Production method for preparing thermal insulation material by using enteromorpha

A technology of thermal insulation and production method, which is applied in the field of thermal insulation materials, can solve the problems of wasting natural resources and destroying the environment, and achieve the effect of realizing waste utilization, protecting the environment, and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

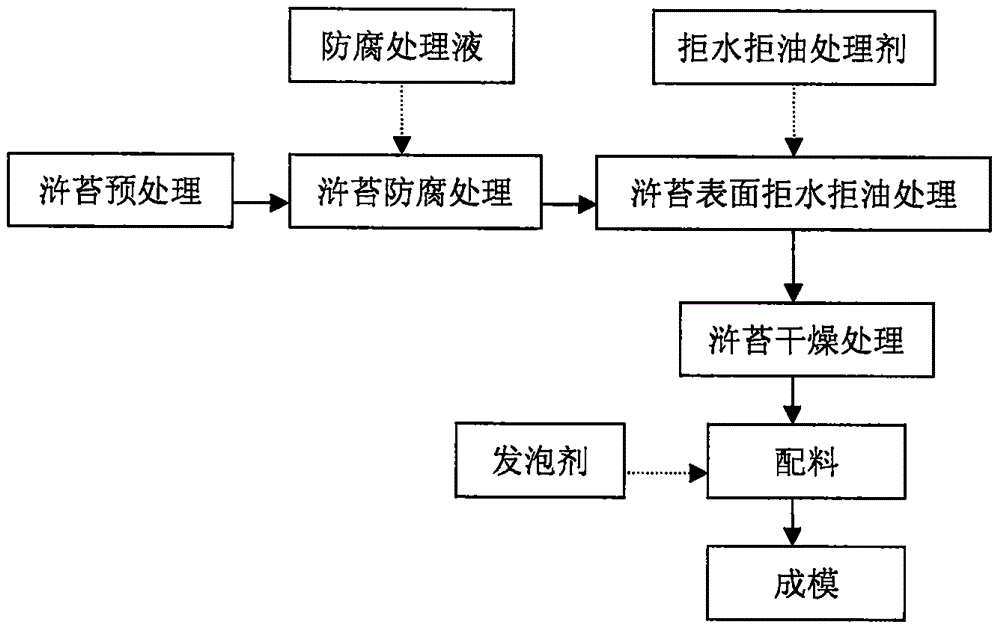

Image

Examples

Embodiment 1

[0026] A production method utilizing enteromorpha to prepare thermal insulation materials, comprising the steps of:

[0027] (1) Enteromorpha pretreatment

[0028] Use the Enteromorpha fishing device to catch fresh Enteromorpha, wash and remove impurities such as sediment, then dry and crush;

[0029] (2) Enteromorpha antiseptic treatment

[0030] The Enteromorpha obtained in step (1) is immersed in a dehydroacetic acid solution with a mass fraction of 0.05% for 10 min;

[0031] (3) Water-repellent and oil-repellent treatment on the surface of Enteromorpha

[0032] Add a silicone-based water and oil repellent treatment agent to the antiseptic treatment solution in step (2), and continue soaking for 1 hour;

[0033] (4) Enteromorpha drying treatment

[0034] After the Enteromorpha treated in the step (3) is cleaned with clear water for 2 times, vacuum filtration is performed to obtain modified Enteromorpha;

[0035] (5) Ingredients

[0036] Ingredients according to the fo...

Embodiment 2

[0040] A production method utilizing enteromorpha to prepare thermal insulation materials, comprising the steps of:

[0041] (1) Enteromorpha pretreatment

[0042] Use the Enteromorpha fishing device to catch fresh Enteromorpha, wash and remove impurities such as sediment, then dry and crush;

[0043] (2) Enteromorpha antiseptic treatment

[0044] The Enteromorpha that step (1) obtains is immersed in the sodium dehydroacetate solution that mass fraction is 0.1% and processes 20min;

[0045] (3) Water-repellent and oil-repellent treatment on the surface of Enteromorpha

[0046] Add a silicone-based water and oil repellent treatment agent to the antiseptic treatment solution in step (2), and continue soaking for 1.5 hours;

[0047] (4) Enteromorpha drying treatment

[0048] After the Enteromorpha treated in the step (3) is cleaned with clear water for 2 times, vacuum filtration is performed to obtain modified Enteromorpha;

[0049] (5) Ingredients

[0050] Ingredients acco...

Embodiment 3

[0054] A production method utilizing enteromorpha to prepare thermal insulation materials, comprising the steps of:

[0055] (1) Enteromorpha pretreatment

[0056] Use the Enteromorpha fishing device to catch fresh Enteromorpha, wash and remove impurities such as sediment, then dry and crush;

[0057] (2) Enteromorpha antiseptic treatment

[0058] The Enteromorpha obtained in step (1) was immersed in a 0.2% sodium dehydroacetate solution for 30 minutes;

[0059] (3) Water-repellent and oil-repellent treatment on the surface of Enteromorpha

[0060] Add an organic fluorine-based water and oil repellent treatment agent to the antiseptic treatment solution in step (2), and continue soaking for 2 hours;

[0061] (4) Enteromorpha drying treatment

[0062] After the Enteromorpha processed in the step (3) is cleaned with clear water for 3 times, vacuum filtration is performed to obtain modified Enteromorpha;

[0063] (5) Ingredients

[0064] Ingredients according to the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com