Patents

Literature

215 results about "Fire-retardant fabric" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire-retardant fabrics are textiles that are naturally more resistant to fire than others through chemical treatment or manufactured fireproof fibers.

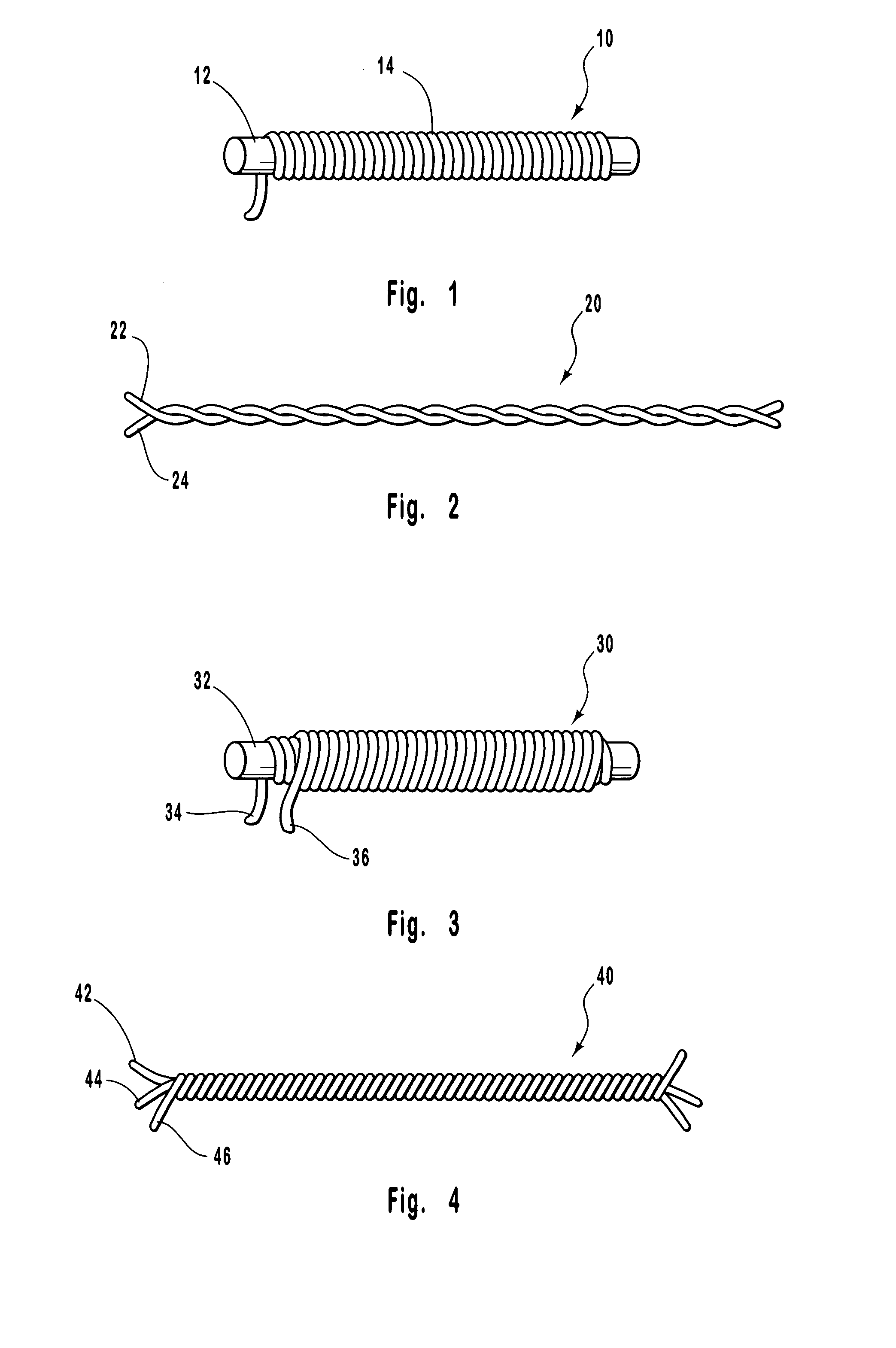

Fire retardant and heat resistant yarns and fabrics made therefrom

InactiveUS6358608B1Improve heat resistanceIncrease abrasionNatural mineral layered productsYarnYarnEngineering

Fire retardant and heat resistant yarns, fabrics, felts and other fibrous blends which incorporate high amounts of oxidized polyacrylonitrile fibers. Such yarns, fabrics, felts and other fibrous blends have a superior LOI, TPP and continuous operating temperature compared to conventional fire retardant fabrics. The yarns, fabrics, felts and other fibrous blends are also more soft and supple, and are therefore more comfortable to wear, compared to conventional fire retardant fabrics. The yarns, fabrics, felts and other fibrous blends incorporate up to 99.9% oxidized polyacrylonitrile fibers, together with at least one additional fiber, such as p-aramid, in order to provide increased tensile strength and abrasion resistance of the inventive yarns, fabrics, felts and other fibrous blends. The yarns may be woven, knitted or otherwise assembled into a desired fabric.

Owner:CHAPMAN THERMAL PRODS

Flame retardant fiber blends comprising flame retardant cellulosic fibers and fabrics and garments made therefrom

An intimate blend of staple fibers has from 10 to 75 parts by weight of at least one aramid staple fiber, from 15 to 80 parts by weight of at least one flame retardant cellulosic staple fiber, and from 5 to 30 parts by weight of at least one polyamide staple fiber. The intimate blend of staple fibers provides yarns and fabrics that are flame retardant, also referred to as fire resistant, and can be used to make flame retardant articles, such as clothing. The flame retardant fabrics may have a basis weight from 4 to 15 ounces per square yard.

Owner:EI DU PONT DE NEMOURS & CO

Flame retardant fiber blends comprising modacrylic fibers and fabrics and garments made therefrom

An intimate blend of staple fibers has from 10 to 75 parts by weight of at least one aramid staple fiber, from 15 to 80 parts by weight of at least one modacrylic staple fiber, and from 5 to 30 parts by weight of at least one polyamide staple fiber. The intimate blend of staple fibers provides yarns and fabrics that are flame retardant, also referred to as fire resistant, and can be used to make flame retardant articles, such as clothing. The flame retardant fabrics may have a basis weight from 4 to 15 ounces per square yard.

Owner:EI DU PONT DE NEMOURS & CO

High-strength stretch-proof flame-retardant textile

InactiveCN101748549ASolve the difficulty of weavingSolve not easy to dyeWoven fabricsYarnCompound aEngineering

The invention provides a high-strength stretch-proof flame-retardant textile. The flame-retardant textile is formed by weaving a flame-retardant composite yarn, wherein the flame-retardant composite yarn is formed by compounding a core yarn and a leather yarn and is one of a covering yarn and a fasciated yarn; the core yarn adopts a flame-retardant filament yarn as a raw material; the leather yarn adopts a flame-retardant short fiber as a raw material; and the weight ratio of the flame-retardant filament yarn to the flame-retardant short fiber is 30-90:10-70. Compared with the conventional flame-retardant textile, the high-strength stretch-proof flame-retardant textile has higher strength and overcomes the defects of difficult weaving, difficult dyeing and uncomfortableness of the high-strength fiber; the high-strength stretch-proof flame-retardant textile has permanent flame retardance which cannot decrease after the textile is washed, and better textile strength; the textile has soft and comfortable handfeel, rich color and good strength, meets the requirements of various flame-retardant clothes and related standards; the product has rich and varied appearances and is durable; and the combustion performance of the textile can meet the national standards of flame-retardant products.

Owner:汕头市奥山服饰有限公司

Patterned, flame resistant fabrics and method for making same

The present disclosure relates to patterned, flame resistant fabrics and methods of making them. Generally speaking, the fabrics comprise a plurality of high tenacity, flame resistant fibers, and a plurality of cellulosic fibers containing a flame retardant compound, and at least one color which is printed on the fabric to form the pattern. In a preferred embodiment, the flame resistant fibers are para-aramid fibers and the cellulosic fibers are rayon fibers to yield a strong, flame resistant fabric.

Owner:SOUTHERN MILLS

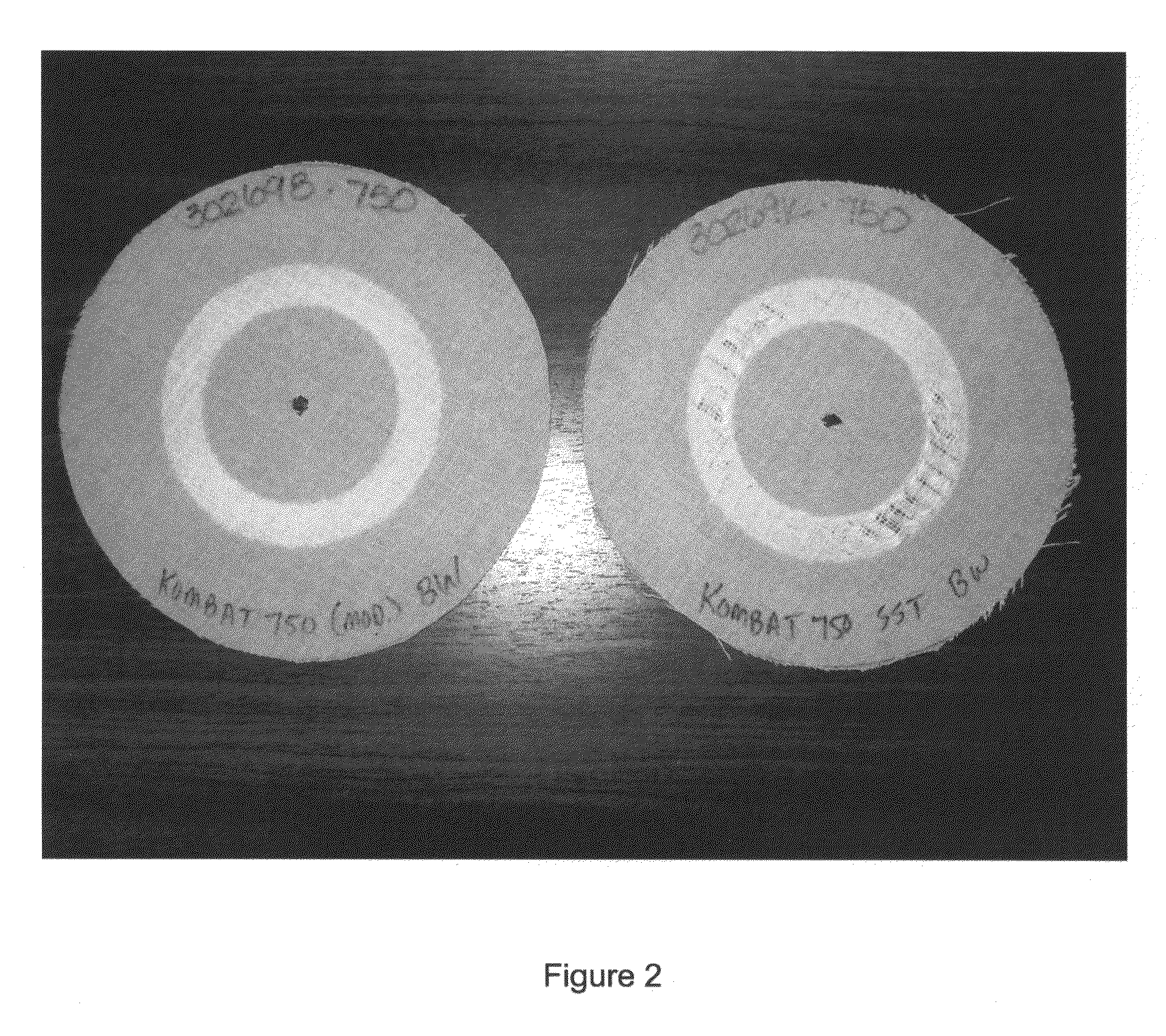

Fire-retardant fabric with improved tear, cut, and abrasion resistance

A woven fabric useful in protective apparel made from yarn components comprising a body fabric yarn component, a synthetic ripstop yarn component having at least 20% greater tensile strength than the body fabric yarn component, and a cut resistant yarn component comprising a yarn having a synthetic staple-fiber sheath and inorganic core, the body fabric yarn component, the ripstop yarn component, and cut-resistant yarn components all being comprised of at least one yarn and each yarn component distinguished from the adjacent yarn component by interweaving orthogonal yarn components.

