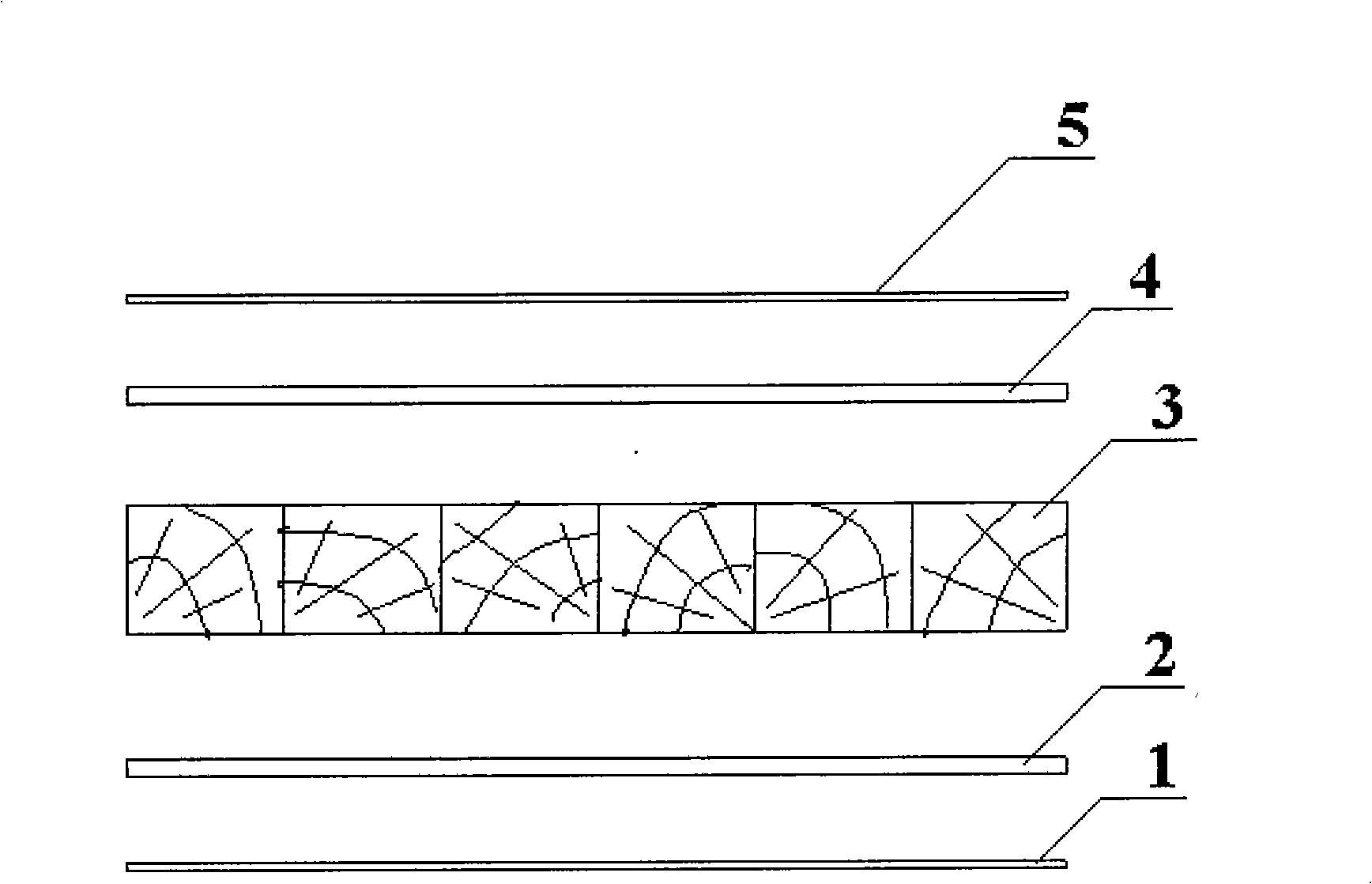

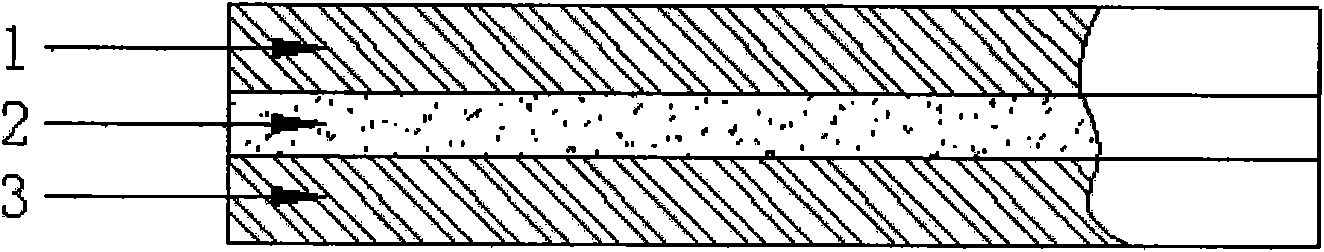

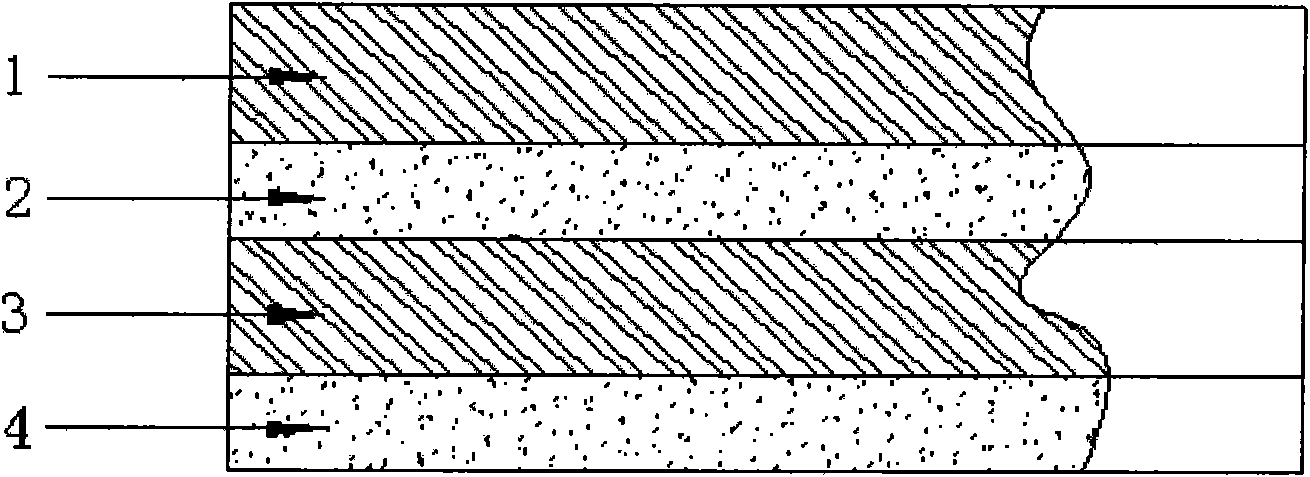

Flame-retardant viscose/aramid 1313 blended camouflage fabric, active carbon fiber fabric and PTFE (polytetrafluoroethylene) film combined multifunctional protective fabric

InactiveCN102440466ALong lastingImprove performanceSynthetic resin layered productsWoven fabricsCamouflagePolytetrafluoroethylene

