Flexible conductive heat-generating carbon-based flame-retardant composite fabric and preparation method thereof

A flame-retardant composite, flexible and conductive technology, applied in heating/cooling fabrics, electric heating devices, ohmic resistance heating, etc., can solve the problems of reduced electrothermal conversion rate, flammability, low production rate, etc., and achieve high thermal efficiency and low resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a flexible conductive and heat-generating carbon-based flame-retardant composite fabric, specifically comprising the following steps:

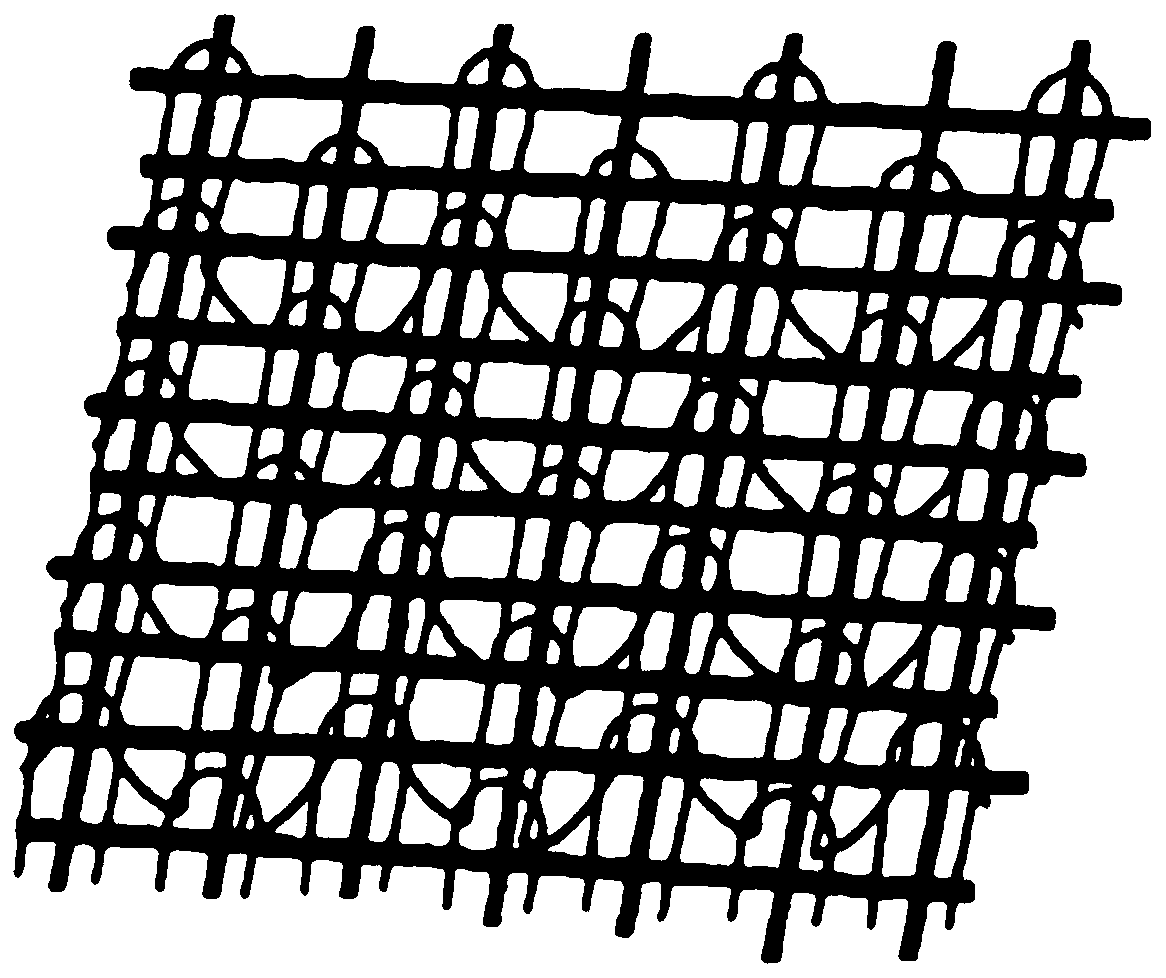

[0027] (1) Preparation of carbon fiber precursor fabric, polyacrylonitrile filaments are twisted and spun so that they are arranged biaxially in the direction of +40 degrees and -40 degrees (such as figure 1 ), the weaving method can also be a conventional weaving, knitting or non-woven process;

[0028] (2) Preparation of carbon fiber flame retardant fabric, the carbon fiber precursor fabric made in step (1) is passed through the phosphate (mixed solution of ammonium phosphate and ammonium dihydrogen phosphate, mass ratio is 0.5) solution equipped with 10% concentration at a constant speed The preprocessor is subjected to padding and drying treatment at a drying temperature of 120°C for 3 minutes;

[0029] (3) Pre-oxidize the pre-oxidized carbon fiber precursor fabric at 450°C for 30 minutes, and perform anaerob...

Embodiment 2

[0035] A method for preparing a flexible conductive and heat-generating carbon-based flame-retardant composite fabric, specifically comprising the following steps:

[0036] (1) The preparation of carbon fiber precursor fabrics, viscose filaments are twisted, twisted and spun; it is formed by biaxial arrangement in the direction of +30 degrees and -30 degrees;

[0037] (2) The preparation of carbon fiber flame-retardant fabric, the carbon fiber precursor fabric that step (1) is made passes through the phosphate (mixed solution of ammonium phosphate and ammonium dihydrogen phosphate, mass ratio is 0.4) solution that is equipped with 5% concentration The preprocessor is subjected to padding and drying treatment at a drying temperature of 100°C for 2.5 minutes;

[0038] (3) Pre-oxidize the pre-oxidized carbon fiber precursor fabric at 300°C for 20 minutes, and perform anaerobic (pure nitrogen) low-temperature carbonization on the pre-oxidized carbon fiber precursor fabric at 1000°...

Embodiment 3

[0044] A method for preparing a flexible conductive and heat-generating carbon-based flame-retardant composite fabric, specifically comprising the following steps:

[0045] (1) The preparation of carbon fiber precursor fabrics, the polyacrylonitrile filaments are cut into short filaments with a single fiber length of not less than 5cm, and then spinning and twisting, so that it is biaxial in the direction of +20 degrees and -20 degrees to arrange;

[0046] (2) The preparation of carbon fiber flame-retardant fabric, the carbon fiber precursor fabric that step (1) is made passes through the phosphate (mixed solution of ammonium phosphate and ammonium dihydrogen phosphate, ratio is 0.2) aqueous solution that 1% concentration is housed The preprocessor is subjected to padding and drying treatment at a drying temperature of 90°C for 2 minutes;

[0047] (3) Pre-oxidize the pre-oxidized carbon fiber precursor fabric at 200°C for 10 minutes, and perform anaerobic (pure nitrogen) low-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com