Owner:EI DU PONT DE NEMOURS & CO

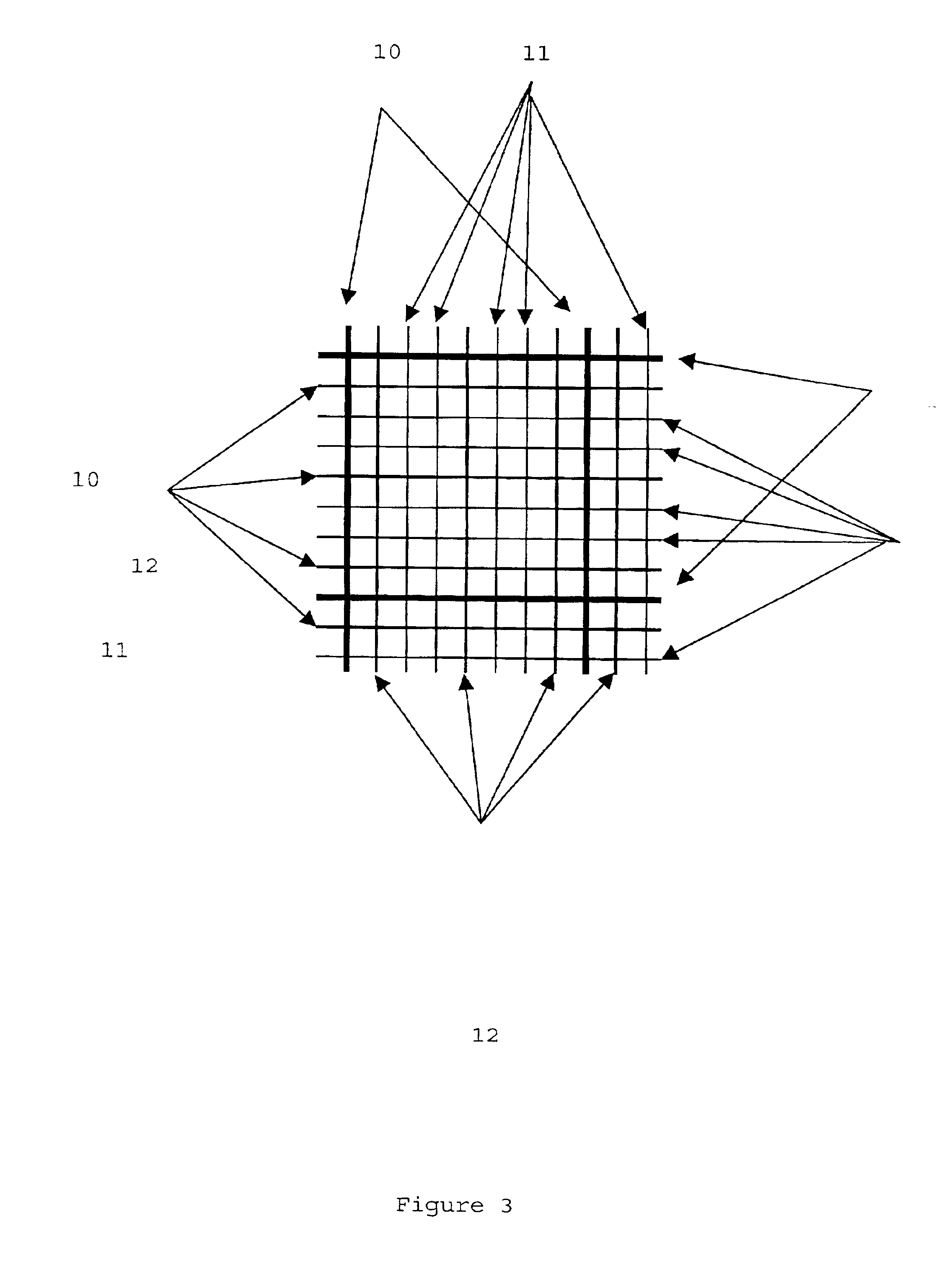

Flame Resistant Fabric With Anisotropic Properties

InactiveUS20110010827A1Increased durabilityChemical protectionHeat protectionFiberFire-retardant fabric

Flame resistant fabrics are formed by warp and fill yams having different fiber contents. The fabrics are constructed, for example, by selection of a suitable weaving pattern, such that the body side of the fabric and the face side of the fabric have different properties. The fabrics described herein can be printable and dyeable on both sides of the fabric and are suitable for use in military and industrial garments. Methods of forming flame resistant fabrics, and methods for forming garments from the fabrics, are also described.

Owner:SOUTHERN MILLS

Flame Resistant Fabric With Anisotropic Properties

Flame resistant fabrics are formed by warp and fill yarns having different fiber contents. The fabrics are constructed, for example, by selection of a suitable weaving pattern, such that the body side of the fabric and the face side of the fabric have different properties. The fabrics described herein can be printable and dyeable on both sides of the fabric and are suitable for use in military and industrial garments. Methods of forming flame resistant fabrics, and methods for forming garments from the fabrics, are also described.