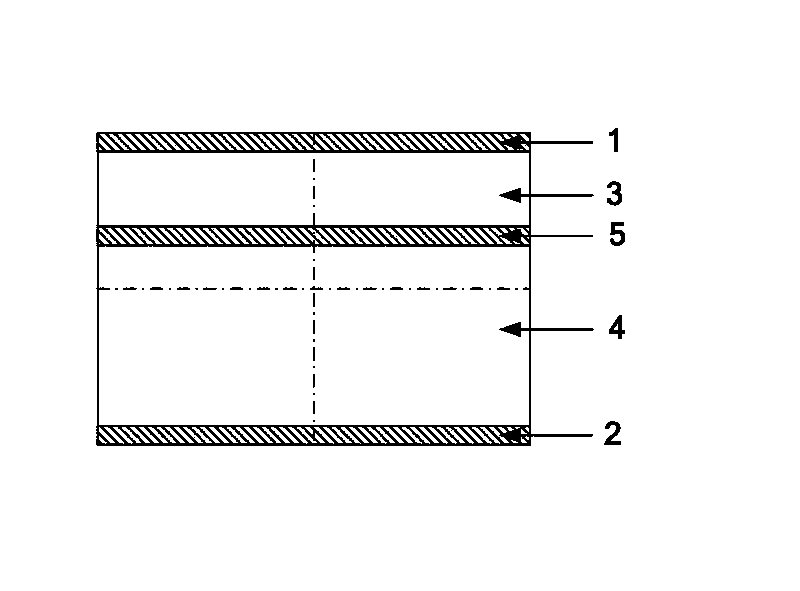

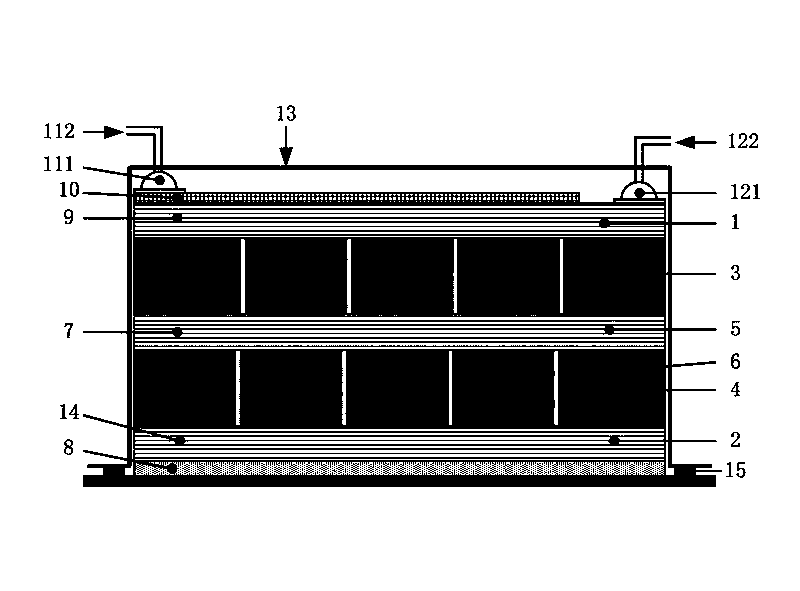

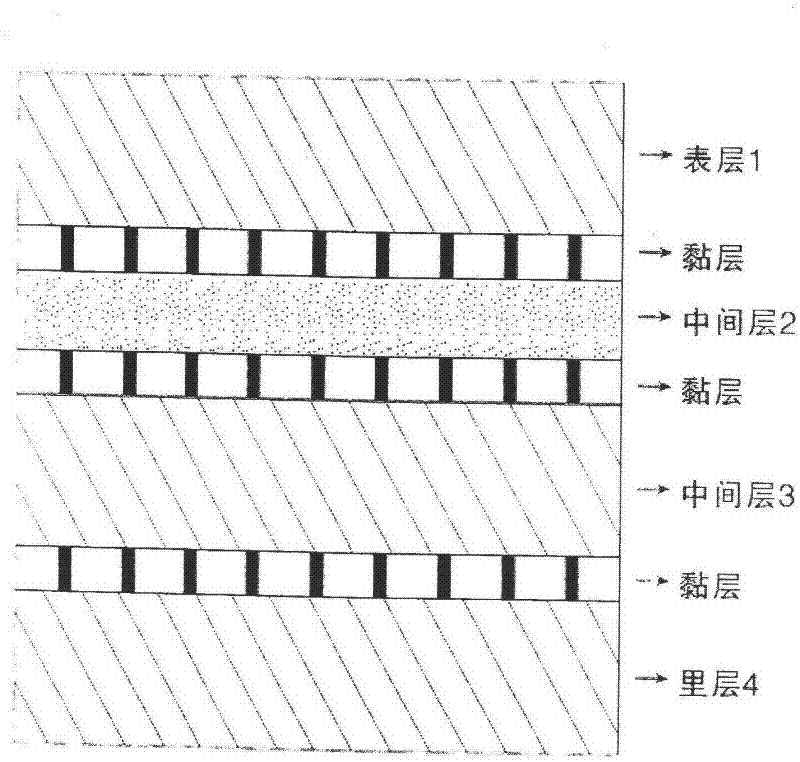

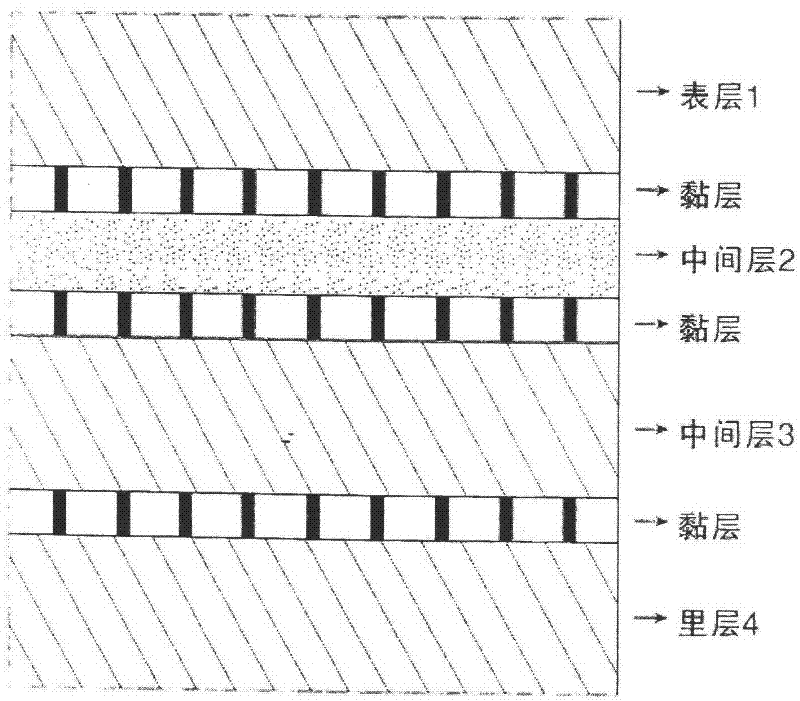

The invention discloses a flame-retardant viscose / aramid 1313 blended camouflage fabric, active carbon fiber fabric and PTFE film combined multifunctional protective fabric, which adopts four combined layers (a surface layer (1), a middle layer (2), a middle layer (3) and an inner layer (4) which are combined). Since a flame-retardant viscose / aramid 1313 blended camouflage fabric, a PTFE garment film, an active carbon fiber fabric, conductive fibers and other textile materials chosen by the invention have special functions and have persistent efficacy, the combined multifunctional protective fabric can effectively prevent the permeation of biological warfare agents, chemical warfare agents, high nuclear temperature and radioactive nuclear dust, also has the functions of water proofing, wind proofing, flame retardance, static electricity resistance, bacteria resistance, moisture permeation, detection resistance (camouflage) and the like, and is a special protective garment fabric which can be widely applied in military, fire fighting, gas proofing and the like.