Owner:SOUTHERN MILLS

Flame resistant fabric having antimicrobials and methods for making them

Owner:SOUTHERN MILLS

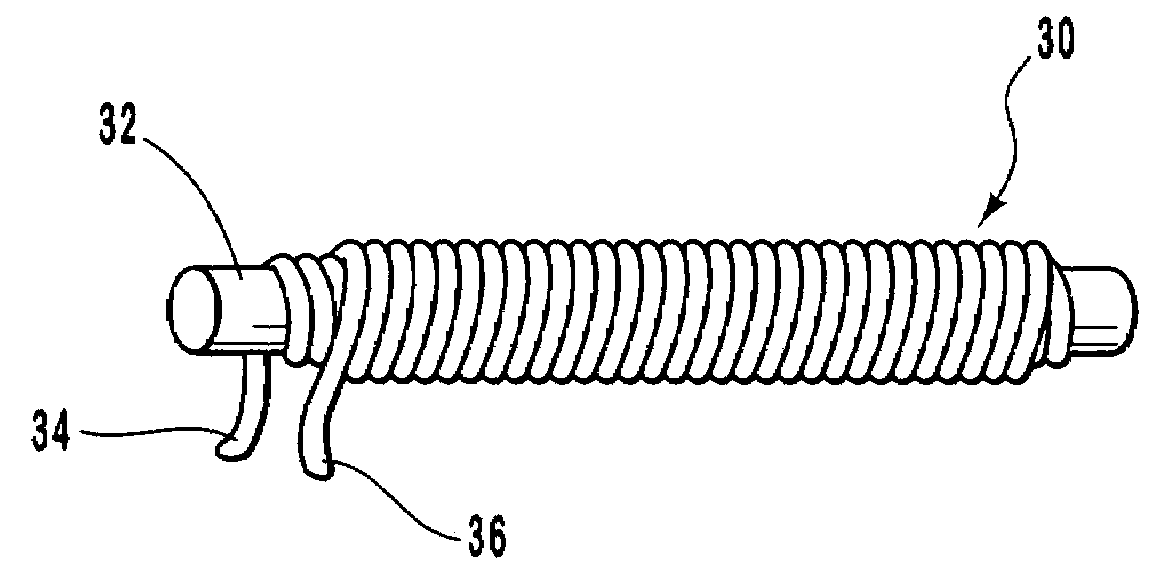

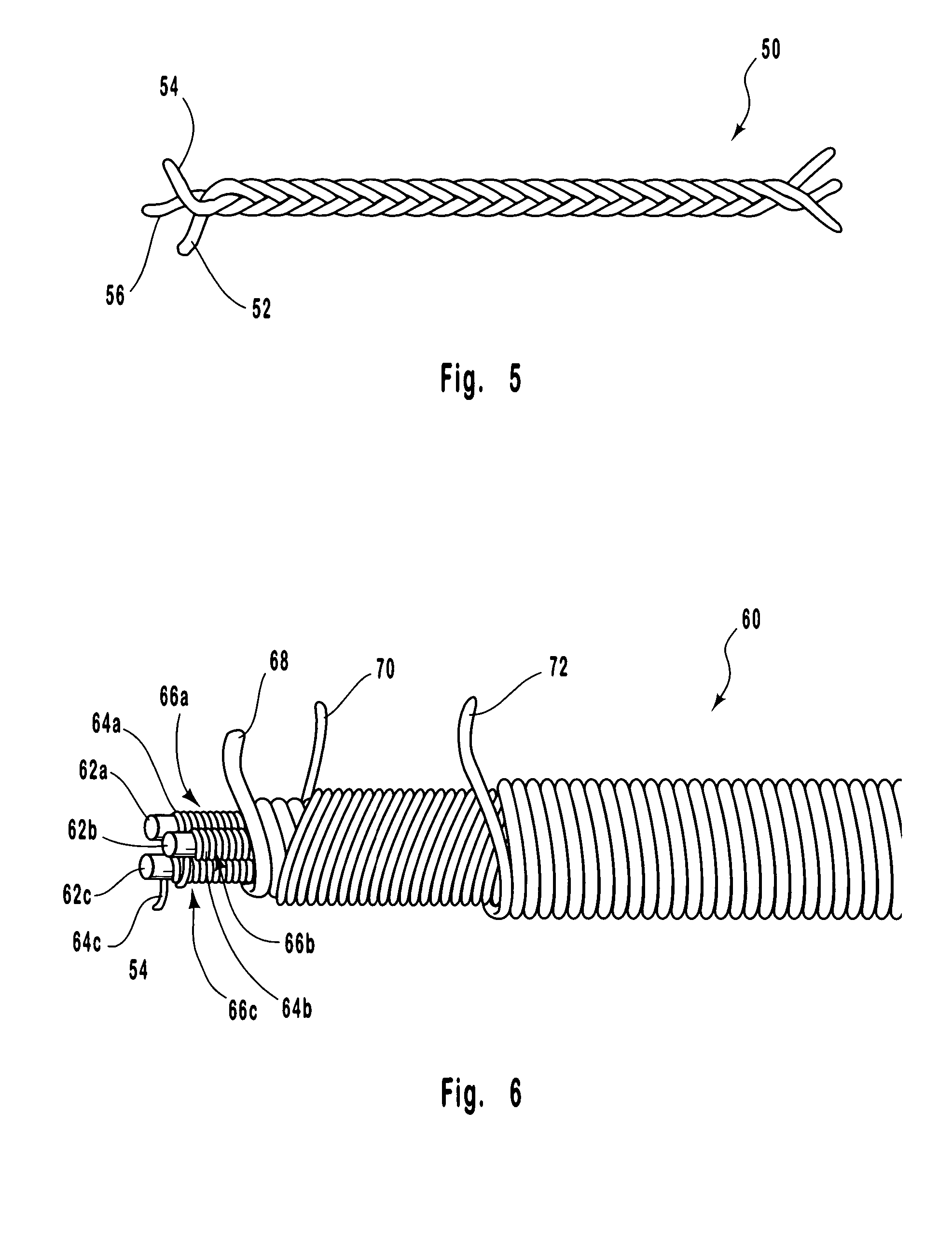

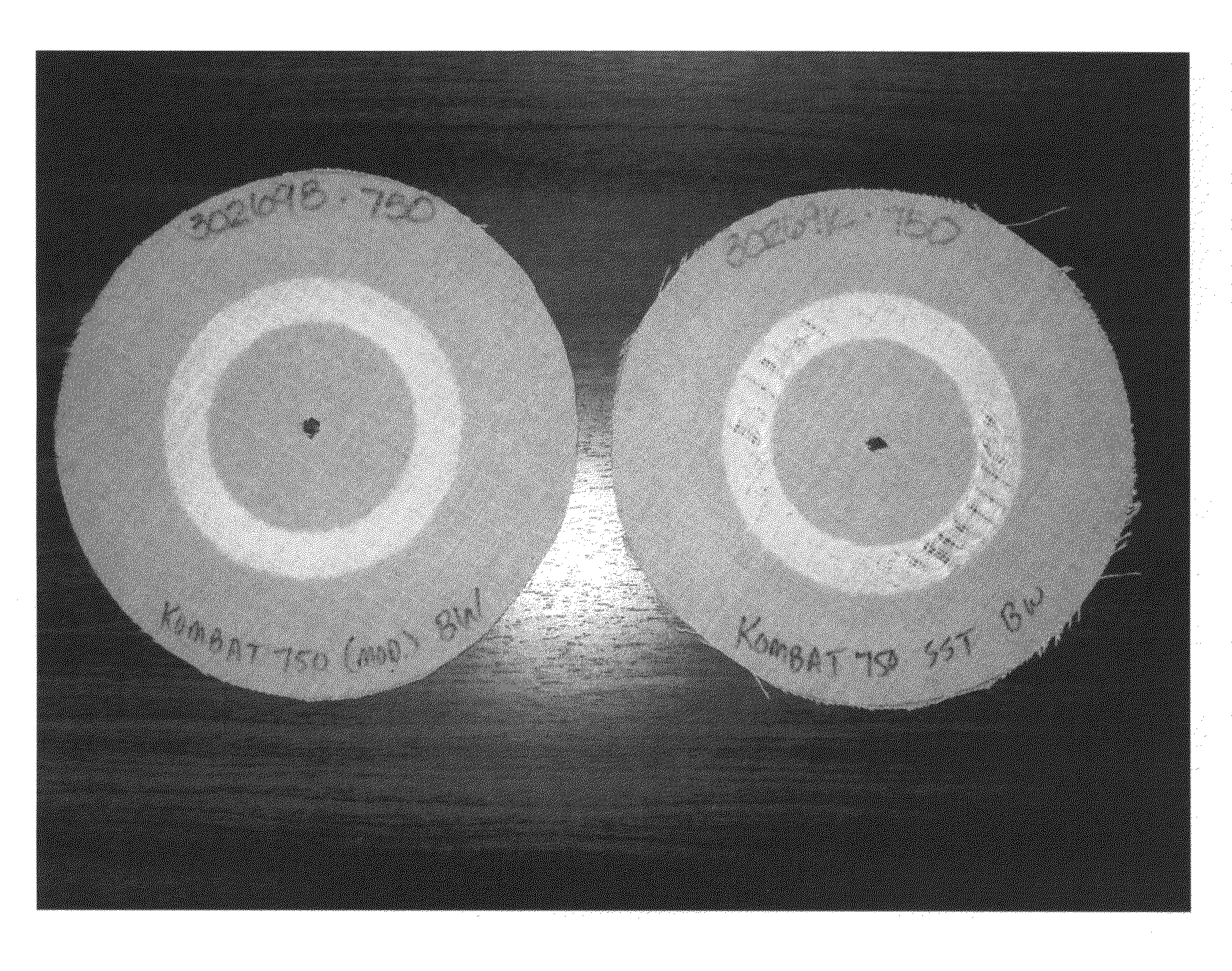

Fire retardant and heat resistant yarns and fabrics incorporating metallic or other high strength filaments

InactiveUS7087300B2Feel comfortableSuperior water regainSynthetic resin layered productsWarp knittingYarnPolymer science

Fire retardant and heat resistant yarns, fabrics, and other fibrous blends incorporate one or more fire retardant and heat resistant strands comprising oxidized polyacrylonitrile and one or more strengthening filaments such as metallic filaments (e.g., stainless steel), high strength ceramic filaments, or high strength polymer filaments. Such yarns, fabrics, and other fibrous blends have a superior tensile strength, cut resistance, abrasion resistance, LOI, TPP and continuous operating temperature compared to conventional fire retardant fabrics. The yarns, fabrics, and other fibrous blends are also more soft, supple, breathable and moisture absorbent and are therefore more comfortable to wear, compared to conventional fire retardant fabrics. The inventive yarns may be woven, knitted or otherwise assembled into a desired fabric or other article of manufacture.

Owner:CHAPMAN THERMAL PRODS

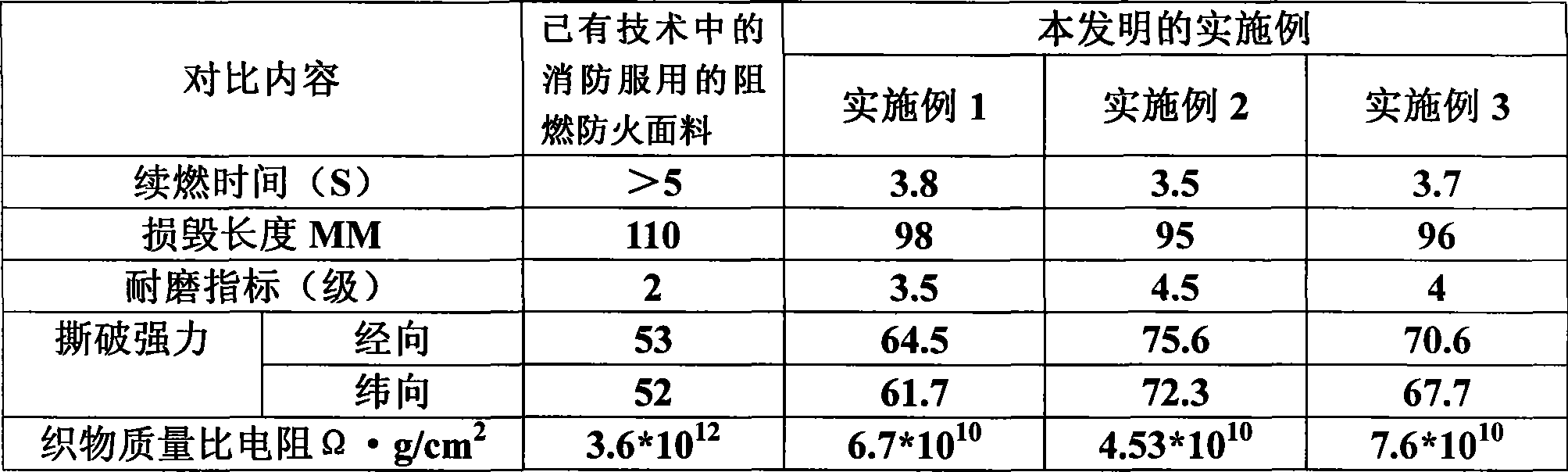

Flame-proof fireproof facing material

InactiveCN101368313AImprove flame retardant performanceShort afterburn timeWoven fabricsTextile technologyEngineering

Disclosed is fire-retardant fabric, belonging to textile technical field. The fire-retardant fabric is composed of warp tissue and weft tissue which are both made of meta-aramid aromatic polyamide fiber, para-aramid fiber and antistatic fiber. The fire-retardant fabric has the advantages of good fire retardant effect, short after-flame time, high wear resistance, high tear strength in both weft and warp and good quality-to-resistance ratio.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

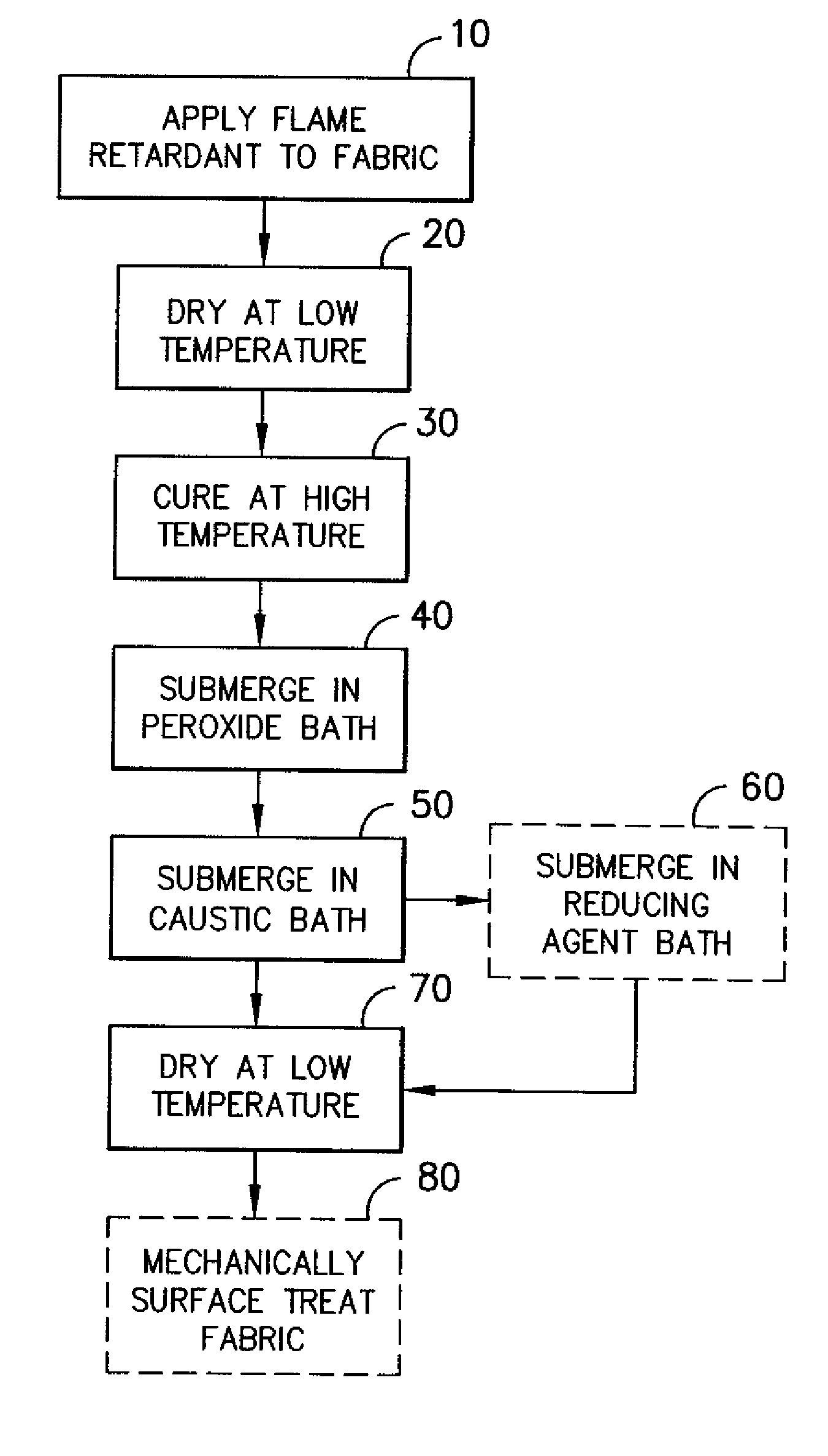

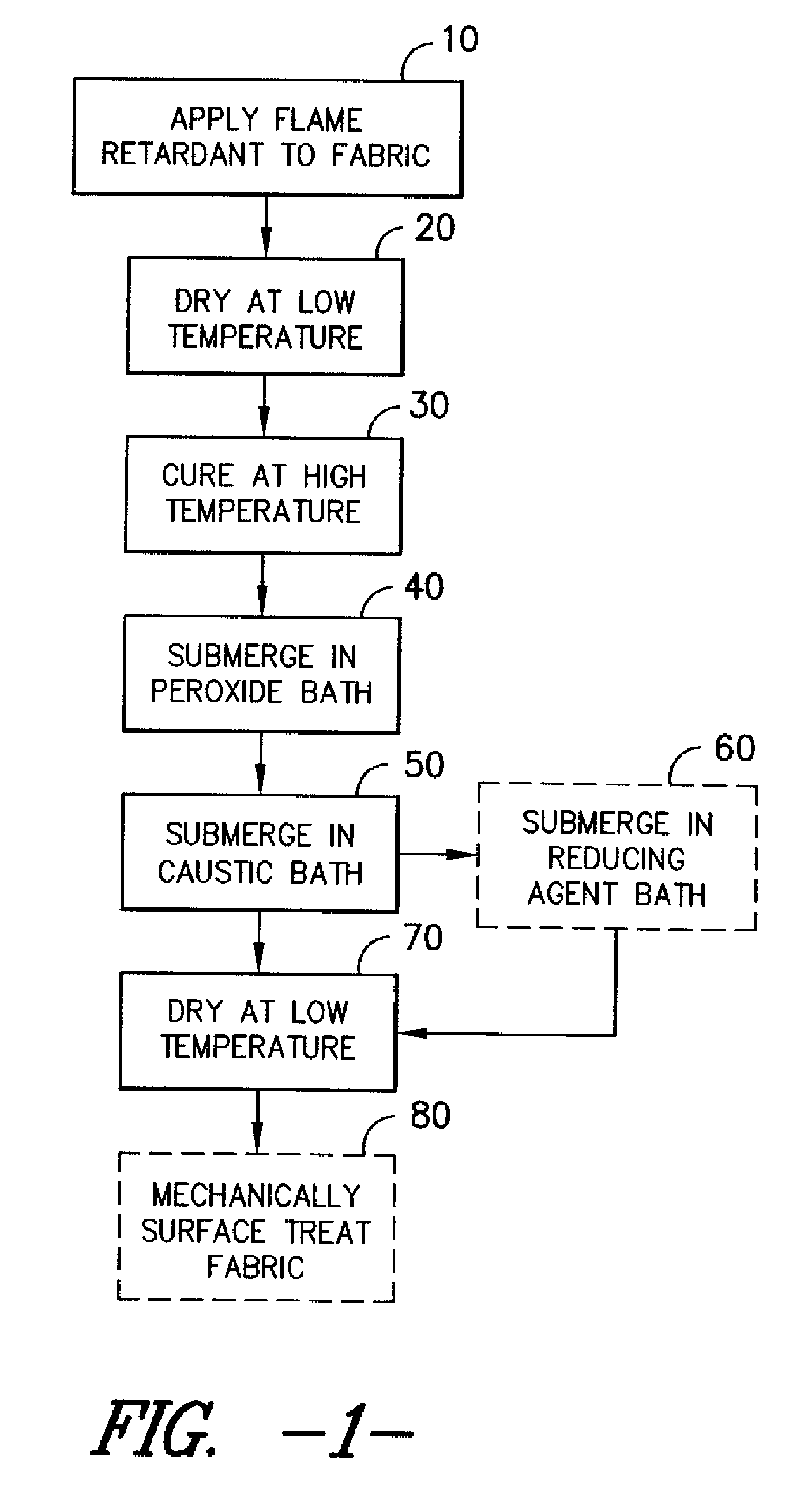

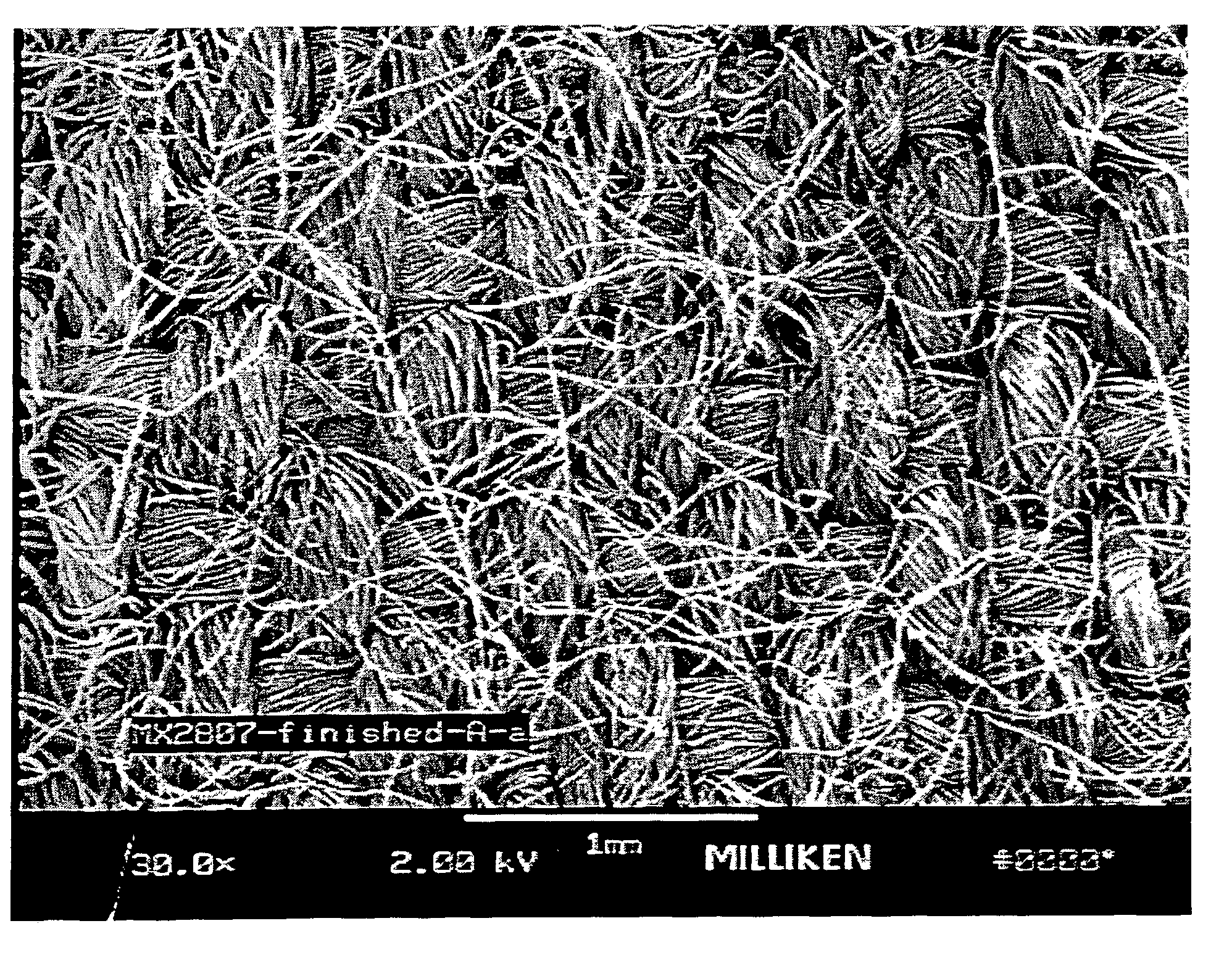

Flame resistant fabrics having a high synthetic content and process for making

ActiveUS8012890B1Good flexibilityImprove performanceSynthetic resin layered productsClothingsPolymer scienceFire-retardant fabric

Provided herein are flame resistant fabrics having a thermoplastic fiber content of as much as 65% (where no more than 5% of the fibers are non-thermoplastic synthetic fibers). The flame resistant properties are imparted by treating the fabric with one or more flame retardant chemicals and then by curing the treated fabric at high temperatures. Optionally, softeners, stain release agents, soil repellent agents, permanent press resins, and the like may be added to the bath of flame retardant chemicals. Alternately, the treated fabric may be subjected to mechanical treatment to increase softness. The fabrics produced by the present process exhibit improved performance and tear strength, as compared to conventionally treated fabrics.

Owner:MILLIKEN & CO

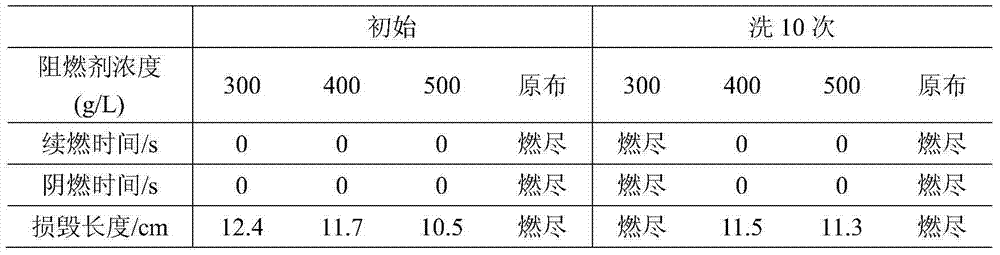

Inflaming retarding working solution and inflaming retarding finishing method of pure cotton fabric and/or cotton-polyester blended fabric

InactiveCN104746338AAvoid it happening againLess severeHeat resistant fibresVegetal fibresPolyesterPolymer science

Provided are a flame retardant working solution and flame retardant finishing method for pure cotton fabrics and / or cotton-polyester blend fabrics employing the flame retardant working solution. The flame retardant working solution comprises the following components: a flame retardant, a crosslinking agent, and the balance being water; the flame retardant in the flame retardant working solution has the concentration of 200-600 g / L, and the crosslinking agent has the concentration of 30-100 g / L. Cotton-polyester fabrics or pure cotton fabrics obtained by employing the flame retardant working solution and finishing method has good flame retardant effect and good washing resistance; the cotton-polyester fabrics pass through the GB / T 5455-1997 test, with the afterflaming time and smoldering time of less than 5 seconds after being washed thirty times, and a damaged length of less than 15 centimeters, reaching level B1 according to the GB / T 17591-2006 "flame retarded fabrics" standards, and can be widely used in flame retardant finishing of clothing, tents, upholstery fabrics and fabrics for transportation vehicles.