Owner:SHAOXING SHULILE TEXTILE PROD

Waterborne polyurethane high-resilience plastic foam for automobile seats and preparation process thereof

The invention discloses waterborne polyurethane high-resilience plastic foam for automobile seats and a preparation process thereof. The plastic foam is prepared from the following raw materials in parts by weight: 70-80 parts of glycerol, 25-30 parts of ethylene oxide, 30-35 parts of propylene oxide, 4-8 parts of liquid paraffin, 3-5 parts of polypropylene oxide-ethylene oxide copolyether, 160-170 parts of methylene diphenyl diisocyanate, 6-8 parts of potassium isooctanoate, 2-4 parts of quaternary ammonium formate, 5-7 parts of polydimethylsiloxane, 3-7 parts of sodium acetate, 8-12 parts of aluminium hydroxide, 6-10 parts of carbon black, 4-7 parts of antioxidant TNP, 3-5 parts of ultraviolet absorber UVP-327, 2-3 parts of butyl stearate, 7-11 parts of organosilicon foam stabilizer and 10-12 parts of auxiliaries. The polyurethane high-resilience plastic foam prepared by the preparation process disclosed by the invention has a great resilience, improves the quality of plastic foam, reduces the cost of the plastic foam, consolidates the stability of the plastic foam, and the like; the automobile seats filled by the plastic foam disclosed by the invention have the advantages of good resilience, flame retardance, safety, environment friendliness and the like.

Owner:泉州泉港华博化工科技有限公司

Flex banner and processing technology thereof

ActiveCN106079781ASolve the lack of spacePracticalSynthetic resin layered productsLaminationEpoxyAntioxidant

The invention provides a flex banner and a processing technology thereof and solves the technical problems that the conventional flex banner has simple composition and single function and does not have anti-oxidation, water-proof and flame-retardant characteristics as well as a processing technology and the like. The flex banner comprises three layers, wherein the upper layer and the lower layer are PVC (polyvinyl chloride) films, and the middle layer is mesh cloth, wherein each PVC film is prepared from components in parts by weight as follows: 80-90 parts of PVC resin, 10-18 parts of epoxy resin, 10-16 parts of calcium carbonate, 15-35 parts of a plasticizer, 3-9 parts of an antioxidant, 5-10 parts of butyltin dilaurate, 1-3 parts of a flame retardant and 3-6 parts of a liquid stabilizer. The processing technology of the flex banner is also provided. The flex banner has the advantage of high universality.

Owner:山东汇锋新材料有限公司

Flexible conductive heat-generating carbon-based flame-retardant composite fabric and preparation method thereof

InactiveCN110284322AGood dispersionFlame retardant hasCarbon fibresHeating/cooling textile fabricsFiberCarbon fibers

The invention discloses a flexible conductive heat-generating carbon-based flame-retardant composite fabric and a preparation method thereof and belongs to the technical field of preparation of conductive materials. The method comprises the following steps that a carbon fiber original filament is woven into a carbon fiber original filament fabric; the carbon fiber original filament fabric is sequentially subjected to pad-drying treatment, pre-oxidation treatment, oxygen-free low-temperature carbonization and oxygen-free high-temperature carbonization to prepare a carbon fiber flame-retardant fabric; the carbon fiber flame-retardant fabric is immersed in a graphene / carbon nanotube mixture liquid and then subjected to high-temperature and high-pressure padding and drying treatment to obtain the composite fabric. By placing graphene and carbon nanotubes in an organic solvent for mixing separately, the carbon nanotubes can be well dispersed in a graphene-based body without surface modification or modification of the carbon nanotubes, the conductivity of the heat-generating composite carbon fiber is greatly enhanced, and favorable conditions are provided for further application of the flexible conductive heat-generating carbon-based flame-retardant fabric.