Owner:DYMATIC CHEM +1

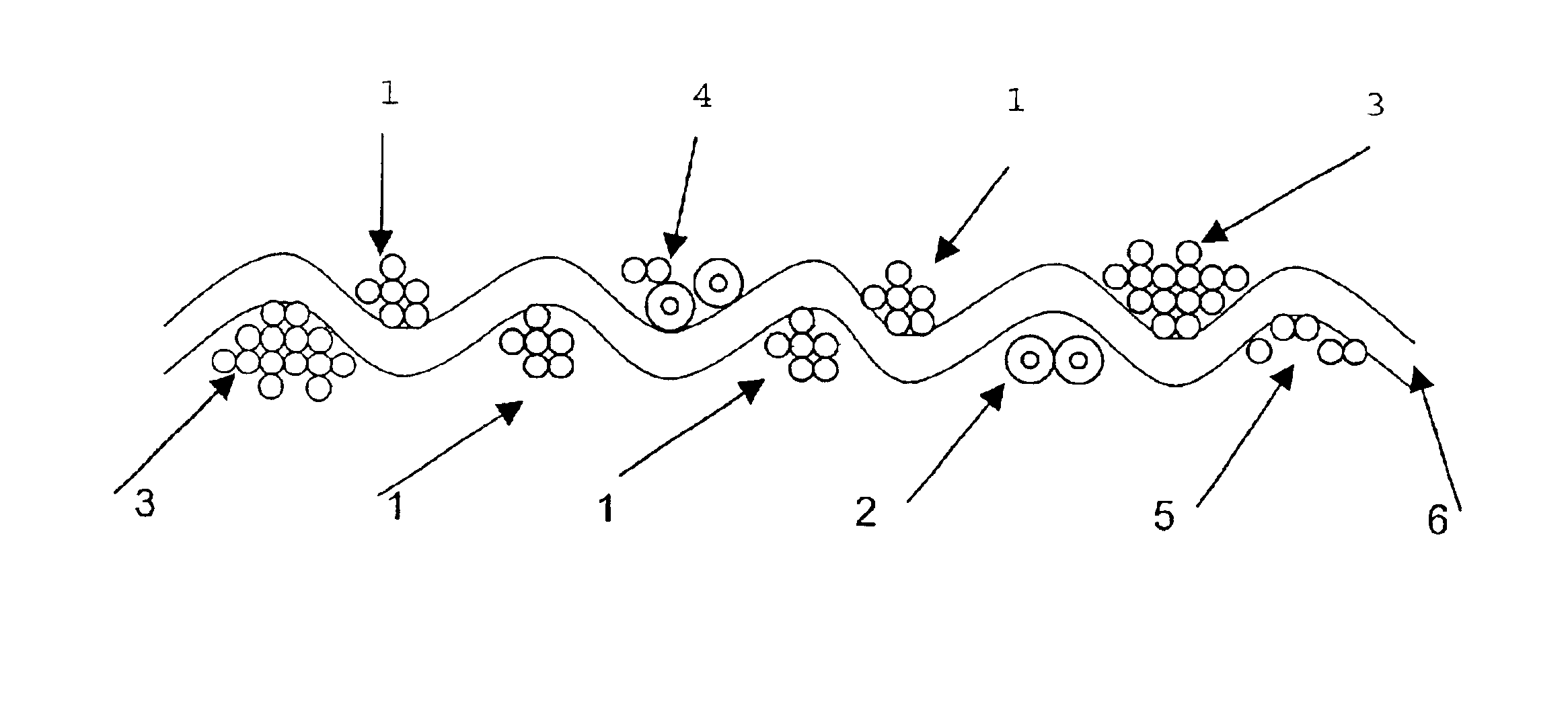

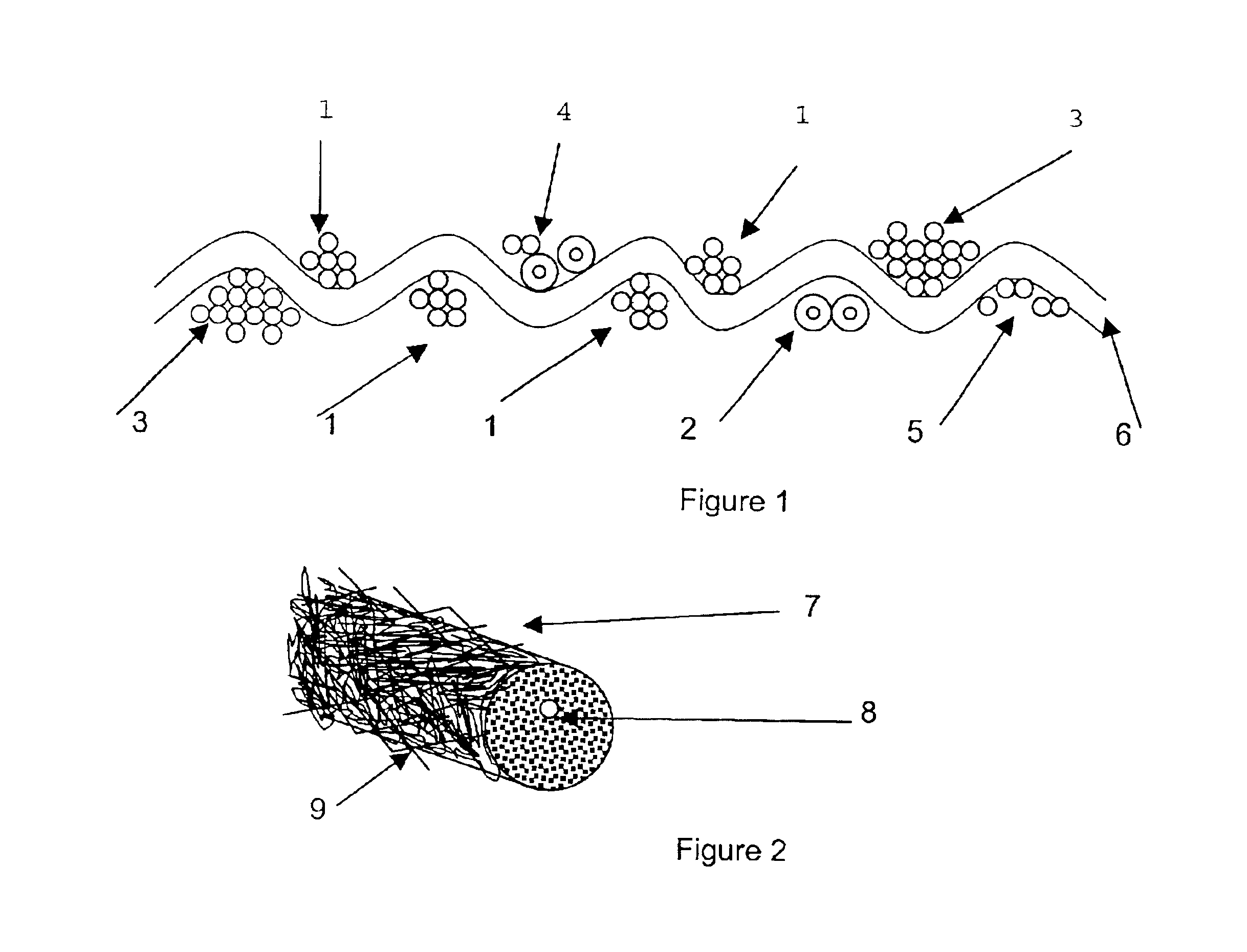

Reinforced nonwoven fire blocking fabric, method for making such fabric, and articles fire blocked therewith

ActiveUS20050215142A1Increasing the thicknessStuffed mattressesSynthetic resin layered productsEngineeringFire-retardant fabric

This invention relates to a thin reinforced nonwoven fabric for fire blocking an article, articles containing such fabrics, and methods for making the fabrics and fire blocking the articles. When exposed to heat or flame, the fabric is capable of increasing its thickness by at least three times. The fabric comprises an open mesh scrim having a having crimped, heat-resistant organic fibers compressed thereon and held in a compressed state by a thermoplastic binder. When subjected to high heat or flame, the binder in the structure softens and flows, releasing the restrained crimped fibers and allowing the thickness of the fabric to increase dramatically.

Owner:DUPONT SAFETY & CONSTR INC

Thermally protective flame retardant fabric

InactiveUS20090061131A1High protection levelLow costChemical protectionHeat protectionFiberEngineering

A thermally protective, flame retardant fabric includes a substrate treated with a combination of a flame retardant agent and an intumescent agent. The substrate includes non-thermoplastic fibers or a blend of non-thermoplastic fibers and thermoplastic fibers having a basis weight ranging from 2.0 to 15.0 ounces per square yard. The fabric has a contact thermal protective performance value of at least 4.5 and a contact thermal protective performance efficiency greater than 1.1. Applications of the fabric include protective garments, articles of furniture, vehicle components, building components, electrical components, decorative components, appliances, and containers.

Owner:PRECISION FABRICS GROUP

Flame Resistant Fabrics Having Improved Resistance to Surface Abrasion or Pilling and Methods for Making Them

ActiveUS20090178186A1Improve the immunityImprove surface wear resistanceChemical protectionHeat protectionFiberYarn

Flame resistant fabrics and garments that have improved resistance to pilling and / or abrasion are disclosed. The fabrics, the fibers or yarns that make up the fabrics, or garments made from the fabrics are treated with a finish composition that is applied to the fibers, yarns, fabrics, or garments and then cured. The finish composition increases the resistance to pilling and / or abrasion of the fibers, yarns, fabrics, or garments. The finish composition includes a polymeric abrasion resistance aid, an alkylfluoropolymer, a polyethylene, and a wetting agent.

Owner:SOUTHERN MILLS

Wide-range flame-retarding canvas and preparation method thereof

The invention discloses a wide-range flame-retarding canvas. The wide-range flame-retarding canvas includes a fire retardant fabric base material; a layer of flame-retarding primer is coated on the fire retardant fabric base material, and the flame-retarding coating is coated on the flame-retarding primer; the formula and dosage of the flame-retarding primer according to part by weight are: 20-40 parts of ammonium polyphosphate APP, 5-15 parts of melamine MEL, 10-20 parts of dipentaerythritol DPER, 0.5-2 parts of wetting agent, 0.5-2 parts of antifoaming agent, 10-30 parts of pure acrylic emulsion, 40-50 parts of ethylene-vinyl acetate copolymer emulsion, 20-30 parts of 70% of titanium dioxide powder syrup, 0.5-2 parts of brightening agent, 100-110 parts of water, and 5-8 parts of thickening agent. The wide-range flame-retarding canvas can be printed by compatible solvent type, weak solvent type and UV solidifying type inks, and has excellent smoothness and fineness, coating firmness, good weather resistance, moisture-resisting humidity and exquisite grain line and inkjet resolution rate. Meanwhile, the wide-range flame-retarding canvas can satisfy the foreign canvas flame-retarding standard and reach the highest flame-retarding standard B1 grade at home.

Owner:江苏耐斯数码科技股份有限公司

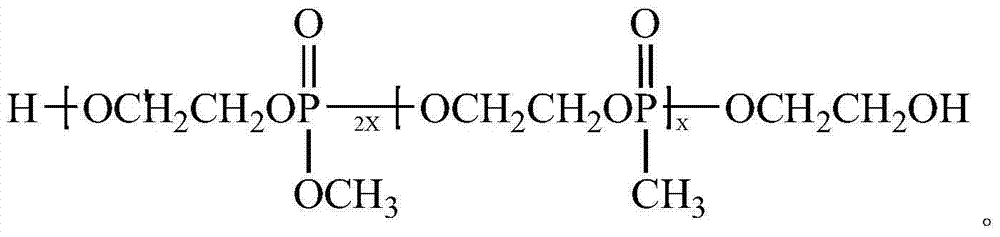

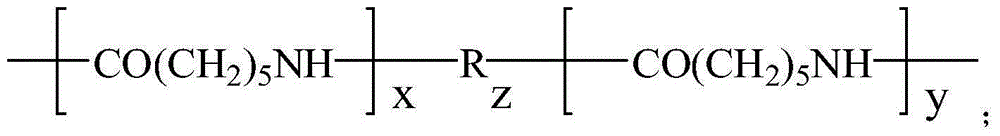

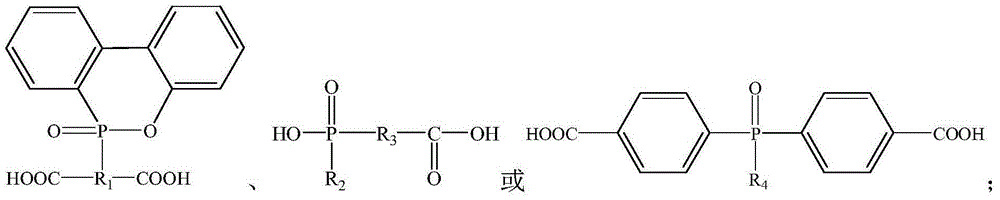

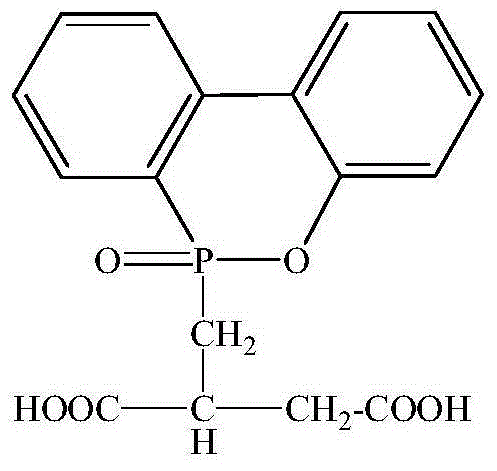

Permanent-flame-retardant nylon 6 material and preparation method therefor

InactiveCN105153414AAdd lessGood and long-lasting flame retardantFireproof paintsFiberPolymer science

The invention relates to a permanent-flame-retardant nylon 6 material and a preparation method therefor and particularly relates to a preparation method for a block copolymerized flame-retardant nylon 6 material obtained through continuously and respectively carrying out two-step polymerization reaction on a phosphoric reactive flame retardant. The method is characterized by comprising the steps of firstly enabling the flame retardant to react with diamine or dibasic alcohol so as to obtain a flame retardant prepolymer, and then, enabling the flame retardant prepolymer to react and copolymerize with a prepolymer of nylon 6, thereby obtaining the permanent-flame-retardant nylon 6 material. The flame-retardant nylon 6 material prepared by the method has the characteristics of low flame retardant addition level and durable flame-retardant effect, the limiting oxygen index is over 30%, the vertical firing test reaches UL94V-0, and the mechanical properties are excellent; and the nylon 6 material can be subjected to injection molding directly or form films and can also become into fibers so as to further prepare flame-retardant fabrics.

Owner:DONGHUA UNIV

Reinforced nonwoven fire blocking fabric having ridges and grooves and articles fire blocked therewith

ActiveUS7247585B2Increasing the thicknessStuffed mattressesDomestic upholsteryPolymer scienceFire-retardant fabric

Owner:DUPONT SAFETY & CONSTR INC

Reinforced nonwoven fire blocking fabric, method for making such fabric, and articles fire blocked therewith

ActiveUS7229937B2Increasing the thicknessStuffed mattressesSynthetic resin layered productsFire-retardant fabricEngineering

Owner:DUPONT SAFETY & CONSTR INC

Composite aramid fiber aviation flame retardant fabric and processing technology thereof

InactiveCN103160996AReduce thick and thin knotsImprove the level of evennessDry-cleaning apparatus for textilesWoven fabricsAfter treatmentFire-retardant fabric

The invention relates to composite aramid fiber aviation flame retardant fabric and a processing technology thereof. The fabric is formed by aramid fiber 1313 and aramid fiber 1414 fiber in a woven mode, wherein the percentage ratio, by weight, of the aramid fiber 1313 and aramid fiber 1414 fiber is 50 to 50. The fabric construction of the fabric is 2 / 2 right hand twill fabric. The process technology of the composite aramid fiber aviation flame retardant fabric solves the technical problems of fire retardant fiber in the process of spinning, weaving and after treatment. The composite aramid fiber aviation flame retardant fabric has the advantages that the blank space of aramid fiber aviation flame retardant fabric in the country is filled, the aramid fiber 1313 and aramid fiber 1414 composite aviation flame retardant fabric do not burn when meeting fire, do not drip melt and do not generate smoke and have good fireproof effects, and when the aramid fiber 1313 and aramid fiber 1414 composite aviation flame retardant fabric meet a high temperature of 900-1500 DEG C, the fabric surfaces are rapidly carbonized and thickened to form a special heat insulation barrier. The fabric has a permanent flame retardant effect, the flame retardant protecting effect is good and reaches a world standard, the price of the fabric is 20% of the price of a like product imported from a foreign country, and therefore the fabric has good market competitiveness.

Owner:TIANJIN TEXTILE ENG RES INST

Efficient low-smoke flame-retardant textile coating adhesive and preparation method thereof

The invention discloses an efficient low-smoke flame-retardant textile coating adhesive which consists of the following raw materials in parts by mass: 50-70 parts of water-based acrylic emulsion, 25-40 parts of a phosphorus-nitrogen flame-retardant additive, 4-10 parts of a nitrogen flame-retardant additive, 3-8 parts of a flame-retardant synergist, 1-5 parts of a thickening agent and 10-20 parts of a solvent. The invention also discloses a preparation method of the efficient low-smoke flame-retardant textile coating adhesive, and the preparation method comprises the following steps of (1) adding the water-based acrylic emulsion and deionized water into a dispersion kettle, starting stirring and mixing; (2) adding the phosphorus-nitrogen flame-retardant additive, the nitrogen flame-retardant additive and the flame-retardant synergist into the dispersion kettle in sequence, and uniformly mixing and stirring; (3) adding the thickening agent into a reaction kettle, fully stirring uniformly, and filtering to obtain a finished product. The coating adhesive disclosed by the invention has the advantage of low release of corrosive gas and toxic gas, and has good flame retardant property and good storage stability.

Owner:QINGYUAN MEINUOKE NEW MATERIAL +1

Flame retardant composite fabric

A composite flame retardant fabric is provided comprising an interior layer formed of thermoplastic fibers and exterior nonwoven webs on opposite sides of the interior layer. The exterior webs are formed of cellulosic fibers that include a flame retardant chemical. The interior layer provides strength and integrity to the composite fabric while allowing the composite to remain flexible and light in weight. The exterior layers impart flame retardant properties to the composite. Preferably, the interior layer is a spunbonded nonwoven fabric, and in a preferred embodiment the interior layer is a polyester spunbond nonwoven fabric. The exterior layers are preferably carded nonwoven webs, and in a preferred embodiment, the carded webs comprise rayon fibers that have been treated with a flame retardant chemical.

Owner:FIBERWEB INC

Flame retardant fabric for protective clothing

InactiveUS20120270456A1Improve performanceLow costProtective fabricsCellulosic plastic layered productsFire-retardant fabricEngineering

The product of the invention is a flame retardant fabric for use in personal protective clothing which provides a high level of protection from flames or other sources of heat characterized in that it is made from a mixture of a primary yarn which is a blend of FR cellulosic fibers with high temperature resistant polymer fibers and a secondary yarn which is a twisted yarn containing a continuous synthetic filament yarn.

Owner:LENZING AG

Durable flame resistant fabrics

InactiveUS20110275264A1Synthetic resin layered productsPretreated surfacesCross-linkPhosphonium salt

Provided is a flame resistant fabric comprising a fabric substrate comprising cellulosic fibers and thermoplastic fibers, and a finish applied to the fabric substrate comprising a tetrahydroxymethyl phosphonium salt or a condensate thereof, a cross-linking agent, a brominated compound, and optionally a melamine resin. Also provided are methods of preparing the flame resistant fabric.

Owner:MILLIKEN & CO

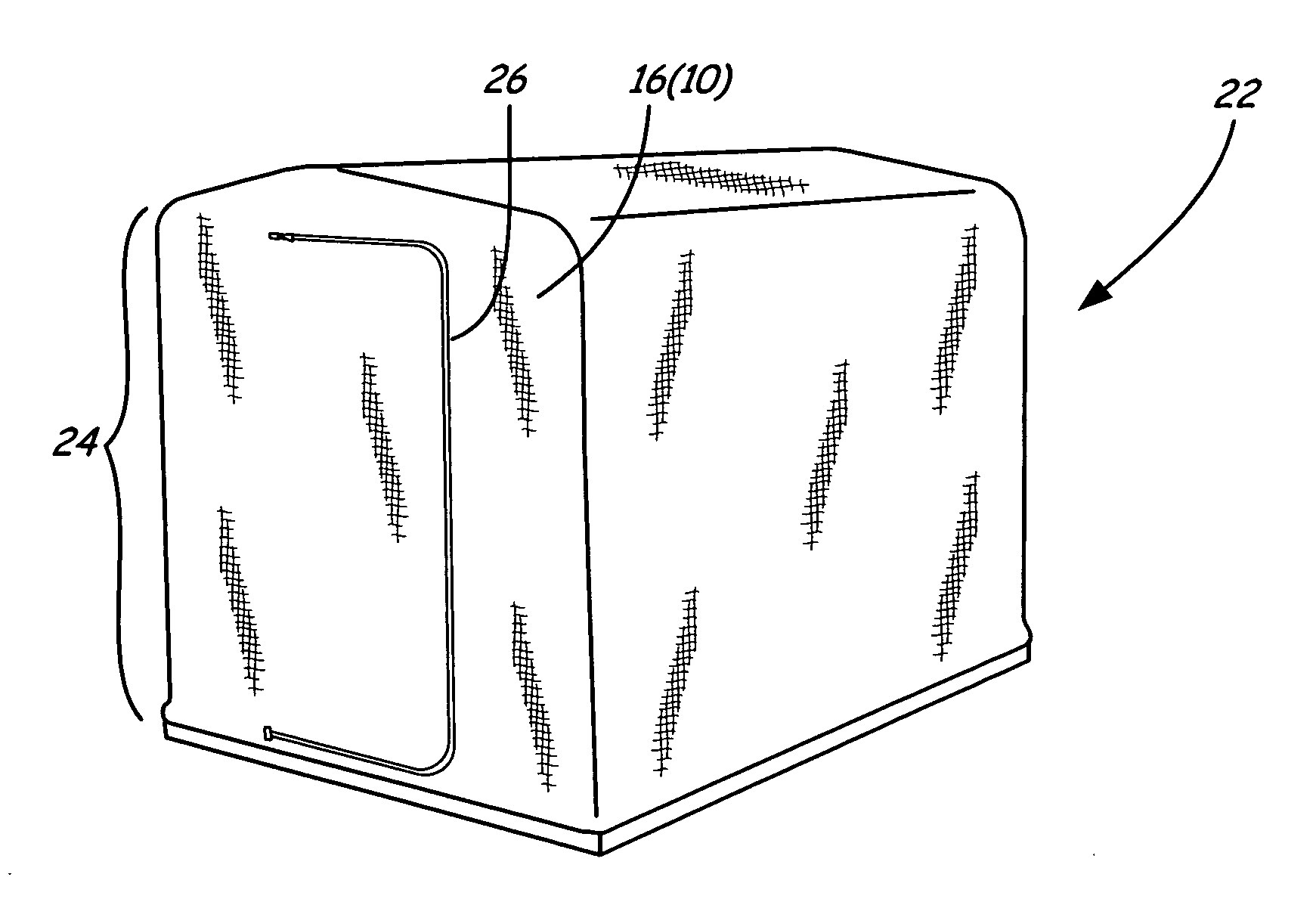

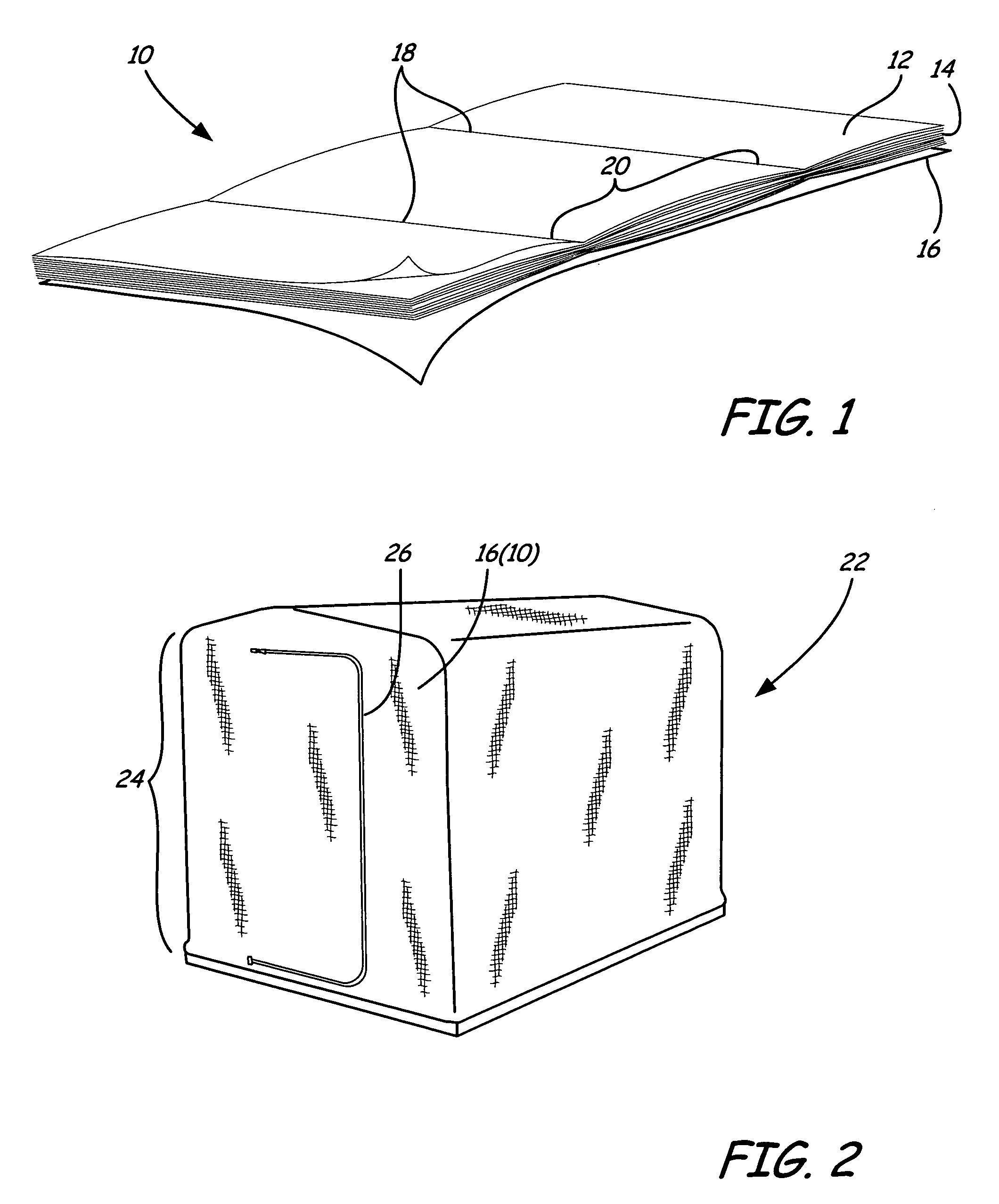

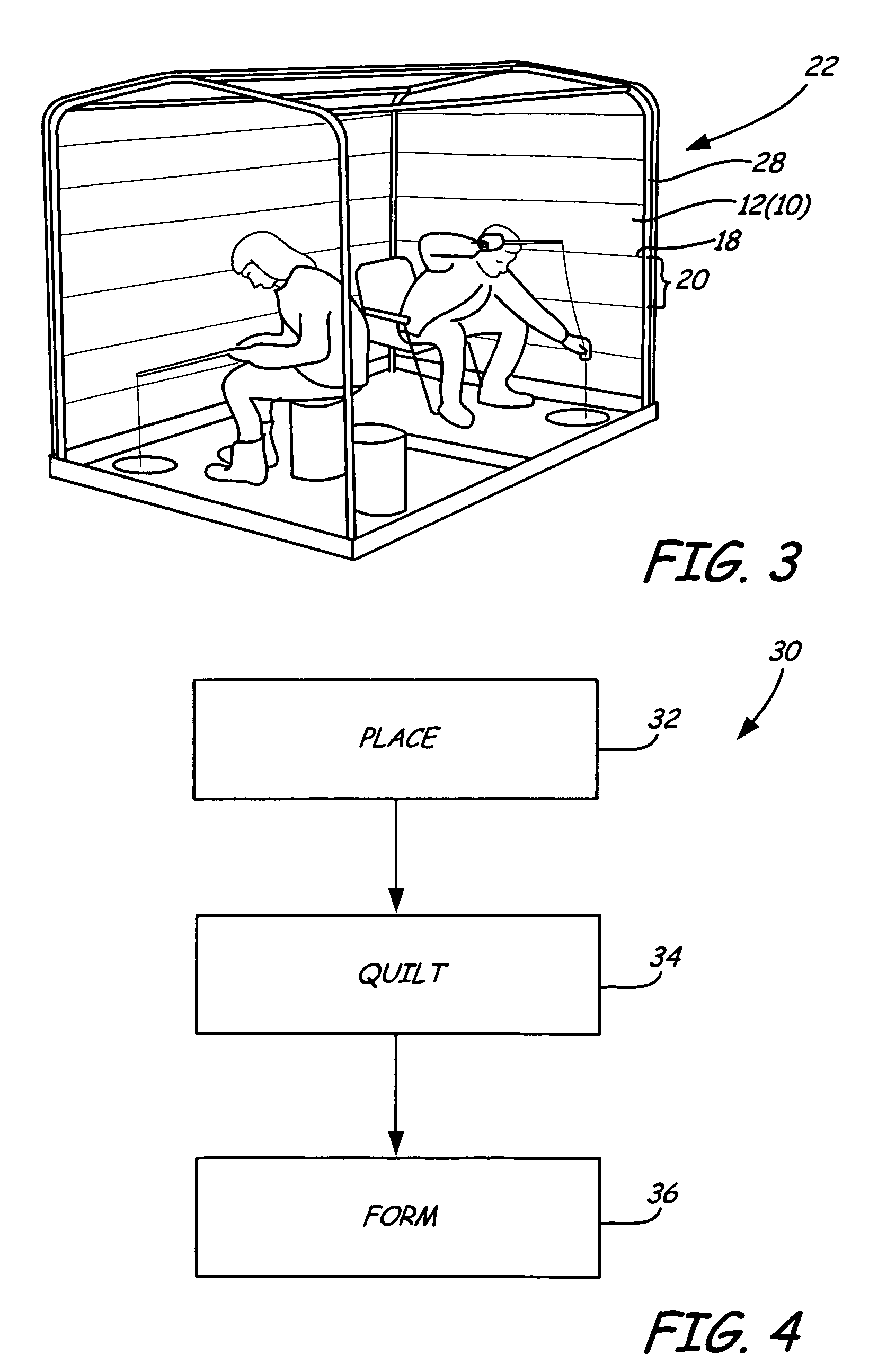

Flame resistant insulated fabric for shelters

InactiveUS7882849B2Synthetic resin layered productsTents/canopiesFire-retardant fabricElectrical and Electronics engineering

A flame-resistant fabric for shelters including a flame-resistant interior layer, an flame-resistant, insulating middle layer adjacent the interior layer, a flame-resistant exterior layer adjacent the insulating middle layer, and at least one threaded seam quilting the insulating middle layer between the interior layer and the exterior layer to form a flame-resistant fabric. The flame-resistant fabric is capable of being formed into a flame-resistant, insulated shelter for use in extreme weather.