Owner:深圳市尼森实业有限公司

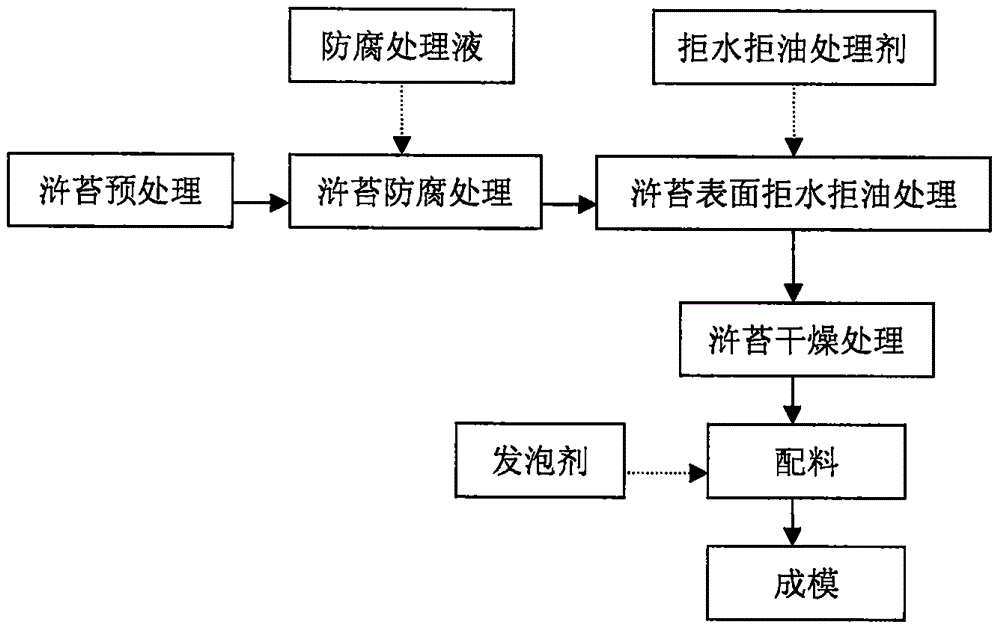

Production method for preparing thermal insulation material by using enteromorpha

InactiveCN105924111AReduced Governance ChallengesIncrease productionSolid waste managementThermal insulationWaste product

The invention discloses a production method for preparing a thermal insulation material by using enteromorpha. The method comprises the following steps: (1) pretreatment of enteromorpha; (2) preservative treatment; (3) oil and water-repellent treatment for the surface of the enteromorpha; (4) drying treatment of the enteromorpha; (5) preparation of materials; (6) molding. The method can effectively solve the problem of enteromorpha treatment, save resources, realize utilization of waste products, and protect environment; the enteromorpha has the advantages of high yield, easy availability and low cost, compared with the traditional insulation materials which do not have flame retardation performance and needs addition of fire retardants in the preparation process, the enteromorpha has flame resistance; after the preservative treatment as well as the oil and water-repellent treatment, the enteromorpha can be used for preparing the thermal insulation material with good anticorrosion, flame retardation, and thermal insulation effects, and the thermal insulation material can be used in places where insulation treatment is needed, such as pipeline insulation, wall insulation, and the like.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

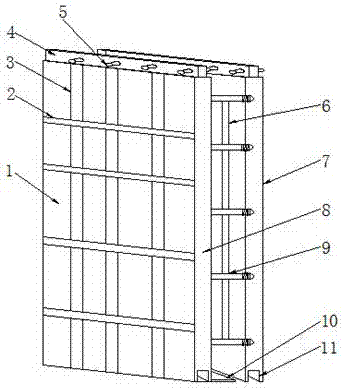

Assembled building wall

ActiveCN107313535AConvenient ArrangementAdjustable thicknessWallsStructural engineeringBuilding construction

The invention discloses an assembled building wall which comprises an assembled wall body, a transverse cover groove, a vertical cover groove, a splicing protrusion, extensible columns, springs and a connecting plate. An exterior wall is arranged on one side of the assembled wall body, an interior wall is arranged on the other side of the assembled wall body, a bottom plate is arranged at the bottom of the inner wall, the splicing protrusion is arranged at the upper end of the interior wall, and a damp-proof layer is arranged on the inner side of the interior wall. The assembled building wall is scientific and reasonable in structure and safe and convenient to use, and interval adjusting bolts are arranged, so that convenience can be brought to working personnel to adjust a distance between the exterior wall and the interior wall, and thickness of the assembled wall body can be adjusted; the splicing protrusion and limiting grooves are arranged, so that convenience is brought to docking of two assembled wall bodies, so that working intensity of the working personnel is reduced effectively; limiting columns are arranged, so that temporary fixing effect is realized during assembling, and working efficiency of the working personnel is improved. The assembled building wall is convenient to mount, low in construction cost and high in building overall performance.