Owner:FRANTA MATT

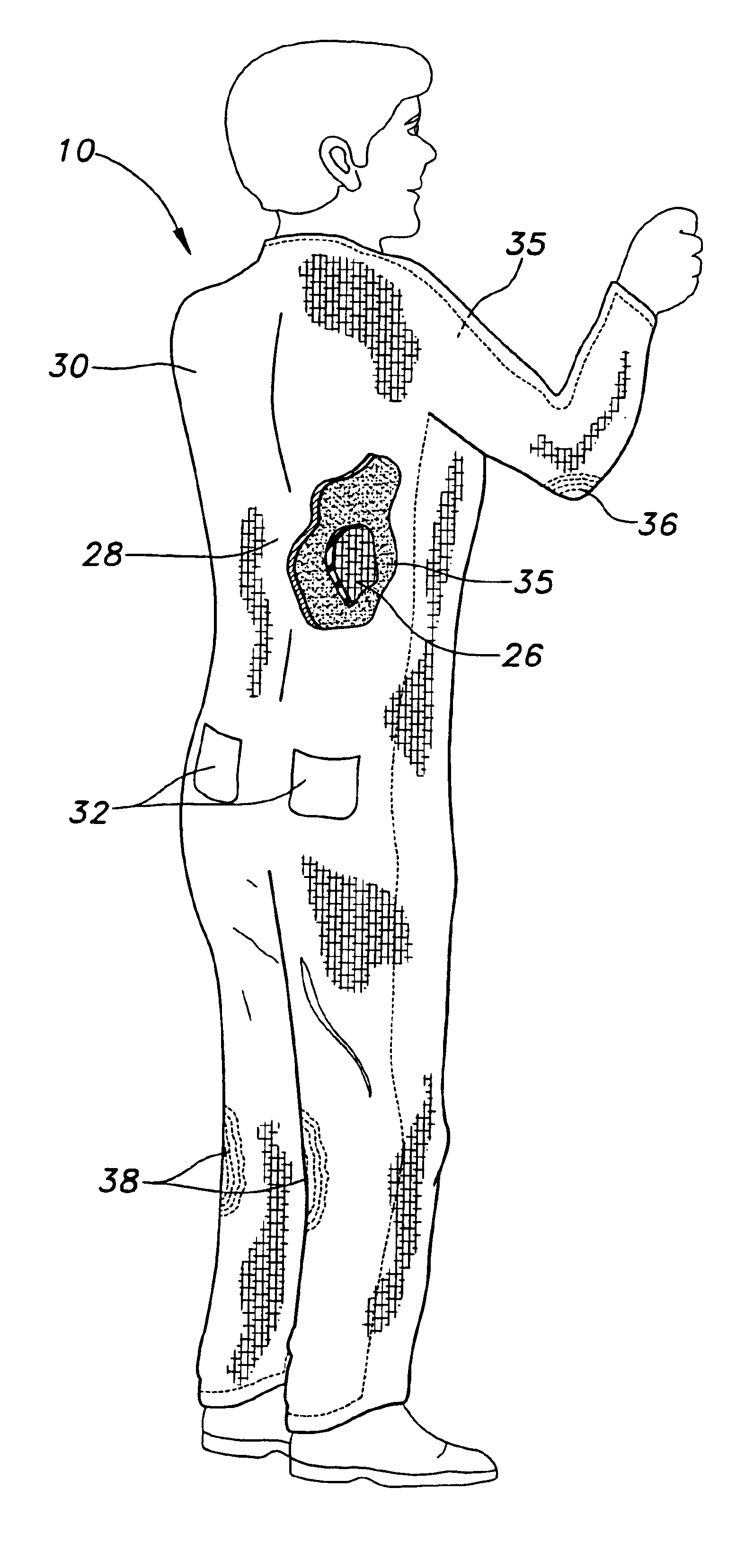

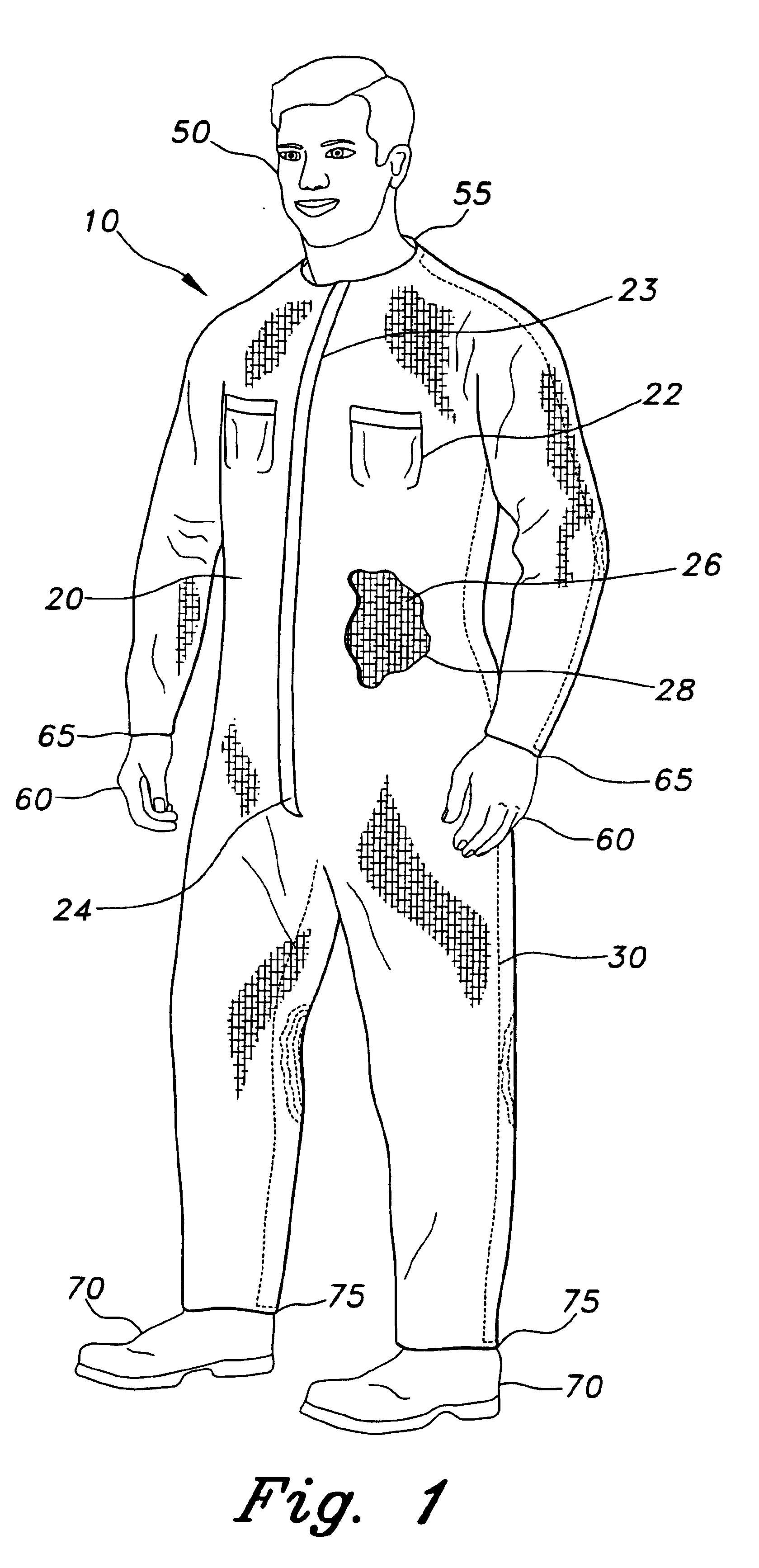

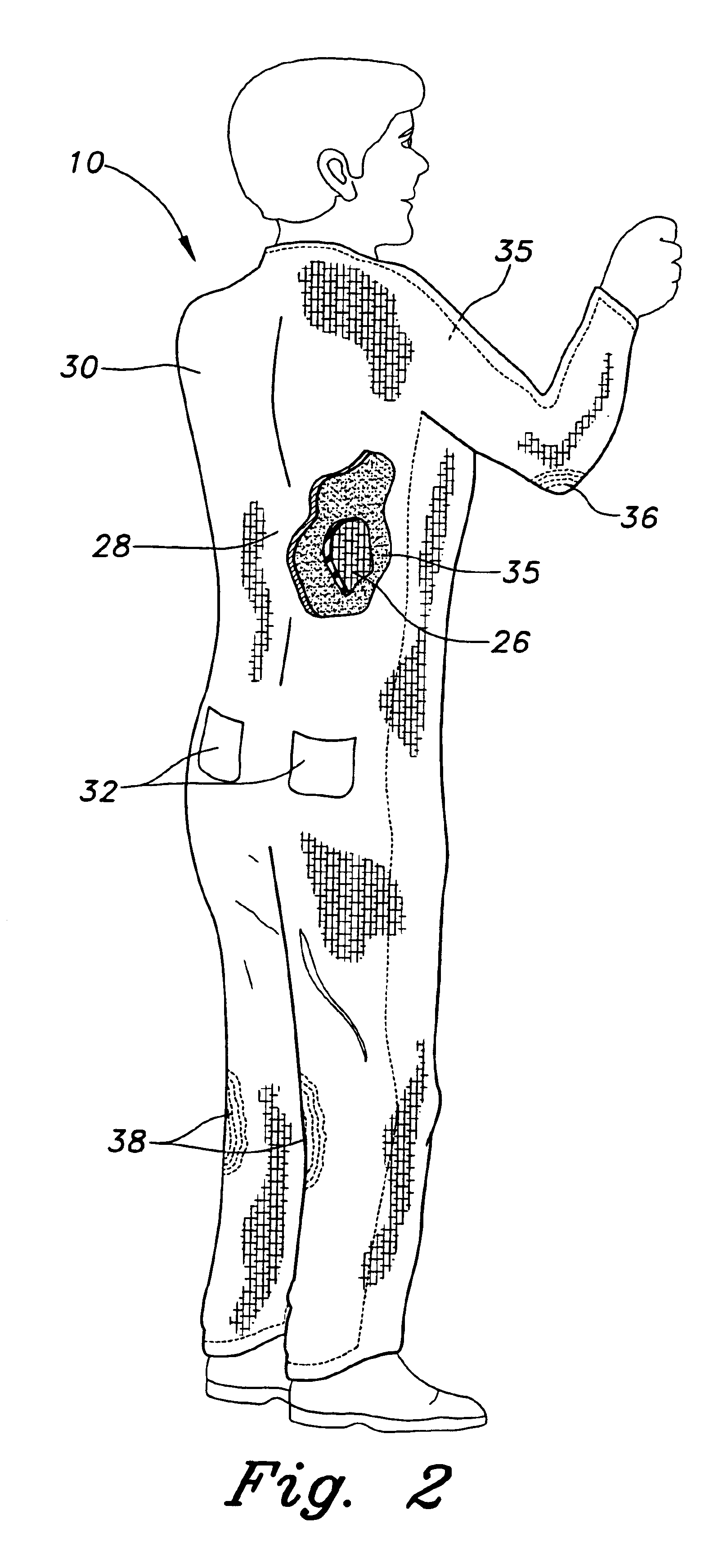

Protective coverall for electrical utility workers

The protective coveralls for electrical utility workers are designed to protect the wearer from fire and other thermal hazards, and particularly designed to insulate the rear half of the body of the wearer from direct contact with an electrical source up to 600 volts. The protective coverall has a front half is constructed from dual layers of fire-retardant fabric, and a rear half which includes electrical insulation provided by a rubber lining disposed between the outer and inner layer of fire-retardant fabric. The stitching on the rear half in the elbow and knee regions is done in concentric circles to increase flexibility.