Owner:QINGDAO ZHONGJIAN COMBINATION CONSTR ENG CO LTD

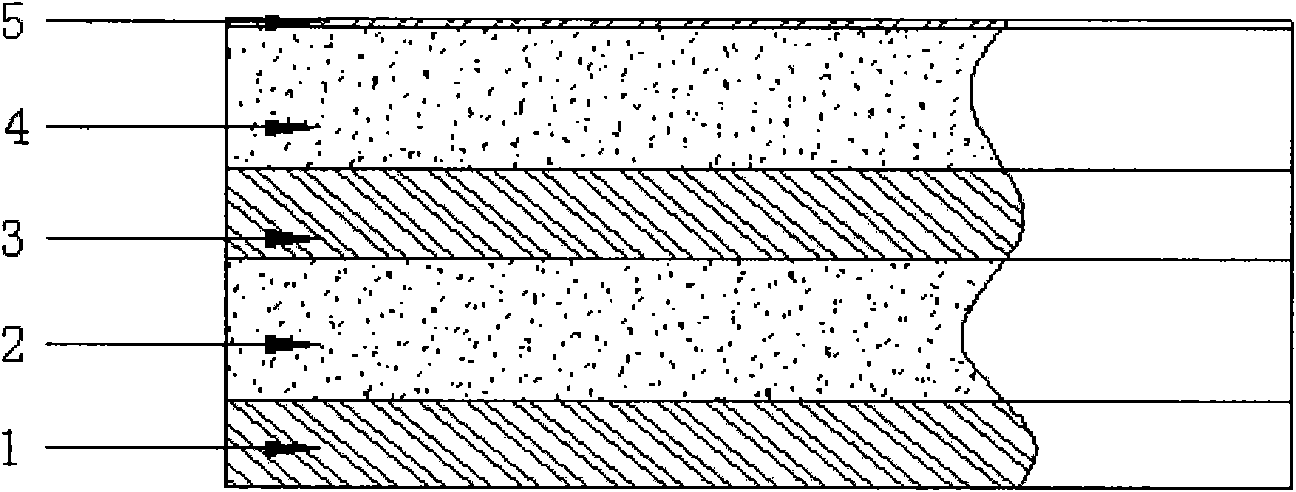

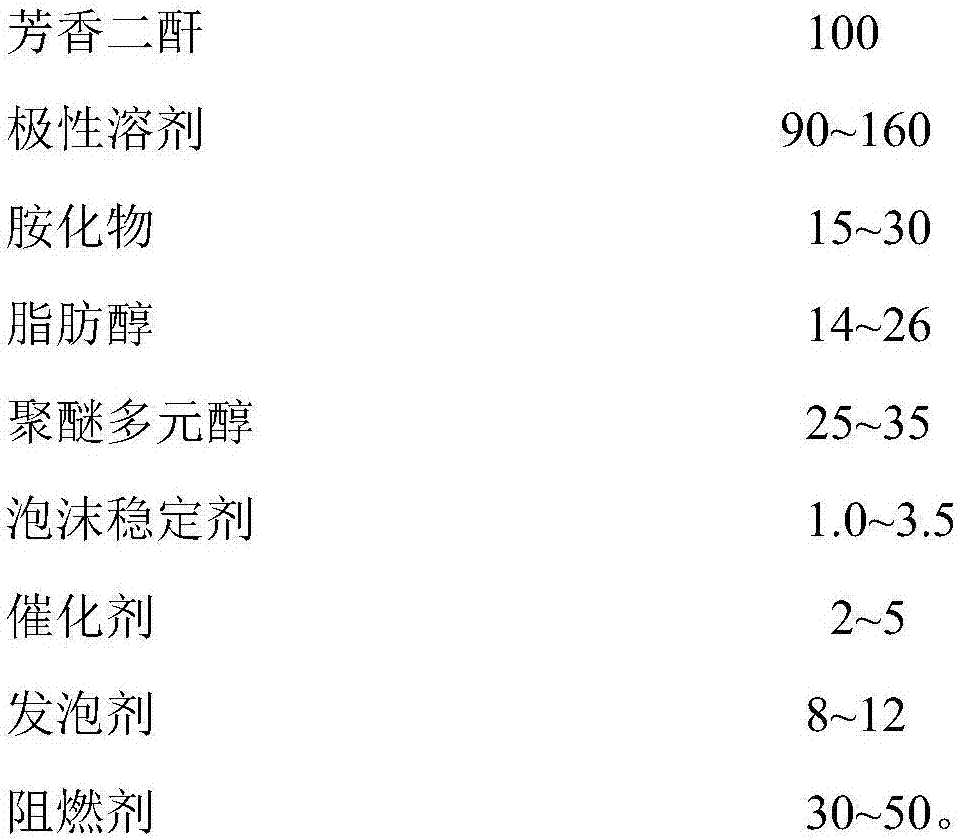

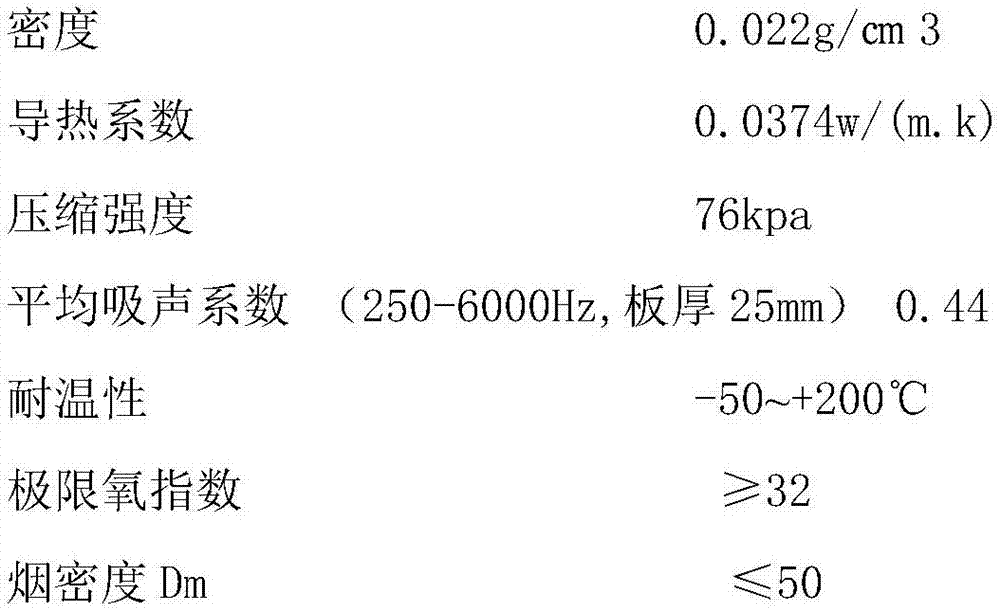

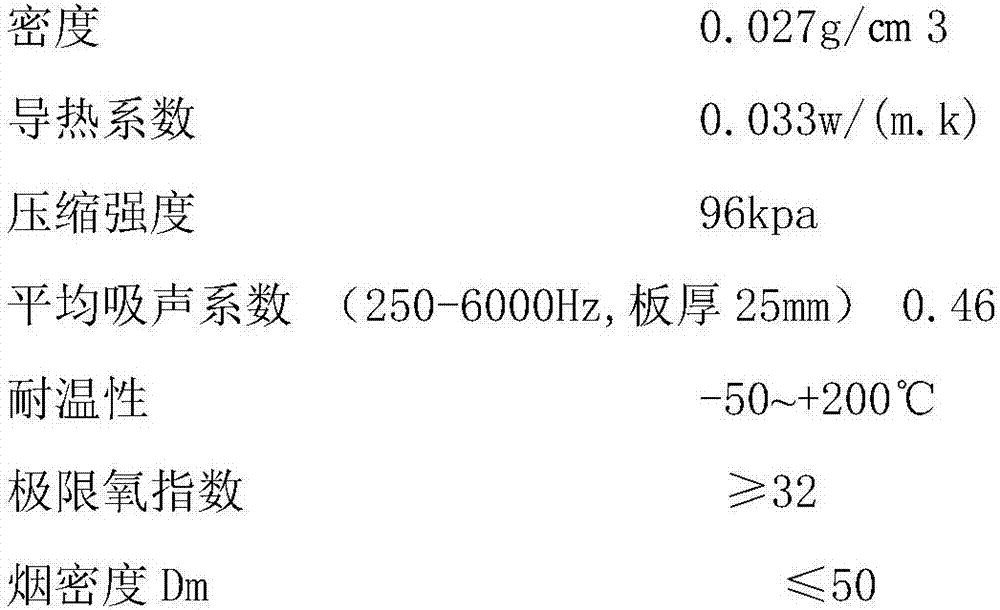

Sound-absorbing damping foam core sandwich composite material, and manufacturing method thereof

InactiveCN106945375AImprove practicalityLow densitySynthetic resin layered productsGlass fiberPolyurethane elastomer

The invention discloses a sound-absorbing damping foam core sandwich composite material, and a manufacturing method thereof. The sound-absorbing damping foam core sandwich composite material is composed of a core material, a surface material, and a damping coating layer; the core material is an open-cell polyurethane-polyimide foam board; the surface material is a flame-retardant glass fibre cloth coated with a waterproof polyurethane inner cabin coating; and the damping coating layer is polyether polyurethane elastomer. When the frequency ranges from 250 to 6000Hz, and the plate thickness is controlled to be 25mm, the average sound absorbing factor ranges from 0.42 to 0.46, the limit oxygen index is 32 or higher, the smoke density Dm is 50 or lower, the free damping loss factor is 1.0 or higher, and a foam material layer is destroyed when bonding strength N / 25mm.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