Owner:PRINCE ERWIN A

Liquid water impermeable reinforced nonwoven fire blocking fabric, method for making such fabric, and articles fire blocked therewith

This invention relates to a thin reinforced nonwoven fabric comprising a liquid impervious polymeric layer, a compressed web of crimped fiber, a binder, and a reinforcing scrim. The fabric bulks when exposed to heat or flame and is useful as a component for fire blocking mattresses, upholstery, and the like.

Owner:DUPONT SAFETY & CONSTR INC

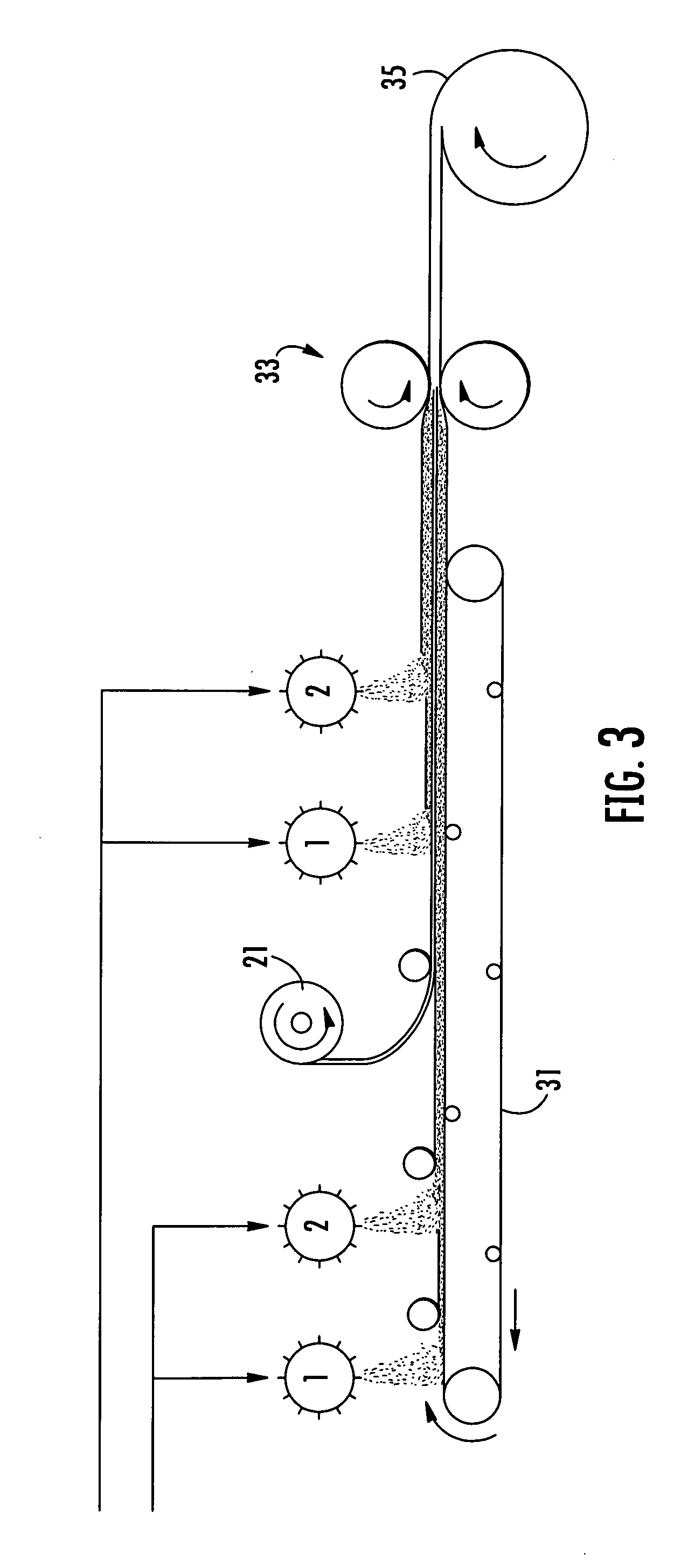

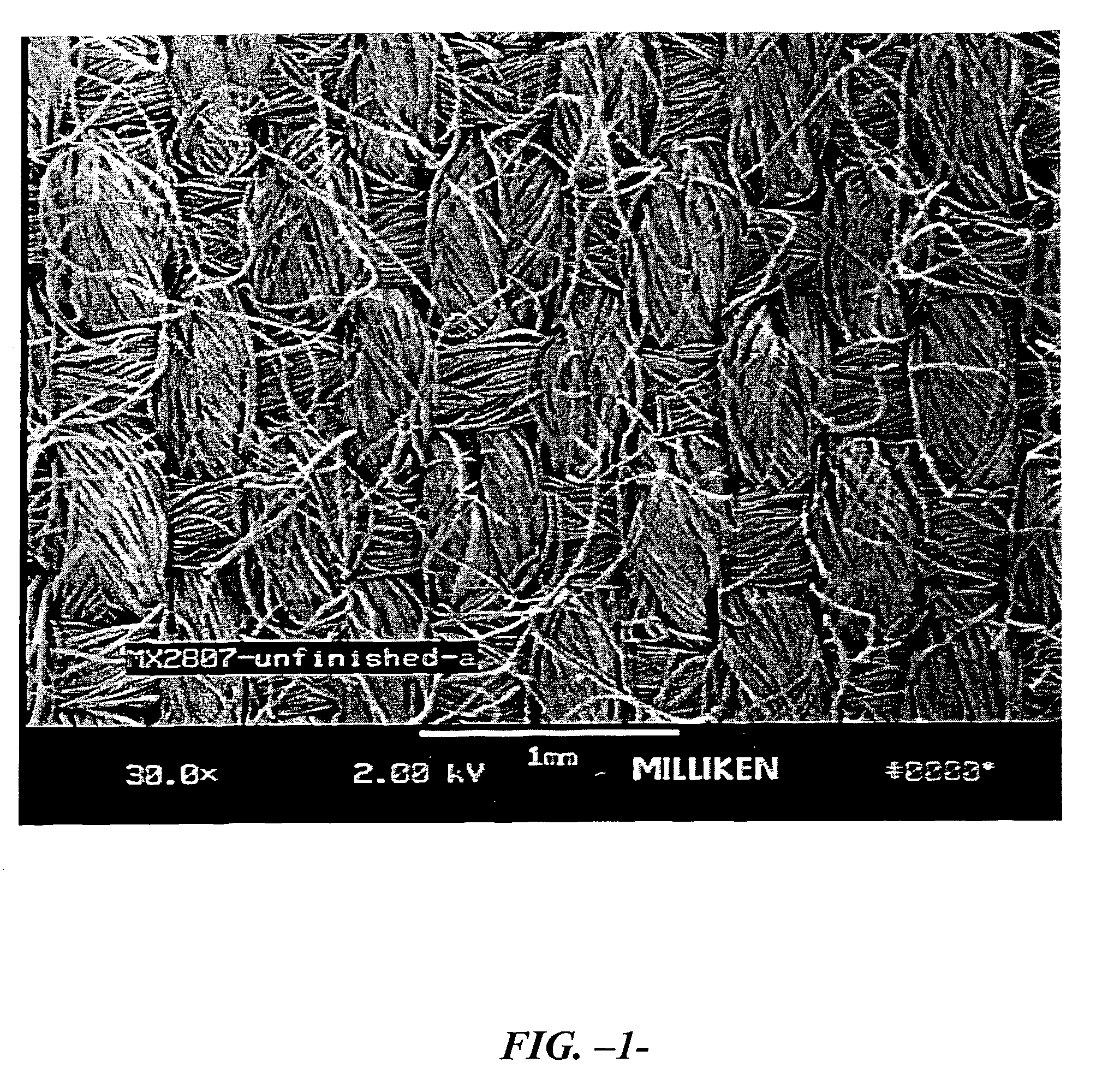

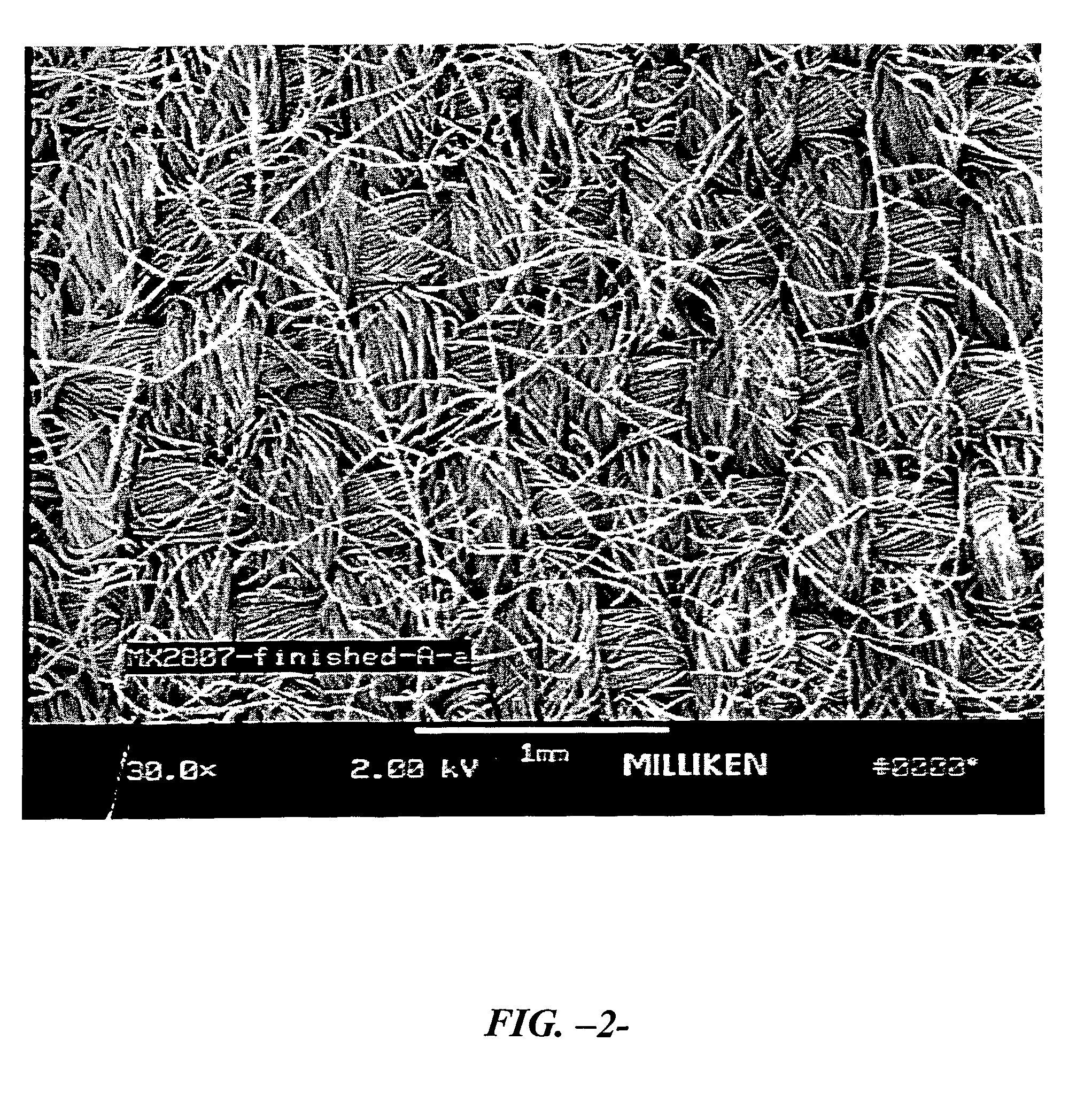

Flame resistant fabrics with improved aesthetics and comfort, and method of making same

InactiveUS7168140B2Improve wearing comfortImprove aestheticsPattern makingDrying machines with progressive movementsFiberYarn

Owner:MILLIKEN & CO

Patterned, flame resistant fabrics and method for making same

Owner:SOUTHERN MILLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com