Environment-friendly flame-retardant inorganic adhesive and preparation method thereof

ActiveCN107216814AImprove water resistanceImprove moisture resistanceNon-macromolecular adhesive additivesWood treatment detailsEnvironmental resistanceAdhesive

The invention discloses an environment-friendly flame-retardant inorganic adhesive. The inorganic adhesive comprises white glue and blue glue, wherein the white glue comprises the following raw materials in parts by weight: 20-80 parts of magnesium oxide, 10-40 parts of magnesium chloride, 5-30 parts of magnesium sulfate, 10-40 parts of nano antimony oxide, 10-40 parts of superfine silica fume, 0.5-1 part of citric acid, 0.5-1 part of sodium phosphate, 0.5-1 part of boric acid and 30-100 parts of deionized water; and the blue glue comprises the following raw materials in parts by weight: 10-40 parts of alumina sol, 10-40 parts of sodium silicate, 20-60 parts of polyvinyl alcohol and 80-200 parts of deionized water. The adhesive disclosed by the invention has excellent bonding strength, can replace the traditional organic MDI (Methylene Diphenyl Diisocyanate) adhesives, and has flame-retardant, formaldehyde release-free, water-resistant, insect-resistant, moisture-resistant and anticorrosive characteristics when applied to manufacturing straw boards.

Owner:石植

Flame-retardant system for acetate cloth tape

InactiveCN103045122AImprove flame retardant performanceAdd lessNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceZinc borate

The invention relates to a flame-retardant system for an acetate cloth tape, which is provided with a halogen-free flame retardant system with environmental-friendliness and high flame retardant efficiency. The halogen-free flame retardant system has excellent compatibility with a rubber pressure sensitive adhesive, does not change mechanical performance of the acetate cloth tape and simultaneously improves heat resistance of the acetate cloth tape. The flame-retardant system does no harm to the environment and a human body; the specific gravity of the halogen-free flame retardant system in the rubber pressure sensitive adhesive is between 10 percent and 20 percent; the halogen-free flame retardant system is a mixture consisting of a halogen-free inrumescent flame retardant (IFR), metal hydrate and superfine zinc borate powder. By the synergistic effect of the flame-retardant system, the flame retardance of a flame retardant is improved, the addition quantity of the flame retardant is reduced, the flame retardant effect which is the same with that obtained when a great quantity of single flame retardant is added is achieved, and the flame-retardant acetate cloth tape has the advantages of resistance to high temperature, resistance to high pressure, insulation, flame retardance and the like, is soft and docile, has tear property and can be used for various electronic components.

Owner:新丰杰力电工材料有限公司

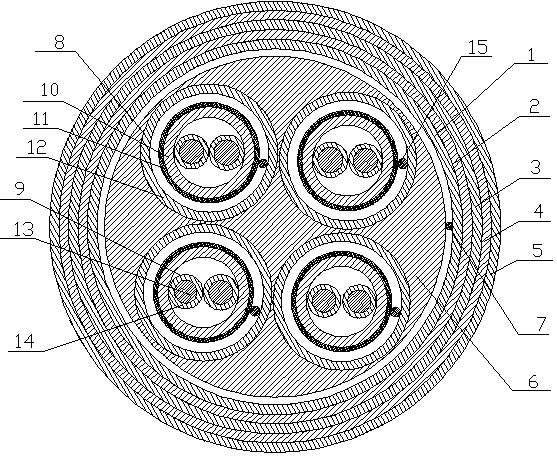

Flexible cable for intrinsic safety DCS

InactiveCN104240802AReduce capacitanceReduce inductanceFlexible cablesFlexible conductorsCapacitanceIntrinsic safety

The invention relates to the technical field of cable manufacturing, in particular to a flexible cable for an intrinsic safety DCS. The flexible cable comprises a cable core, and a lapping cabling layer, a main shielding layer, a lining layer, an armor layer and an outer sheath layer are arranged on the outer side of the cable core in sequence. A filling layer is arranged between the cable core and the lapping cabling layer. A first drainage wire is arranged between the lapping cabling layer and the main shielding layer. The cable core comprises a plurality of strands of stranded wire cores, each wire core comprises a set of insulation conductors twisted in pair, and colored tape layers, belting layers and split-phase shielding layers are sequentially arranged on the outer side of the insulation conductors twisted in pair. Second drainage wires are arranged between the belting layers and the split-phase shielding layers. Each insulation conductor comprises a tinned copper wire bunch stranded conductor, and the tinned copper wire bunch stranded conductors are coated with insulation layers. The flexible cable is reasonable and novel in structure, scientific and particular in material and low in capacitance and inductance, electric sparks are not prone to being generated, and intrinsic safety is achieved. Meanwhile, the excellent properties of flame retardance, interference resistance, oil resistance, ozone resistance and the like are achieved.

Owner:扬州市金阳光电缆有限公司

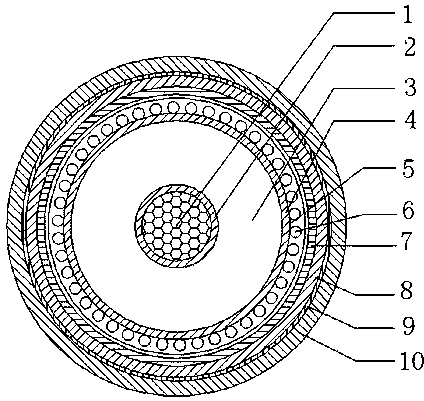

Cross linked polyethylene insulated copper strip armored power cable preventing termites and resisting ultraviolet light

InactiveCN103985470AAvoid bitesNo mechanical damagePower cables with screens/conductive layersInsulated cablesElectric power transmissionPolyolefin

The invention discloses a cross linked polyethylene insulated copper strip armored power cable preventing termites and resisting ultraviolet light. The power cable sequentially comprises an insulated cable core, a semiconductive buffer layer, a metal shielding layer, a high-inflaming-retarding enhancement layer, a lining layer, a metal armored layer and an outer protection sleeve from the inner layer to the outer layer. The semiconductive buffer layer is composed of semiconductor non-woven fabric, the metal shielding layer is composed of copper wires evenly arranged in the peripheral direction and copper strips inversely tied on the outer surface of the copper wires, the lining layer is composed of halogen-free low-smoke high-inflaming-retarding polyolefin outer protection sleeve materials, the metal armored layer is composed of a brass strip armored cable, and the outer protection sleeve is composed of low-smoke halogen-free inflaming-retarding outer protection sleeve materials. Through the mode, the power cable has the special performance of being low in smoke and free of halogen, retarding inflaming, being waterproof and ratproof, preventing insect biting and preventing the ultraviolet light, the service life of the cable is guaranteed, the safe reliability of electric power transmission is improved, and hazards caused by electricity utilization faults are avoided.

Owner:HENGTONG SUBMARINE POWER CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com